Abstract

The issue of enhancing energy recovery efficiency is a key concern within the European Union’s climate protection efforts. In particular, it applies to all processes and plants for the harvesting, gathering, and conversion of energy. The abandonment of fossil fuels in favour of alternative energy sources, and the increasing of energy efficiency and its recovery, is now a widely accepted direction of energy development. This study focuses on facilities that recover and process energy from municipal waste left after recycling processes, known as waste-to-energy (WtE) plants. These plants’ energy recovery efficiency is governed by the R1 Formula in EU countries. This report is based on an analysis of four years of operational data from selected Polish municipal waste incinerators, supplemented by a discussion of various studies on energy recovery efficiency. The primary objective of this report is to evaluate the effectiveness of these plants in contributing to sustainable waste management and energy recovery. The main effect of the developed report is the set of results of the energy recovery efficiency factor values, determined based on the R1 formula valid in the EU legislation, tabulated and graphically illustrated, and calculated for five selected Polish waste-to-energy plants. The presented results, with their graphical interpretation, discussion, and conclusions, provide insights into several factors influencing the value of the R1 efficiency factor. They can be a valuable contribution to operators of waste-to-energy plants, especially those operating in countries outside the EU.

1. Introduction

The EU’s climate policy draws significant attention to the problem of any implementation of increased efficiency in energy recovery and use, which is the most effective way to reduce greenhouse gas emissions. The EU Commission’s actions in this regard are included in the regulatory package called Fit for 55, announced as part of the European Green Deal on 14 July 2021 [1,2]. The regulations adopted in this package aim to achieve the primary climate target of reducing European greenhouse gas emissions by at least 55% by 2030 from 1990 levels and to achieve climate neutrality by 2050. The regulations proposed as part of the Fit for 55 package are also relevant to the energy sector, including an update of the Energy Efficiency Directive [3] requiring member states to reduce energy consumption in several industries. In one of these industries, specifically the energy sector, is the waste-to-energy (WtE) sector; hence, the topic of this publication seems most justified. It aims to analyse the efficiency of energy recovery contained in municipal waste incinerated in WtE plants, presented in the aspect of its possible increase concerning specific WtE installations operated in Poland.

Waste-to-energy plants, treated in this publication as installations for recovering the chemical energy contained in municipal waste (municipal waste incinerators with energy recovery), are not a primary source of electricity and heat, as producing electricity and heat is not their primary purpose. The share of such installations in electricity production in EU countries does not exceed 2% on average, and more than 10% of thermal energy is supplied to district heating networks, and in some EU countries, up to 50% [4]. The electricity generated by WtE plants operating in European countries meets the needs of more than 19 million inhabitants, and the district heating produced and transmitted represents an independent and sovereign source of heat, compared to natural gas or coal, because of the current energy transition. European WtE plants provide a local source of reliable (baseload) energy that complements intermittent renewable energy sources such as wind or solar while treating non-recyclable waste [4]. By 2035, WtE plants could produce 189 TWh of helpful energy per year, equivalent to 19.4 billion m3 of natural gas in primary energy [5].

At the same time, WtE plants fulfil an indispensable role, in line with the waste hierarchy in force in European Union countries, in the practice of comprehensive, sustainable management of municipal waste [6].

The Waste Framework Directive (Directive 2008/98/EC on waste), as amended in 2018 [6], considers waste incineration either as a disposal technique (D10—incineration on land) or a recovery technique (R1—used principally as a fuel or other means to generate energy). In such a case, the requirement for minimum energy efficiency is laid down. Article 10.4 of the abovementioned directive states the following: “Member States shall take measures to ensure that waste that has been separately collected for preparing for re-use and recycling is not incinerated, with the exception of waste resulting from subsequent treatment operations of the separately collected waste for which incineration delivers the best environmental outcome”. The procedure for determining the value of the minimum energy efficiency coefficient, known as the R1 formula, is defined in the annex of the Waste Framework Directive [6].

If the value of this coefficient for WtE plants put into operation after 31 December 2008 exceeds 0.65, energy recovery, known as R1, is involved. If the value is less, then the waste incineration process is a D10 process and does not differ in its nature from the lowest treated waste management method in the waste hierarchy, which is landfilling, also known as D10. This view is indeed disputed by opponents of the waste-to-energy idea, especially those representing Zero Waste advocates [7]. On the other hand, the waste-to-energy and R1 formula ideas are widely represented in EU countries, where more than 500 WtE plants are in operation. An example is Germany, where the development of more than 100 WtE plants is planned by 2040, including an essential consideration of the importance of the R1 formula [8]. One of the first R1 formula analyses in Poland, based only on the available data for project WtE plants in Poland in 2010–2012, is included in the paper [9]. There are also examples of R1 formula analysis for WtE plants in non-EU countries, such as in the UK [10,11] or Turkey [12], and from outside Europe, even in South Korea, as evidenced by a very interesting R1 coefficient analysis [13].

In the following part of this publication, the R1 formula will be extensively described and commented on regarding the correctness of its definition and practical use for the classification of a given municipal waste incineration process. Based on the definition of the R1 formula, the energy efficiency coefficients for selected WtE plants in Poland will be determined and presented for the years 2020 to 2023 within this publication. These results will be extensively analysed regarding their potential for increasing energy efficiency or the reasons for its current state.

The analysis, which constitutes this publication’s substantive (and title) content, has been developed based on collected data recorded in the information systems of selected Polish WtE plants operated in the years 2020 to 2023. On their basis, using the R1 formula, the values of the R1 coefficient have been determined. A description of the current state of WtE development in Poland has also been presented, together with the prospects for further development because of the requirements arising from the circular economy 2035 policy, which applies to EU member states. These are the main objectives of this publication.

According to the implementation of the EU’s circular economy policy, the share of recycling in municipal waste management in 2035 should be 65%, and the share of appropriately treated waste allowed to be landfilled should be no more than 10%. The only method that can make up for the missing share of 25% in this balance is WtE. This thesis has been proven many times, with the guiding concept of circular economy, a waste-to-energy initiative (document: The role of waste to energy in the circular economy) adopted in 2017 [14] as a confirming example among much of the literature and many international conference presentations. This guide states: “When waste cannot be prevented or recycled, recovering its energy content is usually better than landfilling it”.

The share of WtE can be higher than 25% if one considers that part of the share attributable to landfilling of treated waste is also diverted to incineration. It should be emphasised that WtE plants only make energetic use of non-recyclable municipal waste, which represents an essential source of energy in the form of the chemical energy contained in this waste [14]. It is estimated that currently, according to 2022 data, there are about 525 WtE plants installed in 23 European countries, making energetic use of more than 100 million tonnes of non-recyclable municipal waste per year [15,16]. Germany, Sweden, Denmark, the Netherlands, Austria, and EU-associated Switzerland and Norway, are leading the way.

Among the EU policies currently being implemented for managing municipal waste, the decisions and strategies directly related to climate protection play an essential role [4,5]. In terms of WtE plants, this is the case with the already well-advanced and ready-to-be-implemented CO2-capturing technologies of Carbon Capture and Storage (CCS) and Carbon Capture and Utilisation (CCU). Numerous European WtE plants are exploring usage (CCU) and storage (CCS) technologies, which have the potential to further reduce the carbon footprint of the sector or even to make it carbon negative [17,18].

The efficiency of waste energy recovery directly related to WtE issues is also implied by the EU Implementing Decision (Commission Implementing Decision (EU) 2019/2010/EU of 12 November 2019) on BAT Conclusions for WtE installations. The BAT (Best Available Techniques) Conclusions for waste incineration (WI) were published on 3 December 2019 [19]. All requirements established therein had to be complied with by all existing WtE installations before 3 December 2023. The adopted BAT conclusions that establish methods for increasing the energy efficiency of waste incineration include BAT 19–BAT 20 [19]. The calculation of the R1 factor is defined in Article 3 of the aforementioned Waste Framework Directive in its revised form [6]. Detailed information and guidance on the determination and interpretation of the complex components that can be entered into the general formula for calculating the R1 factor are clearly defined in the guide [20].

Emphasising the primary purpose of this report, which is to analyse and discuss the value of the energy recovery efficiency coefficient in the example of selected waste-to-energy plants operated in Poland, the Authors discuss the procedure in force in EU legislation for calculating this coefficient based on the so-called R1 formula; present the verified operating parameters of the analysed Polish incineration plants, which is necessary for the determination of this coefficient; and, above all, tabulate and graphically illustrate the results of their research, supported by a discussion and the most important conclusions. This structure of the manuscript will allow it to achieve its intended purpose and, at the same time, give a view of the efficiency of recovery of energy contained in the thermally transformed waste represented in Polish incinerators. The authors hope this view will will be interesting for operators of the numerous waste incineration plants already in operation or undergoing the process of construction in many non-European countries.

2. Waste-to-Energy Plants in Poland

Poland is not among the leading countries in the EU regarding the share of WtE in their municipal waste management systems. On the other hand, it is a leader in this aspect among CEE countries, which, together with Poland, joined the EU in May 2004 (Cyprus, Czech Republic, Estonia, Hungary, Lithuania, Latvia, Malta, Slovakia, and Slovenia,) as well as in January 2007 (Bulgaria and Romania) and in 2013 (Croatia). Among these countries, Poland has by far the largest share of WtE in municipal waste management systems, as will be further demonstrated numerically.

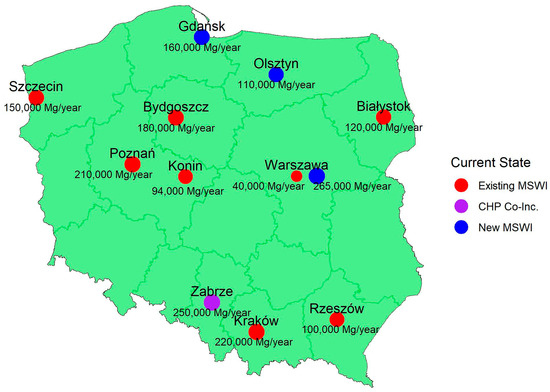

A graphic illustration of the distribution in Poland of the analysed WtE plants, shown in Table 1 in positions from 1 to 12, is presented in Figure 1.

Table 1.

Overview of Poland’s current potential 2024 WtE plants (own study).

Figure 1.

The location of analysed WtE plants in Poland, their capacities, and current state. Abbreviations: MSWI (Municipal Solid Waste Incineration), CHP Co-Inc. (Combined Heat and Power Co-Incineration).

The main period of development of WtE plants in Poland was in the years 2007–2013, during which, with the significant support of one of the most extensive budgeted EU support programmes, the Operational Programme Infrastructure and Environment 2007–2013 [21], the construction of WtE plants in large Polish cities was subsidised [22]. At that time, a so-called indicative list of projects for constructing incinerators (municipal waste incinerators) in large Polish cities was established, and these projects were prioritised among other applications for environmental infrastructure development projects. In its original version, in 2007, the indicative list included the construction of 12 WtE plants. For various reasons, mainly due to problems with public acceptance for WtE plants, six projects were eventually implemented in large Polish cities (Białystok, Bydgoszcz, Konin, Kraków, Poznań, and Szczecin) [22]. In later years, with the support of EU funds, projects were implemented in Rzeszów (2018). At the beginning of 2024, the latest WtE plants projects in Gdańsk, Olsztyn, and Warsaw, currently in their final phases of investment, are being finalised (as of February 2024).

The current potential of WtE plants in Poland, calculated by their total capacity, taking into account the capacity of the mentioned incinerators and the multi-fuel unit at the Fortum CHP Plant in Zabrze, which has been in operation since 2018 and which can potentially co-incinerate about 250 thousand tonnes of Refuse Derived Fuels, is about 1365 thousand tonnes per year [23]. Adding the possibility of incinerating about 535,000 tonnes of RDF fuel in the newest incineration plants in Olsztyn, Gdansk, and Warsaw; that potential will reach about 1.9 million tonnes per year in the second half of 2024. It should also be noted that the cement industry in Poland currently uses about 1.1 million tonnes of RDF fuel produced from municipal waste for the energy-intensive clinker-burning process [23]. On average, the cement industry in Poland bases almost 85% of its energy needs on the recovery of the energy contained in suitably adapted RDF fuel, one of the world’s leading achievements in this respect [24].

Adding up the currently available potential for municipal waste management through WtE in Poland, it would amount to 1.365 + 0.535 + 1.1 (million Mg/year) = 3 million tonnes per year, as shown in more detail in Table 1.

Comments for Table 1:

- -

- The name of a given WtE plant should be understood as the official name in force for that WtE plant in Poland;

- -

- The given capacity of the incineration plant is the nominal design capacity, which is considered in terms of the balance of the current WtE potential in Poland. Currently, in many Polish WtE plants, this capacity is a few percent higher as a result of modernisation (upgrading) work undertaken after start up;

- -

- Among the non-recyclable wastes directed to incineration, there are two types of municipal waste. Mixed municipal waste with code 20 03 01 and other wastes, including mixtures of materials, from mechanical waste treatment with code 19 12 12. These waste codes, according to the Polish regulation on the catalogue of wastes [25], are consistent with the European Waste Catalogue (EWC) [26]. The share of waste with code 19 12 12 varies for Polish MSW incinerators, ranging from 20% to 55% by weight of the total waste incinerated;

- -

- All Polish WtE plants are based on the most technically advanced moving grate boiler technology, which meets the current BAT standards [19] for moving grate boiler technology and has a global share of approximately 90% in WtE plant technologies [16,27,28];

- -

- In Table 1 under number 13, the item described as “Co-incineration in cement furnaces” is not a real waste incineration plant. It only a item, which provides the balanced information on the use of energy contained in waste for the energy-intensive clinker-burning process carried out in cement furnaces, as applied in Poland. Such use of waste energy is referred to in EU legislation as waste co-incineration and is also a type of thermal waste treatment;

- -

- Co-incineration of RDF-type waste fuels at Fortum CHP and in cement furnaces requires more physically and chemically processed types of waste fuels. For Fortum CHP Zabrze, these requirements relate to the calorific value of waste and the permissible geometric size of the fuel components, and for the cement industry, in terms of calorific value and required chemical composition.

Taking into account the data given in Table 1 regarding Poland’s WtE potential for 2024, amounting to 3 million tonnes per year, and based on the data presenting the amount of municipal waste generated annually in Poland in 2023, amounting to 13.4 million tonnes [29], this results in a 22% share of WtE in municipal waste management in Poland, which once again confirms its role as a leader among the countries admitted to the EU after 2004 and that it is also ahead of other so-called old EU countries.

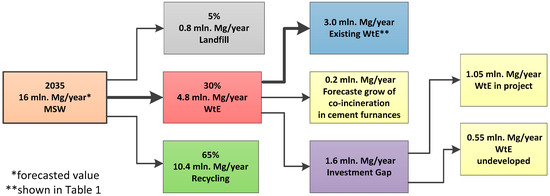

In conclusion, of the presented current (2024) assessment of the WtE share in sustainable municipal waste management in Poland, the necessity for further development of WtE and an increase in that share should be mentioned. The need for an increase of the current WtE share is a direct consequence of the necessity mentioned in the introduction, in which Poland must achieve the 65% share of municipal waste recycling required by EU law in 2035, which defines the circular economy in municipal waste management [30]. Assuming, based on the National Waste Management Plan 2028 [31], a 30% share of WtE plants to meet the requirements of circular economy in 2035 and assuming that 16 million tonnes of municipal waste will be generated in 2035 [23], then the target WtE potential should be about 4.8 million tonnes per year.

Assuming further that, by 2035, the cement industry in Poland, using energy-adapted RDF waste, will increase the share of these fuels derived from municipal waste from the current amount equal to 1.1 million tonnes of RDF (Table 1) to 1.3 million tonnes per year [24], then the investment gap for WtE plants will be [4.8 − (3.0 + 0.2)] = 1.6 million tonnes per year for 2035 [23].

A graphical illustration of the balance of the WtE plants’ investment gap towards the requirements of circular economy 2035 is shown in Figure 2. In that figure, the bold line indicates the most relevant direction of growth in WtE’s share in Poland’s municipal waste management as of 2024. Subsequent blocks are assigned colours specific to the waste treatment methods: grey—landfilling, green—recycling, and red—waste to energy. Blue and purple describe the next steps in describing the balance of WtE potential in Poland. Yellow blocks describe the realistic forecasts for WtE share growth and the investment gap in this area.

Figure 2.

WtE Polish WtE plants vs. circular economy—perspective 2035 (the meanings of colours and line thickness are explained in the paragraph above).

In order to mitigate this gap as much as possible, intensive measures led by the Warsaw-based National Fund for Environmental Protection and Water Management have already been undertaken, as of 2021 [32].

In addition to the fundamental objective of meeting the requirements of a circular economy by 2035, the existing investment gap in WtE plants is to be filled primarily by small local incineration plants that will use locally produced RDF waste fuel, of which there is an excess compared to the current potential of WtE plants. At the same time, small local WtE plants will be replaced, have already been heavily decapitalised and, moreover, are not conducive to climate change, with local coal-fired heating plants located in various towns and cities in Poland. According to the plans, 17 local WtE plant projects with a total capacity of 770,000 tonnes/year, ranging from a single treated capacity of 16,000 tonnes/year to 100,000 tonnes/year of RDF fuel, are qualified for implementation at the beginning of 2024 [32]. These plans include the far-fetched project to build three waste incineration lines with a capacity of 100,000 tonnes/year for the WtE Plant ZTPO Kraków [33]. Independently of these plans, constructing two waste incineration lines with a capacity of 80,000 tonnes was started at WtE Plant ITPOE Rzeszów at the beginning of 2024 [34]. Also, the third largest city in Poland in terms of population, Łódź, has realistic plans to build a WtE plant with a capacity of 200,000 tonnes per year [35]. Realistic plans for constructing the mentioned WtE plants in the 2035 timeframe will bridge the investment gap by 1.05 million tonnes. That will leave WtE plants with a target capacity of 550,000 tonnes to be further planned (Figure 2).

3. R1 Energy Efficiency Formula

The basic definition of energy efficiency in EU law states: “Energy efficiency—means the ratio of outputs, services, goods or energy produced to energy input” [3]. An energy efficiency indicator can classify each process associated with a particular waste treatment method. However, it is only logical to compare installations in terms of the energy efficiency achieved if they involve the same type of installation and the same type of waste being transformed. Assessing the energy efficiency of a given type of installation should primarily enable the selection of technological solutions that maximise the potential of the waste being treated. In the case of municipal waste incineration plants (MSWI), their potential is primarily determined by their ability to generate a certain amount of energy during waste incineration, which is defined as energy efficiency. The energy efficiency index quantifies the amount of recovered energy, in its utilisable forms, recovered from the total chemical energy contained in the transformed waste. The essential mathematical relationship describing energy efficiency can be represented by the following general Formula (1):

The relationship defined by Formula (1) can only be used to make an elementary comparison between a waste incineration plant and any other plant that allows the extraction of heat or electricity from the chemical energy contained in the fuel.

Due to the higher complexity of waste to energy compared to conventional energy sources, a special R1 formula has been developed for calculating the energy efficiency of MSWI.

According to the WFD [6], incineration facilities which process non-hazardous residual waste can be regarded as “Recovery” operations if the energy efficiency of the plant is greater than 0.65 (for plants permitted after January 2009). That is referred to as achieving “R1 status”. Plants that do not meet the energy efficiency criterion are classed as “Disposal” operations and, therefore, are considered equivalent to landfills in terms of the waste hierarchy.

The European Commission has published guidance titled “Guidelines on the Interpretation of the R1 Energy Efficiency Formulae for Incineration Facilities Dedicated to Processing Municipal Solid Waste According to Annex II of Directive 2008/98/EC on Waste” [20]. Within the European Commission guidance, the formula to calculate the efficiency of a facility is explained as follows. It is called R1 formula, and expressed by Formula (2):

where [20] the following definitions apply:

- Ep means annual energy produced as heat or electricity. It is calculated with energy in the form of electricity being multiplied by 2.6 and heat produced for commercial use multiplied by 1.1 (units of GJ/year);

- Ef means annual energy input to the system from fuels contributing to the production of steam (units of GJ/year);

- Ew means annual energy contained in the treated waste calculated using the lower calorific value of the waste (units of GJ/year);

- Ei means annual energy imported, excluding Ew and Ef (units of GJ/year);

- The value of 0.97 accounts for energy losses due to bottom ash and radiation.

For determining the energy efficiency R1 value, weights were adopted to distinguish between thermal and electrical energy quality. In addition, the needs of the waste incineration process for external forms of energy, such as fuel for initiating or supporting the process and electricity, were taken into account.

The equivalence factors for electricity and heat generation, which are taken directly from the BAT References Document for Waste Incineration [19] and Guidelines [20], can be explained as follows:

- The factor 2.6 for electricity is based on an average European coefficient of 38% of coal plants, which means an energy demand of 2.6 kWh for producing one kWh of electricity.

- The factor 1.1 for generated heat is based on an average European coefficient of heat plants of 91%.

The R1 formula is not strictly speaking to an expression of efficiency in physics but a performance indicator for the level of energy recovery from waste in a plant dedicated to the incineration of municipal solid waste (MSWI).

For EU countries with a warmer climate the operation of WtE plants in cogeneration (which can be defined as CHP) is not justifiable as there is no need for district heating or other forms of heat. In these countries the energy efficiency R1 value will be low, as the Ep factor will be low. To compensate for the disparity resulting from a comparison with the energy efficiency R1 value of WtE plants operated in EU countries with a colder climate, a climate correction factor (CCF) has been introduced, by which the energy efficiency R1 value for WtE plants determined for countries with a warmer climate is multiplied. The local climate correction factor comes from comparing the average winter temperature for the reference year and the average for the winter period over a long period (for example, 30 years in France and 20 years in Germany). This issue is addressed in papers [36,37].

According to data available on the Eurostat website, the average number of heating degree days (HDD) for Poland from the 20 years preceding the year for which the coefficient is determined (e.g., for the R1 for 2020, the years 1999–2018) was 3358 [38]. Based on the above, the climate correction factor (CCF) is assumed to be equal to 1.0, which does not result in an increase in the determined energy efficiency index (according to Annex II of Directive 2008/98/EC of the European Parliament and of the Council on waste [6,20]).

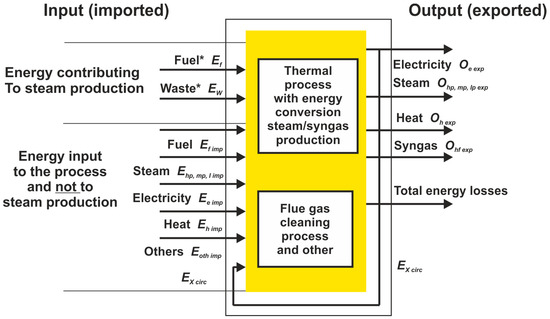

The R1 formula does not apply to co-incineration plants and facilities dedicated to the incineration of hazardous waste, hospital waste, sewage sludge, or industrial waste. The system boundaries for the calculation of the R1 formula are the incineration facility as defined in Figure 3, including the incineration furnace, combustion chamber(s), boiler(s), the flue gas cleaning system and, often, energy transformation and recovery equipment such as the heat exchangers feeding a district heating or cooling network, or a turbine generator [20].

Figure 3.

Energy efficiency system boundaries of R1 formula [20].

The meanings of variables and symbols in Figure 3 are listed as follows [20]:

- Ef—annual energy input to the system from fuels contributing to the steam production, as defined by the Formula (2) parameters;

- Ew—annual energy contained in the treated waste calculated using the lower calorific value of the waste, as defined by the Formula (2);

- Ef imp—annual energy consumption at the burner during start-up and shut-down periods. It is roughly 50% of Ef;

- Ehp,mp,I imp, Ee imp, Eh imp, Eoth imp—electricity, other kinds of imported non-fuel energy such as steam and hot water, and the fuel used during start-up and shut-down processes before connecting and after disconnecting to the steam grid;

- Ex circ—energy circulated in heat or/and electricity;

- Oe exp, Ohp,mp,lp exp, Oh exp, Ohf exp—annual exported energy of electricity, other kinds energy such as steam and hot water, heat, syngas (combined total of heat plus electricity as equivalents).

4. Analysis of Energy Efficiency R1 Values for Polish WtE Plants

Based on the EU regulatory framework in previous chapters and the guidelines on interpreting the R1 formula [20], R1 values were determined for selected Polish WtE plants. In order to achieve the purpose of this report, the five most characteristic incinerators in terms of their performance (described in Table 1 with numbers 1–5) were selected. The incinerators labelled in Table 1 with numbers 6–8 were not considered as installations with capacities that coincide with those already selected. The plant labelled in Table 1 with the number 9 was not considered since as co-incineration, it is not subject to the R1 formula in EU law. Incineration plants numbered 10, 11, and 12 were also not included because they are only in trial operation (numbers 10 and 11) or the final stage of investment (number 12) and thus there is not any information on the efficiency of their operation. Thus, the values of the R1 coefficient for Polish WtE plants in the years 2020 to 2023 were determined for the following plants:

The calculated and verified coefficients for the components Ep, Ef, Ew and Ei necessary to determine the final energy efficiency R1 are given for the Polish WtE plants studied in Table 2, Table 3, Table 4, Table 5 and Table 6. It should be emphasised that all calculations were based on verified and measured values and the calculation of the energy efficiency R1 was conducted according to the guidelines on the interpretation of the R1. All the facilities studied were commissioned after 2008 (Table 1), so the energy efficiency R1 value should be above 0.65 for a WtE plant to be considered R1.

Table 2.

Constituent factors Ep, Ef, Ew and Ei for WtE Plant ZUOK Białystok, 2020–2023.

Table 3.

Constituent factors Ep, Ef, Ew and Ei for WtE Plant ZTPOK Bydgoszcz, 2020–2023.

Table 4.

Constituent factors Ep, Ef, Ew and Ei for WtE Plant ZTUOK Konin, 2020–2023.

Table 5.

Constituent factors Ep, Ef, Ew and Ei for WtE Plant ZTPOK Kraków, 2020–2023.

Table 6.

Constituent factors Ep, Ef, Ew and Ei for WtE Plant ITPOK Poznań, 2020–2023.

Comments on the measurement results from Table 2:

- The weight of the waste was determined from measurements taken at the weighbridge at the WtE plant;

- The lower caloric value was determined either based on the balance in the DCS system or based on the Regulation of the Minister of the Environment of 8 June 2016 on the technical conditions for qualifying part of the energy recovered from thermal treatment of waste (Journal of Laws of 2016, item 847) [39].

Comments on the measurement results from Table 3:

- Supplying energy to the system was unnecessary; other fuels were used for steam production. Ef = 0;

- The bleed-condensing steam turbine failed in 2023. That significantly reduced the annual energy produced as heat or electricity and decreased the Ep value and, thus, the energy efficiency R1 value.

Comments on the measurement results from Table 4:

- Annual energy imported excluding Ew and Ef, i.e., Ei = 0.00;

- The annual energy contained in the treated waste (Ew) was obtained by measuring the energy contained in the steam produced in the boiler and determining the efficiency of the steam boiler: ;

- WtE Plant ZTUOK Konin has not been the leading supplier of heat to the local district heating network for many years. The local biomass-fired heating plant fulfils that role. Therefore, the value of the Ep coefficient and, consequently, energy efficiency R1 is low.

Comments on the measurement results from Table 5:

- The annual energy imported excluding Ew and Ef, i.e., Ei = 0.00;

- The measurement of annual energy contained in the treated waste (Ew) was made based on direct waste tests carried out by an accredited laboratory;

- Currently, at the end of 2023, a significant upgrade has been carried out in terms of commissioning the installation for the condensation of the moisture contained in the treated flue gases and the resulting heat recovery. This will decisively increase the energy efficiency of ZTPO Krakow’s WtE Plant. The modernisation and its effects are worthy of a separate subsequent publication.

Comments on the measurement results from Table 6:

- The annual energy contained in the treated waste (Ew) was obtained by measuring the energy in the steam produced in the boiler and determining the efficiency of the steam boiler;

- WtE Plant ITPOK Poznań shows a systematic increase in the generation and sale of district heat from 2020 onwards, resulting in a systematic increase in the value of annual energy produced as heat, which confirms the upward trend in the Ep coefficient and thus the systematic increase in energy efficiency R1.

5. Discussion

As mentioned in Section 4, five Polish WtE plants described in Table 1, items 1 to 5, were tested for the value of R1. Their total nominal (design) capacity for thermal treatment of municipal waste is 824 thousand Mg/year. It represents about 75% of the capacity of all Polish incineration plants operating for at least six years. Therefore, it can be assumed that the comments presented hereafter and the discussed conclusions resulting from these studies are, to a similar extent, representative of all Polish incineration plants listed in Table 1, items 1 to 9.

In order to justify the high degree of representativeness of the results obtained for the value of the R1 coefficient, it should be added that the study covered two incineration plants of the lowest capacity (ZTUOK Konin and ZUOK Białystok), one of medium capacity (ZTPOK Bydgoszcz) and the two largest plants in terms of capacity (ITPOK Poznań and ZTPO Kraków). Thus, studies on the value of the R1 coefficient were carried out across the entire cross-section of Polish incineration plant capacities. In addition, all conclusions were based on studies carried out for four years of operation of Polish incineration plants, analysed from 2020 to 2023. For reasons beyond the control of the authors of this report, the incineration plants listed in Table 1 under items 6 to 8 were not analysed. Also, for obvious reasons, the incineration plants listed in Table 1 under items 10, 11 and 12 were not analysed.

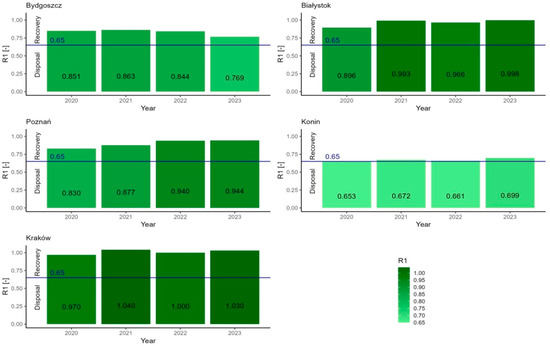

Figure 4, Figure 5, Figure 6 and Figure 7 are graphical illustrations of the test results obtained. All figures contained in the graphs presented in these figures are taken from Table 2, Table 3, Table 4, Table 5 and Table 6.

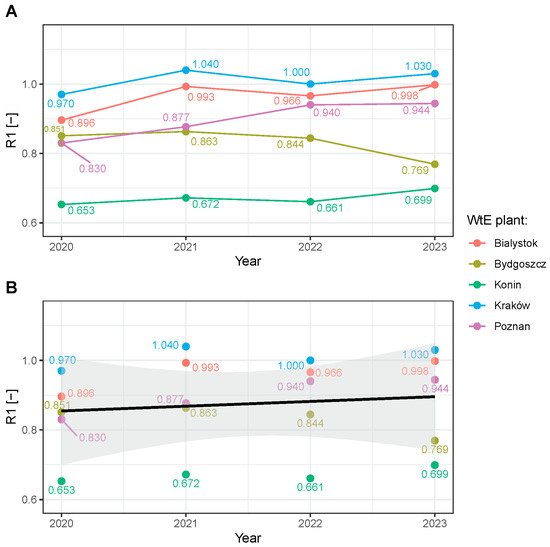

Figure 4.

Summary of annual average R1 values for WtE plants under study.

Figure 5.

Summary of changes in R1 values for the incineration plants studied (A) and the trend line of R1 values with confidence band at the 99.5% level (B).

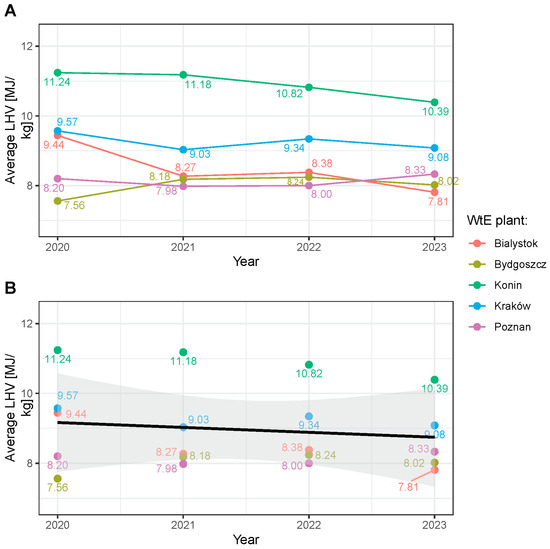

Figure 6.

Change in LHV of waste incinerated at different Polish incineration plants (A) and the trend line of changes in average LHV value with confidence band at the 99.5% level (B).

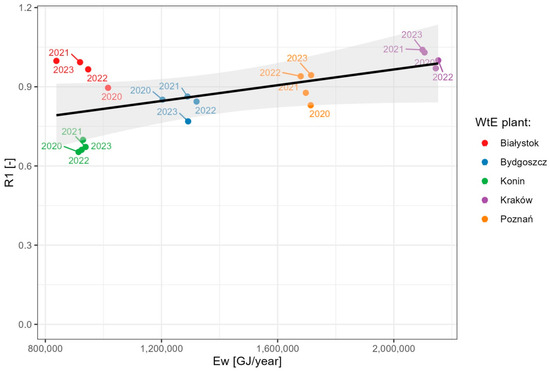

Figure 7.

Dependence of the value of R1 on the value defined by the parameter Ew, accompanied by a confidence band at the 99.5% level.

A summary of the values of the R1 coefficient for each of the incineration plants under study over its operating period from 2020 to 2023 is presented in Figure 4, thus providing a baseline and starting point for further analysis of the value of this coefficient for a given incineration plant under study.

The bars presented in Figure 4, showing the annual average R1 values for the surveyed Polish incineration plants operated from 2020 to 2023, lead to the following conclusions:

- Each of the analysed incineration plants meets the primary criterion for qualifying an incineration plant as recovering, as for each of the analysed incineration plants and each year of operation, the R1 coefficient is greater than 0.65, which is the primary statutory condition for this qualification [6]. However, significant differences can be seen, for example, when comparing the value of the R1 coefficient for the WtE Plant ZTPO Kraków and the WtE Plant ZTUOK Konin;

- The apparent differences in the value of the R1 coefficient are primarily the result of the mode of operation of a given incineration plant and, more specifically, depend on the reciprocal relationship of cogeneration, the simultaneous generation of electricity and heat in a given incineration plant, which, if such a relationship is met, leads to an increase in the energy efficiency of a given incineration plant and, at the same time, an increase in the value of the R1 coefficient. Such an incineration plant can then be considered as having the character of a combined heat and power plant (called WtE CHP—waste-to-energy combined heat and power plant) and, as mentioned at the beginning of this publication, the climatic conditions in Poland are favourable for a highly efficient mode of operation of incineration plants such as this;

- In most cases, Polish incineration plants operating as WtE CHP plants have no problems selling the heat generated in cogeneration. However, there are cases where there may be significant competition from other sources of district heating generation in the region where the incinerator is operating. Such is the case at the WtE Plant ZTUOK Konin, where the competing source of district heating is a biomass-fired heat plant, which prioritises heat sales. Hence, the values of the R1 coefficient for WtE Plant ZTUOK are very low;

- An interesting case of an orderly increase in R1 over the years 2020 to 2023 is WtE Plant ITPOK Poznań, where there has been a systematic increase in and sale of district heating in cogeneration operation since 2020 for heating and in the summer season for the domestic hot water needs of the city of Poznań;

- Also worth commenting on is the high value of R1 for WtE Plant ZUOK Białystok, which is the result of network heat sales systematised from 2021 to 2023. A similar conclusion could also be drawn for WtE Plant ZTPOK Bydgoszcz. However, in 2023, there was a failure of the steam turbine and generator (steam turbine-driven generator), resulting in a significant decrease in heat and power production and, thus, a decrease in R1;

- It is also easy to see that WtE Plant ZTPO Kraków represents the highest value of R1. That is due to modernising this incineration plant by extending it with a flue gas condensation heat recovery installation. Additional heat is then generated; thus, the parameter Ep’s value means annual energy produced as heat or electricity increases. At the same time, there is no change in the value of the parameter Ew, which is the annual energy contained in the treated waste, which, according to the R1 formula, directly increases the value of the R1.

A summary comparison of the R1 coefficient values for the WtE plants under study, is presented in Figure 5. It illustrates the annual change of R1 in each WtE plant (Figure 5A), and the common average trend of R1 accompanied by a confidence band at the 99.5% level (Figure 5B).

Figure 5 confirms all the conclusions and comments based on the graphical relationships presented in Figure 4. What is interesting here, however, is the upward trend line of the R1 value—shown in Figure 5B. This trend is primarily the result of increased production and sale of heat generated at Polish incineration plants due to the recovery of chemical energy contained in waste.

Another graphical illustration of the analysed results of energy efficiency studies of Polish incineration plants is presented in Figure 6, which gives an overview of the changes from 2020 to 2023 in the annual average lower heating value (LHV) of waste incinerated at each of the studied incineration plants. Figure 6A shows the changes in each individual plant, and Figure 6B shows the average trend of these changes, accompanied by a confidence band at the 99.5% level.

As reported in Section 2, Table 1 and as the comments to this table, a waste mix is incinerated in Polish incineration plants: mixed municipal waste code 200103 and fuels from waste code 191212 [25]. Waste with code 191212, referred to as RDF, has a significantly higher value of lower heating value (LHV) than non-recyclable mixed waste with code 200103. The share of fuels with code 191212 is varies periodically, depending on the demand for this type of waste fuel. The share of this type of fuel reaches an average of 55% in Polish incineration plants. In some incineration plants, it can be higher; e.g., at WtE Plant ZTUOK Konin, resulting in a calorific value for this incineration plant that is high for Polish conditions—shown in Figure 6A—of about 11 MJ/kg on average. A relatively high calorific value is also presented by the WtE Plant ZTPO Kraków, which is also due to the high share of RDF-type waste fuels, reaching 55%. The other Polish WtE Plants analysed—ZUOK Białystok, ZTPOK Bydgoszcz and ITPOK Poznań—present a similar heating value in the years 2021 to 2023, contained within the range of 7.8 to 8.4 MJ/kg.

Considering the above comments, the logical conclusion, presented in graphical form in Figure 6B, is the trend line of the LHV calorific value for the analysed Polish WtE plants. The noticeable slight decrease in the average calorific value for the analysed Polish WtE Plants in the years 2020–2023 is the result of a slight decrease in the share of combustion of RDF-type waste, code 191212, while the calorific value of mixed municipal waste, code 200103, stabilised in this period. The slight decreasing trend of LHV, visible in Figure 6B, can also be explained by the thermal protection of boilers of Polish WtE Plants against the too high thermal output of the fuel mix with the share of RDF-type fuels.

Figure 7, presented at the end of this discussion, provides additional insight into the analysed R1 values for Polish WtE plants. It illustrates the dependence of the R1 coefficient on the Ew value, meaning the annual energy contained in the treated waste is calculated using the lower calorific value of the waste. At the same time, the Ew parameter is also a direct illustration of the scale of efficiency of the WtE plant under analysis.

The trend shown in Figure 7 of an increase in the value of R1 with an increase in the value of the Ew parameter can be explained primarily by an increase in the share of heat production in the cogeneration operation of Polish WtE plants. The other parameters mentioned in the formula for R1 Formula (2), such as Ef, which means annual energy input to the system from fuels contributing to the production of steam, and Ei, which means annual energy imported, excluding Ew and Ef, do not play a significant role here.

For high-capacity incineration plants (ZTPO Kraków and ITPOK Poznań), and thus with a high value for the parameter Ew, the share of cogeneration heat production is significantly higher compared to other incineration plants. These are incineration plants operated in large Polish cities (Kraków and Poznań) and have the potential to sell more significant amounts of district heat, which significantly increases the value of the parameter Ep, which means annual energy produced as heat or electricity in the formula for R1 Formula (2). In addition, the increasing trend of the line depicted in Figure 7 is influenced by the minimal share of heat in the cogeneration operation of the WtE Plant ZTUOK Konin, the reasons for which are explained by presenting the results of the R1 Formula for this incineration plant in the comments under Figure 4. Thus, the upward trend in the value of the R1 coefficient as a function of the Ew parameter shown in Figure 7 is mainly due to the varying shares of heat generated in the cogeneration mode of the analysed Polish WtE plants.

6. Summary and Conclusions

This publication has the typical character of a report analysing the Polish WtE plants in many dimensions regarding the efficiency of recovery of energy contained in thermally transformed municipal waste. In outlining the report’s aim, as stated in the title, the report discusses the European Union’s climate protection legislation in detail and the consequent need to increase the efficiency of energy recovery from various sources of energy production, particularly in municipal waste incineration plants. Poland’s current potential for municipal waste management, supported also by waste to energy, is presented, and the necessary capacity potential of municipal waste incineration plants in Poland because of the requirements of a circular economy applicable by 2035 is outlined.

The essential chapters of this report, however, are the chapter presenting the relationship known as the R1 Formula Equation (2) and, above all, the subsequent chapters presenting the results of the R1 value tests, together with a detailed graphical presentation of these results and an extensive discussion of them.

The energy recovery efficiency ratio R1 values were tested for five Polish WtE Plants. These WtE plants represent 75% of the capacity of all incineration plants operated in Poland for at least six years, assuming a similar representativeness of the obtained test results for all incineration plants in Poland operated under this assumption. The 4-year operation period of the selected five incineration plants was studied.

When discussing the results obtained from the study of the R1 coefficient values, all due care was taken resulting from the theory of thermal cycles characteristic of WtE CHP plants.

The obtained results of the values of the efficiency coefficient of energy recovery R1 studied and presented for selected Polish incineration plants, it can be said that these results do not differ in any way from the typical values of the R1 coefficient represented by incineration plants in such European countries as Germany, Denmark, Switzerland or Scandinavian countries, where waste incineration plants have been in operation for decades. In Poland for about 8 years. At the same time, it is fully justified to conclude that the values of the R1 coefficient for Polish incineration plants, through the high efficiency of recovery of energy contained in waste, fit very well into the legal regulations and plans for climate protection that are in force in the countries of the European Union. Considering the highly energy-efficient Polish waste-to-energy industry, that is a very valuable prognosis in this aspect.

In addition to graphically illustrating and extensively discussing the results of the R1 factor study, the presented report also presents a detailed characterisation of the current state of Poland’s waste-to-energy potential, including the prospects for its development implied by the circular economy requirements envisaged for EU countries in 2035. This report confirms that specific projects are already being undertaken in Poland to build more waste-to-energy plants. Taking into account the three newest Polish incineration plants, two of which are already in the start-up phase and the third will be launched at the end of 2024 (Table 1), as well as taking into account further projects to expand Poland’s waste-to-energy potential, one can be optimistic about Poland’s fulfilment of its climate protection obligations under EU law for 2030 and 2050.

At the same time, the authors of this report hope that, through its content, this publication will be interesting reading for waste-to-energy specialists from Asian countries and beyond, where municipal waste incineration plants are increasing at a very high rate.

Author Contributions

Conceptualisation, M.B. and T.P.; methodology, T.P. and M.B.; software, M.B.; validation, T.P., M.B. and W.W.; formal analysis, T.P., M.B. and J.C.; investigation, M.B. and T.P.; resources, J.B. and W.W.; data curation, J.B. and W.W.; writing—original draft preparation, T.P., M.B. and J.C.; writing—review and editing, M.B., T.P. and J.C.; visualisation, M.B.; supervision, T.P. and M.B.; funding acquisition, M.B. and T.P. All authors have read and agreed to the published version of the manuscript.

Funding

The publishing fee was financed by the AGH research project no. 16.16.130.942 supported by the Polish Ministry of Education and Science.

Data Availability Statement

All data presented in this text are at the disposal of the corresponding author.

Acknowledgments

The authors would like to thank the management of five Polish WtE Plants (Bialystok, Bydgoszcz, Konin, Poznan, Krakow), who were willing to provide data on selected indicators of WtE exploitation used in this report.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- European Commission. Communication from the Commission to the European Parliament, the European Council, the Council, the European Economic and Social Committee and the Committee of the Regions. The European Green Deal.COM (2019) 640 Final. Brussels, 11.12.2019. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:52019DC0640 (accessed on 17 February 2024).

- Commission Welcomes Completion of Key ‘Fit for 55’ Legislation, Putting EU on Track to Exceed 2030 Targets. Available online: https://ec.europa.eu/commission/presscorner/detail/en/IP_23_4754 (accessed on 17 February 2024).

- Directive (EU) 2023/1791 of the European Parliament and of the Council of 13 September 2023 on Energy Efficiency and Amending Regulation (EU) 2023/955 (Recast). Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32023L1791 (accessed on 17 February 2024).

- Industry Barometer Waste-to-Energy 2023; CEWEP, ECOPROG: Cologne, Germany, 2023.

- Poretti, F.; Stengler, E. The Climate Roadmap of the European Waste-to-Energy Sector. The Path to Carbon Negative. In Proceedings of the 16th International Conference on Greenhouse Gas Control Technologies, GHGT-16, Lyon, France, 23–27 October 2022; Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=4284664 (accessed on 17 February 2024).

- Waste Framework Directive (EU) 2018/851 of the European Parliament and of the Council of 30 May 2018 Amending Directive 2008/98/EC on Waste (Text with EEA Relevance). Available online: https://eur-lex.europa.eu/eli/dir/2018/851/oj (accessed on 17 February 2024).

- Debunking Efficient Recovery. The Performance of EU Incineration Facilities. Equanimator Ltd. for Zero Waste Europe. Report January 2023. Available online: https://zerowasteeurope.eu/wp-content/uploads/2023/01/Debunking-Efficient-Recovery-Full-Report-EN.docx.pdf (accessed on 17 February 2024).

- Studie: Perspektiven der Thermischen Abfallbehandlung-Roadmap 2040. Prof. Martin Faulstich. Im Auftrag der ITAD–Interessengemeinschaft der Thermischen Abfallbehandlungsanlagen in Deutschland e.V. August 2020. Available online: https://www.itad.de/wissen/studien/tab_roadmap-2040.pdf (accessed on 17 February 2024).

- Pająk, T. Municipal solid waste as an efficient and renewable source of energy. Pol. J. Environ. Studies 2012, 21, 332–337. [Google Scholar]

- Available online: https://wikiwaste.org.uk/R1_Recovery_Facility (accessed on 17 February 2024).

- Available online: https://consult.environment-agency.gov.uk/psc/ba13-4we-northacre-renewable-energy-limited/supporting_documents/Application%20%20Bespoke%20%20Appendix%20K%20%20R1%20Technical%20Note.pdf (accessed on 17 February 2024).

- Basaran, A. A study on the renewable energy potential of incineration of municipal solid wastes produced in Izmir province. Int. Adv. Res. Eng. J. 2022, 6, 123–131. [Google Scholar] [CrossRef]

- Kwon, Y. Evaluation of Incinerator Performance and Policy Framework for Effective Waste Management and Energy Recovery: A Case Study of South Korea. Sustainability 2024, 16, 448. [Google Scholar] [CrossRef]

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. The Role of Waste-to-Energy in the Circular Economy. The Role of Waste-to-Energy in the Circular Economy. COM (2017) 34 Final. Brussels, 26.1.2017. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX%3A52017DC0034 (accessed on 17 February 2024).

- Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Waste_management_indicators (accessed on 17 February 2024).

- Waste-to-Energy Climate Roadmap. Technical Annex (TA). Main Assumptions & Methodology. CEWEP Confederation of European Waste-to-Energy Plants. June 2022. Available online: https://www.cewep.eu/wp-content/uploads/2022/06/TA-Technical-Annex_CEWEP-Climate-Roadmap_June22.pdf (accessed on 17 February 2024).

- International Energy Agency GHG Program (IEAGHG), “CCS on Waste to Energy”, 2020-06, December 2020. Available online: https://www.club-co2.fr/files/2021/01/2020-06-CCS-on-Waste-to-Energy.pdf (accessed on 17 February 2024).

- Parliamentary Questions 3 February 2021, Subject: Contribution of Waste-to-Energy Plants to Reducing CO2 Emissions, 19 February 2021. Available online: https://www.europarl.europa.eu/doceo/document/E-9-2021-000670_EN.html (accessed on 17 February 2024).

- Commission Implementing Decision (EU) 2019/2010 of 12 November 2019 Establishing the Best Available Techniques (BAT) Conclusions, under Directive 2010/75/EU of the European Parliament and of the Council, for Waste Incineration (Notified under Document C (2019) 7987). Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32019D2010 (accessed on 17 February 2024).

- Guidelines on the Interpretation of the R1 Energy Efficiency Formula for Incineration Facilities Dedicated to the Processing of Municipal Solid Waste According to Annex II of Directive 2008/98/EC on Waste. Available online: https://ec.europa.eu/environment/pdf/waste/framework/guidance.pdf (accessed on 17 February 2024).

- European Commission. Operational Programme Infrastructure and Environment 2007–2013. Available online: https://trimis.ec.europa.eu/programme/operational-programme-infrastructure-and-environment-2007-2013 (accessed on 17 February 2024).

- Pająk, T. Polish Waste-to-Energy Projects and Their Perspectives; Thomé-Kozmiensky, K.J., Thiel, S., Eds.; Waste Management. Volume 3, Recycling and Recovery; TK Verlag Karl Thomé-Kozmiensky: Neuruppin, Germany, 2012; pp. 87–95. ISBN 978-3-935317-83-2. [Google Scholar]

- Termiczne Przekształcanie Odpadów Komunalnych w Polsce w 2021 r. Instytut Ochrony Środowiska. Państwowy Instytut Badawczy. Warszawa 2021. Available online: https://ios.edu.pl/wp-content/uploads/2023/12/raport-termika.pdf (accessed on 17 February 2024).

- Spajamy Europejski Zielony Ład—Osiągnięcie Neutralności Emisyjnej w Łańcuchu Eartości Cementu i Betonu do Roku 2050. The European Cement Association. Polish Cement Association. Available online: https://www.polskicement.pl/mapa-drogowa-2050/ (accessed on 17 February 2024).

- Regulation of the Minister of Climate of January 2, 2020 on the Catalogue of Wastes. Poland. Journal of Laws 2020 Pos. 10. Original Title: Rozporządzenie Ministra Klimatu z dnia 2 Stycznia 2020 r. w Sprawie katalogu odpadów. (Dz. U. 2020 poz. 10). Available online: https://leap.unep.org/en/countries/pl/national-legislation/regulation-catalogue-wastes-0 (accessed on 17 February 2024).

- Commission of the European Communities. Guidance on Classification of Waste According to EWC-Stat Categories. Available online: https://ec.europa.eu/eurostat/documents/342366/351806/Guidance-on-EWCStat-categories-2010.pdf/0e7cd3fc-c05c-47a7-818f-1c2421e55604 (accessed on 17 February 2024).

- Rachael Lew. Moving Grate Incineration: The Most Common WTE Technology. 29 November 2022. Available online: https://www.bioenergyconsult.com/moving-grate-incineration/#google_vignette (accessed on 17 February 2024).

- Cyranka, M.; Jurczyk, M. Energy recovery from municipal waste based on moving grate technology. Agric. Eng. 2016, 20, 23–33. [Google Scholar] [CrossRef][Green Version]

- Główny Urząd Statystyczny. Ochrona środowiska 2023. Warszawa 2023. Statistics Poland. Environment 2023. Warsaw 2023. Available online: https://stat.gov.pl›ochrona_srodowiska_2023 (accessed on 17 February 2024).

- Circular Economy—European Commission. Available online: https://environment.ec.europa.eu/topics/circular-economy_en (accessed on 17 February 2024).

- Krajowy Plan GospodarkiOdpadami 2028. National Waste Management Plan 2028. Available online: https://isap.sejm.gov.pl/isap.nsf/download.xsp/WMP20230000702/O/M20230702.pdf (accessed on 17 February 2024).

- National Fund for Environmental Protection and Water Management. Available online: https://www.gov.pl/web/nfosigw-en (accessed on 17 February 2024).

- Budowa Zakładu Odzysku Energii—Trzeciej Linii z Dofinansowaniem. Construction of the Energy Recovery Plant—Third Line with Co-Financing. Available online: https://khk.krakow.pl/pl/aktualnosci/budowa-zakladu-odzysku-energii-trzeciej-linii-z-dofinansowaniem-nfosigw/ (accessed on 17 February 2024).

- Powstanie II Linia ITPOE w Rzeszowie. The Second ITPOE Line Will Be Built in Rzeszów. Available online: https://pgeenergiaciepla.pl/aktualnosci/powstanie-ii-linia-itpoe-w-rzeszowie (accessed on 17 February 2024).

- Budowa Instalacji Termicznego Przekształcania Odpadów (ITPO). Construction of the Energy Recovery Facility. Available online: https://www.veolia.pl/budowa-instalacji-termicznego-przeksztalcania-odpadow-itpo (accessed on 17 February 2024).

- Hoque, K.M.R.; Ozansoy, C.; Fahrioglu, M. Climate and Size Correction in European Union’s Waste Framework Directive and R1 Energy Efficiency Criteria. Waste Manag. Res. 2018, 36, 670–688. [Google Scholar] [CrossRef] [PubMed]

- Medarac, H.; Scarlat, N.; Monforti, F.; Bódis, K. Report on the Impact of R1 Climate Correction Factor on the Waste-to-Energy (WtE) Plants Based on Data Provided by Member States. European Commission. Joint Research Centre. Technical Report. September 2014. Available online: https://www.researchgate.net/publication/265600682_Report_on_the_impact_of_R1_climate_correction_factor_on_the_Waste-toEnergy_WtE_plants_based_on_data_provided_by_Member_States (accessed on 17 February 2024).

- EUROSTAT Statistics Explained. Heating and Cooling Degree Days—Statistics. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Heating_and_cooling_degree_days_-_statistics (accessed on 17 February 2024).

- Rozporządzenie Ministra Środowiska z dn. 8 Czerwca 2016 r. w Sprawiewarunkówtechnicznychkwalifikowaniaczęścienergiiodzyskanej z Termicznego Przekształcania Odpadów (Dz. U. 2016, poz. 847). Regulation of the Minister of the Environment of 8 June, 2016 on the Technical Conditions for Qualifying Part of the Energy Recovered from Thermal Treated of Waste (Journal of Laws of 2016, Item 847). Available online: https://isap.sejm.gov.pl/isap.nsf/download.xsp/WDU20160000847/O/D20160847.pdf (accessed on 17 February 2024).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).