Lithium-Ion Battery Life Prediction Method under Thermal Gradient Conditions

Abstract

1. Introduction

2. Battery-Aging Data Acquisition

2.1. Experimental Objects and Equipment

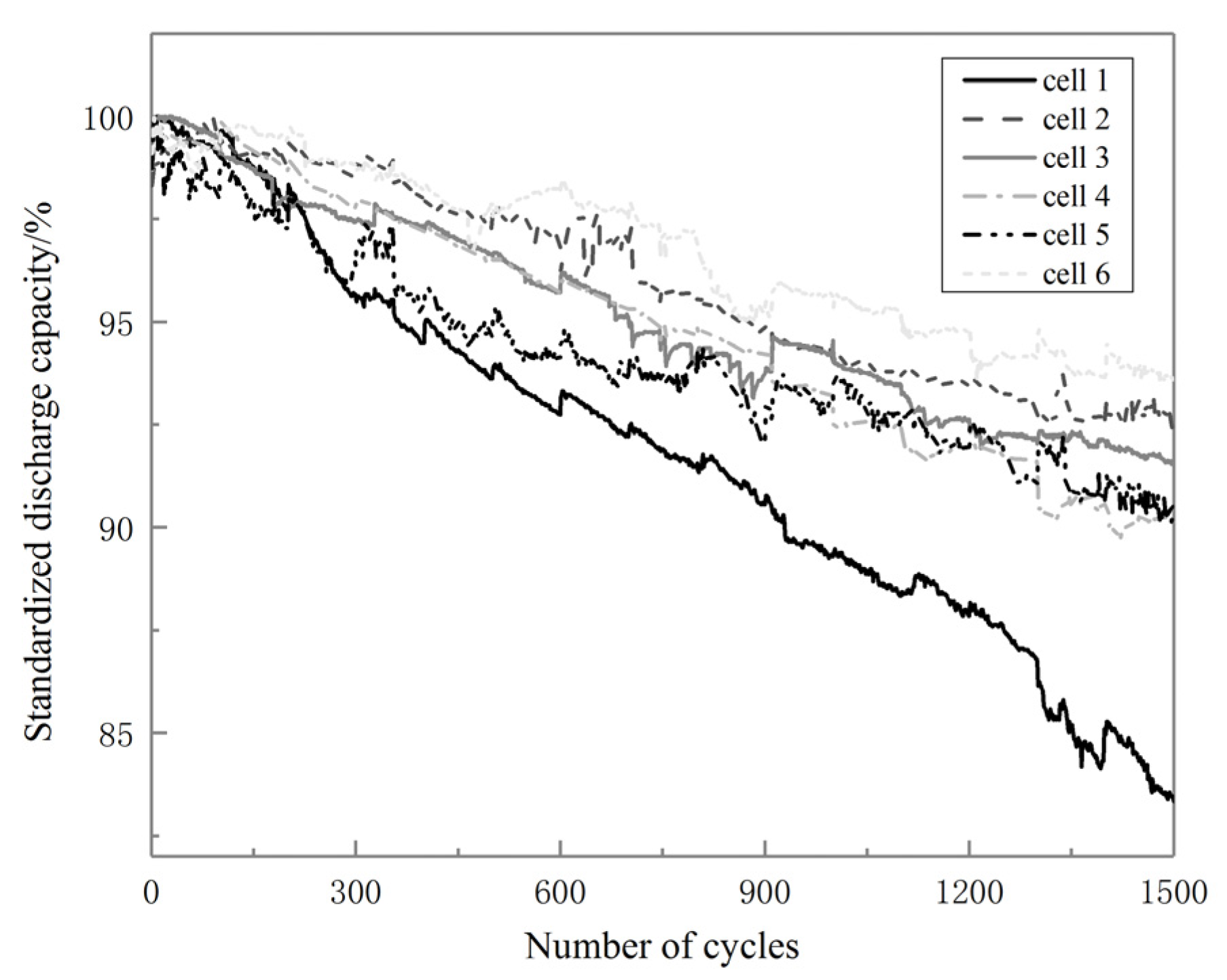

2.2. Aging Experimental Design and Results

3. Proposed Prediction Model

3.1. Extreme Learning Machine

3.2. Sparrow Search Algorithm

- (1)

- Explorers have higher energy reserve capabilities and provide foraging directions and areas for followers in the population. The health status of an individual determines its energy reserve level.

- (2)

- When a sparrow perceives a predator, it chirps to tell other sparrows that danger is coming. When the danger level is above the threshold, the explorer guides the sparrows in following it to areas away from the predator.

- (3)

- Sparrows become explorers on the premise of finding a better food source, but the ratio of explorers to followers remains constant across the population.

- (4)

- Sparrows with higher energy will become explorers. Many hungry followers will fly to other places to get food, hoping to gain enough energy to become explorers.

- (5)

- Because the explorer has a good food source, followers will follow the explorer to find food. Meanwhile, to gain energy, followers may spy on the explorer and snatch food when the time is right.

- (6)

- When perceiving danger, sparrows at the edge of the group will immediately move away from the predator, while those in the middle of the group will fly closer to other sparrows and move around at will.

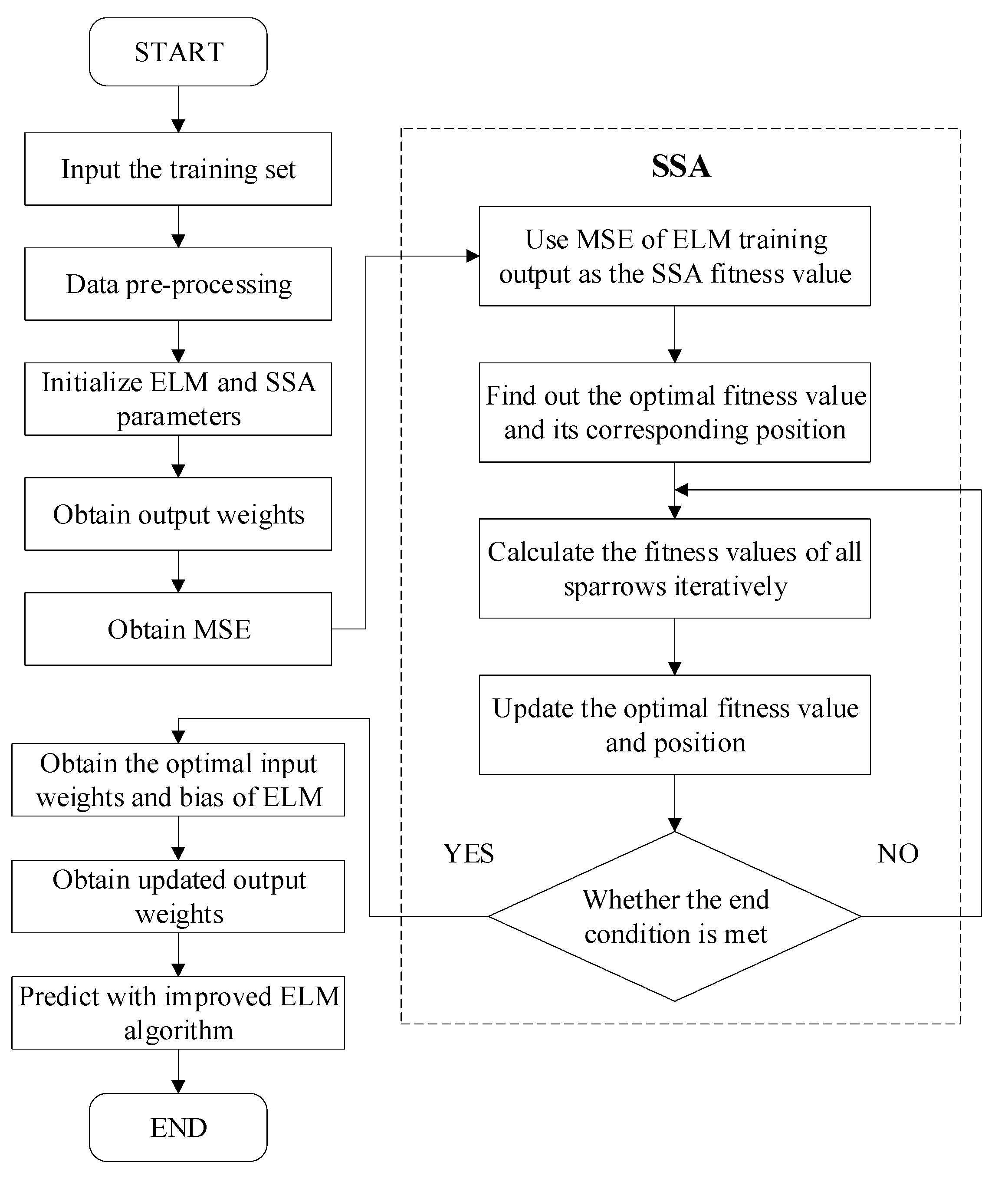

3.3. SSA-ELM Prediction Model

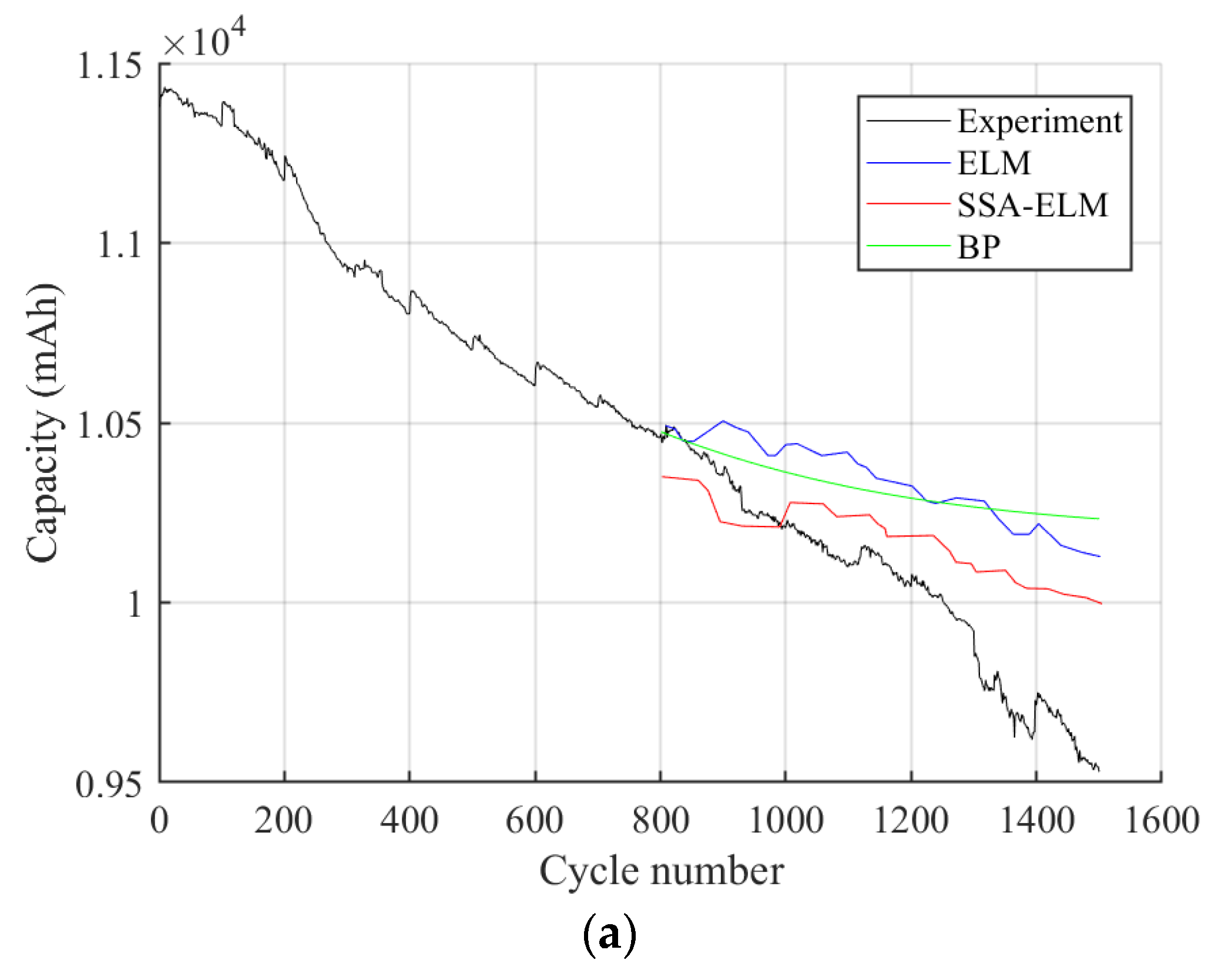

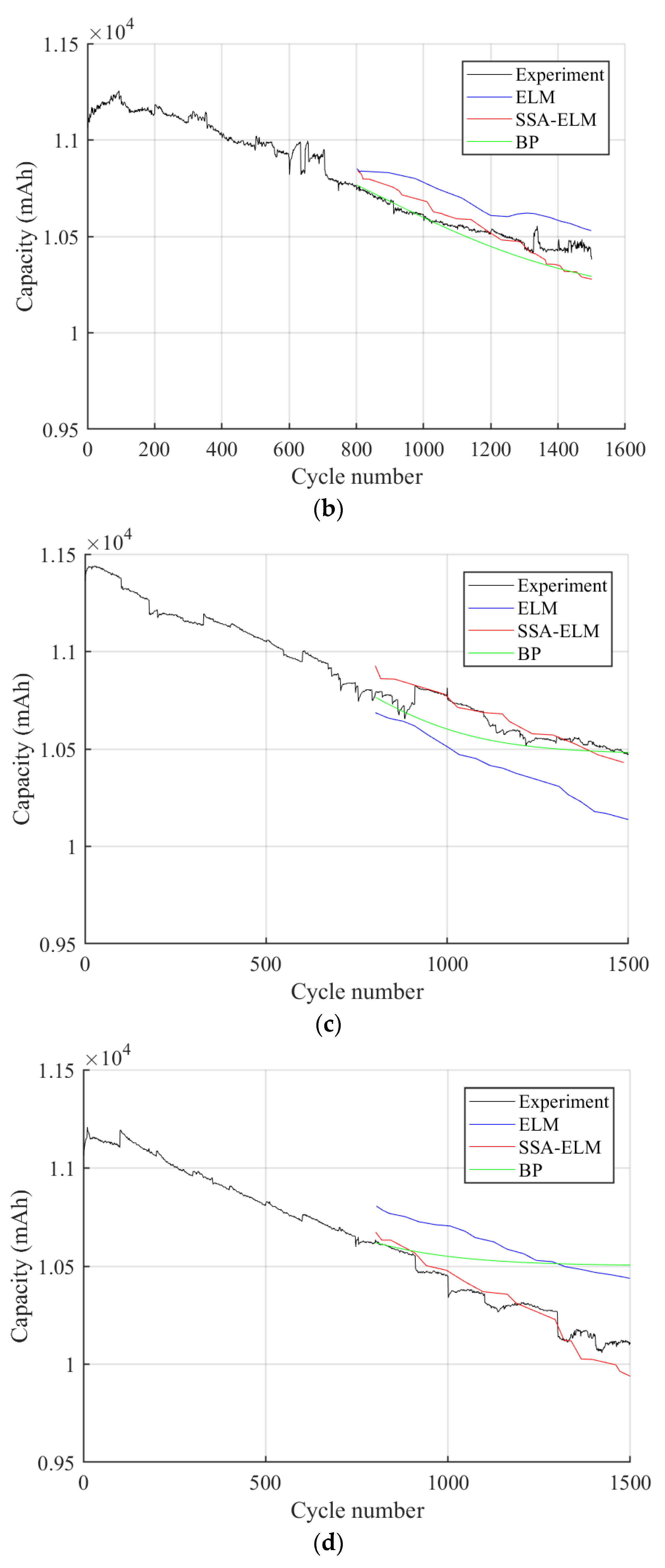

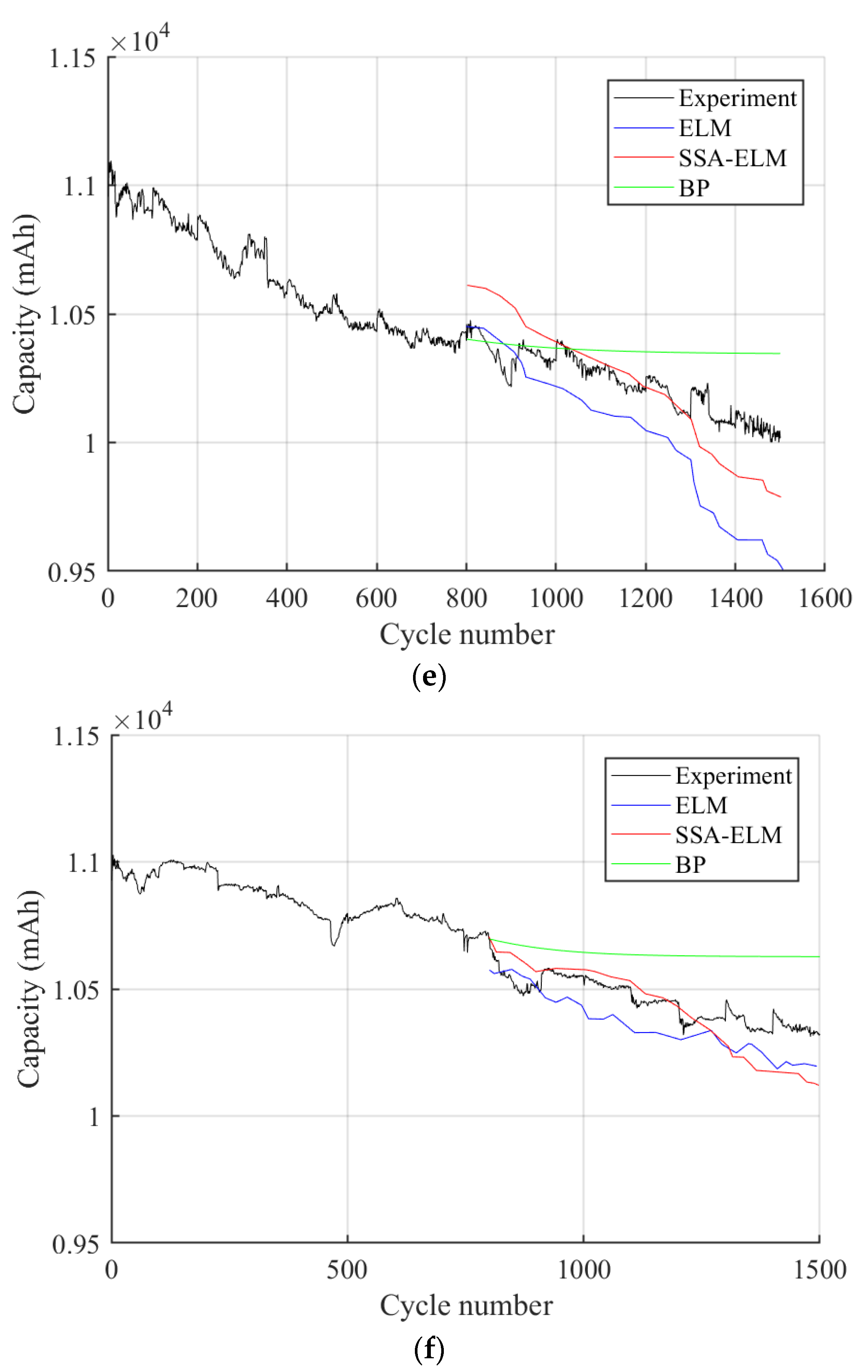

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chen, W.; Liang, J.; Yang, Z.; Li, G. A review of lithium-ion battery for electric vehicle applications and beyond. Energy Procedia 2019, 158, 4363–4368. [Google Scholar] [CrossRef]

- Reddy, R.C.K.; Lin, J.; Chen, Y.; Zeng, C.; Lin, X.; Cai, Y.; Su, C.Y. Progress of nanostructured metal oxides derived from metal–organic frameworks as anode materials for lithium–ion batteries. Coord. Chem. Rev. 2020, 420, 213434. [Google Scholar] [CrossRef]

- Reddy, R.; Lin, X.; Zeb, A.; Su, C.Y. Metal–Organic Frameworks and Their Derivatives as Cathodes for Lithium-Ion Battery Applications: A Review. Electrochem. Energy Rev. 2022, 5, 312–347. [Google Scholar] [CrossRef]

- Han, X.; Lu, L.; Zheng, Y.; Feng, X.; Li, Z.; Li, J.; Ouyang, M. A review on the key issues of the lithium ion battery degradation among the whole life cycle. ETransportation 2019, 1, 100005. [Google Scholar] [CrossRef]

- Liu, J.; Duan, Q.; Qi, K.; Liu, Y.; Sun, J.; Wang, Z.; Wang, Q. Capacity fading mechanisms and state of health prediction of commercial lithium-ion battery in total lifespan. J. Energy Storage 2022, 46, 103910. [Google Scholar] [CrossRef]

- Hu, Y.; Choe, S.Y.; Garrick, T.R. Measurement of heat generation rate and heat sources of pouch type Li-ion cells. Appl. Therm. Eng. 2021, 189, 116709. [Google Scholar] [CrossRef]

- Troxler, Y.; Wu, B.; Marinescu, M.; Yufit, V.; Patel, Y.; Marquis, A.J.; Brandon, N.P.; Offer, G.J. The effect of thermal gradients on the performance of lithium-ion batteries. J. Power Sources 2014, 247, 1018–1025. [Google Scholar] [CrossRef]

- Hu, Y.; Choe, S.Y.; Garrick, T.R. Measurement of two-dimensional heat generation rate of pouch type lithium-ion battery using a multifunctional calorimeter. J. Power Sources 2022, 532, 231350. [Google Scholar] [CrossRef]

- Liu, X.; Ai, W.; Marlow, M.N.; Patel, Y.; Wu, B. The effect of cell-to-cell variations and thermal gradients on the performance and degradation of lithium-ion battery packs. Appl. Energy 2019, 248, 489–499. [Google Scholar] [CrossRef]

- Werner, D.; Paarmann, S.; Wiebelt, A.; Wetzel, T. Inhomogeneous temperature distribution affecting the cyclic aging of Li-ion cells. Part I: Experimental investigation. Batteries 2020, 6, 13. [Google Scholar] [CrossRef]

- Liu, D.; Luo, Y.; Liu, J.; Peng, Y.; Guo, L.; Pecht, M. Lithium-ion battery remaining useful life estimation based on fusion nonlinear degradation AR model and RPF algorithm. Neural Comput. Appl. 2014, 25, 557–572. [Google Scholar] [CrossRef]

- Hosen, M.S.; Youssef, R.; Kalogiannis, T.; Van Mierlo, J.; Berecibar, M. Battery cycle life study through relaxation and forecasting the lifetime via machine learning. J. Energy Storage 2021, 40, 102726. [Google Scholar] [CrossRef]

- Deng, Y.; Ying, H.; Jiaqiang, E.; Zhu, H.; Wei, K.; Chen, J.; Zhang, F.; Liao, G. Feature parameter extraction and intelligent estimation of the State-of-Health of lithium-ion batteries. Energy 2019, 176, 91–102. [Google Scholar] [CrossRef]

- Long, B.; Li, X.; Gao, X.; Liu, Z. Prognostics comparison of lithium-ion battery based on the shallow and deep neural networks model. Energies 2019, 12, 3271. [Google Scholar] [CrossRef]

- Ng SS, Y.; Xing, Y.; Tsui, K.L. A naive Bayes model for robust remaining useful life prediction of lithium-ion battery. Appl. Energy 2014, 118, 114–123. [Google Scholar]

- Cao, W.; Li, J.; Wu, Z. Cycle-life and degradation mechanism of LiFePO4-based lithium-ion batteries at room and elevated temperatures. Ionics 2016, 22, 1791–1799. [Google Scholar] [CrossRef]

- Xue, J.; Shen, B. A novel swarm intelligence optimization approach: Sparrow search algorithm. Syst. Sci. Control Eng. 2020, 8, 22–34. [Google Scholar] [CrossRef]

| Battery Number | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| Cooling surface temperature (°C) | 24 | 24 | 28 | 28 | 20 | 20 |

| Heating surface temperature (°C) | 24 | 28 | 32 | 36 | 24 | 28 |

| Thermal gradient (°C) | 0 | 4 | 4 | 8 | 4 | 8 |

| Step | Working Condition | End Condition | Time |

|---|---|---|---|

| 1 | 1C CC-CV Charging | Cut-off current 0.6 A | —— |

| Cut-off voltage 3.65 V | |||

| 2 | Rest | —— | 30 min |

| 3 | 1.5C CC Discharging | Cut-off voltage 2.6 V | —— |

| 4 | Rest | —— | 30 min |

| 5 | Loop: Steps 1–4 | Number of cycles: 100 | —— |

| Battery Number | MAPE | RMSE (mAh) | ||||

|---|---|---|---|---|---|---|

| ELM | SSA-ELM | BP | ELM | SSA-ELM | BP | |

| Battery 1 | 2.9639% | 1.8129% | 2.8011% | 334.63 | 218.82 | 342.01 |

| Battery 2 | 1.3194% | 0.6150% | 0.5375% | 143.62 | 77.48 | 72.78 |

| Battery 3 | 2.1539% | 0.4189% | 0.6779% | 241.02 | 59.25 | 90.41 |

| Battery 4 | 2.7101% | 0.5236% | 2.0839% | 285.52 | 69.34 | 250.17 |

| Battery 5 | 2.1598% | 1.1032% | 1.3193% | 267.29 | 145.80 | 165.65 |

| Battery 6 | 0.9815% | 0.7615% | 1.8256% | 111.91 | 102.74 | 203.69 |

| Average value | 2.0481% | 0.8725% | 1.54% | 230.67 | 112.24 | 187.45 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, D.; Wang, S.; Di, L.; Zhang, W.; Wang, Q.; Wang, J.V. Lithium-Ion Battery Life Prediction Method under Thermal Gradient Conditions. Energies 2023, 16, 767. https://doi.org/10.3390/en16020767

Song D, Wang S, Di L, Zhang W, Wang Q, Wang JV. Lithium-Ion Battery Life Prediction Method under Thermal Gradient Conditions. Energies. 2023; 16(2):767. https://doi.org/10.3390/en16020767

Chicago/Turabian StyleSong, Dawei, Shiqian Wang, Li Di, Weijian Zhang, Qian Wang, and Jing V. Wang. 2023. "Lithium-Ion Battery Life Prediction Method under Thermal Gradient Conditions" Energies 16, no. 2: 767. https://doi.org/10.3390/en16020767

APA StyleSong, D., Wang, S., Di, L., Zhang, W., Wang, Q., & Wang, J. V. (2023). Lithium-Ion Battery Life Prediction Method under Thermal Gradient Conditions. Energies, 16(2), 767. https://doi.org/10.3390/en16020767