Performance Assessment of Cellulose Paper Impregnated in Nanofluid for Power Transformer Insulation Application: A Review

Abstract

1. Introduction

2. Chemical Indicators

2.1. CO and CO2 Content

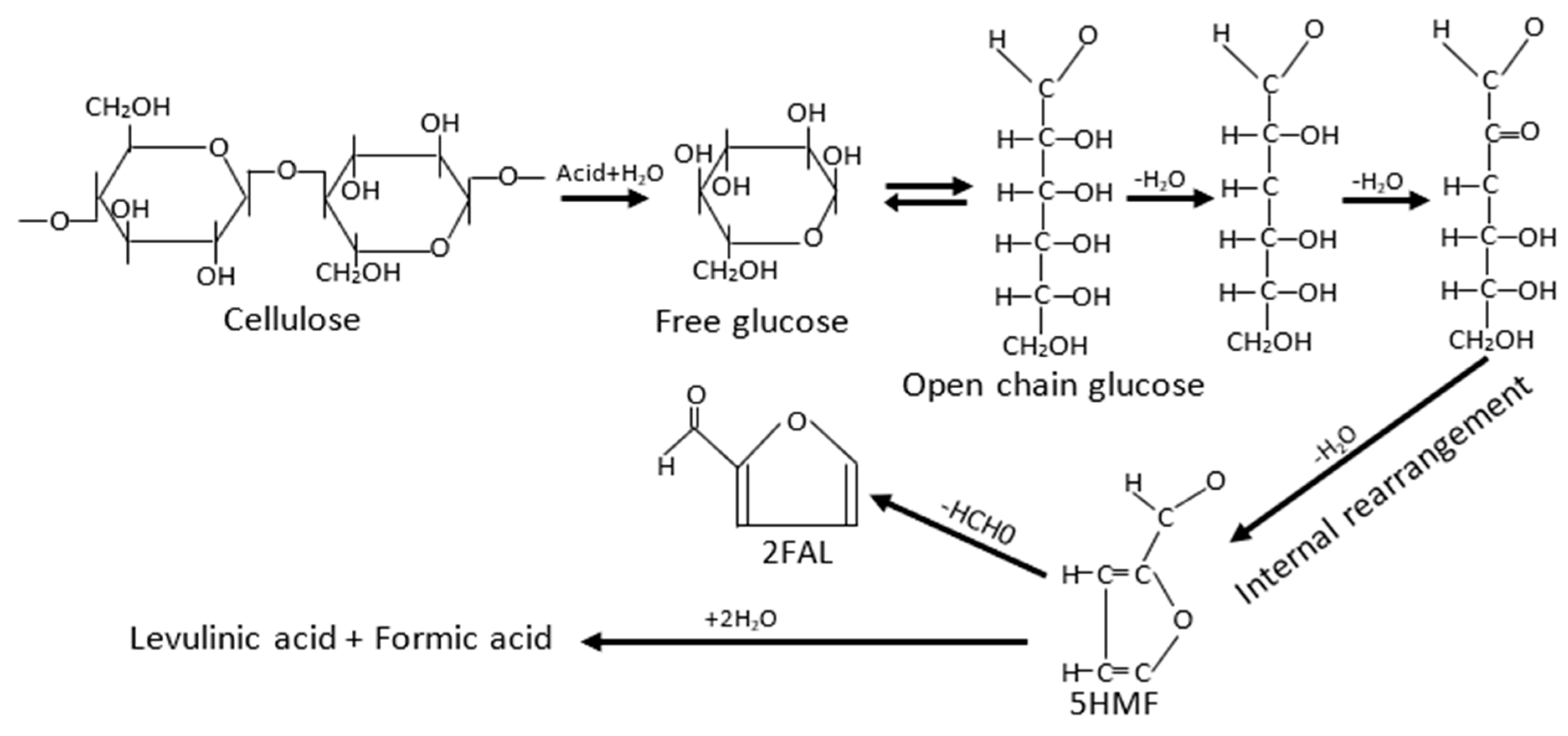

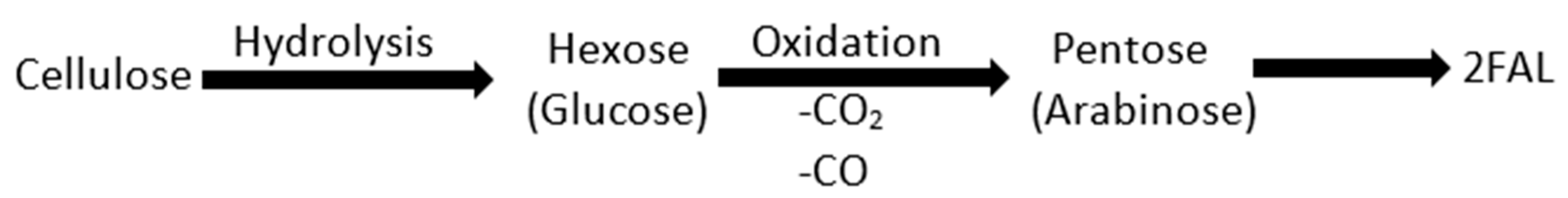

2.2. Furan Content

2.3. Methanol (MeOH) Content

3. Lifetime Model

4. Ageing Assessment

4.1. Post-Mortem Analysis

4.2. Acid Assessment

4.3. Water Content

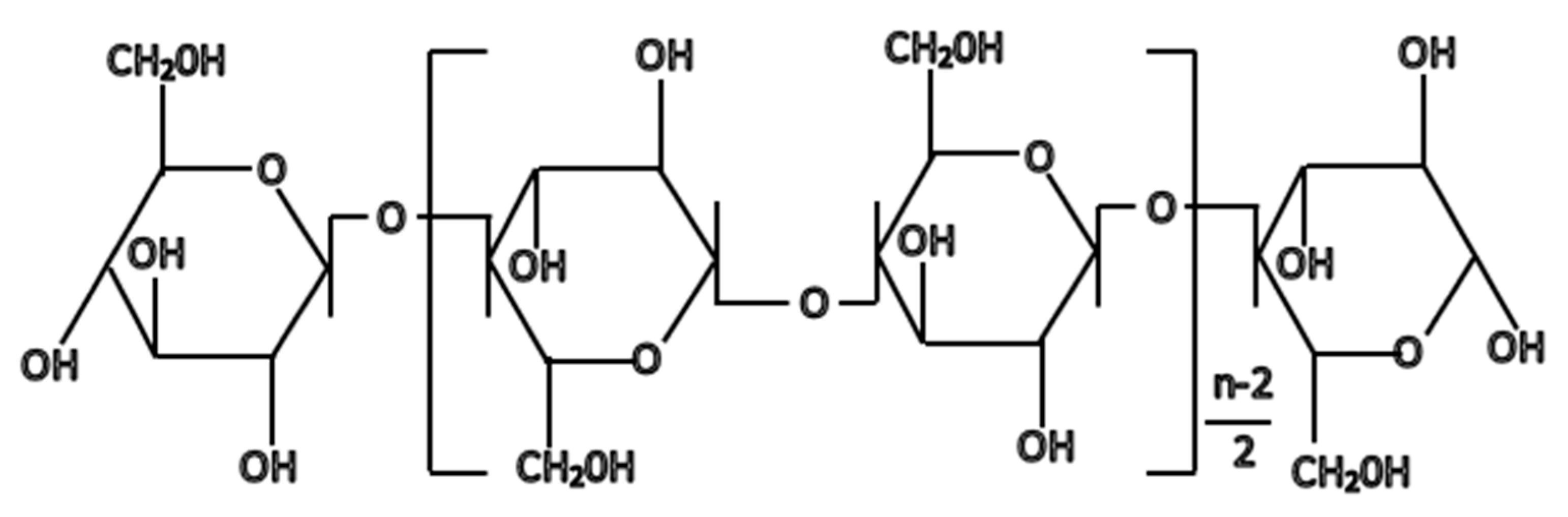

4.4. Degree of Polymerization

4.4.1. Viscometric Method

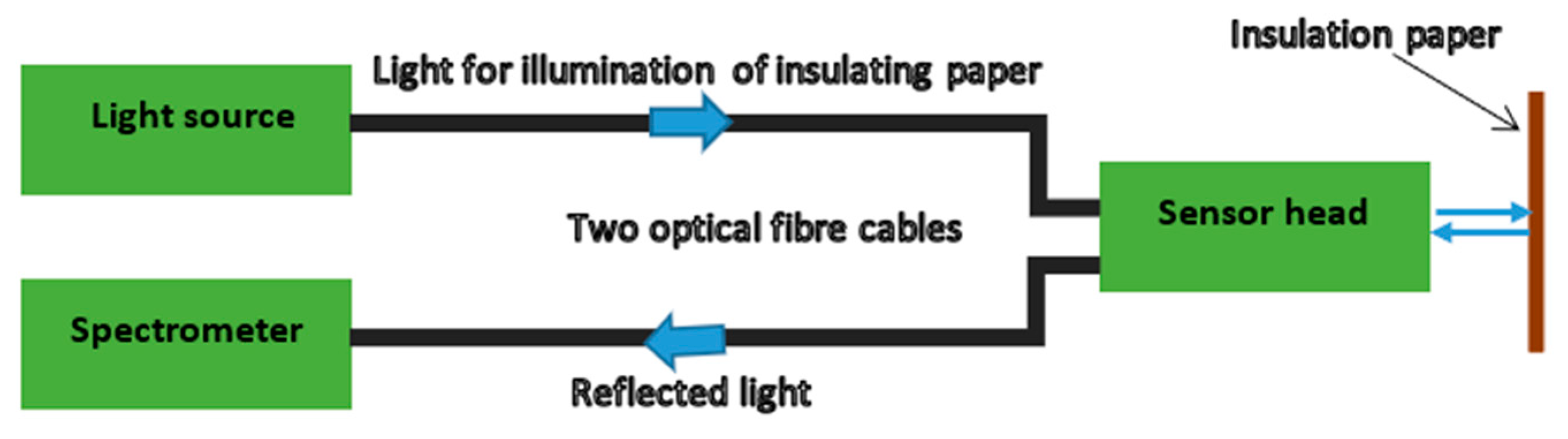

4.4.2. Optical Sensor Method

4.5. Tensile Strength

5. Electrical Properties

5.1. Dielectric Loss

5.2. Breakdown Strength

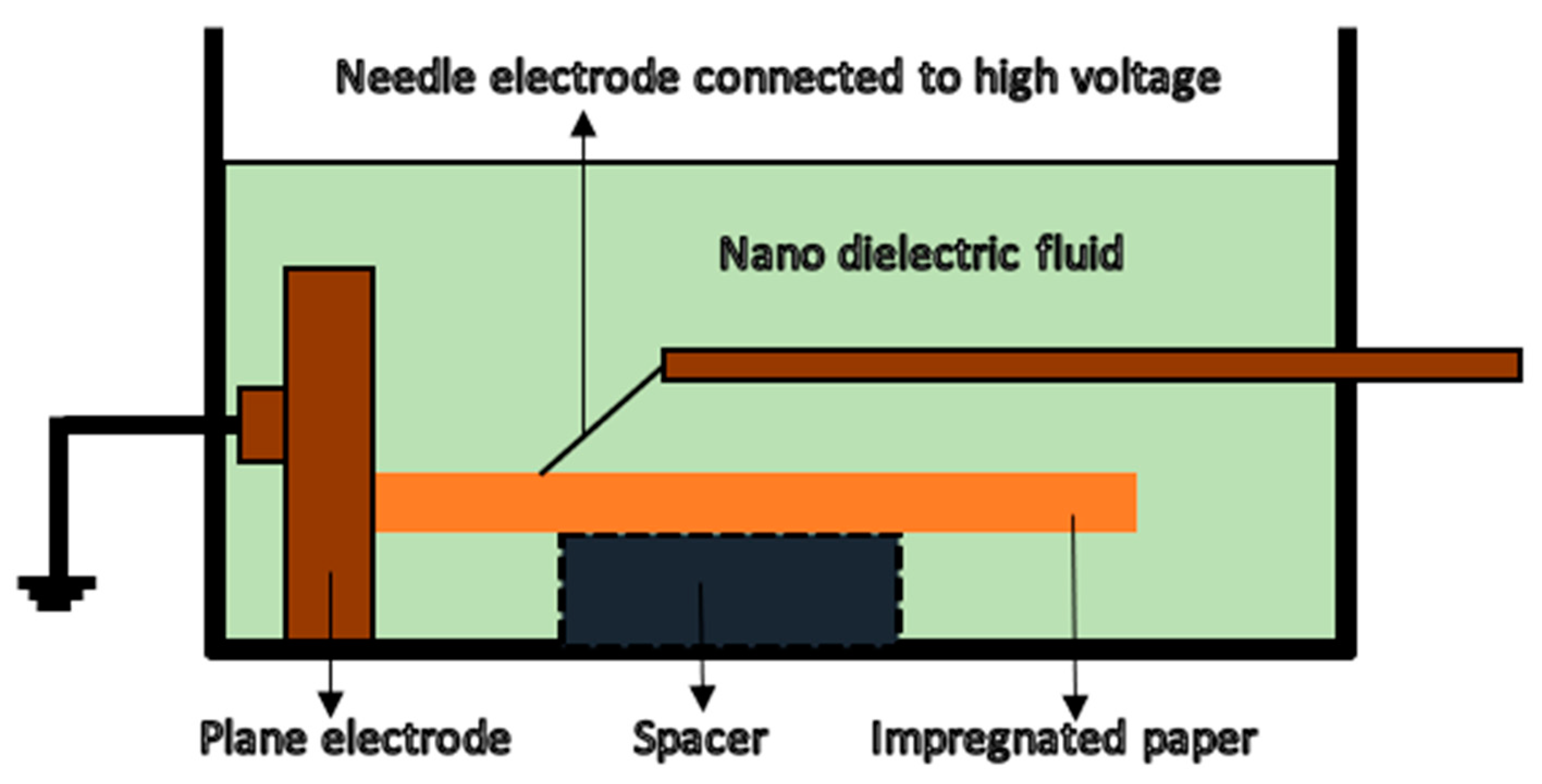

5.3. Creeping Flashover Voltage

5.4. Partial Discharge

5.5. Space Charge

6. Challenges and Future Directions

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, Q.; Rafiq, M.; Lv, Y.; Li, C.; Yi, K. Preparation of Three Types of Transformer Oil-Based Nanofluids and Comparative Study on the Effect of Nanoparticle Concentrations on Insulating Property of Transformer Oil. J. Nanotechnol. 2016, 2016, 5802753. [Google Scholar] [CrossRef]

- Morsalin, S.; Phung, T.B.; Danikas, M.; Mawad, D. Diagnostic challenges in dielectric loss assessment and inter-pretation: A review. IET Sci. Meas. Technol. 2019, 13, 767–782. [Google Scholar] [CrossRef]

- Behjat, V.; Emadifar, R.; Pourhossein, M.; Rao, U.; Fofana, I.; Najjar, R. Improved Monitoring and Diagnosis of Transformer Solid Insulation Using Pertinent Chemical Indicators. Energies 2021, 14, 3977. [Google Scholar] [CrossRef]

- Cong, H.; Pan, H.; Qian, D.; Zhao, H.; Li, Q. Reviews on sulphur corrosion phenomenon of the oil–paper insulating system in mineral oil transformer. High Volt. 2021, 6, 193–209. [Google Scholar] [CrossRef]

- Tong, X.; Liang, Z.; Li, N.; Zhao, B.; Li, K.; Zhang, G. Comprehensive Analysis and Evaluation of Shandong Power Grid Station Automation Equipment. In Proceedings of the 2020 Asia Energy and Electrical Engineering Symposium (AEEES), Chengdu, China, 29–31 May 2020; pp. 632–637. [Google Scholar]

- Metwally, I.A. Failures, Monitoring and New Trends of Power Transformers. IEEE Potentials 2011, 30, 36–43. [Google Scholar] [CrossRef]

- Yu, S.; Zhao, D.; Chen, W.; Hou, H. Oil-immersed Power Transformer Internal Fault Diagnosis Research Based on Probabilistic Neural Network. Procedia Comput. Sci. 2016, 83, 1327–1331. [Google Scholar] [CrossRef]

- Faiz, J.; Soleimani, M. Dissolved gas analysis evaluation in electric power transformers using conventional methods a review. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 1239–1248. [Google Scholar] [CrossRef]

- El-Saied, H.; El-Meligy, M.G.; Mohamed, S.H.; Abd El-Mongy, S. Electrical insulated paper from cotton lint-er. Carbohydr. Polym. 2012, 90, 147–151. [Google Scholar] [CrossRef]

- Coulibaly, M.-L.; Perrier, C.; Marugan, M.; Beroual, A. Aging behavior of cellulosic materials in presence of mineral oil and ester liquids under various conditions. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 1971–1976. [Google Scholar] [CrossRef]

- Mishra, D.; Baral, A.; Haque, N.; Chakravorti, S. Condition Assessment of Power Transformer Insulation Using Short-Duration Time-Domain Dielectric Spectroscopy Measurement Data. IEEE Trans. Instrum. Meas. 2019, 69, 4404–4411. [Google Scholar] [CrossRef]

- Maharana, M.; Baruah, N.; Nayak, S.K.; Sahoo, N. Comparative study of mechanical and electrical strength of kraft paper in nanofluid based transformer oil and mineral oil. In Proceedings of the 2017 International Symposium on Electrical Insulating Materials (ISEIM), Toyohashi, Japan, 11–15 September 2017; Volume 2, pp. 646–649. [Google Scholar]

- Oparanti, S.O.; Salaudeen, I.K.; Adekunle, A.A.; Oteikwu, V.E.; Galadima, A.I.; Abdelmalik, A.A. Physico-chemical and Dielectric study on Nigerian Thevetia Peruviana as a potential green alternative fluid for transformer cool-ing/insulation. Waste Biomass Valorization 2022, 1–11. [Google Scholar] [CrossRef]

- Rao, U.M.; Fofana, I.; Rozga, P.; Picher, P.; Sarkar, D.K.; Karthikeyan, R. Influence of Gelling in Natural Esters Under Open Beaker Accelerated Thermal Aging. IEEE Trans. Dielectr. Electr. Insul. 2022, 30, 413–420. [Google Scholar] [CrossRef]

- Madavan, R.; Balaraman, S. Comparison of antioxidant influence on mineral oil and natural ester properties under accelerated aging conditions. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 2800–2808. [Google Scholar] [CrossRef]

- Soni, R.; Mehta, B. Review on asset management of power transformer by diagnosing incipient faults and faults identification using various testing methodologies. Eng. Fail. Anal. 2021, 128, 105634. [Google Scholar] [CrossRef]

- Der Houhanessian, V. Measurement and Analysis of Dielectric Response in Oil-Paper Insulation Systems. Ph.D. Thesis, ETH Zurich, Zürich, Switzerland, 1998. [Google Scholar]

- Tang, C.; Chen, G.; Fu, M.; Liao, R.-J. Space charge behavior in multi-layer oil-paper insulation under different DC voltages and temperatures. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 775–784. [Google Scholar] [CrossRef]

- Setnescu, R.; Badicu, L.V.; Dumitran, L.M.; Notingher, P.V. Thermal lifetime of cellulose insulation material evaluated by an activation energy based method. Cellulose 2013, 21, 823–833. [Google Scholar] [CrossRef]

- Fernández, I.; Delgado, F.; Ortiz, F.; Ortiz, A.; Fernández, C.; Renedo, C.J.; Santisteban, A. Thermal degradation assessment of Kraft paper in power transformers insulated with natural esters. Appl. Therm. Eng. 2016, 104, 129–138. [Google Scholar] [CrossRef]

- Heathcote, M.J. The J & P Transformer Book: A Practical Technology of the Power Transformer; Newnes: London, UK, 1998. [Google Scholar]

- Perez-Rosa, D.; Garcia, B.; Burgos, J.C. Dielectric Response of the Oil-Paper Insulation System in Nanofluid-Based Transformers. IEEE Access 2021, 9, 83797–83805. [Google Scholar] [CrossRef]

- Zheng, Z.; Jin, Z.; Chen, L.; Chen, M.; Liu, J.; Yu, H.; Meng, Q.; Xie, P.; Xu, R. A comparative study of the ageing phenomena in Kraft paper and pressboard used in 500 kV class transformer. In Proceedings of the 2011 Annual Report Conference on Electrical Insu-lation and Dielectric Phenomena, Cancun, Mexico, 16–19 October 2011; pp. 620–623. [Google Scholar]

- Abu Bakar, N.; Abu-Siada, A.; Islam, S. A review on chemical diagnosis techniques for transformer paper insulation degradation. In Proceedings of the 2013 Australasian Universities Power Engineering Conference (AUPEC), Hobart, TAS, Australia, 29 September–3 October 2013; pp. 1–6. [Google Scholar]

- Tarasov, D.; Leitch, M.; Fatehi, P. Lignin–carbohydrate complexes: Properties, applications, analyses, and methods of extraction: A review. Biotechnol. Biofuels 2018, 11, 1–28. [Google Scholar] [CrossRef]

- Arshad, M.; Islam, S.M. Significance of cellulose power transformer condition assessment. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 1591–1598. [Google Scholar] [CrossRef]

- Zhou, H.; Long, Y.; Meng, A.; Li, Q.; Zhang, Y. The pyrolysis simulation of five biomass species by hemi-cellulose, cellulose and lignin based on thermogravimetric curves. Thermochim. Acta 2013, 566, 36–43. [Google Scholar] [CrossRef]

- McShane, C.P.; Rapp, K.J.; Corkran, J.L.; Gauger, G.A.; Luksich, J. Aging of paper insulation in natural ester dielectric fluid. In Proceedings of the 2001 IEEE/PES Transmission and Distribution Conference and Exposition. Developing New Perspectives (Cat. No. 01CH37294), Atlanta, GA, USA, 2 November 2001; Volume 2, pp. 675–679. [Google Scholar]

- Ese MH, G.; Liland, K.B.; Lesaint, C.; Kes, M. Esterification of low molecular weight acids in cellulose. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 662–665. [Google Scholar] [CrossRef]

- Tang, C.; Zhang, S.; Xie, J.; Lv, C. Molecular simulation and experimental analysis of Al2O3-nanoparticle-modified insulation paper cellulose. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 1018–1026. [Google Scholar] [CrossRef]

- Arroyo, O.H.; Jalbert, J.; Fofana, I.; Ryadi, M. Temperature dependence of methanol and the tensile strength of insulation paper: Kinetics of the changes of mechanical properties during ageing. Cellulose 2016, 24, 1031–1039. [Google Scholar] [CrossRef]

- Abu-Siada, A.; Islam, S. A new approach to identify power transformer criticality and asset management decision based on dissolved gas-in-oil analysis. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 1007–1012. [Google Scholar] [CrossRef]

- Dumitran, L.M.; Setnescu, R.; Notingher, P.V.; Badicu, L.V.; Setnescu, T. Method for lifetime estimation of power transformer mineral oil. Fuel 2014, 117, 756–762. [Google Scholar] [CrossRef]

- Rodriguez-Celis, E.M.; Duchesne, S.; Jalbert, J.; Ryadi, M. Understanding ethanol versus methanol formation from insulating paper in power transformers. Cellulose 2015, 22, 3225–3236. [Google Scholar] [CrossRef]

- Thiviyanathan, V.A.; Ker, P.J.; Leong, Y.S.; Abdullah, F.; Ismail, A.; Jamaludin, M.Z. Power transformer insula-tion system: A review on the reactions, fault detection, challenges and future prospects. Alex. Eng. J. 2022, 61, 7697–7713. [Google Scholar] [CrossRef]

- Arroyo, O.H.; Fofana, I.; Jalbert, J.; Ryadi, M. Relationships between methanol marker and mechanical performance of electrical insulation papers for power transformers under accelerated thermal aging. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 3625–3632. [Google Scholar] [CrossRef]

- Liu, J.; Fan, X.; Zhang, Y.; Zheng, H.; Wang, Z.; Zhao, X. A Modified Aging Kinetics Model for Aging Condition Prediction of Transformer Polymer Insulation by Employing the Frequency Domain Spectroscopy. Polymers 2019, 11, 2082. [Google Scholar] [CrossRef]

- Garcia, D.F.; Garcia, B.; Burgos, J.C. A review of moisture diffusion coefficients in transformer solid insulation-part 1: Coefficients for paper and pressboard. IEEE Electr. Insul. Mag. 2013, 29, 46–54. [Google Scholar] [CrossRef]

- Azis, N. Ageing Assessment of Insulation Paper with Consideration of In-Service Ageing and Natural Ester Application; The University of Manchester: Manchester, UK, 2012. [Google Scholar]

- Kaliappan, G.; Rengaraj, M. Aging assessment of transformer solid insulation: A review. Mater. Today Proc. 2021, 47, 272–277. [Google Scholar] [CrossRef]

- Lelekakis, N.; Wijaya, J.; Martin, D.; Saha, T.; Susa, D.; Krause, C. Aging rate of grade 3 presspaper insulation used in power transformers. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 2355–2362. [Google Scholar] [CrossRef]

- Koufakis, E.; Karagiannopoulos, C.; Bourkas, P. Thermal coefficient measurements of the insulation in distribution transformers of a 20kv network. Measurement 2008, 41, 10–19. [Google Scholar] [CrossRef]

- Malik, H.; Yadav, A.K.; Mishra, S.; Mehto, T. Application of neuro-fuzzy scheme to investigate the winding insulation paper deterioration in oil-immersed power transformer. Int. J. Electr. Power Energy Syst. 2013, 53, 256–271. [Google Scholar] [CrossRef]

- Baral, A.; Chakravorti, S. Condition assessment of cellulosic part in power transformer insulation using transfer function zero of modified debye model. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 2028–2036. [Google Scholar] [CrossRef]

- Sun, H.-C.; Huang, Y.-C.; Huang, C.-M. A Review of Dissolved Gas Analysis in Power Transformers. Energy Procedia 2012, 14, 1220–1225. [Google Scholar] [CrossRef]

- Ojewski, T.; Zięba, K.; Kołodziej, A.; Łojewska, J. Following cellulose depolymerization in paper: Comparison of size exclusion chromatography techniques. Cellulose 2011, 18, 1349–1363. [Google Scholar] [CrossRef]

- Wang, M.; Cha, R. Industrialization progress of nanocellulose in China. Pap. Biomater. 2019, 4, 63–68. [Google Scholar]

- Wang, D.; Liao, J.; Zhuo, R.; Liu, Z.; Xu, Y. Cantilever enhanced PA spectroscopy detection for CO decom-position in SF 6 equipment. In Proceedings of the 2022 IEEE 5th International Electrical and Energy Conference (CIEEC), Nangjing, China, 27–29 May 2022; pp. 3769–3774. [Google Scholar]

- Chen, Q.; Kang, M.; Xie, Q.; Wang, J. Effect of melamine modified cellulose nanocrystals on the performance of oil-immersed transformer insulation paper. Cellulose 2020, 27, 7621–7636. [Google Scholar] [CrossRef]

- Huaqiang, L.; Yaning, Z.; Lisheng, Z.; Qinxue, Y.; Xu, L.; Guangqi, L.; Mori, S.; Yamada, S. The DC breakdown of mineral insulating oil and oil-pressboard. In Proceedings of the 2013 Annual Report Conference on Electrical Insulation and Dielectric Phenomena, Shenzhen, China, 20–23 October 2013; pp. 929–931. [Google Scholar]

- Zhang, M.; Liu, J.; Qi, P.; Chen, Q.; Liao, L.; Chen, X.; Yin, M. Measurement of dielectric response of transformer moisture content. IET Sci. Meas. Technol. 2018, 12, 594–602. [Google Scholar] [CrossRef]

- Suleiman, A.A.; Muhamad, N.A.; Bashir, N.; Arief, Y.Z.; Rahman, M.N.A.; Phung, B.T. Moisture effect on conductivity of kraft paper immersed in power transformer vegetable-based insulation oils. IET Gener. Transm. Distrib. 2017, 11, 2269–2274. [Google Scholar] [CrossRef]

- Zhu, M.; Liao, R.; Du, X.; Zhou, J.; Zhu, W. Simulation of diffusion of moisture in insulation paper and the effect on mechanical properties of the paper. Trans. China Electrotech. Soc. 2015, 30, 338–345. [Google Scholar]

- Zaengl, W. Dielectric spectroscopy in time and frequency domain for HV power equipment. I. Theoretical considerations. IEEE Electr. Insul. Mag. 2003, 19, 5–19. [Google Scholar] [CrossRef]

- Choudhary, S.; Sengwa, R.J. Morphological, structural, dielectric and electrical properties of PEO–ZnO nano-dielectric films. J. Polym. Res. 2017, 24, 54. [Google Scholar] [CrossRef]

- Barrios, E.; Fox, D.; Li Sip, Y.Y.; Catarata, R.; Calderon, J.E.; Azim, N.; Afrin, S.; Zhang, Z.Y.; Zhai, L. Nanomaterials in Advanced, High-Performance Aerogel Composites: A Review. Polymers 2019, 11, 726. [Google Scholar] [CrossRef]

- Yao, Y.; Zhao, F.; Wang, B.; Hu, Z.; Huang, Y. The designing of degradable unsaturated polyester based on selective cleavage activated hydrolysis and its application in recyclable carbon fiber composites. Compos. Sci. Technol. 2022, 229, 109692. [Google Scholar] [CrossRef]

- Nazir, M.T.; Phung, B.T.; Zhang, Y.; Li, S. Dielectric and thermal properties of micro/nano boron nitride co-filled EPDM composites for high-voltage insulation. Micro Nano Lett. 2019, 14, 150–153. [Google Scholar] [CrossRef]

- Zhang, S. The Micromechanism on the Doping Modification of Nano SiO2 to the Oil-Immersed Cellulose Insulating Paper. Ph.D. Thesis, Southwest University, Chongqing, China, 2018. [Google Scholar]

- Chan, K.-Y.; Yang, D.; Demir, B.; Mouritz, A.P.; Lin, H.; Jia, B.; Lau, K.-T. Boosting the electrical and mechanical properties of structural dielectric capacitor composites via gold nanoparticle doping. Compos. Part B Eng. 2019, 178, 107480. [Google Scholar] [CrossRef]

- Lv, C. Study on the Preparation and Properties of Cellulose Insulation Paper Modified by Nano-TiO2. Ph.D. Thesis, Chongqing University, Chongqing, China, 2014. [Google Scholar]

- Wang, Q.; Zhou, Y.; Chen, X. Effect of TiO2 nanoparticles on surface discharge characteristics of transformer oil impregnated pressboard. Insul. Mater. 2015, 48, 36–40. [Google Scholar]

- Liao, R.; Lv, C.; Wu, W.Q.; Liang, N.C.; Yang, L.J. Insulating properties of insulation paper modified by nano-Al2O3 for power transformer. J. Electr. Power Sci. Technol. 2014, 9, 3–7. [Google Scholar]

- Shen, J.; Song, Z.; Qian, X.; Ni, Y. A Review on Use of Fillers in Cellulosic Paper for Functional Applications. Ind. Eng. Chem. Res. 2011, 50, 661–666. [Google Scholar] [CrossRef]

- Liao, R.; Lv, C.; Yang, L.; Zhang, Y.; Wu, W.; Tang, C. The insulation properties of oil-impregnated insulation paper reinforced with nano-TiO2. J. Nanomater. 2013, 2013, 1. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, L.; Cui, K.; Ge, S.; Cheng, X.; Yan, M.; Yu, J.; Liu, H. Flexible electronics based on micro/nanostructured paper. Adv. Mater. 2018, 30, 1801588. [Google Scholar] [CrossRef]

- Momen, G.; Farzaneh, M. Survey of micro/nano filler use to improve silicone rubber for outdoor insulators. Rev. Adv. Mater. Sci. 2011, 27, 1–13. [Google Scholar]

- Sethi, J.; Oksman, K.; Illikainen, M.; Sirviö, J.A. Sonication-assisted surface modification method to expedite the water removal from cellulose nanofibers for use in nanopapers and paper making. Carbohydr. Polym. 2018, 197, 92–99. [Google Scholar] [CrossRef]

- Adekunle, A.; Oparanti, S. A Review on Physicochemical and Electrical Performance of Vegetable Oil-Based Nanofluids for High Voltage Equipment. Electr. Power Syst. Res. 2023, 214, 108873. [Google Scholar] [CrossRef]

- Sima, W.; Shi, J.; Yang, Q.; Huang, S.; Cao, X. Effects of conductivity and permittivity of nanoparticle on transformer oil insulation performance: Experiment and theory. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 380–390. [Google Scholar] [CrossRef]

- Primo, V.A.; Pérez-Rosa, D.; García, B.; Cabanelas, J.C. Evaluation of the Stability of Dielectric Nanofluids for Use in Transformers under Real Operating Conditions. Nanomaterials 2019, 9, 143. [Google Scholar] [CrossRef]

- Prevost, T.A.; Oommen, T.V. Cellulose insulation in oil-filled power transformers: Part I-history and development. IEEE Electr. Insul. Mag. 2006, 22, 28–35. [Google Scholar] [CrossRef]

- Shayesteh-Zeraati, A. Synthesis of Multifunctional One-Dimensional and Two-Dimensional Highly Conductive Nano-Materials for Charge Storage Applications; University of Calgary: Calgary, AB, Canada, 2020. [Google Scholar] [CrossRef]

- Mildemberger, L.; Andreoli, M.C.; Silva GC, D.; Motta HN, D.; Gulmine, J.V.; Munaro, M. Correlation between stabilizer consumption and degree of polymerization of thermally upgraded paper aged in insulating natural ester and insulating mineral oil. Polímeros 2016, 26, 61–65. [Google Scholar] [CrossRef]

- Lundgaard, L.E.; Hansen, W.; Linhjell, D.; Painter, T.J. Aging of oil-impregnated paper in power transformers. IEEE Trans. Power Deliv. 2004, 19, 230–239. [Google Scholar] [CrossRef]

- Prevost, T.A. Thermally upgraded insulation in transformers. In Proceedings of the Electrical Insulation Conference and Electrical Manufacturing Expo, Indianapolis, IN, USA, 23–26 October 2005; pp. 120–125. [Google Scholar]

- Primo, V.A.; García, B.; Burgos, J.C.; Pérez-Rosa, D. Investigation of the Lightning Impulse Breakdown Voltage of Mineral Oil based Fe3O4 Nanofluids. Coatings 2019, 9, 799. [Google Scholar] [CrossRef]

- Dai, J.; Dong, M.; Li, Y.; Zhou, J.; Wen, F. Influence of nanoparticle concentration on the frequency domain spectroscopy properties of transformer oil-based nanofluids. In Proceedings of the 2016 IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Toronto, ON, Canada, 16–19 October 2016; pp. 587–590. [Google Scholar]

- Du, Y.; Lv, Y.; Li, C.; Chen, M.; Zhong, Y.; Zhou, J.; Li, X.; Zhou, Y. Effect of semiconductive nanoparticles on insulating performances of transformer oil. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 770–776. [Google Scholar] [CrossRef]

- Zerinç, S.; Kakaç, S.; Yazıcıoğlu, A.G. Enhanced thermal conductivity of nanofluids: A state-of-the-art review. Microfluid. Nanofluidics 2010, 8, 145–170. [Google Scholar] [CrossRef]

- Pérez-Rosa, D.; García, B.; Burgos, J.C.; Febrero, A. Morphological analysis of transformer Kraft paper impregnated with dielectric nanofluids. Cellulose 2020, 27, 8963–8975. [Google Scholar] [CrossRef]

- N’Cho, J.S.; Fofana, I.; Hadjadj, Y.; Beroual, A. Review of Physicochemical-Based Diagnostic Techniques for Assessing Insulation Condition in Aged Transformers. Energies 2016, 9, 367. [Google Scholar] [CrossRef]

- Zhang, E.; Zheng, H.; Zhang, C.; Wang, J.; Shi, K.; Guo, J.; Schwarz, H.; Zhang, C. Aging state assessment of transformer cellulosic paper insulation using multivariate chemical indicators. Cellulose 2021, 28, 2445–2460. [Google Scholar] [CrossRef]

- Carrascal, I.A.; Fernández-Diego, C.; Casado, J.A.; Diego, S.; Fernández, I.; Ortiz, A. Quantification of Kraft paper ageing in mineral oil impregnated insulation systems through mechanical characterization. Cellulose 2018, 25, 3583–3594. [Google Scholar] [CrossRef]

- Fernández-Diego, C.; Ortiz, A.; Carrascal, I.A.; Fernández, I.; Renedo, C.J.; Delgado, F.; Diego, S. Damage assessment of transformer Kraft paper insulation aged in mineral and vegetable oils. Cellulose 2019, 26, 2653–2672. [Google Scholar] [CrossRef]

- Aciu, A.-M.; Nitu, M.C.; Nicola, M.; Nicola, C.-I.; Lazarescu, F. Complementary analysis of the degree of polymerization based on chemical markers 2-furaldehyde and methanol using the fuzzy logic. In Proceedings of the 2020 21st International Symposium on Electrical Apparatus & Technologies (SIELA), Bourgas, Bulgaria, 3–6 June 2020; pp. 1–6. [Google Scholar]

- van Bolhuis, J.; Gulski, E.; Smit, J. Monitoring and diagnostic of transformer solid insulation. IEEE Trans. Power Deliv. 2002, 17, 528–536. [Google Scholar] [CrossRef]

- Saha, T.K. Review of modern diagnostic techniques for assessing insulation condition in aged transformers. IEEE Trans. Dielectr. Electr. Insul. 2003, 10, 903–917. [Google Scholar] [CrossRef]

- Abu-Siada, A.; Islam, S.; Lai, S. Remnant Life Estimation of Power Transformer using Oil UV-Vis Spectral Response. In Proceedings of the IEEE PES Power Systems Conference & Exhibition (PSCE), Seattle, WA, USA, 15–20 March 2009; pp. 1–5. [Google Scholar]

- Stevens, G.C.; Herman, H.; Baird, P. Insulation condition assessment through spectroscopic and chemometrics analysis. In Proceedings of the 2007 IEEE International Conference on Solid Dielectrics, Winchester, UK, 8–13 July 2007; pp. 717–720. [Google Scholar]

- Srivastava, R.; Kumar, Y.; Banerjee, S.; Kale, S.N. Real-time transformer oil monitoring using planar frequency-based sensor. Sens. Actuators A Phys. 2022, 347, 113892. [Google Scholar] [CrossRef]

- Prasojo, R.A.; Suwarno, S. Power Transformer Paper Insulation Assessment based on Oil Measurement Data using SVM-Classifier. Int. J. Electr. Eng. Inform. 2018, 10, 661–673. [Google Scholar] [CrossRef]

- Bakar, N.A.; Abu-Siada, A.; Islam, S. A review of dissolved gas analysis measurement and interpretation techniques. IEEE Electr. Insul. Mag. 2014, 30, 39–49. [Google Scholar] [CrossRef]

- Malik, H.; Tarkeshwar; Jarial, R. Make Use of DGA to Carry Out the Transformer Oil-Immersed Paper Deterioration Condition Estimation with Fuzzy-Logic. Procedia Eng. 2012, 30, 569–576. [Google Scholar] [CrossRef]

- Ghoneim, S. The Degree of Polymerization in a Prediction Model of Insulating Paper and the Remaining Life of Power Transformers. Energies 2021, 14, 670. [Google Scholar] [CrossRef]

- Zhang, E.; Zheng, H.; Zhang, Y.; Liu, J.; Shi, Z.; Shi, K.; Zhang, C.; Shao, G.; Zhang, C.; Schwarz, H. Lifespan Model of the Relationships between Ethanol Indicator and Degree of Polymerization of Transformer Paper Insulation. IEEE Trans. Dielectr. Electr. Insul. 2021, 28, 1859–1866. [Google Scholar] [CrossRef]

- Dessouky, S.S.; Kalas, A.E.; Abd El-Aal, R.A.; Hassan, A.M.M. Study and examination of transformer oil while exposed to air during operation. In Proceedings of the 2017 Nineteenth International Middle East Power Systems Conference (MEPCON), Cairo, Egypt, 19–21 December 2017; pp. 445–450. [Google Scholar]

- Jalbert, J.; Rodriguez-Celis, E.; Duchesne, S.; Morin, B.; Ryadi, M.; Gilbert, R. Kinetics of the production of chain-end groups and methanol from the depolymerization of cellulose during the ageing of paper/oil systems. Part 3: Extension of the study under temperature conditions over 120 °C. Cellulose 2014, 22, 829–848. [Google Scholar] [CrossRef]

- He, L.; Liao, R.; Lv, Y.; Yang, L.; Zhao, X.; Yan, S. Effect of nano-Al2O3 on the thermal aging phys-icochemical properties of insulating paper. In Proceedings of the 2016 International Conference on Condition Monitoring and Diagnosis (CMD), Xi’an, China, 25–28 September 2016; pp. 254–257. [Google Scholar]

- Scheirs, J.; Camino, G.; Avidano, M.; Tumiatti, W. Origin of furanic compounds in thermal deg radation of cel-lulosic insulating paper. J. Appl. Polym. Sci. 1998, 69, 2541–2547. [Google Scholar] [CrossRef]

- Lelekakis, N.; Martin, D.; Wijaya, J. Ageing rate of paper insulation used in power transformers Part 1: Oil/paper system with low oxygen concentration. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 1999–2008. [Google Scholar] [CrossRef]

- Cui, H.; Abu-Siada, A.; Li, S.; Islam, S. Correlation between dissolved gases and oil spectral response. In Proceedings of the 2017 1st International Conference on Electrical Materials and Power Equipment (ICEMPE), Xi’an, China, 14–17 May 2017; pp. 28–32. [Google Scholar]

- ASTM D5837; Standard Test Method for Furanic Compounds in Electrical Insulating Liquids by High-Performance Liquid Chromatography (HPLC). ASTM International: West Conshohocken, PA, USA, 2015.

- Zong, P.; Jiang, Y.; Tian, Y.; Li, J.; Yuan, M.; Ji, Y.; Chen, M.; Li, D.; Qiao, Y. Pyrolysis behavior and product distributions of bi-omass six group components: Starch, cellulose, hemicellulose, lignin, protein and oil. Energy Convers. Manag. 2020, 216, 112777. [Google Scholar] [CrossRef]

- Thango, B.A.; Bokoro, P.N. Prediction of the Degree of Polymerization in Transformer Cellulose Insulation Using the Feedforward Backpropagation Artificial Neural Network. Energies 2022, 15, 4209. [Google Scholar] [CrossRef]

- Pesavento, M.; Merli, D.; Biesuz, R.; Alberti, G.; Marchetti, S.; Milanese, C. A MIP-based low-cost electrochemical sensor for 2-furaldehyde detection in beverages. Anal. Chim. Acta 2020, 1142, 201–210. [Google Scholar] [CrossRef] [PubMed]

- En-Wen, L.; Bin, S. Transformer health status evaluation model based on multi-feature factors. In Proceedings of the 2014 International Conference on Power System Technology, Chengdu, China, 20–22 October 2014; pp. 1417–1422. [Google Scholar]

- Leibfried, T.; Jaya, M.; Majer, N.; Schafer, M.; Stach, M.; Voss, S. Postmortem investigation of power transform-ers—Profile of degree of polymerization and correlation with furan concentration in the oil. IEEE Trans. Power Deliv. 2013, 28, 886–893. [Google Scholar] [CrossRef]

- Cheim, A.; Dupont, C. A new transformer aging model and its correlation to 2FAL. In Cigré Transformer Colloquium; CIGRE: Paris, France, 2003. [Google Scholar]

- Cheim, L.; Platts, D.; Prevost, T.; Xu, S. Furan analysis for liquid power transformers. IEEE Electr. Insul. Mag. 2012, 28, 8–21. [Google Scholar] [CrossRef]

- Teymouri, A.; Vahidi, B. Power transformer cellulosic insulation destruction assessment using a calculated index composed of CO, CO2, 2-Furfural, and Acetylene. Cellulose 2020, 28, 489–502. [Google Scholar] [CrossRef]

- Talib, M.A.; Aziz, M.A.A.; Balasubramaniam, Y.; Ghazali, Y.Z.Y.; Abidin, M.R.Z.; Yousof, M.F.M. Transformer Ageing Investigation and Correlation of Furanic Compound and Degree of Polymerization for Power Trans-former Life Assessment. In Proceedings of the 2020 IEEE International Conference on Power and Energy (PECon), Penang, Malaysia, 7–8 December 2020; pp. 240–244. [Google Scholar]

- Ramazani, A.; Rahmati, R.; Bigdeli, S.; Rahmani, S.; Hamidi, M. Aging Study of Transformer Oil-Impregnated Re-Pulped and Standard Cellulose by Measuring of 2-Furfural Content of the Oil; ACECR, Scientific Information Database: Tehran, Iran, 2015. [Google Scholar]

- Arroyo-Fernandez, O.H.; Fofana, I.; Jalbert, J.; Rodriguez, E.; Rodriguez, L.B.; Ryadi, M. Assessing changes in thermally upgraded papers with different nitrogen contents under accelerated aging. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 1829–1839. [Google Scholar] [CrossRef]

- Meissner, M.; Darmann, M.; Schober, S.; Mittelbach, M.; Sumereder, C. Reliability Study of Furan Level Analysis for Transformer Health Prediction. In Proceedings of the 2019 IEEE 20th International Conference on Dielectric Liquids (ICDL), Roma, Italy, 23–27 June 2019; pp. 1–4. [Google Scholar]

- Imani, M.T.; Homeier, K.; Werle, P.; Drager, G. How Far are Furan Compounds Reliable Indicators for Thermal Aging of Oil Impregnated Cellulose Insula-tion? In Proceedings of the 2018 IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Cancun, Mexico, 21–24 October 2018; pp. 438–441. [Google Scholar]

- Shen, S. Comparative Investigation on the Properties of Transformer-Used High Temperature Resistant Oil and Paper Insulation Materials; POLITesi: Politecnico, Italy, 2016. [Google Scholar]

- Jalbert, J.; Gilbert, R.; Denos, Y.; Gervais, P. Methanol: A novel approach to power transformer asset management. IEEE Trans. Power Deliv. 2012, 27, 514–520. [Google Scholar] [CrossRef]

- Schaut, A.; Autru, S.; Eeckhoudt, S. Applicability of methanol as new marker for paper degradation in power transformers. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 533–540. [Google Scholar] [CrossRef]

- Jalbert, J.; Rodriguez-Celis, E.M.; Arroyo-Fernández, O.H.; Duchesne, S.; Morin, B. Methanol marker for the detection of insulating paper degradation in transformer insulating oil. Energies 2019, 12, 3969. [Google Scholar] [CrossRef]

- Fernández OH, A.; Fofana, I.; Jalbert, J.; Gagnon, S.; Rodriguez-Celis, E.; Duchesne, S.; Ryadi, M. Aging charac-terization of electrical insulation papers impregnated with synthetic ester and mineral oil: Correlations between mechanical properties, depolymerization and some chemical markers. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 217–227. [Google Scholar] [CrossRef]

- Li, C.; Wu, K.; Li, Z.; Yang, Y.; Qian, K.; Kang, X. Effect of Electric Field on Methanol Generation in Transformer. In Proceedings of the 2018 IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Cancun, Mexico, 21–24 October 2018; pp. 382–385. [Google Scholar]

- Li, S.; Ge, Z.; Abu-Siada, A.; Yang, L.; Li, S.; Wakimoto, K. A new technique to estimate the degree of polymerization of insulation paper using multiple aging parameters of transformer oil. IEEE Access 2019, 7, 157471–157479. [Google Scholar] [CrossRef]

- Souza, E.M.P.V.S.; Mildemberger, L.; Akcelrud, L.; Andreoli, M.C.; Dos Santos, K.; Da Silva, G.C.; Da Motta, H.N.; Gulmine, J.V.; Munaro, M. Evaluation of the chemical stability of methanol generated during paper degradation in power transformers. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 3209–3214. [Google Scholar] [CrossRef]

- Molavi, H.; Yousefpour, A.; Mirmostafa, A.; Sabzi, A.; Hamedi, S.; Narimani, M.; Abdi, N. Static Headspace GC/MS Method for Determination of Methanol and Ethanol Contents, as the Degradation Markers of Solid Insulation Systems of Power Transformers. Chromatographia 2017, 80, 1129–1135. [Google Scholar] [CrossRef]

- Martin, D.; Cui, Y.; Ekanayake, C.; Ma, H.; Saha, T. An updated model to determine the life remaining of trans-former insulation. IEEE Trans. Power Deliv. 2014, 30, 395–402. [Google Scholar] [CrossRef]

- C57.91-2011; IEEE Guide for Loading Mineral-Oil-Immersed Transformers and STP-Voltage Regulators. IEEE Standard: New York, NY, USA, 2012.

- Godina, R.; Rodrigues, E.M.; Matias, J.C.; Catalão, J.P. Effect of loads and other key factors on oil-transformer ageing: Sustainability benefits and challenges. Energies 2015, 8, 12147–12186. [Google Scholar] [CrossRef]

- IEC Central Office. Power Transformers–Part 7: Loading Guide for Oil-Immersed Power Transformers; IEC Central Office: Geneva, Switzerland, 2005. [Google Scholar]

- Yang, D.; Chen, W.; Zhou, W.; Zou, J.; Fan, Z. Recognition of Aging Stage of Oil–Paper Insulation Based on Surface Enhanced Raman Scattering and Kernel Entropy Component Analysis. IEEE Access 2019, 7, 127862–127873. [Google Scholar] [CrossRef]

- Yang, D.; Chen, W.; Wan, F.; Zhou, Y.; Wang, J. Identification of the Aging Stage of Transformer Oil-Paper Insulation via Raman Spectroscopic Characteristics. IEEE Trans. Dielectr. Electr. Insul. 2020, 27, 1770–1777. [Google Scholar] [CrossRef]

- Krause, C. Power transformer insulation–history, technology and design. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 1941–1947. [Google Scholar] [CrossRef]

- Duval, M.; De Pablo, A.; Atanasova-Hoehlein, I.; Grisaru, M. Significance and detection of very low degree of polymerization of paper in transformers. IEEE Electr. Insul. Mag. 2017, 33, 31–38. [Google Scholar] [CrossRef]

- Liao, R.; Guo, C.; Wang, K.; Yang, L.; Grzybowski, S.; Sun, H. Investigation on thermal aging characteristics of vegetable oil-paper insulation with flowing dry air. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 1649–1658. [Google Scholar] [CrossRef]

- Medina, R.D.; Romero, A.A.; Mombello, E.E.; Ratta, G. Assessing degradation of power transformer solid insulation considering thermal stress and moisture variation. Electr. Power Syst. Res. 2017, 151, 1–11. [Google Scholar] [CrossRef]

- Kouassi, K.D.; Fofana, I.; Cissé, L.; Hadjadj, Y.; Yapi, K.M.L.; Diby, K.A. Impact of Low Molecular Weight Acids on Oil Impregnated Paper Insulation Degradation. Energies 2018, 11, 1465. [Google Scholar] [CrossRef]

- Yao, W.; Li, J.; Huang, Z.; Li, X.; Xiang, C. Acids generated and influence on electrical lifetime of natural ester impregnated paper insulation. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 1904–1914. [Google Scholar] [CrossRef]

- Aizpurua, J.I.; McArthur, S.D.; Stewart, B.G.; Lambert, B.; Cross, J.G.; Catterson, V.M. Adaptive power trans-former lifetime predictions through machine learning and uncertainty modeling in nuclear power plants. IEEE Trans. Ind. Electron. 2018, 66, 4726–4737. [Google Scholar] [CrossRef]

- Ghunem, R.A.; Assaleh, K.; El-Hag, A.H. Artificial neural networks with stepwise regression for predicting transformer oil furan content. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 414–420. [Google Scholar] [CrossRef]

- Fernández-Diego, C.; Fernández, I.; Ortiz, F.; Carrascal, I.; Renedo, C.; Delgado, F. Assessment of dielectric paper degradation through mechanical characterisation. In Simulation and Modelling of Electrical Insulation Weaknesses in Electrical Equipment; IntechOpen: London, UK, 2018; p. 1. [Google Scholar]

- Feng, D. Life Expectancy Investigation of Transmission Power Transformers; The University of Manchester: Manchester, UK, 2013. [Google Scholar]

- Zhang, J.; Tang, C.; Qiu, Q.; Yang, L. Effect of water on the diffusion of small molecular weight acids in nano-SiO2 modified insulating oil. J. Mol. Liq. 2020, 314, 113670. [Google Scholar] [CrossRef]

- Frimpong, G.; Oommen, T.V.; Asano, R. A survey of aging characteristics of cellulose insulation in natural ester and mineral oil. IEEE Electr. Insul. Mag. 2011, 27, 36–48. [Google Scholar] [CrossRef]

- Yan, Z.W.; Kihampa, T.; Matharage, S.Y.; Liu, Q.; Wang, Z.D. Measuring Low Molecular Weight Acids in Mineral and Ester Transformer Liquids. In Proceedings of the 2020 8th International Conference on Condition Monitoring and Diagnosis (CMD), Phuket, Thailand, 25–28 October 2020; pp. 354–357. [Google Scholar]

- Lundgaard, L.E.; Hansen, W.; Ingebrigtsen, S. Ageing of Mineral Oil Impregnated Cellulose by Acid Catalysis. IEEE Trans. Dielectr. Electr. Insul. 2008, 15, 540–546. [Google Scholar] [CrossRef]

- Zdemir, B.; Münster, T.; Werle, P.; Hämel, K.; Preusel, J. Investigations on Detectability of Different Acids in Paper-Oil Insulation. In Proceedings of the IET: 22nd International Symposium on High Voltage Engineering (ISH 2021), Hybrid Conference, Xi’an, China, 21–26 November 2021. [Google Scholar]

- Venkatasubramanian, R.; Liu, Q.; Wang, Z.D.; Marshall, P. Assessment of regenerated oil through accelerated thermal ageing experiments. In Proceedings of the 2015 50th International Universities Power Engineering Conference (UPEC), Stoke on Trent, UK, 1–4 September 2015; pp. 1–4. [Google Scholar]

- Allaf, H.N.; Mirzaei, H. Investigations on reclaimed oil performance through measurement of the relative free radical content. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 3481–3489. [Google Scholar] [CrossRef]

- Zhang, J.; Tang, C.; Wang, Q.; Liu, X.; Du, D. Analysis of nano-SiO2 affecting the acids diffusion in the interface between oil and cellulose paper. Chem. Phys. 2020, 529, 110557. [Google Scholar] [CrossRef]

- Han, S.; Li, Q.; Li, C.; Yan, J. Electrical and mechanical properties of the oil-paper insulation under stress of the hot spot temperature. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 179–185. [Google Scholar] [CrossRef]

- Jiang, J.P.; Du, B.X.; Cavallini, A. Effect of moisture migration on surface discharge on oil-pressboard of power transformers under cooling. IEEE Trans. Dielectr. Electr. Insul. 2020, 27, 1743–1751. [Google Scholar] [CrossRef]

- Lelekakis, N.; Martin, D.; Wijaya, J. Ageing rate of paper insulation used in power transformers Part 2: Oil/paper system with medium and high oxygen concentration. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 2009–2018. [Google Scholar] [CrossRef]

- Yin, F.; Tang, C.; Li, X.; Wang, X. Effect of Moisture on Mechanical Properties and Thermal Stability of Meta-Aramid Fiber Used in Insulating Paper. Polymers 2017, 9, 537. [Google Scholar] [CrossRef]

- Martin, D.; Saha, T. A review of the techniques used by utilities to measure the water content of transformer insulation paper. IEEE Electr. Insul. Mag. 2017, 33, 8–16. [Google Scholar] [CrossRef]

- Kierczynski, K.; Zukowski, P.; Sebok, M.; Gutten, M. Comparison of DC conductivity of the insulating oil and moisturized electrical pressboard impregnated with insulating oil. In 2018 ELEKTRO; IEEE: Mikulov, Czech Republic, 2018; pp. 1–4. [Google Scholar]

- Martin, D.; Saha, T.; Perkasa, C.; Lelekakis, N.; Gradnik, T. Fundamental concepts of using water activity probes to assess transformer insulation water content. IEEE Electr. Insul. Mag. 2016, 32, 9–16. [Google Scholar] [CrossRef]

- Martin, D.; Saha, T.; Gray, T.; Wyper, K. Determining water in transformer paper insulation: Effect of measuring oil water activity at two different locations. IEEE Electr. Insul. Mag. 2015, 31, 18–25. [Google Scholar] [CrossRef]

- Saha, T.K.; Yao, Z.T. Experience with return voltage measurements for assessing insulation conditions in service-aged transformers. IEEE Trans. Power Deliv. 2003, 18, 128–135. [Google Scholar] [CrossRef]

- Martin, D.; Perkasa, C.; Lelekakis, N. Measuring Paper Water Content of Transformers: A New Approach Using Cellulose Isotherms in Nonequilibrium Conditions. IEEE Trans. Power Deliv. 2013, 28, 1433–1439. [Google Scholar] [CrossRef]

- Mukherjee, M.; Martin, D.; Kulkami, S.V.; Saha, T. A mathematical model to measure instantaneous moisture content in transformer insulation cellulose. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 3207–3216. [Google Scholar] [CrossRef]

- Xia, G.; Wu, G.; Gao, B.; Yin, H.; Yang, F. A New Method for Evaluating Moisture Content and Aging Degree of Transformer Oil-Paper Insulation Based on Frequency Domain Spectroscopy. Energies 2017, 10, 1195. [Google Scholar] [CrossRef]

- Teymouri, A.; Vahidi, B. CO2/CO concentration ratio: A complementary method for determining the degree of polymerization of power transformer paper insulation. IEEE Electr. Insul. Mag. 2017, 33, 24–30. [Google Scholar] [CrossRef]

- IEC-60450; Measurement of the Average Viscometric Degree of Polymerization of New and Aged Cellulosic Electrically Insulating Materials. IEC: London, UK, 2004.

- Wang, Y.; Gao, J.; Liao, R.; Zhang, Y.; Hao, J.; Liu, J.; Ma, Z. Investigation of characteristic parameters for condition evaluation of transformer oil-paper insulation using frequency domain spectroscopy. Int. Trans. Electr. Energy Syst. 2014, 25, 2921–2932. [Google Scholar] [CrossRef]

- Tang, C.; Zhang, S.; Wang, X.; Hao, J. Enhanced mechanical properties and thermal stability of cellulose insulation paper achieved by doping with melamine-grafted nano-SiO2. Cellulose 2018, 25, 3619–3633. [Google Scholar] [CrossRef]

- Martin, D.; Saha, T.; Dee, R.; Buckley, G.; Chinnarajan, S.; Caldwell, G.; Zhou, J.B.; Russell, G. Determining water in transformer paper insulation: Analyzing aging transformers. IEEE Electr. Insul. Mag. 2015, 31, 23–32. [Google Scholar] [CrossRef]

- Gouda, O.E.; El Dein, A.Z. Prediction of Aged Transformer Oil and Paper Insulation. Electr. Power Compon. Syst. 2019, 47, 406–419. [Google Scholar] [CrossRef]

- Oria, C.; Carrascal, I.; Ortiz, A.; Fernandez, I.; Ferreno, D.; Afshar, R.; Gamstedt, K. Experimental and numerical analysis of cellulosic insulation failures of continuously transposed conductors under short circuits and thermal ageing in power transformers. IEEE Trans. Dielectr. Electr. Insul. 2020, 27, 325–333. [Google Scholar] [CrossRef]

- Fernández-Diego, C.; Carrascal, I.A.; Ortiz, A.; Fernández, I.; Ferreño, D.; Diego, S.; Casado, A. Fracture toughness as an alternative approach to quantify the ageing of insulation paper in oil. Cellulose 2021, 28, 11533–11550. [Google Scholar] [CrossRef]

- Liang, N.; Liao, R.; Xiang, M.; Mo, Y.; Yuan, Y. Effect of Nano Al2O3 Doping on Thermal Aging Properties of Oil-Paper Insulation. Energies 2018, 11, 1176. [Google Scholar] [CrossRef]

- Münster, T.; Werle, P.; Peter, I.; Hämel, K.; Barden, R.; Preusel, J. Optical sensor for determining the degree of polymerization of the insulation paper inside transformers. Transform. Mag. 2021, 8, 106–117. [Google Scholar]

- Lee, C.L.; Chin, K.L.; H’Ng, P.S.; Hafizuddin, M.S.; Khoo, P.S. Valorisation of Underutilized Grass Fibre (Stem) as a Potential Material for Paper Production. Polymers 2022, 14, 5203. [Google Scholar] [CrossRef]

- Azis, N.; Liu, Q.; Wang, Z.D. Ageing assessment of transformer paper insulation through post mortem analysis. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 845–853. [Google Scholar] [CrossRef]

- Lv, Y.; Zhou, Y.; Li, C.; Ge, Y.; Qi, B. Creeping Discharge Characteristics of Nanofluid-Impregnated Pressboards Under AC Stress. IEEE Trans. Plasma Sci. 2016, 44, 2589–2593. [Google Scholar] [CrossRef]

- Yuan, Y.; Liao, R. A Novel Nanomodified Cellulose Insulation Paper for Power Transformer. J. Nanomater. 2014, 2014, 1–6. [Google Scholar] [CrossRef]

- Hollertz, R.; Wågberga, L.; Pitois, C. Novel cellulose nanomaterials. In Proceedings of the 2014 IEEE 18th International Conference on Dielectric Liquids (ICDL), Bled, Slovenia, 29 June–3 July 2014; pp. 1–4. [Google Scholar]

- Xiang, M.; Liao, R.; Wang, J.; Liang, N.; Lv, Y. Investigation on the effects of KH550 on the properties of alumina nanoparticles modified paper. In Proceedings of the 2016 IEEE International Conference on High Voltage Engineering and Application (ICHVE), Chengdu, China, 19–22 September 2016. [Google Scholar]

- Huang, J.; Zhou, Y.; Dong, L.; Zhou, Z.; Liu, R. Enhancement of mechanical and electrical performances of insulating presspaper by introduction of nanocellulose. Compos. Sci. Technol. 2017, 138, 40–48. [Google Scholar] [CrossRef]

- Chen, Q.; Liu, H.; Chi, M.; Wang, Y.; Wei, X. Experimental Study on Influence of Trap Parameters on Dielectric Characteristics of Nano-Modified Insulation Pressboard. Materials 2017, 10, 90. [Google Scholar] [CrossRef] [PubMed]

- Pérez-Rosa, D.; García, B.; Burgos, J.C. Influence of Nanoparticles on the Degradation Processes of Ester-Based Transformer Insulation Systems. Energies 2022, 15, 1520. [Google Scholar] [CrossRef]

- Ibrahim, A.; Nasrat, L.; Elnoby, A.; Eldebeiky, S. Thermal ageing study of ZnO nanofluid–cellulose insulation. IET Nanodielectrics 2020, 3, 124–130. [Google Scholar] [CrossRef]

- Pradhan, A.K.; Koley, C.; Chatterjee, B.; Chakravorti, S. Determination of optimized slope of triangular excitation for condition assessment of oil-paper insulation by frequency domain spectroscopy. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 1303–1312. [Google Scholar] [CrossRef]

- Chakraborty, B.; Raj, K.; Pradhan, A.; Chatterjee, B.; Chakravorti, S.; Dalai, S. Investigation of Dielectric Properties of TiO2 and Al2O3 nanofluids by Frequency Domain Spectroscopy at Different Temperatures. J. Mol. Liq. 2021, 330, 115642. [Google Scholar] [CrossRef]

- Sheykhnazari, S.; Tabarsa, T.; Mashkour, M.; Khazaeian, A.; Ghanbari, A. Multilayer bacterial cellulose/resole nanocomposites: Relationship between structural and electro-thermo-mechanical properties. Int. J. Biol. Macromol. 2018, 120, 2115–2122. [Google Scholar] [CrossRef] [PubMed]

- Mo, Y.; Yang, L.; Hou, W.; Zou, T.; Huang, Y.; Zheng, X.; Liao, R. Preparation of cellulose insulating paper of low dielectric constant by OAPS grafting. Cellulose 2019, 26, 7451–7468. [Google Scholar] [CrossRef]

- Le Bras, D.; Strømme, M.; Mihranyan, A. Characterization of Dielectric Properties of Nanocellulose from Wood and Algae for Electrical Insulator Applications. J. Phys. Chem. B 2015, 119, 5911–5917. [Google Scholar] [CrossRef]

- Tang, C.; Chen, R.; Zhang, J.; Peng, X.; Chen, B.; Zhang, L. A review on the research progress and future development of nano-modified cellulose insulation paper. Iet Nanodielectrics 2022, 5, 63–84. [Google Scholar] [CrossRef]

- Yan, S.; Liao, R.; Yang, L.; Zhao, X.; Yuan, Y.; He, L. Influence of nano-Al2O3 on electrical properties of insulation paper under thermal aging. In Proceedings of the 2016 IEEE International Conference on High Voltage Engineering and Application (ICHVE), Chengdu, China, 19–22 September 2016. [Google Scholar]

- Oparanti, S.O.; Khaleed, A.A.; Abdelmalik, A.A.; Chalashkanov, N.M. Dielectric characterization of palm kernel oil ester-based insulating nanofluid. In Proceedings of the 2020 IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), East Rutherford, NJ, USA, 18–30 October 2020; pp. 211–214. [Google Scholar]

- Cimbala, R.; Bucko, S.; Kruželák, L.; Kosterec, M. Thermal degradation of transformer pressboard impregnated with magnetic nanofluid based on transformer oil. In Proceedings of the 2017 18th International Scientific Conference on Electric Power Engineering (EPE), Kouty nad Desnou, Czech Republic, 17–19 May 2017; pp. 1–5. [Google Scholar]

- Lv, Y.; Ge, Y.; Li, C.; Wang, Q.; Zhou, Y.; Qi, B.; Yi, K.; Chen, X.; Yuan, J. Effect of TiO2nanoparticles on streamer propagation in transformer oil under lightning impulse voltage. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 2110–2115. [Google Scholar] [CrossRef]

- Oparanti, S.O.; Khaleed, A.A.; Abdelmalik, A.A. Nanofluid from palm kernel oil for high voltage insulation. Mater. Chem. Phys. 2021, 259, 123961. [Google Scholar] [CrossRef]

- Oparanti, S.O.; Adekunle, A.A.; Oteikwu, V.E.; Galadima, A.I.; Abdelmalik, A.A. An experimental investigation on composite methyl ester as a solution to environmental threat caused by mineral oil in transformer insulation. Biomass-Convers. Biorefinery 2022, 1–11. [Google Scholar] [CrossRef]

- Revathi, B.; Rajamani, M. Investigations on the flashover characteristics of ester oil impregnated pressboard under the influence of na-noparticles. In Proceedings of the 2015 IEEE International Conference on Electrical, Computer and Communication Tecnologies (ICECCT), Coimbatore, India, 5–7 March 2015; pp. 1–5. [Google Scholar]

- El-Refaie, E.-S.M.; Elrahman, M.K.A.; Abdo, M.H.; Mansour, D.-E.A. Electrical discharge analysis on nanofluid/pressboard surface under AC voltage application. In Proceedings of the 2017 Nine-teenth International Middle East Power Systems Conference (MEPCON), Cairo, Egypt, 19–21 December 2017; pp. 1048–1052. [Google Scholar]

- Huang, M.; Ying, Y.; Liu, B.; Lv, Y.; Qi, B.; Li, C. Enhanced voltage distribution and breakdown strength performances of oil-paper composite insulation by adding TiO2 nanoparticles. High Volt. 2021, 6, 42–50. [Google Scholar] [CrossRef]

- Liu, D.; Deng, C.G.; Xu, X.; Jing, Y.; Li, X.; Noubissi, R.K.; Li, X. Investigation on heating aging mechanism of cellulose paper for oil-immersed transformer main insulation. In Proceedings of the 2019 IEEE 20th International Conference on Dielectric Liquids (ICDL), Roma, Italy, 23–27 June 2019; pp. 1–3. [Google Scholar]

- Shan, B.; Ying, Y.; Huang, M.; Niu, M.; Qi, B.; Li, C.; Sun, Q.; Lv, Y. Effect of TiO2 nanoparticles on DC breakdown performance of transformer oil-impregnated pressboard. IEEE Trans. Dielectr. Electr. Insul. 2019, 26, 1998–2004. [Google Scholar] [CrossRef]

- Abd-Elhady, A.M.; Abdul-Aleem, A.A.; Izzularab, M.A. Electrical properties evaluation of double-layer nano-filled oil-paper composites. IET Sci. Meas. Technol. 2021, 15, 77–84. [Google Scholar] [CrossRef]

- Du, B.; Liu, Q.; Shi, Y.; Zhao, Y. The Effect of Fe3O4 Nanoparticle Size on Electrical Properties of Nanofluid Impregnated Paper and Trapping Analysis. Molecules 2020, 25, 3566. [Google Scholar] [CrossRef] [PubMed]

- Pérez-Rosa, D.; Montero, A.; García, B.; Burgos, J.C. Dielectric Strength of Nanofluid-Impregnated Transformer Solid Insulation. Nanomaterials 2022, 12, 4128. [Google Scholar] [CrossRef]

- Qi, B.; Wei, Z.; Li, C. Creepage discharge of oil-pressboard Insulation in AC-DC composite field: Phenomenon and characteristics. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 237–245. [Google Scholar] [CrossRef]

- Thirumurugan, C.; Kumbhar, G.B.; Oruganti, R. Surface Discharge Characteristics of Different Solid–Liquid Insulation Materials in Power Transformers. IEEE Trans. Plasma Sci. 2019, 47, 5013–5022. [Google Scholar] [CrossRef]

- Liu, Q.; Wang, Z.D. Streamer characteristic and breakdown in synthetic and natural ester transformer liquids under standard lightning impulse voltage. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 285–294. [Google Scholar] [CrossRef]

- Wilson, M.P.; Timoshkin, I.V.; Given, M.J.; Macgregor, S.J.; Sinclair, M.A.; Thomas, K.J.; Lehr, J.M. Effect of applied field and rate of voltage rise on surface breakdown of oil-immersed polymers. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 1003–1010. [Google Scholar] [CrossRef]

- Li, C.; Lin, C.; Zhang, B.; Li, Q.; Liu, W.; Hu, J.; He, J. Understanding surface charge accumulation and surface flashover on spacers in compressed gas insulation. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 1152–1166. [Google Scholar] [CrossRef]

- Dai, J.; Wang, Z.D.; Jarman, P. Creepage discharge on insulation barriers in aged power transformers. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 1327–1335. [Google Scholar] [CrossRef]

- Michelarakis, M.; Widger, P.; Beroual, A.; Haddad, A. Electrical Detection of Creeping Discharges over Insulator Surfaces in Atmospheric Gases under AC Voltage Application. Energies 2019, 12, 2970. [Google Scholar] [CrossRef]

- Sun, G.-Y.; Guo, B.-H.; Song, B.-P.; Su, G.-Q.; Mu, H.-B.; Zhang, G.-J. Simulation on the dynamic charge behavior of vacuum flashover developing across insulator involving outgassing. Phys. Plasmas 2018, 25, 063502. [Google Scholar] [CrossRef]

- Zhao, Z.; Huang, D.D.; Wang, Y.N.; He, J.X.; Li, C.J.; Wang, Y.F.; Li, J.T. Evolution of streamer dynamics and discharge mode transition in high-pressure nitrogen under long-term repetitive nanosecond pulses with different time-scales. Plasma Sources Sci. Technol. 2019, 28, 085015. [Google Scholar] [CrossRef]

- Madhar, S.A.; Mráz, P.; Mor, A.R.; Ross, R. Study of corona configurations under DC conditions and recommendations for an identification test plan. Int. J. Electr. Power Energy Syst. 2020, 118, 105820. [Google Scholar] [CrossRef]

- Zhao, J.; An, Z.; Lv, B.; Wu, Z.; Zhang, Q. Characteristics of the Partial Discharge in the Development of Conductive Particle-Initiated Flashover of a GIS Insulator. Energies 2020, 13, 2481. [Google Scholar] [CrossRef]

- Zhou, Y.; Jin, F.; Huang, M.; Sha, Y.; Zhang, L.; Huang, J. Influence of temperature on developing process of surface flashover in oil-paper insulation under combined AC-DC voltage. In Proceedings of the 2013 Annual Report Conference on Electrical Insulation and Dielectric Phenomena, Shenzhen, China, 20–23 October 2013; pp. 486–489. [Google Scholar]

- Rafiq, M.; Chengrong, L.; Lv, Y. Effect of Al2O3 nanorods on dielectric strength of aged transformer oil/paper insulation system. J. Mol. Liq. 2019, 284, 700–708. [Google Scholar] [CrossRef]

- Lv, Y.Z.; Zhou, Y.; Li, C.R.; Ma, K.B.; Wang, Q.; Wang, W.; Zhang, S.N.; Jin, Z.Y. Nanoparticle effects on creeping flashover characteristics of oil/pressboard interface. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 556–562. [Google Scholar] [CrossRef]

- Abdul-Aleem, A.A.; Abd-Elhady, A.M.; Izzularab, M.A. Experimental evaluation of creeping flashover at nanofilled oil/pressboard interface. In Proceedings of the 2017 Nineteenth International Middle East Power Systems Conference (MEPCON), Cairo, Egypt, 19–21 December 2017; pp. 695–701. [Google Scholar]

- Ge, Y.; Lv, Y.; Han, Q.; Sun, Q.; Huang, M.; Li, C.; Qi, B.; Yuan, J. Effects of TiO2 Nanoparticles on Streamer Propagation at the Surface of Oil-Impregnated Insulation Paper. IEEE Trans. Plasma Sci. 2018, 46, 2491–2496. [Google Scholar] [CrossRef]

- Huang, M.; Han, Q.-B.; Lv, Y.-Z.; Wang, L.; Shan, B.-L.; Ge, Y.; Qi, B.; Li, C.-R. Effect of nanoparticle shapes on creeping flashover characteristics at the interface of nanofluid-impregnated pressboard. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 1135–1141. [Google Scholar] [CrossRef]

- Shan, B.; Huang, M.; Ying, Y.; Niu, M.; Sun, Q.; Lv, Y.; Li, C.; Qi, B.; Xing, Z. Research on creeping flashover characteristics of nanofluid-impregnated pressboard modified based on Fe3O4 nanoparticles under lightning impulse voltages. Nanomaterials 2019, 9, 524. [Google Scholar] [CrossRef]

- El-Refaie, E.-S.M.; Mansour, D.-E.A.; Elrahmen, M.A.; Abdo, M.H. Enhancing flashover strength along oil/pressboard interface using nanofluids. Alex. Eng. J. 2020, 59, 475–483. [Google Scholar] [CrossRef]

- Abu-Elanien, A.E.; Salama, M. Asset management techniques for transformers. Electr. Power Syst. Res. 2010, 80, 456–464. [Google Scholar] [CrossRef]

- Zhou, H.; Li, X.; Zhu, Y.; Liu, J.; Wu, A.; Ma, G.; Wang, X.; Jia, Z.; Wang, L. Review of flash sintering with strong electric field. High Volt. 2021, 7, 1–11. [Google Scholar] [CrossRef]

- Ilkhechi, H.D.; Samimi, M.H.; Yousefvand, R. Generation of acoustic phase-resolved partial discharge patterns by utilizing UHF signals. Int. J. Electr. Power Energy Syst. 2019, 113, 906–915. [Google Scholar] [CrossRef]

- Pan, C.; Wu, K.; Chen, G.; Gao, Y.; Florkowski, M.; Lv, Z.; Tang, J. Understanding Partial Discharge Behavior from the Memory Effect Induced by Residual Charges: A Review. IEEE Trans. Dielectr. Electr. Insul. 2020, 27, 1951–1965. [Google Scholar] [CrossRef]

- Cheng, Y.; Zhang, S.; Mao, T.; Guo, S.; Niu, Z.; Hao, Z. Propagation Mechanism of Carbonized Trees in Oil-cellulose Insulation Systems of Power Transformers. In Proceedings of the 2020 IEEE Electrical Insulation Conference (EIC), Knoxville, TN, USA, 22 June–July 2020; pp. 486–489. [Google Scholar]

- Liu, D.; Wu, Y.; Xu, X.; Ye, J.; Li, J.; Yu, S.; Li, X. Suppression Mechanism of TiO2 for the Partial Discharge of Oil-paper Insulation in Intensive Electric Field. In Proceedings of the 2019 IEEE 20th International Conference on Dielectric Liquids (ICDL), Roma, Italy, 23–27 June 2019; pp. 1–4. [Google Scholar]

- Chen, G.; Fu, M.; Liu, X.Z.; Zhong, L.S. ac aging and space-charge characteristics in low-density polyethylene polymeric insulation. J. Appl. Phys. 2005, 97, 083713. [Google Scholar] [CrossRef]

- Huang, M.; Zhou, Y.; Chen, W.; Sha, Y.; Jin, F. Influence of voltage reversal on space charge behavior in oil-paper insulation. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 331–339. [Google Scholar] [CrossRef]

- Wang, F.; He, L.; Khan, M.Z.; Zhang, T.; Zhao, Q.; He, Y.; Huang, Z.; Zhao, H.; Li, J. Accelerated Charge Dissipation by Gas-Phase Fluorination on Nomex Paper. Appl. Sci. 2019, 9, 3879. [Google Scholar] [CrossRef]

- Mo, Y.; Yuan, Y.; Liao, R. Study on improving the space charge behavior in insulating paper by depositing nanostructured alumina on its surface via magnetron sputtering. Thin Solid Film. 2020, 709, 138219. [Google Scholar] [CrossRef]

- Wu, K.; Zhu, Q.; Wang, H.; Wang, X.; Li, S. Space charge behavior in the sample with two layers of oil-immersed-paper and oil. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 1857–1865. [Google Scholar] [CrossRef]

- Min, X.; Yuan, Y.; Ruijin, L. Improvement in space charge behavior of cellulose paper by coating with AlOx nanostructure film. Mater. Lett. 2018, 230, 253–256. [Google Scholar] [CrossRef]

- Li, L.; Zhao, Z. Effect of switch parameters and polarity on the repetitive performance of a corona-stabilized switch viewed from behavior of space charge. Phys. Plasmas 2020, 27, 043509. [Google Scholar] [CrossRef]

- Li, J.; Wang, Y.; Bao, L. Space Charge Behavior of Oil-Impregnated Paper Insulation Aging at AC-DC Combined Voltages. J. Electr. Eng. Technol. 2014, 9, 635–642. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, J.; Yin, Y. Space Charge and Trap in High-Voltage Power Module Packaging Insulation: Simultaneous Measurement and 2-D Simulation. IEEE Trans. Dielectr. Electr. Insul. 2022, 29, 1400–1408. [Google Scholar] [CrossRef]

- Hao, M.; Zhou, Y.; Chen, G.; Wilson, G.; Jarman, P. Space charge behavior in thick oil-impregnated pressboard under HVDC stresses. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 72–80. [Google Scholar] [CrossRef]

- Huang, M.; Zhou, Y.; Chen, W.; Lu, L.; Jin, F.; Huang, J. Space charge dynamics at the physical interface in oil-paper insulation under DC voltage. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 1739–1746. [Google Scholar] [CrossRef]

- Wei, Y.; Han, W.; Li, G.; Liang, X.; Gu, Z.; Hu, K. Aging Characteristics of Transformer Oil-Impregnated Insulation Paper Based on Trap Parameters. Polymers 2021, 13, 1364. [Google Scholar] [CrossRef]

- Sun, P.; Sima, W.; Zhang, D.; Jiang, X.; Zhang, H.; Yin, Z. Failure Characteristics and Mechanism of Nano-Modified Oil-Impregnated Paper Subjected to Repeated Impulse Voltage. Nanomaterials 2018, 8, 504. [Google Scholar] [CrossRef]

- Liao, R.J.; Lv, C.; Yang, L.J.; Zhang, Y.Y.; Liu, T. Space charge behavior in oil-impregnated insulation paper reinforced with nano-TiO2. BioResources 2013, 8, 5655–5665. [Google Scholar] [CrossRef]

- Liao, R.; Wang, J.; Gao, F.; Yuan, Y.; Xu, Z. Effects of aluminum nitride nanoparticles on the space charge behavior of cellulose paper. J. Mater. Sci. 2016, 51, 10701–10713. [Google Scholar] [CrossRef]

| DP Value | 2FAL (ppm) | MeOH (ppb) | CO2 (ppm) | CO (ppm) | Oil-Paper State |

|---|---|---|---|---|---|

| 1200–700 | 0–0.1 | 0–50 | 0–2500 | 0–350 | Healthy insulation |

| 700–450 | 0.1–1 | 51–200 | 2501–4000 | 351–570 | Moderate degradation |

| 450–250 | 1–10 | 201–250 | 4001–10,000 | 571–1400 | Extensive degradation |

| <250 | >10 | >250 | >10,000 | >1400 | End of useful life |

| Furanic Derivatives | Sources |

|---|---|

| 2FAL | Increase in temperature, normal ageing |

| 5MEF | Excessive temperature |

| 2ACF | Rare, no common cause |

| 5HMF | Oxidation |

| 2FOL | High moisture |

| Ref. | Year | Nanoparticle | Average Size | Particle Loading | Standard | Comment on TS |

|---|---|---|---|---|---|---|

| [65] | 2013 | TiO2 | <60 nm | 1% to 4% with 1% step | Not stated | Decreases slightly |

| [99] | 2016 | Al2O3 | 20 nm | 2 wt% at 130 °C | ISO 1924-2-2008 | Increases |

| [177] | 2016 | Al2O3 + KH50 | 30 nm | Not stated | ISO 1924-94 | Increases by 16.7% |

| [179] | 2017 | SiC/Al2O3 | 30 nm | 2.5 wt% and 7.5 wt% | ISO 186:2002 | Decreases moderately |

| [181] | 2020 | ZnO | <100 nm | Not stated | BS EN ISO 1924-2 | Decreases by 3% |

| [180] | 2022 | Fe3O4 | 10 nm | 0.1 g/L | ASTM D828-97 | Decreases slightly |

| Ref. | Year | Nanoparticle | Average Size | Cellulose Material | Optimal Loading | Standard | Percentage Improvement |

|---|---|---|---|---|---|---|---|

| [65] | 2013 | TiO2 | <60 nm | pulp paper | 3 wt% | IEC 60241 | +20.8% of DC BDV at 3 wt% |

| [194] | 2015 | SiO2 | Not specified | pressboard | 0.02% | Not specified | +6.25% AC BDV |

| [99] | 2016 | Al2O3 | 20 nm | pulp paper | 2 wt% | IEC 60243 | Increase in AC BDV |

| [177] | 2016 | Al2O3 + KH50 | 30 nm | pulp paper | Not specified | GB/T1408 | +17.2% AC BDV |

| [195] | 2017 | Al2O3 | 13 nm | pressboard | 0.04 g/L | Not specified | +11.5% AC BDV |

| [196] | 2021 | TiO2 | 25 nm | Kraft paper | 0.02 g/L | IEC 60243 | +3.6% (negative)and +22.5% (positive) DC BDV |

| [198] | 2019 | TiO2 | 5 nm | pressboard | 0.075 wt% | ASTM D149&D3755 | +13% DC BDV |

| [199] | 2021 | Al2O3/SiO2/Pb3O4 | 25 nm | Kraft paper | 0.2 g/L | ASTM | +33% (Al2O3), +30% (SiO2) and +30% (SiO2) |

| [200] | 2020 | Fe3O4 | 42 nm | Not specified | Not specified | ASTM D3755& D149 | +10% (DC) and +10% (DC) and |

| [201] | 2022 | Fe3O4 | 10–15 nm | Kraft paper | 0.2 g/L | IEC 60243 | +26% (AC) BDV |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Adekunle, A.A.; Oparanti, S.O.; Fofana, I. Performance Assessment of Cellulose Paper Impregnated in Nanofluid for Power Transformer Insulation Application: A Review. Energies 2023, 16, 2002. https://doi.org/10.3390/en16042002

Adekunle AA, Oparanti SO, Fofana I. Performance Assessment of Cellulose Paper Impregnated in Nanofluid for Power Transformer Insulation Application: A Review. Energies. 2023; 16(4):2002. https://doi.org/10.3390/en16042002

Chicago/Turabian StyleAdekunle, Andrew Adewunmi, Samson Okikiola Oparanti, and Issouf Fofana. 2023. "Performance Assessment of Cellulose Paper Impregnated in Nanofluid for Power Transformer Insulation Application: A Review" Energies 16, no. 4: 2002. https://doi.org/10.3390/en16042002

APA StyleAdekunle, A. A., Oparanti, S. O., & Fofana, I. (2023). Performance Assessment of Cellulose Paper Impregnated in Nanofluid for Power Transformer Insulation Application: A Review. Energies, 16(4), 2002. https://doi.org/10.3390/en16042002