Neuromodel of an Eddy Current Brake for Load Emulation

Abstract

:1. Introduction

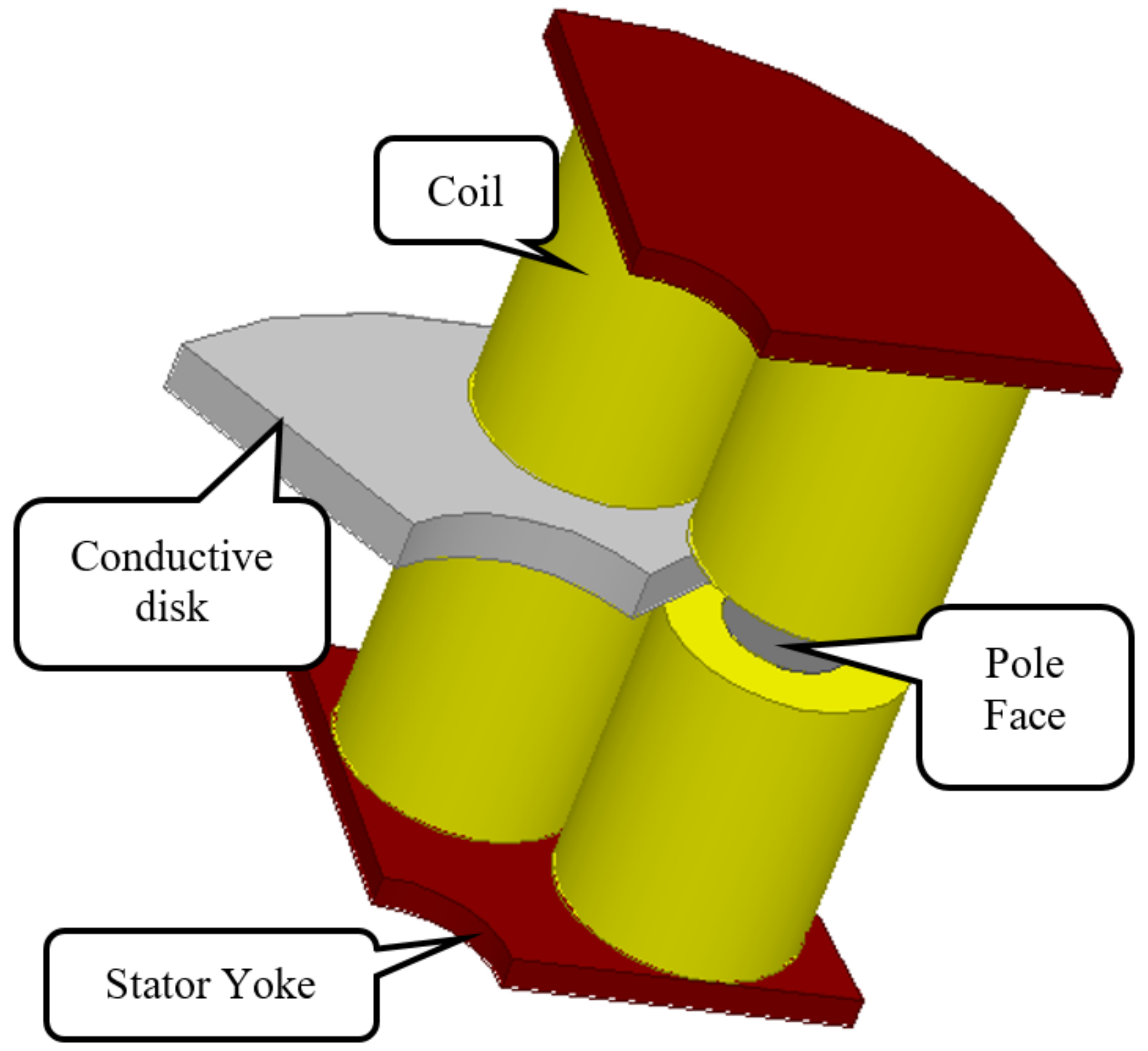

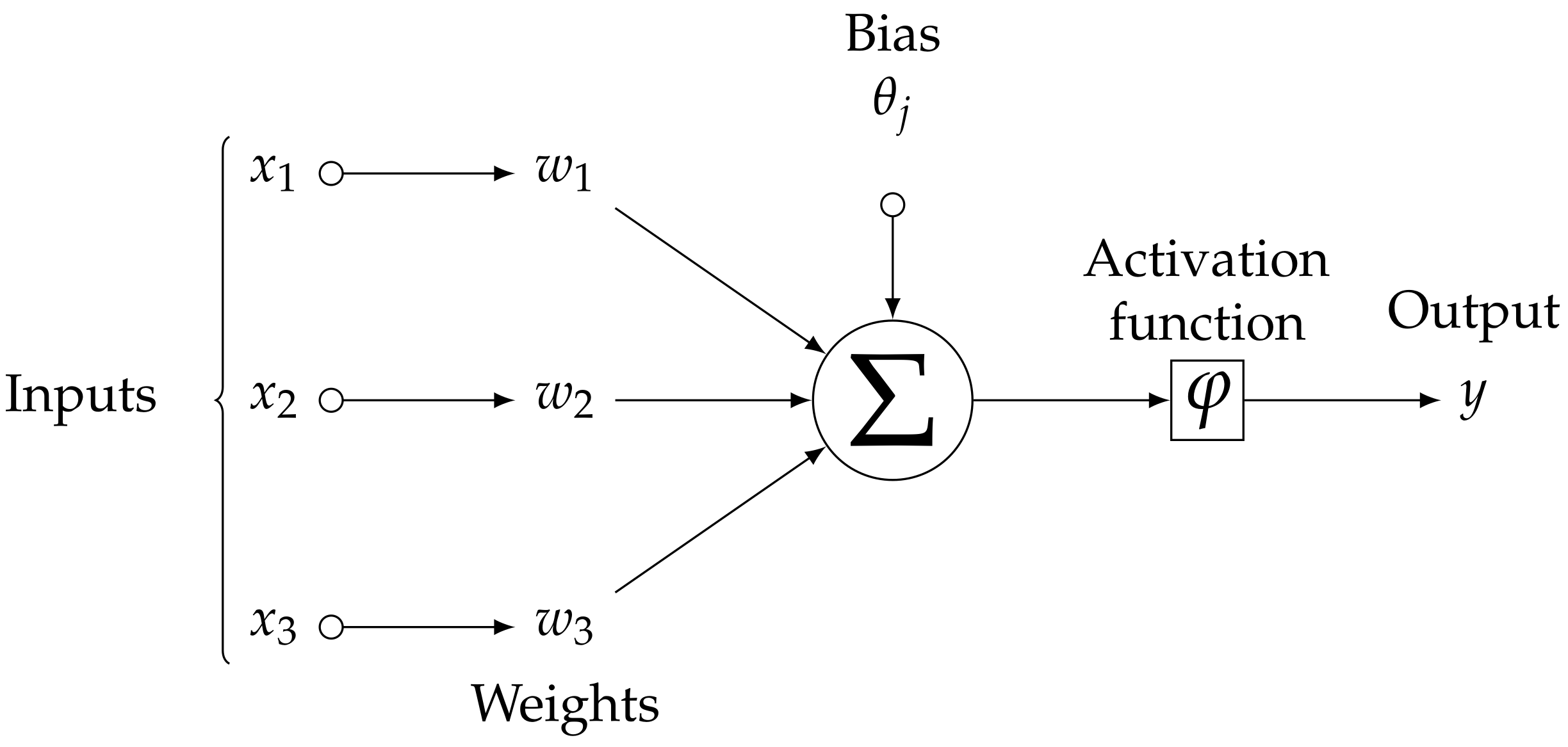

2. Analytical Torque Expression of ECB

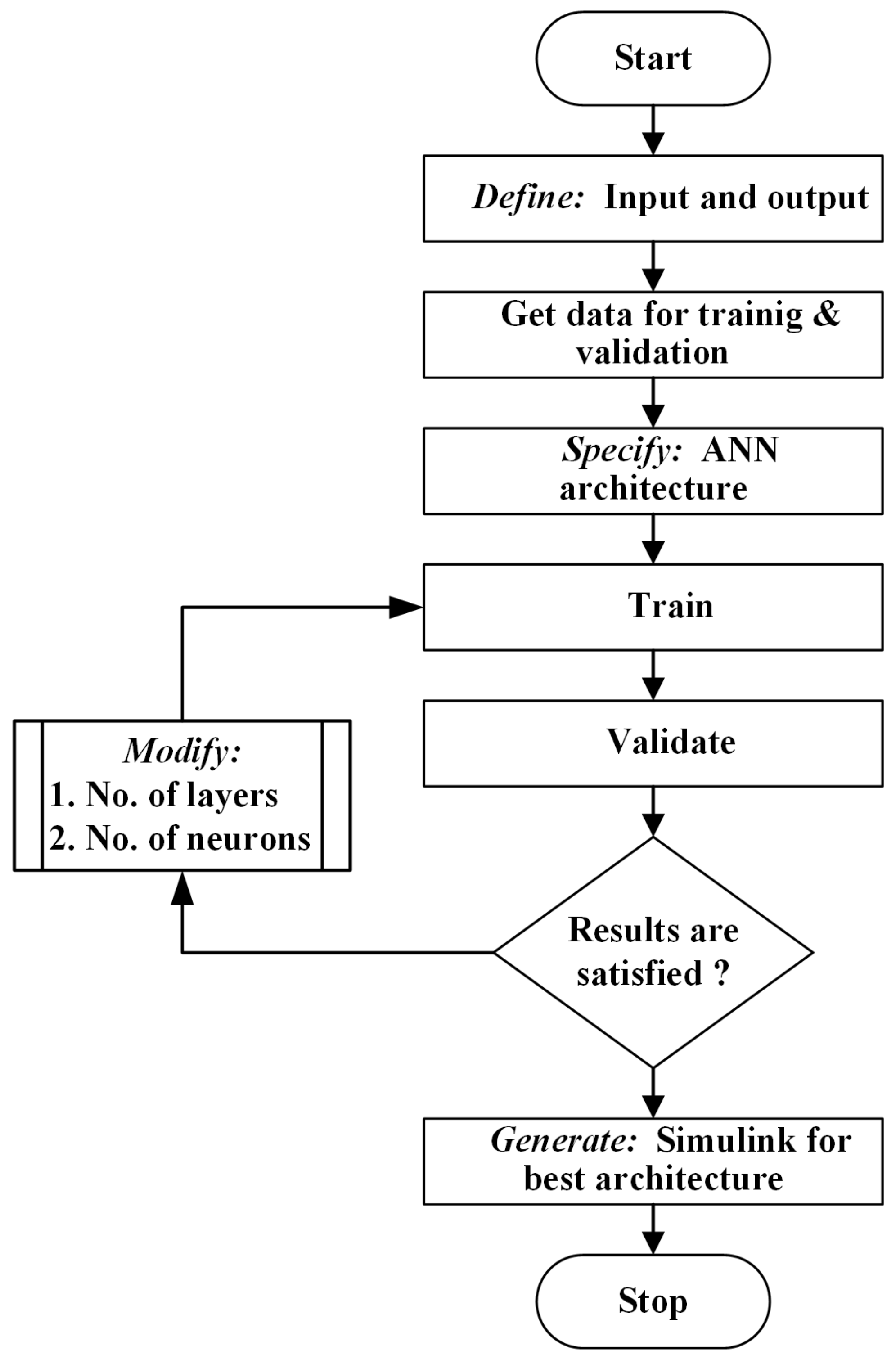

3. Artificial Neural Network for Nonlinear System Modeling

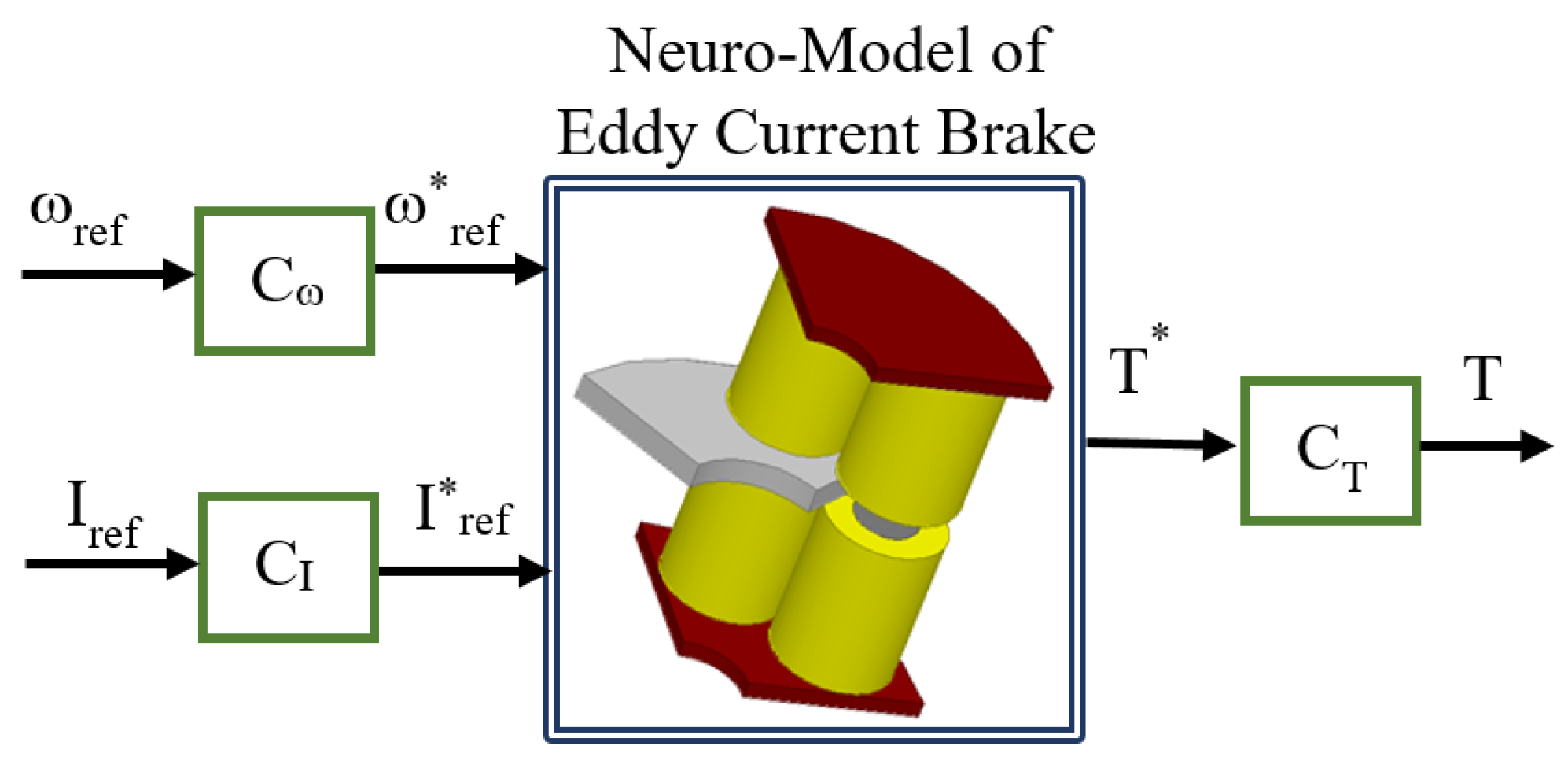

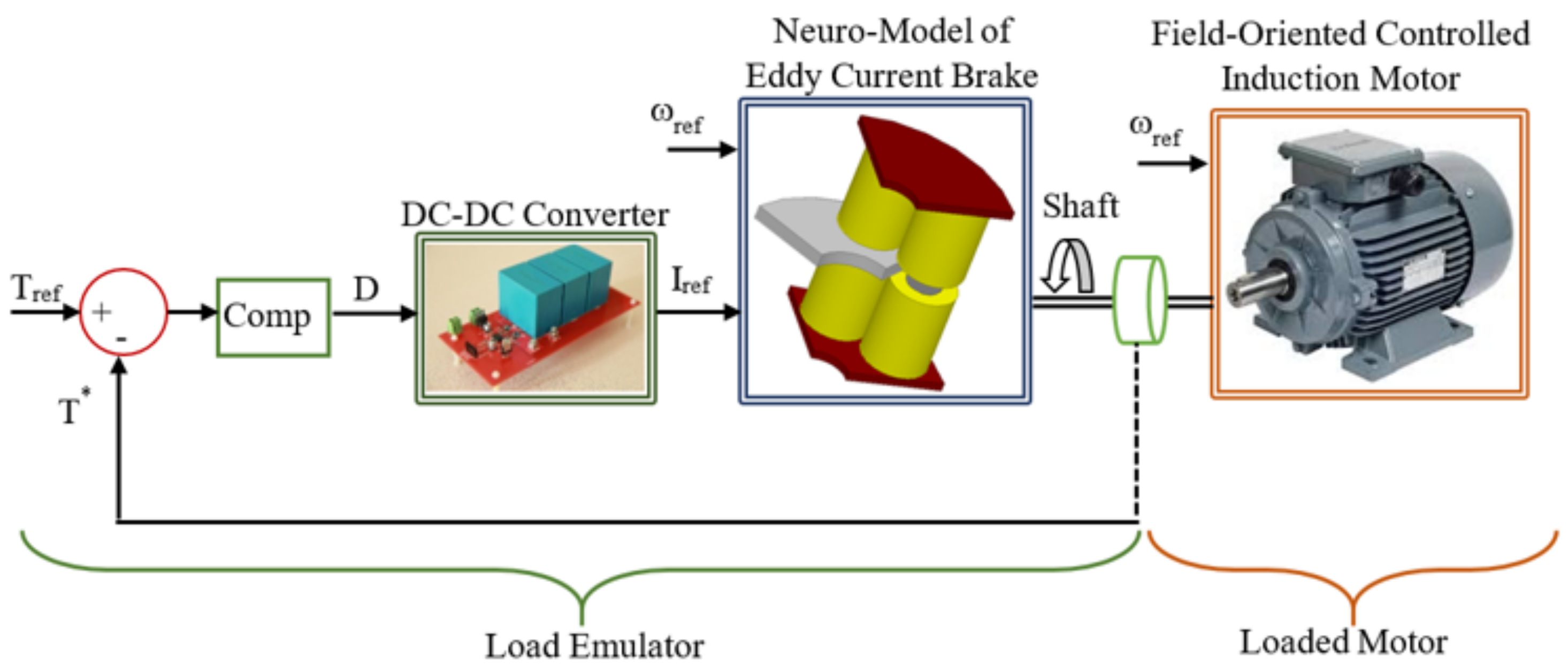

4. Implementation of the Method on ECB

4.1. Experimental Setup for Collecting Data

4.2. ANN Modeling of ECB

4.3. Scalability of Neuromodel of ECB

- The system cannot have an eddy current impact if there is no relative movement between the poles and the conductive disk. This operational point crosses the axes’ origin since the poles are fixed, which means that there is “No torque at zero speed”. A time invariant flux density never produces an electric field according to Faraday’s law.

- Linear torque region: Since the breaking effect is greater as the relative speed increases while the magnetic circuit operation takes place at linear regions and produces linearly increasing magnetic fields, the reverse effect of the magnetic field produced by the eddy current at the beginning of the rotational movement is negligible against the main magnetic field generated by the poles.

- The critical speed is the velocity at which the maximum braking torque occurs. The decreasing influence of the magnetic field produced by the eddy currents becomes prominent as the relative speed rises, which causes a significant drop in the braking torque.

- High speed region: above the critical speed, angular speed rises are accompanied by higher increases in the reaction field, which lowers the overall magnetic flux density and eddy currents and causes the braking torque to constantly decrease.

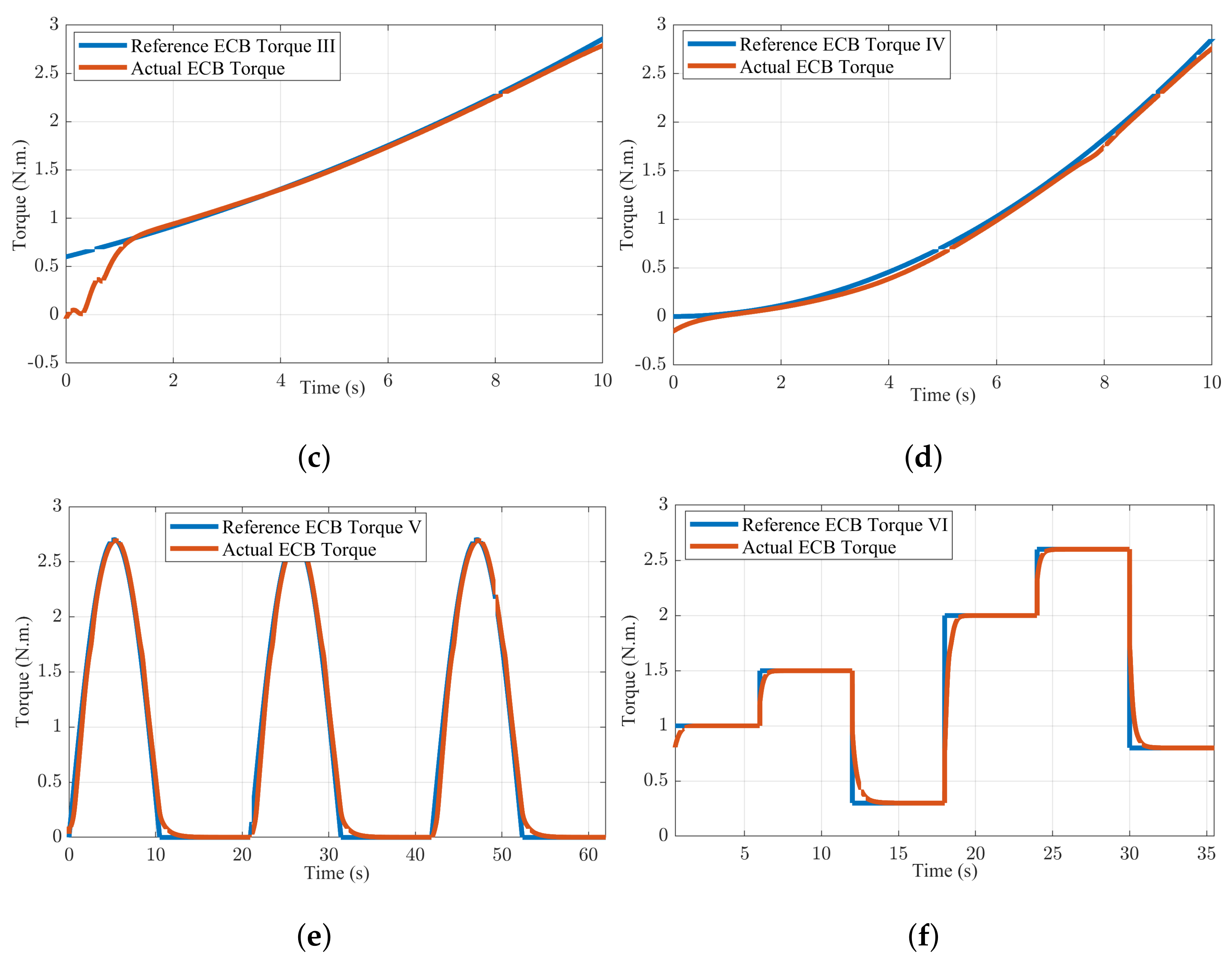

5. Investigation of Performance of Neuromodel under Different Load Scenarios

6. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

References

- Akpolat, Z.H.; Asher, G.M.; Clare, J.C. Experimental dynamometer emulation of nonlinear mechanical loads. IEEE Trans. Ind. Appl. 1999, 35, 1367–1373. [Google Scholar] [CrossRef]

- Gulbahce, M.O.; Nak, H.; Kocabas, D.A. Design of a Mechanical Load Simulator Having an Excitation Current Controlled Eddy Current Brake. In Proceedings of the 3rd International Conference on Electric Power and Energy Conversion Systems, Istanbul, Turkey, 2–4 October 2013; pp. 1–5. [Google Scholar] [CrossRef]

- Collins, E.R.; Huang, Y. A programmable dynamometer for testing rotating machinery using a three-phase induction machine. IEEE Trans. Energy Convers. 1994, 9, 521–527. [Google Scholar] [CrossRef]

- Gulbahce, M.O.; Nak, H.; Kocabas, D.A. A New Approach for Temperature Rising Test of an Induction Motor Loaded by a Current Controlled Eddy Current Brake. In Proceedings of the 3rd International Conference on Electric Power and Energy Conversion Systems, Istanbul, Turkey, 2–4 October 2013; pp. 1–6. [Google Scholar] [CrossRef]

- Arellano-Padilla, J.; Asher, G.M.; Sumner, M. Control of an AC Dynamometer for Dynamic Emulation of Mechanical Loads with Stiff and Flexible Shafts. IEEE Trans. Ind. Electron. 2006, 53, 1250–1260. [Google Scholar] [CrossRef]

- Lee, K.; Lee, J.; Back, J.; Lee, Y.I. A Robust Emulation of Mechanical Loads Using a Disturbance-Observer. Energies 2019, 12, 2236. [Google Scholar] [CrossRef]

- Newton, R.W.; Betz, R.E.; Penfold, H.B. Emulating Dynamic Load Characteristics Using a Dynamic Dynamometer. In Proceedings of the International Conference on Power Electronics and Drive Systems, Singapore, 21–24 February 1995; pp. 465–470. [Google Scholar]

- Akpolat, Z.H.; Asher, G.M.; Clare, J.C. Emulation of High Bandwidth Mechanical Loads Using Vector Controlled AC Dynamometer. In Proceedings of the 8th International Power Electronics & Motion Control Conference, Prague, Czech Republic, 8–10 September 1998; pp. 133–138. [Google Scholar]

- Gulbahce, M.O.; Kocabas, D.A.; Nayman, F. Investigation of the Effect of Pole Shape on Braking Torque for a Low Power Eddy Current Brake by Finite Elements Method. In Proceedings of the 9th International Conference on Electrical and Electronics Engineering (ELECO), Bursa, Turkey, 26–28 November 2015; pp. 263–267. [Google Scholar] [CrossRef]

- Sinmaz, A.; Gulbahce, M.O.; Kocabas, D.A. Design and Finite Element Analysis of a Radial-Flux Salient-Pole Eddy Current Brake. In Proceedings of the 9th International Conference on Electrical and Electronics Engineering (ELECO), Bursa, Turkey, 26–28 November 2015; pp. 590–594. [Google Scholar]

- Gulbahce, M.O.; Kocabas, D.A. A comprehensive approach to determining the speed/torque relationships of eddy current brakes. Electr. Eng. 2018, 100, 1579–1587. [Google Scholar] [CrossRef]

- Gay, S.E.; Ehsani, M. Parametric analysis of eddy-current brake performance by 3-D finite-element analysis. IEEE Trans. Magn. 2006, 42, 319–328. [Google Scholar] [CrossRef]

- Jeong, H.; Ji, H.; Choi, S.; Baek, J. Parametric Study of Eddy Current Brakes for Small-Scale Household Wind Turbine Systems. Energies 2021, 14, 6633. [Google Scholar] [CrossRef]

- Wang, M.; Kou, B. Design of the Low Inertia Composite-Disc Type Magnetic Brake. In Proceedings of the 25th International Conference on Electrical Machines and Systems (ICEMS), Chiang Mai, Thailand, 29 November–2 December 2022; pp. 1–5. [Google Scholar] [CrossRef]

- Xiang, C.; Chen, S.; Yao, M.; Gu, Y.; Yang, X. Optimization of Braking Force for Electromagnetic Track Brake Using Uniform Design. IEEE Access 2020, 8, 146065–146074. [Google Scholar] [CrossRef]

- Hassoun, M.H. Fundamentals of Artificial Neural Networks, 1st ed.; MIT Press: Cambridge, UK, 1995. [Google Scholar]

- Zhong, K.; Meng, Q.; Sun, M.; Luo, G. Artificial Neural Network (ANN) Modeling for Predicting Performance of SBS Modified Asphalt. Materials 2022, 15, 8695. [Google Scholar] [CrossRef] [PubMed]

- George, A. Anastassiou Intelligent Systems: Approximation by Artificial Neural Networks, 1st ed.; Springer Press: Berlin, Germany, 2011. [Google Scholar]

- Kevin, L.P.; Paul, E.K. Artificial Neural Networks: An Introduction, 1st ed.; SPIE Press: Washington, DC, USA, 2005. [Google Scholar]

- Hagan, M.T.; Demuth, H.B.; Jesus, O.D. An introduction to the use of neural networks in control systems. Int. J. Robust Nonlinear Control 2002, 12, 959–985. [Google Scholar] [CrossRef]

- Fausett, L. Fundamentals of Neural Networks: Architectures, Algorithms and Applications, 1st ed.; Prentice Hall International Press: Upper Saddle River, NJ, USA, 1994. [Google Scholar]

- Avunduk, E.; Tumac, D.; Atalay, A.K. Prediction of roadheader performance by artificial neural network. Tunn. Undergr. Space Technol. 2014, 44, 3–9. [Google Scholar] [CrossRef]

- Novotny, D.W.; Lipo, T.A. Vector Control and Dynamics of AC Drives, 1st ed.; Clarendon Press: Oxford, UK, 2008. [Google Scholar]

| Symbol | Quantity | Value |

|---|---|---|

| I | Excitation current | 5 A |

| N | Number of turns per pole | 205 |

| P | Number of pole pairs | 8 |

| Pole width | ||

| g | Air-gap width | 2 mm |

| d | Thickness of disk | 10 mm |

| Radius of electromagnet | 20 mm | |

| R | Radius of disk | 140 mm |

| Relative permeability of conductive disk | 1 | |

| Conductivity of disk | 18,560,000 S/m |

| Average Train | Average Validation | Average Test | Average Test |

|---|---|---|---|

| MSE (%) | Error (%) | Error (%) | Correlation |

| 0.2526 | 0.1279 | 0.0933 | 0.9114 |

| 0.0838 | 0.0573 | 0.0619 | 0.9017 |

| 0.0139 | 0.0150 | 0.0167 | 0.9764 |

| 0.0078 | 0.0085 | 0.0093 | 0.9844 |

| 0.0060 | 0.0054 | 0.0085 | 0.9857 |

| 0.0030 | 0.0060 | 0.0068 | 0.9901 |

| 0.0056 | 0.0081 | 0.0117 | 0.9837 |

| 0.0061 | 0.0094 | 0.0114 | 0.9813 |

| 0.0072 | 0.0146 | 0.0271 | 0.9730 |

| 0.0064 | 0.0161 | 0.0235 | 0.9639 |

| 0.0074 | 0.0218 | 0.0328 | 0.9560 |

| 0.0144 | 0.0324 | 0.0475 | 0.9347 |

| 0.0105 | 0.0312 | 0.0609 | 0.9166 |

| 0.0186 | 0.0424 | 0.0618 | 0.9061 |

| 0.0171 | 0.0485 | 0.0714 | 0.9088 |

| 0.0233 | 0.0655 | 0.0762 | 0.8921 |

| 0.0197 | 0.0594 | 0.0968 | 0.8616 |

| 0.0206 | 0.0763 | 0.1155 | 0.8492 |

| 0.0264 | 0.0846 | 0.1092 | 0.8552 |

| 0.0223 | 0.0819 | 0.1283 | 0.8313 |

| MSE | R2 | |

|---|---|---|

| Train Data | 0.000843 | 0.999468 |

| Validation Data | 0.0018 | 0.998963 |

| Test Data | 0.001408 | 0.99772 |

| All Data | 0.001147 | 0.99921 |

| Load Type | Accuracy (%) | R2 |

|---|---|---|

| 1 | 99.9248 | 0.9999 |

| 2 | 99.9505 | 0.9999 |

| 3 | 99.8595 | 0.9999 |

| 4 | 99.8490 | 0.9999 |

| 5 | 99.6729 | 0.9999 |

| 6 | 99.7850 | 0.9999 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gulbahce, M.O. Neuromodel of an Eddy Current Brake for Load Emulation. Energies 2023, 16, 3649. https://doi.org/10.3390/en16093649

Gulbahce MO. Neuromodel of an Eddy Current Brake for Load Emulation. Energies. 2023; 16(9):3649. https://doi.org/10.3390/en16093649

Chicago/Turabian StyleGulbahce, Mehmet Onur. 2023. "Neuromodel of an Eddy Current Brake for Load Emulation" Energies 16, no. 9: 3649. https://doi.org/10.3390/en16093649

APA StyleGulbahce, M. O. (2023). Neuromodel of an Eddy Current Brake for Load Emulation. Energies, 16(9), 3649. https://doi.org/10.3390/en16093649