1. Introduction

The aviation industry is widely considered to have emissions reduction challenges because aircraft operations depend strongly on fossil fuels, the aviation infrastructure faces persistent carbon lock-in, and fleet turnover is rather slow [

1]. In the aviation industry, carbon reduction measures mainly include developing new aircraft and engine technologies with better fuel efficiency, enhancing operational efficiency in the air and on the ground, and utilizing sustainable aviation fuel (SAF), hydrogen, electricity, and other alternative energy sources. Among these, SAF can be directly blended with aviation kerosene without requiring significant changes to aircraft engines, airframes, or ground infrastructure. It represents the most commercially applicable measure for emission reduction in the short to medium term within the aviation industry [

2]. Assessments by international organizations, such as the International Civil Aviation Organization (ICAO), the International Air Transport Association (IATA), and the Air Transport Action Group (ATAG), indicate that SAF has a decarbonization potential exceeding 55% [

3,

4]. SAF refers to aviation fuel made from renewable resources or waste materials, certified for safety and sustainability. Its lifecycle greenhouse gas (GHG) emissions can be reduced by over 50% compared to traditional fossil fuels. It can even achieve negative carbon emissions. The significant emission reduction potential drives the potential consumer market of SAF. In 2021, global SAF consumption reached 125 million liters, accounting for only 0.55% of global aviation fuel usage in that year [

5,

6]. This still falls short of the requirements for large-scale applications. The main obstacle to scaling up SAF application is its low cost-effectiveness. Currently, SAF costs and prices are approximately 2–4-fold higher than traditional aviation kerosene, posing a cost burden that will overwhelm financially weak airlines [

7]. Reducing SAF costs and prices is crucial for increasing SAF usage, enhancing carbon reduction efforts in the aviation industry, and helping the industry achieve carbon peaking and neutrality.

The production technologies associated with biofuels are incredibly diverse, encompassing variable pressure and adsorption technology [

8], Alcohol-to-Jet fuel (ATJ) technology [

9,

10], catalytic hydrothermal decomposition technology [

9], hydrodepolymerization of cellulose technology [

9], gas-to-jet fuel technology, gas fermentation processes [

11,

12], direct disaccharide-to-jet fuel technology [

9], aqueous-phase reforming technology [

13,

14,

15], etc. The use of renewable bioresources for aviation fuel production holds great promise for the aviation industry, offering a means to reduce its reliance on fossil fuels and achieve carbon emission reduction goals. While various studies have focused on the techno-economic evaluation of specific SAF production routes to assess their costs and environmental impacts [

16,

17,

18,

19], there is a noticeable dearth of research directly comparing the economic viability of these different technology routes in China.

The cost structure of SAF includes raw material and additive costs, fixed asset investments, and transportation and storage costs, with raw material costs and fixed asset investments being the main driving factors of SAF cost [

20,

21,

22]. Different production technology pathways have significant heterogeneity in raw material requirements and the necessary fixed asset investments, resulting in cost and price differences. As the world’s largest developing country and a net importer of energy and crops, China faces the dual tasks of improving energy and food governance. Thus, China’s selection of SAF raw materials and preparation processes must consider multiple aspects, such as food security, energy security, social development, and resource conservation. It requires comprehensive governance that integrates food, energy, and climate security, promoting the sustainable development of the industry and the economy. SAF production technology pathways that align with China’s national conditions and meet the needs of aviation transport are crucial for promoting the development of China’s SAF industry and achieving carbon peaking and carbon neutrality.

In order to determine SAF production technology pathways that align with China’s national conditions, this study centers on assessing the suitability of four sustainable aviation fuel (SAF) production technology pathways, HEFA, AtJ, G + FT, and PtL, at various developmental stages within China. These four types of technology routes are currently widely recognized by the aviation industry as having greater development prospects in the future, and are also areas of focus for major global fuel providers. The outcomes of this article will provide essential input for SAF production companies and financing entities to implement investing analysis, as well as for local government to formulate supporting policies. The remainder of this article is organized as follows.

Section 2 utilizes the grey model to segmentally predict the future SAF demand in China, which is a vital data input for the techno-economic assessment of the SAF production routes.

Section 3 introduces the application of TOPSIS to assess the suitability of the SAF production routes in China across various time periods.

Section 4 shows the results and discuss the findings.

Section 5 provides recommendations to propose suggestions on improving the SAF industry. To make this paper more readable, we have added raw data in

Appendix A.

2. SAF Demand Prediction

In order to calculate China’s SAF demand, we constructed a SAF demand calculation model, as shown in Equation (1):

where

is the annual demand volume of SAF,

is the annual carbon intensity and

is the controlled target of annual carbon intensity,

is the annual air transport turnover which is measured with the ton-kilometer,

is the emission reduction potentiality share of SAF,

is the carbon emission factor of aviation fuel, and

is the lifecycle emission reduction value of SAF which is measured with the percentage of the lifecycle emission.

forecasting is an essential step in SAF demand prediction as illustrated in Equation (1). We firstly project the

in China by 2050 and calculate the SAF demand, subsequently.

2.1. Projection of Air Transport Turnover

Civil aviation transportation is greatly affected by macroeconomic development. The relevant macroeconomic factors can be divided into two categories: demand-motivated factors (foreign trade, tourism demand and industrial structure, etc.) and purchasing power factors (per capita purchasing power, effective purchasing power and overall purchasing power) [

23]. We examine the correlation between China’s

and macroeconomic indicators, such as gross domestic product (GDP), GDP per capita, value of tertiary industry as a percentage of GDP, urbanization rate, disposable income per capita, total import and export of goods, and international and domestic tourism revenue from 2001 to 2019. The Pearson correlation coefficients are illustrated in

Table 1, indicating that the correlation relationship between

and GDP is the strongest. Considering the maturity of GDP forecasting, the difficulty of other influencing factors estimation and the strong correlation with GDP, this paper utilizes the quantitative relationship between GDP and

to project China’s air transport turnover.

2.1.1. The Segmented Ensemble Prediction Mode

The linear prediction value (

) of the actual value of

(

) can be calculated through the unitary linear regression model of

and GDP. Actual deviation rate (

between

and

can be calculated using Equation (2).

Equation (2) can be changed the form to Equation (3) and indicates that both

and

will affect the prediction accuracy of

. In order to improve the accuracy of long-period forecasting and solve the problem that the traditional linear regression equation forecasting will produce large deviation, we construct a segmented ensemble prediction mode of

and

.

First step: Linear regression prediction. We make use of historical data from 1978 to 2022 to construct a linear regression equation L(1978–2022) between and GDP of China’s civil aviation. Then, L(1978, 2022) is utilized to calculate from 1978 to 2022.

Second step: Actual deviation rate prediction. First, we calculate the actual deviation rate between and from 1978 to 2022. Subsequently, the gray prediction model is used to construct the actual deviation rate prediction models, which are E(1978–1987) for the period from 1978 to 1987, E(1988–1997) for the period from 1988 to 1997, E(1998–2007) for the period from 1998 to 2007 and E(2008–2022) for the period from 2008–2022. Then, we make use of the actual deviation rate prediction models to calculate the prediction deviation rate .

Third step: Calculate the ensemble prediction value (

) of historical air transport turnover for the period from 2008 to 2022. The calculation formula of the

is shown in Equation (4).

Fourth step: Forecasting the air transport turnover. China’s national economic and social development planning is based on a five-year planning period. In view of this, we divide the period 2023–2050 into six phases, namely, 2023–2025, 2026–2030, 2031–2035, 2036–2040, 2041–2045 and 2046–2050, and forecast the air transport turnover in stages. First, the annual projected GDP of the period from 2023 to 2025 is introduced into the previous stage linear regression equation L(1978–2022) to obtain for the period from 2023 to 2025. Then, E(2008–2022) of the previous period is used to calculate an approximation of the actual deviation rate for the period from 2023 to 2025, and make use of the to construct the deviation rate projection model E(2023–2025) for the period from 2023 to 2025. Subsequently, the forecast deviation rate is calculated using E(2023–2025) and the ensemble prediction value () from 2023 to 2025 can also be valued through Equation (3). Finally, L(2023–2025) is constructed using and projected GDP for the period from 2023 to 2025, for the purpose to carry out projections of the next period from 2026 to 2030. We repeat the process period by period to project the air transport turnover for the next few decades.

2.1.2. Segmented Ensemble Prediction of Air Transport Turnover

According to the steps described in

Section 2.1.1, L(1978–2022) is constructed which is illustrated in Equation (5), and the hypothesis testing results are shown in

Table 2. Annual data of China’s air transport turnover are obtained from the Civil Aviation Statistics Yearbook of China. Annual GDP sourced from the National Bureau of Statistics.

Then, we implement grey estimating and deviation rate prediction model of 1978–1987, 1988–1997, 1998–2007, and 2008–2022, are illustrated from Equation (6) to Equation (9).

Using the above equations, we calculate the ensemble forecast value of China’s air transport turnover from 1978 to 2022. The results show that the average deviation rate between the actual air transport turnover and ensemble prediction value () during the period of 1978–2022 is 0.11, whereas the average deviation rate between and the linear forecast value () is 2.2. Therefore, the segmented ensemble prediction mode can substantially improve the accuracy of long-term transportation turnover prediction.

In 2023, China’s target for GDP growth is 5% [

24]. The World Bank also holds a positive and optimistic attitude towards China’s economic development after the pandemic and raise its forecast for China’s GDP growth rate in 2023 to 5.1% [

25]. As a result, we assume that China’s GDP growth rate will maintain an average annual growth rate of 5% from 2023 to 2025. After 2026, the GDP growth rate will reasonably slow down and we assume GDP growth rate will remain an average annual growth rate of 4.8%, 4.5% and 4.3% for the period from 2026 to 2030, from 2031 to 2035 and from 2036 to 2040, respectively. Afterwards, we assume the average annual growth rate will decrease by 0.1% every five years. Based on the assumption of the GDP growth rate, we calculate the projected value of China’s GDP from 2023 to 2050 and air transport turnover. The prediction process and results are shown in

Table 3 and

Figure 1, respectively.

2.2. SAF-and-Market-Based Emission Reduction

Taking the average carbon emission intensity of 0.928 kg/RTK during the “13th Five-Year Plan” period as the intensity baseline and making use of the air transport turnover calculated in

Section 2.1, it is possible to calculate the future carbon emissions of China’s civil aviation if no effective emission reduction measures are implemented. We use it as the emission baseline.

During the “14th Five-Year Plan” period, China’s major airlines (which account for over 90% of the industry’s total TKM) are expected to achieve an average annual carbon intensity reduction at a rate of no more than 0.5%. After 2026, with the continuous optimization of operational emission reduction technology, the annual carbon intensity reduction rate is expected to increase. However, due to the gradual aging of the fleet, China’s civil aviation carbon intensity is expected to decline continuously at a rate not exceeding 0.5% annually from 2026 to 2030, reaching 0.8826 kg/RTK by 2030. Considering further optimization of operational emission reduction technology and a new round of renewal cycle of the fleet after 2030, carbon intensity of China’s civil aviation may be greatly decreased. We assume the portion of China’s air transport emission compared with the baseline emission after 2030, will meet the level of the ICAO’s prediction [

26].

The IATA proposed a fuel efficiency goal of annual average improvement of 1.5% [

25], which is similar to the ICAO’s prediction [

26]. China’s civil aviation industry aims to realize peak carbon emissions by 2035 [

26]. With the fuel efficiency goal proposed by the IATA, we calculated the annual control target of carbon emission until 2035 and assume annual emissions will decrease proportionally to zero, achieving carbon neutrality from 2036 to 2060.

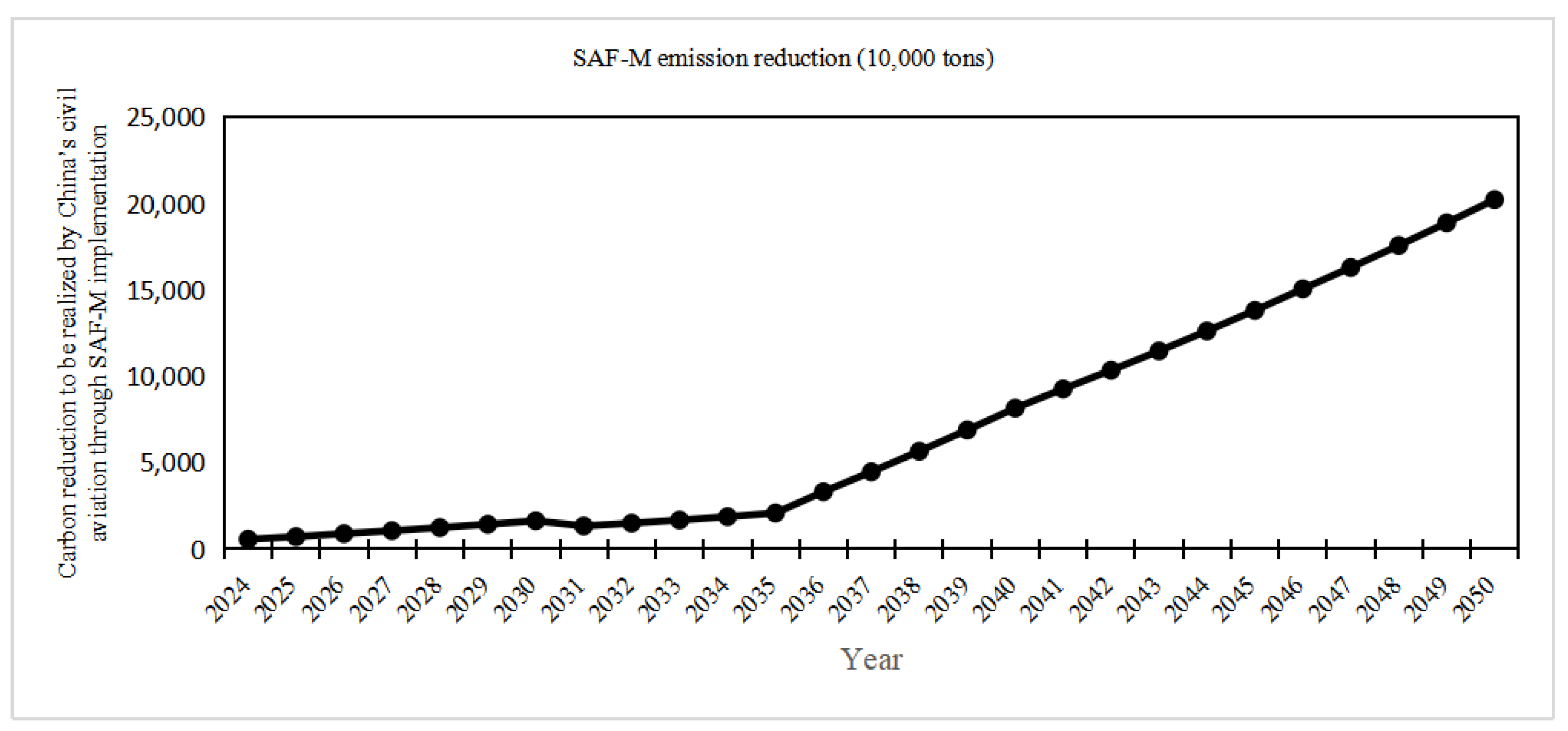

Based on the above calculation results and reasonable assumptions, this study calculates the carbon emission reduction to be realized by China’s civil aviation through SAF and market-based measures (hereinafter referred to as SAF-M), as illustrated in

Figure 2.

2.3. SAF Demand

According to the Special Planning for the Green Development of Civil Aviation in the “14th Five-Year Plan” Period, the industry-wide use of SAF should reach 20,000 tons by 2025, equivalent to 0.05% of the industry’s fuel consumption [

26]. To promote the civil aviation industry’s realization of carbon peaking and carbon neutrality, the National Development and Reform Commission, Ministry of Science and Technology, National Energy Administration, and Civil Aviation Administration, among others, have successively put forward policies and measures to support the research and production of biomass aviation kerosene [

26,

27,

28,

29]. This will facilitate the development of China’s SAF industry and drive the large-scale production and utilization of SAF. Furthermore, the Special Planning identifies the establishment and implementation of a civil aviation carbon market as an important task to promote green development during the “14th Five-Year Plan” period [

26]. Relevant departments and research institutions have conducted studies and deployments to construct the civil aviation carbon market mechanism [

30]. Considering the above situation, we assume application of SAF in China will occupy the portion of SAF-M emission reduction as the ICAO analysis [

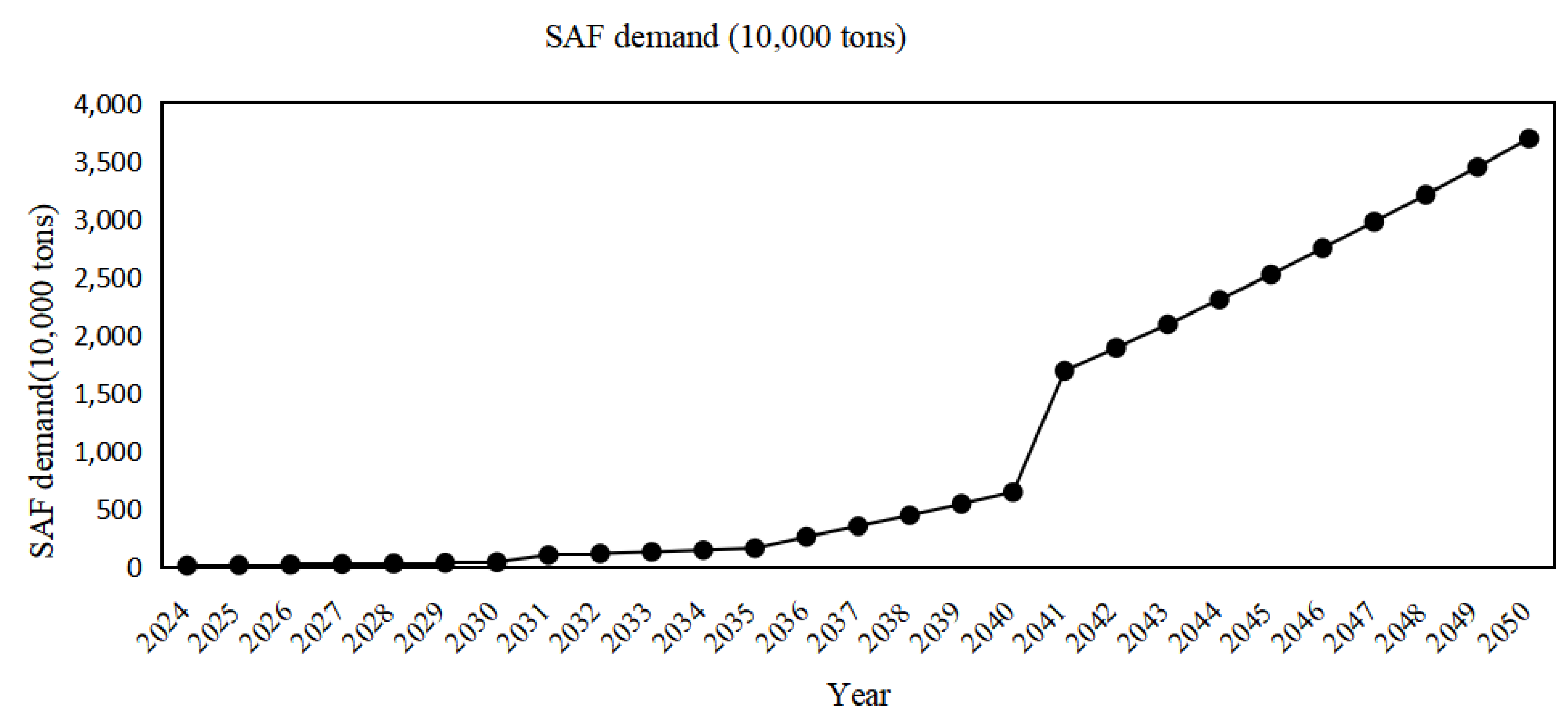

5]: 7% (2024–2030); 20% (2031–2040); 46% (2041–2050).

The EF (emission factor) for aviation kerosene is 3.15 tons of carbon per ton of fuel [

31]. We also assumed that the lifecycle emission reduction ratio of SAF used in China’s civil aviation can reach 80% due to improvements in research and production technologies. Subsequently, this study calculates the SAF demand from 2024 to 2050 for China’s civil aviation using Equation (1). As illustrated in

Figure 3, the projected SAF demand for China’s civil aviation in 2050 is estimated to be 36.92 million tons. The total SAF demand from 2024 to 2050 is estimated to be 297 million tons. China’s demand for SAF rises sharply from 2024 to 2050.

3. Technology Pathway Arrangement for SAF Production

In this section, we make use of the TOPSIS (Technique for Order Preference by Similarity to Ideal Solution) method to assess the applicability of the technological pathways at different stages in China. TOPSIS was introduced by C.L. Hwang and K. Yoon in 1981 [

32], which has become a widely adopted approach in multi-objective decision analysis. This method is primarily employed to identify practical solutions that represent both optimal and worst-case scenarios, achieved through the normalization of the original data matrix. Subsequently, a formula is applied to calculate the distances between the evaluation objects and the optimal and worst-case solutions. This process yields the proximity of each evaluation object to the optimal solution, forming the basis for quality evaluation [

33,

34].

3.1. Technology Pathways for SAF Production

As of October 2021, nine technology pathways for SAF production have been certified by American Society for Testing and Materials (ASTM) standards—seven by ASTM D7566 and two by ASTM D1655. This study focuses on three technology pathways that produce aviation fuels—HEFA, Gas+Fischer–Tropsch (G + FT), and AtJ—and one uncertified pathway—PtL (Power-to-Liquid). Currently, there are two synthetic pathways for PtL (Power-to-Liquid) fuel production. They are the Fischer–Tropsch synthesis method and the methanol synthesis method. The PtL route has obtained ASTM approval when using the Fischer–Tropsch synthesis, but the methanol pathway has not yet received approval [

35,

36,

37]. These four pathways are widely considered to have significant development prospects in the aviation industry and are focus areas for major global fuel providers [

38,

39,

40].

The AtJ (Alcohol-to-Jet) route centers on the production of SAF from alcohol [

41]. This alcohol source can be derived from biomass, including those with sugar and starch or lignocellulosic content, such as crops like corn and sugarcane. Notably, two alcohol types, isobutanol and ethanol, have received certification for SAF production in accordance with ASTM specifications. The AtJ route, utilizing isobutanol as the feedstock, has obtained certification from ASTM D7566 in April 2016 [

42], and ethanol was added as an approved feedstock for the AtJ route from ASTM D1655 in April 2018 [

43]. Compared to fossil aviation fuels, this approach has a GHG emission reduction potential of approximately 85–94% and a conversion rate (conversion rate, which refers to the proportion of total output (including aviation and road fuels and other by-products) to feedstock inputs) of 13%. SAF accounts for 77% of the total production in this pathway (SAF overall yield (SAF overall yield: This refers to the ratio of SAF produced to total output)) [

44]. The availability of raw materials varies significantly between countries and regions. For example, the abovementioned crops provide stable and abundant sources of raw materials in countries with vast agricultural land—the United States and Brazil. Thus, AtJ is the main promoted technology pathway for SAF production in these countries. However, the availability of such raw materials is limited in China.

The PtL pathway primarily utilizes green electricity, hydrogen, and carbon capture, utilization, and sequestration (CCUS) to produce SAF. The entire process chain for platinum liquefaction (Power-to-Liquid) fuel production should rely entirely on electricity sourced from renewable energy, such as wind, solar, hydropower, and geothermal energy. Carbon dioxide should originate from the atmosphere or renewable sources. The electricity used in the process of electrolyzing water should be derived from renewable energy and not from fossil sources. Currently, there are two ways to synthesize PtL fuel: Fischer–Tropsch synthesis and methanol synthesis. The PtL pathway is in its early stages but has significant potential in carbon emission reduction. It can utilize photovoltaics and wind energy to power the electrolysis process and use CO

2 captured from other sources (DAC technology), resulting in good emission reduction benefits. In theory, PtL aviation fuel can achieve almost 100% emissions reduction throughout its lifecycle, with a conversion rate of approximately 17–18% [

44]. SAF can account for 60% of the total production, and further process improvements can increase this proportion to 70% [

44]. Compared to plant-based SAF pathways (biofuels), PtL has a lower greenhouse gas footprint (based on lifecycle analysis), reduced water demand, and higher yields. Moreover, PtL does not increase the demand for arable land, avoiding the food versus fuel conflict. From a technological perspective, PtL could potentially produce fuel suitable for purifying fossil fuels (non-blended fuels). Nevertheless, the production cost and capacity of the PtL pathway are significantly influenced by the availability of green electricity, the cost of hydrogen production, and the maturity of CCUS technology. It will take a considerable period for the production conditions and technological maturity of PtL to reach commercial application. Meanwhile, as of 2020, the price of hydrogen was USD 7.3 per kilogram, which is relatively expensive compared to fossil fuels, posing a challenge for competing with fossil aviation fuels. This calls for policy incentives, regulatory actions, and further technological improvements [

45].

The HEFA pathway mainly involves processing and refining raw materials such as animal and vegetable oils, waste cooking oil (gutter oil), and algae using hydrogenation to produce SAF. The HEFA pathway is already mature. It is adopted by most existing SAF projects worldwide. Compared to fossil aviation fuels, HEFA has a GHG emission reduction potential of 73–84% [

44]. There is additional emission reduction potential when sustainably produced “green” hydrogen is used in production. The conversion rate of the HEFA pathway is approximately 90%, and SAF can account for 46% of the total production. This proportion can be increased to 70% through process optimization [

44]. From a global perspective, the reduction in production costs and the scale expansion of the HEFA pathway are considerably influenced by raw material availability.

The G + FT pathway involves the decomposition and recombination of carbon-containing materials such as energy crops, agricultural and forestry waste, and municipal solid waste in the form of syngas. This approach is currently in the experimental stage and can reduce carbon dioxide emissions by 85–94% (World Economic Forum, 2020). The conversion rate is 20%, and SAF can account for 60% of the total production. Through technological improvements, the overall yield of SAF can be increased to 70% [

44]. However, there are challenges regarding the collection difficulties and high costs associated with urban solid waste, agricultural and forestry waste, and other raw materials. Nevertheless, energy crops can adapt to marginal land, minimizing the need to convert food crops to biofuel production. They can also reduce sediment loss, water quality degradation, and other negative externalities, avoiding the displacement of productive farmland and meeting sustainable land use requirements. Therefore, the production technology that utilizes the G + FT process and energy crops as raw materials can meet the needs of civil aviation in terms of production volume and achieve negative carbon emissions through the carbon sink generated during the cultivation process. Thus, carbon emissions can be reduced in light of local conditions.

A comparison of the relevant descriptions of the four SAF production technology routes is shown in

Table 4 [

44].

3.2. Method Description

The TOPSIS method is adopted in this article to assess the techno-economic applicability of the four technology routes, HEFA, AtJ, G + FT, and PtL, at future time points. The following is a description of the comprehensive analysis process using the TOPSIS method. Since we need to assess techno-economic applicability of the four technology pathways at different time periods, separate TOPSIS evaluations should be conducted for each year.

- (1)

Step 1. Select evaluation criteria for the four technology pathways. Detailed criteria are listed in

Section 3.3.

- (2)

Step 2. Normalize and standardize the raw value of the evaluation criteria for the four SAF routes. Data normalization is outlined in formula (10), where

represents the value of i-th technical and economic indicator in the j-th technology pathway, and

represents the normalized value of

. Data standardization is described in formula (11), where

represents the standardized value.

- (3)

Step 3. Calculate the largest value and the smallest value.

represents the maximum value within the i-th technical and economic indicator. The maximum values in each row,

, constitute the vector

, as specified in formula (12). Similarly,

represents the minimum value within the i-th technical and economic indicator. The minimum values in each row,

, constitute the vector

, as specified in formula (13). In this context, “m” represents the total number of technology pathways, where

, and “n” represents the number of technical and economic indicators, where

.

- (4)

Step 4. Calculate the distance of each SAF technology route from the best solution and the worst solution, as seen in Formulas (14) and (15), where

represents the distance of the j-th technology pathway from the optimal solution,

represents the distance of the j-th technology pathway from the worst solution.

- (5)

Step 5. Calculate the overall score, as described in Formula (16). Where

represents the overall composite score for the j-th solution. We compare the comprehensive scores of the four technology pathways at each time point using

to determine the suitability of different technology pathways in China.

3.3. Indicator Selection

The research focuses on four SAF technology pathways (HEFA, AtJ, G + FT, PtL), and the goal is to assess their applicability at different stages of development in China, in order to help aviation sector to reach carbon peak and carbon neutrality goals. Therefore, this study uses ‘greenhouse gas emission reductions’, ‘conversion rate’, ‘technological maturity’, ‘SAF overall yield’, ‘availability of raw materials’, ‘SAF production cost’, ‘feedstock costs’, ‘operating costs’, and ‘capital expenditure’ as the primary assessment indicator. The specific descriptions of the assessment indicators are as follows:

- (1)

Greenhouse gas emission reductions. This indicator considers the GHG emissions generated at all stages of SAF production and is defined as the proportion of GHG emissions reduction compared to total emissions over the lifecycle [

44].

- (2)

Conversion rate. The conversion rate represents the proportion of total yield to raw material input. The HEFA pathway has the highest conversion rate, reaching 90%.

- (3)

Technological maturity is currently classified into nine levels [

46]. The fuel readiness level (FRL) serves as an assessment of the technical and commercial maturity of alternative fuel production pathways proposed by the Commercial Aviation Alternative Fuels Initiative (CAAFI) [

47]. FRL is categorized into levels ranging from 1 to 9, with levels 1–5 signifying the research and development (R&D) stage, levels 6–7 indicating the certification stage, and levels 8–9 representing the commercialization stage.

Furthermore, the Technology Readiness Level (TRL) spans from 1, denoting “basic technology research,” to 9, signifying “very mature technology,” enabling the evaluation of technology maturity across different processes [

48].

Table 5 provides a summary of the TRL and FRL levels for various technologies utilized in the production of bioaviation coal.

- (4)

SAF overall yield. This indicator represents the proportion of SAF yield to total output. This study makes assumptions regarding the SAF overall yield for each pathway. The known data are the SAF overall yield in 2020, and it is assumed that all four pathways will reach their maximum SAF overall yield by 2050 through technological improvements and other measures. The annual growth rate for 2020–2050 is assumed to be 3.3% for all four pathways [

44].

- (5)

Availability of raw materials. For the HEFA pathway, the required raw materials are mostly waste oils. These raw materials are difficult to collect because of their decentralized distribution. In China, 3.4 million tons of these raw materials are available yearly [

50]. The G + FT pathway benefits from abundant sources of raw materials such as agricultural and forestry waste, municipal solid waste, and energy crops. Each year, 425.5 million tons of raw materials are available for this pathway. The AtJ technology route mainly involves the fermentation of corn, sugarcane, lignocellulose and exhaust gas to produce fuel ethanol, which is then converted into SAF. The production of fuel ethanol in China is 2.5726 million tons [

51]. Theoretically, the raw materials for the PtL pathway (carbon dioxide, hydrogen, and renewable electricity) have unlimited sources. Thus, this study does not specifically evaluate the availability of raw materials for this pathway. To unify the indicator of raw material availability, this study defines it as the ratio of raw material yield to raw material demand based on the predicted SAF demand in

Section 2. If this ratio is greater than 100%, the availability of raw materials is considered 100%, indicating that the raw material yield can meet the demand. According to the aforementioned assumptions, the raw material yield can support the raw material demand for the PtL pathway.

Using the SAF demand data calculated in

Section 2, along with conversion rate data and SAF overall yield data obtained from [

44], and the feedstock availability data provided earlier, we have computed the feedstock obtainability for the four technology routes. The specific calculation process can be found in formulas (17) and (18).

where

represents “demand for raw material” for the j-th technology pathway in the i-th year;

represents “SAF demand” for the j-th technology pathway in the i-th year;

represents “SAF overall yield” for the j-th technology pathway in the i-th year;

represents “conversion rate” for the j-th technology pathway in the i-th year;

represents “raw material availability” for the j-th technology pathway in the i-th year;

represents “the feedstock availability” for the j-th technology pathway in the i-th year; i represents the years, such as 2025, 2030, 2035, 2040, 2045, and 2050; j represents the four technology pathways. The projection results are listed in

Table 6.

- (6)

SAF production cost. In the HEFA pathway, the SAF production cost includes raw material cost, hydrogen production cost, operational and execution cost, and capital expenditures. Raw material cost accounts for a significant portion of the total cost. For the G + FT pathway, the SAF production cost includes raw material costs, operational and execution costs, and capital expenditures, with capital expenditures playing a major role. In the AtJ pathway, the SAF production cost comprises raw material costs, operational and execution costs, and capital expenditures. Operational and execution cost is relatively high due to the high cost of refining ethanol into aviation fuel. In the PtL pathway, the SAF production cost includes raw material costs, capital expenditures for hydrogen production, operational and execution cost, and capital expenditures for FT + RWGS (Fischer–Tropsch and Reverse Water–Gas Shift) processes. Among these, hydrogen production costs contribute the most. With other measures such as technological improvements, the production costs of SAF using the HEFA technology will progressively decrease. For the other three production technology routes, which are not yet commercially available, cost reductions are not anticipated until 2030 [

44].

- (7)

Feedstock costs. Feedstock costs vary depending on the type of feedstock used for each technology route. The cost data for feedstock are from [

44].

- (8)

Operating costs. Operating costs play a significant role in the economics of bioaviation fuel production. Data on operating costs can be found in [

44].

- (9)

Capital expenditure. Each of the four technology routes has distinct capital expenditures, which we also consider as an assessment indicator. Specific data can be found in [

44].

The detailed raw value can be found in

Appendix A.

3.4. Assessment Results

We calculate the composite scores for different time periods based on Equations (10)–(16). Subsequently, we rank the overall scores for the four technology routes. The final results can be found in

Table 7,

Table 8,

Table 9,

Table 10,

Table 11 and

Table 12.

4. Results and Discussion

4.1. HEFA Is the Most Suitable Route for SAF Production in China before 2035

HEFA has the highest composite score from

Table 7 to

Table 9. These highest scores show that HEFA pathway is the best choice in China until 2035, ranking the 1st among the four pathways.

The HEFA pathway is already in a mature stage and boasts competitive advantages in terms of potential lifecycle emissions reduction, overall SAF yield, and producing cost. The primary raw material required for HEFA pathway is waste oils.

Table 6 show that the availability of waste oil resources can meet the raw material demand for the HEFA pathway from 2024 to 2035, further confirming its strong suitability during this period. Most of China’s SAF producers currently employ this technology pathway. By 2035, HEFA will continue to be the most efficient and cost-competitive pathway due to its relatively low capital investment requirement for a proven technology.

4.2. The G + FT Technology Route Experiences Rapid Growth and Takes the Lead in SAF Production from 2035 to 2050

Table 10 and

Table 11 highlight the growing suitability of the G + FT pathway in China, and

Table 6 confirms that agricultural waste, forestry waste, and energy crops within China can meet the raw material demand G + FT pathway from 2035 to 2050. This solidifies the G + FT pathway’s dominance in China during that period, reinforcing its suitability.

The increasing maturity of G + FT technology, especially when based on energy crops, alongside continuous cost reductions in SAF production and the availability of various raw material options (agricultural and forestry waste, municipal solid waste, industrial waste, and energy crops grown on marginal land), will make G + FT pathway highly favorable. China has already validated the FT and hydroprocessing quality-upgrading processes through coal-to-oil projects. The only remaining steps involve pilot tests for pyrolysis and gas modulation processes, alongside intensified research and development on the separation of raw material components, efficient conversion of hemicellulose-derived furfural and lignin, and bio-jet fuel production technology integration. Once these milestones are achieved, large-scale commercialization becomes possible.

HEFA pathway faces challenges related to raw material collection, and its performance weakens after 2035. The market share of G + FT is expected to keep growing from 2035 to 2050, potentially making it the most competitive SAF production pathway in China. Utilizing energy crops grown on marginal land is regard as the best raw material option for developing the SAF industry in China. China’s current maximum production capacity is 75 million tons per year, aligning with civil aviation demand projections. Moreover, the cultivation of energy crops generates a carbon sink, achieving negative carbon emissions and delivering substantial environmental benefits.

4.3. The PtL Technology Route Becomes the Most Suitable for SAF Production in China after 2050

As shown in

Table 12, the overall score index for the PtL production pathway has significantly improved, surpassing the G + FT pathway and taking the top position.

Table 6 further corroborates the viability of the PtL pathway, emphasizing its nearly unrestricted access to raw materials.

As the dominant long-term technology pathway, PtL eliminates concerns about the availability of raw materials for SAF production, reinforcing its leading position in China after 2050. Although PtL is yet to achieve full commercialization, it offers a substantial emission reduction potential of up to 99% compared to conventional aviation fuel [

44]. Furthermore, it can capture carbon dioxide and green electricity directly from the air as raw materials, ensuring a high level of availability.

In the PtL pathway, operating and input costs make up 80–90% of the current production costs, depending on the specific production process [

44]. These costs are influenced by hydrogen production or cooperative electrolysis. With the advancement of technology, the production costs of PtL are expected to decrease significantly, making it the most competitive technology pathway beyond 2050.

4.4. The AtJ Technology Route Is Less Suitable for SAF Production in China Compared to the Other Three Technology Routes

The TOPSIS analysis consistently ranks the AtJ production pathway relatively low in China from 2020 to 2050 due to the limited availability of raw materials for SAF production. The AtJ technology route primarily utilizes feedstocks such as corn, sugarcane, lignocellulose, and waste gas to produce SAF. However, the yields of fuel ethanol obtained from these feedstocks are relatively low, and this is compounded by the need to adhere to the principles of “not competing with food resources” and “not competing with land resources.” These constraints, along with technological limitations, result in a restricted supply of raw materials. Consequently, large-scale SAF production for civil aviation in China faces significant challenges when adopting the AtJ pathway.

5. Conclusions

In this paper, we forecast SAF demand in China for the next few decades and utilize the TOPSIS method to conduct a comprehensive assessment of the suitability of SAF production pathways in China at different stages. This article yields the following conclusions.

5.1. The Potential for SAF Emissions Reduction and Its Future Demand in China Is Substantial

China, as the second-largest aviation market, is responsible for approximately 1% of the country’s total carbon emissions, which equates to approximately 100 million tons [

52]. With the post-pandemic recovery of air travel, carbon emissions from China’s aviation sector are expected to continue rising. It is imperative to implement comprehensive and effective measures aimed at reducing carbon emissions in the civil aviation industry in China, thereby contributing to the country’s carbon peak and carbon neutrality goals.

This study’s findings suggest that cumulative SAF demand in China from 2024 to 2050 is projected to reach 297.17 million tons, resulting in a reduction of 93.04 million tons of carbon emissions by 2050. Consequently, a well-planned schedule for SAF production pathways is essential to meet the rapidly increasing demand.

5.2. Applicability of the Four Technical Routes

The findings of this study reveal that HEFA technology exhibits strong suitability for China’s SAF production before 2035, given the relatively advanced industrial technology in this domain. This technology provides positive support for future SAF capacity expansion in the country. Among the four technical pathways, G + FT also demonstrates clear advantages. As China strengthens its technical capabilities and research and development efforts in the G + FT pathway, it is likely to be the most applicable technology pathway for China’s national conditions from 2035 to 2050, effectively meeting the demands of civil aviation.

PtL technology ranks first in the overall assessment, suggesting that with a decrease in green power costs, advancements in CCUS and SAF synthesis technologies, and clear policy support, PtL holds great potential to become the most promising technology route for SAF production in China after 2050, in the long term.

Conversely, the AtJ pathway has the lowest rating among the four technical routes, indicating that its applicability in China is limited. This limitation primarily stems from the strict principles of “not competing for food resources” and “not competing for land resources.” Large-scale SAF production from crops like corn and sugarcane in China faces significant challenges.

In summary, considering China’s national conditions and realities, HEFA technology is mature, making it the most suitable SAF production method before 2035. G + FT becomes the dominant production route from 2035 to 2050, and PtL technology is the most suitable option for SAF production in China after 2050.

6. Recommendations

From the analysis presented earlier in this article, it is evident that while SAF offers significant potential for emission reduction in China, a thorough understanding of the current state of SAF development in the country reveals a range of issues. These challenges include the absence of mature technology in the development of SAF production routes, high fuel costs, increased demand for raw materials, an imperfect SAF management system, and a lack of comprehensive policy guidance. To expedite the mass production and large-scale commercial application of SAF in China, we put forward several recommendations aimed at reducing cost barriers and enhancing the environmental and economic viability of SAF.

6.1. Enhance Technical Research on Both the G + FT and PtL Technology Routes

In China, the G + FT process is still in the commercial pilot stage and has limited widespread applications. The PtL process is in the early stages of development. Both of these pathways, which hold long-term potential, are not yet fully mature. When it comes to the G + FT pathway using energy plants, a significant focus is placed on advancing G + FT process techniques to improve the economic feasibility of SAF. Research and development projects should encompass the purification of pyrolysis gas, its conversion to synthesis gas, Fischer–Tropsch-directed conversion, as well as the technology and application of fractionating raw material components, utilizing cellulose derived from furfural, and efficiently converting lignin into bio aviation oil. For the PtL pathway, it is advisable to conduct advanced research in building a highly efficient composite catalytic system (such as photocatalytic, photoelectric catalytic, or photothermal synergistic catalytic) to convert carbon dioxide into methane and other carbon-based fuels.

6.2. Continuously Exploring New Raw Materials Is Essential to Progressively Achieve Fuel Expansion and Cost Reduction

In terms of raw materials, considering the G + FT pathway based on energy plants is the most feasible technology route for China between 2035 and 2050, it is suggested to develop energy plants and microalgae resources suitable for cultivation in saline-alkali lands. China possesses abundant saline-alkali land resources in regions such as the Northwest, Northeast, and North China, as well as extensive coastal areas. Therefore, we suggest vigorous development of salt-tolerant plants in the Northwest, Northeast, and North China regions and the cultivation of microalgae resources in coastal areas. This strategy helps gradually expand cultivation scale, increase the supply of raw materials, boost farmers’ income, reduce heavy dependence on foreign energy sources, and strengthen energy security.

6.3. Improve Economic Policies and Establish a Market-Oriented Mechanism for SAF

Policy guidance is a crucial measure for enhancing the economic feasibility, production capacity, and demand for SAF. Firstly, we suggest to establish a comprehensive tax policy system to support the entire supply chain of SAF, including raw material supply and research and development, by providing tax incentives. This will better leverage the tax policies to promote the large-scale use of SAF and further reduce the price gap between SAF and traditional aviation fossil fuels. Secondly, to overcome the economic barriers in the aviation industry’s adoption of SAF, it is recommended to actively promote green financial tools, such as green loans, green funds, carbon financial products to support the development of SAF. At the same time, it is proposed to motivate private capital to establish SAF industrial investment funds in a market-oriented manner. Furthermore, close cooperation between airlines and fuel producers, is also suggested to promote the research and development of SAF and expand its production scale.