Techno-Economic Analysis of Hydrogen Production from Swine Manure Biogas via Steam Reforming in Pilot-Scale Installation

Abstract

:1. Introduction

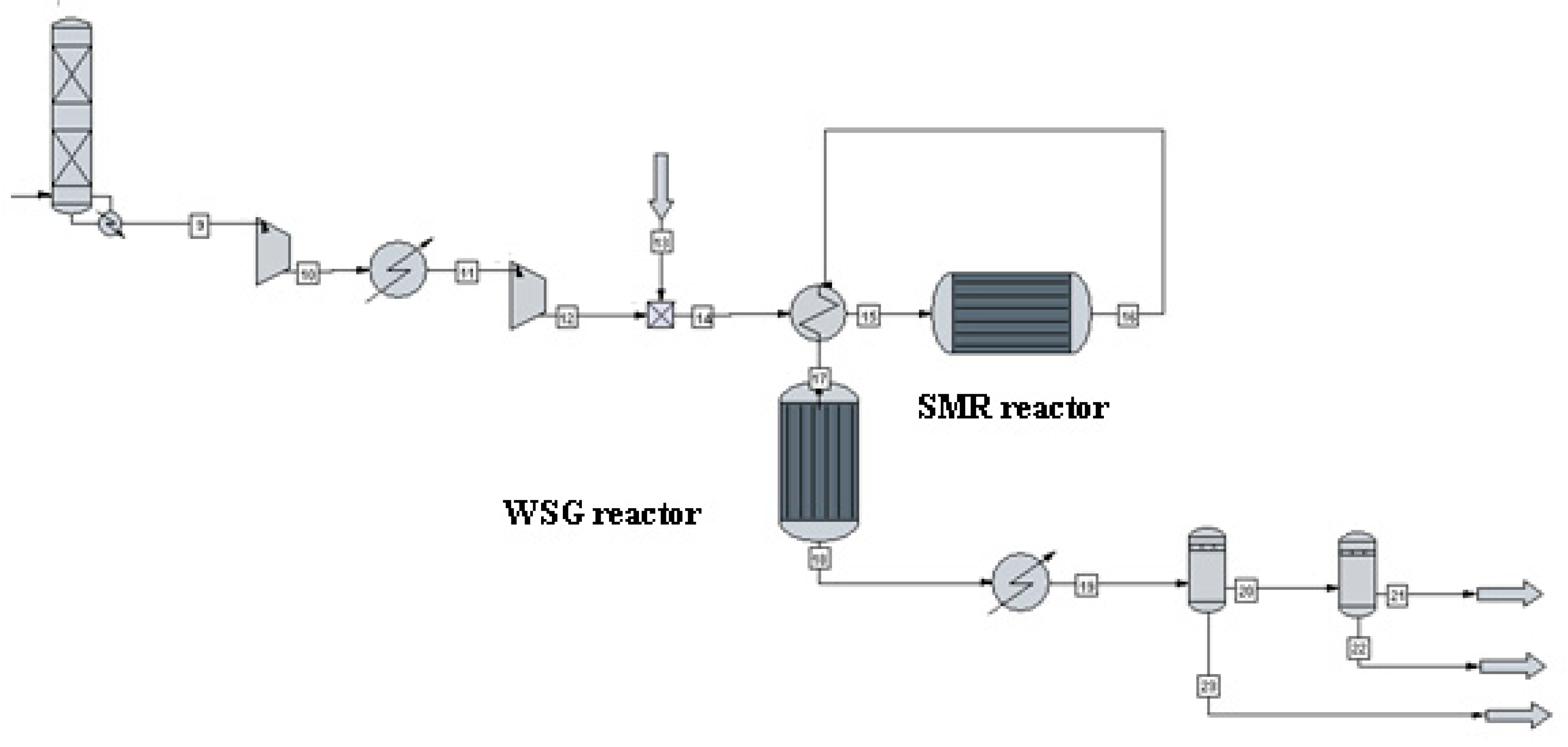

2. Materials and Methods

- -

- It is assumed that 1 pig produces 2.3 kg/day of manure, and the farm consists of 13,050 pigs.

- -

- The basic composition of the biogas in the simulation is 61.3% methane, 26.78% CO2, and 11.92% H2S.

- -

- The steam generator has an air excess of 30%, with an energy efficiency of 86%.

- -

- The reformer reactor operates at a temperature of 700 °C, under the following conditions: a steam to methane ratio of 3:1, and a pressure of 105 kPa.

- -

- The water–gas shift reactor operates at a temperature of 350 °C, and a pressure of 4 MPa.

3. Results and Discussion

3.1. Gas Cleanup and Reaction Flowsheet Results

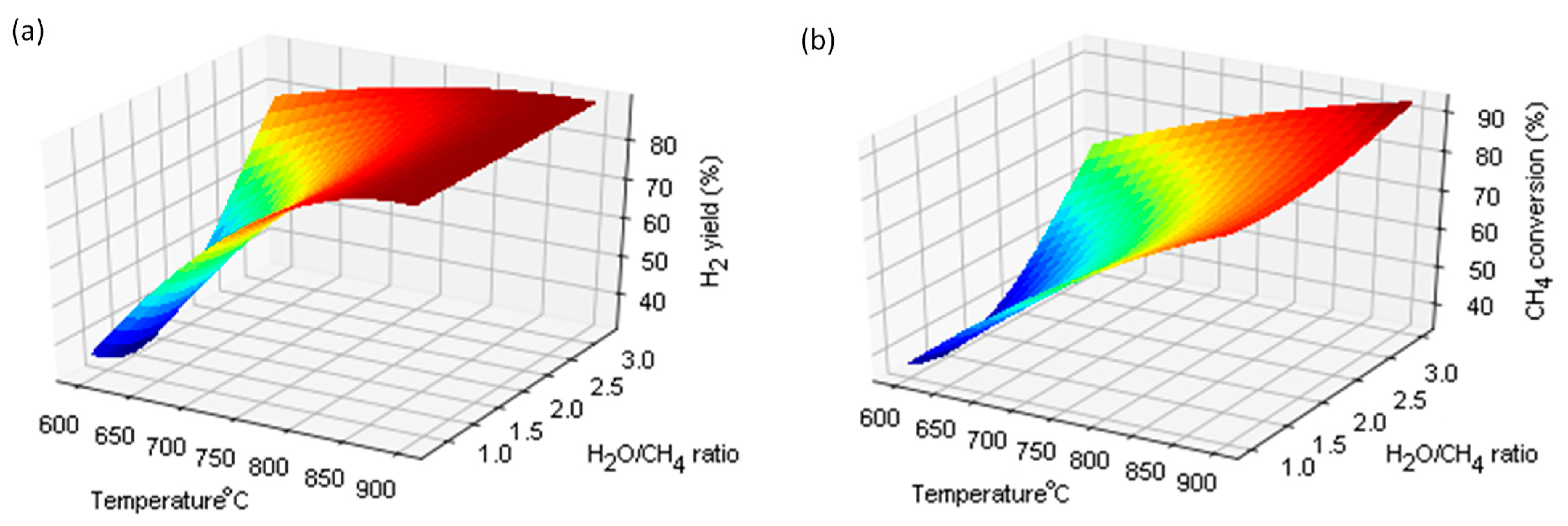

3.2. Influencing Parameters on Process Operating Conditions

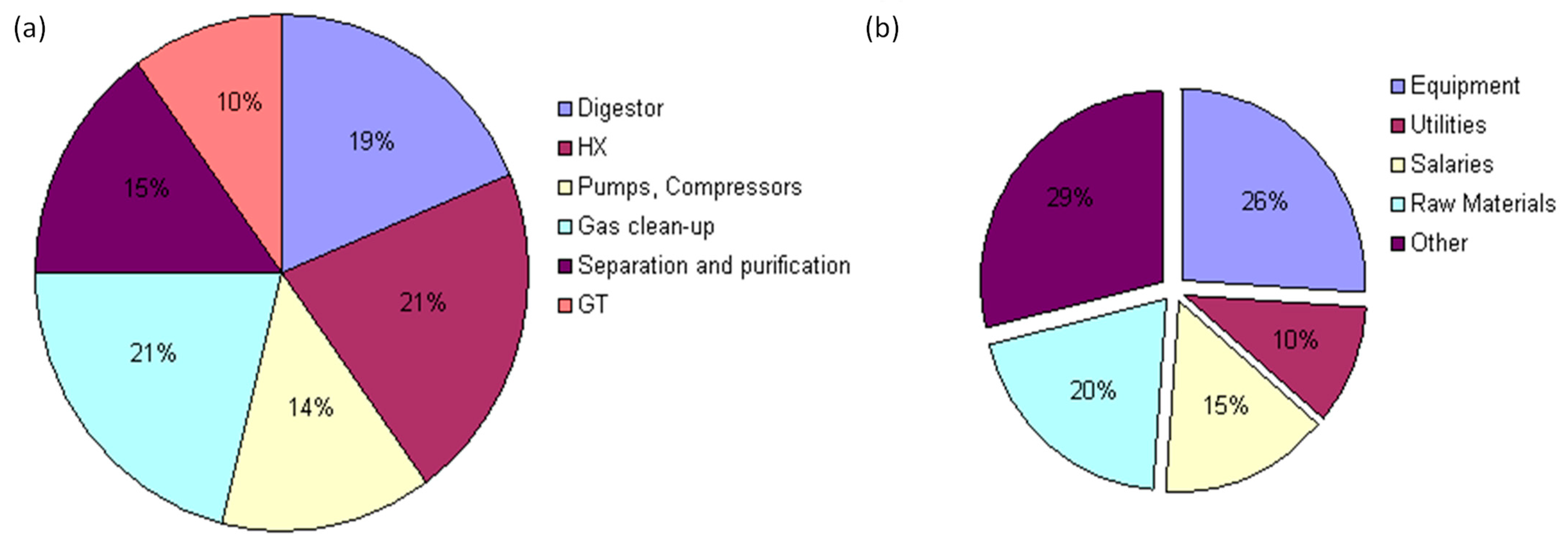

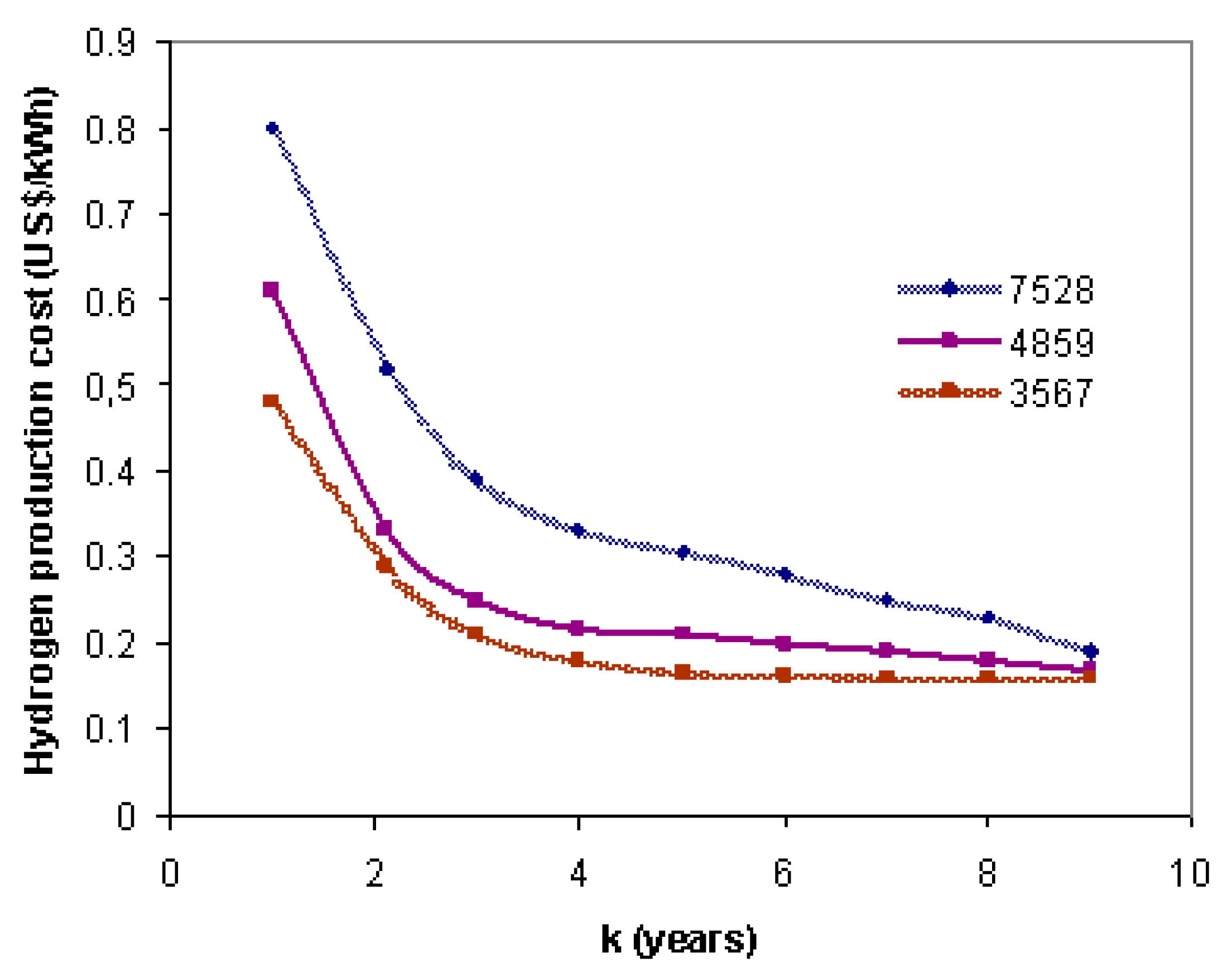

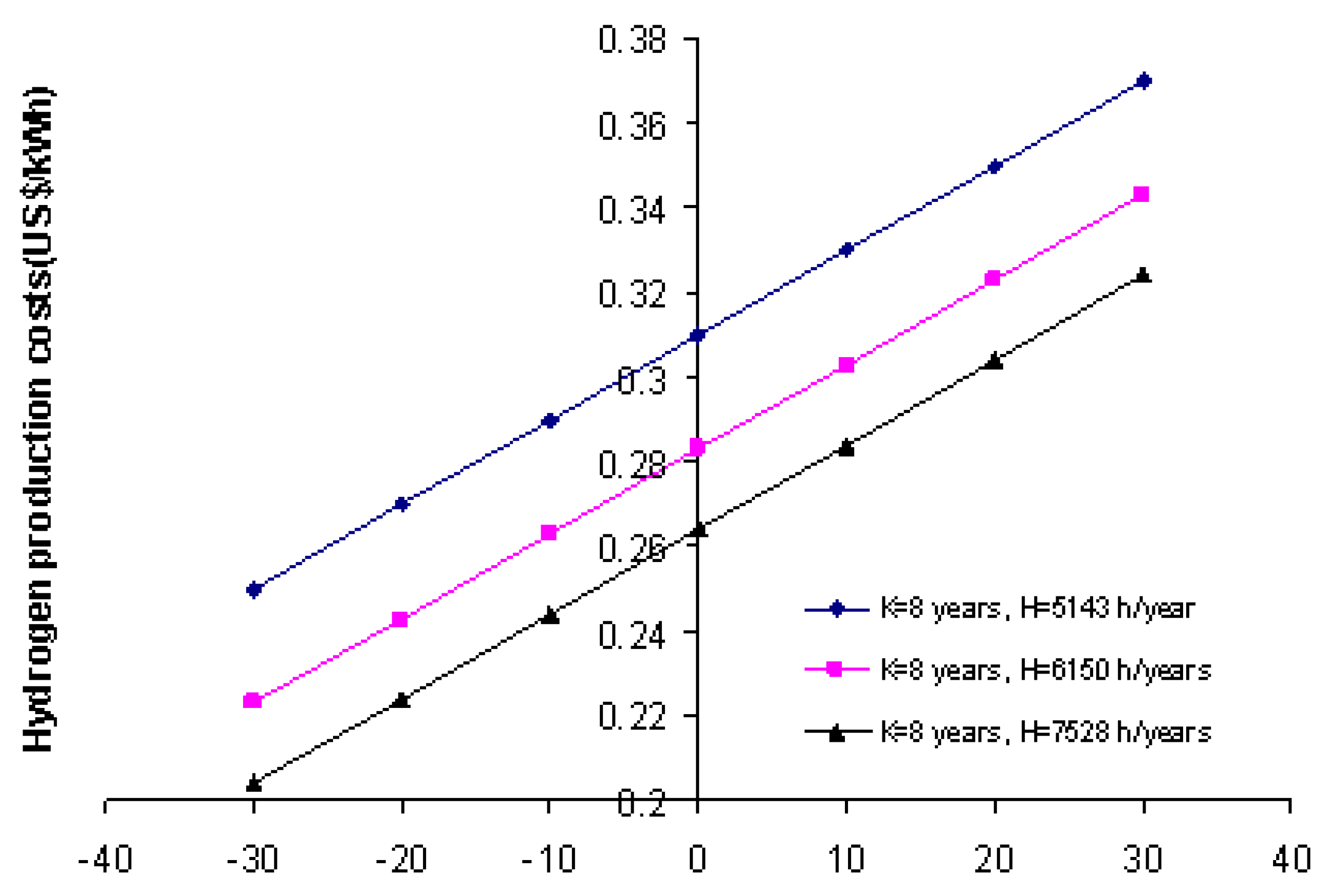

3.3. Results of the Financial Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Srivastava, N.; Srivastava, M.; Malhotra, B.D.; Gupta, V.K.; Ramteke, P.W.; Silva, R.N. Nano engineered cellulosic biohydrogen production via dark fermentation: A novel approach. Biotechnol. Adv. 2019, 4, 321–325. [Google Scholar]

- Madeira, J.G.; Mendes de Oliveira, E.; Oliveira de Arau’ jo, V.; val Springer, M.; Lopes Cabral, H.; Silva Melgac, H. Optimum Co-digestion ratio of cattle manure and manipueira in a single-stage anaerobic digester for biogas production. Clean 2020, 48, 2000096. [Google Scholar]

- Boyano, A.; Blanco-Marigorta, A.M.; Morosuk, T.; Tsatsaronis, G. Exergo environmental analysis of a steam methane reforming process for hydrogen production. Energy 2011, 36, 2202–2214. [Google Scholar] [CrossRef]

- Zdeb, J.; Howaniec, N.; Smolinski, A. Experimental Study on Combined Valorization of Bituminous Coal Derived Fluidized Bed Fly Ash and Carbon Dioxide from Energy Sector. Energy 2023, 265, 126367. [Google Scholar] [CrossRef]

- Howaniec, N.; Smoliński, A.; Cempa-Balewicz, M. Experimental study of nuclear high temperature reactor excess heat use in the coal and energy crops co-gasification process to hydrogen-rich gas. Energy 2015, 84, 455–461. [Google Scholar] [CrossRef]

- Madeira, J.G.F.; Boloy, R.A.M.; Delgado, A.R.S.; Lima, F.R.; Coutinho, E.R.; de Castro Pereira Filho, R. Ecological analysis of hydrogen production via biogas steam reforming from cassava flour processing wastewater. J. Clean. Prod. 2017, 162, 709–716. [Google Scholar] [CrossRef]

- Cruz, P.L.; Iribarren, D.; Dufour, J. Exergy analysis of alternative configurations of a system coproducing synthetic fuels and electricity via biomass gasification, Fischer-Tropsch synthesis and a combined-cycle scheme. Fuel 2017, 194, 375–394. [Google Scholar] [CrossRef]

- Vidal, M.; Martín, M. Optimal coupling of biomass and solar energy for the production of electricity and chemicals. Comp. Chem. Eng. 2015, 72, 273–283. [Google Scholar] [CrossRef]

- Yingjian, L.; Qi, Q.; Xiangzhu, H.; Jiezhi, L. Energy balance and efficiency analysis for power generation in internal combustion engine sets using biogas. Sustain. Energy Technol. Assess. 2014, 3, 25–33. [Google Scholar] [CrossRef]

- Smolinski, A.; Wojtacha-Rychter, K.; Król, M.; Magdziarczyk, M.; Polański, J.; Howaniec, N. Co-gasification of waste-derived-fuel and bituminous coal with oxygen/steam blend to hydrogen rich gas. Energy 2022, 254, 124210. [Google Scholar] [CrossRef]

- Wojtacha-Rychter, K.; Smoliński, A. The interactions between coal and multi-component gas mixtures in the process of coal self-heating at different various temperatures ranges: An experimental study. Fuel 2018, 213, 150–157. [Google Scholar] [CrossRef]

- Urych, B.; Smoliński, A. Sewage sludge and phytomass co-pyrolysis and the gasification of its chars: A kinetics and reaction mechanism study. Fuel 2021, 285, 119186. [Google Scholar] [CrossRef]

- Lantz, M. The economic performance of combined heat and power from biogas produced from manure in Sweden—A comparison of different technologies. Appl. Energy 2012, 3, 502–511. [Google Scholar] [CrossRef]

- Kang, J.Y.; Kang, D.W.; Kim, T.S.; Hur, K.B. Comparative economic analysis of gas turbine-based power generation and combined heat and power systems using biogas fuel. Energy 2014, 4, 309–318. [Google Scholar] [CrossRef]

- Bruno, J.C.; Ortega-López, V.; Coronas, A. Integration of absorption cooling systems into micro gas turbine trigeneration systems using biogas: Case study of a sewage treatment plant. Appl. Energy 2009, 86, 837–847. [Google Scholar] [CrossRef]

- Peerapong, P.; Limmeechokchai, B. Biogas-based electricity generation in swine farm in Thailand: Economic and CO2 reduction aspects. Energy Procedia 2017, 138, 657–661. [Google Scholar] [CrossRef]

- Putmai, N.; Jarunglumlert, T.; Prommuak, C.; Pavasant, P.; Flood, A.E. Economic analysis of swine farm management for the enhancement of biogas production and energy efficiency. Waste Biomass Valorization 2020, 2, 5635–5645. [Google Scholar] [CrossRef]

- Xiao, Y.; Yang, H.; Yang, H.; Wang, H.; Zheng, D.; Liu, Y. Improved biogas production of dry anaerobic digestion of swine manure. Bioresour. Technol. 2019, 294, 122–188. [Google Scholar] [CrossRef] [PubMed]

- Soares, C.A.; Viancelli, A.; Michelon, W.; Sbardelloto, M.; Camargo, A.F.; Vargas, G.D.L.; Treichel, H. Biogas yield prospection from swine manure and placenta in real-scale systems on circular economy approach. Biocatal. Agric. Biotechnol. 2020, 101, 598–603. [Google Scholar] [CrossRef]

- Lee, T.-H.; Huang, S.-R.; Chen, C.-H. The experimental study on biogas power generation enhanced by using waste heat to preheat inlet gases. Renew. Energy 2013, 50, 342–347. [Google Scholar] [CrossRef]

- Braga, L.B.; Silveira, J.L.; da Silva, M.E.; Tuna, C.E.; Machin, E.B.; Pedroso, D.T. Hydrogen production by biogas steam reforming: A technical, economic and ecological analysis. Renew. Sustain. Energy Rev. 2013, 28, 166–173. [Google Scholar] [CrossRef]

- Chouhan, K.; Sinha, S.; Kumar, S.; Kumar, S. Simulation of steam reforming of biogas in an industrial reformer for hydrogen production. Int. J. Hydrogen Energy 2021, 46, 26809–26824. [Google Scholar] [CrossRef]

- Appari, S.; Janardhanan, V.M.; Bauri, R.; Jayanti, S.; Deutschmann, O. A detailed kinetic model for biogas steam reforming on Ni and catalyst deactivation due to sulfur poisoning. Appl. Catal. A 2014, 471, 118–125. [Google Scholar] [CrossRef]

| Parameter | Unit | Filter | Absorber | Adsorber | Cleaned Gas |

|---|---|---|---|---|---|

| Temperature | °C | 30 | 75 | 45 | 20 |

| Pressure | kPa | 100 | 489 | 356 | 108 |

| CO2 | Composition, % | 28.78 | 0.0008 | 0 | 0 |

| CH4 | 61.3 | 61.3 | 61.3 | 61.3 | |

| H2S | 11.90 | 11.90 | 0 | 0 | |

| NH3 | 0.002 | 0 | 0 | 0 | |

| Solids | 0 | 0 | 0 | 0 |

| Parameter | Unit | Reformer Reactor | Water–Gas Shift Reactor | Flash Column | H2 Product |

|---|---|---|---|---|---|

| Temperature | °C | 456 | 350 | 38 | 38 |

| Pressure | kPa | 108 | 107.5 | 89 | 106 |

| Molar Flow | kg·mole/h | 64.1 | 60.24 | 59.52 | 38.72 |

| Mass Flow | kg/h | 1260 | 1243.25 | 1240.81 | 250.67 |

| Heat Flow | kJ/h | −29,602,558.63 | −24,569,976.17 | −29,879,945.14 | 3258.17 |

| Mass Enthalpy | kJ/kg | −6358.17 | −7582.43 | −9186.87 | 195.82 |

| Mass Entropy | kJ/kg·C | 8.14 | 12.74 | 11.7 | 61.85 |

| Mass Density | Kg/m3 | 0.39 | 0.31 | 0.32 | 0.09 |

| Vapor Fraction | 0.75 | 0.82 | 0.756 | 1 |

| Component | Mass Balance (kg/kgH2) |

|---|---|

| Biomethane | 5.26 |

| Water steam | 14.87 |

| Carbon monoxide | 7.25 |

| Direct CO2 emissions | 0.16 |

| Indirect CO2 emissions | 0.22 |

| Equipment | Electricity Needs (MWh/Mg H2) |

|---|---|

| Compressors | 0.31 |

| Heating | 0.2286 |

| Cooling | 0.352 |

| Pumps | 0.29 |

| Reactor Steam Reformer | 0.82 |

| Reactor Water–Gas Shift Reactor | 0.35 |

| Electricity Demand for Biogas Purification kWh/m3 | 0.029 |

| 59.41 | |

| 45.81 |

| CAPEX | 18,960,021 |

|---|---|

| Material costs (with recycling), /h | 2405.85 |

| Energy costs, /h | 326.6589 |

| Total utility costs, /y | 4,309,855.2 |

| Additional costs (fittings, valves, etc.) | 358,699.77 |

| Depreciation costs, /y | 38,952.74 |

| Revenue, /y | 7,509,213.4 |

| Rate of return (without purchase equipment costs), /y | 8.86% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wodołażski, A.; Magdziarczyk, M.; Smoliński, A. Techno-Economic Analysis of Hydrogen Production from Swine Manure Biogas via Steam Reforming in Pilot-Scale Installation. Energies 2023, 16, 6389. https://doi.org/10.3390/en16176389

Wodołażski A, Magdziarczyk M, Smoliński A. Techno-Economic Analysis of Hydrogen Production from Swine Manure Biogas via Steam Reforming in Pilot-Scale Installation. Energies. 2023; 16(17):6389. https://doi.org/10.3390/en16176389

Chicago/Turabian StyleWodołażski, Artur, Małgorzata Magdziarczyk, and Adam Smoliński. 2023. "Techno-Economic Analysis of Hydrogen Production from Swine Manure Biogas via Steam Reforming in Pilot-Scale Installation" Energies 16, no. 17: 6389. https://doi.org/10.3390/en16176389

APA StyleWodołażski, A., Magdziarczyk, M., & Smoliński, A. (2023). Techno-Economic Analysis of Hydrogen Production from Swine Manure Biogas via Steam Reforming in Pilot-Scale Installation. Energies, 16(17), 6389. https://doi.org/10.3390/en16176389