Development and Performance Evaluation Experiment of a Device for Simultaneous Reduction of SOx and PM

Abstract

1. Introduction

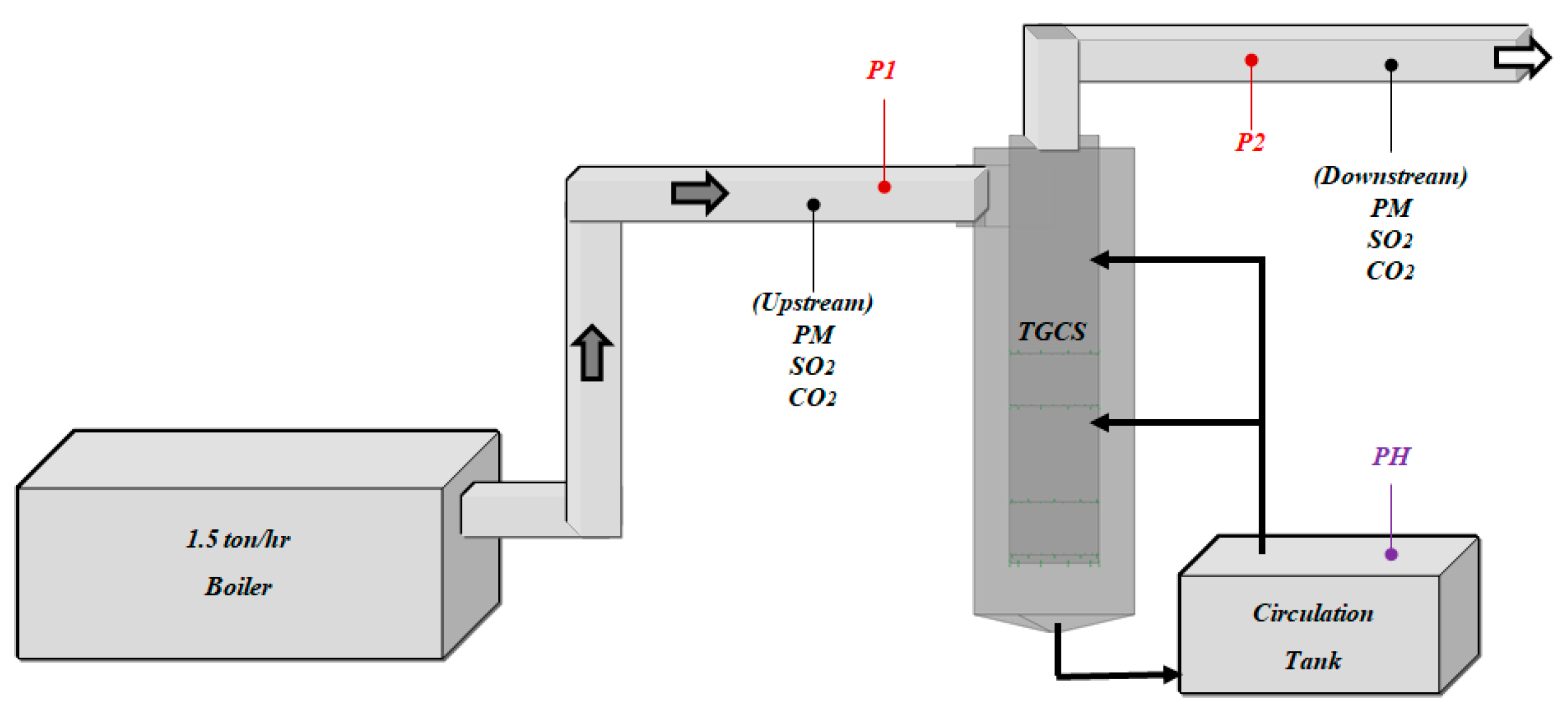

2. Development and Configuration of Total Gas Cleaning System

3. Experimental Procedure

4. Results and Discussions

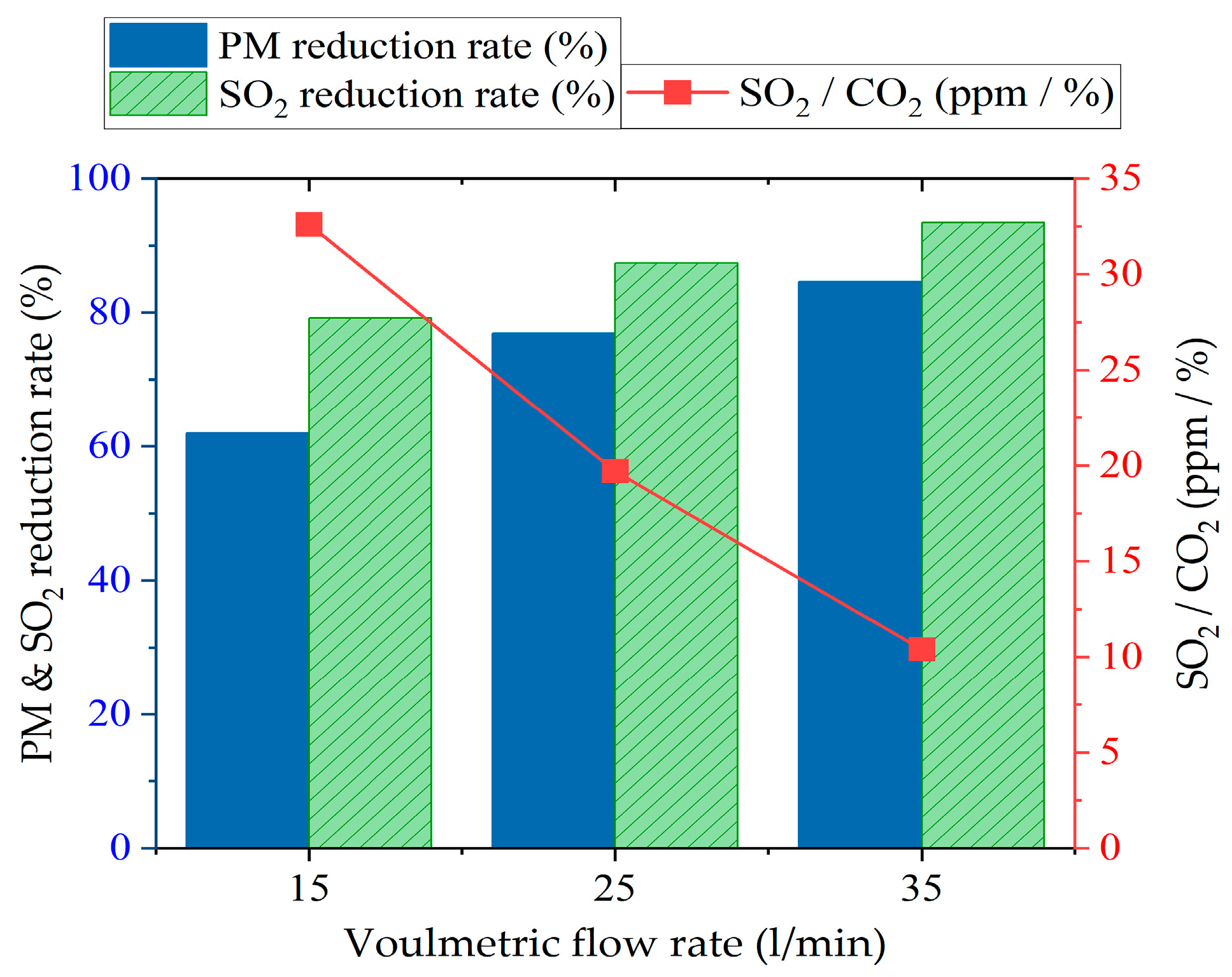

4.1. Pall Ring Height 500 mm

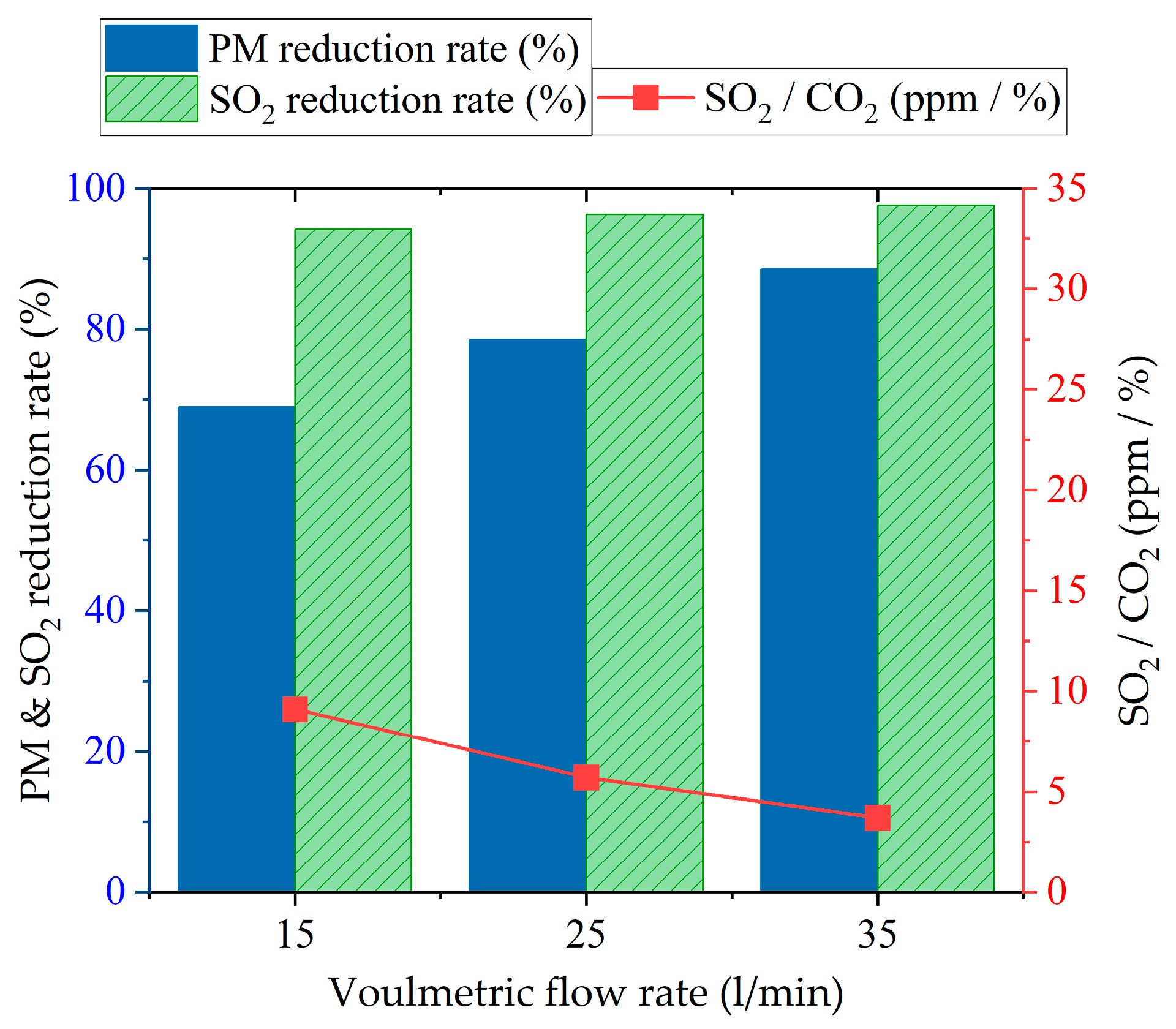

4.2. Pall Ring Height 1000 mm

5. Conclusions

- (1)

- Increasing the cleaning solution’s volumetric flow rate enhanced PM reduction effects.

- (2)

- Compared to a Pall ring height of 500 mm, a height of 1000 mm exhibited superior SOx reduction effects, particularly meeting SECA standards at a volumetric flow rate of 35 L/min.

- (3)

- As the Pall ring height increased, back pressure increased, necessitating analysis of interactions with ship engines during TGCS installation.

6. Patents

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Aakko-Saksa, P.T.; Lehtoranta, K.; Kuittinen, N.; Järvinen, A.; Jalkanen, J.-P.; Johnson, K.; Jung, H.; Ntziachristos, L.; Gagné, S.; Takahashi, C.; et al. Reduction in Greenhouse Gas and Other Emissions from Ship Engines: Current Trends and Future Options. Prog. Energy Combust. Sci. 2023, 94, 101055. [Google Scholar] [CrossRef]

- Osipova, L. Global Scrubber Washwater Discharges under IMO’s 2020 Fuel Sulfur Limit; International Council on Clean Transportation: Washington, DC, USA, 2021. [Google Scholar]

- Teuchies, J.; Cox, T.J.S.; Van Itterbeeck, K.; Meysman, F.J.R.; Blust, R. The Impact of Scrubber Discharge on the Water Quality in Estuaries and Ports. Environ. Sci. Eur. 2020, 32, 103. [Google Scholar] [CrossRef]

- Cao, D.N.; Hoang, A.T.; Luu, H.Q.; Bui, V.G.; Tran, T.T.H. Effects of Injection Pressure on the NOx and PM Emission Control of Diesel Engine: A Review under the Aspect of PCCI Combustion Condition. Energy Sources Part A Recovery Util. Environ. Eff. 2020, 1–18. [Google Scholar] [CrossRef]

- Zannis, T.C.; Katsanis, J.S.; Christopoulos, G.P.; Yfantis, E.A.; Papagiannakis, R.G.; Pariotis, E.G.; Rakopoulos, D.C.; Rakopoulos, C.D.; Vallis, A.G. Marine Exhaust Gas Treatment Systems for Compliance with the IMO 2020 Global Sulfur Cap and Tier III NOx Limits: A Review. Energies 2022, 15, 3638. [Google Scholar] [CrossRef]

- Amoresano, A.; Langella, G.; Iodice, P.; Roscioli, S. Numerical Analysis of SO2 Absorption inside a Single Water Drop. Atmosphere 2023, 14, 1746. [Google Scholar] [CrossRef]

- Kunche, A.; Mielczarek, B. Using Simulation Modelling for Designing Optimal Strategies of Fuel Mix to Comply for SOx and NOx Emission Standards in Industrial Boilers. Energies 2022, 16, 149. [Google Scholar] [CrossRef]

- Yang, J.; Tang, T.; Jiang, Y.; Karavalakis, G.; Durbin, T.D.; Wayne Miller, J.; Cocker, D.R.; Johnson, K.C. Controlling Emissions from an Ocean-Going Container Vessel with a Wet Scrubber System. Fuel 2021, 304, 121323. [Google Scholar] [CrossRef]

- Hu, S.; Gao, Y.; Feng, G.; Hu, F.; Liu, C.; Li, J. Experimental Study of the Dust-Removal Performance of a Wet Scrubber. Int. J. Coal Sci. Technol. 2021, 8, 228–239. [Google Scholar] [CrossRef]

- Yang, Z.; Chen, H.; Li, C.; Guo, H.; Tan, Q. Performance Test and Structure Optimization of a Marine Diesel Particulate Filter. Energies 2023, 16, 4336. [Google Scholar] [CrossRef]

- Syrek-Gerstenkorn, Z.; Syrek-Gerstenkorn, B.; Paul, S. A Comparative Study of SOx, NOx, PM2.5 and PM10 in the UK and Poland from 1970 to 2020. Appl. Sci. 2024, 14, 3292. [Google Scholar] [CrossRef]

- Lu, M.; Tzillah, A.; Chai, M.; Aloraimi, O. Compositional Analysis of Biodiesel Particulate Matter (BPM) from a Non-Road Diesel Generator. Energies 2023, 16, 5010. [Google Scholar] [CrossRef]

- Qi, J.; Feng, R.; Wang, S. Optimization of Fleet Scrubber Installation and Utilization Considering Sulfur Emission Control Areas and Marine Fuel Switching. J. Mar. Sci. Eng. 2023, 11, 1849. [Google Scholar] [CrossRef]

- Chivu, R.M.; Martins, J.; Popescu, F.; Uzuneanu, K.; Ion, I.V.; Goncalves, M.; Codău, T.-C.; Onofrei, E.; Brito, F.P. Turpentine as an Additive for Diesel Engines: Experimental Study on Pollutant Emissions and Engine Performance. Energies 2023, 16, 5150. [Google Scholar] [CrossRef]

- Zhao, J.; Wei, Q.; Wang, S.; Ren, X. Progress of Ship Exhaust Gas Control Technology. Sci. Total Environ. 2021, 799, 149437. [Google Scholar] [CrossRef] [PubMed]

- Choi, W.; Choi, S.; Na, S.; Shin, D.; Jeong, H.; Sung, Y. Numerical Study on Compact Design in Marine Urea-SCR Systems for Small Ship Applications. Energies 2023, 17, 187. [Google Scholar] [CrossRef]

- Wilailak, S.; Yoo, B.-H.; Kim, Y.; Lee, C.-J. Parametric Analysis and Design Optimization of Wet SOx Scrubber System in Marine Industry. Fuel 2021, 304, 121369. [Google Scholar] [CrossRef]

- Delcourt, F.; Izerroukyene, A.; Méresse, D.; Uystepruyst, D.; Beaubert, F.; Morin, C. Experimental Study of Pollutant Emissions from Biomass Combustion and Modeling of PM Transportation. Energies 2024, 17, 2586. [Google Scholar] [CrossRef]

- Karatuğ, Ç.; Arslanoğlu, Y.; Guedes Soares, C. Feasibility Analysis of the Effects of Scrubber Installation on Ships. J. Mar. Sci. Eng. 2022, 10, 1838. [Google Scholar] [CrossRef]

- Järvinen, A.; Lehtoranta, K.; Aakko-Saksa, P.; Karppanen, M.; Murtonen, T.; Martikainen, J.; Kuusisto, J.; Nyyssönen, S.; Koponen, P.; Piimäkorpi, P.; et al. Performance of a Wet Electrostatic Precipitator in Marine Applications. J. Mar. Sci. Eng. 2023, 11, 393. [Google Scholar] [CrossRef]

| Item | Value | Unit |

|---|---|---|

| Exhaust gas velocity | 8 | m/s |

| Exhaust gas standard flow rate | 1750 | Sm3/h |

| Exhaust gas temperature | 280 | °C |

| Component | Design Factor | Unit |

|---|---|---|

| Pall ring height | 500, 1000 | mm |

| Volumetric flow rate | 15, 25, 35 | L/min (liters/min) |

| Measuring Item | Measuring Position | Volumetric Flow Rate (L/min) | Unit | ||

|---|---|---|---|---|---|

| 15 | 25 | 35 | |||

| Particle Matter (PM) | Upstream | 185.6 | 185.6 | 185.6 | mg/Sm3 |

| Downstream | 70.5 | 42.9 | 28.5 | ||

| PM reduction rate | 62.0 | 76.9 | 84.6 | % | |

| SO2 | Upstream | 1690 | 1690 | 1690 | ppm |

| Downstream | 352 | 213 | 112 | ||

| SO2 reduction rate | 79.2 | 87.4 | 93.4 | % | |

| CO2 | Upstream | 10.9 | 10.9 | 10.9 | % |

| Downstream | 10.8 | 10.8 | 10.8 | ||

| SO2 (ppm)/CO2 (%) | 32.6 | 19.7 | 10.4 | ppm/% | |

| TGCS Pressure | Upstream | 98 | 100 | 101 | mmH2O |

| Measuring Item | Measuring Position | Volumetric Flow Rate (L/min) | Unit | ||

|---|---|---|---|---|---|

| 15 | 25 | 35 | |||

| Particle Matter (PM) | Upstream | 187.2 | 187.2 | 187.2 | mg/Sm3 |

| Downstream | 58.2 | 40.3 | 21.5 | ||

| PM reduction rate | 68.9 | 78.5 | 88.5 | % | |

| SO2 | Upstream | 1690 | 1690 | 1690 | ppm |

| Downstream | 98 | 62 | 40 | ||

| SO2 reduction rate | 94.2 | 96.3 | 97.6 | % | |

| CO2 | Upstream | 10.9 | 10.9 | 10.9 | % |

| Downstream | 10.8 | 10.8 | 10.8 | ||

| SO2 (ppm)/CO2 (%) | 9.1 | 5.7 | 3.7 | ppm/% | |

| TGCS Pressure | Upstream | 140 | 145 | 150 | mmH2O |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kong, K.-J.; Hwang, S.-C. Development and Performance Evaluation Experiment of a Device for Simultaneous Reduction of SOx and PM. Energies 2024, 17, 3337. https://doi.org/10.3390/en17133337

Kong K-J, Hwang S-C. Development and Performance Evaluation Experiment of a Device for Simultaneous Reduction of SOx and PM. Energies. 2024; 17(13):3337. https://doi.org/10.3390/en17133337

Chicago/Turabian StyleKong, Kyeong-Ju, and Sung-Chul Hwang. 2024. "Development and Performance Evaluation Experiment of a Device for Simultaneous Reduction of SOx and PM" Energies 17, no. 13: 3337. https://doi.org/10.3390/en17133337

APA StyleKong, K.-J., & Hwang, S.-C. (2024). Development and Performance Evaluation Experiment of a Device for Simultaneous Reduction of SOx and PM. Energies, 17(13), 3337. https://doi.org/10.3390/en17133337