Abstract

Marginal abatement cost (MAC) plays an essential role in pricing pollutants and guiding environmental policies. Considering the heavy polluting nature of China’s coal power industry, this paper aims at providing companies and policymakers with more comprehensive information on the cost of abatement by estimating the MACs of CO2 and SO2 for coal-fired power plants (CFPPs) in China. This study contributes to the literature by considering an interconnected two-stage production system to investigate. The estimation framework is advanced in combining the electricity production and pollution abatement process of CFPPs into a convex quantile regression (CQR) model. The results show that the averages of MAC for CO2 and SO2 are estimated to be 367.56 Yuan/ton and 662.30 Yuan/ton, respectively, indicating that the reduction of such emissions is still costly. The heterogeneous analysis then indicates that large CFPPs, central-government-owned power plants (CGOPPs), and low-regulated CFPPs tend to possess lower MACs for CO2. Regarding SO2, large and medium-sized power plants show significantly larger MACs than small plants. In addition, the MACs of SO2 for CGOPPs and high-regulated CFPPs are more concentrated at high levels. In the second part, the Tobit regression analysis was used to discuss the determinants of MACs for CO2 and SO2. Factors like carbon emission intensity, load, and operating hours can notably decrease MACs for CO2, while MACs for SO2 tend to be positively affected by the total abatement cost and the abatement rate of the FGD equipment. In addition, the MACs for the large CFPPs, CGOPPs, and high-regulated CFPPs are more likely to be affected by the selected influence factors. Based on these results, we conclude with some policy recommendations.

1. Introduction

Over the past few decades, the world has experienced severe greenhouse gas and air pollution emission problems due to the development of coal-fired power plants (CFPPs) to meet the increasing electricity demand. According to IEA [1], CFPPs contributed almost 30% of energy-related carbon emissions, and coal power generation also leads to about two-thirds of pollution emissions growth. In particular, the condition is much worse in China, whose power sector mainly depends on coal burning [2]. In 2019, 5238 Mt CO2 were emitted in the Chinese electricity and heat production sector, while coal-fired power generation contributed almost 97% of that amount (5078.1 Mt) [3]. Therefore, CFPPs should be the main regulatory objective to improve China’s current carbon emissions condition. Better than carbon emissions, the situation of SO2 emissions has changed significantly in China since the development of end-of-pipe abatement technology such as the flue gas desulfurization (FGD) system. After being required to install FGD facilities since the 11th FYP, SO2 emissions per unit of thermal power generation in China has decreased significantly from 6.36 g/kWh in 2005 to 0.16 g/kWh in 2020. However, it is worth noting that China’s electricity and heat supply sector still accounts for 32% of total industrial SO2 emissions at 805,407 tons [4], indicating that further reduction of SO2 emissions produced by CFPPs is still of great necessity.

It is inevitable that CFPPs will eventually be phased out as China proposes carbon peak and carbon neutrality targets. However, China still plays an important role in maintaining the stability of the world economy and the global supply chain, especially when facing increasing detrimental factors like COVID-19 and the global supply chain crisis. Therefore, the power sector in China, which is one of the main factors in maintaining the stability and security of the economy and society, must continue its dominant role in meeting the expected increase in demand for various goods and services [5]. In this context, China’s central government should not phase out CFPPs too quickly, by simply focusing on the environmental targets and ignoring the economic and social role of coal-fired power plants.

The Chinese government has made great efforts to improve the environmental performance of CFPPs such as implementing the policy of “replacing small units with large ones” to accelerate the retirement of outdated coal power units and shrink new coal power capacity in construction, and introducing ultra-low emission standards to regulate CFPPs. However, any shift will come at a cost, especially for the coal-fired power sector, which would incur huge sunk costs due to upgrades to generating units or pollution abatement equipment. In order to maintain the enthusiasm of certain companies to reduce emissions, the Chinese government has introduced some market-based environmental policies. An emissions trading scheme is one of the main practical tools to meet the emission goals. In July 2021, the national carbon emission trading scheme (CETS), which encourages firms with lower marginal abatement costs (MACs) to obtain benefits by reducing emissions and those with higher MACs to pay less after purchasing carbon allowances through the carbon market, was officially launched online [6]. Unlike carbon emissions, the desulfurization price subsidy policy is a more general instrument to encourage firms to reduce SO2 emissions, but a unified SO2 emissions trading market has not yet been established. Therefore, a plant-level MAC estimate is still necessary to provide market participants with more detail about the actual CO2 and SO2 emissions prices.

Extant studies have estimated the marginal abatement costs of hazardous emissions many times, hence providing a theoretical and empirical reference for evaluating the cost of emission reduction in China [7,8,9,10,11,12,13]. Estimating the MAC based on the production process with abundant input and output data is easier in practice and thus more popular [2]. In this content, MAC is regarded as the opportunity cost to reduce undesirable outputs in terms of less desirable outputs or rather more abatement input use [14]. The first and most important step to measure the MAC with an econometric approach is how to integrate undesirable outputs such as CO2 and SO2 emissions into the production function. The distance function makes this possible as it can simultaneously satisfy the desirable output increase and undesirable output decrease [15]. Non-parametric and parametric methods are both commonly used methods to estimate the MAC with a “top-down” approach. Since the distance function imposes fewer theoretical assumptions and is consistent with realistic observations, these two types of models have been applied extensively to estimate the MAC of undesirable output at different levels [16,17].

Despite the massive work on MAC estimation in the literature, we still identified some research gaps. First, most previous studies preferred to concentrate on a specific pollutant like CO2 or SO2 to conduct their MAC analysis, but rarely estimated the MAC of carbon emissions and other pollutant emissions simultaneously. For example, Lee et al. [18] estimated the shadow price of CO2 in South Korean power plants using the DEA method. Mekaroonreung et al. [19] took 336 U.S. bituminous coal-burning electricity plants as examples to estimate the shadow prices of SO2 providing valuable information about market prices of pollution. However, in some pollution-generating sectors such as coal-fired power sector, both CO2 and SO2 are the by-product along with the electricity generation because of fuel burning. Therefore, measuring the MAC of CO2 and SO2 simultaneously can provide more comprehensive information about further pollution abatement both for companies and policymakers. Second, few studies have noted the difference in the way companies treat CO2 and SO2. To the best of our knowledge, the imbalance in the development of end-of-pipe abatement devices for CO2 and SO2 often leads companies to take different actions to deal with them. Specifically, with the popularization of end-of-pipe mitigation technologies toward SO2, companies prefer to install desulfurization equipment to treat SO2 considering both its technology and cost effectiveness. However, facing the challenge of high energy consumption and the high cost of carbon capture, utilization and storage (CCUS) technology, companies are more likely to reduce carbon emission at the expense of decreasing energy input. This identification is therefore essential, as such a distinction determines what kind of frontier function we can construct to perform the MAC measurement. Third, although both parametric and non-parametric methods have been widely employed, they often project the decision-making units (DMUs) onto the frontier and subsequently derive the MAC based on the frontier. Such a schema tends to ignore the inefficiency that exists in the company itself and causes overestimation. Finally, in past literature, although the determinants of the MACs have been widely studied, most simply identified some industrial or city level factors such as GDP, the environmental regulation stringency, or the industrial structure [20,21,22]; very few studies recognize the influencing factors of MACs on China’s coal-fired power plants and take plant-level elements such as operating hours into consideration.

Therefore, the major contributions of this study are as follows: in addition to the MAC of CO2 emissions, the MAC of SO2 is creatively computed in this study. Meanwhile, our paper also considers the different emission reduction characteristics between CO2 and SO2, and production and cost frontier functions are constructed to estimate the MAC for CO2 and SO2, respectively. Furthermore, according to Kuosmanen et al. [23], we use a novel data-driven approach called the convex quantile regression approach (CQR) to solve the overestimation issue. Instead of projecting DMUs to the frontier, this approach makes it possible to estimate MACs in the production set’s interior based on the specific quantile, which directly takes the inefficiency into account. The price information is then used to explore the determinants of the MACs in our second stage of analysis. Finally, we seek to make policy recommendations based on the empirical results.

The remainder of this paper is organized as follows. Section 2 provides a review of relevant literature. Section 3 describes the proposed method. Section 4 describes the variables we choose and the data we use. Section 5 presents the empirical results. Section 6 develops a discussion about the determinants. Section 7 concludes and proposes policy implications.

2. Literature Review

Previous studies focusing on pollutant emissions reduction have flourished in recent years. In addition to estimating the MACs for some sectors like manufacturing [7,21,24] or agriculture [25,26], or discussing MACs at a national/regional level [8,9,22,27], the MACs of pollutants such as CO2 and SO2 generated from CFPPs have also been discussed in the literature many times [2,16,23,28,29,30,31,32,33,34].

Engineering and econometric approaches are two main tools to measure the MACs of various pollutants. The engineering approach is a “bottom-up” approach, which involves technical evaluation of various mitigation measures based on feasible engineering solutions on account of experts’ suggestions [35]. This method will always identify detailed cost information for one unit of pollution abatement and thus can directly provide policymakers with a rich set of pollution control tools. Therefore, several scholars have used it to evaluate the MAC in Poland, Mexico, Ireland and other countries [36,37,38], or on a global level [39]. In the field of thermal power engineering, previous literature has selected specific power plants for the cost assessment of abatement systems to seek the most economical operation [40,41,42,43]. For instance, Luo [44] in particular, established a national primary information database of coal power units in China, which contained 2157 operating coal power units in 2017. Based on this database, he assessed the cost of pollution control in the coal power industry nationwide. The calculations show that the average marginal SO2 control cost of the coal power industry in all provinces of China is between 1453.2 and 12,306.5 Yuan/ton. Wu et al. [42] took the Beijing-Tianjin-Hebei and the Pearl River Delta regions in China as study areas. They proved that the marginal cost of SO2 removal technology ranged from 965 Yuan/ton to 6268 Yuan/ton, most of which were less than 5000 Yuan/ton in the power industry. Liu et al. [45] selected 13 key abatement technologies for the Chinese power industry, and evaluated and compared the abatement potential of each and the trend of the MAC of CO2. The aforementioned studies mainly focused on describing the total or unit cost of desulfurization for a given power unit or plant. If we want to curve the changes of MAC over various power units or plants, it makes more sense to estimate the MAC with econometric methods, which estimate the MACs with the input and output data by assuming the production possibility set..

The most common approach forming a production technology is to portray a black-box production system with several input vectors such as energy, labor, and capital to generate desirable and undesirable outputs simultaneously [16,32,33,34,46,47]. The directional distance function (DDF) approach can perfectly satisfy decision-makers’ expectations about simultaneously increasing desirable output and decreasing undesirable output [48]. Accordingly, the most commonly used framework estimating MACs includes two parts: using distance functions to characterize a certain production technology and obtaining the MACs of undesirable outputs by estimating their shadow prices considering the duality between the output distance function and the revenue function [15]. For instance, Shen et al. [11] evaluated the shadow price of carbon emission for several groups of countries (OECD, ASEAN, BRICS) with the DDF approach. Zeng et al. [12] used the directional output distance function (DODF) to estimate the shadow prices of China’s SO2 emissions at province level for the period 2001–2013. Du et al. [32] applied the meta-directional output distance function to identify the carbon abatement cost of 648 Chinese coal-fired power plants in 2008. The results showed that state-owned power plants tended to obtain lower marginal abatement costs for CO2. Liu et al. [29] employed the DODF to derive the shadow price of CO2 emissions of 92 of China’s large coal-fired power plants in 2010 and considered the different plant scale and provincial carbon intensity targets. All these studies provide a theoretical and empirical reference for MAC analysis toward CFPPs, however, they all focused on one specific pollutant. To the best of our knowledge, there would be multiple undesirable by-products along with the desirable output production in some industries, especially in the coal-fired power industry [49]. Therefore, it is necessary to include both CO2 and SO2 in a marginal abatement cost analysis framework as the price information can guide companies and governments to conduct further synergistic emission reduction activities. For example, Zhao et al. [10] jointly evaluated shadow prices of CO2, SO2, and NOx for U.S. coal power plants from 2010 to 2017. Wei et al. [30] took 93 Chinese CFPPs as observations, and employed the quadratic directional distance function (QDDF) method to estimate the shadow prices of CO2 and SO2, but the data was only from 2005 to 2010.

Another fact about by-produced undesirable outputs is that they may possess different abatement characteristics. With the development of end-of-pipe abatement technology, pollution like SO2 can be significantly handled by installing FGD facilities. However, since CCUS technology has not realized full application, CO2 emission reduction is still highly related to controlling carbon-generating input use like coal. Considering this, several studies have proved that it is essential to divide the production system into a production stage with carbon emission and a pollution abatement stage with end-of-pipe treatment [50,51,52,53,54,55,56,57,58,59,60,61]. Previous studies related to CFPPs would treat an undesirable output like SO2 or CO2 emissions or an actual energy input as a link variable between production and abatement stages [50,51,52], and assumed that they satisfied a common weak disposability feature, meaning that if the undesired output decreases, the other output will necessarily decrease by some amount [62]. However, Wei et al. [30] pointed out that under different treatment approaches, only CO2 emission satisfies weak disposability, while FGD technology can change SO2 from being weakly disposable to strongly disposable, indicating that the desirable output does not need to be reduced in order to reduce the undesired output [19]. Regardless of the difference between assumptions about the disposability of undesirable outputs, all of these studies estimated the MAC of CO2 and SO2 from the perspective of the production frontier. However, as we mentioned above, SO2 emission or abatement is poorly connected with the production stage, but highly relevant to the use of abatement equipment. Therefore, we build production and cost frontiers separately to estimate the MAC for CO2 and SO2, respectively. Accordingly, in this study, part of the generated electricity is considered as part of abatement input at the end-of-pipe abatement stage and regarded as the link between the two stages.

Marginal abatement cost has been widely measured both with parametric [16,32,33,34,63,64] and non-parametric approaches [9,22,23,29]. The production frontier constructed by the parametric method mainly includes a parametric stochastic frontier analysis (SFA) and a parametric linear programming (PLP) approach. The SFA approach always demonstrates the production frontier with econometric estimates, meaning that it takes into account statistical noise like measurement errors and random disturbances. Considering this, some studies, for example, Zhang et al. [21], Tian et al. [33], and Wei et al. [16] employed the SFA approach to discuss the MACs of coal-fired power plants. On the other hand, Du et al. [34] pointed out that a PLP approach is more suitable for frontier estimation since it accounts for the constraints of environmental production technologies in its estimation process, although its estimated production frontier is as differentiable as the SFA approach. Based on this method, both Du et al. [32] and Nakaishi [2] estimated the shadow price of coal-fired power plants in China. In addition, a non-parametric data envelopment analysis (DEA) approach is also frequently used in frontier analysis considering its flexibility, such as not assuming the production function form [65]. Based on this, several studies have conducted a MAC estimation for coal-fired power plants, for example, Wang et al. [9] and Kuosmanen et al. [23]. However, the approaches mentioned above strongly rely on the full frontier, where all DMUs are uniformly projected. The estimated MAC derived based on this frontier can cause an overestimation since inefficiencies operating far below the frontier are ignored completely [14]. Therefore, the MACs of pollutants can vary under different efficiency levels even with the same technology [14,66]. To solve this problem, Kuosmanen et al. [23] developed a data-driven approach called the convex quantile regression approach. This approach perfectly accounts for the inefficiency as it estimates the MAC based on a specific quantile, instead of projecting the DMUs onto the full frontier. Kuosmanen et al. [67] then used this method to estimate the average MAC of CO2 for a panel of 28 OECD countries during the period 1990–2015. Dai et al. [14] estimated the marginal CO2 abatement costs for 30 Chinese provinces in the period 1997–2015 and then presented a forward-looking assessment of the abatement costs for Chinese provinces for 2016–2020. Following them, we also conduct a convex quantile regression in both stages to curve the quantile frontiers for each power plant (with different efficiency levels) to measure the MACs of CO2 and SO2, respectively.

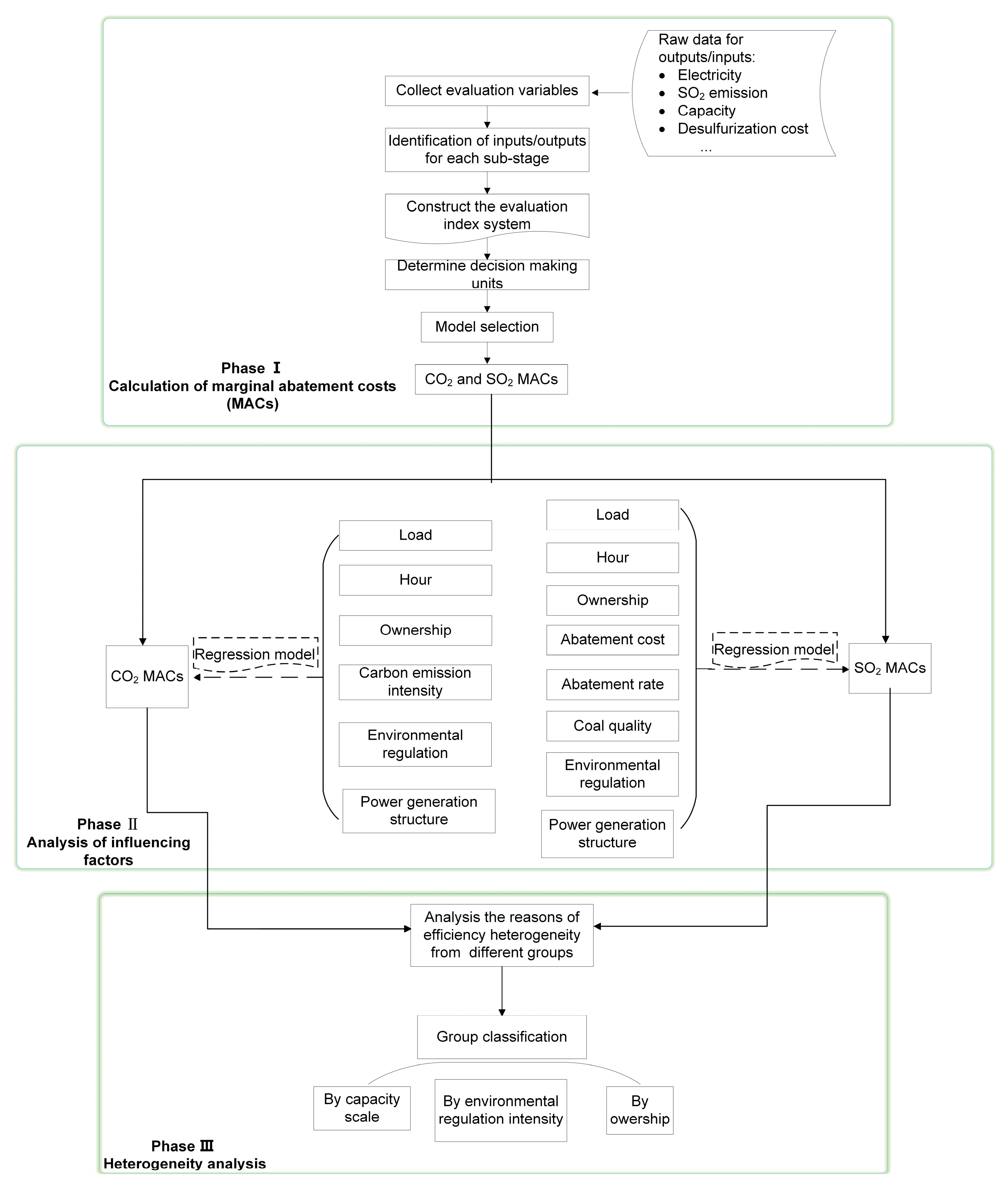

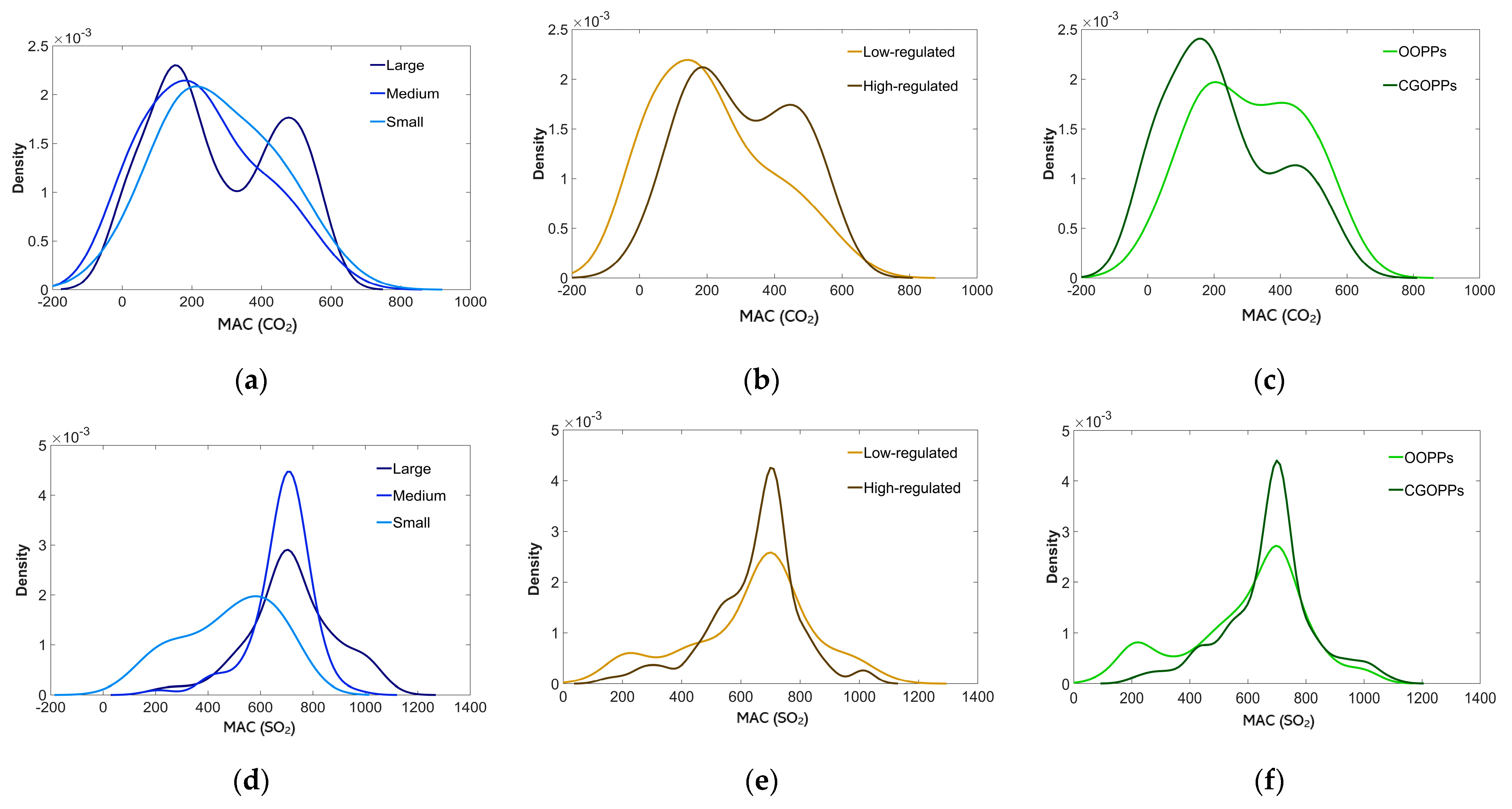

Figure 1 demonstrates a flowchart of our research framework. A three-phase analysis is presented to assess the CO2 and SO2 marginal abatement costs and the impact of possible factors on them. First, we estimate the MACs for CO2 and SO2 of 221 CFPPs in China in 2018. Unlike previous studies, the MACs of CO2 and SO2 are separately derived from the production and cost frontiers based on the input and output index system of the electricity generation stage and the emission abatement stage. Part of the electricity produced in the first stage is used as the variable cost to reduce SO2 emissions. Furthermore, the convex quantile regression (CQR) is carried out to form quantile frontiers to take the inefficiency into account, which can overcome the shortcomings of overestimation that often occurs in most other methods. Second, plant-level factors such as annual operating hours, load, carbon emission intensity, abatement cost, and abatement rate are considered to affect the MACs. Finally, we identify the diversity of results of empirical studies based on heterogeneous grouping by capacity scale, environmental regulation, and ownership.

Figure 1.

Research framework of this study.

3. Methodology

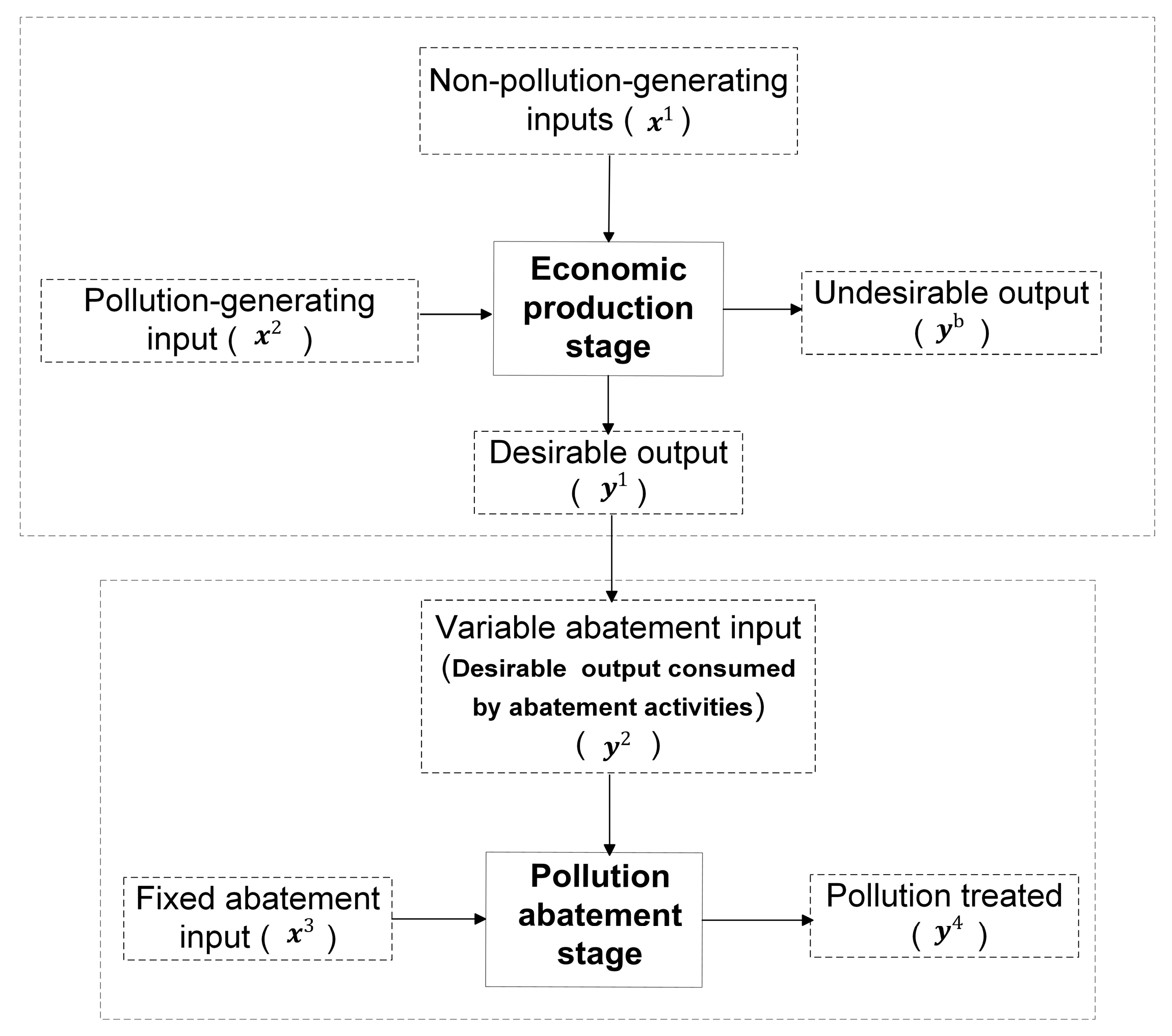

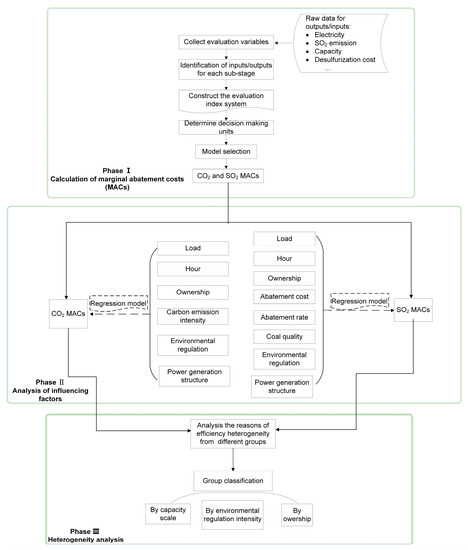

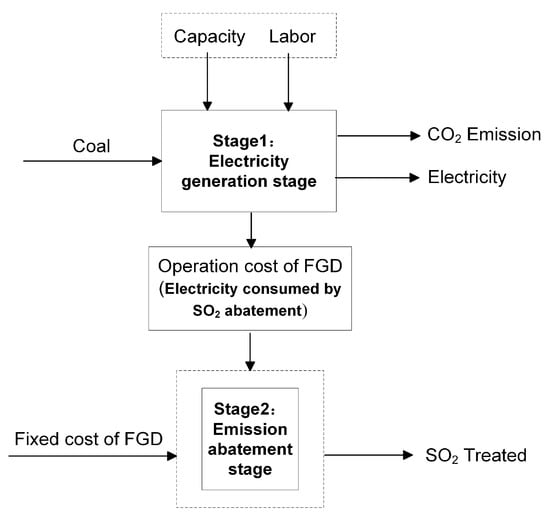

Following Førsund [68], this study divides the production process into two sub-stages—the desirable output production stage and the undesirable output control stage (Figure 2). The production system can be described as follows:

Figure 2.

The production system with a two-stage structure.

In the economic production stage, the non-pollution-generating inputs such as labor and capital are defined as . The pollution-generating input like energy is defined as . The inputs can be converted to the desirable output , and undesirable output with the traditional production technology [69]. Moreover, we assume all the input and desirable output vectors satisfy free disposability, but the undesirable output satisfies cost disposability, consistent with Murty et al. [49], which is detailed in Appendix A. In the abatement stage, the pollution control technology is used to treat undesirable outputs separately from the abatement inputs [68]. Accordingly, the investment cost for the device is denoted as the fixed abatement input, and part of the desirable output used to support the operation of the equipment is regarded as the variable abatement input . Considering the removal efficiency of undesirable output control technology cannot reach 100% in practice, and some undesirable output will still remain, we define the treated pollution as .

The marginal abatement cost of pollutants is usually denoted as the cost paid for each additional pollutant reduction unit by reducing desirable outputs or increasing the input use [23]. In this study, we assume different emission reduction approaches for the production and abatement stages, indicating different MAC estimation methods for the two stages.

At the economic production stage, firms aim to achieve the minimum undesirable output only at the cost of reducing desirable output. Therefore, the MAC is regarded as the marginal rate of transformation between the desirable and undesirable outputs: . We use a benchmark production function which satisfies the disposability assumptions and convexity to describe this process [23].

However, traditional DEA techniques always simply estimate the marginal abatement cost using the full frontiers for all individual aspects, including inefficient ones, which neglects the actual performance of each DMU. Following Kuosmanen et al. [23], we conduct the DDF estimator combined with the quantile formulation, which is better able to deal with scattered data, that is, better able to deal with sensitivity to extreme values during frontier construction [70,71].

Therefore, in the economic production stage, for a given quantile τ, we can solve the following linear programming (LP) problem:

The composite error term is broken down into two non-negative components ( and ) in Model (1). The objective function minimizes the asymmetric absolute deviations from the frontier instead of symmetric deviations. The preassigned weight defines the quantile to be estimated [71]. For example, by setting = 0.05, the function will allow a maximum of 5% of observations to lie above the fitted function and envelope at almost 95% of the observed data points. The first set of constraints is the multivariate regression equation. The second inequality constraint implies the convexity of the production technology. The third set of constraints can be described as the translation property. The fourth constraint imposes the monotonicity assumption. The coefficients , , and characterize the shadow prices of , , and on the efficient frontier under a certain quartile . Accordingly, the MAC of undesirable output can be estimated as .

As for the abatement stage, the firm aims to achieve the minimum undesirable output by installing end-of-pipe abatement devices. Therefore, we describe the MAC as the marginal cost of treated pollutants. Following Kuosmanen [72], a cost function consistent with the classical axioms including monotonic increasing in all outputs and globally convex is defined in this stage. Similar to the classical DEA approach, we do not assume a specific functional form for either function. According to this, the marginal cost of the treated pollutant in the pollution abatement stage is the first derivative of the cost function, which is estimated with the convex quantile regression model shown in Model (2).

In Model (2), is the vector for the total abatement cost of the treated pollutants for the unit ; the coefficient vector can be described as the marginal abatement cost of the treated pollutants, which is also specific under each quantile .

4. Variable Selection and Data Description

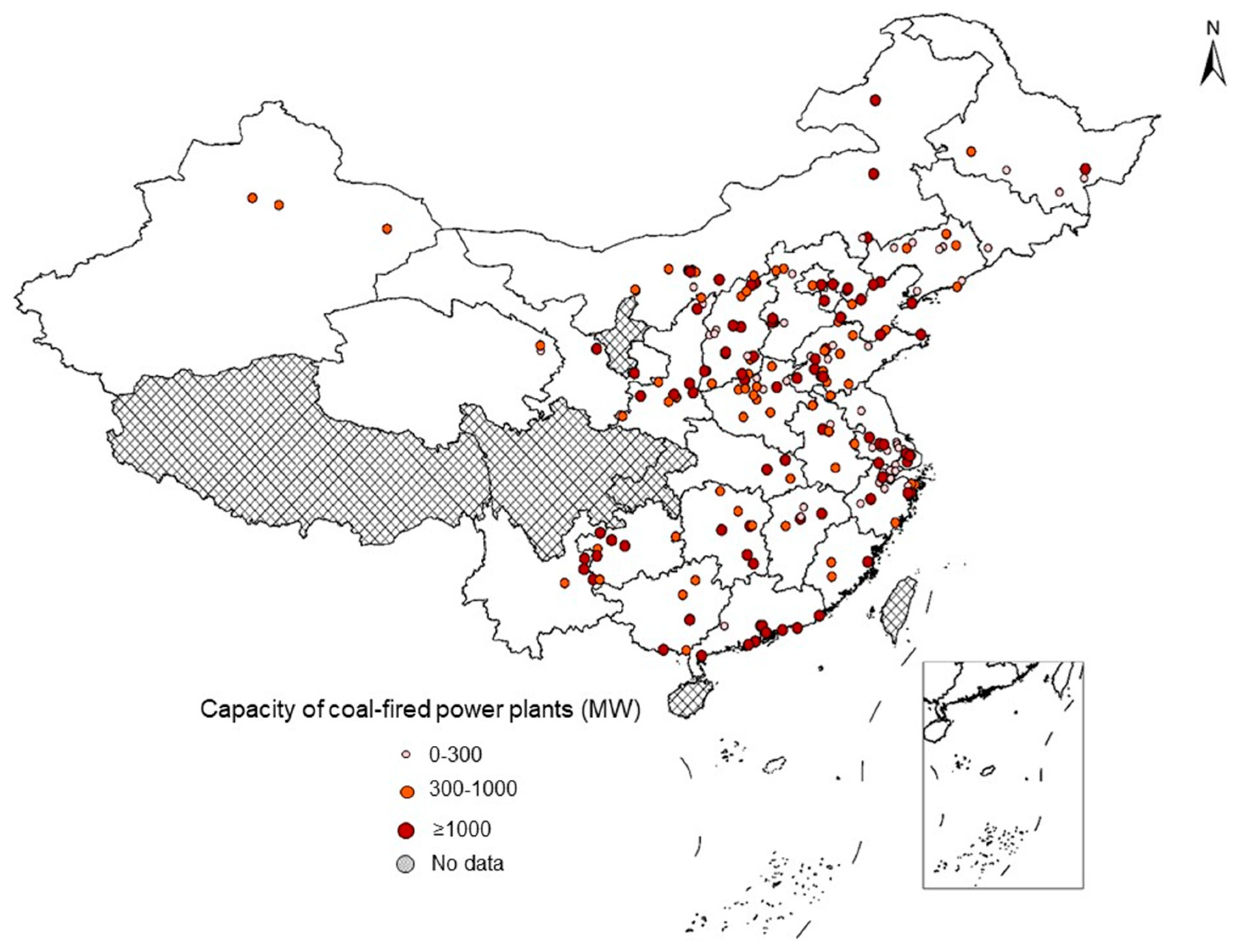

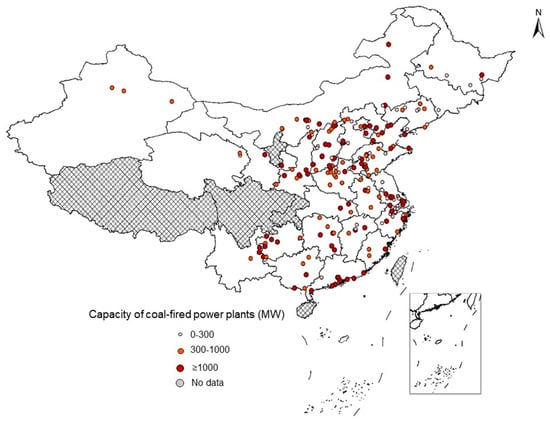

Figure 3 shows the distribution of the selected power plants. The samples in this paper include 221 observations from 26 provinces in China in 2018. Considering that coal-rich regions such as Shanxi, Shaanxi, Inner Mongolia, Henan, Anhui, Yunnan, and Guizhou, as well as areas with a high population density such as Shandong, Hebei, Guangdong, Zhejiang, and Jiangsu, tend to have more coal-fired power plants in China, we also include more CFPPs from these areas in our samples, which is sufficiently similar to the overall distribution of CFPPs in China. In addition, Table 1 shows a wide range of the input and output data for the chosen plants. The heterogeneity among these plants provides the possibility to estimate the production and cost frontiers.

Figure 3.

Geographic distribution of the coal–fired power plants in this study.

Table 1.

Input and output factors.

Table 1 shows the descriptive statistics of the input and output data for the production and abatement stages. The dataset of Chinese coal-fired plants in this study contains operational data from 221 observations in 2018. As data is missing for Xinjiang, Ningxia, Sichuan, Chongqing, Hainan, Macau, and Taiwan, the research area of this study contains 26 provinces of China. This study only considers the treatment of sulfur dioxide by power plants because the cost data for nitrogen oxide removal equipment and dust removal equipment of each power plant were not available.

We collected the basic information about power plants, such as installed capacity, annual operating hours, coal consumption, and electricity generation, from China Electricity Council and China Electricity Statistical Yearbook. As we all know, coal-fired power plants generate electricity accompanied by carbon emissions. Therefore, the method of calculating carbon emissions from burning coal is described as follows [73]:

where is the CO2 emission of the th power plant, is the total coal consumption for electricity generation, and represents the CO2 emission factor for province . is the tons of the net carbon content per trillion joules of energy produced (tC TJ−1), represents the carbon oxidation factor, 44/12 is the molecular weight ratio of CO2 to carbon, and is the heating value for coal consumption by the unit of TJ/104 t. In this study, we collected the carbon oxidation factor, the carbon contents, and the heating value data from the Provincial Emissions Inventory Guideline [74].

The fixed cost of desulfurization equipment is the sum of fixed asset investments associated with desulfurization facilities. Table 2 shows the investment density of the desulfurization device, which is calculated as the rate of the total fixed cost of the FGD equipment and the total installed capacity of each power plant at the 2018 price level. From Table 2, we can see that CFPPs with higher capacities tend to have lower investment densities in desulphurization devices. In particular, the investment density of desulfurization equipment for 1000 MW units could be as low as 130.14 Yuan/kW, while power generation units with 300 MW might only achieve 230.64 Yuan/kW [75].

Table 2.

Investment density of desulfurization equipment.

In this study, we used the concept of annualized investment to calculate the fixed cost of the FGD equipment [76]. The initial investment is equalized over the lifetime of the power plant, and the annual equalized investment is calculated as follows:

where is the coal-fired power plant, is the coal-fired power unit in the power plant, is the annually equalized investment of the FGD equipment, is the annual averaging coefficient. represents the initial total investment of the FGD equipment in the power plant, which is calculated by summing all the power units’ investments. is the discount rate, is the service life of desulfurization equipment in power plants. Referring to Liu [76], we assume a discount rate of 8% and a service lifetime of 20 years for the FGD equipment.

The operation cost of the CFPP mainly includes the cost of materials (absorbent), electricity, water, and labor [77]. Previous studies have proved that electricity consumption of FGD equipment accounts for 76.06–85.9% of the total operating cost [77,78,79]. Therefore, considering the availability of data, we take the electricity cost as the operation cost of FGD equipment, which is calculated by the following equations:

where is the power generation of the th power plant, represents the electricity consumption rate of the FGD equipment. Each power unit for the th power plant may install the FGD equipment in different years, so we use , which indicates the increase of the auxiliary power consumption rate for the th unit from the year before to the year after running the FGD equipment () to define the electricity consumption rate of the FGD equipment for the th power unit. Then, for the th power plant, the electricity consumption rate of the FGD equipment can be calculated by the weighted average of (, where is the proportion of the th coal-fired power unit’s installed capacity to the th power plant’s total installed capacity). According to previous studies, the values of in our sample are within a reasonable range. The details of can be seen in Appendix B (Table A2). is the electricity price in theth province where the th power plant is located. As the on-grid price of each firm was not available, we used the price of each province in 2018 as a substitute—which is shown in Appendix B (Table A1). Then summing up the fixed cost and variable cost , we can obtain the total abatement cost of the th power plant ().

If we do not consider the existence of the desulfurization equipment, the SO2 generation level is mainly related to the sulfur content of coal [73]. Therefore, we used the following equations to calculate the amount of sulfur dioxide being treated:

where represents the SO2 emission factor without considering the abatement process of the power plant, is the sulfur content of coal. Since we do not know the specific coal type of each power plant, we used the average sulfur content of the coal in the province where the power plant is located as a substitute [80]. The average sulfur content of coal in each province is also shown in Appendix B (Table A1). denotes the fraction of sulfur retention in ash, which is uniformly assumed to be 15% in this paper due to the unavailability of data [80]. is the total SO2 generation, is the coal consumption, and and represent final SO2 emission and the amount of SO2 being treated, respectively. We collected the SO2 final emission data for each power plant () from the annual report of each enterprise on the national emission permit information management platform (Available online: http://permit.mee.gov.cn/perxxgkinfo/syssb/xkgg/xkgg!licenseInformation.action (accessed on 12 July 2022). (In Chinese)).

5. Results

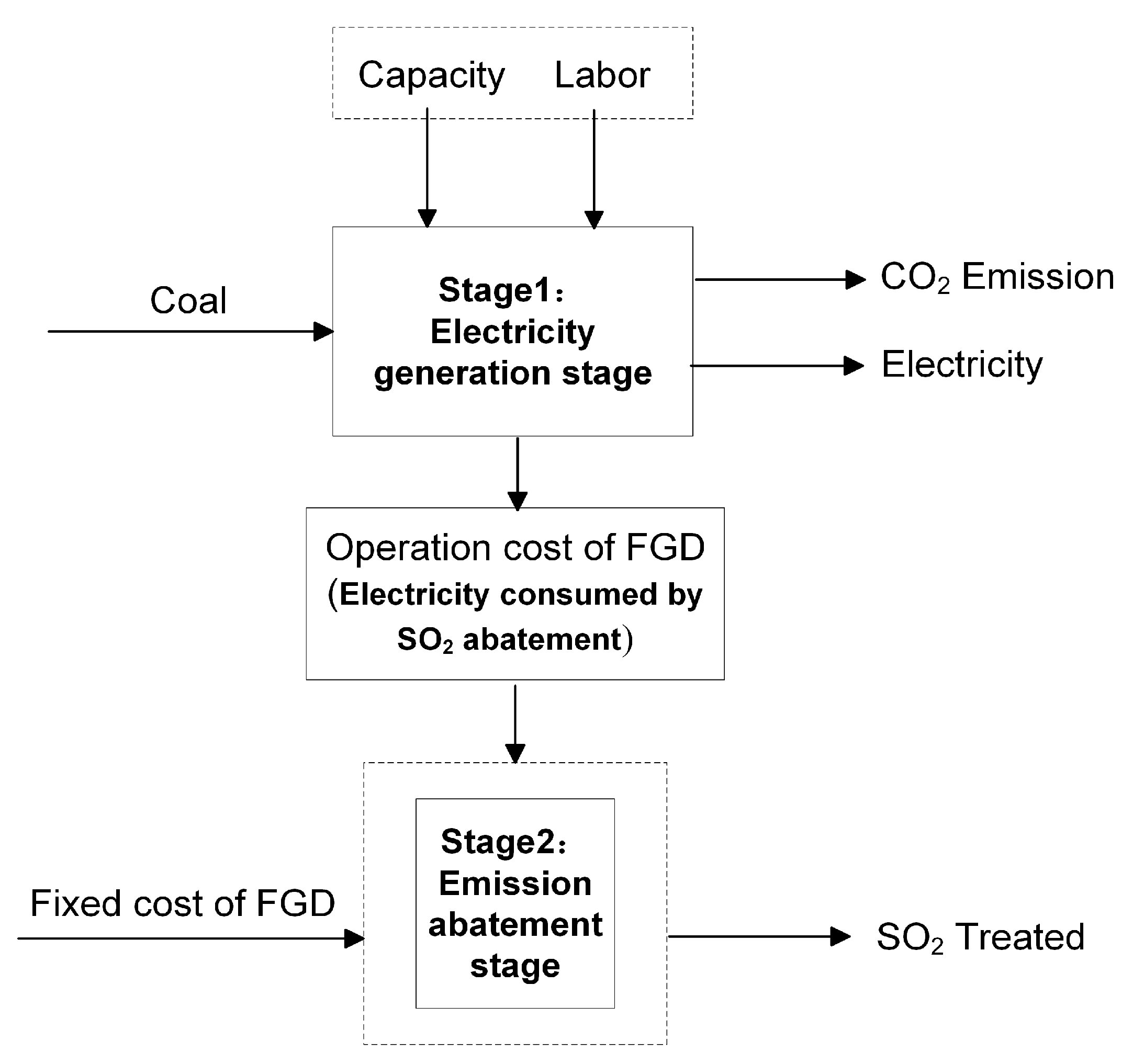

Considering that we divide the power plant production system into two stages, the marginal abatement cost of CO2 in the power production stage and the marginal abatement cost of SO2 in the abatement stage are measured in this section. Following the two-stage production system we established in Section 3, the specific input and output vectors for each stage of the power plant are shown in Figure 4.

Figure 4.

The production and abatement system of the coal-fired power plant.

At the electricity production stage, each power plant has two non-pollution-generating inputs, capacity () and labor (), and one pollution-generating input, coal (), to produce one desirable output electricity () and one undesirable output CO2 emission ().

In the abatement stage, abatement technology was used to reduce pollution as much as possible. Abatement inputs like FGD investment cost () and operation cost () were used to decrease the final SO2 emission level and the treated SO2 is defined as .

We then obtained 221 quantile functions with τ = (1/221, 2/221, 3/221, …, 1) by solving the convex quantile regression models (1) and (2). The solution was performed using the software MOSEK. More detailed information is reported in Table 3.

Table 3.

Descriptive statistics of marginal abatement cost of CO2 and SO2.

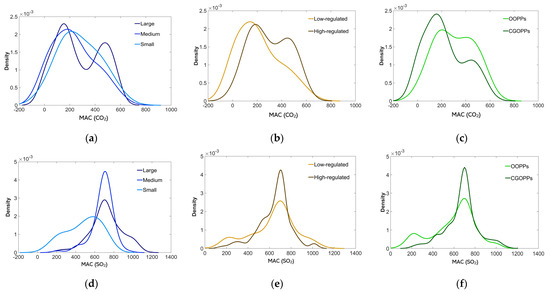

Table 3 summarizes the average, standard deviation, and minimum and maximum values of MACs of CO2 and SO2. The average MACs of CO2 and SO2 for 221 power plants are 367.56 Yuan/ton and 662.30 Yuan/ton, respectively. Referring to other studies on the estimation of MACs, the values of MACs in our study are within a reasonable range. Related references are shown in Appendix B (Table A3). However, the average MAC of SO2 estimated in our study is a little smaller than in other studies as we did not consider the cost of other materials like absorbents, water, and labor. The large standard deviation in the estimated MACs of CO2 and SO2 among the 221 power plants indicates substantial heterogeneity in the behavior of the enterprises with regard to reducing emissions. Therefore, following Zhang et al. [21], we explore the distribution differences of the MAC of CO2 and SO2 in three dimensions: capacity scale, location, and ownership. We classify the 221 CFPPs into three groups according to their installed capacities: small CFPPs—installed capacities smaller than 300 MW, medium-sized CFPPs—between 300 and 1000 MW capacity, and large CFPPs—capacities larger than 1000 MW. Regarding the provincial CO2 emission and SO2 emission reduction targets set in the 13th FYP (2016–2020), we classify the power plants into two groups—high-regulated and low-regulated plants based on the regions in which they are located. Specifically, when discussing the MACs of CO2, we consider those provinces whose CO2 emission reduction targets are lower than 19.5% as low-regulated areas, and the others as high-regulated areas. But when exploring the MACs of SO2, we regard the provinces whose SO2 emission reduction targets are lower than 20% as low-regulated areas, and the others as high-regulated areas. (Detailed information of the provincial CO2 emission and SO2 emission reduction targets for each province is provided in Table A4). Concerning firm ownership, we divide the power plants into central-government-owned power plants (CGOPPs) and other-owned power plants (OOPPs) based on the type of beneficial owner following Lam et al. [81].

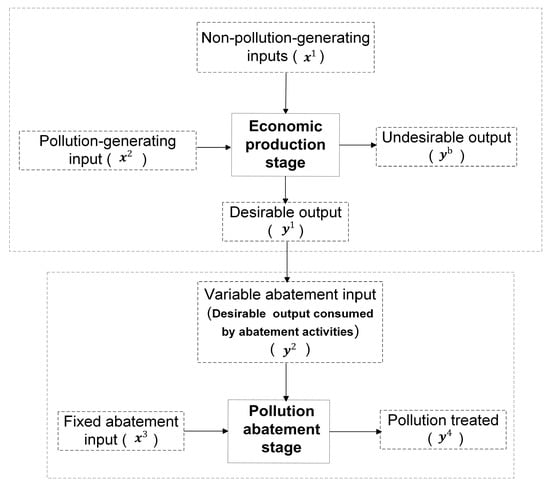

Figure 5 shows the distribution of kernel densities for the MAC of CO2 and SO2 in different groups. Significant differences exist across the scale, the intensity of environmental regulation, and ownership. As Figure 5a shows, the distribution of CO2 for large power plants is bimodal. The first wave peak is significantly higher than the second, indicating that the share of large plants with lower CO2 MACs is larger than those with higher CO2 MACs. Similarly, the small and medium CFPPs also have convergence clubs near the first wave peak of large plants, but both are located to the right of the kernel density curve of large power plants. Considering the difference from the intensity of environmental regulation, as shown in Figure 5b, the kernel density curve of high-regulated CFPPs is to the right of low-regulated CFPPs, indicating that the abatement cost of high-regulated CFPPs is relatively high. This result is consistent with Zhang et al. [21], who demonstrated that high-regulated firms tend to be equipped with a high level of emission reduction technology, thus leading to high MACs. Figure 5c provides the distribution of MACs of CO2 for CFPPs with different ownerships. The kernel density curve of CGOPPs is obviously to the left of OOPPs, revealing that most CGOPPs show higher carbon emission reduction potential than OOPPs due to their lower MACs of CO2. This is reasonable because state-owned power plants usually have cheaper abatement costs since they can get more financial support from central and local governments [21,32].

Figure 5.

Kernel density distributions of CO2 and SO2 marginal abatement costs with different groups: (a) Kernel density plot of CO2 marginal abatement costs for large, medium-sized, and small CFPPs; (b) Kernel density plot of CO2 marginal abatement costs for high- and low-regulated CFPPs; (c) Kernel density plot of CO2 marginal abatement costs for CGOPPs and OOPPs; (d) Kernel density plot of SO2 marginal abatement costs for large, medium, and small CFPPs; (e) Kernel density plot of SO2 marginal abatement costs for high- and low-regulated CFPPs; (f) Kernel density plot of SO2 marginal abatement costs for CGOPPs and OOPPs.

Compared with CO2, the distributions of kernel densities for the MAC of SO2 in different groups show different variations (Figure 5d–f). The kernel density curves of large and medium power plants are both to the right of small power plants (Figure 5d), indicating that the MACs of SO2 of large and medium power plants are significantly larger than that of small ones. This can be explained by the performance gap of FGD equipment in large, medium, and small power plants. Previous studies have demonstrated that large power plants tend to be equipped with more advanced equipment, whether for electricity production or pollution abatement [82,83]. Our study sample also shows that large and medium-sized power plants have higher SO2 control rates at average levels of 98.6% and 97.83%, respectively, while small power plants only achieve 91.22% at average levels. Figure 5e,f show that the kernel density curves of high-regulated CFPPs and CGOPPs also have narrow widths, indicating that the marginal abatement costs for these two kinds of CFPPs are more convergent to the peak value. This can be attributed to the fact that high-regulated CFPPs and CGOPPs prefer to purchase high-end abatement equipment due to the stricter environmental regulations and the positive response to stronger investment capacity. Their great demands on FGD equipment then give those FGD engineering companies that provide them with desulfurization equipment an inherent advantage and a higher market share. Consequently, a more uniform standard for technical indicators such as emission reduction rate as well as investment intensity for desulfurization equipment may exist in such companies. Therefore, the distribution of MACs for SO2 can be more concentrated in high-regulated CFPPs and CGOPPs.

6. Discussion

To identify the determinants of the MACs for CO2 and SO2, we selected variables to construct a Tobit regression analysis for the marginal abatement costs of CO2 and SO2, respectively, and conducted a heterogeneity analysis. The details can be seen in Section 6.1 and Section 6.2.

6.1. Influencing Factors of CO2 Marginal Abatement Costs

Previous studies have demonstrated that the factors influencing the MAC of CO2 include emission reduction policies, carbon emissions, carbon intensity, power generation structure, and ownership [9,29,47]. However, considering that this study analyzes factors at the plant level, we also take into account the technical indicators of power plant operation, such as the load and annual operating hours of power plants. Therefore, we assume the following six variables can influence the MAC of CO2:

CARBON INTENSITY (CEI). We use the CO2 emissions per unit of electricity generated to describe the carbon emission intensity of each power plant. Given that power plants with high carbon intensity have more room for improvement in carbon emission reduction and are expected to have lower abatement costs, a negative coefficient is predicted for this indicator.

LOAD. An independent variable that indicates the capacity utilization ratio of the power plant, calculated as the ratio of the actual operating capacity to the installed capacity, where the actual operating capacity is defined as the ratio of electricity generation to operating hours. Typically, it is easier for power plants with low electricity generation loads to increase their efficiency by increasing their operating capacity and thus achieve emission reductions [46], which indicates that their abatement costs will be lower, so the coefficient is expected to be negative.

HOUR. An independent variable denotes the annual operating hours of each power plant. This variable has also been illustrated to have a significant positive effect on the efficiency of power plants in other studies [34,84]. Therefore, we assume that it will also have a negative effect on the MAC of CO2.

POWER GENERATION STRUCTURE (PGS). An independent variable indicates the proportion of clean power generation in the power supply. Accordingly, we denote it by the percentage of clean energy generation in the region where the power plant is located. Generally, the lower the percentage of clean power generation in a region, the more thermal power will be there. Therefore, the more room there is for coal-fired power plants in that region to reduce carbon emissions, the lower the abatement cost. Thus, the coefficient is expected to be positive.

ENVIRONMENTAL REGULATION (ERC). Due to the group heterogeneity between high-regulated and low-regulated CFPPs in terms of the MAC of CO2, we assume that the local carbon emission reduction targets may have certain impacts on the CO2 marginal abatement costs.

OWNERSHIP (CGO). To evaluate the effect of ownership on the CO2 marginal abatement costs, we use dummy variables with 0 and 1 to denote OOPPs and CGOPPs, respectively.

The regression results are shown in Table 4. CEI has a significantly negative effect on the MAC of CO2 at the 0.01 level, implying that as the intensity of carbon emissions decreases, power plants will have less room to release their carbon reduction potential. On average, an increase of one unit of carbon emission intensity will result in a 2.507-unit decrease in MACs of CO2. In addition, we find that both technical indicators (LOAD and HOUR) have significant negative effects on the MACs of CO2. The coefficients are all significant at the 0.01 level, meaning that increasing the capacity utilization ratio and raising the operating hours of a power plant can simultaneously decrease the cost of carbon emission reduction. This is reasonable because the high load and more operating hours can contribute to a more efficient electricity generation [46,84,85]. Additionally, the power generation structure (PGS) can positively affect the MAC of CO2 with a coefficient of 258.077 at the 0.01 level. The main reason is that a smaller PGS indicates a larger proportion of thermal power in the power generation structure, which can then lead to higher carbon emissions from power generation and a larger potential for emission reduction. Subsequently, the cost of emission reduction is relatively lower.

Table 4.

Baseline regression analysis.

We found that power plants with different installed sizes, ownership, and environmental regulation intensities exhibit significant variations in the MACs of CO2. Furthermore, we investigated whether these elements play a role in the effect of the specific factors regressed on the MACs of CO2. The detailed regression results are shown in Table 5. The cost of reducing CO2 emissions from large power plants is not only more sensitive to their own technical specifications, such as carbon intensity, capacity utilization ratio and operating hours, but also more affected by external factors. To be specific, CEI, LOAD, and HOUR all have a significant negative impact on the CO2 marginal abatement costs for large, medium, and small plants but show huge differences in terms of the influencing degree. The CEI factor’s effect on MACs of CO2 in large power plants (−4.159) is almost twice as large than that of medium and small plants. The LOAD factor, which has an impact on the MAC of CO2 of large plants with coefficients of (−299.452), is almost 1.5 times larger than that of medium plants (−192.013) and 10 times greater than that of small plants (−26.142). Moreover, the MAC of CO2 for large and medium-sized power plants can also be positively affected by the power generation structure of the region in which they are located, with coefficients of 237.75 and 219.407. The results in Table 5 additionally indicate that high-regulated CFPPs are more affected by the listed factors, especially for LOAD (−152.727), which is almost six times larger than that of low-regulated CFPPs (−25.231). This can be explained by the fact that some regions may limit the operating hours of CFPPs or require them to operate at low loads to meet the high carbon emission reduction targets and achieve a significant reduction in total carbon emissions, which will also significantly increase the MAC of CO2. Considering ownership, the coefficient of CEI to the MAC of CO2 for CGOPPs is larger (−2.831 than −2.374), indicating that the MAC of CGOPPs is more sensitive to a change in CEI. Meanwhile, higher coefficients of LOAD (−211.854) and HOUR (−0.052) for MAC of CO2 of CGOPPs are in line with our finding that CGOPPs still have a larger space for emission reduction, which can be realized by increasing the load or the operating hours.

Table 5.

Heterogeneity analysis of influencing factors on MACs of CO2.

6.2. Influencing Factors of SO2 Marginal Abatement Costs

In addition to the operation indicators LOAD and HOUR, the environmental regulation intensity (SO2 reduction targets for each province) ERS, electricity supply structure PGS, and ownership CGO influence the MAC of SO2, so we also consider the following factors:

AVERAGE COST (AC): an independent variable that indicates the cost of reducing one unit of SO2, calculated as the ratio of the total cost of FGD equipment to the controlled SO2, where the actual operating capacity is defined as the ratio of electricity generation to operating hours. It has been generally accepted that marginal cost will also increase as the average cost increases. Therefore, we assume there is a positive relationship between AC and the MAC of SO2.

ABATEMENT RATE(AR): this variable describes the SO2 abatement rate. A higher abatement rate always represents less room for reducing one more unit of SO2. Thus, we also assume a positive correlation between AR and MAC of SO2.

COAL QUALITY (CQ): an independent variable that indicates the sulfur content of coal consumed by each power plant. Given that the higher the sulfur content of the coal, the more sulfur dioxide will be yielded by burning the coal, meaning there is more room for improvement in SO2 emission reduction, we assume that the sulfur content of coal will have a negative impact on the MAC of SO2.

From Table 4, we can identify that both AC and AR have a significantly positive effect on the MAC of SO2 with coefficients of 22.732 and 11.448 at the 0.05 and 0.01 levels, respectively. It is also important to note that the coefficients of operation indicators of CFPPs like LOAD and HOUR are insignificant. Such a difference between CO2 and SO2 indicates that considering the existence of abatement constraints, the MAC of SO2 is more closely linked to the abatement behavior of enterprises including the cost of their abatement inputs and the advancement of their FGD equipment. In addition, we also found that the effects of environmental regulation intensity and ownership on the MAC of SO2 are the opposite to that of CO2. Environmental regulation, however, is irrelevant. This can be attributed to the fact that during the 11th FYP and the 12th FYP, the Chinese government strictly required all coal-fired operating units to install FGD facilities. By the end of 2016, the proportion of thermal power units with FGD was close to 100%. As a remarkable result, coal power’s sulfur dioxide emission intensity decreased significantly from 2005 to 2016 [86]. Therefore, the SO2 reduction targets do not have an obvious incentive on the abatement behavior of the power plant due to the prominent SO2 reduction effect of the FGD equipment. It is worth pointing out that the coefficients of CGO are quite the opposite between CO2 and SO2, implying a large difference between the carbon and pollutant reduction methods in enterprises, especially for CGOPPs. CGOPPs have the advantage of super-enterprise scale and ample capital, which will reduce their MACs of CO2. However, end-of-pipe abatement technologies may weaken the link between pollutant abatement such as SO2 reduction and electricity generation. Hence, CGOPPs can acquire advanced abatement devices to achieve higher abatement rates with high MACs of SO2. Furthermore, the CQ factor shows a significant negative impact on the MAC of SO2 (−180.721), implying that when CFPPs produce electricity with coal of a lower sulfur content, they are more likely to face a higher MAC of SO2.

Similarly, to further identify whether the influencing factors exist group heterogeneity, we also conducted several regression models in these three dimensions: capacity scale, location, and ownership. The details are listed in Table 6.

Table 6.

Heterogeneity analysis of influencing factors on MACs of SO2.

As expected, the AC factor has a larger impact on large (78.01) and medium (46.271) CFPPs than on small ones (31.063). Furthermore, we found that coal quality is another key factor influencing the MAC of SO2 of large and medium-sized power plants. The reason is that large and medium-sized power plants always need to consume large amounts of coal, and the abatement cost of SO2 is more sensitive to the sulfur content of coal. The coefficient of LOAD is significantly negative for both high-regulated CFPPs and CGOPPs with the values of −129.813 and −157.489, respectively. This implies that end-of-pipe abatement can be affected by the operating condition of power-generating units. Therefore, improving the operation efficiency of power units could achieve a synergistic reduction in the MAC of CO2 and SO2.

7. Conclusions and Policy Suggestions

This paper considers a two-stage production system for CFPPs: an electricity generation stage and a pollution abatement stage. Specifically, noting that electricity generation enterprises tend to select different ways to treat CO2 and SO2, respectively, we define the MAC of CO2 as the marginal rate of transformation between desirable and undesirable outputs, and regard the MAC of SO2 in the pollution abatement stage as the marginal cost of the treated pollutant. After combining the quantile formulation with the traditional DDF estimator and the marginal cost estimation, we further analyzed the heterogeneous characteristics of the MACs in three dimensions: capacity scale, location, and ownership. In addition, the effect of possible influencing factors on the MACs of CO2 and SO2 emission is also discussed with a few regression models.

The results show that the average levels of the MACs of CO2 and SO2 for 221 CFPPs are 367.56 Yuan/ton and 662.30 Yuan/ton, indicating that it would cost them on average 367.56 yuan and 662.30 yuan to reduce one more ton of CO2 and SO2, respectively. The results of the heterogeneous analysis of the CO2 MACs prove that on the whole large power plants possess lower CO2 MACs compared with medium and small plants, though some of the large power plants obviously had high MACs of CO2 with low CO2 reduction potential. Furthermore, CFPPs not owned by central government (OOPPs) and high-regulated CFPPs have higher MACs of CO2 than CGOPPs and low-regulated CFPPs. However, the heterogeneous characteristics of SO2 MACs do not show similar trends. To be precise, the MACs of SO2 for large and medium-sized power plants are significantly larger than those for small power plants, but the distribution is more concentrated for large power plants. Moreover, the distribution of MACs of SO2 for high-regulated CFPPs and CGOPPs is also more centrally concentrated at higher levels.

The results of the regression model indicate that factors such as carbon emission intensity, provincial electricity generation structure, and provincial CO2 emission reduction targets can all positively affect the MACs of CO2 of CFPPs. The operation indicators of CFPPs like LOAD and HOUR can also significantly decrease the MAC of CO2, while the SO2 MACs are less likely to be influenced by such factors, but strongly affected by the emission reduction costs and the abatement rate of certain equipment. In addition, we also explore the differences in terms of the influencing degree of these factors. It can be concluded that large- and medium-sized power plants are likely to spend more for further CO2 and SO2 emission reductions. On the one hand, they are more sensitive to the changes of their own carbon emission intensities and external factors like environmental regulation. On the other hand, given their large pollution generation, they are likely to invest more in pollution treatment. Furthermore, improving the operating condition of CFPPs like LOAD and HOUR could more significantly decrease the MACs of CO2 and SO2 for both high-regulated CFPPs and CGOPPs.

Based on the above analysis, we propose the following policy recommendations:

First, the electricity generation capacity rather than the installed capacity of China’s CFPPs should be given adequate attention. The overcapacity problem in China’s coal-fired power sector is widespread, but even now electricity shortages can occur seasonally, rooted in a lack of operating capacity at coal-fired power plants. For coal-fired power plants, generating electricity with low load or insufficient hours will significantly harm their comprehensive efficiency levels in terms of increasing the coal consumption per unit of electricity generation or reducing the thermal efficiency of the boiler, which could have a negative impact on their economic and environmental benefits. Therefore, the government should strengthen its guiding role in power planning, carefully analyze the situation around the country and strengthen the rationality and practicality of the national power supply design. A boom in power supply construction should also be avoided, as it would result in wasteful resource allocation and increase the overall cost of the power sector.

Second, the existing large gap in marginal abatement costs for CO2 and SO2 across CFPPs suggests that a market-oriented emissions trading system would indeed have considerable benefits for reducing emissions from the coal-fired power sector, in particular encouraging coal-fired power companies to take action to reduce emissions. Therefore, the government should reasonably limit financing support for backward projects of high-emission enterprises with the help of the guiding ability of the market mechanism, and force high-emission enterprises to actively carry out industrial upgrading and transformation to achieve green and coordinated development, which will in turn bring about a sustainable positive impact. In addition, the price formation mechanism should be improved in the design of the national emissions trading market system, and the guiding role of the emissions trading market on the behavior of enterprises should be given full play.

Third, after analyzing the possible factors’ effects on CO2 and SO2 marginal abatement costs, we believe that both high-regulated and central-government-controlled CFPPs show larger pollution abatement potentials. Therefore, on the one hand, considering that command-and-control environmental regulation policies have significantly restricted the production activities of high-regulated power plants, the government could prioritize the improvement of market-based mechanisms in the implementation of environmental policies in those high-regulated regions, and maximize the release of the economic dividend effect of the policies through some market-based incentive instruments such as electricity price subsidy policies and emissions trading systems to promote green economic development. On the other hand, the government should pay more attention to the motivation of CGOPPs to reduce emissions, and implement a proper environmental impact assessment system for them to supervise high-pollution projects.

This paper still has limitations. First, we only estimate the MAC of coal-fired power plants in China. For subsequent research, we would consider estimating the MAC of pollutants for firms from other industrial sectors such as the mining and manufacturing industries. Further study could also include more countries in the sample. Second, the data we use in this paper is just cross-sectional data from 2018, which cannot reveal the dynamic characteristics of MACs. Therefore, the usage of an expanded panel data is necessary for further work.

Author Contributions

Conceptualization, B.G. and Z.S.; Formal analysis, B.G.; Funding acquisition, Z.S.; Investigation, B.G.; Methodology, Z.S. and B.G.; Project administration, Z.S.; Resources, B.G.; Supervision, Z.S.; Validation, B.G. and Z.S.; Writing original draft, B.G. and Z.S.; Writing review editing, Z.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the National Natural Science Foundation of China, Grant No. 71704095; Shandong Social Science Planning Research Project, Grant No. 22CJJJ24; Humanities and Social Science Project of Shandong Province, Grant No. 2021-YYJJ-09; Young Scholars Program of Shandong University Weihai, and the National Social Science Foundation of China, Grant No. 21BGL304.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All data and materials will be available based on reader request.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

The traditional production function cannot describe the by-production relationship between desirable and undesirable outputs. Therefore, according to Färe et al. [62], the basic model can be described as the following equation:

Both the input and the undesirable output vectors satisfy the free disposability as shown in assumptions (A2), which means that keeping outputs and constant, the technology set can absorb any number of additional inputs and, similarly, leaving the inputs unchanged, additional desirable outputs can be disposed without any cost. However, Murty et al. [49] also pointed that under a certain level of pollution-generating inputs, undesirable outputs were just possible to be maintained as a minimum level, and any further reduction of undesirable outputs would need an extra cost, indicating the weak disposability of undesirable outputs.

Appendix B

Table A1.

Electricity price and sulfur content of coal of each province in 2018.

Table A1.

Electricity price and sulfur content of coal of each province in 2018.

| Province | Electricity Price (Yuan/kWh) | Sulfur Content of Coal (%) |

|---|---|---|

| Anhui | 0.3828 | 0.48 |

| Beijing | 0.3705 | 0.56 |

| Fujian | 0.3893 | 0.65 |

| Gansu | 0.2953 | 0.73 |

| Tianjin | 0.3519 | 0.76 |

| Hebei | 0.3209 | 1.02 |

| Shandong | 0.4110 | 1.09 |

| Shanxi | 0.3216 | 1.1 |

| Inner Mongolia | 0.2725 | 0.79 |

| Liaoning | 0.3706 | 0.64 |

| Jilin | 0.3654 | 0.38 |

| Heilongjiang | 0.3735 | 0.33 |

| Shaanxi | 0.3268 | 1.29 |

| Ningxia | 0.2487 | 1.07 |

| Qinghai | 0.2802 | 0.8 |

| Xinjiang | 0.2151 | 0.58 |

| Shanghai | 0.4102 | 0.59 |

| Jiangsu | 0.3919 | 0.79 |

| Zhejiang | 0.4163 | 0.76 |

| Hubei | 0.4365 | 1.27 |

| Hunan | 0.4590 | 1.1 |

| Henan | 0.3562 | 0.77 |

| Jiangxi | 0.4182 | 1.13 |

| Sichuan | 0.4403 | 1.67 |

| Chongqing | 0.4126 | 3.04 |

| Guangdong | 0.4411 | 0.69 |

| Guangxi | 0.3994 | 1.88 |

| Yunnan | 0.4125 | 1.23 |

| Guizhou | 0.3324 | 2.43 |

| Hainan | 0.4385 | 1.08 |

Table A2.

The reference value of power consumption rate of desulfurization facilities.

Table A2.

The reference value of power consumption rate of desulfurization facilities.

| 0–300 MW | 300–600 MW | 600–1000 MW | ||||

|---|---|---|---|---|---|---|

| Related Research | Capacity (MW) | Power Consumption Rate (%) | Capacity (MW) | Power Consumption Rate (%) | Capacity (MW) | Power Consumption Rate (%) |

| Du et al. [87] | 200 | 1.49 | 600 | 1.21 | 1000 | 0.95 |

| 300 | 1.4 | |||||

| Wang et al. [88] | 300 | 1.75 | ||||

| Yang et al. [89] | 300 | 1.78 | ||||

| Li et al. [90] | 300 | 1.5 | ||||

| Yuan [91] | 300 | 1.04 | 320 | 1.15 | 600 | 1.04 |

| 300 | 1.01 | 320 | 0.96 | 600 | 0.97 | |

| 300 | 1.15 | 320 | 1.29 | 600 | 0.93 | |

| 300 | 1.09 | 320 | 1.63 | 600 | 0.9 | |

| 300 | 1.2 | 325 | 0.9 | 600 | 1.27 | |

| 300 | 1.21 | 325 | 1.09 | 600 | 1.36 | |

| 300 | 1.41 | 325 | 0.94 | 600 | 1.29 | |

| 300 | 1.47 | 325 | 0.99 | 600 | 1.6 | |

| 300 | 1.5 | 325 | 1.23 | 600 | 1.32 | |

| 300 | 1.51 | 330 | 1.33 | 630 | 1.06 | |

| 300 | 1.77 | 330 | 1.56 | 1000 | 1.63 | |

| 330 | 1.61 | |||||

| 350 | 0.93 | |||||

| 350 | 1.15 | |||||

| 350 | 1.03 | |||||

| 350 | 1.3 | |||||

| 350 | 1.04 | |||||

| 350 | 1.03 | |||||

| Jiang et al. [92] | 300 | 1.18 | 315 | 1.69 | 600 | 1.08 |

| 300 | 1.16 | 315 | 1.53 | 635 | 0.92 | |

| 300 | 1.21 | 330 | 1.44 | 660 | 0.82 | |

| 300 | 1.22 | 330 | 1.32 | 660 | 0.9 | |

| 300 | 1.71 | 330 | 1.13 | 670 | 2.12 | |

| 300 | 1.97 | 330 | 1.1 | 670 | 1.93 | |

| 300 | 1.08 | 335 | 1.55 | 1000 | 1.63 | |

| 300 | 1.93 | 335 | 1.55 | 1000 | 0.83 | |

| 300 | 1.54 | 335 | 1.48 | 1000 | 0.86 | |

| 335 | 1.25 | 1000 | 1.38 | |||

| 335 | 2.02 | 1000 | 1.28 | |||

| Mo et al. [93] | 330 | 1.197 | ||||

| 330 | 1.205 | |||||

| Xu et al. [94] | 350 | 0.622–1.095 | ||||

| 350 | 0.612–0.155 | |||||

| Han [95] | 430 | 1.6 | ||||

| Long et al. [96] | 600 | 1.01 | ||||

| 600 | 1.778 | |||||

| 600 | 1.98 | |||||

| Yu et al. [97] | 600 | 1.92 | ||||

| Qiu et al. [98] | 600 | 1.13 | ||||

| 600 | 1.62 | |||||

| Cheng [99] | 660 | 0.6–0.7 | ||||

| Jiang et al. [100] | 1000 | 0.918 | ||||

| 1000 | 0.973 | |||||

| Xu et al. [101] | 1000 | 1.18 | ||||

| 1000 | 1.1 | |||||

Table A3.

The reference value of MACs of CO2 and SO2.

Table A3.

The reference value of MACs of CO2 and SO2.

| Related Research | Research Scale | Year | MAC (CO2) | MAC (SO2) |

|---|---|---|---|---|

| Wu et al. [102] | Power industry | 2005–2015 | 533.71–588.38 Yuan/ton | |

| Liu et al. [45] | Power industry | 2020–2035 | 0.15 Yuan/ton~1133 Yuan/ton | |

| ICCSD [103] | National level | 2030–2050 | 126 Yuan/ton~1364 Yuan/ton | |

| Wang et al. [104] | Provincial level | 2015–2020 | 18.8~37.1 USD/ton | |

| Lu et al. [105] | Plant level | 2015 | 250–800 Yuan/ton | |

| Yang et al. [106] | Plant level | 2015 | 1296–3662 Yuan/ton | |

| Ma et al. [107] | Plant level | 2000–2010 | 1024–1529 Yuan/ton | |

| Luo [44] | Plant level | 2017 | 1453.2–12306.5 Yuan/ton |

Table A4.

The provincial CO2 and SO2 emission reduction targets.

Table A4.

The provincial CO2 and SO2 emission reduction targets.

| Province | CO2 Emission Reduction Target (%) | SO2 Emission Reduction Target (%) |

|---|---|---|

| Anhui | 18 | 16 |

| Beijing | 20.5 | 35 |

| Fujian | 19.5 | - |

| Gansu | 17 | 8 |

| Tianjin | 20.5 | 25 |

| Hebei | 20.5 | 28 |

| Shandong | 20.5 | 27 |

| Shanxi | 18 | 20 |

| Inner Mongolia | 17 | 11 |

| Liaoning | 18 | 20 |

| Jilin | 18 | 18 |

| Heilongjiang | 17 | 11 |

| Shaanxi | 18 | 15 |

| Ningxia | 17 | 12 |

| Qinghai | 12 | 6 |

| Xinjiang | 12 | 3 |

| Shanghai | 20.5 | 20 |

| Jiangsu | 20.5 | 20 |

| Zhejiang | 20.5 | 17 |

| Hubei | 19.5 | 20 |

| Hunan | 18 | 21 |

| Henan | 19.5 | 28 |

| Jiangxi | 19.5 | 12 |

| Sichuan | 19.5 | 16 |

| Chongqing | 19.5 | 18 |

| Guangdong | 20.5 | 3 |

| Guangxi | 17 | 13 |

| Yunnan | 18 | 1 |

| Guizhou | 18 | 7 |

| Hainan | 12 | - |

References

- IEA. Global Energy & CO2 Status Report 2019; IEA: Paris, France, 2019; Available online: https://www.iea.org/reports/global-energy-co2-status-report-2019 (accessed on 9 August 2022).

- Nakaishi, T. Developing effective CO2 and SO2 mitigation strategy based on marginal abatement costs of coal-fired power plants in China. Appl. Energy 2021, 294, 17. [Google Scholar] [CrossRef]

- IEA. Energy Statistics Data Browser. Available online: https://www.iea.org/data-and-statistics/data-tools/energy-statistics-data-browser (accessed on 15 July 2022).

- CEC. Annual Development Report of China’s Power Industry; China Building Materials Press: Beijing, China, 2021; ISBN 978-7-5160-3261-9. [Google Scholar]

- Wang, C.; Du, X.; Rao, C. Supplier selection mechanism in electric coal procurement under sustainability. Environ. Sci. Pollut. Res. 2021, 28, 51674–51692. [Google Scholar] [CrossRef] [PubMed]

- Peng, H.-R.; Cui, J.; Zhang, X. Does China emission trading scheme reduce marginal abatement cost? A perspective of allowance allocation alternatives. Sustain. Prod. Consum. 2022, 32, 690–699. [Google Scholar] [CrossRef]

- Huang, Y.-H.; Wu, J.-H.; Liu, T.-Y. Bottom-up analysis of energy conservation and carbon dioxide mitigation potentials by extended marginal abatement cost curves for pulp and paper industry. Energy Strategy Rev. 2022, 42, 100893. [Google Scholar] [CrossRef]

- Cheng, J.; Xu, L.; Wang, H.; Geng, Z.; Wang, Y. How does the marginal abatement cost of CO2 emissions evolve in Chinese cities? An analysis from the perspective of urban agglomerations. Sustain. Prod. Consum. 2022, 32, 147–159. [Google Scholar] [CrossRef]

- Wang, Z.; Chen, H.; Huo, R.; Wang, B.; Zhang, B. Marginal abatement cost under the constraint of carbon emission reduction targets: An empirical analysis for different regions in China. J. Clean. Prod. 2020, 249, 119632. [Google Scholar] [CrossRef]

- Zhao, S.; Qiao, G. The shadow prices of CO2, SO2 and NOx for U.S. coal power industry 2010–2017: A convex quantile regression method. J. Prod. Anal. 2022, 57, 243–253. [Google Scholar] [CrossRef]

- Shen, Z.; Bai, K.; Hong, T.; Balezentis, T. Evaluation of carbon shadow price within a non-parametric meta-frontier framework: The case of OECD, ASEAN and BRICS. Appl. Energy 2021, 299, 117275. [Google Scholar] [CrossRef]

- Zeng, S.; Jiang, X.; Su, B.; Nan, X. China’s SO2 shadow prices and environmental technical efficiency at the province level. Int. Rev. Econ. Financ. 2018, 57, 86–102. [Google Scholar] [CrossRef]

- Yang, H.; Zhang, Y.; Zheng, C.; Wu, X.; Chen, L.; Fu, J.S.; Gao, X. Cost estimate of the multi-pollutant abatement in coal-fired power sector in China. Energy 2018, 161, 523–535. [Google Scholar] [CrossRef]

- Dai, S.; Zhou, X.; Kuosmanen, T. Forward-looking assessment of the GHG abatement cost: Application to China. Energy Econ. 2020, 88, 104758. [Google Scholar] [CrossRef]

- Fare, R.; Grosskopf, S.; Lovell, C.A.K.; Yaisawarng, S. Derivation of shadow prices for undesirable outputs: A distance function approach. Rev. Econ. Stat. 1993, 75, 374–380. [Google Scholar] [CrossRef]

- Wei, C.; Löschel, A.; Liu, B. An empirical analysis of the CO2 shadow price in Chinese thermal power enterprises. Energy Econ. 2013, 40, 22–31. [Google Scholar] [CrossRef]

- Zhou, P.; Zhou, X.; Fan, L.W. On estimating shadow prices of undesirable outputs with efficiency models: A literature review. Appl. Energy 2014, 130, 799–806. [Google Scholar] [CrossRef]

- Lee, S.-C.; Oh, D.-H.; Lee, J.-D. A new approach to measuring shadow price: Reconciling engineering and economic perspectives. Energy Econ. 2014, 46, 66–77. [Google Scholar] [CrossRef]

- Mekaroonreung, M.; Johnson, A.L. Estimating the shadow prices of SO2 and NOx for U.S. coal power plants: A convex nonparametric least squares approach. Energy Econ. 2012, 34, 723–732. [Google Scholar] [CrossRef]

- Zhi, H.; Ni, L.; Zhu, D. The impact of emission trading system on clean energy consumption of enterprises: Evidence from a quasi-natural experiment in China. J. Environ. Manag. 2022, 318, 115613. [Google Scholar] [CrossRef]

- Zhang, N.; Huang, X.; Qi, C. The effect of environmental regulation on the marginal abatement cost of industrial firms: Evidence from the 11th Five-Year Plan in China. Energy Econ. 2022, 112, 106147. [Google Scholar] [CrossRef]

- Wu, J.; Ma, C.; Tang, K. The static and dynamic heterogeneity and determinants of marginal abatement cost of CO2 emissions in Chinese cities. Energy 2019, 178, 685–694. [Google Scholar] [CrossRef]

- Kuosmanen, T.; Zhou, X. Shadow prices and marginal abatement costs: Convex quantile regression approach. Eur. J. Oper. Res. 2018, 289, 666–675. [Google Scholar] [CrossRef]

- Peng, Y.; Wenbo, L.; Shi, C. The margin abatement costs of CO2 in Chinese industrial sectors. Energy Procedia 2012, 14, 1792–1797. [Google Scholar] [CrossRef]

- Färe, R.; Grosskopf, S.; Weber, W.L. Shadow prices and pollution costs in U.S. agriculture. Ecol. Econ. 2006, 56, 89–103. [Google Scholar] [CrossRef]

- Tang, K.; Gong, C.; Wang, D. Reduction potential, shadow prices, and pollution costs of agricultural pollutants in China. Sci. Total Environ. 2016, 541, 42–50. [Google Scholar] [CrossRef] [PubMed]

- Ji, D.J.; Zhou, P. Marginal abatement cost, air pollution and economic growth: Evidence from Chinese cities. Energy Econ. 2020, 86, 104658. [Google Scholar] [CrossRef]

- Zhang, Y.; Luo, C.; Lu, Y.; Zhang, Y.; Zhou, C.; Zhou, Z.; Wu, X.; Zheng, C.; Gao, X. Technology development and cost analysis of multiple pollutant abatement for ultra-low emission coal-fired power plants in China. J. Environ. Sci. 2022, 123, 270–280. [Google Scholar] [CrossRef] [PubMed]

- Liu, Q.; Qi, R.; Zhao, Y.; Zhou, T. Comparative analysis of the marginal abatement cost modeling for coal-fired power plants in China. J. Clean. Prod. 2022, 356, 131883. [Google Scholar] [CrossRef]

- Wei, X.; Zhang, N. The shadow prices of CO2 and SO2 for Chinese Coal-fired Power Plants: A partial frontier approach. Energy Econ. 2020, 85, 104576. [Google Scholar] [CrossRef]

- Lee, C.-Y.; Wang, K. Nash marginal abatement cost estimation of air pollutant emissions using the stochastic semi-nonparametric frontier. Eur. J. Oper. Res. 2019, 273, 390–400. [Google Scholar] [CrossRef]

- Du, L.; Hanley, A.; Zhang, N. Environmental technical efficiency, technology gap and shadow price of coal-fuelled power plants in China: A parametric meta-frontier analysis. Resour. Energy Econ. 2016, 43, 14–32. [Google Scholar] [CrossRef]

- Tian, S.; Shi, G.; Xiong, H. Shadow Price of SO2 and NOx in the Thermal Power Plants in Hunan Province. Environ. Sustain. Dev. 2015, 40, 53–57. [Google Scholar] [CrossRef]

- Du, L.M.; Mao, J. Estimating the environmental efficiency and marginal CO2 abatement cost of coal-fired power plants in China. Energy Policy 2015, 85, 347–356. [Google Scholar] [CrossRef]

- Jain, R.K.; Kumar, S. Shadow price of CO2 emissions in Indian thermal power sector. Environ. Econ. Policy Stud. 2018, 20, 879–902. [Google Scholar] [CrossRef]

- Motherway, B.; Neil, W. Ireland’s Low-Carbon Opportunity: An analysis of the costs and benefits of reducing greenhouse gas emissions. Sustain. Energy Irel. 2009. Available online: https://scholar.google.com/ (accessed on 6 May 2021).

- Johnson, T.; Alatorre, C.; Romo, Z.; Liu, F. Low-Carbon Development for Mexico; The World Bank: Washington, DC, USA, 2010. [Google Scholar]

- Poswiata, J.; Bogdan, W. Assessment of Greenhouse Gas Emissions Abatement Potential in Poland by 2030; McKinsey Co.: Warsaw, Poland, 2009. [Google Scholar]

- Per-Anders, E.; Jens, D.; Charles, L. Impact of the Financial Crisis on Carbon Economics: Version 2.1 of the Global Greenhouse Gas Abatement Cost Curve; McKinsey & Company: Warsaw, Poland, 2010; Available online: https://www.mckinsey.com/capabilities/sustainability/our-insights/impact-of-the-financial-crisis-on-carbon-economics-version-21 (accessed on 8 August 2022).

- Chen, D.; Tan, X.; Zhou, K.; Shi, L.; Ma, Z. Analysis of desulphurization electricity price policy based on the desulphurization cost of coal-fired power plants. Environ. Prot. Sci. 2019, 45, 1–5. [Google Scholar] [CrossRef]

- Wei, H.; Chen, T.; Du, Z.; Jiang, J.; Zhang, Y. Research of FGD project’ s composite cost computational model based on coal cost control. Electr. Power Technol. Environ. Prot. 2020, 36, 8–12. [Google Scholar] [CrossRef]

- Wu, D.; Lie, Y.; Liu, L.; Zhang, L.; Yang, Z. Abatement cost of sulfur dioxide in Beijing-Tianjin-Hebei Region and the Pearl River Delta and its policy implications. Environ. Sustain. Dev. 2019, 44, 56–63. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, Z.; Zhao, Y. Research on the reform of environmental electricity price-based on the analysis of environmental management cost of coal-fired power generation enterprises. Price Theory Pract. 2017, 3, 57–60. [Google Scholar] [CrossRef]

- Luo, C. Research on Performance Evaluation and Economic Optimization Strategy of coal-Fired Flue Gas Pollutant Control Technologies. Master’s Thesis, Zhejiang University, Hangzhou, China, 2021. [Google Scholar] [CrossRef]

- Liu, H.; Cai, B.; Zhang, L.; Wang, Z.; Chen, Y.; Xia, C.; Yang, L.; Dong, J.; Song, X. Research on carbon dioxide abatement technologies and cost in China’s power industry. Environ. Eng. 2021, 39, 8–14. [Google Scholar] [CrossRef]

- Nakaishi, T.; Kagawa, S.; Takayabu, H.; Lin, C. Determinants of technical inefficiency in China’s coal-fired power plants and policy recommendations for CO2 mitigation. Environ. Sci. Pollut. Res. 2021, 28, 52064–52081. [Google Scholar] [CrossRef]

- Peng, J.; Yu, B.-Y.; Liao, H.; Wei, Y.-M. Marginal abatement costs of CO2 emissions in the thermal power sector: A regional empirical analysis from China. J. Clean. Prod. 2018, 171, 163–174. [Google Scholar] [CrossRef]

- Färe, R.; Grosskopf, S. Theory and application of directional distance functions. J. Prod. Anal. 2000, 13, 93–103. [Google Scholar] [CrossRef]

- Murty, S.; Russell, R.R.; Levkoff, S.B. On modeling pollution-generating technologies. J. Environ. Econ. Manage. 2012, 64, 117–135. [Google Scholar] [CrossRef]

- Bi, G.; Shao, Y.; Song, W.; Yang, F.; Luo, Y. A performance evaluation of China’s coal-fired power generation with pollutant mitigation options. J. Clean. Prod. 2018, 171, 867–876. [Google Scholar] [CrossRef]

- Hampf, B. Separating environmental efficiency into production and abatement efficiency: A nonparametric model with application to U.S. power plants. J. Product. Anal. 2014, 41, 457–473. [Google Scholar] [CrossRef]

- Yu, S.W.; Liu, J.; Li, L.X. Evaluating provincial eco-efficiency in China: An improved network data envelopment analysis model with undesirable output. Environ. Sci. Pollut. Res. 2020, 27, 6886–6903. [Google Scholar] [CrossRef]

- Fu, L.F.; Meng, J.; Liu, Y. Evaluation of supply chain efficiency based on a novel network of data envelopment analysis model. Int. J. Bifurc. Chaos 2015, 25, 14. [Google Scholar] [CrossRef]

- Kamarudin, N.; Ismail, W.R.; Mohd, M.A. Network Russell-Based Measure with Undesirable Outputs: Empirical Study on Malaysian Water Utilities’ Performance. In Proceedings of the 25th National Symposium on Mathematical Sciences (SKSM), Kuantan, Malaysia, 27–29 August 2017; Amer Inst Physics: Kuantan, Malaysia, 2017; p. 040024. [Google Scholar]

- Khalili-Damghani, K.; Shahmir, Z. Uncertain network data envelopment analysis with undesirable outputs to evaluate the efficiency of electricity power production and distribution processes. Comput. Ind. Eng. 2015, 88, 131–150. [Google Scholar] [CrossRef]

- Lozano, S. Technical and environmental efficiency of a two-stage production and abatement system. Ann. Oper. Res. 2017, 255, 199–219. [Google Scholar] [CrossRef]

- Mirhedayatian, S.M.; Azadi, M.; Saen, R.F. A novel network data envelopment analysis model for evaluating green supply chain management. Int. J. Prod. Econ. 2014, 147, 544–554. [Google Scholar] [CrossRef]

- Mocholi-Arce, M.; Sala-Garrido, R.; Molinos-Senante, M.; Maziotis, A. Measuring the eco-efficiency of the provision of drinking water by two-stage network data envelopment analysis. Environ. Dev. Sustain. 2021, 23, 17. [Google Scholar] [CrossRef]

- Roudabr, N.; Najafi, S.E.; Moghaddas, Z.; Sobhani, F.M. A new modeling approach for undesirable factors in efficiency evaluation of cement industry with four stages structure based on piecewise linear NDEA model. Econ. Comput. Econ. Cybern. Stud. Res. 2022, 56, 57–74. [Google Scholar] [CrossRef]