Enhanced DC Building Distribution Performance Using a Modular Grid-Tied Converter Design

Abstract

1. Introduction

1.1. Related Works

1.2. Aims and Contributions of the Present Work

- A novel rule-based battery dual-objective operation (DOO) and modular GC design;

- The importance and quantified effect on GC losses from a reduced partial-load operation are highlighted;

- A quantified effect on battery degradation from the proposed battery controls;

- An economic assessment of LOC for net annual billing and monetised battery degradation.

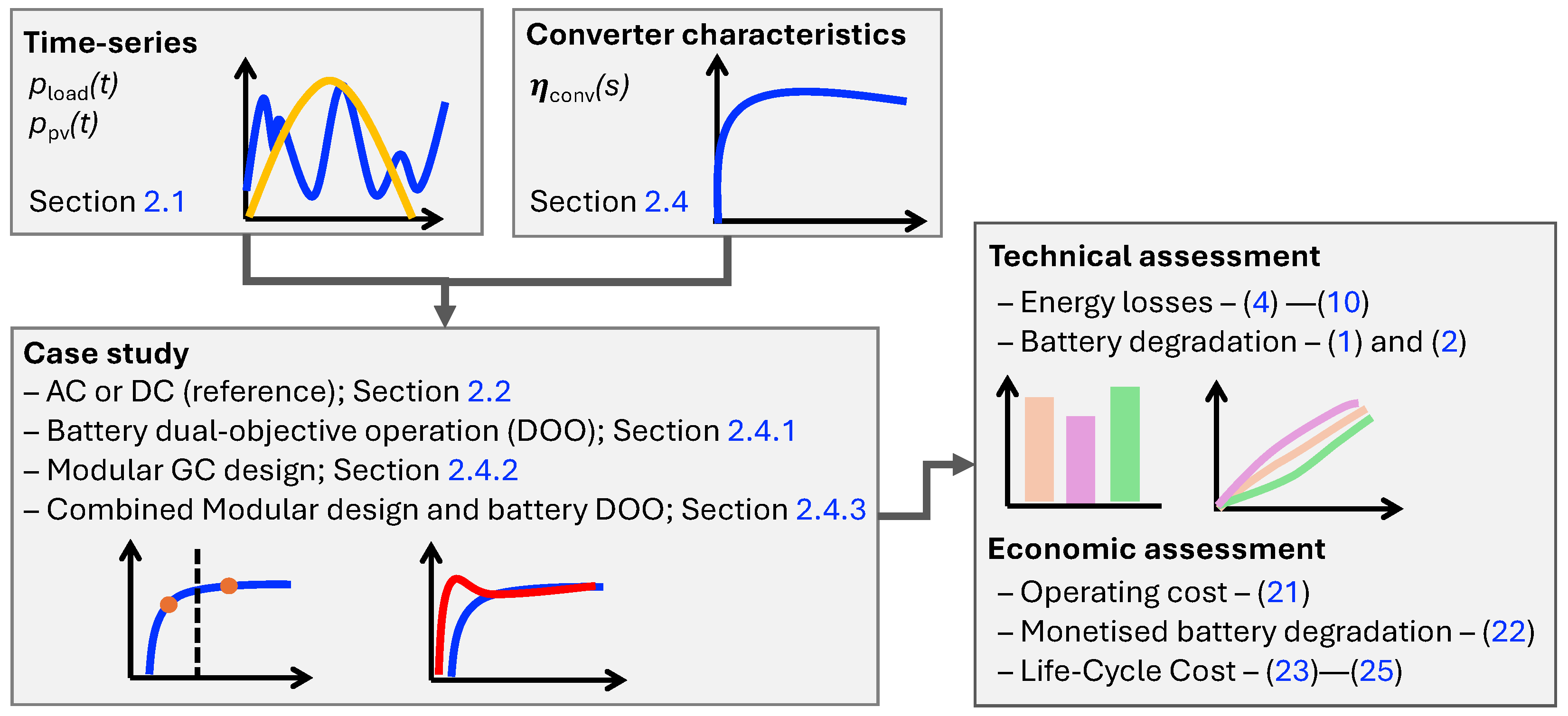

2. Methods

2.1. Use-Case—Single-Family Residential Building

2.2. AC and DC Building Distribution

2.3. Battery System and Operation

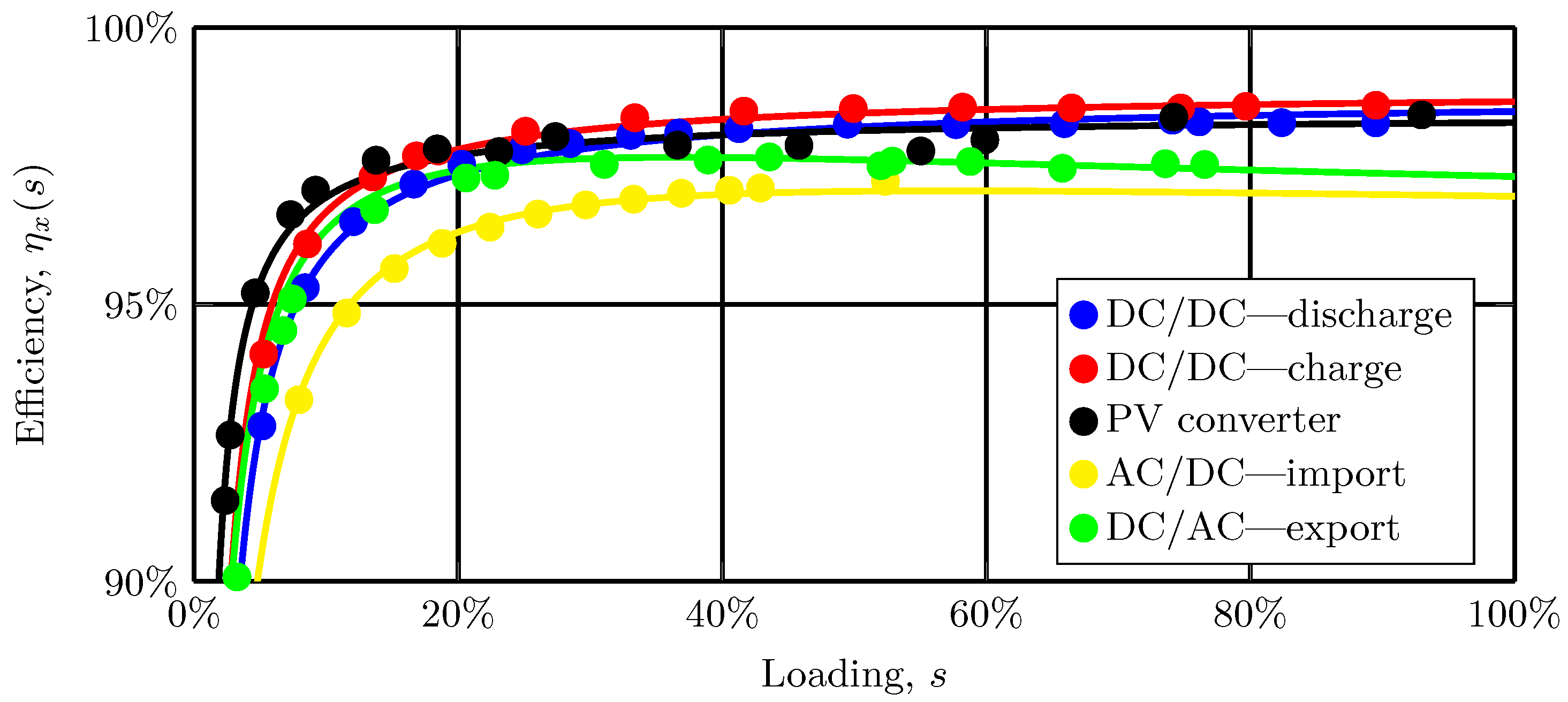

2.4. Electrical Loss Modelling

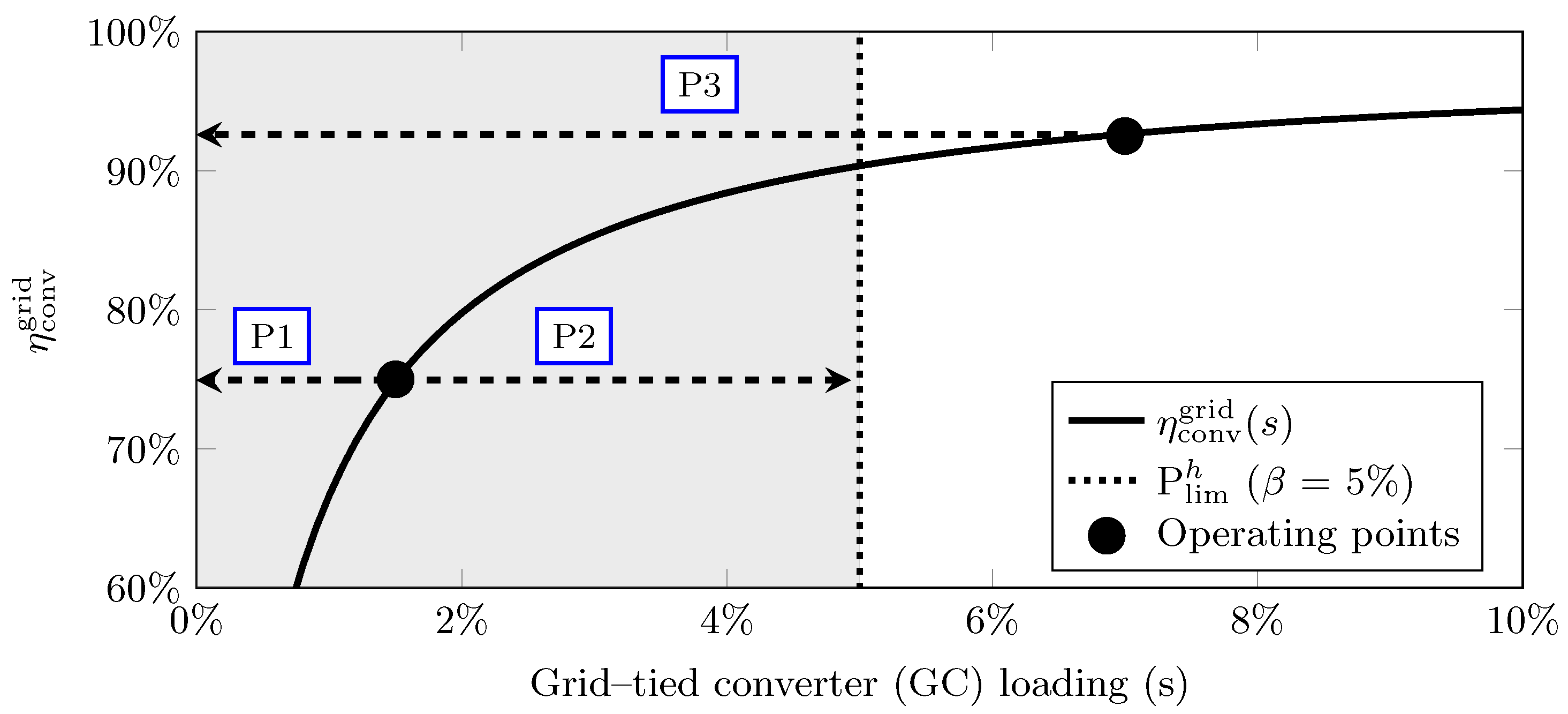

2.4.1. Battery Dual-Objective Operation

- Suppose net demand is lower than . In that case, a check is made whether the available charge content (or gap) can meet the net demand completely. The battery charge gap is defined as available storage capacity to 100% SOC. If true, the battery uses full DoD to charge or discharge to meet the net demand (P1). If this is false, the battery either charges or discharges the extra amount so that the GC throughput equals (P2).

- If the available charge content (or gap) can fully meet the net demand, it charges or discharges so that the power through the converter is zero, i.e., no grid interaction occurs (P3). If this is false, the battery is not engaged for partial-load coverage and passes all net demands through the GC.

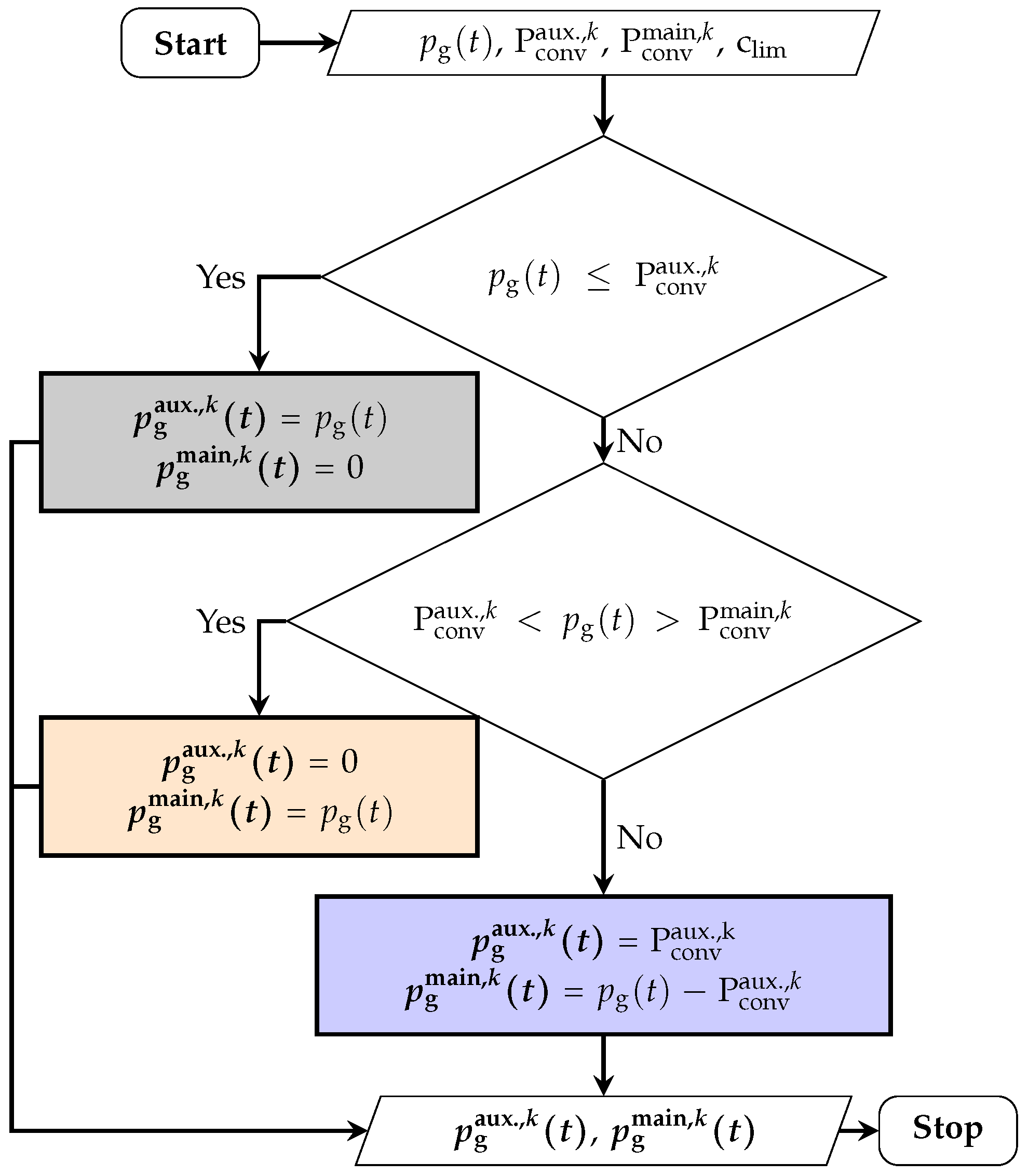

2.4.2. Modular GC Design

2.4.3. Combined Modular Design and Battery DOO Operation

2.5. Economic Assessment

3. Results and Discussion

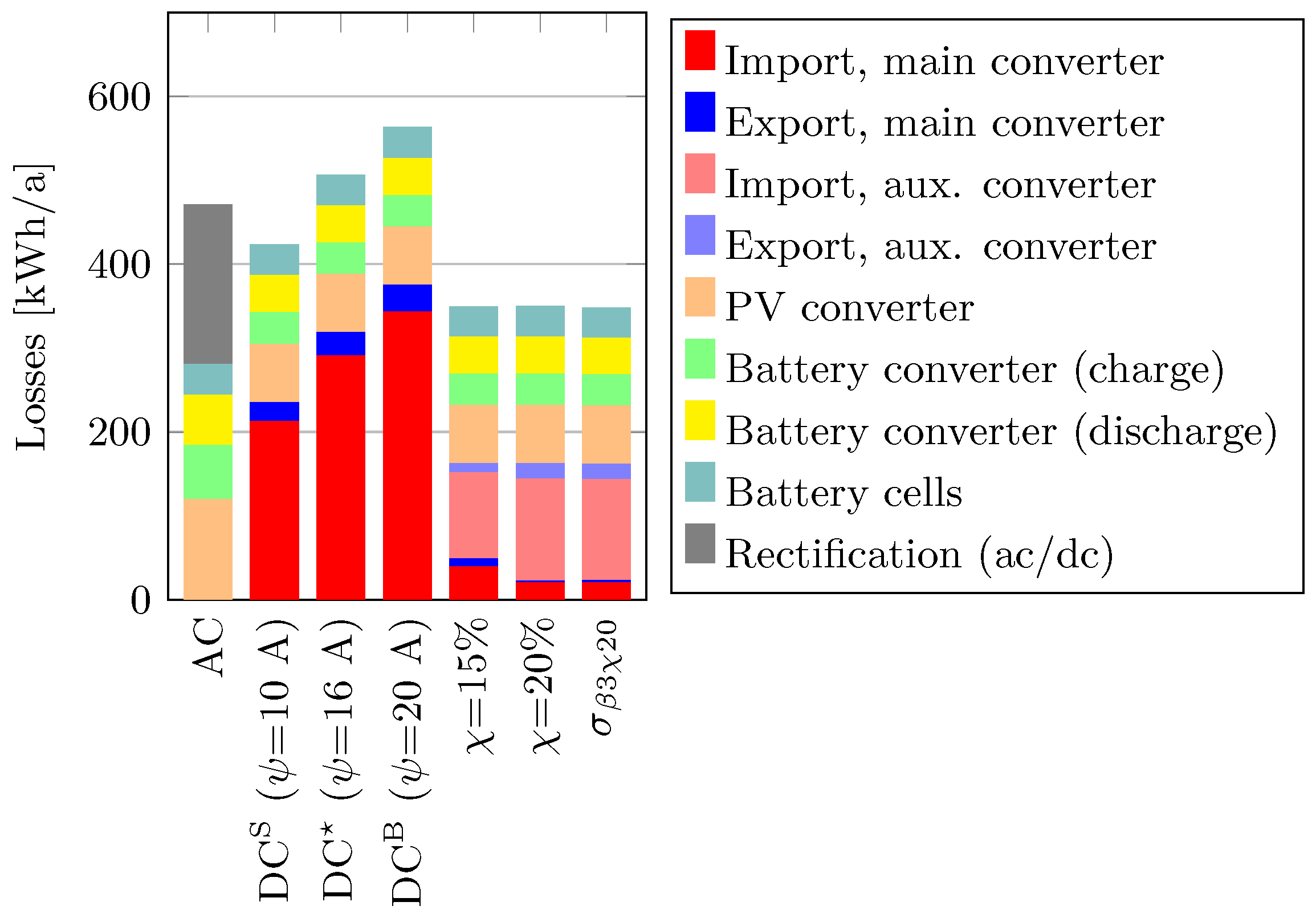

3.1. DC Distribution Enhancement Methods

3.1.1. Effect on Battery Ageing from Battery DOO

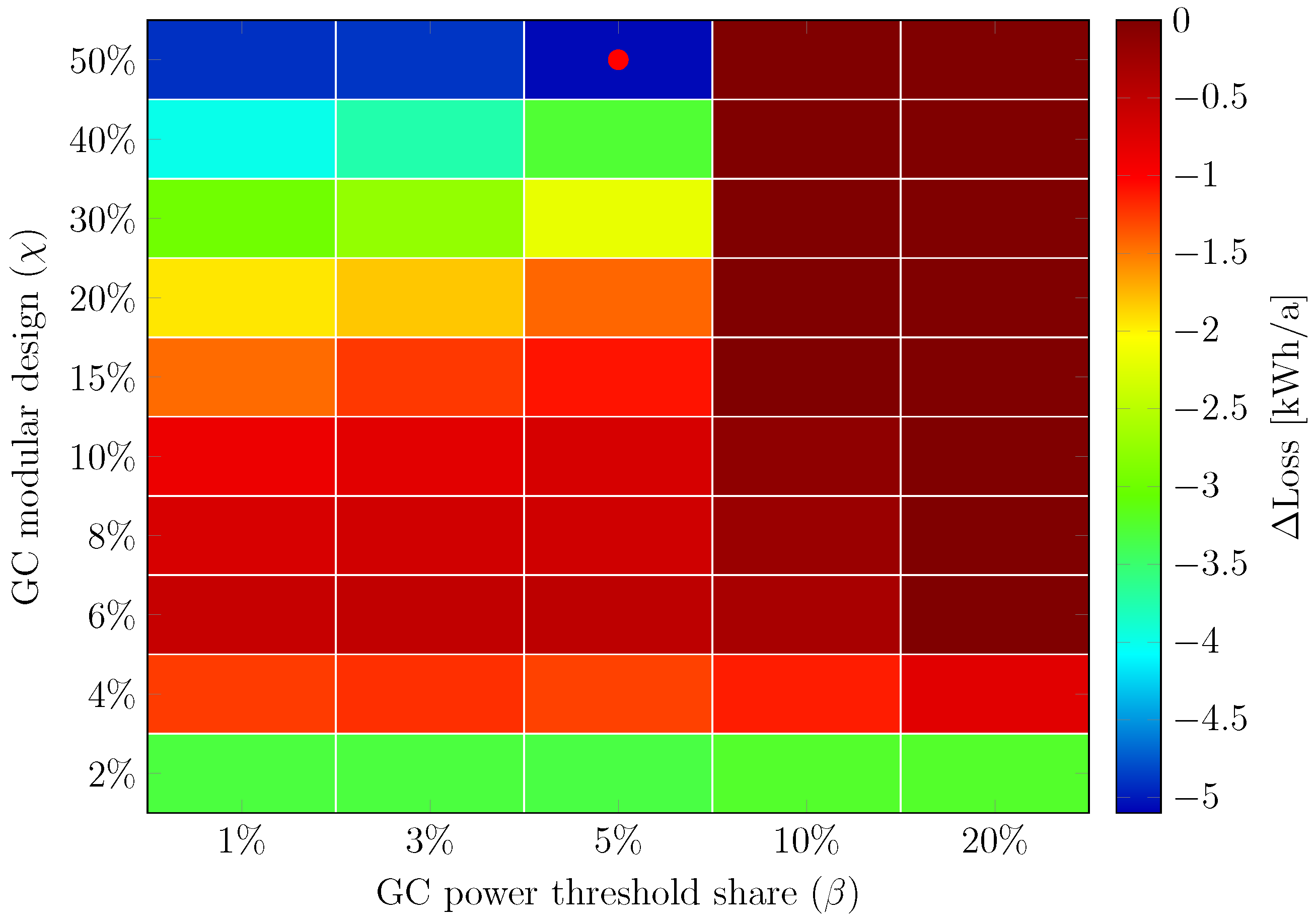

3.1.2. Combined Modular and Battery DOO

3.2. Loss Comparison—AC vs. DC

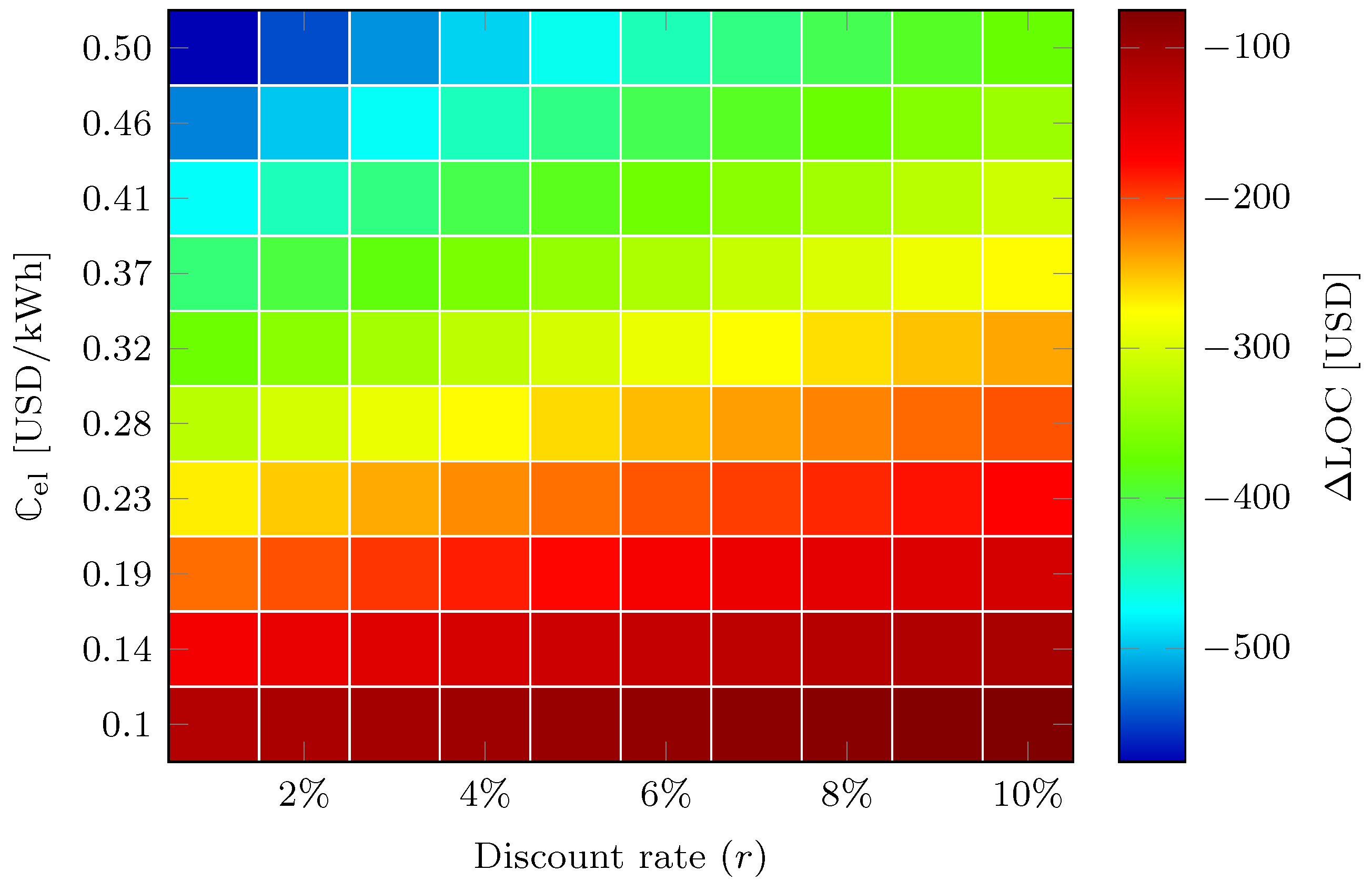

3.3. Life-Cycle Cost Comparison

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| DOO | Dual-objective operation |

| GC | Grid-tied converter |

| DoD | Depth-of-discharge |

| LCC | Life-cycle cost |

| OC | Operational cost |

| PEC | Power electronic converter |

| Grid-tied converter threshold value | |

| Size ratio of smaller grid-tied converter | |

| Building main fuse | |

| Price for bought electricity | |

| Net electricity bill | |

| Revenue from sold electricity | |

| Scenarios from parametric sweep of and | |

| Ah | Battery capacity throughput |

| DC∗ | DC reference ( = 16 A and = 0%) |

| DCB | DC with bigger GC ( = 20 A) |

| DCS | DC with smaller GC ( = 10 A) |

| Grid-tied converter power threshold | |

| PLS | Proposed load sharing |

References

- Masson, G.; Kaizuka, I. Trends in Photovoltaic Applications; Technical Report; International Energy Agency Photovoltaic Power Systems Programme: Paris, France, 2022; ISBN 978-3-907281-35-2. [Google Scholar]

- Henze, V. Energy Storage Investments Boom as Battery Costs Halve in the Next Decade; Bloomberg New Energy Finance: New York, NY, USA, 2019; Volume 31. [Google Scholar]

- Elsayed, A.T.; Mohamed, A.A.; Mohammed, O.A. DC microgrids and distribution systems: An overview. Electr. Power Syst. Res. 2015, 119, 407–417. [Google Scholar] [CrossRef]

- Sabry, A.H.; Shallal, A.H.; Hameed, H.S.; Ker, P.J. Compatibility of household appliances with DC microgrid for PV systems. Heliyon 2020, 6, e05699. [Google Scholar] [CrossRef]

- Gerber, D.L.; Liou, R.; Brown, R. Energy-saving opportunities of direct-DC loads in buildings. Appl. Energy 2019, 248, 274–287. [Google Scholar] [CrossRef]

- Gerber, D.L.; Nordman, B.; Brown, R.; Poon, J. Cost analysis of distributed storage in AC and DC microgrids. Appl. Energy 2023, 344, 121218. [Google Scholar] [CrossRef]

- Ollas, P.; Thiringer, T.; Chen, H.; Markusson, C. Increased photovoltaic utilisation from direct current distribution: Quantification of geographical location impact. Prog. Photovoltaics Res. Appl. 2021, 29, 846–856. [Google Scholar] [CrossRef]

- Glasgo, B.; Azevedo, I.L.; Hendrickson, C. How much electricity can we save by using direct current circuits in homes? Understanding the potential for electricity savings and assessing feasibility of a transition towards DC powered buildings. Appl. Energy 2016, 180, 66–75. [Google Scholar] [CrossRef]

- Kang, J.; Hao, B.; Li, Y.; Lin, H.; Xue, Z. The Application and Development of LVDC Buildings in China. Energies 2022, 15, 7045. [Google Scholar] [CrossRef]

- Vossos, V.; Gerber, D.; Bennani, Y.; Brown, R.; Marnay, C. Techno-economic analysis of DC power distribution in commercial buildings. Appl. energy 2018, 230, 663–678. [Google Scholar] [CrossRef]

- Vossos, V.; Gerber, D.L.; Gaillet-Tournier, M.; Nordman, B.; Brown, R.; Bernal Heredia, W.; Ghatpande, O.; Saha, A.; Arnold, G.; Frank, S.M. Adoption Pathways for DC Power Distribution in Buildings. Energies 2022, 15, 786. [Google Scholar] [CrossRef]

- Vossos, V.; Garbesi, K.; Shen, H. Energy savings from direct-DC in US residential buildings. Energy Build. 2014, 68, 223–231. [Google Scholar] [CrossRef]

- Gerber, D.L.; Vossos, V.; Feng, W.; Marnay, C.; Nordman, B.; Brown, R. A simulation-based efficiency comparison of AC and DC power distribution networks in commercial buildings. Appl. Energy 2018, 210, 1167–1187. [Google Scholar] [CrossRef]

- Spiliotis, K.; Gonçalves, J.E.; Saelens, D.; Baert, K.; Driesen, J. Electrical system architectures for building-integrated photovoltaics: A comparative analysis using a modelling framework in Modelica. Appl. Energy 2020, 261, 114247. [Google Scholar] [CrossRef]

- Ollas, P.; Thiringer, T.; Persson, M.; Markusson, C. Energy Loss Savings Using Direct Current Distribution in a Residential Building with Solar Photovoltaic and Battery Storage. Energies 2023, 16, 1131. [Google Scholar] [CrossRef]

- Erteza Gelani, H.; Dastgeer, F.; Ali Shah, S.A.; Saeed, F.; Hassan Yousuf, M.; Afzal, H.M.W.; Bilal, A.; Chowdhury, M.S.; Techato, K.; Channumsin, S.; et al. Comparative Efficiency and Sensitivity Analysis of AC and DC Power Distribution Paradigms for Residential Localities. Sustainability 2022, 14, 8220. [Google Scholar] [CrossRef]

- Ollas, P. Energy Savings Using a Direct-Current Distribution Network in a PV and Battery Equipped Residential Building; Technical Report; Chalmers University of Technology: Göteborg, Sweden, 2020. [Google Scholar]

- Seo, G.S.; Baek, J.; Choi, K.; Bae, H.; Cho, B. Modeling and analysis of DC distribution systems. In Proceedings of the 8th International Conference on Power Electronics-ECCE Asia, Jeju, Republic of Korea, 30 May–3 June 2011; pp. 223–227. [Google Scholar] [CrossRef]

- Boscaino, V.; Guerrero, J.; Ciornei, I.; Meng, L.; Sanseverino, E.R.; Zizzo, G. Online optimization of a multi-conversion-level DC home microgrid for system efficiency enhancement. Sustain. Cities Soc. 2017, 35, 417–429. [Google Scholar] [CrossRef]

- Sanseverino, E.R.; Favuzza, S.; Di Silvestre, M.L.; Tran, Q.T.; Zizzo, G.; Pham, T.N.; Kieu, T. Improved primary regulation for minimum energy losses in islanded microgrids. In Proceedings of the 2017 IEEE PES Innovative Smart Grid Technologies Conference Europe (ISGT-Europe), Torino, Italy, 26–29 September 2017; pp. 1–6. [Google Scholar] [CrossRef]

- Guerrero, J.M.; Vasquez, J.C.; Matas, J.; De Vicuña, L.G.; Castilla, M. Hierarchical control of droop-controlled AC and DC microgrids—A general approach toward standardization. IEEE Trans. Ind. Electron. 2010, 58, 158–172. [Google Scholar] [CrossRef]

- Nasirian, V.; Davoudi, A.; Lewis, F.L.; Guerrero, J.M. Distributed adaptive droop control for DC distribution systems. IEEE Trans. Energy Convers. 2014, 29, 944–956. [Google Scholar] [CrossRef]

- Meng, L.; Dragicevic, T.; Vasquez, J.C.; Guerrero, J.M. Tertiary and secondary control levels for efficiency optimization and system damping in droop controlled DC–DC converters. IEEE Trans. Smart Grid 2015, 6, 2615–2626. [Google Scholar] [CrossRef]

- Chinnathambi, N.D.; Nagappan, K.; Samuel, C.R.; Tamilarasu, K. Internet of things-based smart residential building energy management system for a grid-connected solar photovoltaic-powered DC residential building. Int. J. Energy Res. 2022, 46, 1497–1517. [Google Scholar] [CrossRef]

- Alshammari, M.; Duffy, M. Feasibility Analysis of a DC Distribution System for a 6 kW Photovoltaic Installation in Ireland. Energies 2021, 14, 6265. [Google Scholar] [CrossRef]

- Zhang, Y.; Lundblad, A.; Campana, P.E.; Benavente, F.; Yan, J. Battery sizing and rule-based operation of grid-connected photovoltaic-battery system: A case study in Sweden. Energy Convers. Manag. 2017, 133, 249–263. [Google Scholar] [CrossRef]

- Ollas, P.; Persson, J.; Peter, K. Effect of Energy Storage on Self-Consumption and Self-Sufficiency: A Field Study in a Nordic Climate. In Proceedings of the 38th European Photovoltaic Solar Energy Conference and Exhibition, Online, 6–10 September 2021; pp. 1459–1463. [Google Scholar] [CrossRef]

- Stephan, A.; Battke, B.; Beuse, M.D.; Clausdeinken, J.H.; Schmidt, T.S. Limiting the public cost of stationary battery deployment by combining applications. Nat. Energy 2016, 1, 16079. [Google Scholar] [CrossRef]

- Han, X.; Garrison, J.; Hug, G. Techno-economic analysis of PV-battery systems in Switzerland. Renew. Sustain. Energy Rev. 2022, 158, 112028. [Google Scholar] [CrossRef]

- Nyholm, E.; Goop, J.; Odenberger, M.; Johnsson, F. Solar photovoltaic-battery systems in Swedish households–Self-consumption and self-sufficiency. Appl. energy 2016, 183, 148–159. [Google Scholar] [CrossRef]

- Siraj, K.; Khan, H.A. DC distribution for residential power networks—A framework to analyze the impact of voltage levels on energy efficiency. Energy Rep. 2020, 6, 944–951. [Google Scholar] [CrossRef]

- Dastgeer, F.; Gelani, H.E. A Comparative analysis of system efficiency for AC and DC residential power distribution paradigms. Energy Build. 2017, 138, 648–654. [Google Scholar] [CrossRef]

- Gelani, H.E.; Dastgeer, F.; Nasir, M.; Khan, S.; Guerrero, J.M. AC vs. DC distribution efficiency: Are we on the right path? Energies 2021, 14, 4039. [Google Scholar] [CrossRef]

- Eskander, M.M.; Silva, C.A. Techno-economic and environmental comparative analysis for DC microgrids in households: Portuguese and French household case study. Appl. Energy 2023, 349, 121495. [Google Scholar] [CrossRef]

- Castillo-Calzadilla, T.; Cuesta, M.; Olivares-Rodriguez, C.; Macarulla, A.; Legarda, J.; Borges, C. Is it feasible a massive deployment of low voltage direct current microgrids renewable-based? A technical and social sight. Renew. Sustain. Energy Rev. 2022, 161, 112198. [Google Scholar] [CrossRef]

- Khorsandi, A.; Ashourloo, M.; Mokhtari, H.; Iravani, R. Automatic droop control for a low voltage DC microgrid. IET Gener. Transm. Distrib. 2016, 10, 41–47. [Google Scholar] [CrossRef]

- Glasgo, B.; Azevedo, I.L.; Hendrickson, C. Expert assessments on the future of direct current in buildings. Environ. Res. Lett. 2018, 13, 074004. [Google Scholar] [CrossRef]

- Ollas, P.; Persson, J.; Markusson, C.; Alfadel, U. Impact of battery sizing on self-consumption, self-sufficiency and peak power demand for a low energy single-family house with PV production in Sweden. In Proceedings of the 2018 IEEE 7th World Conference on Photovoltaic Energy Conversion (WCPEC) (A Joint Conference of 45th IEEE PVSC, 28th PVSEC & 34th EU PVSEC), Waikoloa, HI, USA, 10–15 June 2018; pp. 618–623. [Google Scholar] [CrossRef]

- Collath, N.; Tepe, B.; Englberger, S.; Jossen, A.; Hesse, H. Aging aware operation of lithium-ion battery energy storage systems: A review. J. Energy Storage 2022, 55, 105634. [Google Scholar] [CrossRef]

- Bloom, I.; Cole, B.; Sohn, J.; Jones, S.A.; Polzin, E.G.; Battaglia, V.S.; Henriksen, G.L.; Motloch, C.; Richardson, R.; Unkelhaeuser, T.; et al. An accelerated calendar and cycle life study of Li-ion cells. J. Power Sources 2001, 101, 238–247. [Google Scholar] [CrossRef]

- Wang, J.; Liu, P.; Hicks-Garner, J.; Sherman, E.; Soukiazian, S.; Verbrugge, M.; Tataria, H.; Musser, J.; Finamore, P. Cycle-life model for graphite-LiFePO4 cells. J. Power Sources 2011, 196, 3942–3948. [Google Scholar] [CrossRef]

- Hu, X.; Zou, C.; Tang, X.; Liu, T.; Hu, L. Cost-optimal energy management of hybrid electric vehicles using fuel cell/battery health-aware predictive control. IEEE Trans. Power Electron. 2019, 35, 382–392. [Google Scholar] [CrossRef]

- Zhang, L.; Hu, X.; Wang, Z.; Sun, F.; Deng, J.; Dorrell, D.G. Multiobjective optimal sizing of hybrid energy storage system for electric vehicles. IEEE Trans. Veh. Technol. 2017, 67, 1027–1035. [Google Scholar] [CrossRef]

- Guo, N.; Zhang, X.; Zou, Y.; Guo, L.; Du, G. Real-time predictive energy management of plug-in hybrid electric vehicles for coordination of fuel economy and battery degradation. Energy 2021, 214, 119070. [Google Scholar] [CrossRef]

- Brenguier, J.; Vallet, M.; VAILLANT, F. Efficiency gap between AC and DC electrical power distribution system. In Proceedings of the 2016 IEEE/IAS 52nd Industrial and Commercial Power Systems Technical Conference (I&CPS), Detroit, MI, USA, 1–5 May 2016; pp. 1–6. [Google Scholar] [CrossRef]

- Boeke, U.; Wendt, M. DC power grids for buildings. In Proceedings of the 2015 IEEE First International Conference on DC Microgrids (ICDCM), Atlanta, GA, USA, 7–10 June 2015; pp. 210–214. [Google Scholar] [CrossRef]

- Ollas, P.; Thiringer, T.; Persson, M.; Markusson, C. Battery loss prediction using various loss models: A case study for a residential building. J. Energy Storage 2023, 70, 108048. [Google Scholar] [CrossRef]

- Spertino, F.; Corona, F.; Di Leo, P. Limits of advisability for master–slave configuration of DC–AC converters in photovoltaic systems. IEEE J. Photovoltaics 2012, 2, 547–554. [Google Scholar] [CrossRef]

- Gao, F.; Kang, R.; Cao, J.; Yang, T. Primary and secondary control in DC microgrids: A review. J. Mod. Power Syst. Clean Energy 2019, 7, 227–242. [Google Scholar] [CrossRef]

- García-Miguel, P.L.C.; Alonso-Martínez, J.; Arnaltes Gómez, S.; García Plaza, M.; Asensio, A.P. A Review on the Degradation Implementation for the Operation of Battery Energy Storage Systems. Batteries 2022, 8, 110. [Google Scholar] [CrossRef]

- Calearo, L.; Marinelli, M. Profitability of frequency regulation by electric vehicles in Denmark and Japan considering battery degradation costs. World Electr. Veh. J. 2020, 11, 48. [Google Scholar] [CrossRef]

- Fuller, S.K.; Petersen, S.R. Life cycle costing manual. In NIST Handbook; US Department of Energy: Gaithersburg, MD, USA, 1995; Volume 135. [Google Scholar]

- Wikner, E.; Thiringer, T. Extending battery lifetime by avoiding high SOC. Appl. Sci. 2018, 8, 1825. [Google Scholar] [CrossRef]

- Dastgeer, F.; Gelani, H.E.; Anees, H.M.; Paracha, Z.J.; Kalam, A. Analyses of efficiency/energy-savings of DC power distribution systems/microgrids: Past, present and future. Int. J. Electr. Power Energy Syst. 2019, 104, 89–100. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| B | 30,300 |

| −Ea | −31,500 |

| Rg | 8.314 |

| T | 298 |

| z | 0.552 |

| Case | [USD/kWh] | [USD] | [USD] | ∑ [USD] | a [USD] |

|---|---|---|---|---|---|

| AC | 0.1 | 2873 | 748 | 3621 | – |

| ⋮ | ⋮ | ⋮ | ⋮ | ||

| 0.5 | 14,363 | 15,111 | – | ||

| DC∗ (=16 A) | 0.1 | 2901 | 754 | 3655 | 34 |

| ⋮ | ⋮ | ⋮ | ⋮ | ||

| 0.5 | 14,507 | 15,261 | 150 | ||

| = 15% | 0.1 | 2793 | 748 | 3541 | −80 |

| ⋮ | ⋮ | ⋮ | ⋮ | ||

| 0.5 | 13,964 | 14,712 | −399 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ollas, P.; Thiringer, T.; Persson, M. Enhanced DC Building Distribution Performance Using a Modular Grid-Tied Converter Design. Energies 2024, 17, 3105. https://doi.org/10.3390/en17133105

Ollas P, Thiringer T, Persson M. Enhanced DC Building Distribution Performance Using a Modular Grid-Tied Converter Design. Energies. 2024; 17(13):3105. https://doi.org/10.3390/en17133105

Chicago/Turabian StyleOllas, Patrik, Torbjörn Thiringer, and Mattias Persson. 2024. "Enhanced DC Building Distribution Performance Using a Modular Grid-Tied Converter Design" Energies 17, no. 13: 3105. https://doi.org/10.3390/en17133105

APA StyleOllas, P., Thiringer, T., & Persson, M. (2024). Enhanced DC Building Distribution Performance Using a Modular Grid-Tied Converter Design. Energies, 17(13), 3105. https://doi.org/10.3390/en17133105