Emission of Harmful Substances from the Combustion of Wood Pellets in a Low-Temperature Burner with Air Gradation: Research and Analysis of a Technical Problem

Abstract

:1. Introduction

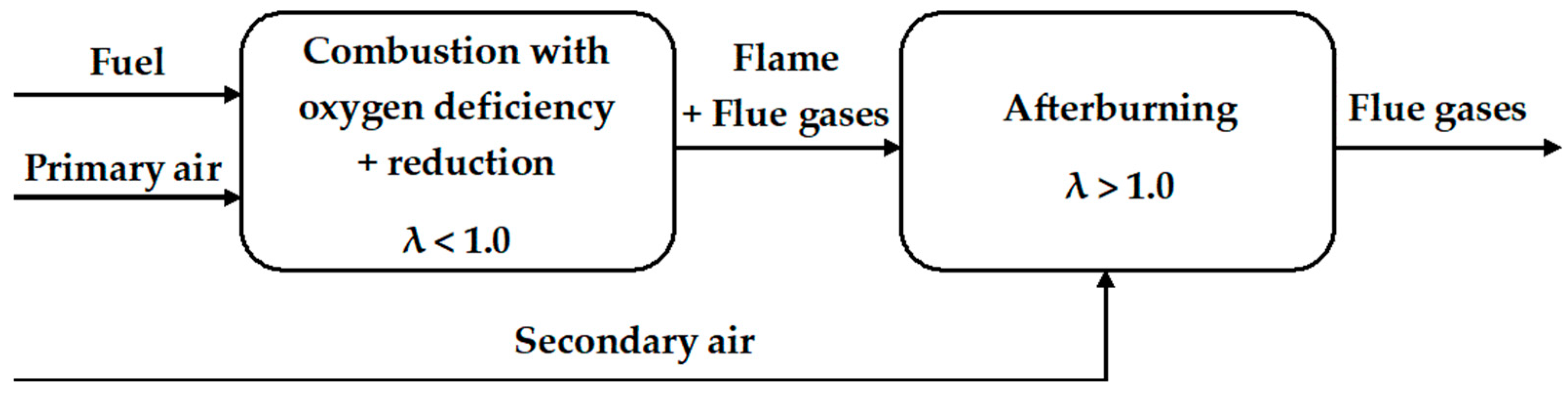

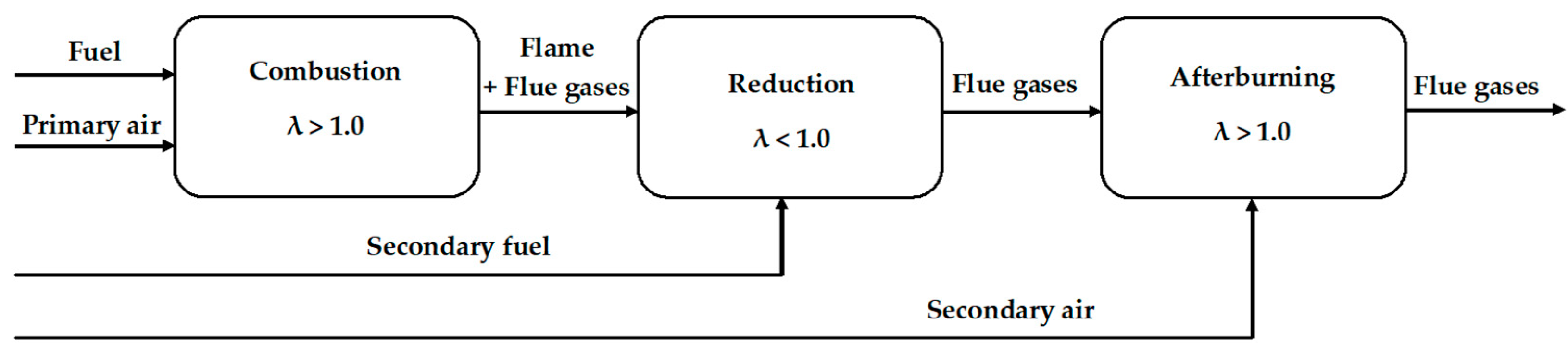

- −

- Air gradation;

- −

- Fuel and air gradation.

- −

- The level of air excess ratios (λ) for a given combustion stage;

- −

- Temperature (T) in respective combustion zones;

- −

- Time (τ) of flue gases staying in a respective reduction and combustion zone;

- −

2. Materials and Methods

2.1. Heating Devices

2.2. Pellet Burner

2.3. Chemical Parameters of the Fuel

2.4. Emission Measurement Devices

2.5. Formulas Used for Calculations

3. Results and Discussion

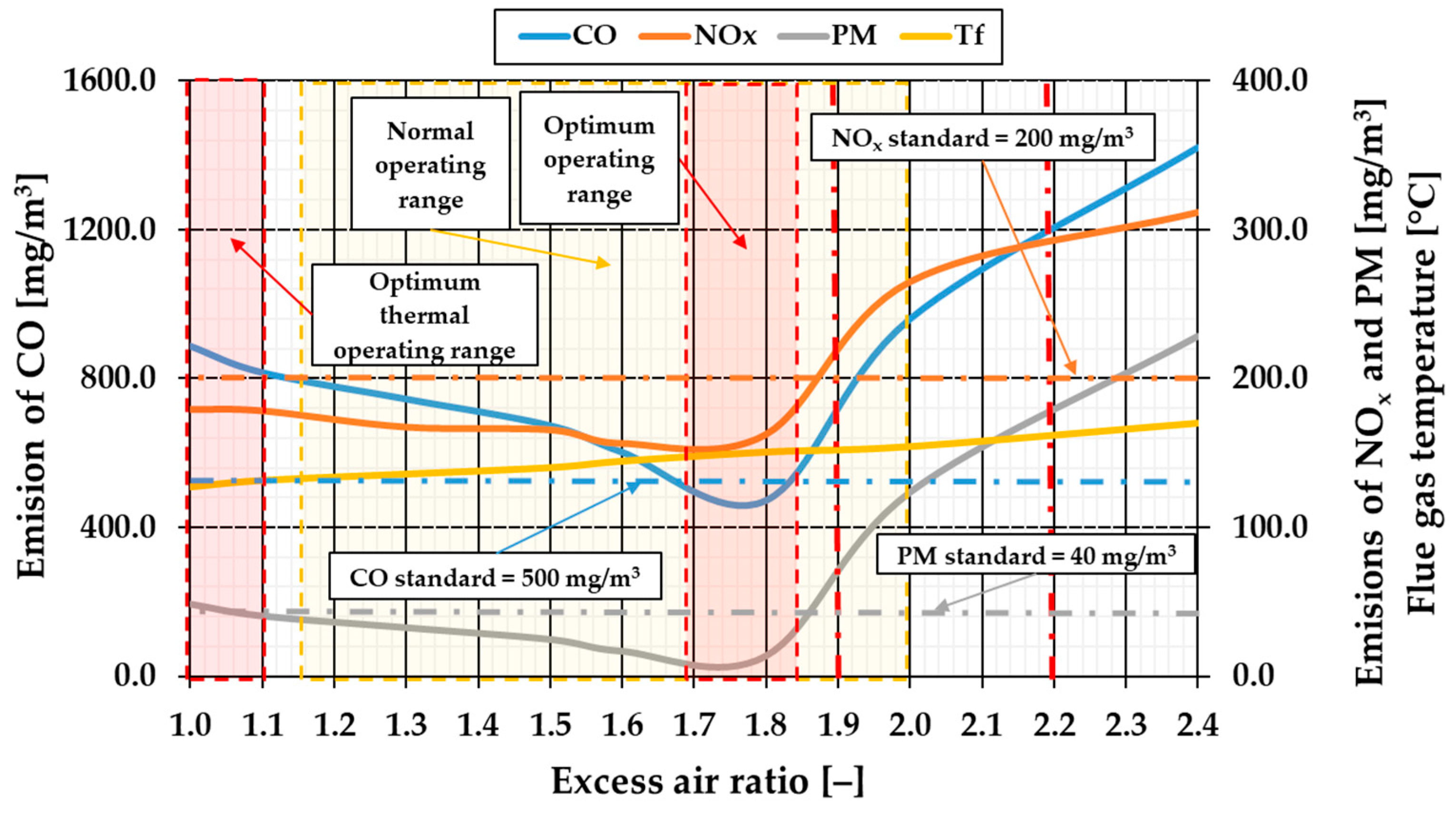

- −

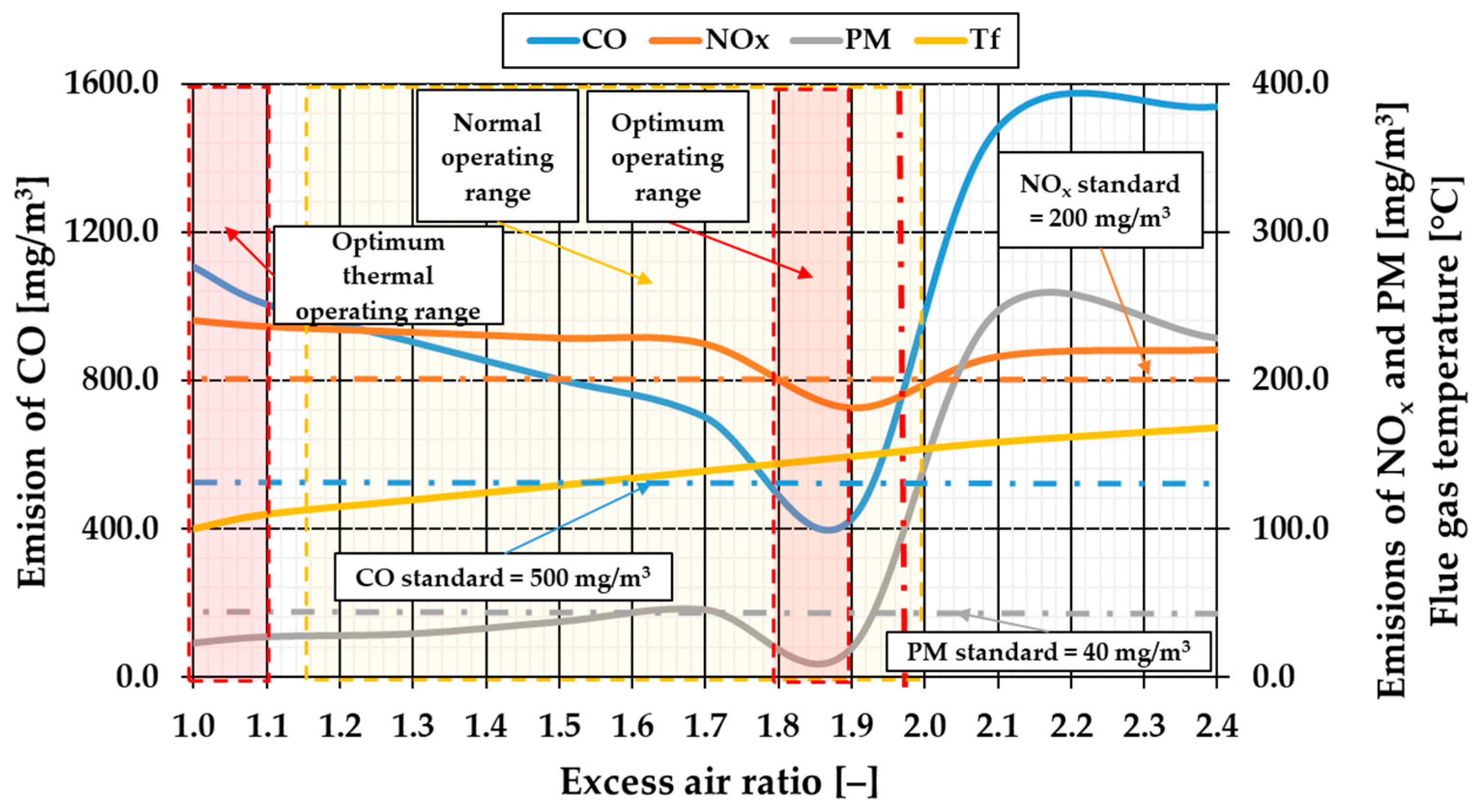

- The normal boiler operating range for the settings of burner-rated power is within the excess air ratio range of λ = 1.15–2.00;

- −

- The burner operating range within λ = 2.00–2.40 is present periodically in the stages preceding the application of a fresh fuel portion (in the combustion chamber of the burner), with a simultaneous abrupt increase in the air stream supplied for cleaning the combustion chamber from the post-combustion process residues;

- −

- The burner operating range within λ = 1.00–1.10 is present periodically in the stages finishing the combustion of a given fuel batch and is related to a severe drop in flue gas temperature and related boiler heating power, which forces the control system to undertake actions to increase the power and which are related directly to the supply of a new fuel portion for combustion;

- −

- The optimal operating range of the burner, in terms of low emission, falls within the range λ = 1.70–1.85, which allows it to satisfy all the requirements for emission parameters for solid fuel heating boilers combusting biomass; at the same time, the most optimal point is λ = 1.78, for which emissions are CO = 470.44 mg/m3, NOx = 162.60 mg/m3, and PM = 13.53 mg/m3 and the flue gas temperature is 150.54 °C;

- −

- There was an increase in flue gas temperature observed, along with the increase in the excess air ratio in the combustion process.

- −

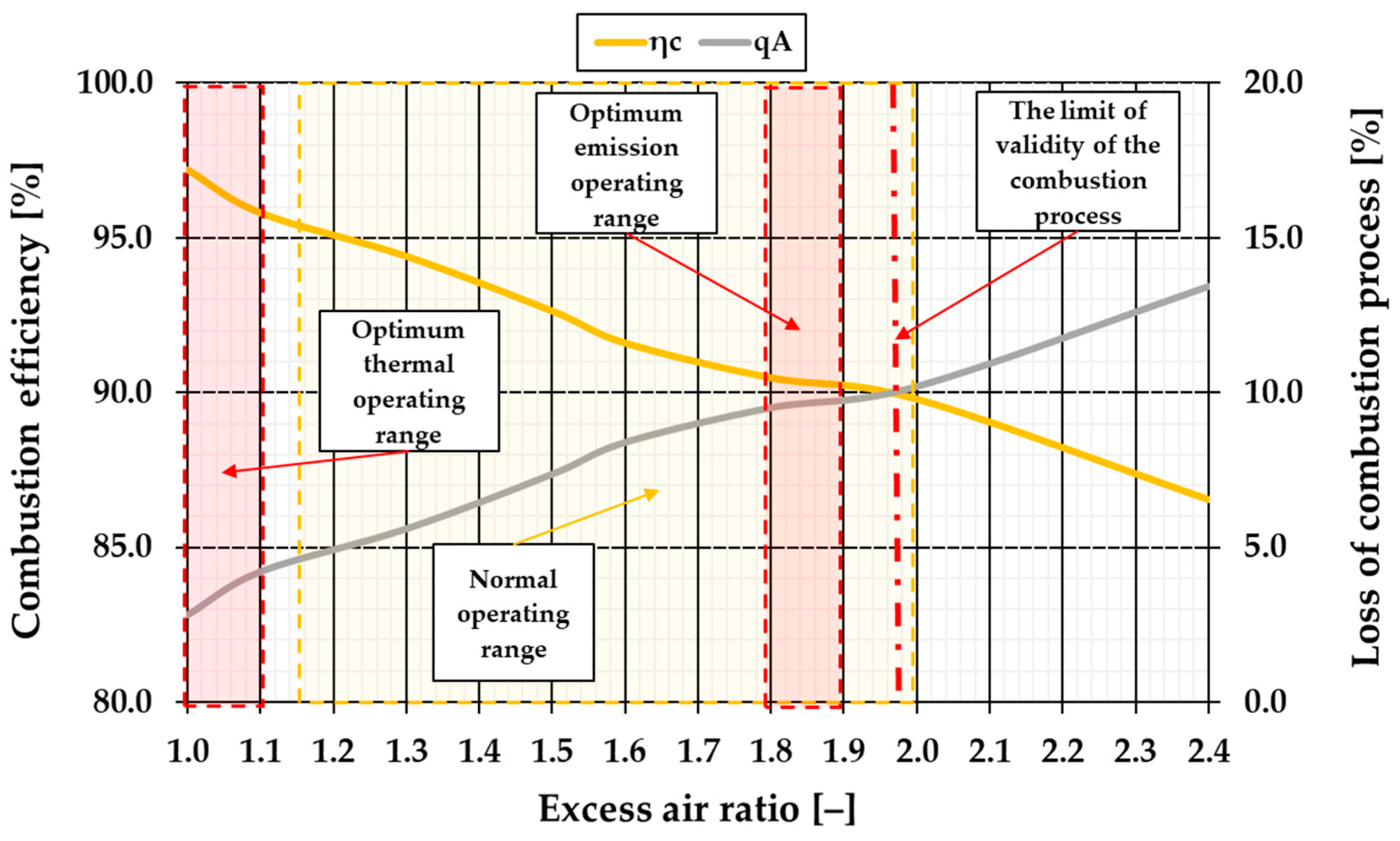

- The range of the combustion process efficiency (ηc) of the burner falls within the following range: 98.93–88.28%;

- −

- The range of the loss of combustion (qA) of the burner falls within the following range: 1.08–11.72%;

- −

- An increase in the loss of combustion was observed, along with an increase in the excess air ratio, simultaneously with a decrease in the combustion process efficiency arising from the excessive air stream supplied for combustion and the occurring adverse thermal phenomena contributing to the excessive emission of CO, NOx, and PM.

- −

- The limit value of the excess air ratio (λ) at which the pellet burner should operate is approximately λ = 1.90; above this value, there is an abrupt decrease in the combustion process efficiency, with its simultaneous decrease below the target value resulting from the valid standard [20]. At the same time, there is a violent growth in the loss of combustion, which contributes to the drop in the economic aspect of the performed combustion process, and there is a simultaneous severe increase in the emissions of all the registered harmful ingredients of flue gases;

- −

- In the range of λ = 1.00–1.10, in which there is a stage finishing the combustion of a given fuel batch, the highest efficiency of the combustion process is obtained (at the simultaneous lowest loss of combustion); however, in this range, the emission of harmful substances, especially related to the combustion process stoichiometry (CO and PM) does not allow us to satisfy the assumptions of the valid standard [20]. This is caused by the radical decrease in the air stream supplied for the combustion process by the air supply system (switched off fan, only airflow to the combustion chamber forced by the stack draught), and there is a minor increase registered in the emission of nitrogen oxide (NOx) caused by the occurrence of the phenomena of their rapid thermal formation activated by the heat transfer by the heated surfaces of the burner grate to the residues of fuel afterburned in its space;

- −

- A burner operation period with an excess air ratio of λ = 1.90–2.40, usually in the phase preceding the application of a fresh fuel portion in the combustion chamber of the burner and the simultaneous execution of the burner cleaning process by increasing the airflow through the combustion and grate spaces of the burner (increasing the mass stream of the flowing air), causes a sudden increase in the emission of harmful substances generated by the solid substances (PM) floating from the burner grate and the cooling down of the combustion process, which is still taking place in the residues of smouldering biomass, resulting in excess carbon monoxide emissions (increased CO). Excessively supplied air flowing through the heated burner ducts removes excess heat from the burner surface (higher flue gas temperature), adversely affecting the formation of secondary nitrogen oxides (NOx), especially in fast and thermal processes, which is also observed in the analysis of harmful substances exiting the boiler through the emitter.

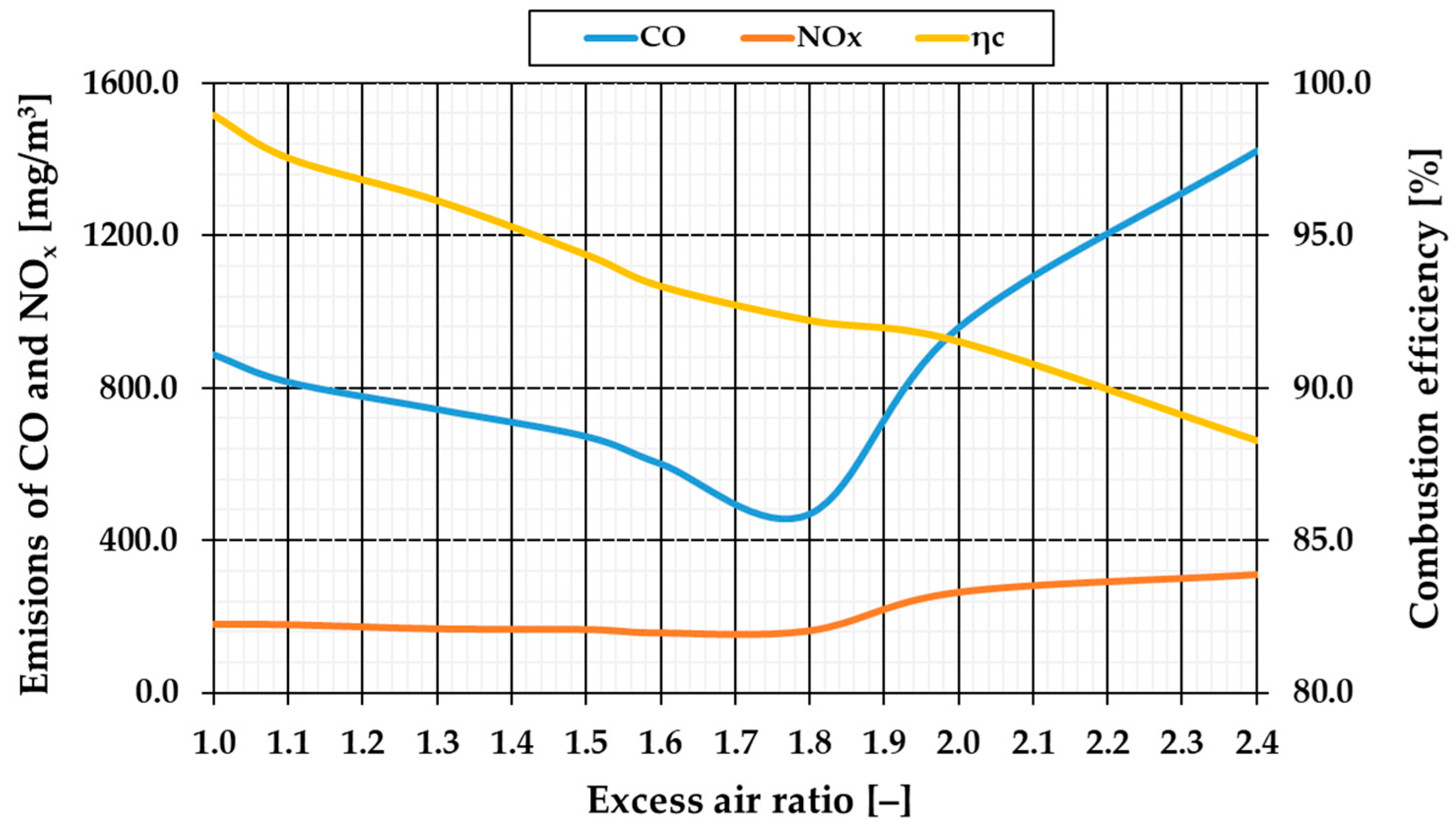

- −

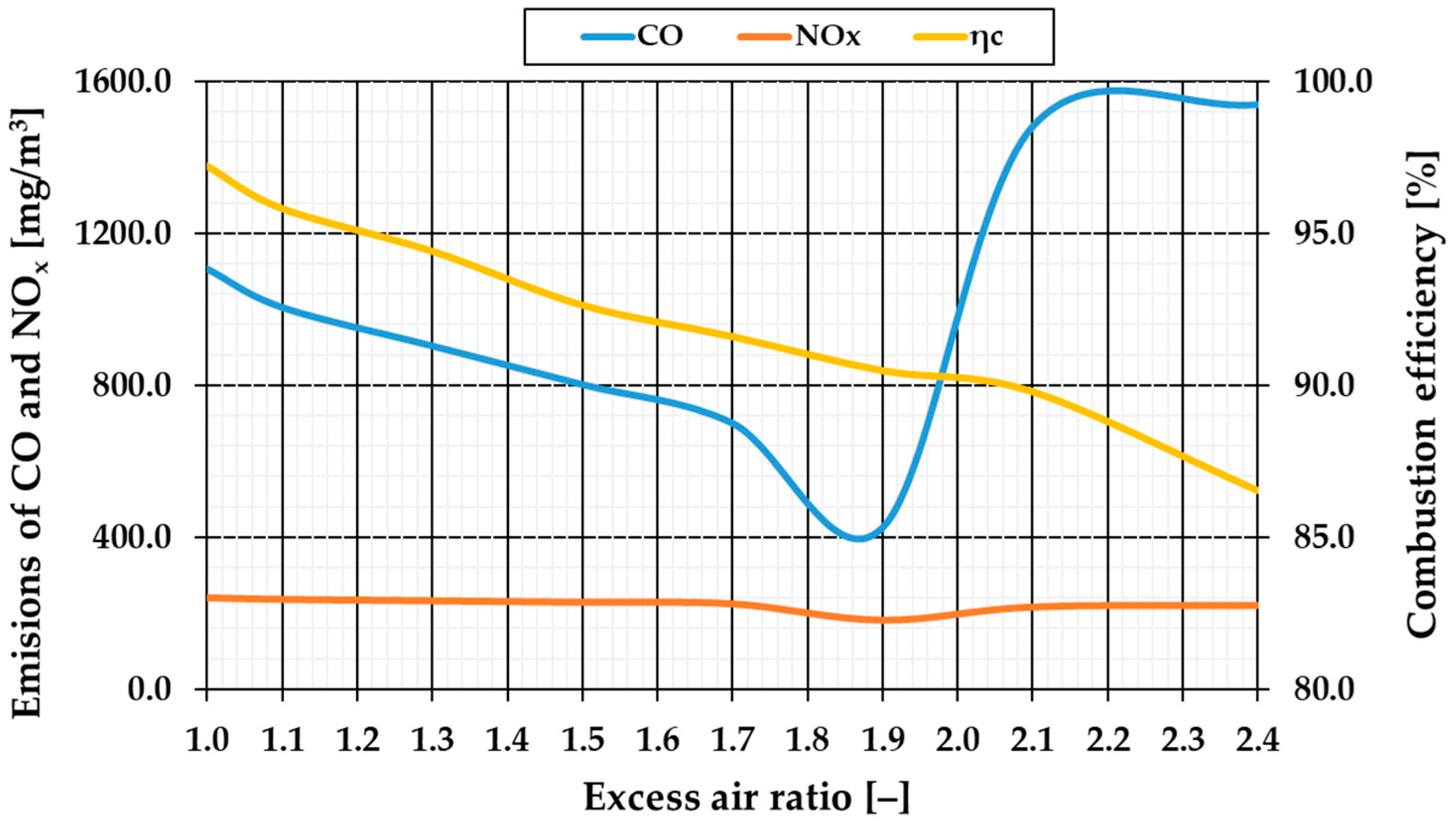

- The normal boiler operating range for the settings of burner-rated power is within the excess air ratio range of λ = 1.15–2.00;

- −

- Periodical change stages of the excess air ratio preceding the application of a fresh fuel portion in the combustion chamber of the burner and finishing the combustion of a given fuel batch take place in identical operating ranges;

- −

- The optimal operating range of the burner, in terms of low emission, falls within the range of λ = 1.80–1.90, which allows it to satisfy all the requirements for emission parameters for solid fuel heating boilers combusting biomass; at the same time, the most optimal point is λ = 1.88, for which the emissions are CO = 425.44 mg/m3, NOx = 181.60 mg/m3, and PM = 18.73 mg/m3 and the flue gas temperature is 148.55 °C;

- −

- As for the process without air gradation for combustion, there was an increase in the flue gas temperature observed, along with an increase in the excess air ratio in the combustion process.

- −

- The range of the combustion process efficiency (ηc) of the burner falls within 97.20–86.56%;

- −

- The range of the loss of combustion (qA) of the burner falls within 2.80–13.44%;

- −

- The shift in the intersection of the curves of efficiency and loss of combustion towards the normal operating range of the burner (λ = 1.15–2.00), with the simultaneous shift in that direction of the feasibility limit for the combustion process implementation, and the shift of thermal variables itself approaches positively towards the optimal operating range in terms of emission. Furthermore, this shift is demonstrated by the considerably lower emission of NOx in relation to the burner operation without air gradation for combustion; in addition, the drop is 18.48% at an efficiency decrease of 1.72%, which results in an adverse increase in the emission of CO–54.33% and PM—99.72%, which suggests the oxygen deficiency of the zone finishing the combustion process (it is suggested to increase the share of the secondary air in the combustion process, but this process could contribute to the growth of NOx emission in the secondary processes).

- −

- The limit value of the excess air ratio (λ) at which the pellet burner should operate has increased and is approximately λ = 1.98, whereas, above this value, there is an abrupt decrease in the combustion process efficiency. At the same time, there is a violent growth in the loss of combustion, which contributes to the drop in the economic aspect of the performed combustion process and causes the simultaneous severe increase in the emissions. This differs from the combustion process without air gradation for combustion, which affects only flue gas ingredients directly related to the combustion process stoichiometry (CO and PM);

- −

- As for the operation of the burner without combustion gradation in the range of λ = 1.00–1.15 with the stage finishing the combustion of a given fuel batch, it is connected with the highest efficiency of the combustion process and the simultaneous lowest loss of combustion; nevertheless, in this range, CO and NOx emissions are higher than for the process without combustion gradation, and it does not allow the assumptions of the current standard [20] to be met, especially in the case of NOx which, during combustion without air gradation, falls within this range of the excess air ratio in the standard;

- −

- A burner operation period with an excess air ratio of λ = 1.90–2.40, usually in the phase preceding the application of a fresh fuel portion in the combustion chamber of the burner and the simultaneous execution of the burner cleaning process by increasing the airflow through the combustion and grate spaces of the burner (increasing the mass stream of the flowing air), causes a sudden increase in the emission of harmful substances related to the combustion process stoichiometry (CO and PM) generated by the solid substances (PM) floating from the burner grate and the distortion of the combustion process in the residues of smouldering biomass, resulting in excess carbon monoxide emission (increased CO) by blowing off the ends of the flame. However, unlike for combustion without air gradation for combustion, nitrogen oxide (NOx) emissions increase slightly in relation to the optimal point (λ = 1.80–1.90) without exceeding the values obtained for the range of λ = 1.00–1.70, making it possible to reduce the emissions of such harmful substances in the crucial period of burner operation, which is not achieved in the standard operation of the device.

- −

- Strong disruption of the emission of harmful substances (their radical growth);

- −

- Operation beyond the range of the significant drop of the combustion process efficiency at the simultaneous significant increase in the loss of combustion.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| C | carbon |

| CHi | hydrocarbon radicals |

| CO | carbon monoxide |

| CO2 | carbon dioxide |

| HCN | hydrogen cyanide |

| N2 | nitrogen |

| NHi | ammonia radicals |

| NH3 | ammonia |

| NO | nitric oxide |

| NO2 | nitrogen dioxide |

| NOx | nitrogen oxides |

| O2 | oxygen |

| PM | particulate matters |

| T | temperature |

| Tf | exhaust gas temperature |

| λ | excess air ratio |

| τ | time |

| Φ | equivalence ratio |

References

- Bogalecka, M.; Grobelna, A. Air Pollution and Its Potential Consequences for Tourism and Career Development from Students’ Perspective: A Case Study of the Gdańsk Agglomeration in Poland. Int. J. Environ. Res. Public Health 2023, 20, 2651. [Google Scholar] [CrossRef] [PubMed]

- Zu, D.; Zhai, K.; Qiu, Y.; Pei, P.; Zhu, X.; Han, D. The Impacts of Air Pollution on Mental Health: Evidence from the Chinese University Students. Int. J. Environ. Res. Public Health 2020, 17, 6734. [Google Scholar] [CrossRef] [PubMed]

- Yan, Z.-G.; Li, Z.-G.; Du, J.-Z. Effects of Environmental Organic Pollutants on Environment and Human Health: The Latest Updates. Toxics 2024, 12, 231. [Google Scholar] [CrossRef] [PubMed]

- Cheng, L.; Chen, Y.; Pei, Y.; Sun, G.; Zou, J.; Peng, S.; Zhang, Y. NO and CO Emission Characteristics of Laminar and Turbulent Counterflow Premixed Hydrogen-Rich Syngas/Air Flames. Processes 2024, 12, 475. [Google Scholar] [CrossRef]

- Kabiesz, J.; Kubica, R. Optimizing the Recovery of Latent Heat of Condensation from the Flue Gas Stream through the Combustion of Solid Biomass with a High Moisture Content. Energies 2024, 17, 1670. [Google Scholar] [CrossRef]

- Chen, M.; Zhao, M.; Wang, Z.; Huang, X.; Zheng, H.; Deng, F. Exploring Vortex–Flame Interactions and Combustion Dynamics in Bluff Body-Stabilized Diffusion Flames: Effects of Incoming Flow Velocity and Oxygen Content. Processes 2024, 12, 622. [Google Scholar] [CrossRef]

- Kim, N.; Lee, M.; Park, J.; Park, J.; Lee, T. A Comparative Study of NOx Emission Characteristics in a Fuel Staging and Air Staging Combustor Fueled with Partially Cracked Ammonia. Energies 2022, 15, 9617. [Google Scholar] [CrossRef]

- Wei, D.; Zhang, Z.; Wu, L.; Wang, T.; Sun, B. Ammonia blend ratio impact on combustion characteristics and NOx emissions during co-firing with sludge and coal in a utility boiler. Energy 2023, 283, 129220. [Google Scholar] [CrossRef]

- Guo, F.; Liu, W.; He, Y.; Li, X.; Zhang, H. Study on the combustion characteristics and pollutant emissions of cold-pressed pellets and pellet powders in fluidized-bed. Renew. Energy 2024, 220, 119689. [Google Scholar] [CrossRef]

- Zhai, M.; Li, X.; Yang, D.; Ma, Z.; Dong, P. Ash fusion characteristics of biomass pellets during combustion. J. Clean. Prod. 2022, 336, 130361. [Google Scholar] [CrossRef]

- Dai, H.; Dai, H. Efficient lean combustion in a novel porous medium burner with the integrated of pellets and ceramic foam: Experimental study of flame propagation and stability. Combust. Flame 2022, 244, 112244. [Google Scholar] [CrossRef]

- Zhang, T.; Mo, Z.; Xu, X.; Liu, X.; Chen, H.; Han, Z.; Yan, Y.; Jin, Y. Advanced Study of Spray Cooling: From Theories to Applications. Energies 2022, 15, 9219. [Google Scholar] [CrossRef]

- Sungur, B.; Basar, C. Experimental investigation of the effect of supply airflow position, excess air ratio and thermal power input at burner pot on the thermal and emission performances in a pellet stove. Renew. Energy 2023, 202, 1248–1258. [Google Scholar] [CrossRef]

- Eskilsson, D.; Rönnbäck, M.; Samuelsson, J.; Tullin, C. Optimisation of efficiency and emissions in pellet burners. Biomass Bioenergy 2004, 27, 541–546. [Google Scholar] [CrossRef]

- Guo, H.; Feng, L.; Wu, Y.; Zhang, Y. Effect of turbulent mixing on combustion behaviours of a single biomass pellet. Fuel 2023, 346, 128291. [Google Scholar] [CrossRef]

- Yuzuru, N.; Yoshiyuki, K.; Masayuki, M.; Kazuya, S.; Takumi, O.; Yusuke, F.; Ryo, H. Effects of spacing between fuel and oxidizer nozzles on NOx emission from spray combustion furnace operating under various oxidizer temperatures. Fuel 2024, 366, 131398. [Google Scholar] [CrossRef]

- Yan, B.; Lv, J.; Zhou, S.; Wu, Z.; Liu, X.; Li, B.; Gao, Q.; Wu, W.; Chen, G. Application of optical diagnosis technology in biomass combustion. Biomass Bioenergy 2024, 184, 107198. [Google Scholar] [CrossRef]

- Yoon, S.H.; Kim, S.J.; Baek, G.U.; Moon, J.H.; Jo, S.H.; Park, S.J.; Kim, J.Y.; Yoon, S.J.; Ra, H.W.; Yoon, S.M.; et al. Operational optimization of air staging and flue gas recirculation for NOx reduction in biomass circulating fluidized bed combustion. J. Clean. Prod. 2023, 387, 135878. [Google Scholar] [CrossRef]

- Ma, D.; Zhang, S.; He, X.; Zhang, J.; Ding, X. Combustion stability and NOX emission characteristics of a 300 MWe tangentially fired boiler under ultra-low loads with deep-air staging. Energy 2023, 269, 126795. [Google Scholar] [CrossRef]

- EN 303-5:2012; Heating Boilers—Part 5: Heating Boilers for Solid Fuels, Manually and Auto-Matically Stocked, Nominal Heat Output of up to 500 kW—Terminology, Requirements, Testing and Marking. Polish Committee for Standardization: Warsaw, Poland, 2012.

- Available online: https://www.walsc.pl/kociol-klasy-5,12 (accessed on 3 November 2023).

- Available online: https://www.ecomat.waw.pl (accessed on 3 April 2024).

- EN ISO 18122:2016; Solid Biofuels—Determination of Ash Content. Polish Committee for Standardization: Warsaw, Poland, 2016.

- EN ISO 18125:2017; Solid Biofuels. Determination of Calorific Value. Polish Committee for Standardization: Warsaw, Poland, 2017.

- EN ISO 18134-2:2017; Solid Biofuels. Determination of Moisture Content. Oven Dry Method. Polish Committee for Standardization: Warsaw, Poland, 2017.

- EN ISO 18123:2015; Solid Biofuels. Determination of Volatile Matter. Polish Committee for Standardization: Warsaw, Poland, 2015.

- EN ISO 16127:2012; Solid Biofuels. Determination of Length and Diameter of Pellets. Polish Committee for Standardization: Warsaw, Poland, 2012.

- Available online: https://www.testo.com (accessed on 3 November 2023).

- Available online: https://madur.com (accessed on 3 April 2023).

- Ciupek, B.; Gołoś, K.; Jankowski, R.; Nadolny, Z. Effect of Hard Coal Combustion in Water Steam Environment on Chemical Composition of Exhaust Gases. Energies 2021, 14, 6530. [Google Scholar] [CrossRef]

- Ciupek, B.; Judt, W.; Gołoś, K.; Urbaniak, R. Analysis of Low-Power Boilers Work on Real Heat Loads: A Case of Poland. Energies 2021, 14, 3101. [Google Scholar] [CrossRef]

- Ciupek, B. Study on hard coal combustion in heating boilers equipped with a steam-fed afterburning chamber. Chem. Ind. 2020, 99, 8. [Google Scholar] [CrossRef]

- Ciupek, B.; Bartoszewicz, J. The influence of geometry of primary air channels in standard retort burners on dust emission. MATEC Web Conf. 2019, 254, 04009. [Google Scholar] [CrossRef]

- Park, J.; Yu, S.; Kim, H.; Jo, H.; Min, K.; Lee, J.; Heo, J.; Ryu, C. Co-combustion of refuse plastic fuel from marine plastics with wood pellets in a fixed-bed: Identification of minimum cofiring ratio and ideal air flow rate. Fuel 2023, 344, 128092. [Google Scholar] [CrossRef]

- Lei, T.; Huang, H.; Tan, M.; Huang, Z.; Li, C.; Liu, P.; Zhou, X.; Zhang, X.; Huang, J.; Li, H. The effect of additives on the co-pelletization of sewage sludge and extraction residue on combustion behavior and off-gas emission reduction. Biomass Bioenergy 2024, 184, 107181. [Google Scholar] [CrossRef]

- Öhman, M.; Boman, C.; Hedman, H.; Nordin, A.; Boström, D. Slagging tendencies of wood pellet ash during combustion in residential pellet burners. Biomass Bioenergy 2004, 27, 585–596. [Google Scholar] [CrossRef]

| Type of Measurement | Pinewood Pellets |

|---|---|

| Hygroscopic moisture content (Wh) % | 1.93 |

| Excess moisture content (Wex) % | 3.14 |

| Total moisture content (Wt) % | 5.00 |

| Volatile matter % | 73.61 |

| Ash content % | 0.47 |

| C % | 54.74 |

| S % | 0.09 |

| H2 % | 4.97 |

| N2 % | 0.19 |

| O2 % | 34.54 |

| High calorific value (Qs) MJ/kg | 14.93 |

| Low calorific value (Qi) MJ/kg | 14.32 |

| Excess Air Ratio | Measurement Value | CO | NOx | PM | Tf | ηc | qA |

|---|---|---|---|---|---|---|---|

| mg/m3 for 10% O2 in Flue Gases | °C | % | |||||

| 1.00 | Average | 887.19 | 179.47 | 48.44 | 127.18 | 98.93 | 1.08 |

| 1.10 | 815.82 | 178.54 | 40.54 | 131.49 | 97.53 | 2.47 | |

| 1.30 | 744.25 | 167.61 | 32.64 | 135.80 | 96.13 | 3.87 | |

| 1.50 | 672.78 | 165.75 | 24.74 | 140.11 | 94.36 | 5.64 | |

| 1.60 | 601.31 | 156.68 | 16.84 | 144.42 | 93.33 | 6.67 | |

| 1.80 | 470.44 | 162.60 | 13.53 | 150.54 | 92.21 | 7.79 | |

| 2.00 | 959.04 | 265.14 | 123.34 | 154.25 | 91.52 | 8.48 | |

| 2.40 | 1421.37 | 311.82 | 228.11 | 169.90 | 88.28 | 11.72 | |

| Excess Air Ratio | Measurement Value | CO | NOx | PM | Tf | ηc | qA |

|---|---|---|---|---|---|---|---|

| mg/m3 for 10% O2 in Flue Gases | °C | % | |||||

| 1.00 | Average | 1107.13 | 240.47 | 22.44 | 100.15 | 97.20 | 2.80 |

| 1.10 | 1005.72 | 236.54 | 26.54 | 109.83 | 95.81 | 4.20 | |

| 1.30 | 904.25 | 232.61 | 28.64 | 119.51 | 94.41 | 5.59 | |

| 1.50 | 802.78 | 228.68 | 36.74 | 129.19 | 92.64 | 7.36 | |

| 1.60 | 701.31 | 224.75 | 44.84 | 138.87 | 91.61 | 8.39 | |

| 1.80 | 425.44 | 181.60 | 18.73 | 148.55 | 90.49 | 9.51 | |

| 2.00 | 1480.04 | 216.14 | 246.34 | 158.23 | 89.80 | 10.20 | |

| 2.40 | 1538.37 | 220.82 | 228.11 | 167.91 | 86.56 | 13.44 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ciupek, B.; Nadolny, Z. Emission of Harmful Substances from the Combustion of Wood Pellets in a Low-Temperature Burner with Air Gradation: Research and Analysis of a Technical Problem. Energies 2024, 17, 3087. https://doi.org/10.3390/en17133087

Ciupek B, Nadolny Z. Emission of Harmful Substances from the Combustion of Wood Pellets in a Low-Temperature Burner with Air Gradation: Research and Analysis of a Technical Problem. Energies. 2024; 17(13):3087. https://doi.org/10.3390/en17133087

Chicago/Turabian StyleCiupek, Bartosz, and Zbigniew Nadolny. 2024. "Emission of Harmful Substances from the Combustion of Wood Pellets in a Low-Temperature Burner with Air Gradation: Research and Analysis of a Technical Problem" Energies 17, no. 13: 3087. https://doi.org/10.3390/en17133087

APA StyleCiupek, B., & Nadolny, Z. (2024). Emission of Harmful Substances from the Combustion of Wood Pellets in a Low-Temperature Burner with Air Gradation: Research and Analysis of a Technical Problem. Energies, 17(13), 3087. https://doi.org/10.3390/en17133087