Abstract

This comprehensive review examines the role of sustainable aviation fuels (SAFs) in promoting a more environmentally responsible aviation industry. This study explores various types of biofuels, including hydroprocessed esters and fatty acids (HEFAs), Fischer–Tropsch (FT) fuels, alcohol-to-jet (ATJ) fuels, and oil derived from algae. Technological advancements in production and processing have enabled SAF to offer significant reductions in greenhouse gas emissions and other pollutants, contributing to a cleaner environment and better air quality. The review addresses the environmental, economic, and technical benefits of SAF, as well as the challenges associated with their adoption. Lifecycle analyses are used to assess the net environmental benefits of SAF, with a focus on feedstock sustainability, energy efficiency, and potential impacts on biodiversity and land use. Challenges such as economic viability, scalability, and regulatory compliance are discussed, with emphasis on the need for supportive policies and international collaboration to ensure the long-term sustainability of SAF. This study also explores current applications of SAF in commercial airlines and military settings, highlighting successful case studies and regional differences driven by policy frameworks and government incentives. By promoting technological innovation and addressing regulatory and economic barriers, SAF has the potential to play a crucial role in the aviation industry’s transition toward sustainability.

1. Introduction

1.1. Background on Aviation and Environmental Concerns

Aviation is a significant contributor to global carbon emissions, posing substantial environmental challenges that exacerbate climate change. Aviation emissions, particularly carbon dioxide (CO2), nitrogen oxides (NOx), and water vapor, directly contribute to global warming and climate change through the greenhouse effect and cloud formation enhancements [1,2]. The persistent growth in air travel demand ensures that these emissions will continue to rise without significant interventions in aircraft fuel technologies and air traffic management [3].

Sustainable aviation fuels (SAFs) are pivotal to the future of aviation, offering a viable alternative to conventional jet fuels, which are major sources of aviation-related emissions. SAFs, derived from bio-based resources, significantly reduce the lifecycle carbon emissions associated with aviation, providing a critical solution to the pressing need for the aviation sector’s decarbonization [4,5]. The adoption of SAFs not only aligns with global carbon reduction targets but also helps in mitigating the climate impact of non-CO2 emissions, such as those from NOx and contrails, which are significant contributors to radiative forcing [6,7].

1.2. Importance of Sustainable Aviation Fuels (SAFs)

The aviation industry is undergoing a resurgence since the COVID-19 pandemic, resulting in a heightened global demand for aviation fuel. The International Air Transport Association (IATA) projects this demand to reach 6.46 million gallons per day, which is equivalent to approximately 19.8 thousand tons per day. The increased consumption of aviation fuel will impact the environment and human health by raising greenhouse gas (GHG) emissions. In 2019, air transport generated 914 million tons of CO2, accounting for 2.1% of total human-produced CO2 emissions and 12% of CO2 emissions from the transport sector [8].

Achieving net zero carbon dioxide (CO2) emissions by 2050 is a key objective for the aviation industry, governments, and regulatory bodies. High-level strategies, scenarios, and roadmaps have been proposed to support this transition. Examples include the European Green Deal with its Fit-for-55 package, IATA’s “Fly Net Zero” strategy, and EUROCONTROL’s aviation outlook for 2050 [9]. The transition to SAFs offers numerous benefits over traditional fuels. SAFs contribute to energy security by diversifying the fuel supply and reducing dependency on oil markets. They also support rural development and agricultural diversification through the use of non-food bio-feedstocks [10,11].

Despite these advantages, the widespread implementation of SAFs faces significant challenges, including high production costs, feedstock availability, and the need for substantial technological and infrastructural developments to support large-scale deployment [12,13]. To realize the full potential of SAFs, coordinated efforts among governments, industry stakeholders, and the scientific community are essential. This includes investments in research and development to improve fuel efficiency and reduce costs, as well as policies to support the market uptake of SAFs [14,15,16].

The main goal of this review paper is to thoroughly investigate the environmental challenges presented by the aviation sector, particularly its substantial contribution to global carbon emissions. The paper examines the impact of these emissions—such as carbon dioxide, nitrogen oxides, and water vapor—on global warming and climate systems, both directly and indirectly. It also explores the role of sustainable aviation fuels (SAFs) as a feasible alternative to conventional jet fuels, emphasizing their potential to lower lifecycle carbon emissions and support the decarbonization of the aviation industry.

2. Methodology

2.1. Data Sources and Selection Criteria

The selection of sources for this comprehensive review was guided by specific criteria to ensure the relevance and reliability of the information pertaining to sustainable aviation fuels and their application in aircraft engines. Initially, the primary data sources were peer-reviewed journal articles, industry reports, and authoritative publications from significant entities in the aviation and environmental sectors, such as the International Air Transport Association (IATA) and the International Civil Aviation Organization (ICAO). The relevance of each source was determined based on its publication date, preferably within the last five years, to ensure the currency of the data in the rapidly evolving field of aviation biofuels.

Reliability was assessed through the source’s peer-reviewed status, citation metrics, and the recognition of the publishing journal or organization within the scientific and aviation communities. Sources were also selected based on the specificity of their focus on biofuels’ lifecycle analysis, emission impacts, economic viability, and regulatory frameworks. This ensured a comprehensive collection of data that spans across the necessary dimensions of the study topic.

2.2. Approach to Literature Review and Analysis

The approach to the literature review and analysis involved a structured process to synthesize and interpret the gathered data effectively. The review started with a broad search of keywords and phrases related to “sustainable aviation fuels”, “biofuel use in aviation”, and “environmental impact of aviation fuels”. This initial search was refined by applying the selection criteria to narrow down the most relevant and reliable sources. Each selected source was then meticulously reviewed to extract data pertinent to the environmental impacts, technical performance, economic aspects, and regulatory environments associated with biofuels in aviation.

The synthesis of information was conducted through a thematic analysis, where data were categorized into themes such as environmental benefits, technical challenges, economic feasibility, and policy implications. This thematic approach allowed for a coherent structure in which to discuss the findings comprehensively. The analysis also included a critical evaluation of conflicting data and gaps in current research, providing a balanced perspective on the potential and limitations of sustainable aviation fuels. The review culminated in integrating these insights into a narrative that reflects both the current state of knowledge and the future directions for research and policymaking in the domain of sustainable aviation fuels.

3. Overview of Aircraft Engine Types

3.1. Piston Engines

Piston engines, also known as reciprocating engines, are among the oldest types of aircraft engines and are primarily used in small general aviation aircraft. They operate similarly to automobile engines, using the expansion of burning gas to drive pistons. These engines are typically powered by avgas (aviation gasoline), which is a high-octane fuel suitable for the high compression ratios of aviation engines [17,18]. The transition to biofuels in piston engines poses challenges primarily due to the biofuels’ different chemical characteristics compared to avgas, such as lower energy content per volume and variations in stoichiometric fuel-to-air ratio, which can affect engine performance and maintenance [19,20]. Research into biofuel compatibility with piston engines has indicated that modifications to the fuel delivery systems and ignition timing may be necessary to accommodate some types of biofuels [21,22]. Studies have also highlighted the potential for biofuels to reduce emissions of unburned hydrocarbons and carbon monoxide in piston aircraft engines, aligning with environmental sustainability goals [20,23].

3.2. Turboprop Engines

Turboprop engines combine aspects of both jet engines and propellers. These engines are used primarily in aircraft that require short take-offs and landings or in those flying at lower speeds for regional transport. Turboprops are known for their efficiency at speeds below 450 miles per hour and are typically more fuel-efficient than turbojets or turbofans at these lower speeds [13,15]. The use of biofuels in turboprop engines has been explored, with studies demonstrating that biofuels such as HEFAs (hydroprocessed esters and fatty acids) can be integrated without significant modifications to the engine [5,9].

Research has shown that SAFs, including those derived from jatropha, camelina, and even used cooking oils, can meet the stringent energy density and freezing point requirements necessary for turboprop applications [12,14]. These studies underline the potential for significant reductions in lifecycle greenhouse gas emissions when switching from conventional jet fuel to biofuels in turboprop engines [5,24].

3.3. Jet Engines (Turbojet and Turbofan)

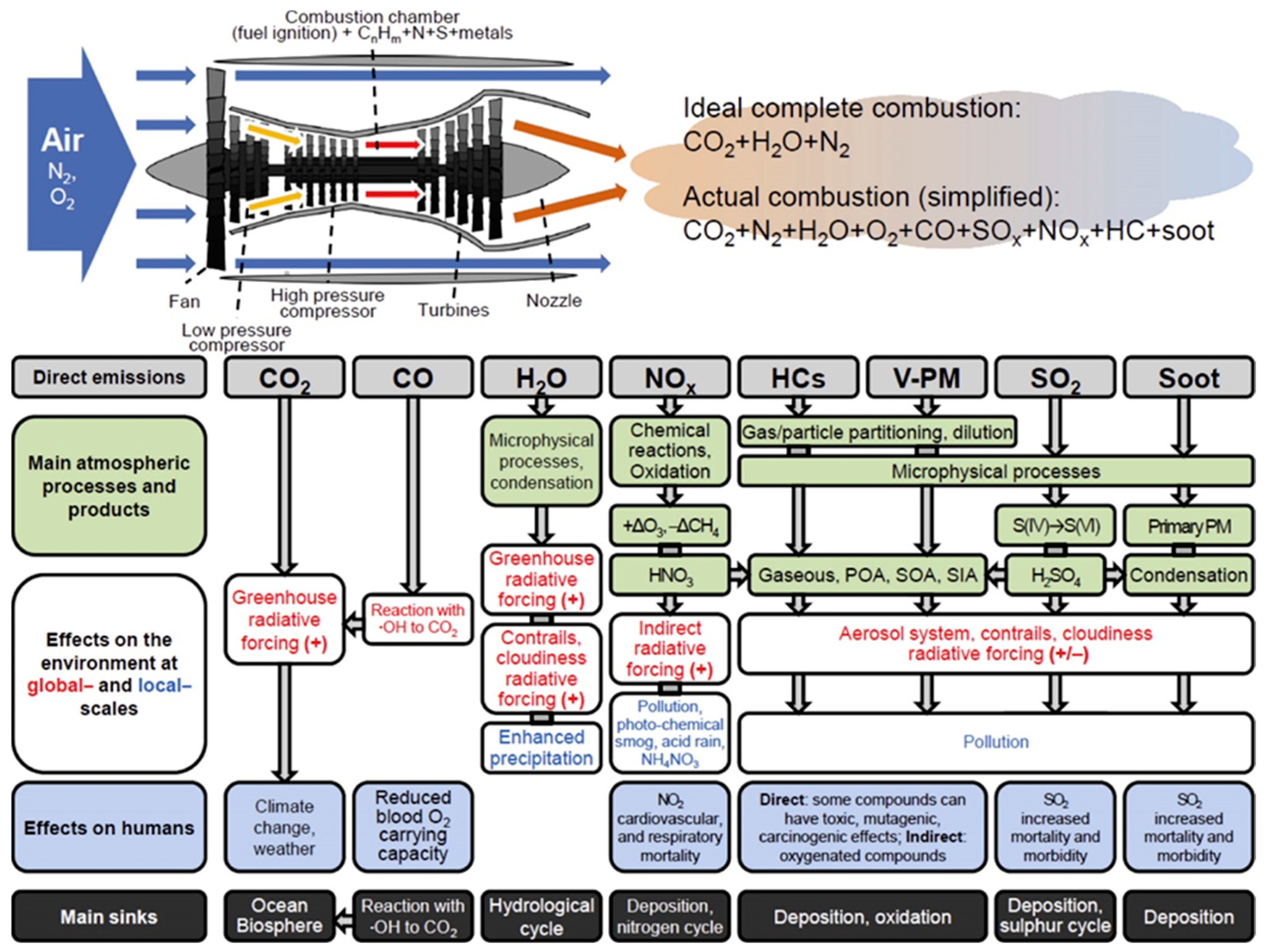

Turbojet and turbofan engines are the most common engines used in commercial aviation, with turbofans being more prevalent due to their greater efficiency and reduced noise output. These engines work by drawing air into the engine, compressing it, mixing it with fuel, and igniting the mixture to produce thrust [25,26]. The compatibility of biofuels with jet engines has been extensively tested, demonstrating that biofuels can replace conventional jet fuel up to a 50% blend with minimal to no modifications required to the engines [22]. Figure 1 shows a basic illustration of a turbofan engine.

Figure 1.

A simplified diagram of a turbofan engine in the upper left corner, and the byproducts of ideal and actual combustion in an aircraft engine in the upper right corner. Various atmospheric processes, products, environmental impacts, effects on human health, and sinks for emitted compounds are in the bottom section [27].

The studies have highlighted that biofuels can significantly reduce the emission of pollutants such as sulfur oxides and particulate matter, which are prevalent in emissions from conventional jet fuels [28,29]. The aviation industry sees this as a crucial step toward achieving carbon-neutral growth, with the added benefit of reducing contrail formation, which has a high climate impact due to its greenhouse gas trapping ability [20,30].

3.4. Compatibility of Different Engines with Biofuels

The compatibility of different engine types with biofuels is a critical area of research, particularly as the aviation industry seeks sustainable fuel alternatives to meet environmental targets. While piston and turboprop engines may require some adjustments for optimal biofuel performance, turbojet and turbofan engines have shown a higher degree of readiness for biofuel integration, particularly with SAFs [10,20]. Each engine type presents unique challenges, from material compatibility and fuel system adjustments to efficiency metrics and emission profiles.

Studies continue to focus on the long-term impacts of biofuel use on engine wear and tear, maintenance schedules, and overall lifecycle costs [19,26]. Additionally, the research emphasizes the need for industry-wide standards and certification processes to ensure that biofuels not only meet the technical requirements of various engines but also contribute positively to environmental sustainability goals without compromising safety or performance [14,15].

4. Types of Biofuels in Aviation

4.1. Hydroprocessed Esters and Fatty Acids (HEFAs)

Hydroprocessed esters and fatty acids (HEFAs) are among the leading types of sustainable aviation fuels (SAFs) currently being integrated into the aviation sector. HEFA fuels are produced through the hydroprocessing of vegetable oils or animal fats, which involves the removal of oxygen and other non-hydrocarbon molecules to create hydrocarbons that are structurally similar to those found in conventional jet fuels. This process results in a renewable jet fuel that can be used as a direct drop-in replacement for traditional jet fuels without requiring modifications to aircraft engines or fuel distribution infrastructure [31,32].

One of the crucial points for HEFA production is hydrogen production. This is a significant factor affecting both the economic viability and the environmental footprint of HEFA, particularly when considering green hydrogen. A recent study by Pipitone et al. (2023) addresses both the economic and environmental impacts of hydrogen production in HEFA processes, underscoring the importance of green hydrogen in reducing lifecycle emissions [33].

The appeal of HEFA fuels lies in their significant environmental benefits. They do not contain sulfur and have the potential to reduce greenhouse gas emissions by up to 80% over their lifecycle compared to conventional jet fuels. This reduction is primarily due to the sustainable nature of the feedstocks and the potential for the carbon dioxide released during combustion to be offset by the carbon dioxide absorbed during the growth of the feedstocks [34]. Technological advancements in the HEFA production process have focused on optimizing yields and improving the cold flow properties of the fuel, which are critical for aviation use. Techniques such as adjusting the isomerization process have been explored to enhance the yield while maintaining the necessary freezing point properties required for aviation fuels [31]. Additionally, ongoing research aims to expand the variety of feedstocks that can be used, thereby increasing the scalability and economic feasibility of HEFA fuels [35].

One of the critical challenges facing the adoption of HEFAs as a sustainable aviation fuel is the economic viability. The cost of production remains higher than that of conventional jet fuels, primarily due to the high cost of bio-based feedstocks and the complexity of the production process. However, economic analyses suggest that with strategic policy support and technological advancements, HEFA fuels could become more competitively priced, fostering broader adoption in the aviation industry [32]. HEFA fuels have been demonstrated to perform comparably to conventional fuels in terms of engine efficiency and emissions. Studies have shown that HEFA can significantly reduce emissions of particulate matter and other pollutants, contributing to cleaner engine operations and less environmental impact. Continued research and development are focusing on further reducing any potential toxicological impacts associated with HEFA fuel usage, ensuring safety and sustainability in its application [33].

4.2. Synthetic Iso-Paraffin (SIP) Fuel

Synthetic iso-paraffin (SIP) fuels, often referred to as synthetic paraffinic kerosene when used in aviation, are a type of sustainable aviation fuel (SAF) that holds significant promise for reducing the aviation sector’s carbon footprint. SIP fuels are produced using the Fischer–Tropsch process or through the hydroprocessing of renewable fats and oils. These processes yield a high-quality fuel that contains no sulfur and has excellent combustion properties [36,37]. The benefits of SIP fuels include their ability to significantly reduce emissions of particulates and greenhouse gases compared to conventional jet fuels. For example, the use of SIP in aircraft engines has demonstrated a reduction in the emission of soot and other particulate matter, which are known contributors to atmospheric warming and pollution [36]. Moreover, due to their cleaner burning characteristics, SIP fuels can help improve air quality around airports and major cities.

Technologically, SIP fuels are compatible with existing aircraft engines and fuel distribution infrastructure, which allows them to be blended with traditional jet fuels without any modifications to aircraft systems. This compatibility is pivotal for the adoption of SIP fuels in the aviation industry, as it enables airlines to transition to greener fuels without incurring substantial retrofitting costs or operational changes [37]. There are challenges associated with the widespread adoption of SIP fuels. The production of SIP is currently more costly than that of conventional jet fuel, primarily due to the high cost of production facilities and the need for significant upfront investment in technology development. Moreover, while the feedstocks used in the production of SIP are renewable, the scalability of these resources and the sustainability of their supply chains are critical factors that need further exploration and optimization to meet the growing demand of the aviation industry [38].

In terms of safety and performance, studies have shown that SIP fuels perform well under various atmospheric conditions, maintaining stability and energy content comparable to traditional fuels. This aspect is crucial for ensuring that the adoption of SIP does not compromise the safety and reliability of air travel [36].

4.3. Fischer–Tropsch (FT) Fuel

Fischer–Tropsch (FT) synthesis is a versatile and well-established process used to convert syngas (a mixture of carbon monoxide and hydrogen) derived from various carbonaceous materials like coal, natural gas, or biomass into liquid hydrocarbons. This technology is critical for producing synthetic fuels, including sustainable aviation fuels (SAFs), that are virtually sulfur-free and have significantly lower greenhouse gas emissions compared to conventional jet fuels [39,40]. FT fuels are praised for their cleanliness and high performance in aircraft engines. They can be tailored to produce a wide range of hydrocarbon chains, making them highly suitable for aviation purposes. The adaptability of FT synthesis allows for the production of fuels that meet stringent aviation fuel standards regarding purity and performance. Furthermore, FT fuels have the potential to significantly reduce particulate matter emissions and other pollutants associated with jet engines, contributing to cleaner airport environments and reducing the aviation industry’s overall carbon footprint [41,42].

Despite their benefits, the scale-up and economic viability of FT fuels face several challenges. The capital-intensive nature of FT synthesis plants and the variability in feedstock costs can hinder the broader deployment of this technology. However, advancements in catalysis and process engineering are continually being explored to reduce these costs and improve efficiency. For instance, innovations in catalyst formulations and reactor designs have shown potential to enhance conversion rates and selectivity towards desired fuel components, thereby optimizing production costs and environmental benefits [43,44]. Moreover, the sustainability of FT fuels largely depends on the source of the hydrogen and carbon monoxide used in the synthesis process. Utilizing biomass or waste-derived syngas aligns with circular economy principles and further enhances the environmental credentials of FT fuels. The integration of carbon capture and utilization technologies into the FT process also presents a promising avenue to reduce the overall carbon intensity of the produced fuels, aligning with global carbon reduction goals [45]. Fischer–Tropsch synthesis can be conducted at varying temperatures. In processes using iron catalysts, the synthesis temperature can range from 220 °C to 340 °C, depending on the specific technology employed [46].

4.4. Alcohol-to-Jet (ATJ)

Alcohol-to-jet (ATJ) technology represents a transformative approach to sustainable aviation fuel (SAF) production, converting alcohols such as ethanol or isobutanol into synthetic paraffinic kerosene suitable for jet engines. This pathway leverages established catalytic processes to dehydrate alcohols into alkenes, which are then oligomerized into larger hydrocarbon chains typical of jet fuels. ATJ fuels are distinguished by their ability to blend seamlessly with conventional jet fuel, meeting the stringent specifications required for commercial aviation without modifications to existing engines or fuel systems [47,48]. ATJ’s appeal lies in its use of renewable feedstocks, including sugars, starches, and lignocellulosic biomass, which can be fermented into alcohols before conversion. This flexibility allows the utilization of a wide range of raw materials, including non-food crops and agricultural residues, potentially reducing competition with food sources and minimizing land use impacts [49,50]. Furthermore, the ATJ process is capable of producing jet fuel that performs comparably to conventional jet fuel in terms of energy density and cold-flow properties while significantly reducing lifecycle greenhouse gas emissions.

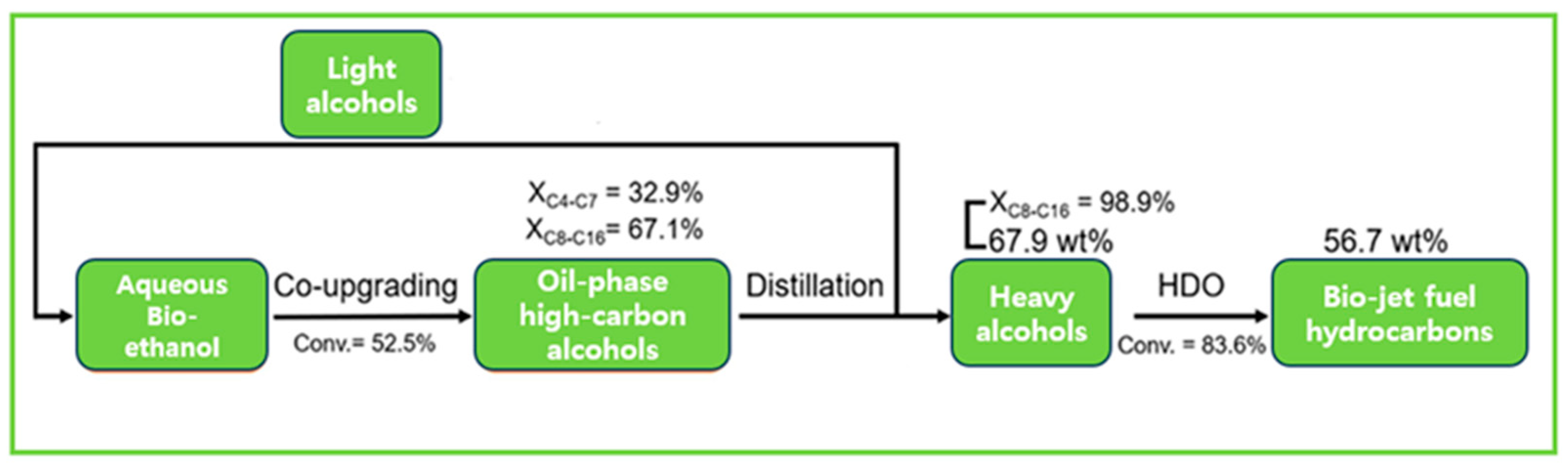

Figure 2 illustrates the process of converting bio-ethanol to bio-jet fuel hydrocarbons. This process includes ethanol C-C coupling, distillation of oil-phase high-carbon alcohols, and hydrodeoxygenation (HDO) of heavy alcohols. Verification of the entire process resulted in the production of bio-jet fuel hydrocarbons, predominantly composed of branched hydrocarbons. Additionally, the C4–C7 high-carbon alcohols present in the light alcohols can be further upgraded to synthesize C8–C16 high-carbon alcohols, thereby enhancing the yield of bio-jet fuel hydrocarbons [51].

Figure 2.

Comprehensive flow diagram of kilogram-scale bio-ethanol to jet fuel hydrocarbon production [51].

Despite its advantages, the adoption of ATJ technology faces challenges, primarily related to the cost-effectiveness of production at scale. The initial capital investment for ATJ facilities is significant, and the economic viability depends heavily on the cost of feedstock and the efficiency of the alcohol fermentation process [52]. Moreover, the regulatory landscape for biofuels can influence the deployment of ATJ technology, necessitating supportive policies to ensure a competitive edge against traditional jet fuels. From an environmental perspective, ATJ fuels promise substantial reductions in particulate emissions and other pollutants. Studies have shown that ATJ fuels can lower the emission of soot and sulfur oxides, contributing to cleaner combustion and less environmental impact at airports and in the upper atmosphere, where jet travel predominates [53].

4.5. Oil from Algae

Oil derived from algae, particularly microalgae, is a promising source of sustainable aviation fuel (SAF). Algae-based oils are regarded for their rapid growth rates and high oil yields per area, making them a highly productive source of biofuels compared to traditional bioenergy crops. Algae can be cultivated in various environments, including freshwater, marine settings, and even in non-arable lands, which minimizes competition for agricultural resources and does not contribute to deforestation [54,55]. The process of converting algae into biofuel typically involves cultivating the algae, harvesting the biomass, extracting the lipids, and then refining these lipids into biofuel through processes like hydroprocessing or transesterification. This biofuel is capable of being a “drop-in” replacement for conventional jet fuels, meaning it can be used without modifications to existing aircraft engines or fuel distribution infrastructures [56,57].

However, despite these advantages, several challenges remain in the path to commercializing algae-based aviation fuels. These include the economic costs associated with large-scale production, the energy-intensive nature of algae cultivation and harvesting, and the need for technological advancements to improve lipid extraction and conversion efficiencies. Studies also focus on optimizing the conditions under which algae grow to maximize lipid production, such as by adjusting light intensity, nutrient availability, and CO2 supplementation [56,58].

The sustainability of algae-based aviation fuel production depends significantly on the lifecycle analysis of emissions and energy use. The integration of algae cultivation with waste management systems, such as using municipal or industrial wastewater as a nutrient source, can improve the sustainability and economic viability of this biofuel source. This integration not only helps in treating wastewater but also in reducing the operational costs associated with algae cultivation [54,59]. Algae-based fuels also present an opportunity for decarbonizing the aviation sector, which is under increasing pressure to reduce its environmental impact. As research continues, the scalability of algae as a biofuel source holds the potential to meet a significant portion of aviation fuel demand, contributing to the reduction of greenhouse gas emissions and reliance on fossil fuels [54,60].

4.6. Other Emerging Biofuels

The landscape of sustainable aviation fuels (SAFs) is rapidly evolving, with several emerging biofuel technologies showing promise for revolutionizing energy sources within the aviation industry. These include advanced biofuels such as lignin-based fuels, solar fuels, and electrofuels, each offering unique benefits and challenges to sustainable aviation [61].

Lignin-Based Biofuels: Lignin, a major component of plant biomass, provides a promising feedstock for biofuel production due to its abundance and relatively low value in the current market. Research into lignin-based biofuels primarily focuses on converting this complex polymer into simpler hydrocarbon chains that can serve as drop-in fuels for aviation. While the process is challenging due to the recalcitrant nature of lignin, advances in catalytic hydroprocessing and genetic engineering are improving the efficiency of these conversions, promising a sustainable route to high-energy-density jet fuels [61].

Solar Fuels: Solar fuels are produced through the conversion of solar energy into chemical energy, typically via processes that mimic natural photosynthesis. Although still at an experimental stage, solar fuels could potentially provide limitless carbon-neutral energy, sourced directly from sunlight and air. The integration of solar energy systems with catalytic processes to produce liquid hydrocarbons could significantly reduce the carbon footprint of aviation fuels, aligning with global decarbonization goals [62].

Electrofuels: Produced from carbon dioxide and water using electrical energy (often sourced from renewable sources), electrofuels represent a groundbreaking approach to sustainable fuel production. This technology is particularly attractive for the aviation industry due to its potential for high energy density and compatibility with existing fuel infrastructure. Electrofuels can be synthesized through various pathways, including the electrochemical reduction of CO2, offering a versatile and potentially scalable solution to reduce aviation’s reliance on fossil fuels [63].

Table 1 serves to highlight the distinct features and considerations of each biofuel type, offering a clear comparison to facilitate understanding of their potential impact on the aviation sector.

Table 1.

Summary of biofuels for aviation: production processes, benefits, challenges, and technological aspects.

5. Production and Processing of Aviation Biofuels

5.1. Feedstock Sources and Sustainability

The production of sustainable aviation fuels (SAFs) starts with the selection of suitable feedstock, which significantly impacts both the sustainability and economic viability of the fuel produced. Feedstocks for SAFs include a wide range of biomass sources, such as agricultural residues, non-edible oil crops, algae, and municipal solid waste. Each of these sources has its own set of sustainability challenges and benefits, making the choice of feedstock crucial for the overall sustainability of the fuel production process [59]. Sustainable feedstock sourcing must consider environmental, social, and economic aspects, ensuring that the production does not adversely affect food security, biodiversity, or lead to deforestation. Technologies such as the hydrothermal liquefaction of algae and the Fischer–Tropsch synthesis using lignocellulosic biomass are being developed to increase the sustainability and efficiency of feedstock conversion. Innovations in genetic engineering and agronomic practices are also improving the yields and reducing the environmental impacts of these crops [64].

5.2. Conversion Processes

The conversion of biomass into aviation biofuel can be achieved through several pathways, each with its own technological and economic challenges. The most common processes include hydroprocessing of oils and fats, Fischer–Tropsch synthesis from syngas, and the alcohol-to-jet (ATJ) pathway. Hydroprocessing involves removing oxygen from triglycerides to form hydrocarbons that can be used directly in jet engines. Fischer–Tropsch synthesis, on the other hand, involves gasifying biomass to produce a synthesis gas, which is then converted into liquid hydrocarbons through a catalytic process. The ATJ pathway involves the conversion of alcohols, which can be produced from sugars or starches, into synthetic paraffinic kerosene [65,66].

Each of these conversion processes requires specific catalysts, temperatures, and pressures, and the efficiency of these processes is continually improving through research and development. Challenges such as catalyst deactivation, high energy requirements, and the need for large-scale infrastructure investment remain, but advances in catalytic science and process engineering are progressively overcoming these barriers [67,68].

5.3. Blending with Conventional Jet Fuels

Blending bio-based aviation fuels with conventional jet fuels is a practical approach to introducing SAF into the current fuel supply without extensive modifications to aircraft or fuel distribution infrastructure. Biofuels must meet stringent specifications for viscosity, freezing point, and energy content to be compatible with existing jet fuels. Research into the blending properties of various biofuels has shown that certain bio-derived synthetic paraffinic kerosenes can be blended at ratios of up to 50% with conventional jet fuels without adverse effects on engine performance or emissions [69,70]. Studies have demonstrated that blends of biofuels and conventional jet fuels can reduce emissions of greenhouse gases and particulate matter, contributing to cleaner combustion and reduced environmental impact. However, the stability, cold flow properties, and combustion characteristics of these blends are critical parameters that need continuous monitoring and optimization to meet the operational requirements of commercial aviation [71,72].

6. Advantages and Challenges

6.1. Economic Viability and Cost Factors

Economic viability remains a significant challenge for SAFs, with production costs typically higher than those of conventional jet fuels. Several factors contribute to these higher costs, including the expense of feedstocks, energy-intensive conversion processes, and the need for large-scale production facilities. Despite these challenges, the growing demand for sustainable fuels and supportive government policies are driving down costs through economies of scale and technological advancements [65]. To achieve economic viability, SAF production must be scalable and cost-effective. This involves optimizing feedstock sourcing, improving conversion efficiency, and developing robust supply chains. Innovative technologies, such as hydroprocessing, Fischer–Tropsch synthesis, and alcohol-to-jet (ATJ), are becoming more efficient, helping to lower costs. Additionally, financial incentives and carbon pricing mechanisms are playing a role in making SAF more competitive with traditional fuels [61].

6.2. Scalability and Supply Chain Issues

Scalability is a critical factor in the widespread adoption of SAF. The aviation industry requires large volumes of fuel, necessitating a scalable supply chain for SAF production and distribution. Challenges in scalability often stem from feedstock availability, transportation logistics, and production capacity. A diverse range of feedstocks, such as algae, agricultural residues, and non-food crops, can improve scalability by reducing reliance on a single source [64]. Developing robust supply chains involves addressing logistical issues related to feedstock transportation, storage, and distribution. The integration of SAF production with existing infrastructure and the ability to blend with conventional jet fuels are essential for ensuring a smooth transition to sustainable aviation. Scalability also requires investment in large-scale production facilities, which can be capital-intensive but are crucial for meeting the aviation industry’s demand [65].

6.3. Technical and Regulatory Challenges

Technical challenges for SAF primarily concern engine compatibility, fuel stability, and combustion characteristics. SAF must meet stringent specifications to ensure safety and performance in aircraft engines. This requires rigorous testing and certification processes to guarantee that SAF blends are safe for use in commercial aviation [67]. Research into the blending properties of SAF with conventional jet fuels is ongoing, focusing on maintaining the necessary energy content, freezing point, and viscosity for aviation applications.

Regulatory challenges also play a significant role in the adoption of SAF. The aviation industry is subject to strict regulations, and any new fuel must comply with these standards. Harmonizing regulations across different countries and regions is crucial for the global adoption of SAF. Supportive policies and financial incentives can encourage airlines to transition to SAF, while international agreements, such as those under the International Civil Aviation Organization (ICAO), are instrumental in setting industry-wide sustainability goals [65].

7. Case Studies and Current Applications

7.1. Use in Commercial Airlines

Sustainable aviation fuels (SAFs) have gained traction in commercial airlines due to their potential to reduce greenhouse gas emissions and dependence on fossil fuels. Commercial airlines have begun incorporating SAF into their operations, with many conducting test flights and some establishing long-term agreements for SAF supply [73]. For example, several major airlines, including British Airways and United Airlines, have partnered with biofuel companies to promote the use of SAFs on their flights. This shift toward biofuels is part of a broader effort to meet international sustainability goals and reduce the environmental impact of air travel [74].

Drop-in biofuels are particularly attractive to commercial airlines as they can be blended with conventional jet fuels, allowing for a smoother transition to sustainability without requiring significant infrastructure changes. Airlines have conducted successful test flights with SAF, demonstrating that these fuels do not adversely impact engine performance or maintenance schedules [75,76]. However, to increase the adoption of SAF in commercial airlines, consistent policies, reliable feedstock sources, and scalable production facilities are required to meet demand and reduce costs [77].

7.2. Military Applications

The military has also shown interest in using biofuels, primarily to increase energy security and reduce reliance on fossil fuels. The U.S. Navy, for example, has used algae-based biofuels in ships and aircraft, demonstrating that blending algal biofuels with ultra-low-sulfur diesel fuel can reduce pollutants and improve fuel economy [78]. Additionally, the military is exploring hybrid propulsion systems for aircraft and other equipment, aiming to enhance energy efficiency and reduce carbon emissions [79].

These military applications of biofuels highlight the potential for broader adoption in the aviation industry. However, challenges remain, including the high costs of biofuels, limited feedstock availability, and the need for specialized infrastructure to support these fuels. The military’s efforts to use biofuels could serve as a catalyst for broader adoption across other sectors, encouraging innovation and investment in sustainable aviation fuels [78,80].

7.3. Regional Differences and Policy Impacts

Regional differences and policy impacts play a significant role in the adoption of SAF. Countries with strict environmental regulations and supportive policies are more likely to foster the growth of biofuels in aviation. For instance, Norway has implemented mandates requiring that a certain percentage of aviation fuels come from renewable sources, driving the adoption of SAF in airports like Oslo Gardermoen [16]. Similarly, Brazil has favorable conditions for SAF production due to its abundant feedstocks and policies encouraging renewable energy sources [81].

In contrast, regions with less supportive policies and limited infrastructure for biofuels face challenges in adopting SAF. The cost of production, transportation logistics, and regulatory compliance can hinder the growth of biofuels in these areas [82]. To promote broader adoption of SAF, policymakers need to address these challenges by providing incentives for biofuel production, encouraging investment in infrastructure, and harmonizing regulations across regions to facilitate the global adoption of sustainable aviation fuels [83].

8. Environmental Impact Assessment

8.1. Environmental Benefits

Sustainable aviation fuels (SAFs) offer considerable environmental benefits compared to conventional jet fuels. One of the primary advantages is the significant reduction in greenhouse gas emissions. SAF, derived from renewable resources, typically has a lower carbon footprint across its lifecycle because the carbon dioxide released during combustion can be offset by the carbon dioxide absorbed during the growth of the biofuel feedstocks [84]. This creates a more circular approach to carbon, contributing to efforts to combat climate change. SAF has the potential to reduce other pollutants such as sulfur oxides (SOx), nitrogen oxides (NOx), and particulate matter, which are common byproducts of fossil-based jet fuels. By using cleaner feedstocks and advanced processing techniques, SAF can contribute to better air quality around airports and reduce environmental impact at high altitudes where contrails and other emissions have significant climate effects [69]. These benefits make SAF an attractive option for airlines aiming to meet stricter environmental regulations and contribute to sustainability goals.

8.2. Reduction in Greenhouse Gas Emissions

Sustainable aviation fuels (SAFs) offer a significant reduction in greenhouse gas (GHG) emissions compared to conventional jet fuels. Lifecycle assessments of various SAFs reveal that they can achieve GHG reductions ranging from 40% to 80%, depending on the feedstock and production process [85]. The key to these reductions lies in the renewable nature of the feedstock, which absorbs CO2 during growth, offsetting the CO2 released during combustion in aircraft engines.

One critical aspect of GHG reduction is induced land use change (ILUC), which can either contribute to or detract from the net environmental benefits of SAF. Certain feedstocks, such as those cultivated on marginal or degraded lands, present lower ILUC risks, leading to significant reductions in GHG emissions [41]. Advanced biofuel pathways, like hydroprocessed esters and fatty acids (HEFAs) and Fischer–Tropsch (FT), have shown promise in reducing GHG emissions when appropriate safeguards are in place to minimize deforestation and other high-emission activities [86]. Another pathway for GHG reduction is the utilization of oilseed cover crops, which can serve as feedstocks for biofuels without requiring additional agricultural land. This approach can lead to significant land-use savings, reduce ILUC emissions, and contribute to overall GHG reduction goals [87]. The successful implementation of these pathways could contribute substantially to aviation’s efforts to achieve net-zero emissions by 2050.

8.3. Lifecycle Analysis and Net Environmental Benefit

Lifecycle analysis (LCA) plays a crucial role in assessing the environmental impact of SAF. This method evaluates the entire lifecycle of aviation biofuels, from feedstock production to fuel combustion, providing a comprehensive view of the net environmental benefits. Studies focusing on LCA demonstrate that while SAF generally offers lower GHG emissions, there are significant variances depending on the production process and feedstock source [88].

A key component of LCA is understanding the broader environmental implications beyond GHG emissions. This includes evaluating the impacts on soil health, water resources, and biodiversity. For instance, biofuels derived from certain feedstocks may require large amounts of water, potentially impacting local ecosystems and water availability. Biodiversity concerns also emerge when biofuel production leads to deforestation or the conversion of natural landscapes into agricultural land [89,90]. Net environmental benefit assessments must also consider the effects of policy interventions and regulatory frameworks. Certain policies may inadvertently incentivize practices that contribute to ILUC or other environmental harms, while others encourage sustainable practices and renewable feedstock use [91]. Harmonizing these policies across regions and ensuring consistent sustainability criteria is essential to achieving a net environmental benefit from SAF.

8.4. Biodiversity and Land Use Considerations

The impact of biofuel production on biodiversity and land use is a critical consideration for the environmental sustainability of SAF. Biodiversity can be adversely affected if biofuel production leads to deforestation or disrupts existing ecosystems. Land use changes driven by biofuel production may also contribute to soil degradation, loss of habitat, and declines in regional food security [89,90].

To minimize biodiversity loss, SAF production must prioritize feedstocks that do not compete with food crops or lead to large-scale land conversion. Utilizing marginal or degraded lands for biofuel production can mitigate some of these risks, providing a sustainable source of feedstock while preserving existing ecosystems [41]. Additionally, implementing policies that promote land use efficiency and encourage the use of sustainable feedstocks can reduce the pressure on biodiversity [89]. Effective land conservation strategies, combined with sustainable agricultural practices, are essential for ensuring that SAF contributes to environmental sustainability without causing undue harm to biodiversity and land use. The integration of SAF production with existing agricultural systems and the use of cover crops can help maintain biodiversity while providing a reliable source of biofuel feedstock [86,87].

9. Future Directions and Research Needs

To further advance the field of sustainable aviation fuels (SAFs), ongoing technological innovations are crucial. Recent developments in production and processing technologies have demonstrated that emerging pathways, such as catalytic hydrothermolysis and electro-fermentation, offer new opportunities for SAF production. These innovations focus on increasing efficiency, reducing energy consumption, and maximizing yield from various feedstocks, including lignocellulosic biomass and microalgae [92,93].

Catalytic hydrothermolysis (CH) is gaining traction due to its ability to produce high-quality renewable jet fuels. It uses high temperatures and pressures to convert biomass into a mixture of hydrocarbons that can be refined into SAF. This technology shows promise for economic viability and environmental sustainability, with the potential to utilize diverse feedstocks, including agricultural waste and non-food crops [94].

Electro-fermentation, on the other hand, represents a novel approach that combines traditional fermentation with electrical stimulation to enhance the production of biofuels and biochemicals. This technology can increase the yield and efficiency of biofuel production, providing a scalable option for SAF [93]. Continued research in this area can lead to breakthroughs in SAF production, offering cost-effective and sustainable solutions for the aviation industry.

10. Conclusions

Sustainable aviation fuels (SAFs) play a pivotal role in transitioning the aviation industry towards a more environmentally responsible future. This review underscores the multifaceted benefits of SAF, from reducing greenhouse gas emissions to promoting sustainability. Through technological innovations such as catalytic hydrothermolysis and electro-fermentation, SAF production is becoming more efficient and cost-effective. Government policies and incentives are essential for driving the adoption of SAF, fostering public-private partnerships, and harmonizing regulations to ensure consistency across regions. The environmental impact assessment, including comprehensive lifecycle analyses, is crucial for evaluating the net environmental benefits of SAF and ensuring that its production does not negatively affect biodiversity, water resources, or land use.

Technological, economic, and regulatory challenges remain, but ongoing research and supportive policies can help overcome these barriers. Policies that encourage investment in SAF production and promote a robust supply chain are critical to the long-term sustainability of SAF. The aviation industry’s future will depend on the collaboration among stakeholders, including airlines, fuel producers, governments, and international organizations, to create a more sustainable aviation sector. By focusing on these key areas, SAF can significantly contribute to the aviation industry’s efforts to reduce its carbon footprint and achieve a greener, more environmentally conscious future.

Author Contributions

Conceptualization, R.K.; methodology, R.K.; software, R.K.; validation, R.K. and H.M.C.; formal analysis, R.K.; investigation, R.K.; resources, H.M.C.; data curation, R.K.; writing—original draft preparation, R.K.; writing—review and editing, R.K. and H.M.C.; visualization, R.K.; supervision, H.M.C.; project administration, H.M.C.; funding acquisition, H.M.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Acknowledgments

This work was supported by the National Research Foundation of Korea (NRF) grant funded by the Korean government (NRF-2022H1A7A2A02000033).

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Hasan, A.; Al Mamun, A.; Rahman, S.M.; Malik, K.; Al Amran, I.U.; Khondaker, A.N.; Reshi, O.; Tiwari, S.P.; Alismail, F.S. Climate Change Mitigation Pathways for the Aviation Sector. Sustainability 2021, 13, 3656. [Google Scholar] [CrossRef]

- Sher, F.; Raore, D.; Klemes, J.J.; Rafi-Ul-Shan, P.M.; Khzouz, M.; Marintseva, K.; Razmkhah, O. Unprecedented Impacts of Aviation Emissions on Global Environmental and Climate Change Scenario. Curr. Pollut. Rep. 2021, 7, 549–564. [Google Scholar] [CrossRef] [PubMed]

- Yin, F.; Grewe, V.; Castino, F.; Rao, P.; Matthes, S.; Dahlmann, K.; Dietmüller, S.; Frömming, C.; Yamashita, H.; Peter, P.; et al. Predicting the climate impact of aviation for en-route emissions: The al-gorithmic climate change function submodel ACCF 1.0 of EMAC 2.53. Geosci. Model Dev. 2023, 16, 3313–3334. [Google Scholar] [CrossRef]

- Undavalli, V.; Olatunde, O.B.G.; Boylu, R.; Wei, C.; Haeker, J.; Hamilton, J.; Khandelwal, B. Recent Advancements in Sustainable Aviation Fuels. Prog. Aerosp. Sci. 2023, 136, 100876. [Google Scholar] [CrossRef]

- Becken, S.; Mackey, B.; Lee, D.S. Implications of preferential access to land and clean energy for Sustainable Aviation Fuels. Sci. Total. Environ. 2023, 886, 163883. [Google Scholar] [CrossRef] [PubMed]

- Grewe, V.; Matthes, S.; Dahlmann, K. The contribution of aviation NOx emissions to climate change: Are we ignoring methodological flaws? Environ. Res. Lett. 2019, 14, 121003. [Google Scholar] [CrossRef]

- Frömming, C.; Grewe, V.; Brinkop, S.; Jöckel, P.; Haslerud, A.S.; Rosanka, S.; van Manen, J.; Matthes, S. Influence of weather situation on non-CO2 aviation climate effects: The REACT4C climate change functions. Atmos. Chem. Phys. 2021, 21, 9151–9172. [Google Scholar] [CrossRef]

- Dinkov, R.; Stratiev, D.; Andreev, I.; Georgiev, G.; Angelova, M.; Dimitrova, R.Z.; Toteva, V. Relation of the Content of Sustainable Components (HEFAs) in Blends with Hydrotreated Straight-Run Kerosene to the Properties of Aviation Fuel. Processes 2024, 12, 1045. [Google Scholar] [CrossRef]

- Braun, M.; Grimme, W.; Oesingmann, K. Pathway to net zero: Reviewing sustainable aviation fuels, environmental impacts and pricing. J. Air Transp. Manag. 2024, 117, 102580. [Google Scholar] [CrossRef]

- Ringbeck, J.; Koch, V. Aviation biofuels: A roadmap towards more carbon-neutral skies. Biofuels 2010, 1, 519–521. [Google Scholar] [CrossRef]

- Burov, E.A.; Ivanova, L.V.; Koshelev, V.N.; Adam, T.A. Additives to Biodiesel Fuels. Chem. Technol. Fuels Oils 2023, 59, 998–1002. [Google Scholar] [CrossRef]

- Panoutsou, C.; Germer, S.; Karka, P.; Papadokostantakis, S.; Kroyan, Y.; Wojcieszyk, M.; Maniatis, K.; Marchand, P.; Landalv, I. Advanced biofuels to decarbonise European transport by 2030: Markets, challenges, and policies that impact their successful market uptake. Energy Strat. Rev. 2021, 34, 100633. [Google Scholar] [CrossRef]

- Carter, R.N.; Smith, L.L.; Karim, H.; Castaldi, M.; Etemad, S.; Muench, G.; Boorse, R.S.; Menacherry, P.; Pfefferle, W.C. Catalytic combustion technology development for gas turbine engine applications. MRS Proc. 1998, 549, 93. [Google Scholar] [CrossRef]

- Atmowidjojo, A.H.; Rianawati, E.; Chin, B.L.; Yusup, S.; Quitain, A.T.; Assabumrungrat, S.; Yiin, C.L.; Kiatkittipong, W.; Srifa, A.; Eiad-ua, A. Supporting Clean Energy in the ASEAN: Policy Opportunities from Sustainable Aviation Fuels Initi-atives in Indonesia and Malaysia. IOP Conf. Ser. Earth Environ. Sci. 2021, 940, 012031. [Google Scholar] [CrossRef]

- Shahriar, F.; Khanal, A. The current techno-economic, environmental, policy status and perspectives of sustainable aviation fuel (SAF). Fuel 2022, 325, 124905. [Google Scholar] [CrossRef]

- Baxter, G. An Assessment of Sustainable energy management at a Major Scandinavian Hub Airport: The Case of Oslo Airport Gardermoen. Int. J. Environ. Agric. Biotechnol. 2021, 6, 328–351. [Google Scholar] [CrossRef]

- Su-Ungkavatin, P.; Tiruta-Barna, L.; Hamelin, L. Framework for Life Cycle Assessment of Sustainable Aviation (Sa) Systems. Sci. Total. Environ. 2023, 885, 163881. [Google Scholar] [CrossRef] [PubMed]

- Kumar, T.; Mohsin, R.; Majid, Z.A.; Ghafir, M.F.A.; Wash, A.M. Experimental study of the anti-knock efficiency of high-octane fuels in spark ignited aircraft engine using response surface methodology. Appl. Energy 2020, 259, 114150. [Google Scholar] [CrossRef]

- Shao, L.; Zhou, Y.; Geng, T.; Zhao, S.; Zhu, K.; Zhong, Z.; Yan, H.; Yu, T.; Xu, Z.; Ding, S. Advanced combustion in heavy fuel aircraft piston engines: A comprehensive review and future directions. Fuel 2024, 370, 131771. [Google Scholar] [CrossRef]

- Grim, R.G.; Ravikumar, D.; Tan, E.C.D.; Huang, Z.; Ferrell, J.R.; Resch, M.; Li, Z.; Mevawala, C.; Phillips, S.D.; Snowden-Swan, L.; et al. Electrifying the production of sustainable aviation fuel: The risks, economics, and environmental benefits of emerging pathways including CO2. Energy Environ. Sci. 2022, 15, 4798–4812. [Google Scholar] [CrossRef]

- Agarwal, A.K. Biofuels (alcohols and biodiesel) applications as fuels for internal combustion engines. Prog. Energy Combust. Sci. 2007, 33, 233–271. [Google Scholar] [CrossRef]

- Richenhagen, J.; Kremer, F.; Küpper, C.; Spilker, T.; Bhardwaj, O.P.; Nijs, M. Biofuels for Combustion Engines: Aspects of Modern Engine Development in the Context of Future Biofuels. In Proceedings of the Fuels from Biomass: An Interdisciplinary Approach, Aachen, Germany, 21–22 November 2011; Springer: Berlin/Heidelberg, Germany, 2015. [Google Scholar] [CrossRef]

- Williams, J.L., Jr. Investigation of the Performance and Emissions Characteristics of Dual Fuel Combustion in a Single Cylinder IDI Diesel Engine. 2018. Available online: https://digitalcommons.georgiasouthern.edu/cgi/viewcontent.cgi?article=2991&context=etd (accessed on 4 February 2024).

- Khosravi, M. Developing Pyrometric and Chemiluminescence Optical Diagnostics for Investigation of Modern Alternative CI Engine Combustion Strategies. Doctoral Dissertation, University of British Columbia, Vancouver, BC, Canada, 2019. Available online: http://hdl.handle.net/2429/70880 (accessed on 4 February 2024).

- Torenbeek, E.; Wittenberg, H. Aircraft Engines and Propulsion. In Flight Physics: Essentials of Aeronautical Disciplines and Technology, with Historical Notes; Springer: Berlin/Heidelberg, Germany, 2009; pp. 181–252. [Google Scholar] [CrossRef]

- Almena, A.; Siu, R.; Chong, K.; Thornley, P.; Röder, M. Reducing the environmental impact of international aviation through sustainable aviation fuel with integrated carbon capture and storage. Energy Convers. Manag. 2024, 303, 118186. [Google Scholar] [CrossRef]

- Masiol, M.; Harrison, R.M. Aircraft engine exhaust emissions and other airport-related contributions to ambient air pollution: A review. Atmos. Environ. 2014, 95, 409–455. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Butler, T.L.; Yang, B. Recent trends, opportunities and challenges of sustainable aviation fuel. In Green Energy to Sustainability: Strategies for Global Industries; Wiley: Hoboken, NJ, USA, 2020; pp. 85–110. [Google Scholar] [CrossRef]

- Ali, A.H.H.; Ibrahim, M.N. Performance and environmental impact of a turbojet engine fueled by blends of biodiesels. Int. J. Environ. Sci. Technol. 2017, 14, 1253–1266. [Google Scholar] [CrossRef]

- Gillespie, C.W. A General Equilibrium Analysis of Climate Policy for Aviation. Doctoral Dissertation, Massachusetts Institute of Technology, Cambridge, MA, USA, 2011. Available online: https://core.ac.uk/download/pdf/4430211.pdf (accessed on 20 March 2024).

- Starck, L.; Pidol, L.; Jeuland, N.; Chapus, T.; Bogers, P.; Bauldreay, J. Production of Hydroprocessed Esters and Fatty Acids (HEFA)—Optimisation of Process Yield. Oil Gas Sci. Technol. Rev. d’IFP Energies Nouv. 2014, 71, 10. [Google Scholar] [CrossRef]

- Hendrawati, T.; Siswahyu, A.; Ramadhan, A.I. Analysis of Technoeconomy of Bioavtur Production with Hydroprocessed Esters And Fatty Acids (Hefa) Process In Indonesia. Int. J. Sci. Technol. Res. 2018, 7, 39–43. [Google Scholar]

- Pipitone, G.; Zoppi, G.; Pirone, R.; Bensaid, S. Sustainable aviation fuel production using in-situ hydrogen supply via aqueous phase reforming: A techno-economic and life-cycle greenhouse gas emissions assessment. J. Clean. Prod. 2023, 418, 138141. [Google Scholar] [CrossRef]

- Mattie, D.; Hurley, J.M.; Riccio, E.; Sterner, T.R. Acute Dermal Irritation Study and Salmonella-Escherichia coli/Microsome Plate Incorporation Assay of Hydroprocessed Esters and Fatty Acids (HEFA) Bio-Based Jet Fuels. 2013. Available online: https://apps.dtic.mil/sti/tr/pdf/ADA584649.pdf (accessed on 29 March 2024).

- Zanata, M.; Amelia, S.T.W.; Mumtazy, M.R.; Kurniawansyah, F.; Roesyadi, A. Synthesis of Bio Jet Fuel from Crude Palm Oil by HEFA (Hydroprocessed Esters and Fatty Acids) Using Ni-Mo Catalyst Supported by Rice Husk Ash-Based SiO2. Mater. Sci. Forum 2019, 964, 193–198. [Google Scholar] [CrossRef]

- Parker, L.H. Investigation of the Low-Temperature Combustion Phenomena of a Fischer-Tropsch Synthetic Aerospace Fuel in a Constant Volume Combustion Chamber for Greenhouse Gas Reduction. Available at Semantic Scholar. 2022. Available online: https://digitalcommons.georgiasouthern.edu/honors-theses/687?utm_source=digitalcommons.georgiasouthern.edu%2Fhonors-theses%2F687&utm_medium=PDF&utm_campaign=PDFCoverPages (accessed on 29 March 2024).

- Barbosa, J.A.; Coronado, C.J.; de Andrade, J.C.; Tuna, C.E.; Silva, M.H.; Junior, J.A.C.; Mendiburu, A.Z. Experimental Determination of Upper Flammability Limits of Synthesized Iso-Paraffins (SIP), Jet Fuel and their Mixtures with Air at Atmospheric and Sub-Atmospheric Pressures. Process Safety and Environmental Protection. Process. Saf. Environ. Prot. 2022, 160, 102–115. [Google Scholar] [CrossRef]

- Barbosa, J.A.; Coronado, C.J.; Tuna, C.E.; Silva, M.H.; Mendiburu, A.Z.; Junior, J.A.C.; de Andrade, J.C. Experimental determination of lower flammability limits of Synthesized Iso-Paraffins (SIP), jet fuel and mixtures at atmospheric and reduced pressures with air. Fire Saf. J. 2021, 121, 103276. [Google Scholar] [CrossRef]

- Otun, K.O.; Yao, Y.; Liu, X.; Hildebrandt, D. Synthesis, structure, and performance of carbide phases in Fischer-Tropsch synthesis: A critical review. Fuel 2021, 296, 120689. [Google Scholar] [CrossRef]

- Liu, Z.; Tang, Z.; Yang, X. Integrating properties and conditions to predict spray performance of alternative aviation fuel by ANN model. Biotechnol. Biofuels Bioprod. 2023, 16, 171. [Google Scholar] [CrossRef] [PubMed]

- Panoutsou, C.; Giarola, S.; Ibrahim, D.; Verzandvoort, S.; Elbersen, B.; Sandford, C.; Malins, C.; Politi, M.; Vourliotakis, G.; Zita, V.E.; et al. Opportunities for Low Indirect Land Use Biomass for Biofuels in Europe. Appl. Sci. 2022, 12, 4623. [Google Scholar] [CrossRef]

- Capaz, R.S.; Guida, E.; Seabra, J.E.A.; Osseweijer, P.; Posada, J.A. Mitigating carbon emissions through sustainable aviation fuels: Costs and potential. Biofuels Bioprod. Biorefining 2020, 15, 502–524. [Google Scholar] [CrossRef]

- Kranenburg, K.V.; Delft, Y.V.; Gavrilova, A.; Kler, R.D.; Schipper, C.; Smokers, R.; Verbeek, M.; Verbeek, R. E-Fuels: Towards a More Sustainable Future for Truck Transport, Shipping and Aviation. 2020. Available online: http://resolver.tudelft.nl/uuid:487a6a47-853d-4a1d-bc2e-dbe21d584cca (accessed on 10 April 2024).

- Reksowadojo, I.K.; Duong, L.; Pham, D. Review of typical biofuel for aviation alternative fuel purposes. ASEAN Eng. J. 2018, 4, 20–30. [Google Scholar] [CrossRef]

- Karatzos, S.; van Dyk, J.S.; McMillan, J.D.; Saddler, J. Drop-in biofuel production via conventional (lipid/fatty acid) and advanced (biomass) routes. Part I. Biofuels Bioprod. Biorefining 2017, 11, 344–362. [Google Scholar] [CrossRef]

- de Klerk, A.; Chauhan, G.; Halmenschlager, C.; Link, F.; Sánchez, N.M.; Gartley, B.; El-Sayed, H.E.M.; Sehdev, R.; Lehoux, R. Sustainable aviation fuel: Pathways to fully formulated synthetic jet fuel via Fischer–Tropsch synthesis. Energy Sci. Eng. 2024, 12, 394–409. [Google Scholar] [CrossRef]

- Kim, K.; Ryu, J.I.; McGann, B.; Min, K.; Temme, J.; Kweon, C.-B.; Lee, T. Correction: Data-Driven Combustion Kinetic Modeling Concept of Alternative Alcohol-to-Jet (ATJ) Fuel. In Proceedings of the AIAA Scitech 2021 Forum, virtual, 11–15 & 19–21 January 2021. [Google Scholar] [CrossRef]

- Prak, D.J.L.; Jones, M.H.; Trulove, P.; McDaniel, A.M.; Dickerson, T.; Cowart, J.S. Physical and Chemical Analysis of Alcohol-to-Jet (ATJ) Fuel and Development of Surrogate Fuel Mixtures. Energy Fuels 2015, 29, 3760–3769. [Google Scholar] [CrossRef]

- Ryu, J.I.; Motily, A.; Lee, T.; Scarcelli, R.; Som, S.; Kim, K.; Kweon, C.-B. Effect of Hot Probe Temperature on Ignition of Alcohol-to-Jet (ATJ) Fuel Spray under Aircraft Propulsion System Conditions. In Proceedings of the AIAA Scitech 2021 Forum, virtual, 11–15 & 19–21 January 2021. [Google Scholar] [CrossRef]

- Dickerson, T.; McDaniel, A.; Williams, S.; Luning-Prak, D.; Hamilton, L.; Bermudez, E.; Cowart, J. Start-up and Steady-State Performance of a New Renewable Alcohol-To-Jet (ATJ) Fuel in Multiple Diesel Engines. In Proceedings of the SAE 2015 World Congress & Exhibition, Detroit, MI, USA, 21–23 April 2015. [Google Scholar] [CrossRef]

- Liao, J.; Zhong, Q.; Gu, J.; Qiu, S.; Meng, Q.; Zhang, Q.; Wang, T. New approach for bio-jet fuels production by hydrodeoxygenation of higher alcohols derived from C-C coupling of bio-ethanol. Appl. Energy 2022, 324, 119843. [Google Scholar] [CrossRef]

- Hutzler, S.A. Alcohol-to-Jet (ATJ) Fuel Blending Study. 2015. Available online: https://apps.dtic.mil/sti/tr/pdf/AD1001842.pdf (accessed on 12 April 2024).

- Kurzawska, P.; Jasiński, R. Overview of Sustainable Aviation Fuels with Emission Characteristic and Particles Emission of the Turbine Engine Fueled ATJ Blends with Different Percentages of ATJ Fuel. Energies 2021, 14, 1858. [Google Scholar] [CrossRef]

- Özdemir, I. Sustainable Aviation Fuel Investment and Feedstock Calculations by Microalgae Applications with Biorefinery Approach. In Proceedings of the Abu Dhabi International Petroleum Exhibition and Conference, Abu Dhabi, UAE, 4–7 October 2023. [Google Scholar] [CrossRef]

- Shi, Z.; Zhao, B.; Tang, S.; Yang, X. Hydrotreating lipids for aviation biofuels derived from extraction of wet and dry algae. J. Clean. Prod. 2018, 204, 906–915. [Google Scholar] [CrossRef]

- Bwapwa, J.K.; Akash, A.; Trois, C. Jet Fuel from Domestic Wastewater Treatment Using Microalgae: A Review. In Green Materials for Wastewater Treatment. Environmental Chemistry for a Sustainable World; Naushad, M., Lichtfouse, E., Eds.; Springer: Cham, Switzerland, 2020; Volume 38. [Google Scholar] [CrossRef]

- Karnis, M.; Fang, L.; Bristow, M. Evaluating Actions Towards Sustainable Aviation: A Case Study Using Action Interdependence in Multiple Criteria Decision Making. In Proceedings of the 2015 IEEE International Conference on Systems, Man, and Cybernetics (SMC), Hong Kong, China, 9–12 October 2015; pp. 592–597. [Google Scholar] [CrossRef]

- Gutiérrez-Antonio, C.; la Cruz, A.G.-D.; Romero-Izquierdo, A.G.; Gómez-Castro, F.I.; Hernández, S. Modeling, simulation and intensification of hydroprocessing of micro-algae oil to produce renewable aviation fuel. Clean Technol. Environ. Policy 2018, 20, 1589–1598. [Google Scholar] [CrossRef]

- Mehariya, S.; Goswami, R.K.; Verma, P.; Lavecchia, R.; Zuorro, A. Integrated Approach for Wastewater Treatment and Biofuel Production in Microalgae Biorefineries. Energies 2021, 14, 2282. [Google Scholar] [CrossRef]

- Darda, S.; Papalas, T.; Zabaniotou, A. Biofuels journey in Europe: Currently the way to low carbon economy sustainability is still a challenge. J. Clean. Prod. 2019, 208, 575–588. [Google Scholar] [CrossRef]

- Chiaramonti, D.; Buffi, M.; Palmisano, P.; Redaelli, S. Lignin-based advanced biofuels: A novel route towards aviation fuels. Chem. Eng. Trans. 2016, 50, 109–114. [Google Scholar] [CrossRef]

- Muelaner, J. Decarbonized Fuel Options for Civil Aviation; SAE Technical Paper EPR2023012; SAE International: Warrendale, PA, USA, 2023. [Google Scholar] [CrossRef]

- Su-Ungkavatin, P.; Tiruta-Barna, L.; Hamelin, L. Biofuels, electrofuels, electric or hydrogen?: A review of current and emerging sustainable aviation systems. Prog. Energy Combust. Sci. 2023, 96, 101073. [Google Scholar] [CrossRef]

- Baidoo, M.F.; Adjei, E.A.; Opoku, R.; Aidam, G.S.K. Rubber seed oil: Potential feedstock for aviation biofuel production. Sci. Afr. 2022, 17, e01393. [Google Scholar] [CrossRef]

- Chong, J.W.; Chemmangattuvalappil, N.G.; Thangalazhy-Gopakumar, S. Aviation Biofuels: Conversion Routes and Challenges. In Sustainable Technologies for the Oil Palm Industry; Foo, D.C.Y., Tun Abdul Aziz, M.K., Yusup, S., Eds.; Springer: Singapore, 2023. [Google Scholar] [CrossRef]

- Fischer, G.; Tramberend, S.; Velthuizen, H.; Bole-Rentel, T.; Reeler, J.; Sustainable Aviation Biofuel Feedstock Potential in Sub-Saharan Africa. A Systems Analysis Investigation into the Current and Future Potential for Biofuel Feedstock Production. 2019. Available online: https://pure.iiasa.ac.at/15626 (accessed on 10 February 2024).

- Viguié, J.; Ullrich, N.; Porot, P.; Bournay, L.; Hecquet, M.; Rousseau, J. BioTfueL Project: Targeting the Development of Second-Generation Biodiesel and Biojet Fuels. Oil Gas Sci. Technol. Rev. D’ifp Energ. Nouv. 2013, 68, 935–946. [Google Scholar]

- Sadykov, V.A.; Simonov, M.N.; Bespalko, Y.N.; Bobrova, L.N.; Eremeev, N.F.; Arapova, M.V.; Smal’, E.A.; Mezentseva, N.V.; Pavlova, S.N. Design and Characterization of Nanocomposite Catalysts for Biofuel Conversion into Syngas and Hydrogen in Structured Reactors and Membranes. Kinet. Catal. 2019, 60, 582–605. [Google Scholar] [CrossRef]

- Attia, N.K.; Abdel Kader, E.A.; ElDiwani, G.; Hussein, H.S.; El-Araby, R. Evaluation of Blending of Lowest Emission Biodiesel with Jet A for Producing Aviation Biofuels. In Utilization and Management of Bioresources; Ghosh, S., Ed.; Springer: Singapore, 2018. [Google Scholar] [CrossRef]

- Duong, L.H.; Reksowardojo, I.K.; Soerawidjaja, T.H.; Pham, D.N.; Fujita, O. The sooting tendency of aviation biofuels and jet range paraffins: Effects of adding aromatics, carbon chain length of normal paraffins, and fraction of branched paraffins. Combust. Sci. Technol. 2018, 190, 1710–1721. [Google Scholar] [CrossRef]

- Stadnichenko, V. Comparative characteristics of biocomponents based on rapeseed and camellina oils for blending with JET fuels. In Proceedings of the 21th Conference for Lithuanian Junior Researchers Science-Future of Lithuania. Transport Engineering and Management, Vilnius, Lithuania, 4–5 May 2018. [Google Scholar]

- Donnelly, J.; Horton, R.; Gopalan, K.; Bannister, C.D.; Chuck, C.J. Branched ketone biofuels as blending agents for Jet-A1 aviation kerosene. Energy Fuels 2016, 30, 294–301. [Google Scholar] [CrossRef]

- Noh, H.M.; Taher, M.N.M.; A Rodrigo, G.; Rahman, N.A.A.; Ismail, S.; Rani, M.M.; Salleh, I.M.; Dahdi, Y.; Wan, W.N.S.; Razak, A.; et al. Refuelling the future: Progress towards testing drop-in biofuels in replacing conventional fuel for commercial flights. IOP Conf. Series Mater. Sci. Eng. 2018, 370, 012037. [Google Scholar] [CrossRef]

- Reals, K. Fuelling the future: Powering commercial flights with biofuels creates good PR, but to genuinely make a difference, airlines must put their money where their mouths are to ensure there is the necessary investment in production ventures. Airl. Bus. 2013, 29. Available online: https://www.library.northwestern.edu/find-borrow-request/requests-interlibrary-loan/lending-institutions.html (accessed on 17 January 2024).

- Mohsin, R.; Kumar, T.; Majid, Z.A.; Nasri, N.S.; Sharer, Z.; Kumar, I.; Wash, A.M. Assessment of biofuels in aviation industry for environmental sustainability. Chem. Eng. Trans. 2017, 56, 1189–1194. [Google Scholar] [CrossRef]

- Mohd Noh, H. Investigation on the Applicability of Biofuels in the Operation of Commercial Aircraft. Doctoral Dissertation, Universidad Politécnica de Madrid Escuela Técnica Superior de Ingenieros Aeronáuticos, Madrid, Spain, 2016. [Google Scholar] [CrossRef]

- Gegg, P.K. Factors Affecting the Emergence, Development and Uptake of Aviation Biofuels. Doctoral Dissertation, Loughborough University, Loughborough, UK, 2014. Available online: https://hdl.handle.net/2134/14074 (accessed on 8 April 2024).

- Savage, P.E. Algae under pressure and in hot water. Science 2012, 338, 1039–1040. [Google Scholar] [CrossRef] [PubMed]

- Santarelli, M.; Cabrera, M. Hybrid solid oxide fuel cell and micro gas turbine for regional jets. J. Aircr. 2011, 48, 1216–1224. [Google Scholar] [CrossRef]

- Miličević, Z.M.; Bojković, Z.S. Military green technology: Present and future. Vojnoteh. Glas. Mil. Tech. Cour. 2023, 71, 136–152. [Google Scholar] [CrossRef]

- Walter, A.; Seabra, J.; Rocha, J.; Guarenghi, M.; Vieira, N.; Damame, D.; Santos, J.L. Spatially Explicit Assessment of Suitable Conditions for the Sustainable Production of Aviation Fuels in Brazil. Land 2021, 10, 705. [Google Scholar] [CrossRef]

- Wang, Z.; Osseweijer, P.; Duque, J.P. Assessing social sustainability for biofuel supply chains: The case of aviation biofuel in Brazil. In Proceedings of the 2017 IEEE Conference on Technologies for Sustainability (SusTech), Phoenix, AZ, USA, 12–14 November 2017; pp. 1–5. [Google Scholar] [CrossRef]

- Loran, O. The Development of Sustainability Requirements for Aviation Biofuels. Master’s Thesis, Lund University, Lund, Sweden, 2013. [Google Scholar]

- Yoo, E.; Lee, U.; Wang, M. Life-cycle greenhouse gas emissions of sustainable aviation fuel through a net-zero carbon biofuel plant design. ACS Sustain. Chem. Eng. 2022, 10, 8725–8732. [Google Scholar] [CrossRef]

- Mawhood, R.; Gazis, E.; Hoefnagels, R.; Jong, S.D.; Slade, R. Technological and commercial maturity of aviation biofuels: Emerging options to produce jet from lignocellulosic biomass. In Proceedings of the 14th International Conference on Sustainable Engineering Technologies, Rhodes, Greece, 3–5 September 2015. [Google Scholar]

- Fiorini, A.C.O.; Angelkorte, G.; Maia, P.L.; Bergman-Fonte, C.; Vicente, C.; Morais, T.; Carvalho, L.; Zanon-Zotin, M.; Szklo, A.; Schaeffer, R.; et al. Sustainable aviation fuels must control induced land use change: An integrated assessment modelling exercise for Brazil. Environ. Res. Lett. 2023, 18, 014036. [Google Scholar] [CrossRef]

- Taheripour, F.; Sajedinia, E.; Karami, O. Oilseed cover crops for sustainable aviation fuels production and reduction in greenhouse gas emissions through land use savings. Front. Energy Res. 2022, 9, 790421. [Google Scholar] [CrossRef]

- de Jong, S.; Antonissen, K.; Hoefnagels, R.; Lonza, L.; Wang, M.; Faaij, A.; Junginger, M. Life-cycle analysis of greenhouse gas emissions from renewable jet fuel production. Biotechnol. Biofuels 2017, 10, 64. [Google Scholar] [CrossRef] [PubMed]

- Palmer, J.R. Biofuels and the politics of land-use change: Tracing the interactions of discourse and place in European policy mak-ing. Environ. Plan. A Econ. Space 2014, 46, 337–352. [Google Scholar] [CrossRef]

- Nunez-Regueiro, M.M.; Siddiqui, S.F.; Fletcher, R.J. Effects of bioenergy on biodiversity arising from land-use change and crop type. Conserv. Biol. 2021, 35, 77–87. [Google Scholar] [CrossRef] [PubMed]

- Ortega, A.; Gkoumas, K.; Tsakalidis, A.; Pekár, F. Low-Emission Alternative Energy for Transport in the EU: State of Play of Research and Innovation. Energies 2021, 14, 7764. [Google Scholar] [CrossRef]

- Eswaran, S.; Subramaniam, S.; Geleynse, S.; Brandt, K.; Wolcott, M.; Zhang, X. Techno-economic analysis of catalytic hydrothermolysis pathway for jet fuel production. Renew. Sustain. Energy Rev. 2021, 151, 111516. [Google Scholar] [CrossRef]

- Chandrasekhar, K.; Kumar, A.N.; Kumar, G.; Kim, D.-H.; Song, Y.-C.; Kim, S.-H. Electro-fermentation for biofuels and biochemicals production: Current status and future directions. Bioresour. Technol. 2021, 323, 124598. [Google Scholar] [CrossRef]

- Stevens, J. A Stochastic Techno-Economic Analysis of Aviation Biofuels Production from Pennycress Seed Oil. Doctoral Dissertation, Purdue University, West Lafayette, IN, USA, 2019. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).