Experimental Electrical Assessment Evaluation of a Vertical n-PERT Half-Size Bifacial Solar Cell String Receiver on a Parabolic Trough Solar Collector

Abstract

1. Introduction

- Commercial and industrial customer electricity bill reductions.

- During peak periods, utilities reduce the operational cost of generating power.

- Reduces the overall cost of demand charges.

- Sustainable operations.

- Eases the incorporation of Renewable Energy Systems into a more stable electrical grid.

- Lower reliance on carbon-based power sources and, therefore, reduce the carbon footprint.

- Flatter loads (e.g., reduced peaks) lead to deferred investment in infrastructures.

2. Experimental Test Method Description

2.1. Low Concentration Photovoltaic Solar Collector Description

2.1.1. Electrical Performance Characterization

2.1.2. Ray-Tracing Software

2.2. Testing Equipment Description

2.3. Outdoor Testing Method

2.3.1. Daily Electrical Performance

2.3.2. Electrical Incidence Angle Modifier Testing Method

3. Results and Discussions

3.1. Outdoor Electrical Measurements

3.2. Electrical Outdoor Measurements

Daily Electrical Power Diagram

3.3. Electrical Incidence Angle Modifier Measurements

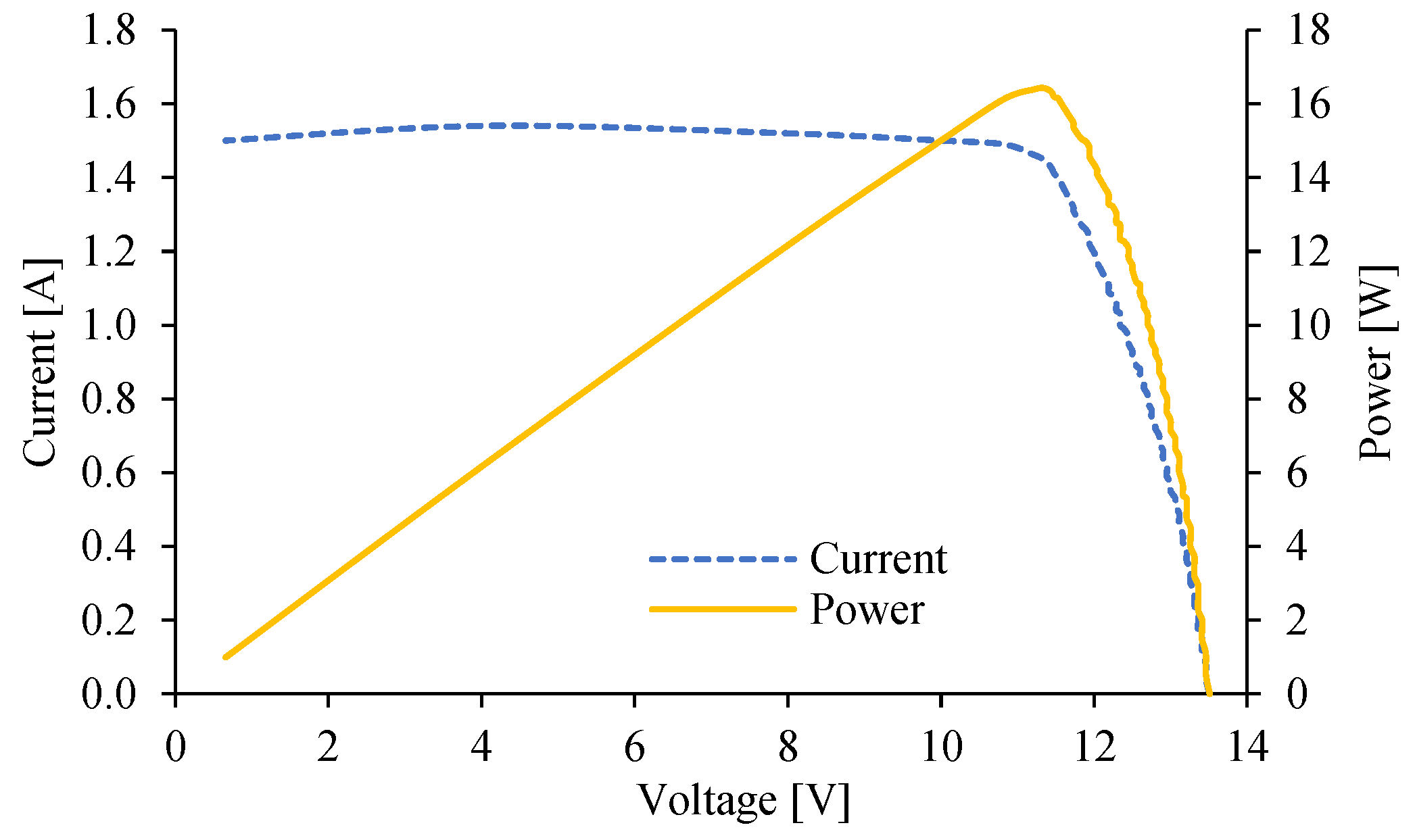

3.3.1. IV Curve Measurement (Transversal Direction)

3.3.2. IAM Validation Pattern

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Symbol | Description [Unit] |

| Ta | Ambient temperature [°C] |

| Gb | Beam solar irradiance [W/m2] |

| Impp | Current at maximum power point [A] |

| ηelect. | Electrical efficiency [%] |

| G | Global solar irradiance [W/m2] |

| Voc | Open-circuit voltage [V] |

| Pmmp | Power at maximum power point [W] |

| Short-circuit current [A] | |

| Specific electrical power output [W/m2] | |

| Vmpp | Voltage at maximum power point [V] |

| θc | Acceptance half-angle [°] |

| β | Collector tilt angle [°] |

| θ | Incidence angle [°] |

| θL | Longitudinal incidence angle [°] |

| Projection angle [°] | |

| Solar azimuth angle [°] | |

| ρcell | Solar reflectance [–] |

| τcell | Solar transmittance [–] |

| Solar zenith angle [°] | |

| South projection angle [°] | |

| θT | Transversal incidence angle [°] |

| Subscripts | |

| CTM | cell-to-module |

| CPV | Concentrating Photovoltaic |

| c-Si | Crystalline Silicon |

| DNI | Direct Normal Irradiance |

| FF | Filling Factor |

| HCPV | High Concentrating Photovoltaic |

| IAM | Incidence Angle Modifier |

| LID | Light Induced Degradation |

| LCOE | Levelized Cost of Energy |

| LCPV | Low Concentrating Photovoltaic |

| PV | Photovoltaic |

| PERT | Passivated Emitter Rear Totally diffused |

References

- Fraunhofer ISE. Photovoltaics Report; Fraunhofer ISE: Freiburg, Germany, 2020; Updated in 18 May 2020. [Google Scholar]

- Qasima, U.; Imrana, H.; Kamrana, M.; Faryad, M.; Butt, N. Computational study of stack/terminal topologies for perovskite based bifacial tandem solar cells. Sol. Energy 2020, 203, 1–9. [Google Scholar] [CrossRef]

- Djebbour, Z.; El-Huni, W.; Dubois, A.M.; Kleider, J.-P. Bandgap engineered smart three-terminal solar cell: New perspectives towards very high efficiencies in the silicon world. Prog. Photovolt. Res. Appl. 2018, 27, 306–315. [Google Scholar] [CrossRef]

- Schnabel, M.; Rienacker, M.; Warren, E.L.; Geisz, J.F.; Peibst, R.; Stradins, P.; Tamboli, A.C. Equivalent Performance in Three-Terminal and Four-Terminal Tandem Solar Cells. IEEE J. Photovolt. 2018, 8, 1584–1589. [Google Scholar] [CrossRef]

- Tockhorn, P.; Wagner, P.; Kegelmann, L.; Stang, J.-C.; Mews, M.; Albrecht, S.; Korte, L. Three-Terminal Perovskite/Silicon Tandem Solar Cells with Top and Interdigitated Rear Contacts. ACS Appl. Energy Mater. 2020, 3, 1381–1392. [Google Scholar] [CrossRef]

- Warren, E.L.; Deceglie, M.G.; Rienäcker, M.; Peibst, R.; Tamboli, A.C.; Stradins, P. Maximizing tandem solar cell power extraction using a three-terminal design. Sustain. Energy Fuels 2018, 2, 1141–1147. [Google Scholar] [CrossRef]

- Janssen, G.J.; Tool, K.C.; Kossen, E.J.; Van Aken, B.B.; Carr, A.J.; Romijn, I.G. Aspects of bifacial cell efficiency. Energy Procedia 2017, 124, 76–83. [Google Scholar] [CrossRef]

- Nussbaumer, H.; Janssen, G.; Berrian, D.; Wittmer, B.; Klenk, M.; Baumann, T.; Baumgartner, F.; Morf, M.; Burgers, A.; Libal, J.; et al. Accuracy of simulated data for bifacial systems with varying tilt angles and share of diffuse radiation. Sol. Energy 2020, 197, 6–21. [Google Scholar] [CrossRef]

- Yamaguchi, S.; Van Aken, B.B.; Stodolny, M.K.; Löffler, J.; Masuda, A.; Ohdaira, K. Effects of passivation configuration and emitter surface doping concentration on polarization-type potential-induced degradation in n-type crystalline-silicon photovoltaic modules. Sol. Energy Mater. Sol. Cells 2021, 226, 111074. [Google Scholar] [CrossRef]

- Yu, B.; Song, D.; Sun, Z.; Liu, K.; Zhang, Y.; Rong, D.; Liu, L. A study on electrical performance of N-type bifacial PV modules. Sol. Energy 2016, 137, 129–133. [Google Scholar] [CrossRef]

- Haedrich, I.; Eitner, U.; Wiese, M.; Wirth, H. Unified methodology for determining CTM ratios: Systematic prediction of module power. Sol. Energy Mater. Sol. Cells 2014, 131, 14–23. [Google Scholar] [CrossRef]

- Kiefer, F.; Krügener, J.; Heinemeyer, F.; Jestremski, M.; Osten, H.; Brendel, R.; Peibst, R. Bifacial, fully screen-printed n-PERT solar cells with BF2 and B implanted emitters. Sol. Energy Mater. Sol. Cells 2016, 157, 326–330. [Google Scholar] [CrossRef]

- Janssen, G.J.; Van Aken, B.B.; Carr, A.J.; Mewe, A.A. Outdoor Performance of Bifacial Modules by Measurements and Modelling. Energy Procedia 2015, 77, 364–373. [Google Scholar] [CrossRef]

- Russell, T.C.R.; Saive, R.; Augusto, A.; Bowden, S.G.; Atwater, H.A. The Influence of Spectral Albedo on Bifacial Solar Cells: A Theoretical and Experimental Study. IEEE J. Photovolt. 2017, 7, 1611–1618. [Google Scholar] [CrossRef]

- Lopez-Garcia, J.; Casado, A.; Sample, T. Electrical performance of bifacial silicon PV modules under different indoor mounting configurations affecting the rear reflected irradiance. Sol. Energy 2018, 177, 471–482. [Google Scholar] [CrossRef]

- Baumann, T.; Nussbaumer, H.; Klenk, M.; Dreisiebner, A.; Carigiet, F.; Baumgartner, F. Photovoltaic systems with vertically mounted bifacial PV modules in combination with green roofs. Sol. Energy 2019, 190, 139–146. [Google Scholar] [CrossRef]

- Kreinin, L.; Bordin, N.; Karsenty, A.; Drori, A.; Eisenberg, N. Outdoor evaluation of power output improvement of the bifacial module. In Proceedings of the 37th IEEE Photovoltaic Specialists Conference, Seattle, WA, USA, 19–24 June 2011; pp. 001827–001831. [Google Scholar] [CrossRef]

- Xia, L.; Chen, J.; Liao, K.; Huang, L.; Li, Q.; Luo, X. Influence of laser cutting conditions on electrical characteristics of half-size bifacial silicon solar cells. Mater. Sci. Semicond. Process. 2019, 105, 104747. [Google Scholar] [CrossRef]

- Appelbaum, J. Bifacial photovoltaic panels field. Renew. Energy 2016, 85, 338–343. [Google Scholar] [CrossRef]

- Cabral, D.; Karlsson, B.O. Electrical and thermal performance evaluation of symmetric truncated C-PVT trough solar collectors with vertical bifacial receivers. Sol. Energy 2018, 174, 683–690. [Google Scholar] [CrossRef]

- Guerrero-Lemus, R.; Vega, R.; Kim, T.; Kimm, A.; Shephard, L. Bifacial solar photovoltaics—A technology review. Renew. Sustain. Energy Rev. 2016, 60, 1533–1549. [Google Scholar] [CrossRef]

- Xuan, Q.; Li, G.; Lu, Y.; Zhao, B.; Zhao, X.; Su, Y.; Ji, J.; Pei, G. Design, optimization and performance analysis of an asymmetric concentrator-PV type window for the building south wall application. Sol. Energy 2019, 193, 422–433. [Google Scholar] [CrossRef]

- Wang, G.; Yao, Y.; Chen, Z.; Hu, P. Thermodynamic and optical analyses of a hybrid solar CPV/T system with high solar concentrating uniformity based on spectral beam splitting technology. Energy 2018, 166, 256–266. [Google Scholar] [CrossRef]

- Danandeh, M.; Mousavi, S.M. Comparative and comprehensive review of maximum power point tracking methods for PV cells. Renew. Sustain. Energy Rev. 2018, 82, 2743–2767. [Google Scholar] [CrossRef]

- Li, G.; Lu, Y.; Shittu, S.; Zhao, X. Scale effect on electrical characteristics of CPC-PV. Energy 2019, 192, 116726. [Google Scholar] [CrossRef]

- Li, G.; Xuan, Q.; Akram, M.; Akhlaghi, Y.G.; Liu, H.; Shittu, S. Building integrated solar concentrating systems: A review. Appl. Energy 2020, 260, 114288. [Google Scholar] [CrossRef]

- Philipps, S.P.; Bett, A.W.; Horowitz, K.; Kurtz, S. Current Status of Concentrator Photovoltaic (CPV) Technology; Fraunhofer ISE and NREL CPV Report 1.3; Fraunhofer ISE: Freiburg, Germany, 2015. [Google Scholar] [CrossRef]

- Wang, G.; Wang, F.; Shen, F.; Jiang, T.; Chen, Z.; Hu, P. Experimental and optical performances of a solar CPV device using a linear Fresnel reflector concentrator. Renew. Energy 2020, 146, 2351–2361. [Google Scholar] [CrossRef]

- Li, G.; Lu, Y.; Xuan, Q.; Akhlaghi, Y.G.; Pei, G.; Ji, J.; Zhao, X. Small scale optimization in crystalline silicon solar cell on efficiency enhancement of low-concentrating photovoltaic cell. Sol. Energy 2020, 202, 316–325. [Google Scholar] [CrossRef]

- Cabral, D.; Gomes, J.; Karlsson, B. Performance evaluation of non-uniform illumination on a transverse bifacial PVT receiver in combination with a CPC geometry. Sol. Energy 2019, 194, 696–708. [Google Scholar] [CrossRef]

- Liu, Y.; Hu, P.; Zhang, Q.; Chen, Z. Thermodynamic and optical analysis for a CPV/T hybrid system with beam splitter and fully tracked linear Fresnel reflector concentrator utilizing sloped panels. Sol. Energy 2014, 103, 191–199. [Google Scholar] [CrossRef]

- Deepak, K.G.; Marco, B.; Matthijs, L. CPV solar cell modeling and metallization optimization. Sol. Energy 2018, 159, 868–881. [Google Scholar]

- Nasseriyan, P.; Gorouh, H.A.; Gomes, J.; Cabral, D.; Salmanzadeh, M.; Lehmann, T.; Hayati, A. Numerical and Experimental Study of an Asymmetric CPC-PVT Solar Collector. Energies 2020, 13, 1669. [Google Scholar] [CrossRef]

- He, W.; Hong, X.; Zhao, X.; Zhang, X.; Shen, J.; Ji, J. Operational performance of a novel heat pump assisted solar façade loop-heat-pipe water heating system. Appl. Energy 2015, 146, 371–382. [Google Scholar] [CrossRef]

- Widyolar, B.; Jiang, L.; Winston, R. Spectral beam splitting in hybrid PV/T parabolic trough systems for power generation. Appl. Energy 2018, 209, 236–250. [Google Scholar] [CrossRef]

- Andrews, R.W.; Pollard, A.; Pearce, J.M. Photovoltaic System Performance Enhancement With Nontracking Planar Concentrators: Experimental Results and Bidirectional Reflectance Function (BDRF)-Based Modeling. IEEE J. Photovolt. 2015, 5, 1626–1635. [Google Scholar] [CrossRef]

- Poulek, V.; Khudysh, A.; Libra, M. Innovative low concentration PV systems with bifacial solar panels. Sol. Energy 2015, 120, 113–116. [Google Scholar] [CrossRef]

- Cabral, D.; Gomes, J.; Hayati, A.; Karlsson, B. Experimental investigation of a CPVT collector coupled with a wedge PVT receiver. Sol. Energy 2021, 215, 335–345. [Google Scholar] [CrossRef]

- IRENA. Renewable Power Generation Costs 2019; IRENA: Masdar City, United Arab Emirates, 2019. [Google Scholar]

- Gorouh, H.A.; Salmanzadeh, M.; Nasseriyan, P.; Hayati, A.; Cabral, D.; Gomes, J.; Karlsson, B. Thermal modelling and experimental evaluation of a novel concentrating photovoltaic thermal collector (CPVT) with parabolic concentrator. Renew. Energy 2021, 181, 535–553. [Google Scholar] [CrossRef]

- Shigenobu, R.; Ito, M.; Taoka, H. Optimal design of bifacial PV system to mitigate duck-curve problem of power system with the UC problem. Energy Rep. 2021, 7, 7004–7014. [Google Scholar] [CrossRef]

- Duffie, J.A.; Beckman, W.A. Solar Engineering of Thermal Processes; John Wiley & Sons: New York, NY, USA, 2013. [Google Scholar]

- Heydenreich, W.; Müller, B.; Reise, C. Describing the world with three parameters: A new approach to PV module power modelling. In Proceedings of the 23rd European Photovoltaic Solar Energy Conference and Exhibition, Valencia, Spain, 1–5 September 2008. [Google Scholar]

- Lämmle, M.; Kroyer, T.; Fortuin, S.; Wiese, M.; Hermann, M. Development and modelling of highly-efficient PVT collectors with low-emissivity coatings. Sol. Energy 2016, 130, 161–173. [Google Scholar] [CrossRef]

- Skoplaki, E.; Palyvos, J. On the temperature dependence of photovoltaic module electrical performance: A review of efficiency/power correlations. Sol. Energy 2009, 83, 614–624. [Google Scholar] [CrossRef]

- Blanco, M.J.; Amieva, J.M.; Mancillas, A. The Tonatiuh Software Development Project: An Open Source Approach to the Simulation of Solar Concentrating Systems. In Proceedings of the Computers and Information in Engineering, Orlando, FL, USA, 5–11 November 2005; ASMEDC: Orlando, FL, USA, 2005; pp. 157–164. [Google Scholar]

- Blanco, M.J.; Mutuberria, A.; Garcia, P.; Gastesi, R.; Martin, V. Preliminary validation of Tonatiuh. In Proceedings of the 15th International Symposium on Solar Power and Chemical Energy Systems Conference, Berlin, Germany, 15–18 September 2009. [Google Scholar]

- Sami Jouttijärvi, S.; Lobaccaro, G.; Kamppinen, A.; Miettunen, K. Benefits of bifacial solar cells combined with low voltage power grids at high latitudes, Renewable and Sust. Energy Rev. 2022, 161, 112354. [Google Scholar]

- Widén, J.; Wäckelgård, E.; Paatero, J.; Lund, P. Impacts of distributed photovoltaics on network voltages: Stochastic simulations of three Swedish low-voltage distribution grids. Electr. Power Syst. Res. 2010, 80, 1562–1571. [Google Scholar] [CrossRef]

- Graabak, I.; Korpås, M.; Jaehnert, S.; Belsnes, M. Balancing future variable wind and solar power production in Central-West Europe with Norwegian hydropower. Energy 2018, 168, 870–882. [Google Scholar] [CrossRef]

- Talavera, D.L.; Muñoz-Rodriguez, F.J.; Jimenez-Castillo, G.; Rus-Casas, C. A new approach to sizing the photovoltaic generator in self-consumption systems based on cost–competitiveness, maximizing direct self-consumption. Renew. Energy 2019, 130, 1021–1035. [Google Scholar] [CrossRef]

- Available online: https://www.almecogroup.com/en/pages/456-reflecting-surfaces-for-solar-applications (accessed on 18 December 2022).

- Cabral, D. Development and performance comparison of a modified glazed CPC hybrid solar collector coupled with a bifacial PVT receiver. Appl. Energy 2022, 325, 119653. [Google Scholar] [CrossRef]

- Sigue, S.; Abderafi, S.; Vaudreuil, S.; Bounahmidi, T. Design and steady-state simulation of a CSP-ORC power plant using an open-source co-simulation framework combining SAM and DWSIM. Therm. Sci. Eng. Prog. 2023, 37, 101580. [Google Scholar] [CrossRef]

- Duan, J. A novel heat sink for cooling concentrator photovoltaic system using PCM-porous system. Appl. Therm. Eng. 2021, 186, 116522. [Google Scholar] [CrossRef]

- Khaliq, A.; Refaey, H.; Alharthi, M.A. Development and analysis of a novel CSP source driven cogeneration cycle for the production of electric power and low temperature refrigeration. Int. J. Refrig. 2021, 130, 330–346. [Google Scholar] [CrossRef]

- Badr, F.; Radwan, A.; Ahmed, M.; Hamed, A.M. An experimental study of the concentrator photovoltaic/thermoelectric generator performance using different passive cooling methods. Renew. Energy 2021, 185, 1078–1094. [Google Scholar] [CrossRef]

- Refaey, H.; Abdelrahman, M.; Alharthi, M.A.; Bendoukha, S.; Khan, S.G.; Emam, M. Passive cooling of highly-concentrator triple-junction solar cell using a straight-finned heat sink: An experimental investigation. Case Stud. Therm. Eng. 2022, 40, 102521. [Google Scholar] [CrossRef]

| Efficiency [%] | Pmpp [W] | Vvpp [V] | Ivpp [A] | Voc [V] | Isc [A] | Dimensions [mm] |

|---|---|---|---|---|---|---|

| 19.6 | 2.4 | 0.53 | 4.4 | 0.63 | 4.7 | 78 × 156 |

| Front Side | Back Side–Albedo | |||

|---|---|---|---|---|

| Efficiency Class | - | 10% | 20% | 30% |

| Efficiency [%] | 19.6 | 21.5 | 23.2 | 25.1 |

| Pmpp [W] | 2.4 | 2.6 | 2.8 | 3 |

| Emissivity [%] | Thickness [mm] | Thermal Conductivity [W/m.K] | Transmittance 1 [%] |

|---|---|---|---|

| 83.7 | 4 | 1 | 91 [+/−2.5] |

| Measurement Equipment | Data | Deviation |

|---|---|---|

| Pyranometer CMP3 [W/m2] | Up to 2000 | ±1.5% |

| Pyranometer CMP6 [W/m2] | Up to 2000 | ±1% |

| I-V Tracer [V] [I] | - | 0.1% |

| Parameters | 0° | 15° | 25° |

|---|---|---|---|

| Voc [V] | 0.6 | 1.5 | 4.4 |

| Isc [A] | 13 | 14 | 14 |

| Pmax [W] | 7 | 16 | 39 |

| Vmpp [V] | 0.6 | 1.5 | 4 |

| Impp [A] | 11 | 11 | 10 |

| FF [%] | 81 | 79 | 63 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cabral, D.; Hayati, A.; Gomes, J.; Gorouh, H.A.; Nasseriyan, P.; Salmanzadeh, M. Experimental Electrical Assessment Evaluation of a Vertical n-PERT Half-Size Bifacial Solar Cell String Receiver on a Parabolic Trough Solar Collector. Energies 2023, 16, 2007. https://doi.org/10.3390/en16042007

Cabral D, Hayati A, Gomes J, Gorouh HA, Nasseriyan P, Salmanzadeh M. Experimental Electrical Assessment Evaluation of a Vertical n-PERT Half-Size Bifacial Solar Cell String Receiver on a Parabolic Trough Solar Collector. Energies. 2023; 16(4):2007. https://doi.org/10.3390/en16042007

Chicago/Turabian StyleCabral, Diogo, Abolfazl Hayati, João Gomes, Hossein Afzali Gorouh, Pouriya Nasseriyan, and Mazyar Salmanzadeh. 2023. "Experimental Electrical Assessment Evaluation of a Vertical n-PERT Half-Size Bifacial Solar Cell String Receiver on a Parabolic Trough Solar Collector" Energies 16, no. 4: 2007. https://doi.org/10.3390/en16042007

APA StyleCabral, D., Hayati, A., Gomes, J., Gorouh, H. A., Nasseriyan, P., & Salmanzadeh, M. (2023). Experimental Electrical Assessment Evaluation of a Vertical n-PERT Half-Size Bifacial Solar Cell String Receiver on a Parabolic Trough Solar Collector. Energies, 16(4), 2007. https://doi.org/10.3390/en16042007