Simulation Research on the Optimization of Domestic Heat Pump Water Heater Condensers

Abstract

:1. Introduction

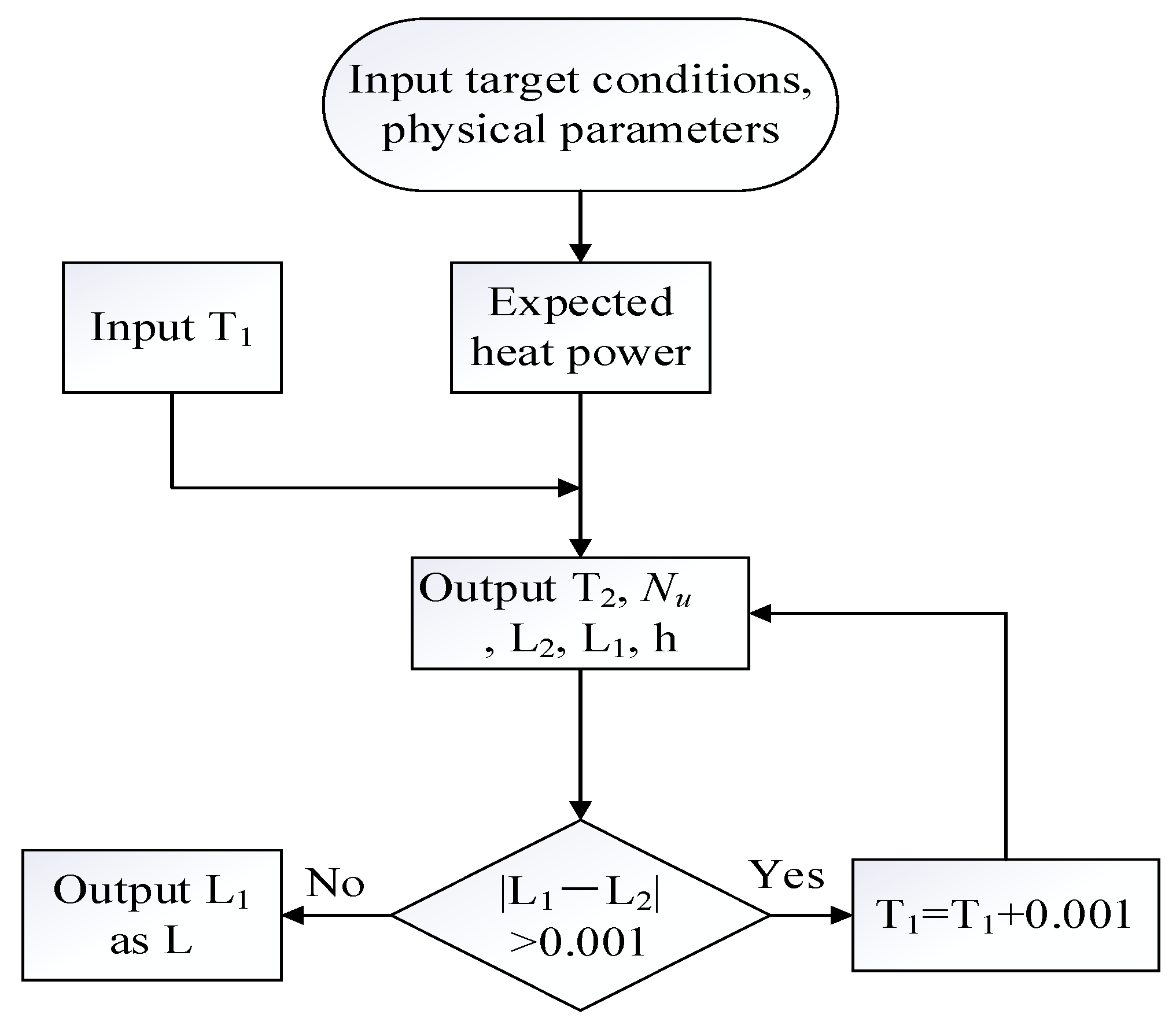

2. Method

2.1. Simulation Setup

- Liquid encapsulating heat exchangers were treated as continuous laminar flow.

- Fluid was incompressible.

- Solution domain mass was conserved.

- The inner wall temperature was a fixed value.

2.2. CFD Simulation

Heat Transfer between Solid and Fluid

2.3. Post-Process Data Analysis

2.4. Model Verification

3. Results and Discussion

3.1. Description of the Simulation Test

3.2. Grid-Independent Verification

3.3. Presentation of Results

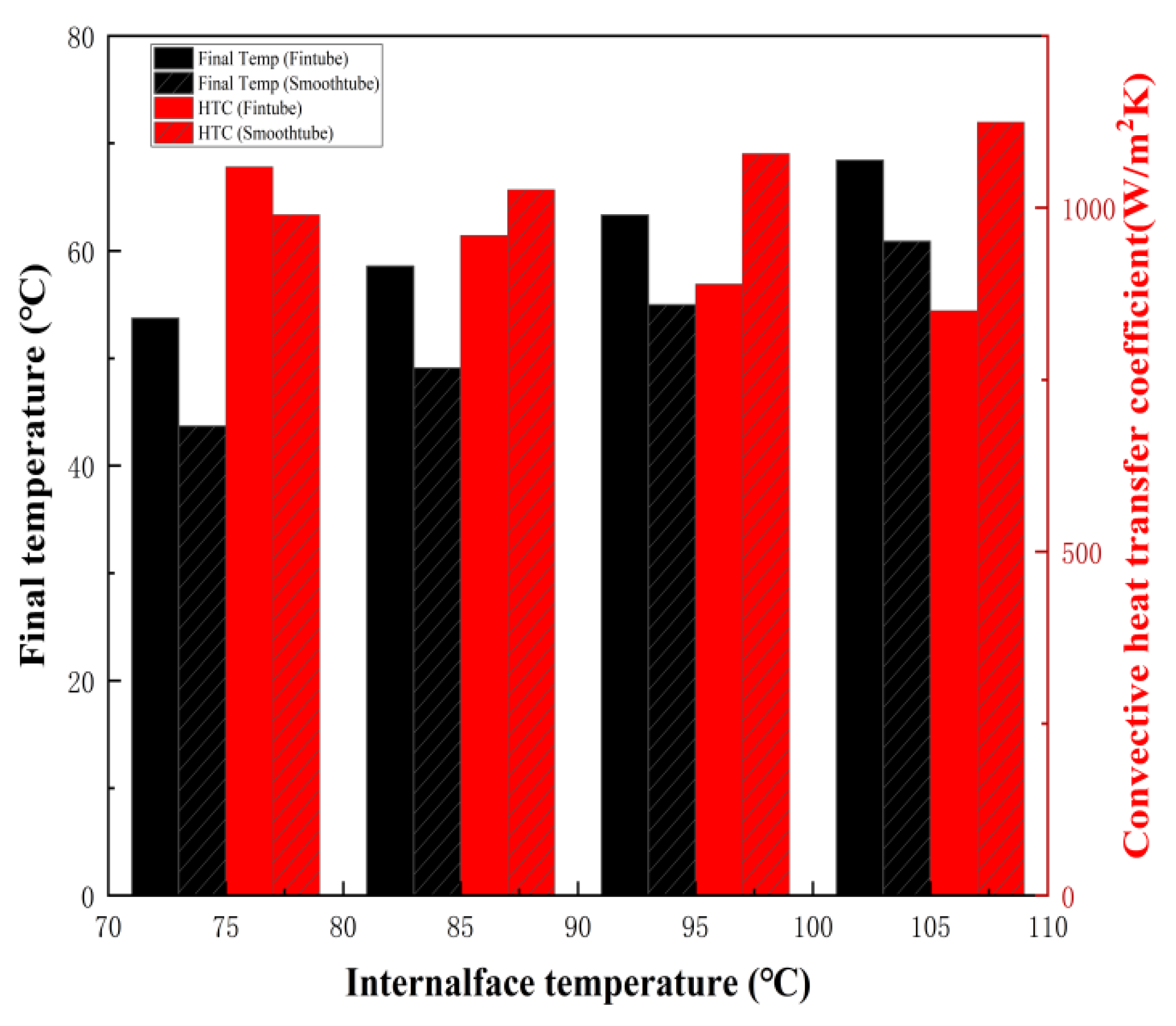

3.3.1. Performance Differences among Fin-Tubes and Smooth-Tubes at Different Constant Internal Wall Temperatures

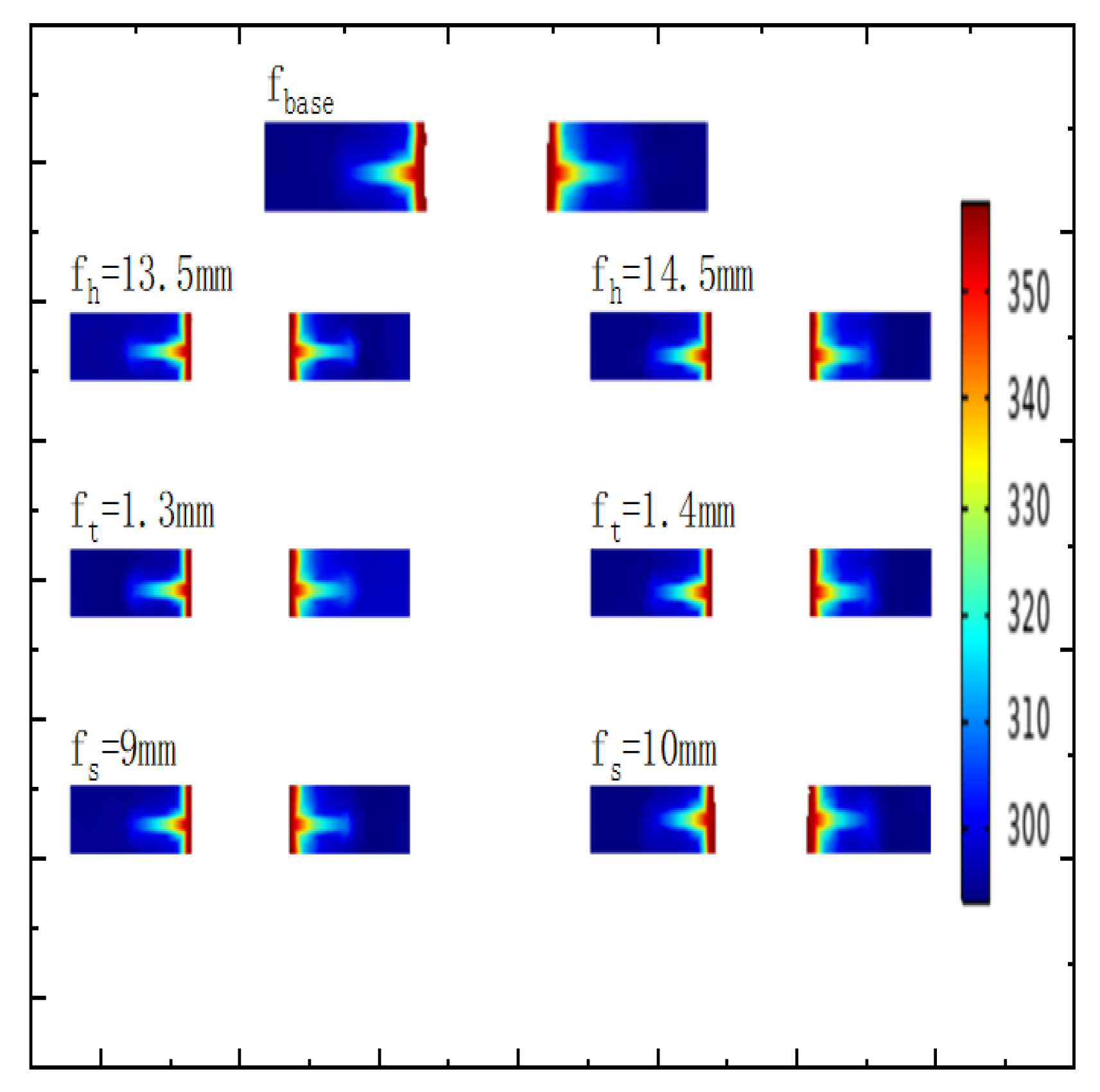

3.3.2. Changes of Fin-Tube Performance with Various Parameters

4. Conclusions

- (1)

- When the constant internal wall temperature were 75 °C, 85 °C, 95 °C and 105 °C, the prototype fin-tube had a heat transfer coefficient improvement of 7.03%, −6.45%, −17.57% and −24.37% over that of smooth-tube, respectively.

- (2)

- Heat transfer coefficient enhanced clearly, and the total thermal resistance of the fin-tube condenser decreased by 7% upon increasing the fin thickness.

- (3)

- The total thermal resistance of the fin-tube condenser increased by 1–1.3% when the fin spacing was increased.

- (4)

- When the temperature of the inner wall of the tube was 85 °C, the maximum temperature of the external waters could reach 56.46 °C. In 600 s, as fin spacing, fin height, fin thickness and inner diameter were 14 mm, 12.5 mm, 1.2 mm and 22.5 mm, respectively, compared to the smooth-tube condenser, the fin-tube condenser could increase the final water temperature by 18.37%, and the heat transfer efficiency would increase by about 95%.

- (5)

- It was found that as the inner diameter increased from 22.5 mm to 25.5 mm, the heat transfer coefficients of the fin-tube increased by 1.2%, 7.1% and 13.1%, respectively, and then showed a decreasing trend with a further increase in the inner diameter. Therefore, from a manufacturing point of view, it was easier to obtain a higher heat transfer efficiency by increasing the fin height.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Density (kg/m3) | |

| Constant pressure specific heat capacity (J/(kg·°C)) | |

| f | Temperature field (°C) |

| Temperature (°C) | |

| Time (s) | |

| Velocity field (m/s) | |

| Heat flux (W/m2) | |

| Heat (W) | |

| Thermal conductivity (W/(m·°C)) | |

| Shear force (N) | |

| Unit tensor (N) | |

| Viscous term (Pa·s) | |

| Body force (N) | |

| Gravity term (m/s2) | |

| m | Mass (kg) |

| Convective heat transfer coefficient (W/(m2·°C)) | |

| Specific heat capacity (J /(kg·°C)) | |

| Tube length (mm) | |

| Subscript | |

| m | Mean temperature |

| d | Inner diameter |

| D | Outer diameter |

| fh | Fin height |

| fs | Fin spacing |

| ft | Fin thickness |

References

- Dizaji, H.S.; Pourhedayat, S.; Aldawi, F.; Moria, H.; Anqi, A.E.; Jarad, F. Proposing an innovative and explicit economic criterion for all passive heat transfer enhancement techniques of heat exchangers. Energy 2022, 239, 122271. [Google Scholar] [CrossRef]

- Zachár, A. Investigation of a new tube-in-tube helical flow distributor design to improve temperature stratification inside hot water storage tanks operated with coiled-tube heat exchangers. Int. J. Heat Mass Transf. 2013, 63, 150–161. [Google Scholar] [CrossRef]

- Ravikumar, M.; Radha Krishnan Beemaraj Arunraja, K.M.; Pandiarajan, P.; Sundaresan, R. Heat transfer analysis in fin and tube exchanger using CFD. Mater. Today Proc. 2022, 52, 1603–1605. [Google Scholar]

- Yu, D.; Jeon, W.; Kim, S.J. Analytic study on pressure drop and heat transfer characteristics for low reynolds number flow in spirally finned tubes. Int. J. Heat Mass Transf. 2020, 158, 119849. [Google Scholar] [CrossRef]

- Pai, Y.-W.; Yeh, R.-H. Experimental investigation of heat transfer and pressure drop characteristics of internal finned tubes. Int. J. Heat Mass Transf. 2022, 183, 122183. [Google Scholar] [CrossRef]

- Nuntaphan, A.; Kiatsiriroat, T.; Wang, C.C. Heat transfer and friction characteristics of crimped spiral finned heat exchangers with dehumidification. Appl. Therm. Eng. 2005, 25, 327–340. [Google Scholar] [CrossRef]

- FaJiang, H.; WeiWu, C.; Ping, Y. Experimental Investigation of Heat Transfer and Flowing Resistance for Air Flow Cross over Spiral Finned Tube Heat Exchanger. Energy Procedia 2012, 17, 741–749. [Google Scholar] [CrossRef]

- Yulianto, M.; Suzuki, T.; Ge, Z.; Tsuchino, T.; Urakawa, M.; Taira, S.; Miyaoka, Y.; Giannetti, N.; Li, L.; Saito, K. Performance assessment of an R32 commercial heat pump water heater in different climates. Sustain. Energy Technol. Assess. 2022, 49, 101679. [Google Scholar] [CrossRef]

- Ye, Q.; Li, S. Investigation on the performance and optimization of heat pump water heater with wrap-around condenser coil. Int. J. Heat Mass Transf. 2019, 143, 118556. [Google Scholar] [CrossRef]

- Liu, M.; He, Y.; Zhang, H.; Su, H.; Zhang, Z. The feasibility of solar thermal-air source heat pump water heaters in renewable energy shortage regions. Energy 2020, 197, 117189. [Google Scholar] [CrossRef]

- Pethkool, S.; Eiamsa-ard, S.; Kwankaomeng, S.; Promvonge, P. Turbulent heat transfer enhancement in a heat exchanger using helically corrugated tube. Int. Commun. Heat Mass Transf. 2011, 38, 340–347. [Google Scholar] [CrossRef]

- Cafiero, G.; Discetti, S.; Astarita, T. Heat transfer enhancement of impinging jets with fractal-generated turbulence. Int. J. Heat Mass Transf. 2014, 75, 173–183. [Google Scholar] [CrossRef]

- Abraham, P.; Sharqawy, M.H.; Shawkat, M.E. Thermal and hydraulic characteristics of multiple row spiral finned tube heat exchangers. Int. J. Refrig. 2021, 130, 56–66. [Google Scholar] [CrossRef]

- Liu, X.; Wang, M.; Liu, H.; Chen, W.; Qian, S. Numerical analysis on heat transfer enhancement of wavy fin-tube heat exchangers for air-conditioning applications. Appl. Therm. Eng. 2021, 199, 117597. [Google Scholar] [CrossRef]

- Tang, S.; Li, H.; Zhou, J.; Li, H.; Zhang, D. Parametric investigation and correlation development for thermal-hydraulic characteristics of honeycomb 4H-type finned tube heat exchangers. Appl. Therm. Eng. 2021, 199, 117542. [Google Scholar] [CrossRef]

- Kiatpachai, P.; Kaewkamrop, T.; Mesgarpour, M.; Ahn, H.S.; Dalkılıç, A.S.; Mahian, O.; Wongwises, S. Air-side performance of embedded and welded spiral fin and tube heat exchangers. Case Stud. Therm. Eng. 2022, 30, 101721. [Google Scholar] [CrossRef]

- Singh, V.; Abdelaziz, O.; Aute, V.; Radermacher, R. Simulation of air-to-refrigerant fin-and-tube heat exchanger with CFD-based air propagation. Int. J. Refrig. 2011, 34, 1883–1897. [Google Scholar] [CrossRef]

- Taler, D.; Ocłoń, P. Determination of heat transfer formulas for gas flow in fin-and-tube heat exchanger with oval tubes using CFD simulations. Chem. Eng. Process. Process Intensif. 2014, 83, 1–11. [Google Scholar] [CrossRef]

- Chen, H.-T.; Hsieh, Y.-L.; Chen, P.-C.; Lin, Y.-F.; Liu, K.-C. Numerical simulation of natural convection heat transfer for annular elliptical finned tube heat exchanger with experimental data. Int. J. Heat Mass Transf. 2018, 127, 541–554. [Google Scholar] [CrossRef]

- Batista, J.; Trp, A.; Lenic, K. Experimentally validated numerical modeling of heat transfer in crossflow air-to-water fin-and-tube heat exchanger. Appl. Therm. Eng. 2022, 212, 118528. [Google Scholar] [CrossRef]

- Guo, J.J.; Wu, J.Y.; Wang, R.Z. A new approach to energy consumption prediction of domestic heat pump water heater based on grey system theory. Energy Build. 2011, 43, 1273–1279. [Google Scholar] [CrossRef]

- Al-Joboory, H.N.S. Comparative experimental investigation of two evacuated tube solar water heaters of different configurations for domestic application of Baghdad- Iraq. Energy Build. 2019, 203, 109437. [Google Scholar] [CrossRef]

- Zukowski, M.; Woroniak, G. Estimation of energy savings resulting from the cooperation of an air to water heat pump with a solar air heater. Sol. Energy 2023, 250, 182–193. [Google Scholar] [CrossRef]

- Engel, R.C.; Deschamps, C.J. Comparative analysis between the performances of reciprocating and rolling piston compressors applied to a domestic heat pump water heater. Int. J. Refrig. 2019, 102, 130–141. [Google Scholar] [CrossRef]

- Ma, H.; Xu, L.; Javaheri, Z.; Moghadamnejad, N.; Abedi, M. Reducing the consumption of household systems using hybrid deep learning techniques. Sustain. Comput. Inform. Syst. 2023, 38, 100874. [Google Scholar] [CrossRef]

- Tian, L.; He, Y.; Tao, Y.; Tao, W. A comparative study on the air-side performance of wavy fin-and-tube heat exchanger with punched delta winglets in staggered and in-line arrangements. Int. J. Therm. Sci. 2009, 48, 1765–1776. [Google Scholar] [CrossRef]

| Components | Model |

|---|---|

| CPU | 12th Gen Intel(R) Core(TM) i7-12700KF 3.60 GHz, Intel, Shanghai, China |

| RAM | 16.0 GB, Kingston, Shanghai, China |

| Operating System | 64-bit |

| GPU | NVIDIA GeForce GTX 1650, GALAX, Qinghai, China |

| Tube Type/Structure (mm) | Inner Diameter | Outer Diameter | Tube Length | Fin Thickness | Fin Height | Fin Spacing |

|---|---|---|---|---|---|---|

| Fin-tube | 22.5 | 25 | 550 | 1.2 | 12.5 | 5 |

| Smooth-tube | 22.5 | 25 | 550 | -- | -- | -- |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, Y.; Feng, R.; Xiao, T.; Guo, M.; Wu, J.; Cui, H. Simulation Research on the Optimization of Domestic Heat Pump Water Heater Condensers. Energies 2023, 16, 7441. https://doi.org/10.3390/en16217441

Han Y, Feng R, Xiao T, Guo M, Wu J, Cui H. Simulation Research on the Optimization of Domestic Heat Pump Water Heater Condensers. Energies. 2023; 16(21):7441. https://doi.org/10.3390/en16217441

Chicago/Turabian StyleHan, Yang, Rong Feng, Taiyang Xiao, Machao Guo, Jiahui Wu, and Hong Cui. 2023. "Simulation Research on the Optimization of Domestic Heat Pump Water Heater Condensers" Energies 16, no. 21: 7441. https://doi.org/10.3390/en16217441

APA StyleHan, Y., Feng, R., Xiao, T., Guo, M., Wu, J., & Cui, H. (2023). Simulation Research on the Optimization of Domestic Heat Pump Water Heater Condensers. Energies, 16(21), 7441. https://doi.org/10.3390/en16217441