5.2.2. Phase Modular AC/DC Converter Topologies for Dual-Stage Architectures

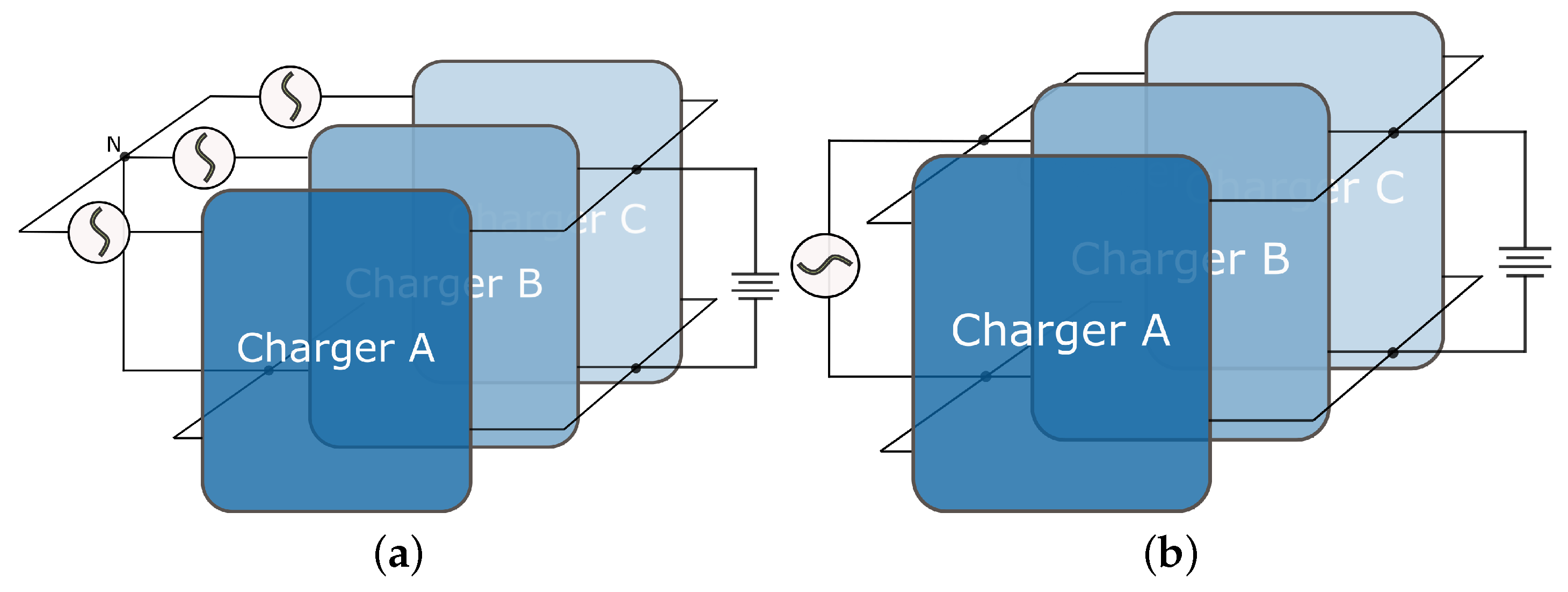

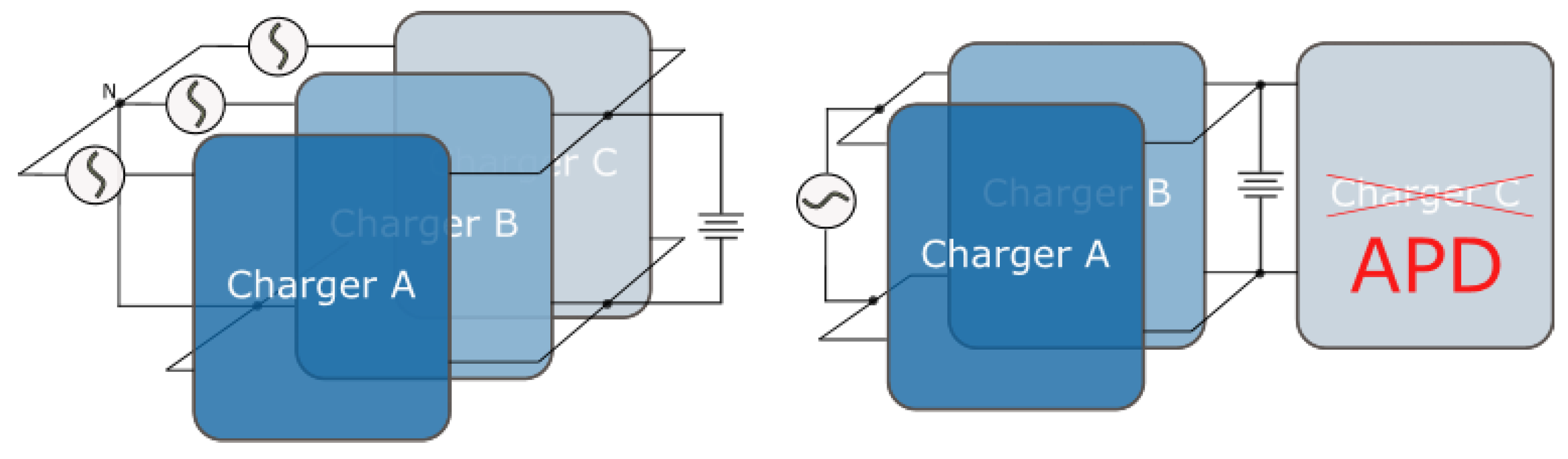

- (a)

Totem Pole Bridgeless PFC and Interleaved Totem Pole PFC

The bridgeless PFC topology is a well-known and preferred topology in the industry [

20] thanks to its bi-directional capability and reduced conduction losses through synchronous rectification. The study reported in [

126] compares the efficiency gain achieved by using MOSFETs instead of rectifying diodes. The results showed that 3.5 kW rated bi-directional bridge-less PFC variant achieves an efficiency improvement of 0.3% when compared to the uni-directional equivalent while operating at 1 kW. When power density is a primary concern, as in the case of an OBC application, this circuit configuration experiences serious losses due to reverse recovery when silicon MOSFETs are used in the high-frequency leg, i.e., in place of switches S1 and S2 in

Figure 16a. Hence, the bridgeless Totem-Pole PFC [

10] and its interleaved variant [

93] shown in

Figure 16a) and

Figure 16b, respectively, based on GaN devices has been widely researched in recent years thanks to their unprecedented switching characteristics [

93] enabling high efficiencies of up to 99.2% [

93]. Finally, to enhance reactive power injection/sinking capabilities while maintaining good THD value and achieving ZVS operation, the authors have proposed the modified T-type PFC topology [

127] shown in

Figure 16c.

Conventionally, the state-of-the-art GaN-based totem-pole PFC converters are operated under CCM [

93]. In CCM, in the positive half cycle of the AC voltage, S1 turns-on under ZVS provided that the inductor current is sufficiently high [

51] and S2 is hard switched and vice versa during the negative half cycle. Despite the absence of reverse recovery issues and notably lower switching losses when compared to silicon MOSFETs, CCM-modulated GaN-based bridgeless PFC converters are typically limited to a switching frequency of a few hundred kHz or lower [

9]. For the applications targeting high power density, switching frequencies in the MHz range is viable by utilizing triangular conduction modulation (TCM) [

51], which is also known as critical conduction mode [

128], allowing ZVS of the transistors [

20]. The extra synchronous rectification (SR) conduction time drives the inductor current to a negative value and subsequently leads to ZVS switching of the upcoming transistor. This operation typically requires additional zero crossing detection (ZCD) hardware. However, the TCM approach comes with the trade-off of increased rms current and substantially higher peak transistor current resulting from discontinuous operation. Moreover, it poses a wide range variable frequency operation, which complicates the EMI filter design [

129].

Table 7 summarizes the advantages and disadvantages of the two methods compared to each other. The well reported zero crossing current distortion phenomena in conventional PFC converters is mainly associated with the improper handling of naturally delayed modulating reference signal due to the existence of Lg, as shown in

Figure 16a, and with very small instantaneous grid voltage build up of the current on the inductor and, finally, limitations of the minimum applicable duty cycle due to dead-time and gate driver capabilities [

127]. Another less common reason is asynchronous PWM signals between HF, i.e., S1,2, and LF, i.e., S3,4 switching legs. Since the duty cycles of the high-frequency leg abruptly change from 100% to 0% and vice-versa at zero crossing, as a solution, a soft start switching pattern for GaN-based PFC has been presented in [

130]. Nevertheless, accounting for the uncertainties of AC crossover sensing circuitry, typically, a dead zone of a few hundred

s is implemented, in which both GaN transistors are kept in the off state. In summary, the existing bridgeless totem-pole PFC topologies, together with the applied modulation techniques, are provided in

Table 8. Since power density is not available in all studies, applied switching frequencies (frequency at peak AC current instant for TCM) and achieved efficiency values in charging mode have been given.

- (b)

Multi-level Flying Capacitor (FCML) Converter

The FCML converters are traditionally used for medium voltage power electronics [

85]. Recently, they have also been demonstrated with high efficiency and high density for low-voltage grid-connected applications [

131] thanks to their modular structure and reduced semiconductor count relative to the ANPC topology and modular aspect. A generalized structure for N-level single-phase AC/DC FCML converter is presented in

Figure 17a,b with H-bridge and half-bridge unfolding/folding legs, respectively. The latter approach results in lower conduction losses to the H-bridge unfolder as there is only one transistor in the conduction path. On the other hand, the H-bridge is preferred in some designs as it alleviates LF common-mode filter effort. For an N-level FCML, N-2 flying capacitors are needed, which are charged at different voltages from

/(N-1) up to

(N-2)/(N-1) [

85]. In GaN-based applications, ceramic capacitors are typically employed due to their very low ESR values [

85] since the ESR of the capacitors is a contributor to conduction losses. [

132] has demonstrated a 6-level 3.7 kW rated PFC rectifier based on GaN-based H-bridge unfolder shown in

Figure 17a for EV charging applications. Although each switch is expected to nominally block 80 V by employing 150 V, 7 m

GaN switching transistors, this design achieves a maximum efficiency of 98.5% in inverter mode including the losses of the active power decoupling circuit. The seven-level FCML design presented in [

100] rated for at 2.2 kW achieves an efficiency of 99.03% with 15.8 kW/L power density. Another study [

85], based on a half-bridge folding leg, as shown in

Figure 17b, and using Si MOSFETs reported 99.25% efficiency for AC/DC rated for 2.5 kW using 200 V rated GaN devices within a boxed volume of 397 cm

.

An important disadvantage of these topologies is the requirement for start-up and pre-charge circuits for these capacitors. Additionally, under transient conditions, the flying capacitor voltages may experience voltage unbalance [

132], resulting in a voltage stress above the nominal value, which may necessitate choosing an inflated voltage rating for the GaN transistors constituting the FCML. The complexity and conduction losses associated with multi-level converters can be detrimental, particularly when applied to GaN-based systems in which switching frequencies in the MHz range are feasible using two-level topologies. As an example, [

131] claims that the three-level FCML design based on Si transistors outperforms the GaN-based counterpart in terms of efficiency.

- (c)

Modular multi-level converters (MMCs)

Modular multi-level converters, which have already established themselves as a viable solution in high-voltage, high-power AC/DC conversion, hold promise for being advantageous in lower-power applications, such as in the on-board chargers of electric vehicles. Reduction of magnetic core losses, increased redundancy, and easier thermal management, strengthened by the plethora of low voltage GaN power device options, clearly make the MMC topology an attractive nominee for EV charging applications, especially for 800 V EV systems. A 6.6 kW experimental prototype of the single-phase 6-level MMC converter design, cf.

Figure 18, using EPC2029 (3.2 m

, 80 V) e-mode GaN transistors was demonstrated in [

8]. This study reports an efficiency of 98.22% within a volume of 0.62 L; this relatively low efficiency is mainly attributed to inductor loss and, unexpectedly, to the switching losses. Moreover, the reduction in EMI filter components counterbalanced with the requirement for a high-capacity sub-module capacitance to achieve satisfactory performance. Additionally, possible considerations regarding the increased cost and complexity remain at a standstill. Nevertheless, multi-level topologies can still be attractive in the OBC applications thanks to reduced

rate, frequency multiplication effect, distributed losses, and resulting reduced cooling effort.

Table 8 provides a summary of the comparison of the phase modular GaN based PFc topologies, with the emphasis on power density and efficiency.

5.2.3. DC/DC Converter Topologies for Dual-Stage Architectures

- (a)

Dual Active Bridge (DAB) DC/DC Converter

The DAB, shown in

Figure 19a, is a well-known topology that has been in use for a few decades [

133] for bi-directional isolated DC/DC converter applications due to its high efficiency, high power density, soft switching possibility, and wide range of voltage transfer ratios [

3,

109,

134]. As opposed to the resonant counterpart [

90], the DAB [

135] has a simpler structure since it does not require a series capacitor bank, which may occupy considerable space. However, due to the non-ideal behaviors such as the discrepancies among driver propagation delay characteristics, variations in the terminal voltage, and the dynamic operational phase-shift variations, the DC-bias becomes a challenging problem in practical applications [

136]. That is why practical DAB applications may also employ a low voltage DC-blocking capacitor in series with the transformer winding to block the DC voltage component which will degrade the power density [

135,

136]. As a remedy, several active flux control methods have been proposed in the literature [

136,

137], which eliminates the use of series capacitors and the DC-bias current problem both during the transient and steady-state conditions. Conventionally, DAB employs only one external inductor on any side of the transformer [

82]; however, as reported in [

138] the inter-winding stray capacitance can cause current resonance and finally worsen soft switching in case of simultaneous switching events in both sides of the transformer. It is shown that splitting the external inductance to both sides of the high-frequency transformer can effectively extend the ZVS for all the switching devices [

138]. Finally, DAB allows modular structures [

99] to scale up to the higher power level thanks to its outstanding feature that paralleling can be easily achieved, as opposed to resonant topologies [

3]. Therefore, by following a modular design approach, light load operation duration can be minimized by shedding some parallel units for efficiency optimization [

5]. Unfortunately, Performance of a 5 kW rated GaN-based DAB DC/DC converter in a 400 V battery charging application has been demonstrated in [

135]. Reportedly, this design has a maximum efficiency of 98.7% while operating at half power and 98% at rated power. Although this study provides valuable information on the magnetic components’ volume, unfortunately, it lacks details on the power density.

The half-bridge variant (DAHB) of DAB, shown in

Figure 19b, for PHEV charging application utilizing GaN transistors has been presented in [

139]. This configuration has the advantage of low transistor count with the compromise of reduced efficiency resulting from a transformer operation with half of the DC-link voltage. Therefore, this topology can be disadvantageous for high power, i.e., 22 kW, OBC applications. Another variant with a three-level ANPC half-bridge at the primary and secondary side is given in

Figure 20a [

137], which is proposed for 800 V EV charging applications. In this work, the proposed three-level DAHB converter achieves a peak efficiency of 98.25% for an experimental prototype with a power rating of 1.5 kW. An additional option with a 10 kW power rating is the series-input, series-output (SISO) DAB converter, shown in

Figure 20b, proposed in the recent study [

99]. This converter is capable of functioning over a broad output voltage range of 250 V to 1000 V. While the efficiency of this converter is not stated in the study, it shows an impressive power density of 10 kW/L, including the AFE stage.

The DAB topology, while advantageous in many ways, is not without its limitations. One of the significant disadvantages of this topology is that its efficiency may fall below 90% under light load [

82], mainly due to the absence of soft-switching and the persisting core losses with a subtle reduction from full load operation.

In the DAB converter, bidirectional power flow is achieved by controlling the phase shift angle between the voltage waveforms of the two bridges [

99]. Modulation techniques for the DAB topology have been thoroughly investigated in the literature [

87,

133,

140,

141,

142,

143,

144]. The most well-known and simplest modulation method is named single-phase-shift (SPS) [

133,

140], in which, primary and secondary bridges are operated with 50% duty cycle, and only their phase difference is controlled to regulate the power flow. Power is sourced from the side modulated with a leading phase angle. Switching the polarity of the phase shift angle enables reverse power flow, and hence, the bidirectional operation can easily be achieved. While operating above one-third of the rated power with input/output voltages close to their nominal values, the SPS modulation achieves ZVS operation and high efficiency. The two basic ZVS requirements state that the inductor current

should be flowing through the reverse conduction path of the upcoming switch which will take over the current and should be higher than a certain level to ensure charge and discharge the output capacitances of commutating transistors [

125]. The ZVS range of DAB is also affected by the utilized dead-band as it ought be set larger than the ZVS resonance transient interval which depends on auxiliary inductor Lp and GaN transistor parasitic capacitances [

87]. With these constraints, SPS requires a high auxiliary inductance Lp, cf.

Figure 19a, to preserve ZVS ability at light load, resulting in high-circulating power and low efficiency for the DAB converter [

133,

140].

Various modulation methods have been proposed to address the efficiency issues of the SPS-modulated DAB topology at light loads. One approach is extended-phase shift (EPS) modulation [

87], which allows for increased control degrees of freedom by operating one side of the converter below 50% duty cycle while the other side remains at 50%. Alternatively, dual-phase-shift (DPS) modulation [

142] reduces the duty cycle of both sides to below 50%. Another method is triple-phase-shift (TPS) modulation, as discussed by Huang et al. and Chen et al. [

143,

145], which achieves greater control flexibility than other symmetrical modulations by using different duty cycles for both full-bridges. TPS includes two well-known sub-forms, namely the triangular (TRM) and trapezoidal modulation methods, whose names comes from the inductor current shape [

134,

141]. TRM provides a discontinuous conducting mode at light load with minimal rms current by reducing the circulating currents. However, for only two of the switches, ZVS turn-on is achieved [

144] as far as the minimum commutation current needed for the resonant transition is available while the rest turns-on under zero current. However, turn-on under zero current, unfortunately, does not mean soft switching, and in fact, turn-on loss can account for as high as 30% of its nominal current value caused by the

losses of high-side and low-side transistors [

146].

As an alternative to the symmetrical modulation methods explained above, by bringing another degree of freedom to the modulator, recently a few asymmetrical modulation methods have been proposed [

144,

147]. In [

147], the duty cycle of the low-voltage side is fixed at 50%, while the other side is operated at a lower duty cycle without following the half wave symmetry. Reportedly, the proposed approach has better ZVS performance, although full ZVS operation is not possible when compared to SPS, DPS, and EPS modulation methods under light load. However, the comparison does not include TRM and TPS modulation methods, and a circulating current is observable on transformer windings during the inactive mode. On the other hand, [

144] presents a hybrid approach by combining EPS, SPS, and a new asymmetrical modulation to minimize rms current while guaranteeing the ZVS operation over a wide range. In their proposal, EPS is modified such that half wave symmetry is violated in a way that transformer winding volt-second balance is not stated. Therefore, this method requires an additional series blocking capacitor.

Depending on the transferred power and input/output voltage levels, the number of operating modes can be as many as twelve for TPS [

125], and it is challenging to obtain the global optimal TPS parameters with three degrees of freedom. The same level of difficulty is also apparent for asymmetrical modulation methods. Several optimization studies have been proposed in the literature [

87,

134,

142,

143], and a review of other studies has been presented in [

141]. The optimum modulation parameters can be obtained via different objective functions such as minimization of peak current stress [

143] and rms values of the primary and secondary side currents [

125,

143,

144], reactive power, i.e., circulating current [

141] or total converter losses [

134] with the constraint of achieving ZVS with different levels of complexities specific to the selected approach.

In DAB topology, both transferred power and circulating current also depend on switching frequency as well as the applied phase shift. Therefore, in addition to the phase-shift modulation methods, manipulation of modulation frequency is another viable approach to ensure ZVS over a wide power range with optimal circulating current [

133,

134,

141]. Obviously, the switching frequency range is not infinite due to transformer saturation, core losses, and frequency-dependent skin/proximity effects on winding losses. Additionally, a wide switching frequency range aggravates the filter design and component choices. Finally, as implemented in [

137] (DPS in their case), the presented modulation techniques are also applicable to multi-level DAB topologies.

Practically, these parameters (i.e., the duty-cycles, the phase-shift angle, and the dead times if adaptive dead-time is implemented) are pre-calculated for possible operating modes and stored as lookup tables in non-volatile memory to be used in the closed-loop control of the DAB converter [

125]. However, as the loss of ZVS can increase losses tremendously, sensitivity analysis against variation of circuit parameters, e.g., inductance and transistor output capacitance, should be conducted and necessary actions should be taken. A large memory is needed to store enough data to cover all possible circuit parameter drift range. This may favor online calculation of global optimal modulation parameters by using closed form equations for some applications, as explained in [

143]. A summary of prominent DAB modulation techniques is given in

Table 9.

- (b)

Resonant Dual-Active-Bridge DC/DC Converter Topologies

Unidirectional series resonant isolated converter, i.e., LLC, [

149,

150] is a well-known DC/DC topology for power electronic applications thanks to its advantages of soft switching and accompanying high-frequency operation capability, high efficiency, and good EMI performance. When the secondary side diodes are replaced with transistors, this topology can be also used for bidirectional charging applications [

149]. However, in the reverse direction, i.e., in V2G mode, large turn-off currents are observed on the secondary side due to full AC-link current superimposed by the magnetizing current [

149], and the efficiency drops towards the upper end of the output voltage range due to increased switching losses. To improve LLC performance for bidirectional power flow, another resonant tank is utilized in the secondary side of LLC topology resulting in CLLC topology as depicted in

Figure 21a, providing similar characteristics in V2G and G2V modes [

151]. Compared to the DAB converter, the CLLC converter is controlled by a variable switching frequency to regulate the voltage gain while achieving soft switching over a wider power range [

3]. While operating in the vicinity of resonant frequency, a peak efficiency of 97.6% can be achievable for a CLLC converter designed for EV charging application utilizing 70 mΩ enhancement mode GaN transistors, with a variable switching frequency between 435 kHz and 575 kHz [

152]. Results of this study show that semiconductor conduction losses occupy almost half of the overall converter losses due to intrinsic high rms currents occurring in a CLLC topology caused by the sinusoidal current shape. Nevertheless, by using high-current-rated devices, conduction losses can be reduced. In fact, for a similar rated CLLC using 34 mΩ GaN-GIT, a peak efficiency above 98% can be possible [

59].

In [

153], an isolated half-bridge CLLC converter, cf.

Figure 21b, a prototype using 650 V GaN devices with a power rating of 1 kW has been demonstrated. This converter has a resonant frequency of 391 kHz. The most prominent advantage of this configuration is halved transistor count compared to the full-bridge CLLC. However, this increases the transformer winding losses and semiconductor conduction losses since the voltages are halved and the current is doubled compared to full-bridge CLLC with the same power rating. Although the demonstrated prototype operates with soft switching across the battery voltage range, it has a relatively low efficiency of up to 95.7% [

153].

Table 10 compares the performance metrics of bi-directional GaN-based resonant DC/DC converter examples to an equivalent resonant converter demonstrated in [

150]. The results indicate that incorporating bidirectional functionality does not necessarily decrease the efficiency or power density. On the contrary, bidirectional functionality can enhance both efficiency and power density. However, it is important to note that bidirectional topologies come with increased complexity, requiring additional power transistors and drivers for both resonant and non-resonant topologies as well as additional battery-side resonant tank components for resonant topologies. This added complexity may be considered a potential downside.

The CLLC topology exhibits serious design challenges to obtain a wide output voltage range [

151]. In wide voltage range applications, a large resonant inductor is required to obtain a steep gain curve by increasing the Q factor to extend the regulation range [

150]. However, a resonant tank with a large resonant inductor incurs high rms current and high peak voltage on the resonant capacitor. Furthermore, the switching frequency range also increases resulting in higher semiconductor and transformer losses. Above the resonant frequency, i.e., inductive region, circulating reactive current further increases the conduction losses [

154] despite the soft switching being retained in which, switches operate in reverse conduction mode for longer duration. In this respect, Si- and SiC-based power transistors presents lower conduction loss thanks to contribution of body diode. That is why, use of GaN transistors in a CLLC converter with long operation time in this mode can be disadvantageous [

155].

Table 10.

Summary of GaN-based isolated DC/DC converter topologies for 400 V and 800 V EV applications.

Table 10.

Summary of GaN-based isolated DC/DC converter topologies for 400 V and 800 V EV applications.

| Topology | Year | Power Rating | Switch Type | Modulation | Switching Frequency | Power Density | Efficiency (Peak/Full Load) | Output Voltage |

|---|

| DAB HB [139] | 2022 | 3.3 kW | GaN | N/A | 100 kHz | N/A | 95.04% (with PFC) | 72 V |

| DAB [135] | 2020 | 5 kW | GaN | DPS | 100 kHz | N/A | 98.7%/98% | 400 V |

| CLLC [155] | 2017 | 3.3 kW | Hybrid (Si sec.) | Frequency + Delay | 140–180 kHz | N/A | 98%/97.4% | 400 V |

| GaN | | 97.4%/96.8% |

| Resonant LCL-T (pri. stacked HB, sec. FB) [94] | 2022 | 6.6 kW | GaN | Phase shift | 500 kHz | 7.3 kW/L | 98.2%/>97% | 400 V |

| CLLC [152] | 2022 | 3.3 kW | GaN | Frequency | 435–575 kHz | 7.9 kW/L | 97.6%/N/A | 400 V |

| CLLC Variable tap [59] | 2017 | 6 kW | GaN | N/A | N/A | 3 kW/L (Including PFC unit) | >98%/98% | 400 V |

| CLLC (fiexed gain) [156] | 2021 | 18 kW | Hybrid (SiC pri.) | Fixed frequency | N/A | 8.7 kW/L | >98.8%/N/A | 400 V |

| HB CLLC [153] | 2020 | 1 kW | GaN | Frequency | 391–500 kHz | N/A | 95.7%/95.7% | 400 V |

| Resonant LCL-T (pri. and sec. stacked HB) [94] | 2022 | 6.6 kW | GaN | Phase shift | 500 kHz | 7.3 kW/L | 98.2%/>97.5% | 800 V |

| DAB (stacked) [99] | 2022 | 10 kW | GaN | Hybrid (SPS+DPS) | 140–400 kHz | 10 kW/L (Including AFE) | N/A | 250–1000 V |

| 3-level DAHB [137] | 2022 | 3.3 kW | GaN | DPS | 100 kHz | N/A | >98.25%/N/A | 800 V |

| Hybrid LLC [150] (PSFB + LLC) * | 2020 | 3.2 kW | GaN FB pri. and Si sec. | Frequency modulation for both modes | 75–300 kHz | 4 kW/L | 98.5%/98.5% | 400 V |

To address the wide operating voltage requirement of the OBC applications, a possible solution could be a variable DC-link operation [

90,

156] for dual-stage architectures. Liu et al. compared the performance of conventional CLLC with variable DC-link operation [

90], where an outstanding overall efficiency improvement, up to 1%, was achieved compared to fixed DC-link voltage operation. However, in this approach, DC-link is driven above typical commercial GaN voltage rating, i.e., 650 V, and thereby these applications typically utilize 1200 V SiC MOSFETs at the primary side. In another approach, input-parallel output-series (IPOS) isolated converter functions as a load-independent constant gain DC transformer (DCX) [

156], allowing it to operate in the vicinity of the resonant frequency throughout the entire charging profile. This gives a flat efficiency profile for DC/DC stage optimized for best efficiency thanks to fixed voltage gain. Another partial power resonant converter was cascaded (cf.

Figure 22b) with a non-isolated bi-polar bi-directional DC/DC converter assigned for battery voltage regulation. The two converters are supplied from a common 750 V DC-link, with the first one functioning as a fixed-gain DCX, which handles the majority of the power and the second one being responsible for output voltage regulation. This results in a peak efficiency of 98.8% and a relatively flat efficiency profile, excluding the light load conditions.

Several methods have been proposed to expand the output voltage range of the series resonant converters [

59,

150]. One of the most popular approaches is reconfigurable transformer taps to allow different transformer turns ratios; for example, ref. [

59] shows reconfigurable turn ratios of 10:10 and 10:8 achieving an efficiency above 98% over a wide voltage range. The ZVS operating range can also be extended by applying hybrid modulation methods, which will be elaborated in the following section. Finally, there are a few studies proposing adjustable resonant tank parameters allowing resonant operation for different battery voltages [

157], and reconfigurable unidirectional LLC converters [

150], allowing resonant and phase-shifted full-bridge or half-bridge and full-bridge operation mode transitions. However, according to the best search of the authors, no such study has been found on GaN transistors that adopted this approach for bi-directional OBC application. Nevertheless, these approaches can also be extended to bi-directional CLLC topology [

158].

Finally, multi-winding transformer-based stacked isolated converters are drawing attention [

99,

100,

106,

159] for solid-state transformer (SST), DC micro-grid, and battery charging applications, especially 800 V systems, as well. In [

94], the authors have proposed a resonant stacked half-bridge converter based on an LCL-T immittance network which operates at fixed 500 kHz switching frequency fed from a 800 V front-end converter. This converter can produce output voltages from 150 V up to 950 V. The measured converter achieves a peak efficiency of 98.2% along with a power density of 7.3 kW/L. Although this converter maintains a flat efficiency profile above > 97% across the whole output voltage range, at rated power, the light load efficiency falls below 90% like the two-level DAB and CLLC counterparts. The tuned LCL-T network presents a high impedance to harmonics generated by the converters, and therefore, the primary and secondary switch and transformer waveforms are approximately sinusoidal, minimizing the reactive power requirement of the converter irrespective of the load. The direction and magnitude of power flow is regulated by controlling the pulse width of primary and secondary side switching pattern (three-level modulation) while keeping the phase shift constant. Since this architecture does not have a series capacitor in its original form, additional dc blocking capacitors are required in both primary and secondary side due to uni-polar exciting voltages of stacked half-bridge. Exclusion of secondary side resonant network can outweigh the volume increase caused by the use of an additional inductor with similar sizing with the one used in CLLC converter. Although performance and switching behavior has been thoroughly analyzed for CC/CP/CV charging modes, the ZVS operation range is not detailed for V2G mode in this study. Since the magnetizing inductance can be designed significantly higher [

94] than conventional LLC converter, problems evident in LLC reverse-mode operation [

149] may not appear in this topology.

A few alternative conceptual topologies are shown in

Figure 22b–d and

Figure 23d based on multiple transformers and have been recommended in [

106]. In case of a 400 V DC-link, ref. [

106] proposes the topology given in

Figure 22b for 800 V EV systems. An important advantage of this approaches is the re-configuring capability of the output circuit for parallel operation, as shown in

Figure 23d for 400 V EV systems, despite the fact that paralleling of resonant converters is a challenging task [

3]. Unfortunately, experimental studies issuing the performance evaluation of these topologies are very limited or not available yet. A stacked structure for 800 V charging application can be formed by connecting the two half-bridges in series [

106,

160], as shown in

Figure 22b.

Table 10 presents a summary of the comparison between GaN-based isolated DC/DC topologies for 400 and 800 V EV charging applications, with a particular focus on power density and efficiency. Finally, the table incorporates information on the modulation techniques used in each topology.

Basic modulation of CLLC converter is known as pulse frequency modulation (PFM) technique [

111], which is based on the DC gain characteristics of the resonant converter practically obtained by fundamental harmonic analysis (FHA) [

161]. In this modulation technique, the timing of rectifying bridge gate signals has a crucial role to achieve ZCS at the secondary side [

152], which necessitates employment of carefully tuned and sensitive zero crossing detection circuits. Dead-time optimization, depending on the loading, is also needed including the effect of GaN transistor output capacitance and the circuit parasitic capacitances [

162,

163]. Ref. [

161] proposes a specialized version of frequency modulation to implement synchronous rectification of secondary side switches without using sensors. As stated in the previous section, this technique has significant disadvantages when applied to wide input/output voltage range applications. In order to address these limitations, numerous alternative techniques have been proposed in the literature, a summary of which is presented in

Table 11.

Among them, the half-bridge mode implements a unipolar switching pattern at the primary side. This method reduces the switching speed by half, although the converter still operates at resonant frequency. Additionally, since half of the input voltage is blocked on the resonant capacitor, the fundamental component of the applied voltage is half of its nominal value [

160]. However, in an EV charging application, converter output current is maximum when battery voltage is low in a CC/CV or CC/CP/CV charging profile [

32,

94,

154]; thus, optimum efficiency may not be attained as the converter operates with a reduced effective input voltage. The burst mode [

151] operation, on the other hand, is the intermittent operation of the converter during the light load conditions while being still excited typically at the frequency providing the best efficiency.

Delay time control [

151,

155] is another approach targeting extension of operation voltage range. In this method primary side is operated like in basic frequency modulation. On the other hand, secondary side HB legs, displaced by a phase difference above 180°, results in a state shorting the secondary side winding. This boost behavior [

151] provides a higher output voltage compared to the conventional frequency control. This mode is typically only applied in the high output voltage CV region, which elevates circuit performance by enabling selection of a larger magnetizing inductance and higher turns ratio to reduce the conduction losses.

In contrast, when the primary side HB leg gate signals are displaced by a phase angle different from 180°, a new modulation technique known as inner phase-shift control (IPS) is obtained [

165]. By controlling the phase shift between the primary side bridge legs, the output voltage can be regulated. Moreover, the primary side zero voltage switching, and secondary side zero current switching features are also ensured. Although the resulting mode is a step-down mode (if transformer turns ratio is equal to 1:1), it can replace the above resonance operation of PFM modulation, narrowing the switching frequency range significantly and eliminating the semiconductor turn-off losses which are inevitable for the above resonance operation [

154].

The extended phase-shift (EPS) control [

164], also known as the dual-phase-shift control technique [

111], introduces an outer phase shift between primary and secondary bridges in addition to the IPS. Fundamental wave amplitude of the square wave voltage of the primary side bridge is adjusted by reducing the duty cycle below 50% to achieve high light load efficiency. Study [

164] shows that by optimizing the phase-shift combinations for EPS control in the CLLC converter throughout the operation range, ZVS can be assured for both primary and secondary side switches. In practical applications, typically a hybrid modulation technique is adopted combining basic PFM and a phase-shift modulation [

158] to optimize the converter design and reduce the operation frequency range.

The modulation techniques given in this study are also applicable to stacked CLLC converters [

94,

160]. Practically, a combination of two-level modulation [

166] and three-level modulation can increase operation voltage range for multi-level resonant converters while achieving full range ZVS operation with reduced circulating current. For instance, in the low battery voltage range, [

94] utilizes an asymmetrical modulation technique that alternates between the top and bottom half-bridges. This method leads to a switching frequency that is half of the resonant frequency. In normal operation, phase-shift modulation resulting in three-level waveforms is implemented. Notoriously, increasing degrees of freedom of stacked CLLC converters enables further extension of conventional modulation methods to achieve ZVS operation over a wide battery voltage range. However, this topic waits as future research, for now.

Table 12 illustrates how the choice of modulation method affects converter efficiency across the battery voltage range. By utilizing advanced modulation techniques, it is possible to achieve a flat efficiency profile throughout the charging process, specifically improving the light load performance, for both resonant and non-resonant isolated DC/DC converter topologies. Therefore, the impact of modulation technique on topology performance should not be overlooked.