State of Health Estimation of Lithium-Ion Battery Based on Electrochemical Impedance Spectroscopy

Abstract

:1. Introduction

2. Battery Information and Related Data

2.1. Battery Information

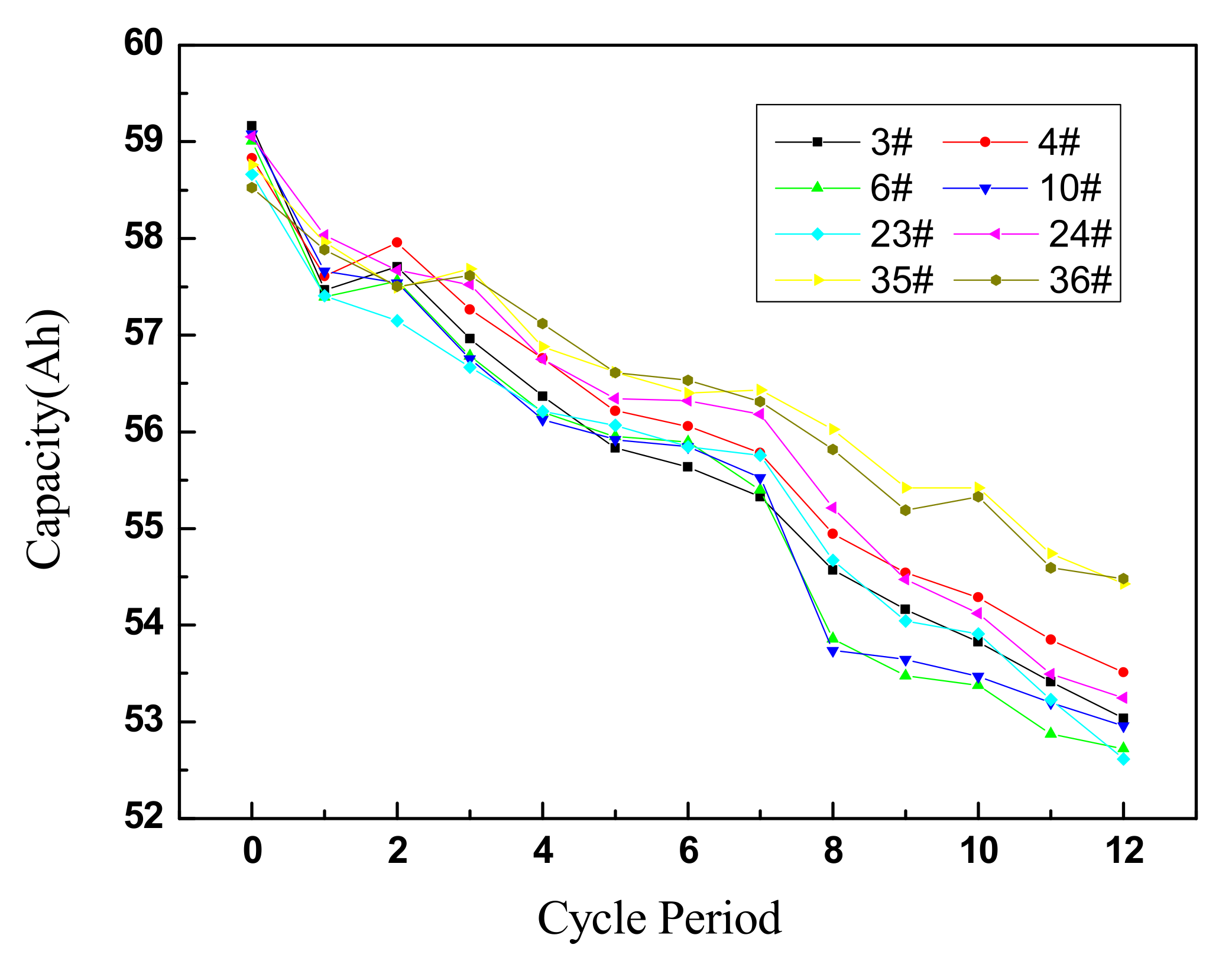

2.2. Battery Cycle Performance Test and Capacity Calibration

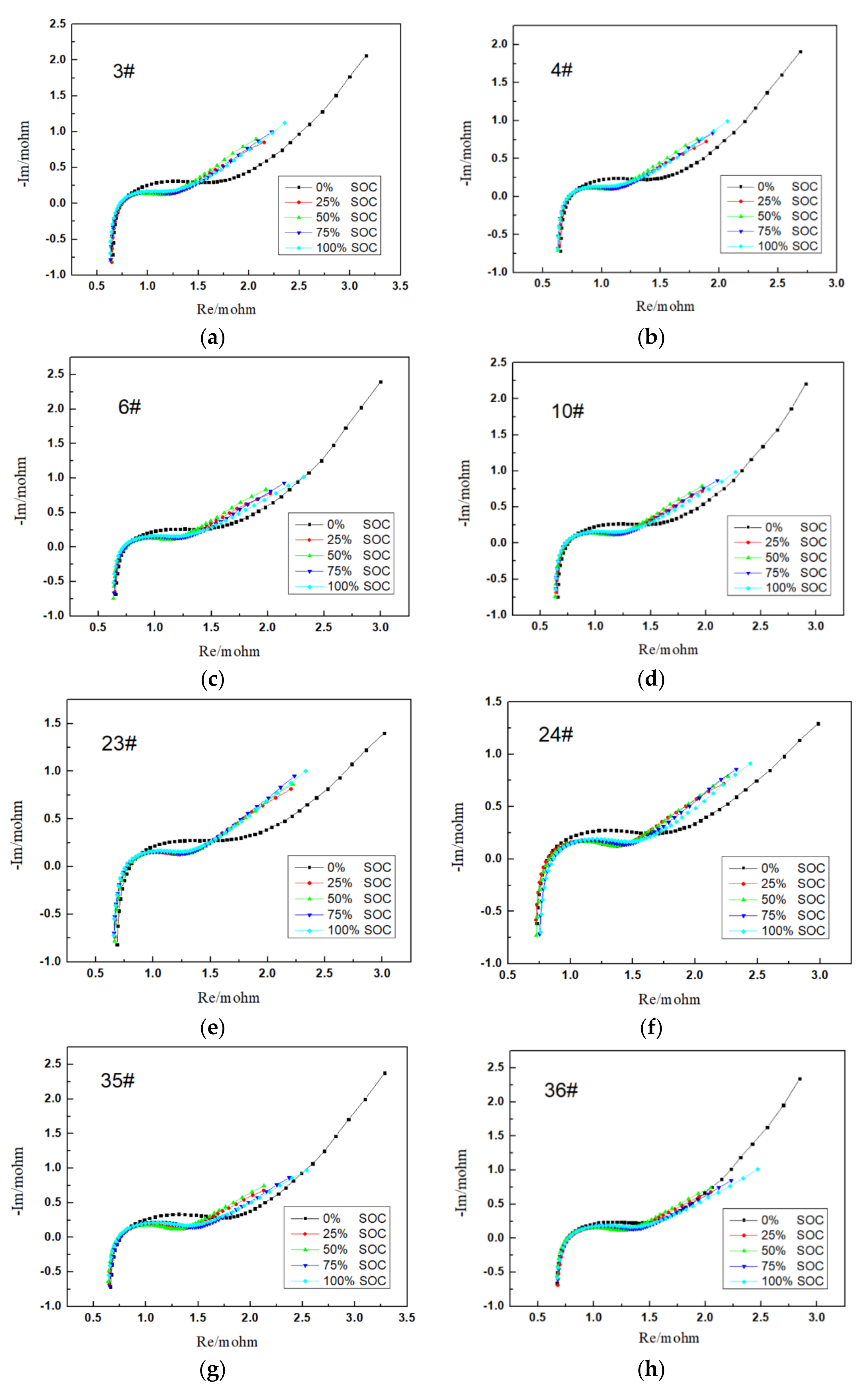

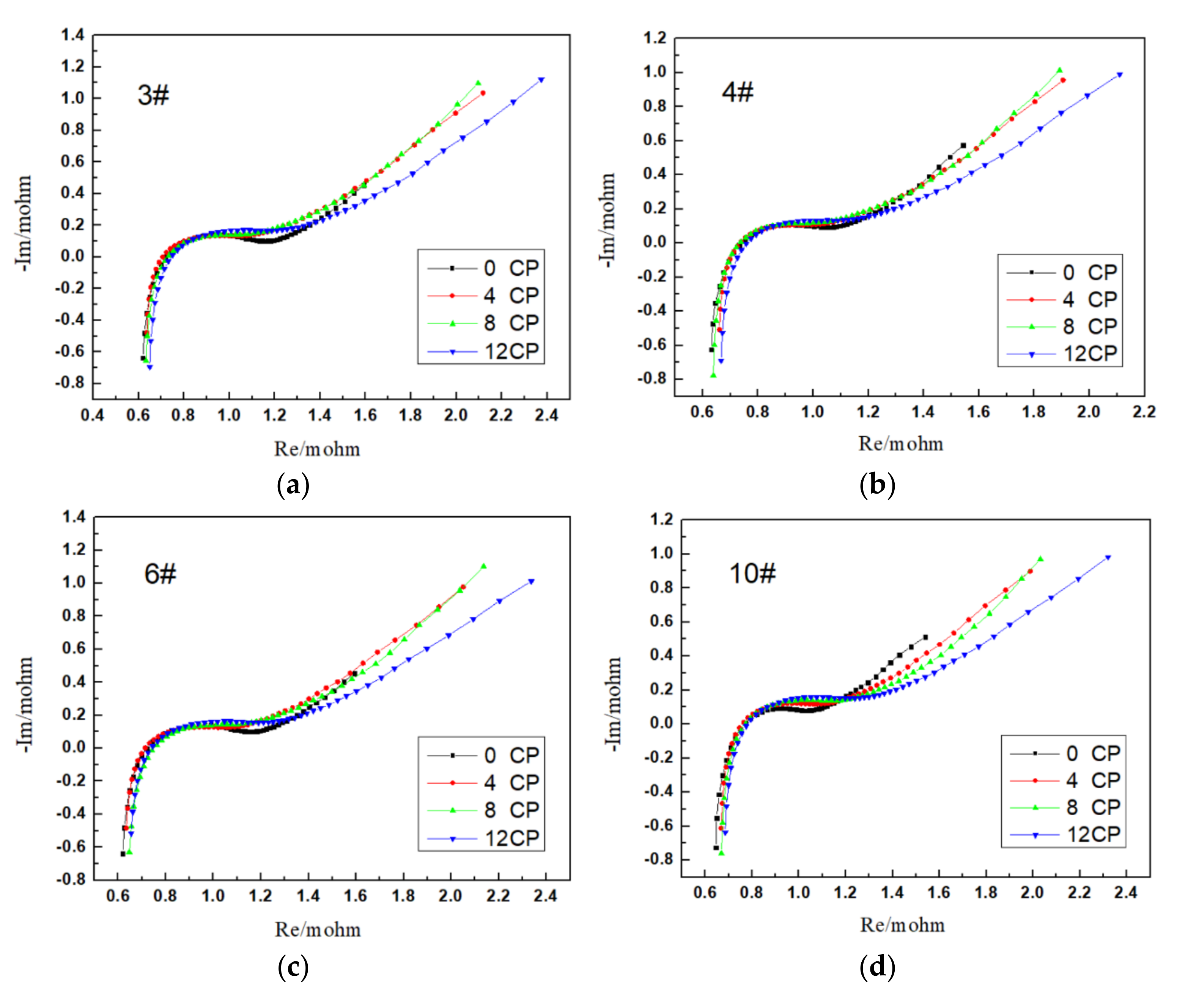

2.3. EIS of Batteries

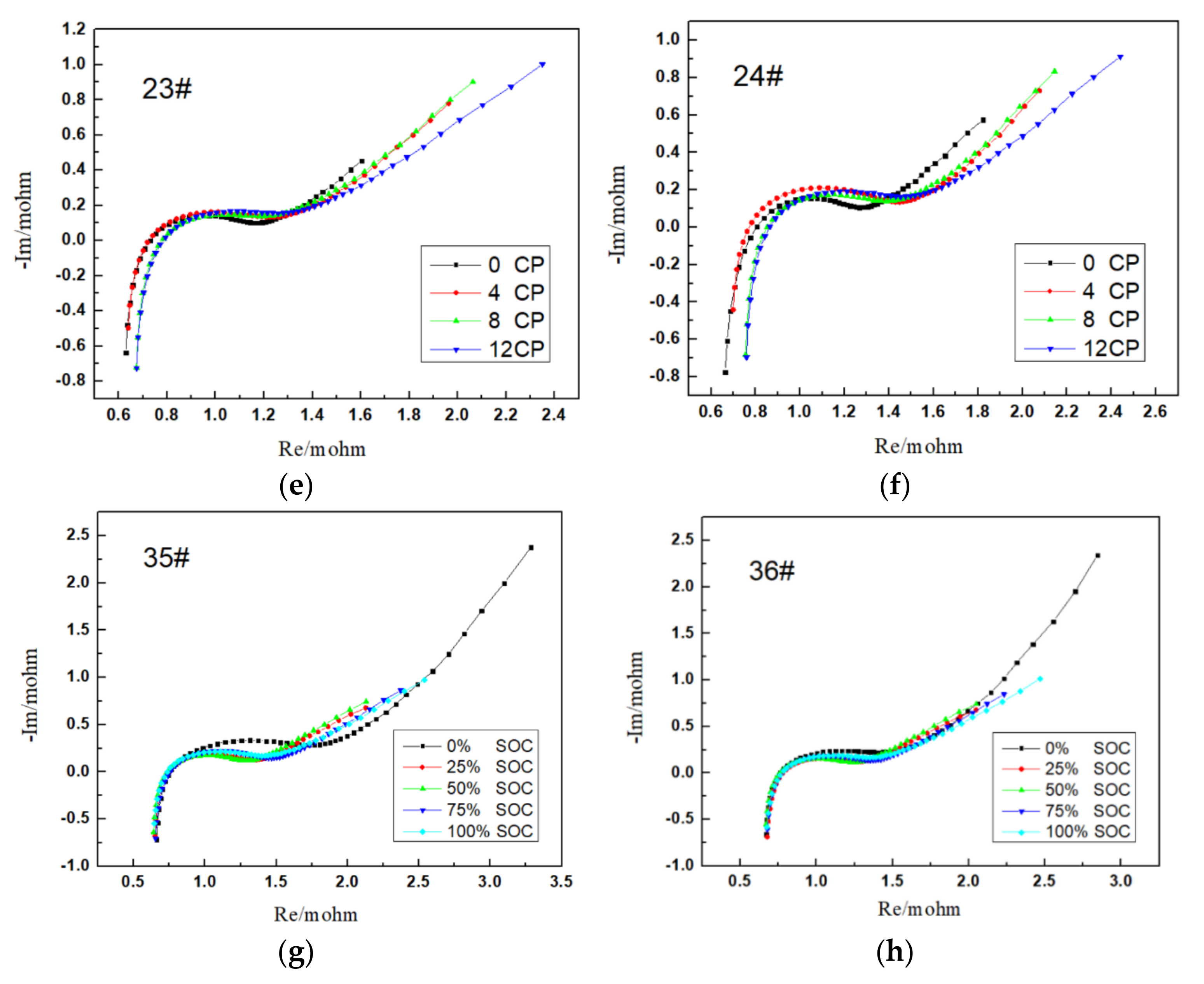

2.3.1. EIS of Battery at Different SOC

2.3.2. EIS at Different SOH

3. Characteristic Parameter Selection

4. Evaluation Model Construction and Verification

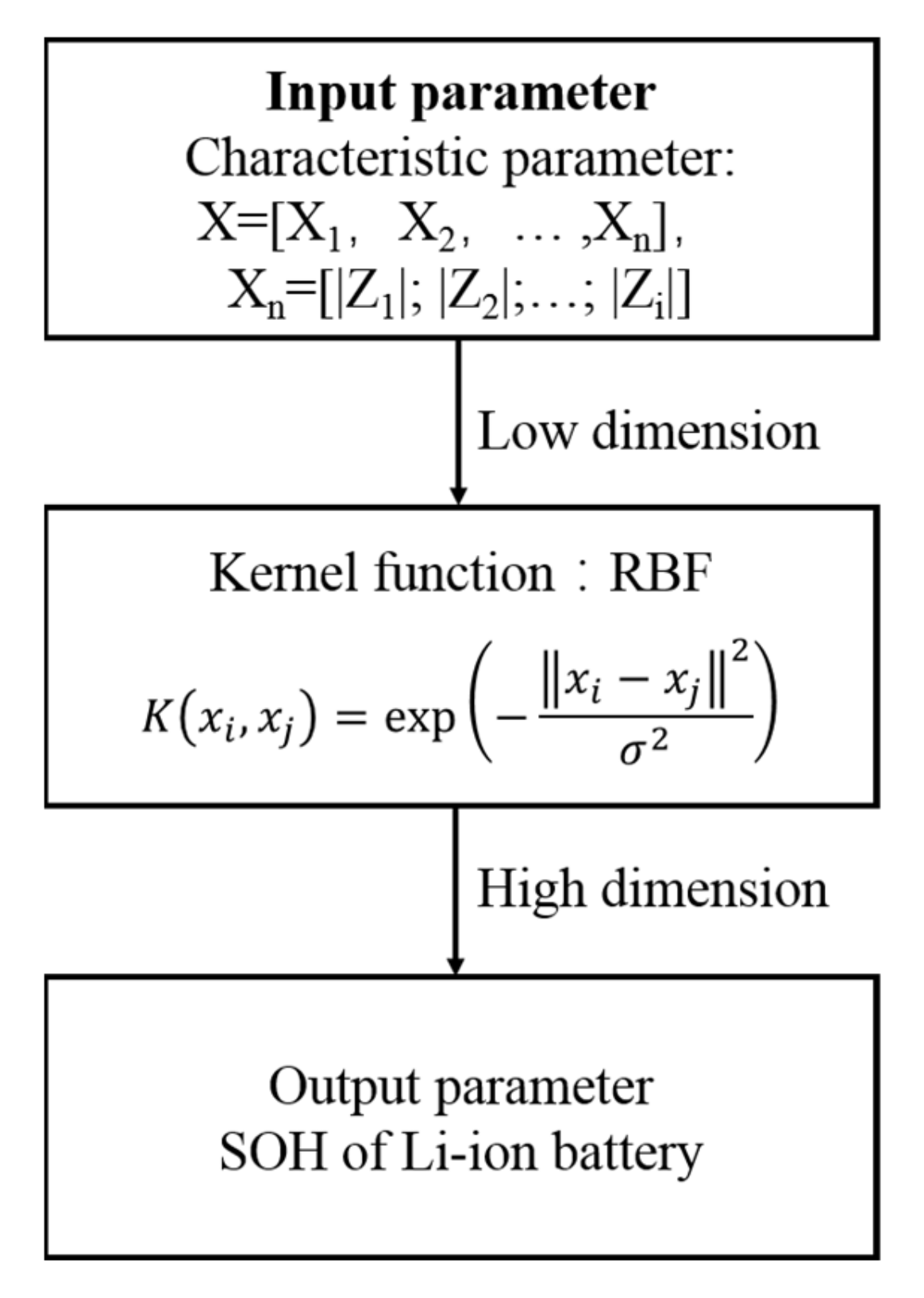

4.1. Principle of SVR Algorithm

4.2. Data Preprocessing

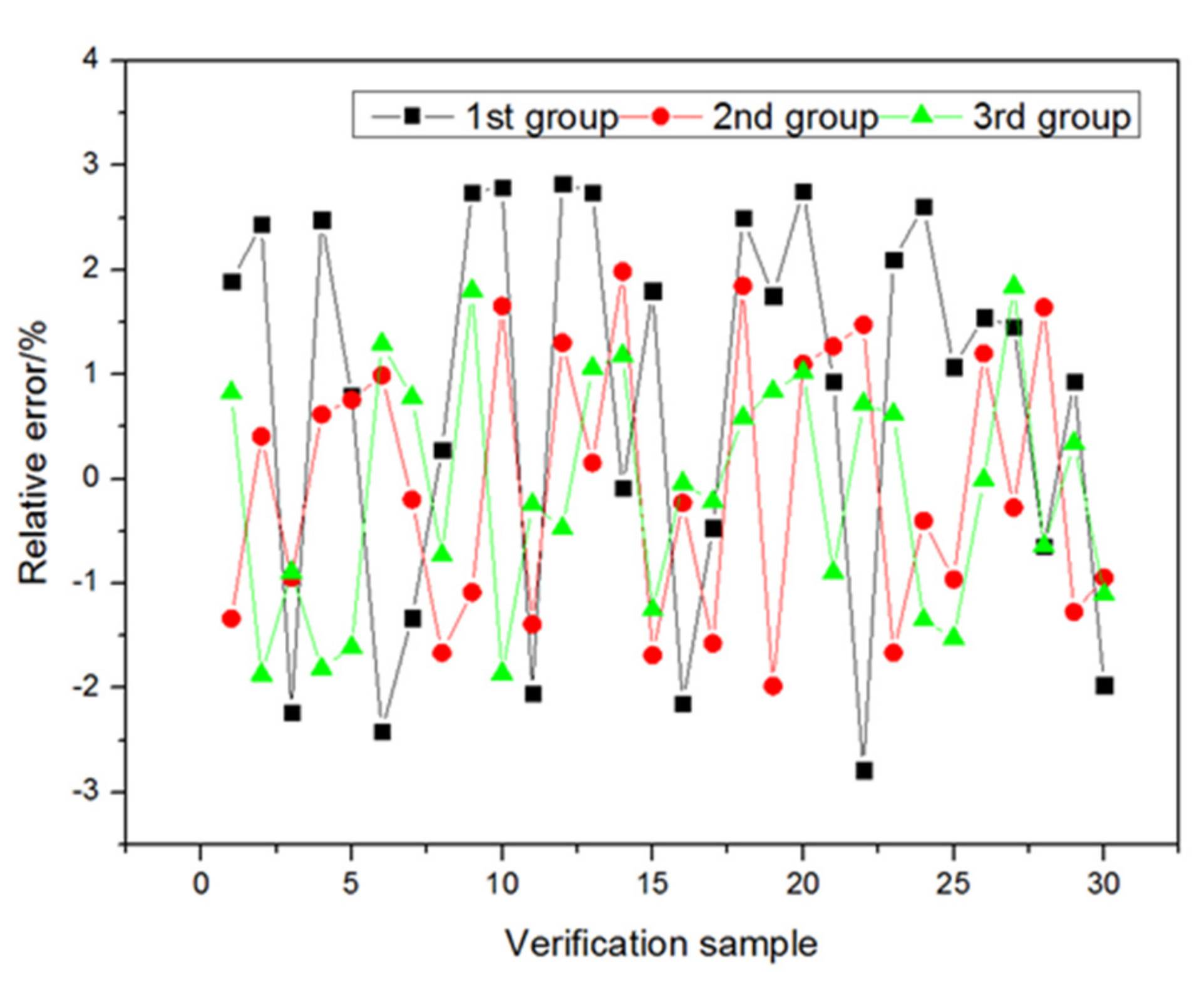

4.3. Evaluation Model Building and Validation

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Offer, G.J.; Yufit, V.; Howey, D.A.; Wu, B.; Brandon, N.P. Module design and fault diagnosis in electric vehicle batteries. J. Power Sources 2012, 206, 383–392. [Google Scholar] [CrossRef] [Green Version]

- Han, X.; Lu, L.; Zheng, Y.; Feng, X.; Li, Z.; Li, J.; Ouyang, M. A review on the key issues of the lithium ion battery degradation among the whole life cycle. eTransportation 2019, 1, 100005. [Google Scholar] [CrossRef]

- Fan, Y.; Xiao, F.; Li, C.; Yang, G.; Tang, X. A novel deep learning framework for state of health estimation of lithium-ion battery. J. Energy Storage 2020, 32, 101741. [Google Scholar] [CrossRef]

- Kashyap, D.; Dwivedi, P.K.; Pandey, J.K.; Kim, Y.H.; Kim, G.M.; Sharma, A.; Goel, S. Application of electrochemical impedance spectroscopy in bio-fuel cell characterization: A review. Int. J. Hydrogen Energy 2014, 39, 20159–20170. [Google Scholar] [CrossRef]

- Ouyang, M.; Chu, Z.; Lu, L.; Li, J.; Han, X.; Feng, X.; Liu, G. Low temperature aging mechanism identification and lithium deposition in a large format lithium iron phosphate battery for different charge profiles. J. Power Sources 2015, 286, 309–320. [Google Scholar] [CrossRef]

- Xu, J.; Mi, C.C.; Cao, B.; Cao, J. A new method to estimate the state of charge of lithium-ion batteries based on the battery impedance model. J. Power Sources 2013, 233, 277–284. [Google Scholar] [CrossRef]

- Eddahech, A.; Briat, O.; Vinassa, J.-M. Determination of lithium-ion battery state-of-health based on constant-voltage charge phase. J. Power Sources 2014, 258, 218–227. [Google Scholar] [CrossRef]

- Zenati, A.; Desprez, P.; Razik, H. Estimation of the SOC and the SOH of Li-ion Batteries, by Combining Impedance Measurements with the fuzzy Logic Inference. In Proceedings of the IECON 2010—36th Annual Conference on IEEE Industrial Electronics Society, IEEE, Glendale, AZ, USA, 7–10 November 2010. [Google Scholar]

- Li, X.; Zhang, L.; Liu, Y.; Pan, A.; Liao, Q.; Yang, X. A fast classification method of retired electric vehicle battery modules and their energy storage application in photovoltaic generation. Int. J. Energy Res. 2019, 44, 2337–2344. [Google Scholar] [CrossRef]

- Ungurean, L.; Cârstoiu, G.; Micea, M.V.; Groza, V. Battery state of health estimation: A structured review of models, methods and commercial devices. Int. J. Energy Res. 2017, 41, 151–181. [Google Scholar] [CrossRef]

- Huet, F. A review of impedance measurements for determination of the state-of-charge or state-of-health of secondary batteries. J. Power Sources 1998, 70, 59–69. [Google Scholar] [CrossRef]

- Stroe, D.I.; Swierczynski, M.; Stroe, A.I.; Knap, V.; Andreasen, S.J. Diagnosis of lithium-ion batteries state-of-health based on electrochemical impedance spectroscopy technique. In Proceedings of the 2014 IEEE Energy Conversion Congress and Exposition (ECCE), IEEE, Pittsburgh, PA, USA, 14–18 September 2014; pp. 4576–4582. [Google Scholar]

- Chin, C.S.; Gao, Z.; Zhang, C.Z. Comprehensive electro-thermal model of 26650 lithium battery for discharge cycle under parametric and temperature variations. J. Energy Storage 2020, 28, 101222. [Google Scholar] [CrossRef]

- Galeotti, M.; Cinà, L.; Giammanco, C.; Cordiner, S.; Di Carlo, A. Performance analysis and SOH (state of health) evaluation of lithium polymer batteries through electrochemical impedance spectroscopy. Energy 2015, 89, 678–686. [Google Scholar] [CrossRef]

- Tian, N.; Wang, Y.; Chen, J.; Fang, H. One-shot parameter identification of the Thevenin’s model for batteries: Methods and validation. J. Energy Storage 2020, 29, 101282. [Google Scholar] [CrossRef] [Green Version]

- Yang, Q.; Xu, J.; Li, X.; Xu, D.; Cao, B. State-of-health estimation of lithium-ion battery based on fractional impedance model and interval capacity. Int. J. Electr. Power Energy Syst. 2020, 119, 105883. [Google Scholar] [CrossRef]

- Zhu, S.; Sun, X.; Gao, X.; Wang, J.; Zhao, N.; Sha, J. Equivalent circuit model recognition of electrochemical impedance spectroscopy via machine learning. Electroanal. Chem. 2019, 855, 113627. [Google Scholar] [CrossRef] [Green Version]

- Xiong, R.; Tian, J.; Mu, H.; Wang, C. A systematic model-based degradation behavior recognition and health monitoring method for lithium-ion batteries. Appl. Energy 2017, 207, 372–383. [Google Scholar] [CrossRef]

- Zhang, Y.; Tang, Q.; Zhang, Y.; Wang, J.; Stimming, U.; Lee, A.A. Identifying degradation patterns of lithium ion batteries from impedance spectroscopy using machine learning. Nat. Commun. 2020, 11, 1706. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ge, M.-F.; Liu, Y.; Jiang, X.; Liu, J. A review on state of health estimations and remaining useful life prognostics of lithium-ion batteries. Measurement 2021, 174, 109057. [Google Scholar] [CrossRef]

- Tian, H.; Qin, P.; Li, K.; Zhao, Z. A review of the state of health for lithium-ion batteries: Research status and suggestions. J. Clean. Prod. 2020, 261, 120813. [Google Scholar] [CrossRef]

| Cell Technical Data Sheet | |

|---|---|

| Model | V0D5N0 |

| Type | LFP/C |

| Rated Voltage | 3.2 V |

| Rated Capacity | 60 Ah |

| Weight | 1710 ± 30 g |

| Internal Resistance (1000 Hz) | ~0.6 mΩ |

| Charge Cut-off Voltage | 3.65 V |

| Discharge Cut-off Voltage | 2.5 V |

| Cycle Period | Discharge Capacity (Ah) | |||||||

|---|---|---|---|---|---|---|---|---|

| 100%DOD | 80%DOD | 50%DOD | 20%DOD | |||||

| 3# | 4# | 6# | 10# | 23# | 24# | 35# | 36# | |

| 0 | 59.162 | 58.833 | 59.008 | 59.078 | 58.663 | 59.051 | 58.762 | 58.527 |

| 1 | 57.467 | 57.612 | 57.395 | 57.663 | 57.406 | 58.029 | 57.963 | 57.884 |

| 2 | 57.709 | 57.959 | 57.562 | 57.540 | 57.149 | 57.672 | 57.489 | 57.505 |

| 3 | 56.962 | 57.263 | 56.784 | 56.757 | 56.667 | 57.524 | 57.683 | 57.616 |

| 4 | 56.366 | 56.758 | 56.201 | 56.126 | 56.208 | 56.750 | 56.879 | 57.120 |

| 5 | 55.832 | 56.214 | 55.950 | 55.921 | 56.068 | 56.346 | 56.615 | 56.613 |

| 6 | 55.637 | 56.056 | 55.897 | 55.847 | 55.847 | 56.323 | 56.402 | 56.535 |

| 7 | 55.328 | 55.781 | 55.395 | 55.526 | 55.759 | 56.184 | 56.434 | 56.312 |

| 8 | 54.568 | 54.944 | 53.857 | 53.736 | 54.673 | 55.211 | 56.025 | 55.819 |

| 9 | 54.163 | 54.540 | 53.476 | 53.645 | 54.045 | 54.473 | 55.421 | 55.187 |

| 10 | 53.827 | 54.289 | 53.379 | 53.469 | 53.908 | 54.122 | 55.418 | 55.327 |

| 11 | 53.413 | 53.849 | 52.873 | 53.199 | 53.230 | 53.493 | 54.742 | 54.594 |

| 12 | 53.035 | 53.510 | 52.720 | 52.957 | 52.613 | 53.248 | 54.425 | 54.482 |

| First Group | Second Group | Third Group | |

|---|---|---|---|

| Characteristic frequency-point combination | 186.7 Hz, 17.9 Hz, 1.4 Hz | 186.7 Hz, 57.8 Hz, 17.9 Hz, 5.6 Hz, 1.4 Hz | 1000 Hz, 186.7 Hz, 57.8 Hz, 17.9 Hz, 5.6 Hz, 1.4 Hz, 0.1 Hz |

| First Group | Second Group | Third Group | |

|---|---|---|---|

| MAPE | 1.82% | 0.96% | 0.98% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, M.; Geng, M.; Yang, K.; Zhang, M.; Liu, H. State of Health Estimation of Lithium-Ion Battery Based on Electrochemical Impedance Spectroscopy. Energies 2023, 16, 3393. https://doi.org/10.3390/en16083393

Fan M, Geng M, Yang K, Zhang M, Liu H. State of Health Estimation of Lithium-Ion Battery Based on Electrochemical Impedance Spectroscopy. Energies. 2023; 16(8):3393. https://doi.org/10.3390/en16083393

Chicago/Turabian StyleFan, Maosong, Mengmeng Geng, Kai Yang, Mingjie Zhang, and Hao Liu. 2023. "State of Health Estimation of Lithium-Ion Battery Based on Electrochemical Impedance Spectroscopy" Energies 16, no. 8: 3393. https://doi.org/10.3390/en16083393