A Hybrid Approach for Low-Voltage AC Series Arc Fault Detection

Abstract

:1. Introduction

- AC arc characteristics in time and frequency domains are illustrated for people to understand critical arc features;

- Laboratory measurements are implemented based on UL 1699 standard; this helps people know the definition of arc fault and know the requirements for how to set up a platform for detections

- Three signal processing-based analysis methods are individually introduced for people to understand the working principle of each. In addition, a hybrid method procedure is proposed to integrate these methods for arc fault detection. The results of the proposed approach can be used as references for technical staff to design and develop AFCI devices.

2. Characteristics of AC Series Arc Fault and Laboratory Experiments

2.1. Characteristic of AC Arc Fault

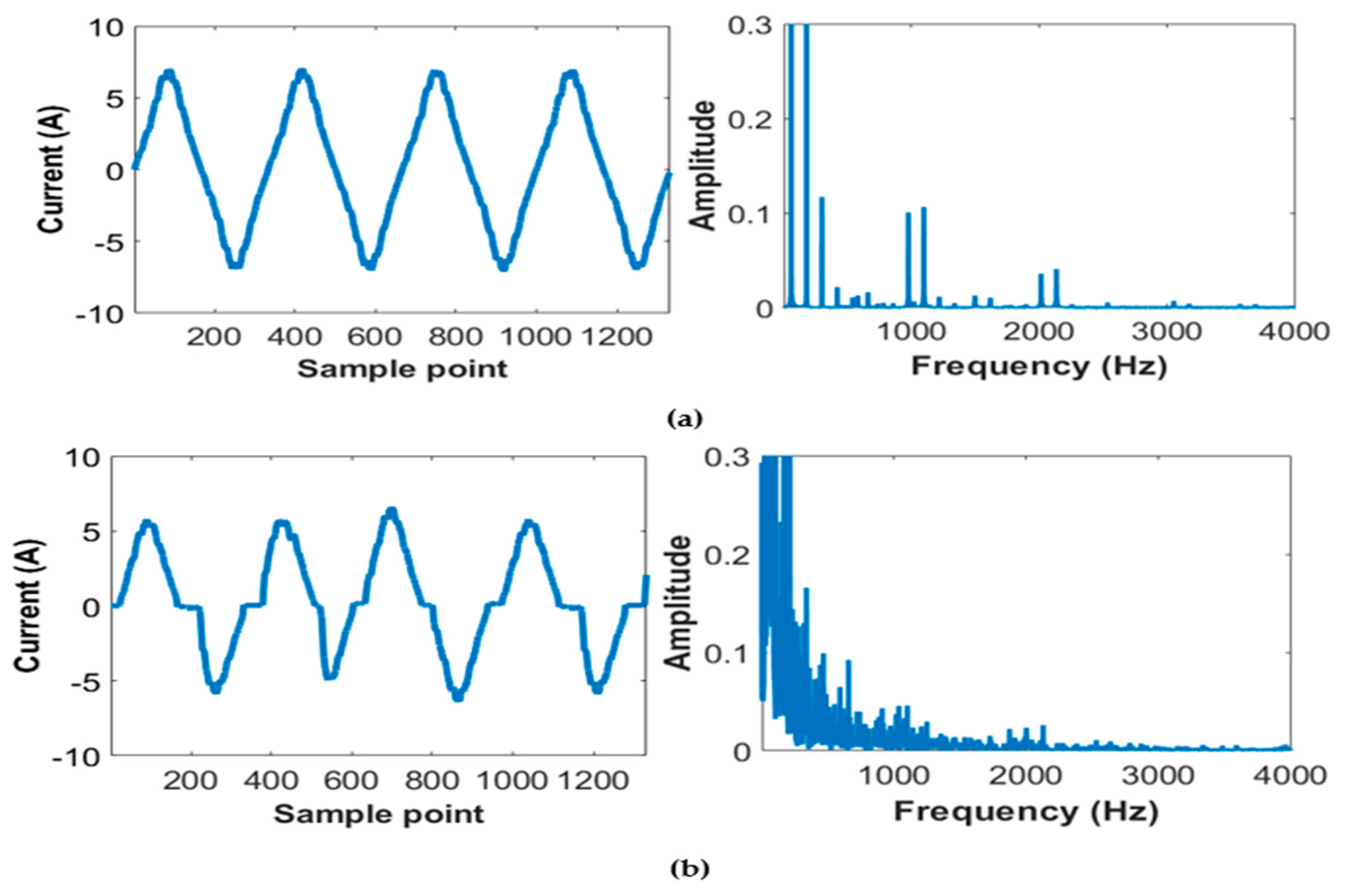

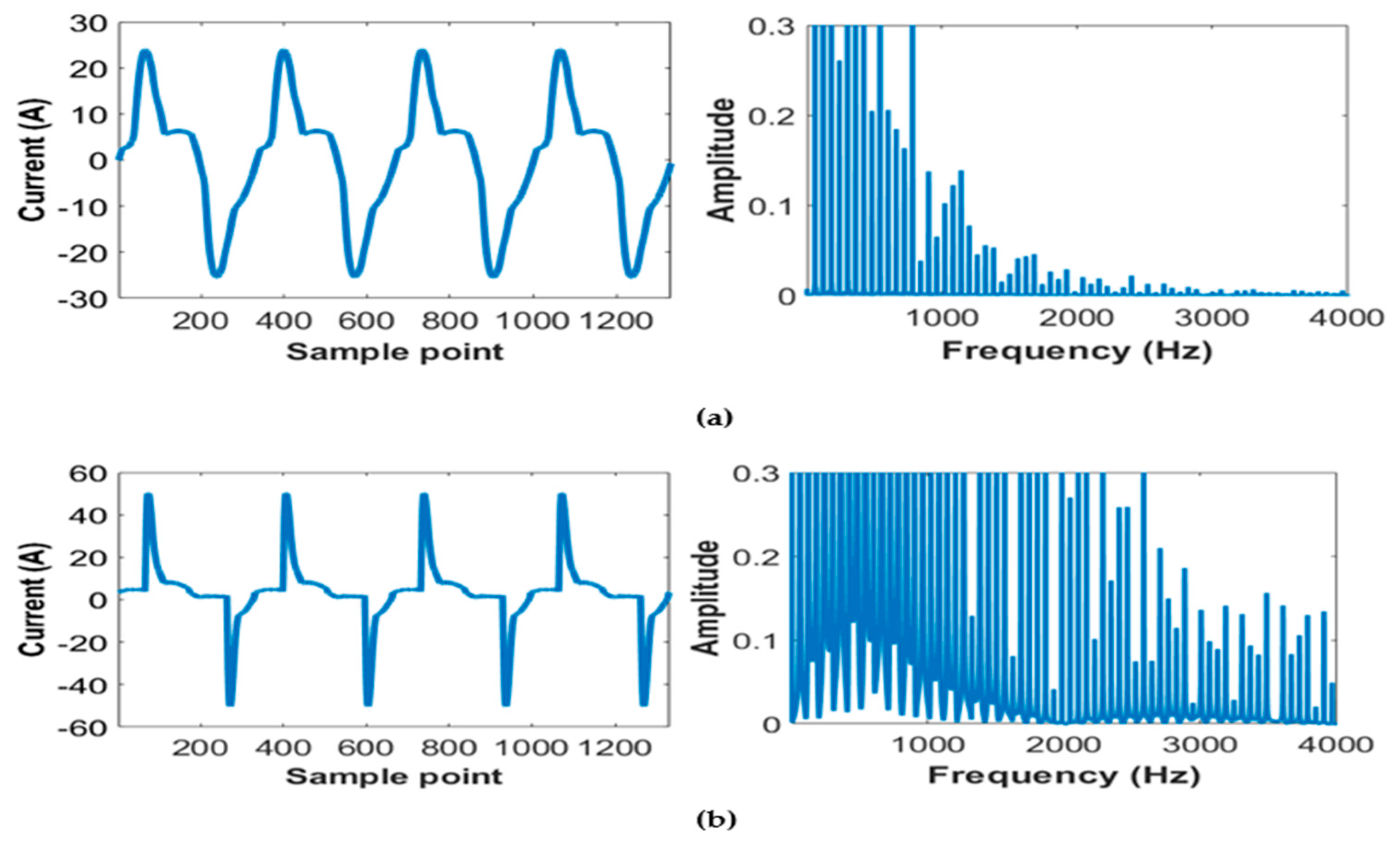

- Arc characteristics in the time domain:

- (a)

- The magnitude of an arc fault current may be generally less than a normal current; this is due to an equivalent impedance existing during the series arc fault which causes the reduction of the current;

- (b)

- A “shoulder” phenomenon can be observed periodically on the current waveform, which is a flat zone at the current pass through zero crossing;

- (c)

- The rising rate of the arc current is steeper than that in normal operation. This is because after the arc has extinguished, it takes some time to let the arc voltage rise enough to re-ignite the arc;

- (d)

- The arc voltage drops instantly when an arc fault occurs; furthermore, the arc voltage waveform presents a square wave.

- Arc characteristics in the frequency domain:

- (a)

- Unsymmetrical distortions can easily be seen on the arc current/voltage waveforms. This means the low order harmonic components may be introduced;

- (b)

- During arc fault, the frequency component of arc current up to 2 kHz is significantly increased because the arc fault features a broadband signal with a temporal jitter in the arc re-ignition duration;

- (c)

- Frequency components of an arc current between 2 kHz to 5 kHz are caused by the above-mentioned steeply rising current edge after arc re-ignition.

2.2. Criteria for Arc Fault Detection in UL 1699 Standard

2.3. Laboratory Experiments

3. Proposed Detection Method

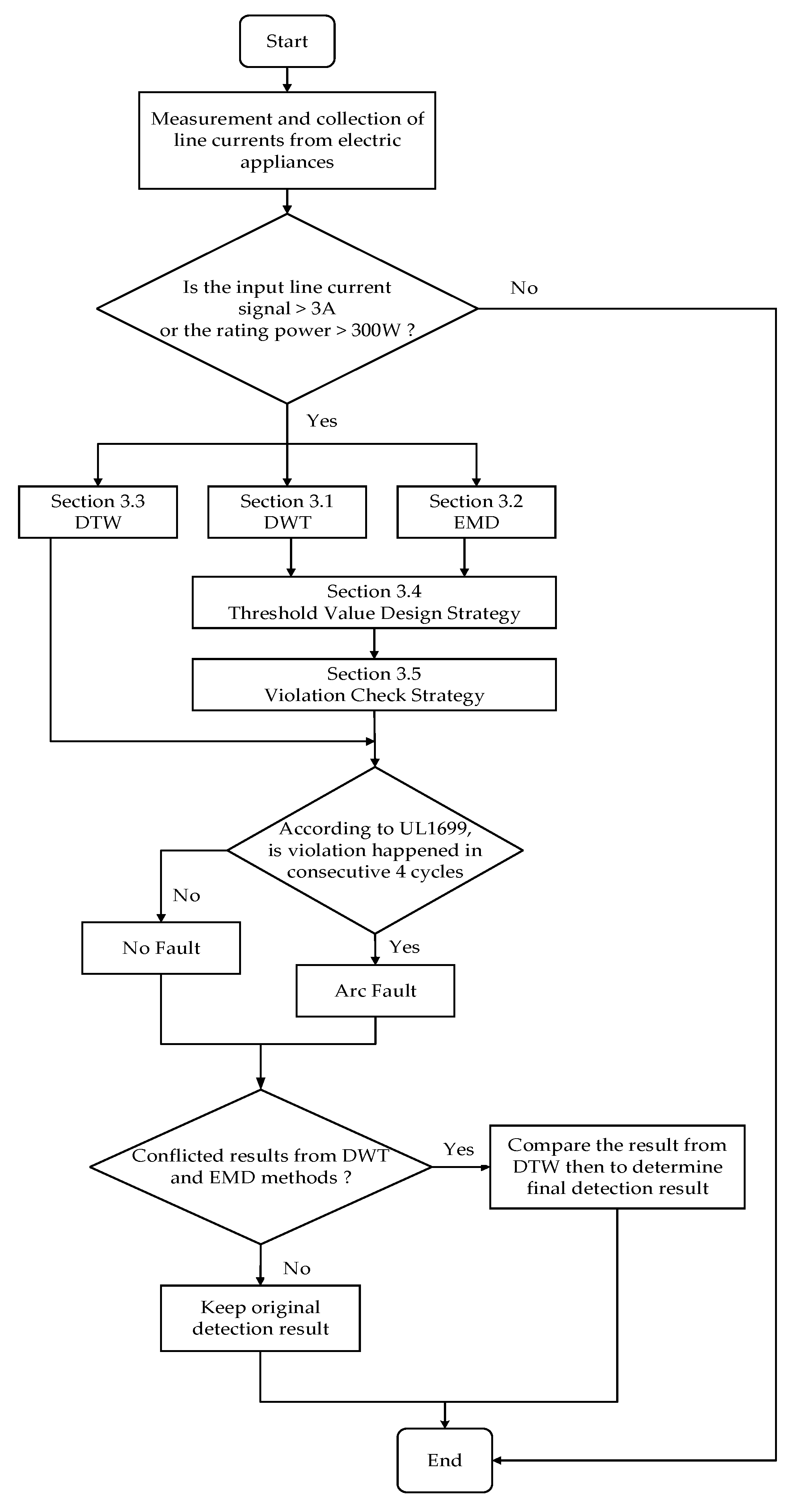

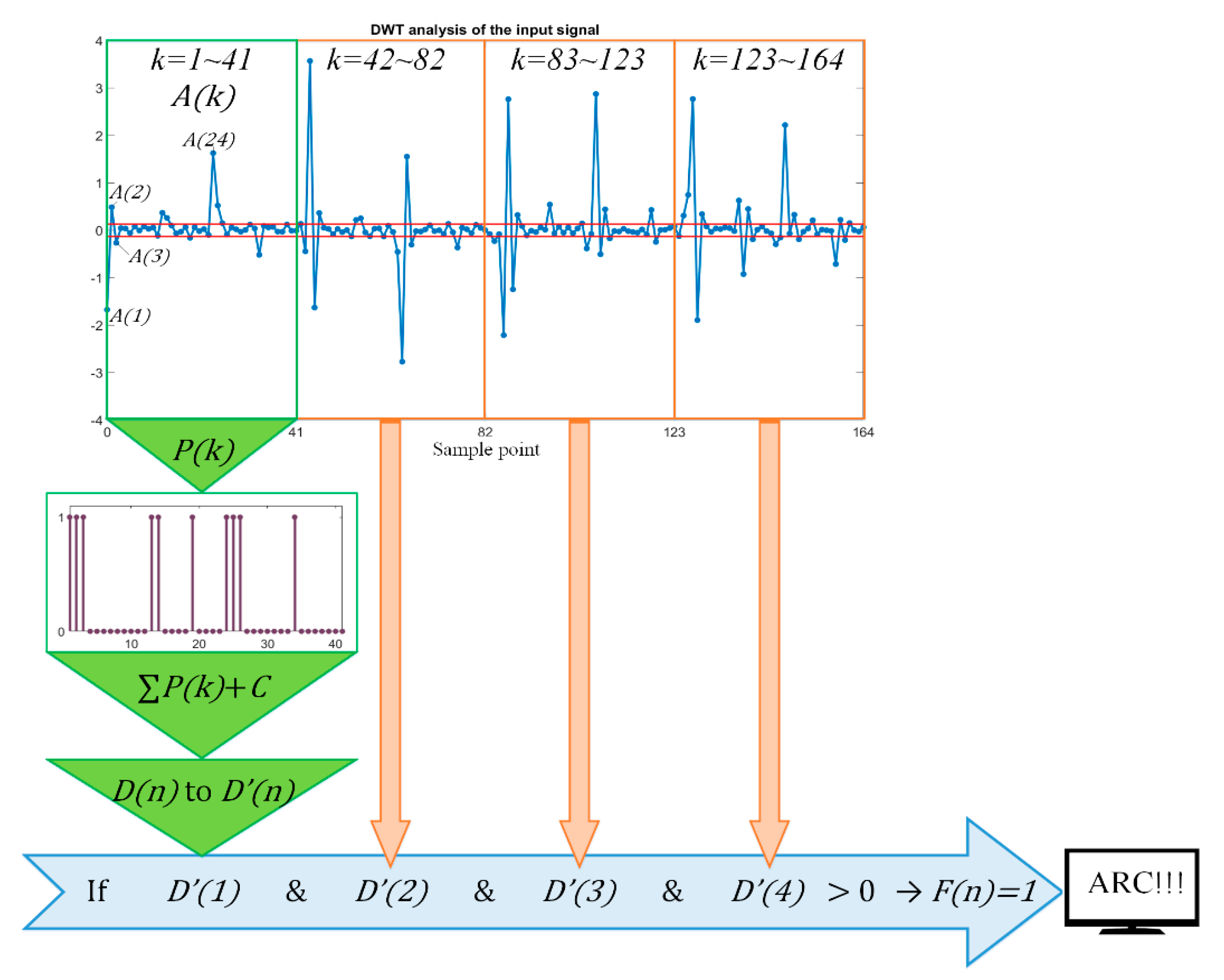

- Step 1: According to the setup in Figure 7, measure the line currents from various electric appliances. Meanwhile, 30 cycles of current signal are collected for the coming detection procedure;

- Step 2: Check if the amplitude of the current or the rating power from the tested electric appliance is higher than 3 A or higher than 300 W, respectively. If not satisfied, stop the detection;

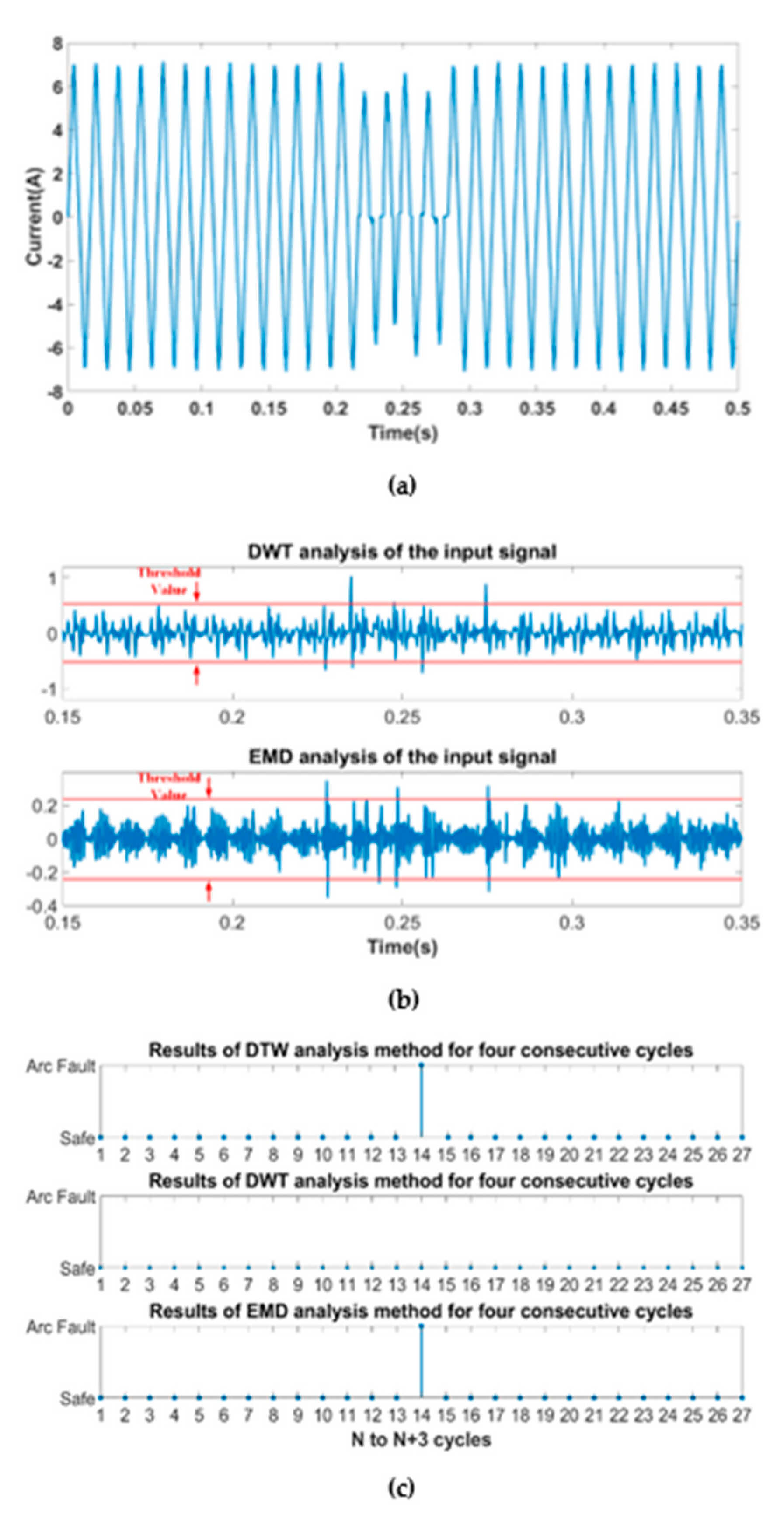

- Step 3: Apply the current signal measured in Step 1 to DWT, EMD, and DTW methods, respectively. The discussion of each method is given in Section 3.1 to 3.3;

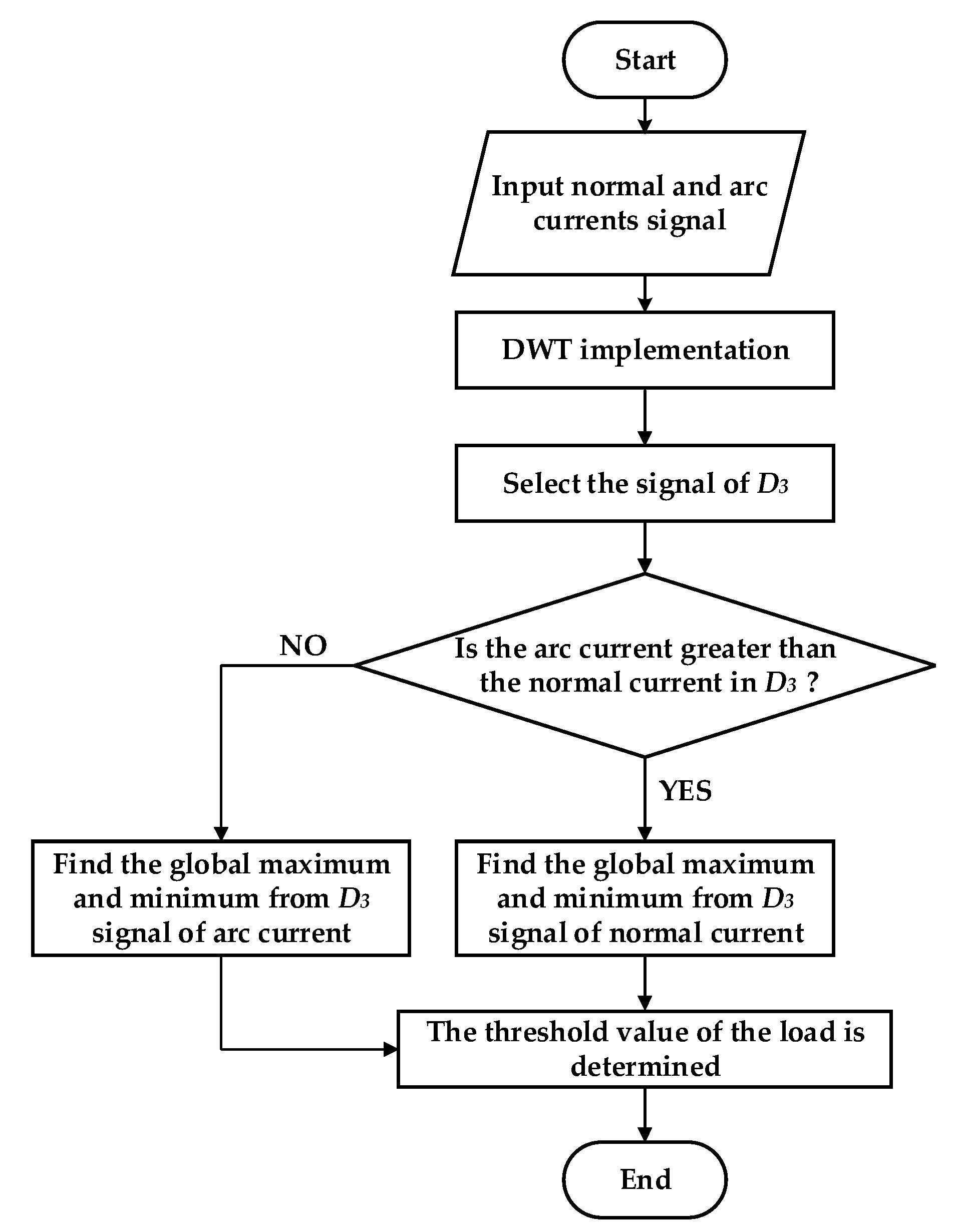

- Step 4: Apply the threshold value design strategies for DWT and EMD methods in Section 3.4 to calculate the violation energy;

- Step 5: According to the calculated violation energy in previous step, the violation strategy is separately applied to the DWT and EMD methods for determining the occurrence of arc fault;

- Step 6: When different detection results are presented from the DWT and EMD methods, the results from the DTW method may be used as a further judgment indicator.

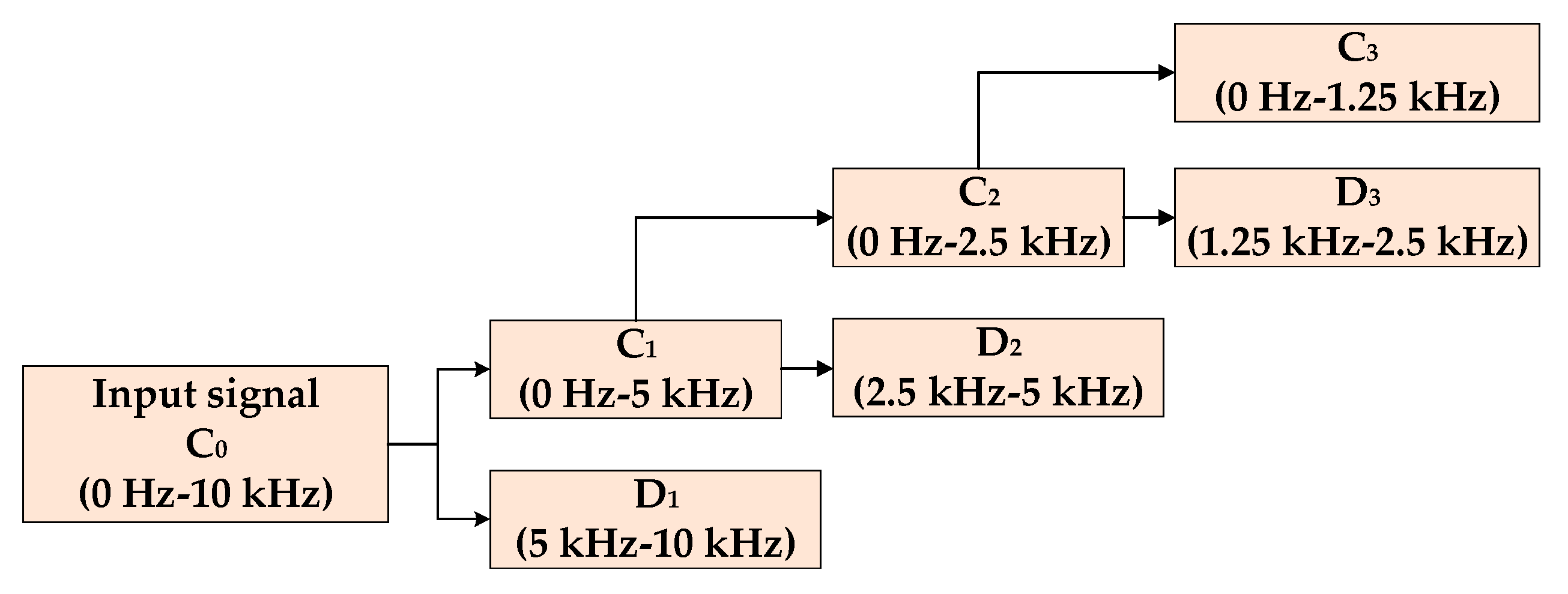

3.1. Discrete Wavelet Transform

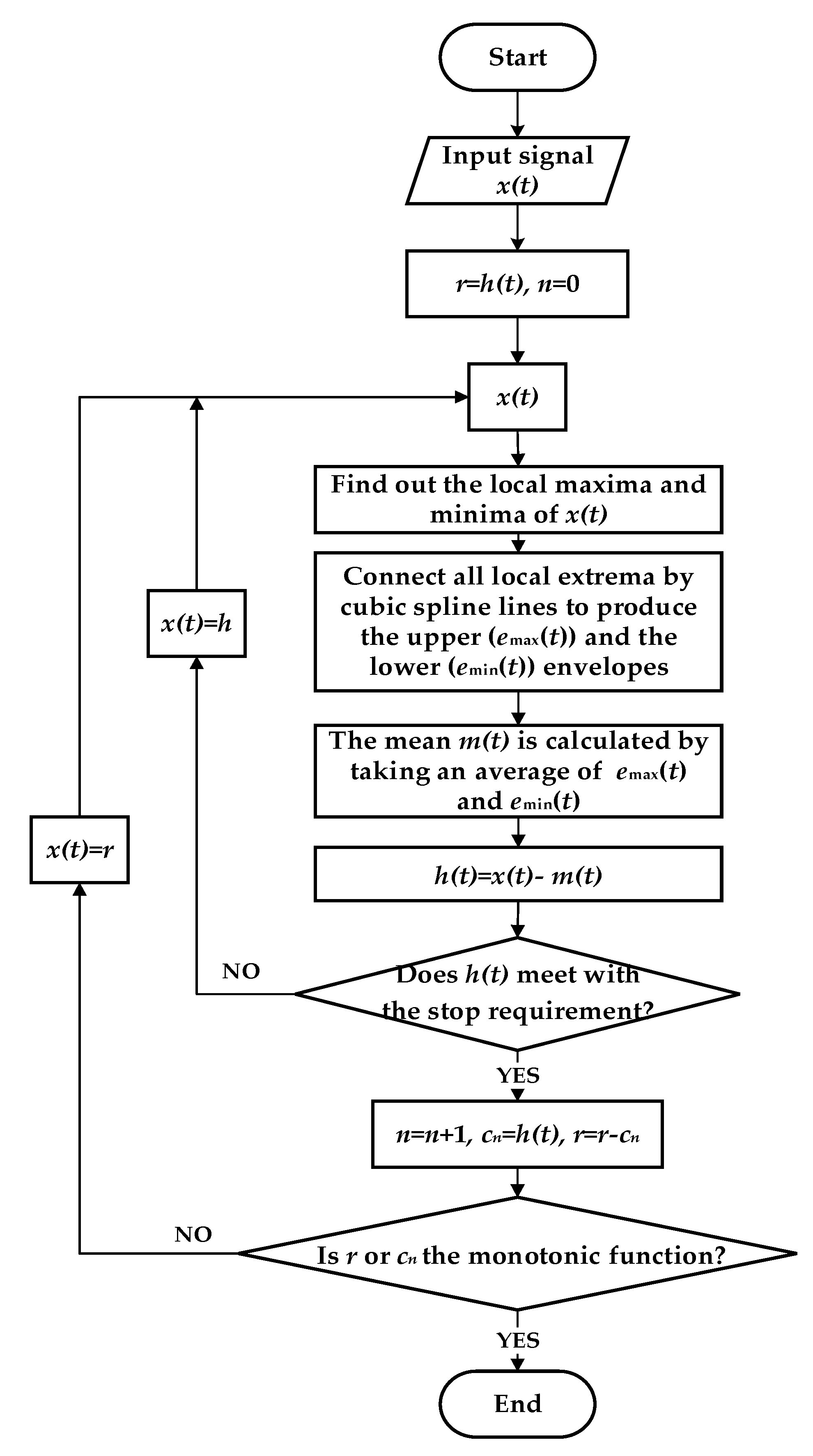

3.2. Empirical Mode Decomposition

- For all datasets of the signal, the number of extrema and the number of zero-crossings must be the same or differ at most by one;

- Within any finite data interval, the mean value of the envelope must be zero.

- Step 1: Find out the local maxima and minima of x(t);

- Step 2: Connect all local extrema by cubic spline lines to produce the upper and the lower envelopes, respectively;

- Step 3: Take an average of and in the previous step, then obtain the mean envelop, ;

- Step 4: By shifting process, calculate the difference between input signal and mean envelop by x(t) − m(t) = h(t);

- Step 5: When h(t) meets with the stop requirement, let c = h(t), where c is designated as IMF1. If the stop requirement is not met, the shifting process will continue until an IMF be found;

- Step 6: Calculate the residual component by input signal and the IMF1, i.e., x(t) − c = r;

- Step 7: If c or r is the monotonic function, the EMD process is finished. Otherwise, repeat the above steps until all IMFs are found.

3.3. Dynamic Time Warping

- Step 1: Suppose two time series data i and j with time lengths m and n are collected from normal and abnormal line currents, as shown in (5) and (6). The relative (or so-called local) distance d(i, j) between the points of two sequences is calculated by (7); meanwhile, k = 1, 2, …., K is the corresponding operation number to finish the local distance calculation among data i and j.

- Step 2: From the calculations in Step 1, build a point-to-point distance table of two data sequences. The cumulative recursive function in (8) is applied to receive d(i, j) and repeatedly makes calculations until all time points in recursive function are completed. Then, another cumulative distance table is built for tracking the optimal warping path. The minimum cumulated distance D (i, j) for data among (1, 1) to (i, j) range can be obtained by (8). For the decision of each warping path, only the current three nearest data sources are concerned. Select the minimum cumulative distance value and add it with the new point-to-point distance value, then to obtain the updated cumulative distance table.

- Step 3: The following constraints must be satisfied when using DTW:

- (a)

- Boundary constraint: let (i1, j1) = (1, 1) and (ik, jk) = (m, n). These are typical for “anchored beginning and end”.

- (b)

- Local constraint: for any given node (i, j) in the path, the possible input nodes are limited to the ranges of (i−1, j), (i, j−1), and (i−1, j−1). The warping path can be thus guaranteed to be monotonically non-decreasing in its first and second arguments by this constraint. In addition, for any given value in i, it should be possible to find at least one corresponding value in j, and vice versa.

3.4. Threshold Value Design Strategy

3.5. Violation Check Strategy

4. Testing and Validations

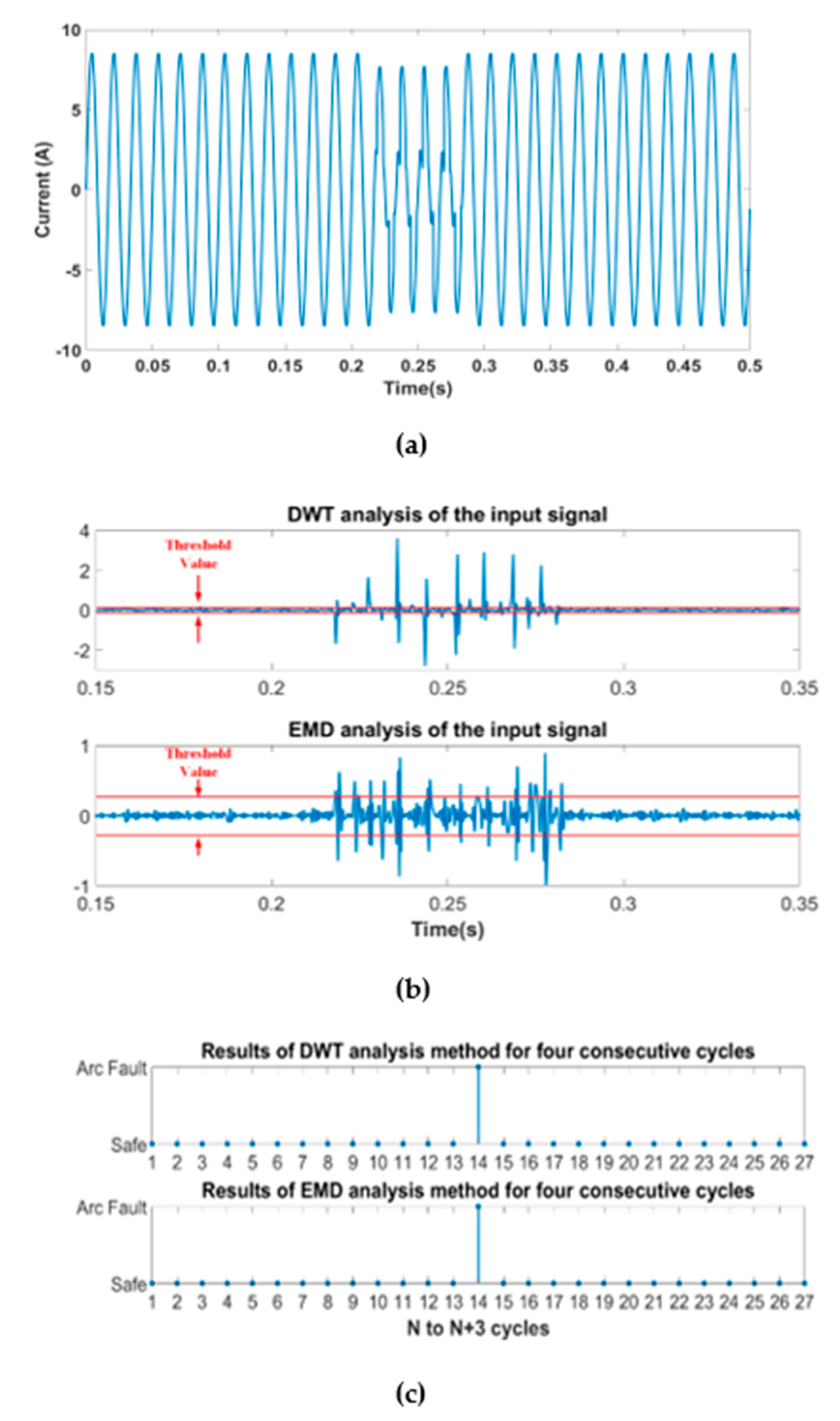

4.1. Case 1: Results of Electric Oven Testing

4.2. Case 2: Results of Vacuum Cleaner Testing

4.3. Case 3: Results of Fluorescent Lamps Testing

4.4. Case 4: Results of Mixed load Testing

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wu, Y.; Song, Z.; Wang, J. A method for parallel arc fault detection and identification. In Proceedings of the 2nd International Conference on Computer Science and Electronics Engineering, Hangzhou, China, 22–23 March 2013. [Google Scholar]

- UL standard for safety: Arc-Fault Circuit Interrupters, UL 1699, 3rd ed.; Underwriter Laboratories Inc.: Northbrook, IL, USA, 2017.

- NFPA70, National Electrical Code, 2017.

- Artale, G.; Cataliotti, A.; Cosentino, V.; Di Cara, D.; Nuccio, S.; Tinè, G. Arc fault detection method based on CZT low-frequency harmonic current analysis. IEEE Trans. Instrum. Meas. 2017, 66, 888–896. [Google Scholar] [CrossRef]

- Lu, S.; Zhang, D.; Phung, T. Arcing fault detection in the scenario with renewable energy generation. In Proceedings of the 43rd Annual Conference of the IEEE Industrial Electronics Society, Beijing, China, 29 October–1 November 2017. [Google Scholar]

- Zhao, Y.; Zhang, X.; Dong, Y.; Li, W. Characteristics analysis and detection of AC arc fault in SSPC based on wavelet transform. In Proceedings of the IEEE International Conference on Aircraft Utility Systems, Beijing, China, 10–12 October 2016. [Google Scholar]

- Zeng, K.; Xing, L.; Zhang, Y.; Wang, L. Characteristics analysis of AC arc fault in time and frequency domain. In Proceedings of the IEEE Prognostics and System Health Management Conference, Harbin, China, 9–12 July 2016. [Google Scholar]

- Müller, P.; Tenbohlen, S.; Maier, R.; Anheuser, M. Characteristics of series and parallel low current arc faults in the time and frequency domain. In Proceedings of the IEEE Holm Conference on Electrical Contacts, Charleston, SC, USA, 4–7 October 2010. [Google Scholar]

- Gregory, G.D.; Wong, K.; Dvorak, R.F. More about arc-fault circuit interrupters. IEEE Trans. Ind. Appl. 2004, 40, 1006–1011. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, F.; Zhang, X.; Zhang, S. Series AC arc fault detection method based on hybrid time and frequency analysis and fully-connected neural network. IEEE Trans. Ind. Inform. 2018, 15, 6210–6219. [Google Scholar] [CrossRef]

- Kim, J.C.; Neacsu, D.O.; Lehman, B.; Ball, R. Series AC arc fault detection using only voltage waveforms. In Proceedings of the IEEE Applied Power Electronics Conference and Exposition, Anaheim, CA, USA, 17–21 March 2019. [Google Scholar]

- Sritrai, E.; Kittiratsatcha, S.; Polmai, S. Low voltage series arc fault detection using Rogowski coil. In Proceedings of the IEEE International Conference on Engineering, Applied Sciences, and Technology, Phuket, Thailand, 4–7 July 2018. [Google Scholar]

- Cai, X.; Wang, L.; Sun, Q.; Meng, Z. AC arc fault detection based on mahalanobis distance. In Proceedings of the IEEE 15th International Power Electronics and Motion Control Conference, Novi Sad, Serbia, 6 September 2012. [Google Scholar]

- Wu, C.J.; Liu, Y.W. Smart detection technology of serial arc fault on low-voltage indoor power lines. Electr. Power Energy Syst. 2015, 69, 391–398. [Google Scholar] [CrossRef]

- Qj, O.; Jovanovic, S.; Lezama, J.; Schweitizer, P. Discrete wavelet transform optimal parameters estimation for arc fault detection in low-voltage residential power networks. Electr. Power Syst. Res. 2017, 143, 130–139. [Google Scholar]

- Li, W.; He, K.; Liu, W.; Zhang, X.; Dong, Y. A fast arc fault detection method for AC solid state power controllers in MEA. Chin. J. Aeronaut. 2018, 31, 1119–1129. [Google Scholar] [CrossRef]

- Saeed, E.A.; Abdulhassan, K.M.; Al-Atbee, O.Y.K. Series and parallel arc fault detection in electrical buildings based on discrete wavelet theory. Iraqi J. Electr. Electron. Eng. 2021, 17, 94–101. [Google Scholar] [CrossRef]

- Yu, Q.; Hu, Y.; Yang, Y. Identification method for series arc faults based on wavelet transform and deep neural network. Energies 2020, 13, 142. [Google Scholar] [CrossRef] [Green Version]

- Lala, H.; Karmakar, S. Classification of arc fault between broken conductor and high-impedance surface: An empirical mode decomposition and stockwell transform-based approach. IET Gener. Transm. Distrib. 2020, 14, 5277–5286. [Google Scholar] [CrossRef]

- Shang, T.; Wang, W.; Peng, J.; Xu, B.; Gao, H.; Zhai, G. Series arc fault identification based on complete ensemble empirical mode decomposition with adaotive noise and convolution neural network. Int. J. Metrol. Qual. Eng. 2022, 13, 11. [Google Scholar] [CrossRef]

- Lang, M.; Jones, K. Exposed to the arc flash hazard. IEEE Trans. Ind. Appl. 2015, 51, 51–61. [Google Scholar] [CrossRef]

- Muhammed Ajmal, C.N.; Venkata Raghavendra, I.; Naik, S.; Ray, A.; Krishnamoorthy, H.S. A modified hybrid DC circuit breaker with reduced arc for low voltage DC grids. IEEE Access 2021, 9, 132267–132277. [Google Scholar] [CrossRef]

- Gregory, G.D.; Scott, G.W. The arc-fault circuit interrupter: An emerging product. IEEE Trans. Ind. Appl. 1998, 34, 928–933. [Google Scholar] [CrossRef]

- Müller, P.; Tenbohlen, S.; Maier, R.; Anheuser, M. Artificial low current arc fault for pattern recognition in low voltage switchgear. In Proceedings of the IEEE Holm Conference on Electrical Contacts, Vancouver, BC, Canada, 14–16 September 2009. [Google Scholar]

- Brito, N.S.D.; Souza, B.A.; Pires, F.A.C. Daubechies wavelets in quality of electrical power. In Proceedings of the IEEE International Conference on Harmonics and Quality of Power, Athens, Greece, 14–16 October 1998. [Google Scholar]

- Plamanescu, R.; Dumitrescu, A.; Albu, M.; Suryanarayanan, S. A hybrid Hilbert-Huang method for monitoring distorted time-varying waveforms. Energies 2021, 14, 1864. [Google Scholar] [CrossRef]

- He, Y.; Zhang, X.; Wu, W.; Zhang, J.; Bai, W.; Guo, A.; Chen, Y. Faulty line selection method based on comprehensive dynamic time warping distance in a flexible grounding system. Energies 2022, 15, 471. [Google Scholar] [CrossRef]

| Load Category | Rating | DWT Range of Threshold Value | EMD Range of Threshold Value |

|---|---|---|---|

| Electric oven | 700 W | 0.1262~−0.1352 | 0.1408~−0.1422 |

| Vacuum cleaner | 500 W | 0.5259~−0.5200 | 0.2300~−0.2400 |

| CFLs * | 322 W | >0.3560 or <−0.3967 | >0.2091 or <−0.2053 |

| Mixed load ** | 1604 W | 1.4736~−1.5927 | 6.3004~−6.7665 |

| Load Types | No. | Power Rating | Load Elements | Only DWT | Only EMD | Proposed Approach |

|---|---|---|---|---|---|---|

| Heating Load | 1 (Case 1) 2 3 | 700 W 600 W 650 W | 1 Electric oven 1 Electric pot 1 Toaster | O O O | O O O | O O O |

| Lighting Load | 4 (Case 3) 5 6 | 432 W 360 W 322 W | 24 LED T5 tubes a 10 Fluorescent tubes b 14 CFLs c | O F O | O O O | O O O |

| Machine Load | 7 8 (Case 2) 9 | 420 W 500 W 500 W | 6 Electric fans 1 Vacuum cleaner RF d + RL e | O F O | O O O | O O O |

| Mixed Load | 10 11 (Case 4) 12 | 1065 W 1604W 1465 W | No. 1 + No. 4 + No. 9 No. 4 + No. 6 + RF + HD f 5 CFLs + No. 8 + RF + HD | O O O | F O F | O O O |

| Method Type | Paper | Framework | Testing Load | Critical Element | Applications |

|---|---|---|---|---|---|

| DWT | [14] | RBFNN+ DWT | Household loads | Db10 mother wavelet and 3-layer | Indoor low-voltage power lines series arc fault detection |

| [15] | DWT | Resistive, inductive, and dimmer loads | Various mother wavelets and layers | DWT parameters estimation for arc fault detection in residential power networks | |

| [16] | FFT+ DWT | Adjustable load | Db10 mother wavelet and 9-layer | Arc fault detection for SSPC in electric aircraft system | |

| [17] | DWT | Mathematic arc model with resistance component | Db2 mother wavelet and 3-layer | Applied DWT to energy-balanced series and parallel arc models | |

| [18] | DNN+ DWT | Filament lamp, inductance coil, and TV | Symplets8 (Sym8) and 5-layer | Combines DWT and DNN models for series arc fault identification | |

| EMD | [19] | EMD+ ST | High-voltage facilities with different conductors and medium surfaces | IMF1~IMF9 | To deal with the high-impedance arc fault classification problem |

| [20] | EMD+ CNN | Heater, induction cooker, computer, microwave oven, and vacuum cleaner | IMF1~IMF8 | Series arc fault identification for residential power networks | |

| Proposed | - | DWT+ EMD+ DTW | As that in Table 2 | Db4 mother wavelet, 3-layer, IMF2 and IMF3 | A hybrid approach for low-voltage series arc fault detection |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.-J.; Chen, C.-I.; Fu, W.-C.; Lee, Y.-D.; Cheng, C.-C.; Chen, Y.-F. A Hybrid Approach for Low-Voltage AC Series Arc Fault Detection. Energies 2023, 16, 1256. https://doi.org/10.3390/en16031256

Liu Y-J, Chen C-I, Fu W-C, Lee Y-D, Cheng C-C, Chen Y-F. A Hybrid Approach for Low-Voltage AC Series Arc Fault Detection. Energies. 2023; 16(3):1256. https://doi.org/10.3390/en16031256

Chicago/Turabian StyleLiu, Yu-Jen, Cheng-I Chen, Wei-Chung Fu, Yih-Der Lee, Chin-Chan Cheng, and Yen-Fu Chen. 2023. "A Hybrid Approach for Low-Voltage AC Series Arc Fault Detection" Energies 16, no. 3: 1256. https://doi.org/10.3390/en16031256

APA StyleLiu, Y.-J., Chen, C.-I., Fu, W.-C., Lee, Y.-D., Cheng, C.-C., & Chen, Y.-F. (2023). A Hybrid Approach for Low-Voltage AC Series Arc Fault Detection. Energies, 16(3), 1256. https://doi.org/10.3390/en16031256