Supercapacitor-Assisted Energy Harvesting Systems

Abstract

:1. Introduction

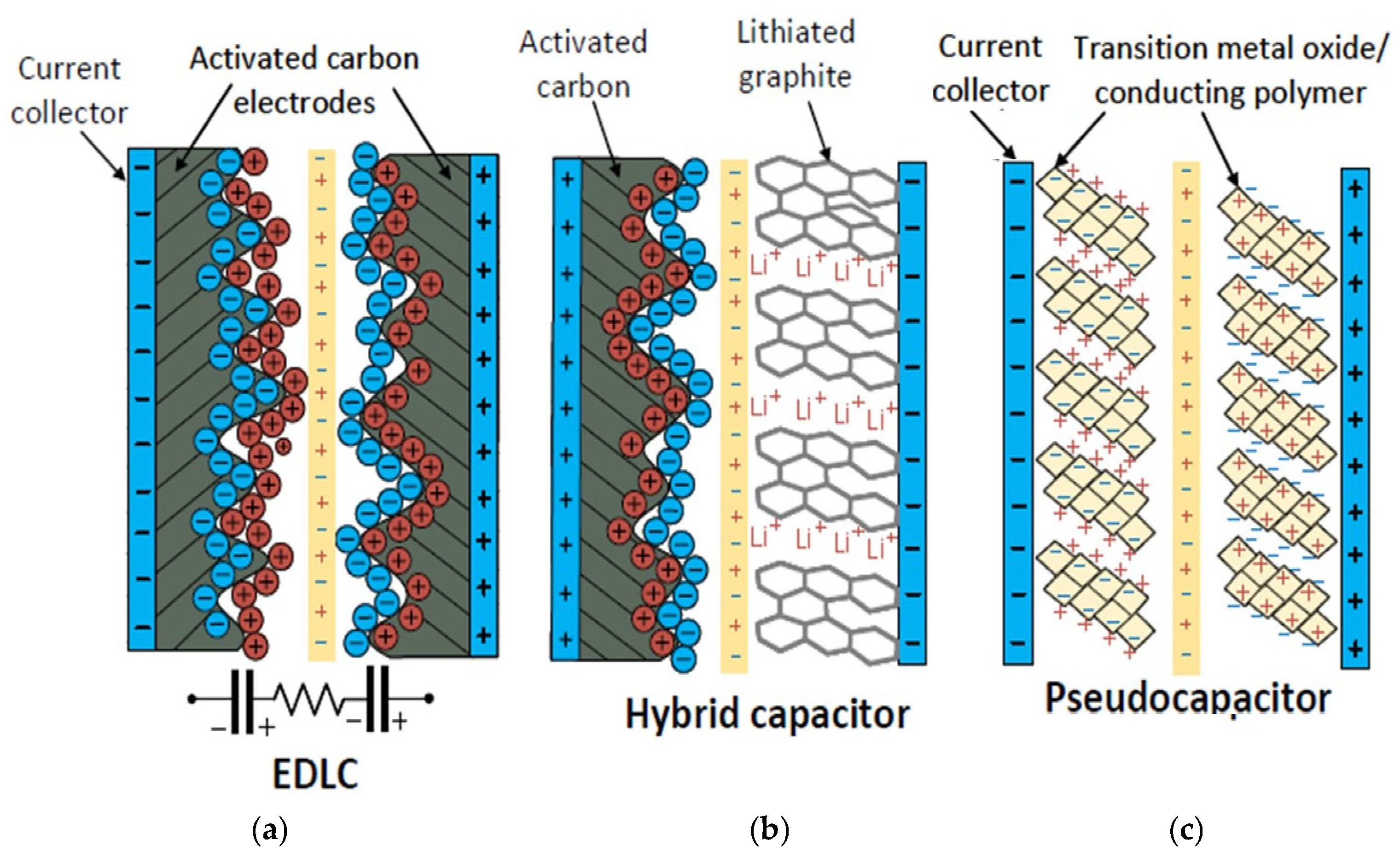

2. Supercapacitors and Their Basic Types

3. Advantages of Supercapacitors in Energy Harvesting

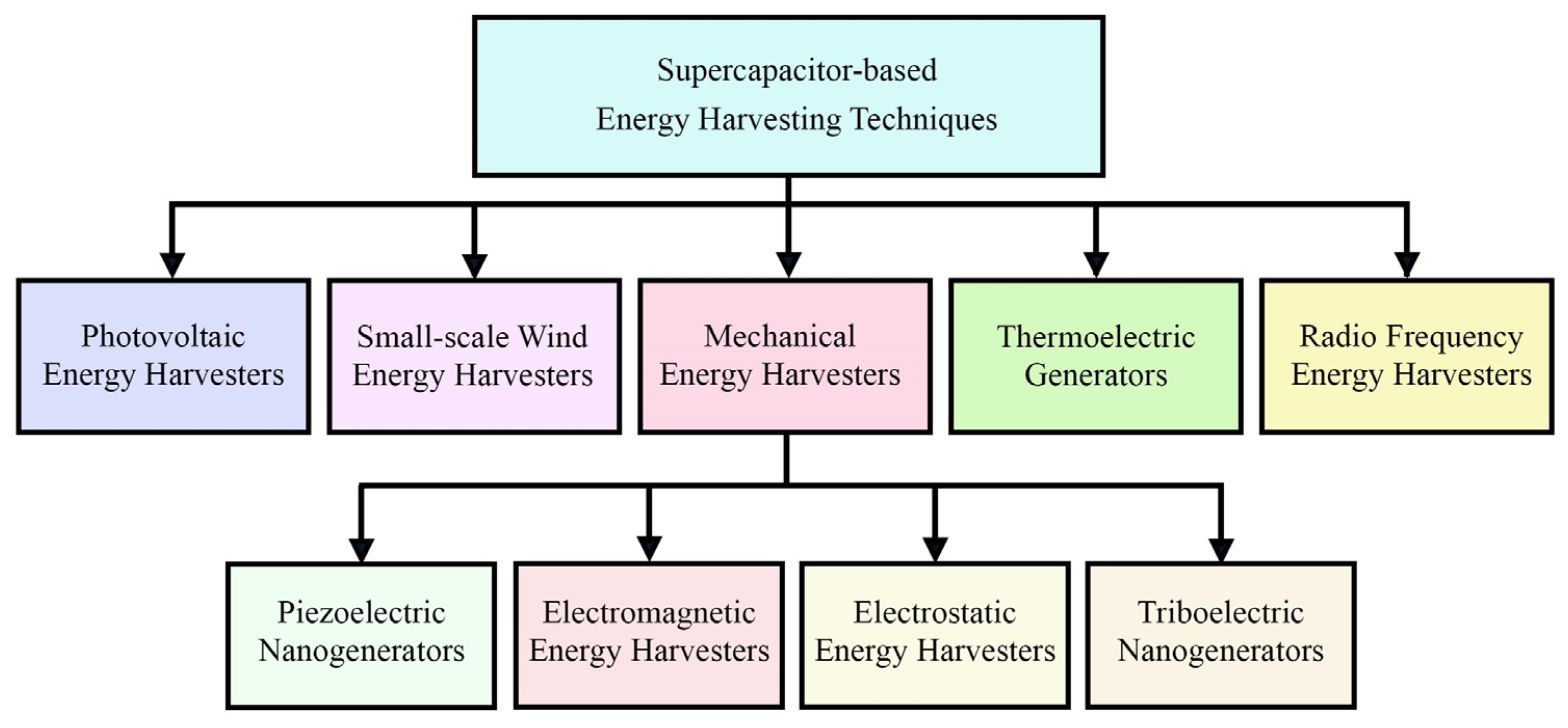

4. Applications of Supercapacitors in Energy Harvesting

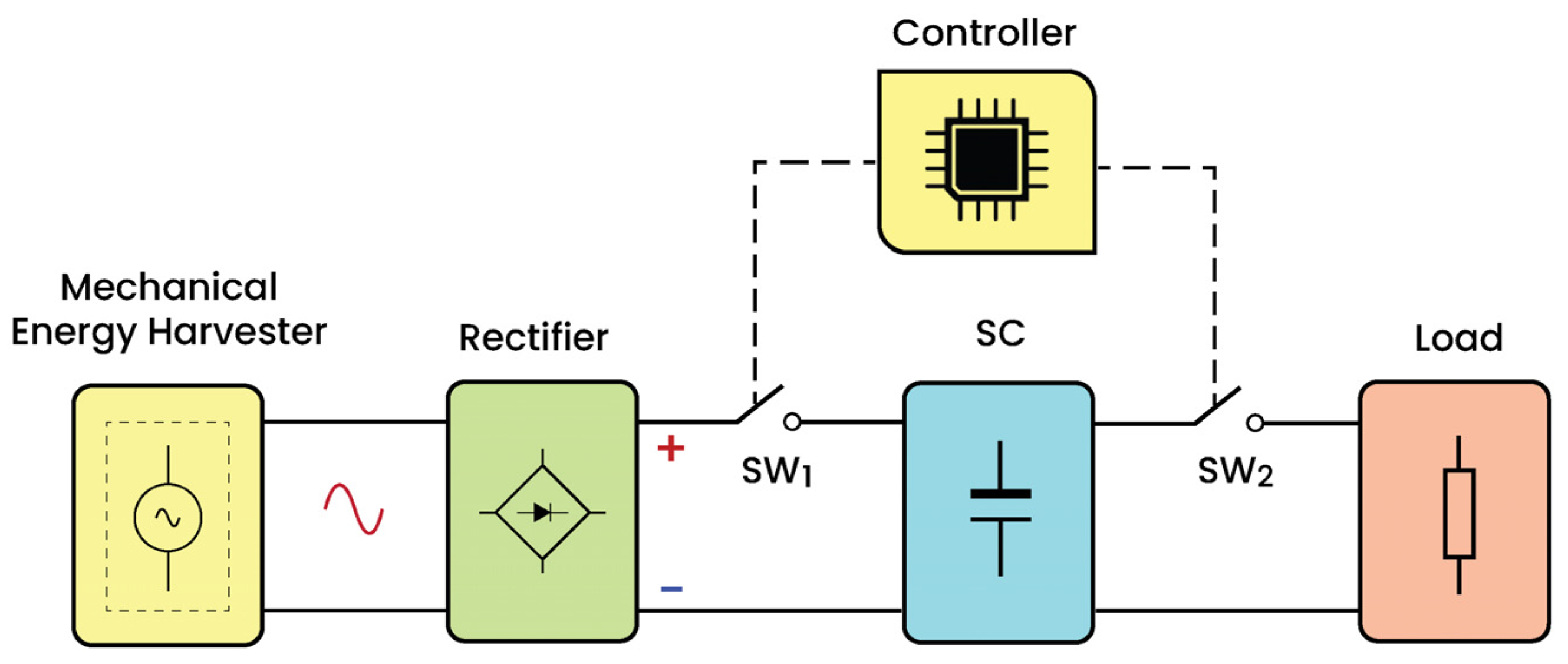

4.1. Supercapacitor-Based Mechanical Energy Harvesting

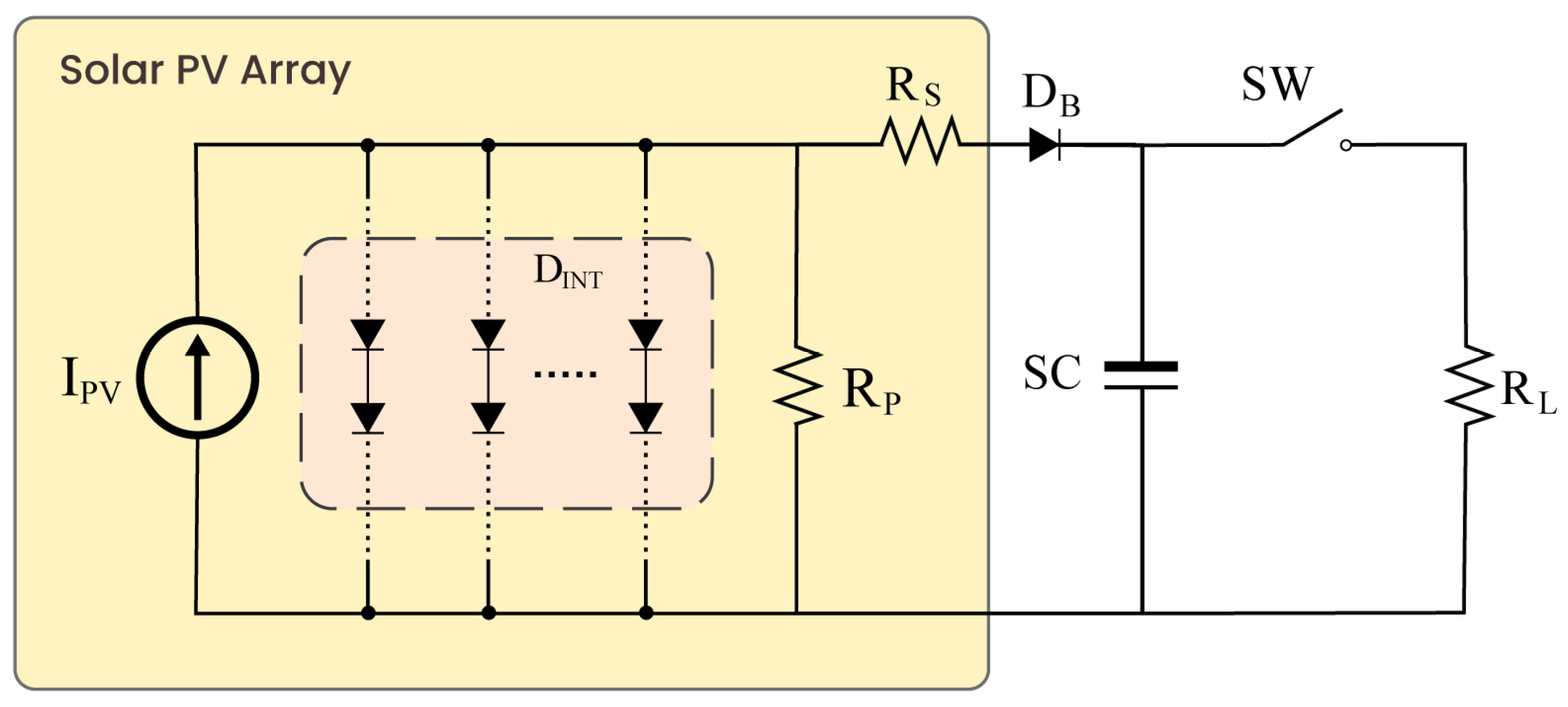

4.2. Supercapacitor-Based Photovoltaic Energy Harvesting

4.3. Supercapacitor-Based Small-Scale Wind Energy Harvesting

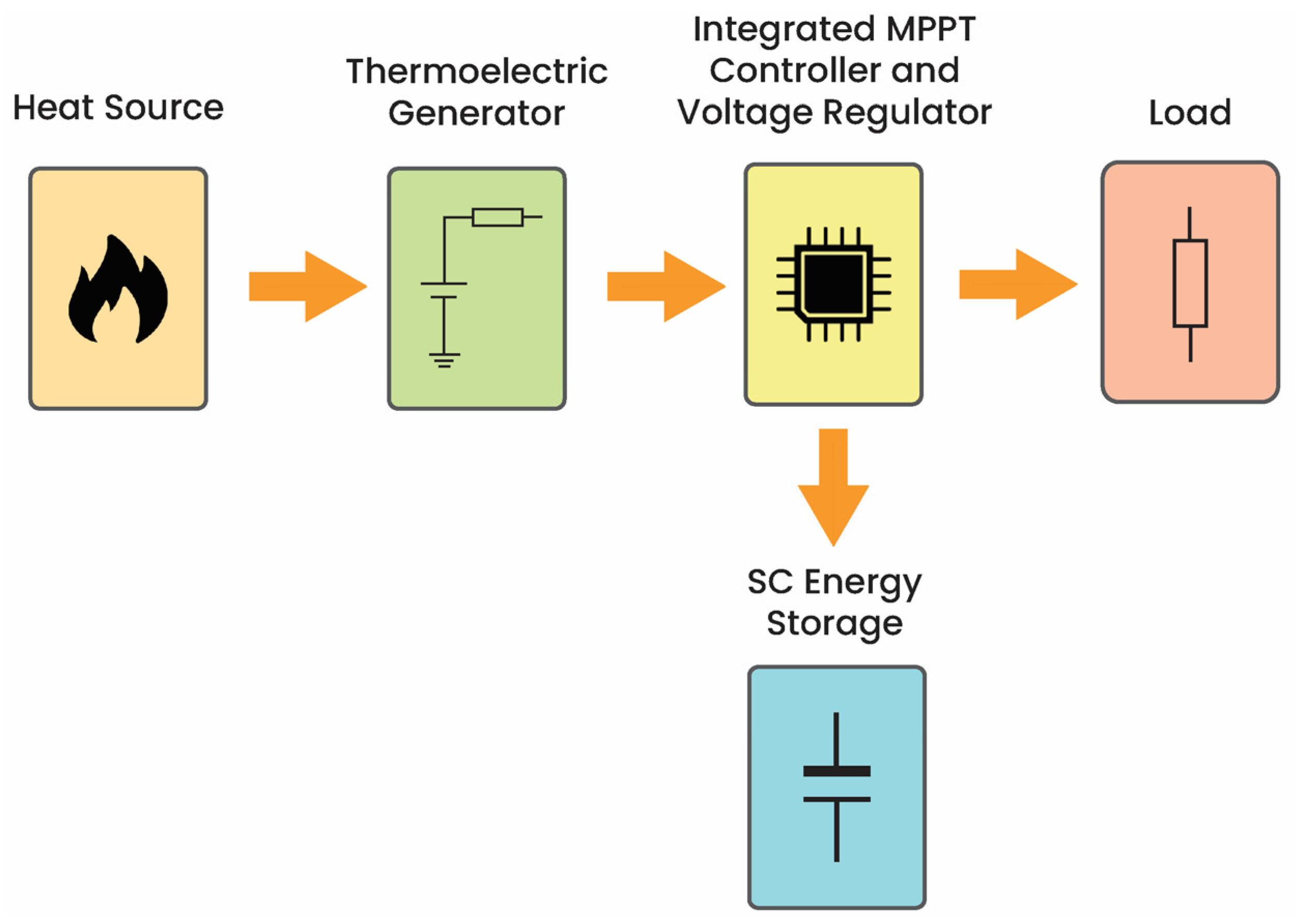

4.4. Supercapacitor-Based Thermoelectric Energy Harvesting

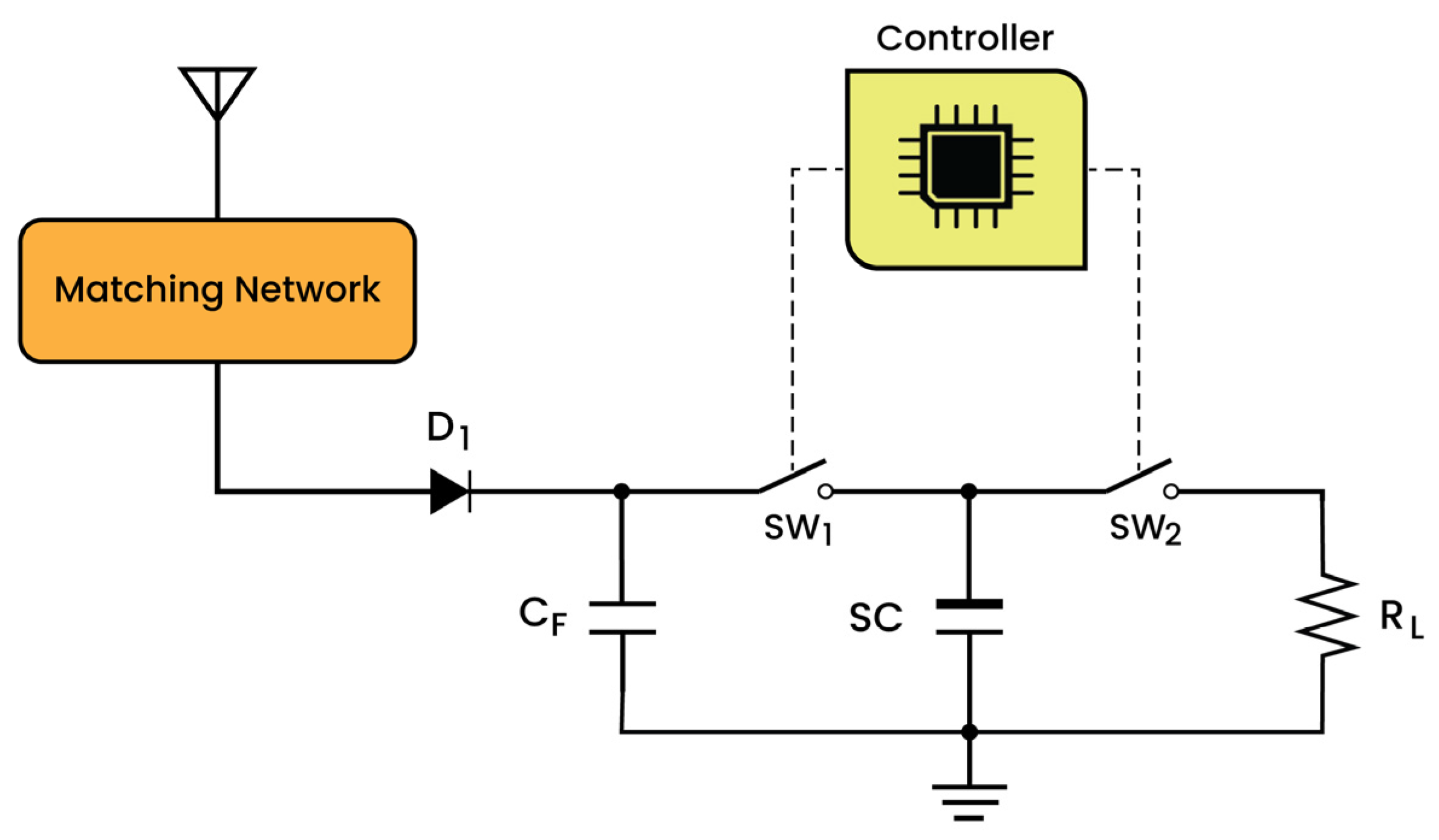

4.5. Supercapacitor-Based RF Energy Harvesting

5. Limitations of Supercapacitors in Energy Harvesting

- The low voltage of a single-cell supercapacitor (typically 2.7 V to 5.5 V) is one major constraint in energy harvesting applications, particularly in scenarios involving systems demanding higher voltage levels. SCs generally come with a maximum voltage rating; exceeding it will lead to damage or malfunction. This constraint may impede their efficiency in energy harvesting setups that rely on higher voltages for optimal functionality. A cascade of serial-connected SCs is a promising solution to expand the voltage range [23]. Nevertheless, voltage balancing circuits are essential in cascaded SC systems due to the tolerance and changes in the capacitance caused by the production or ageing [64].

- Energy density constraint presents a hurdle in some energy harvesting scenarios where optimizing energy storage capacity is essential. The use of hybrid SCs is one solution to increase energy density. As discussed in Section 2, these SCs integrate the benefits of both SCs and batteries, providing a greater energy density compared to conventional SCs alone. Recent studies reveal that the unique blend of electrode materials/composites and electrolytes, coupled with their manufacturing design significantly boosts the energy density of the SCs and also their electrochemical efficiency [65,66].

- Comparatively higher self-discharge rates were observed in SCs as opposed to batteries. Overcoming this obstruction is crucial for maximizing the efficiency and reliability of SCs in energy harvesting applications. Recently, numerous studies have been published aiming to address this drawback using a range of innovative approaches such as the use of enhanced electrolytes and applying a blocking layer with an insulating material on the electrode surface [67].

- The extent of temperature sensitivity further constrains the potential applicability of SCs in certain energy-harvesting contexts. Elevated temperatures can hasten deterioration, whereas lower temperatures can impact capacitance and raise internal resistance, both of which can have a negative effect on overall performance [68]. The use of thermal management systems such as active and passive cooling methods can effectively control the temperature of SCs and mitigate the decline in performance caused by high temperatures [69]. Encapsulating SCs in materials with high thermal conductivity or with insulation properties can help protect them from temperature fluctuations and maintain their performance [68].

- SCs can be a more expensive option than batteries for energy harvesting systems as the cost per kWh of SCs is higher than for Li-ion batteries [70]. Even so, the advantage is seen in long-term cost savings as the Li-ion batteries have close to 1000 lifetime cycles compared to the SCs which have 15,000 to 1,000,000 lifetime cycles [71]. In addition, research continues to enhance the materials and refine the manufacturing processes in order to minimize the costs associated with manufacturing of SCs [72].

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Donovan, J. New Applications for Energy Harvesting. 2024. Available online: https://www.mouser.com/applications/energy-harvesting-new-applications/ (accessed on 10 April 2024).

- Dostal, F. New Advances in Energy Harvesting Power Conversion. Analog. Dialogue 2015, 49, 1–3. [Google Scholar]

- Álvarez-Carulla, A.; Saiz-Vela, A.; Puig-Vidal, M.; López-Sánchez, J.; Colomer-Farrarons, J.; Miribel-Català, P.L. High-efficient energy harvesting architecture for self-powered thermal-monitoring wireless sensor node based on a single thermoelectric generator. Sci. Rep. 2023, 13, 1637. [Google Scholar] [CrossRef] [PubMed]

- Gabay, J. Supercapacitor Options for Energy-Harvesting Systems. 2013. Available online: https://www.digikey.com/en/articles/supercapacitor-options-for-energy-harvesting-systems (accessed on 13 April 2024).

- Mehta, P.; Gaur, A.; Kumar, C.; Nella, A.; Bhowmick, A.; Rajagopal, M. Energy Harvesting Techniques and Trends in Electronic Applications. In Energy Harvesting Trends for Low Power Compact Electronic Devices; Nella, A., Bhowmick, A., Kumar, C., Rajagopal, M., Eds.; Springer International Publishing: Cham, Switzerland, 2023; pp. 205–220. [Google Scholar] [CrossRef]

- Mao, Y.; Li, Y.; Xie, J.; Liu, H.; Guo, C.; Hu, W. Triboelectric nanogenerator/supercapacitor in-one self-powered textile based on PTFE yarn wrapped PDMS/MnO2NW hybrid elastomer. Nano Energy 2021, 84, 105918. [Google Scholar] [CrossRef]

- Nexperia. Designing an Energy Harvesting System Using the NEH2000BY PMIC; Nexperia: Nijmegen, The Netherlands, 2023. [Google Scholar]

- Kalnoskas, A. What’s New in Electrolytic Capacitors and Supercapacitors for Energy Harvesting. Available online: https://www.powerelectronictips.com/whats-new-in-electrolytic-capacitors-and-supercapacitors-for-energy-harvesting/ (accessed on 1 May 2024).

- Zhang, H.; Ma, T. Adaptive energy harvesting from low-level ambient vibrations. Appl. Mater. Today 2023, 34, 101911. [Google Scholar] [CrossRef]

- Lamedica, R.; Ruvio, A.; Tobia, M.; Buffarini, G.G.; Carones, N. A Preliminary Techno-Economic Comparison between DC Electrification and Trains with On-Board Energy Storage Systems. Energies 2020, 13, 6702. [Google Scholar] [CrossRef]

- Subasinghage, K.; Gunawardane, K.; Padmawansa, N.; Kularatna, N.; Moradian, M. Modern Supercapacitors Technologies and Their Applicability in Mature Electrical Engineering Applications. Energies 2022, 15, 7752. [Google Scholar] [CrossRef]

- Biswas, S.; Chowdhury, A. Organic Supercapacitors as the Next Generation Energy Storage Device: Emergence, Opportunity, and Challenges. ChemPhysChem 2023, 24, e202200567. [Google Scholar] [CrossRef] [PubMed]

- Migliorini, L.; Santaniello, T.; Borghi, F.; Saettone, P.; Comes Franchini, M.C.; Generali, G.; Milani, P. Eco-Friendly Supercapacitors Based on Biodegradable Poly(3-Hydroxy-Butyrate) and Ionic Liquids. Nanomaterials 2020, 10, 2062. [Google Scholar] [CrossRef]

- Gunawardane, K.; Bandara, N.; Subasinghage, K.; Kularatna, N. Extending the Input Voltage Range of Solar PV Inverters with Supercapacitor Energy Circulation. Electronics 2021, 10, 88. [Google Scholar] [CrossRef]

- Kularatna, N.; Subasinghage, K.; Gunawardane, K.; Jayananda, D.; Ariyarathna, T. Supercapacitor-Assisted Techniques and Supercapacitor-Assisted Loss Management Concept: New Design Approaches to Change the Roadmap of Power Conversion Systems. Electronics 2021, 10, 1697. [Google Scholar] [CrossRef]

- Subasinghage, K.; Gunawardane, K.; Lie, T.; Kularatna, N. Design of an efficiency improved dual-output DC-DC converter utilizing a supercapacitor circulation technique. In Proceedings of the 2016 IEEE 2nd Annual Southern Power Electronics Conference (SPEC), Auckland, New Zealand, 5–8 December 2016; pp. 1–6. [Google Scholar]

- Subasinghage, K.; Gunawardane, K.; Kularatna, N.; Lie, T.T. Extending the Supercapacitor-Assisted Low-Dropout Regulator (SCALDO) Technique to a Split-Rail DC–DC Converter Application. IEEE Access 2019, 7, 124034–124047. [Google Scholar] [CrossRef]

- Subasinghage, K.; Gunawardane, K.; Kularatna, N.; Lie, T.T. Selection of the Stable Range of the Equivalent Series Resistance (ESR) of the Output Capacitor for a SCALDO Regulator. In Proceedings of the 2018 IEEE 27th International Symposium on Industrial Electronics (ISIE), Cairns, Australia, 13–15 June 2018; pp. 1359–1364. [Google Scholar]

- Subasinghage, K. Advanced Analysis of Supercapacitor-Assisted Low-Dropout (SCALDO) Regulator. Ph.D. Thesis, Electrical and Electronic Engineering, Auckland University of Technology, Auckland, New Zealand, 2019. [Google Scholar]

- Eaton. Eaton’s HS Hybrid Supercapacitors Combine Proprietary Materials to Achieve Greater Energy Density and Cycle Lifetimes; Eaton: Cleveland, OH, USA, 2021. [Google Scholar]

- Zhou, L.; Li, C.; Liu, X.; Zhu, Y.; Wu, Y.; van Ree, T. 7—Metal oxides in supercapacitors. In Metal Oxides in Energy Technologies; Wu, Y., Ed.; Elsevier: Amsterdam, The Netherlands, 2018; pp. 169–203. [Google Scholar] [CrossRef]

- Mars, P. Coupling a supercapacitor with a small energy harvesting source. EDN-Electron. Des. News 2012, 57, 39. [Google Scholar]

- Lehtimäki, S.; Li, M.; Salomaa, J.; Pörhönen, J.; Kalanti, A.; Tuukkanen, S.; Heljo, P.; Halonen, K.; Lupo, D. Performance of printable supercapacitors in an RF energy harvesting circuit. Int. J. Electr. Power Energy Syst. 2014, 58, 42–46. [Google Scholar] [CrossRef]

- Mathúna, C.Ó.; O’Donnell, T.; Martinez-Catala, R.V.; Rohan, J.; O’Flynn, B. Energy scavenging for long-term deployable wireless sensor networks. Talanta 2008, 75, 613–623. [Google Scholar] [CrossRef] [PubMed]

- Puluckul, P.P.; Singh, R.K.; Weyn, M. TEGBed: A thermal energy harvesting testbed for batteryless internet of things. Internet Things 2024, 25, 101060. [Google Scholar] [CrossRef]

- Hassanalieragh, M.; Soyata, T.; Nadeau, A.; Sharma, G. Solar-supercapacitor harvesting system design for energy-aware applications. In Proceedings of the 2014 27th IEEE International System-on-Chip Conference (SOCC), Las Vegas, NV, USA, 2–5 September 2014; pp. 280–285. [Google Scholar]

- Selleri, G.; Poli, F.; Neri, R.; Gasperini, L.; Gualandi, C.; Soavi, F.; Fabiani, D. Energy harvesting and storage with ceramic piezoelectric transducers coupled with an ionic liquid-based supercapacitor. J. Energy Storage 2023, 60, 106660. [Google Scholar] [CrossRef]

- Elahi, H.; Eugeni, M.; Gaudenzi, P. Chapter 3—Energy harvesting. In Piezoelectric Aeroelastic Energy Harvesting; Elahi, H., Eugeni, M., Gaudenzi, P., Eds.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 41–59. [Google Scholar] [CrossRef]

- Miller, J.R.; Simon, P. Materials science: Electrochemical capacitors for energy management. Science 2008, 321, 651–652. [Google Scholar] [CrossRef]

- Conway, B.E. Transition from “Supercapacitor” to “Battery” Behavior in Electrochemical Energy Storage. J. Electrochem. Soc. 1991, 138, 1539. [Google Scholar] [CrossRef]

- Lu, W.; Qu, L.; Henry, K.; Dai, L. High performance electrochemical capacitors from aligned carbon nanotube electrodes and ionic liquid electrolytes. J. Power Sources 2009, 189, 1270–1277. [Google Scholar] [CrossRef]

- Paradiso, J.A.; Starner, T. Energy scavenging for mobile and wireless electronics. IEEE Pervasive Comput. 2005, 4, 18–27. [Google Scholar] [CrossRef]

- Boisseau, S.; Despesse, G.; Seddik, B.A. Electrostatic Conversion for Vibration Energy Harvesting. In Small-Scale Energy Harvesting; Mickael, L., Ed.; IntechOpen: Rijeka, Croatia, 2012; Chapter 5. [Google Scholar] [CrossRef]

- Feng, X.; Zhang, Y.; Kang, L.; Wang, L.; Duan, C.; Yin, K.; Pang, J.; Wang, K. Integrated energy storage system based on triboelectric nanogenerator in electronic devices. Front. Chem. Sci. Eng. 2021, 15, 238–250. [Google Scholar] [CrossRef]

- Das, K.K.; Basu, B.; Maiti, P.; Dubey, A.K. Piezoelectric nanogenerators for self-powered wearable and implantable bioelectronic devices. Acta Biomater. 2023, 171, 85–113. [Google Scholar] [CrossRef] [PubMed]

- Muscat, A.; Bhattacharya, S.; Zhu, Y. Electromagnetic Vibrational Energy Harvesters: A Review. Sensors 2022, 22, 5555. [Google Scholar] [CrossRef]

- Mondal, S.; Thakur, S.; Maiti, S.; Bhattacharjee, S.; Chattopadhyay, K.K. Self-Charging Piezo-Supercapacitor: One-Step Mechanical Energy Conversion and Storage. ACS Appl. Mater. Interfaces 2023, 15, 8446–8461. [Google Scholar] [CrossRef] [PubMed]

- Cepnik, C.; Lausecker, R.; Wallrabe, U. Review on Electrodynamic Energy Harvesters—A Classification Approach. Micromachines 2013, 4, 168–196. [Google Scholar] [CrossRef]

- Li, Y.; Li, J.; Liu, Z.; Hu, H.; Hu, J.; Wang, J.; He, Z. Theoretical and experimental investigation of magnet and coil arrays optimization for power density improvement in electromagnetic vibration energy harvesters. Energy Convers. Manag. 2023, 293, 117411. [Google Scholar] [CrossRef]

- Kim, S.; Chou, P.H. Energy Harvesting with Supercapacitor-Based Energy Storage. In Smart Sensors and Systems; Lin, Y.-L., Kyung, C.-M., Yasuura, H., Liu, Y., Eds.; Springer International Publishing: Cham, Switzerland, 2015; pp. 215–241. [Google Scholar] [CrossRef]

- Liu, X.; Chen, S.; Pu, J.; Wang, X. A Flexible All-Solid-State Micro Supercapacitor and Its Application in Electrostatic Energy Management System. J. Microelectromech. Syst. 2016, 25, 929–936. [Google Scholar] [CrossRef]

- Dong, J.; Huang, S.; Luo, J.; Zhao, J.; Fan, F.R.; Tian, Z.-Q. Supercapacitor-Inspired Triboelectric Nanogenerator Based on Electrostatic Double Layer. Nano Energy 2022, 95, 106971. [Google Scholar] [CrossRef]

- Ammaiyappan, A.B.S.; Seyezhai, R. Piezoelectric-Driven Self-Powered Supercapacitor for Wearable Device Applications. In Supercapacitors for the Next Generation; Daisuke, T., Aneeya Kumar, S., Eds.; IntechOpen: Rijeka, Croatia, 2022; Chapter 12. [Google Scholar] [CrossRef]

- Liew, H.F.; Rahim, R.A.; Isa, M.; Ismail, B.; Hassan, S.I.S. Analysis of batteries or supercapacitor as energy storage device for a sound energy harvester system. IEEJ Trans. Electr. Electron. Eng. 2018, 13, 1699–1708. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, Z.; Pan, H.; Salman, W.; Yuan, Y.; Liu, Y. A portable high-efficiency electromagnetic energy harvesting system using supercapacitors for renewable energy applications in railroads. Energy Convers. Manag. 2016, 118, 287–294. [Google Scholar] [CrossRef]

- Szarka, G.D.; Burrow, S.G.; Proynov, P.P.; Stark, B.H. Maximum Power Transfer Tracking for Ultralow-Power Electromagnetic Energy Harvesters. IEEE Trans. Power Electron. 2014, 29, 201–212. [Google Scholar] [CrossRef]

- Szarka, G.D.; Burrow, S.G.; Stark, B.H. Ultralow Power, Fully Autonomous Boost Rectifier for Electromagnetic Energy Harvesters. IEEE Trans. Power Electron. 2013, 28, 3353–3362. [Google Scholar] [CrossRef]

- Pu, X.; Li, L.; Liu, M.; Jiang, C.; Du, C.; Zhao, Z.; Hu, W.; Wang, Z.L. Wearable Self-Charging Power Textile Based on Flexible Yarn Supercapacitors and Fabric Nanogenerators. Adv. Mater. 2016, 28, 98–105. [Google Scholar] [CrossRef]

- Mars, P. Using Supercapacitors in Energy Harvesting. 2017. Available online: https://www.powersystemsdesign.com/using-supercapacitors-in-energy-harvesting/31 (accessed on 14 April 2024).

- Calautit, K.; Johnstone, C. State-of-the-art review of micro to small-scale wind energy harvesting technologies for building integration. Energy Convers. Manag. X 2023, 20, 100457. [Google Scholar] [CrossRef]

- Sathiendran, R.K.; Sekaran, R.R.; Chandar, B.; Prasad, B.S.A.G. Wind energy harvesting system powered wireless sensor networks for Structural Health Monitoring. In Proceedings of the 2014 International Conference on Circuits, Power and Computing Technologies [ICCPCT-2014], Nagercoil, India, 20–21 March 2014; pp. 523–526. [Google Scholar]

- Khan, M.D.S.A.; Kuni, S.K.; Rajkumar, R.; Syed, A.; Hawladar, M.; Rahman, M.M. Instantaneous charging & discharging cycle analysis of a novel supercapacitor based energy harvesting circuit. AIP Conf. Proc. 2017, 1919, 020046. [Google Scholar] [CrossRef]

- Habibzadeh, M.; Hassanalieragh, M.; Ishikawa, A.; Soyata, T.; Sharma, G. Hybrid Solar-Wind Energy Harvesting for Embedded Applications: Supercapacitor-Based System Architectures and Design Tradeoffs. IEEE Circuits Syst. Mag. 2017, 17, 29–63. [Google Scholar] [CrossRef]

- Boitier, V.; Estibals, B.; Seguier, L. Powering a Low Power Wireless Sensor in a Harsh Industrial Environment: Energy Recovery with a Thermoelectric Generator and Storage on Supercapacitors. Energy Power Eng. 2023, 15, 372–398. [Google Scholar] [CrossRef]

- Yang, X.; Tian, Y.; Wu, B.; Jia, W.; Hou, C.; Zhang, Q.; Li, Y.; Wang, H. High-Performance Ionic Thermoelectric Supercapacitor for Integrated Energy Conversion-Storage. Energy Environ. Mater. 2022, 5, 954–961. [Google Scholar] [CrossRef]

- Deng, F.; Qiu, H.; Chen, J.; Wang, L.; Wang, B. Wearable Thermoelectric Power Generators Combined With Flexible Supercapacitor for Low-Power Human Diagnosis Devices. IEEE Trans. Ind. Electron. 2017, 64, 1477–1485. [Google Scholar] [CrossRef]

- Yang, K.; Cho, K.; Yang, S.; Park, Y.; Kim, S. A laterally designed all-in-one energy device using a thermoelectric generator-coupled micro supercapacitor. Nano Energy 2019, 60, 667–672. [Google Scholar] [CrossRef]

- Gunawardana, B.R. Carbon Nano tube based Thermoelectric generator and Graphite Nanoparticle based supercapacitor for smart wearable sensors. In Proceedings of the 2023 IEEE International Students’ Conference on Electrical, Electronics and Computer Science (SCEECS), Bhopal, India, 18–19 February 2023; pp. 1–3. [Google Scholar]

- Serdijn, W.A.; Mansano, A.L.R.; Stoopman, M. Chapter 4.2—Introduction to RF Energy Harvesting. In Wearable Sensors; Sazonov, E., Neuman, M.R., Eds.; Academic Press: Oxford, UK, 2014; pp. 299–322. [Google Scholar] [CrossRef]

- Ibrahim, H.H.; Singh, M.J.; Al-Bawri, S.S.; Ibrahim, S.K.; Islam, M.T.; Alzamil, A.; Islam, M.S. Radio Frequency Energy Harvesting Technologies: A Comprehensive Review on Designing, Methodologies, and Potential Applications. Sensors 2022, 22, 4144. [Google Scholar] [CrossRef] [PubMed]

- Grante, F.; Abib, G.; Muller, M.; Samama, N. Ultra Low Power RF energy harvesting system using a super capacitor as an energy reservoir for an IoT Node. In Proceedings of the WINSYS 2022: 19th International Conference on Wireless Networks and Mobile Systems, Lisbon, France, 11 July 2022; pp. 15–21. [Google Scholar]

- Luís, M.; Borges, F.J.V. Radio frequency energy harvesting and storing in supercapacitors for wearable sensors. In Wearable Technologies and Wireless Body Sensor Networks for Healthcare; IET: London, UK, 2019; pp. 457–543. [Google Scholar] [CrossRef]

- Borges, L.M.; Chávez-Santiago, R.; Barroca, N.; Velez, F.J.; Balasingham, I. Radio-frequency energy harvesting for wearable sensors. Healthc. Technol. Lett. 2015, 2, 22–27. [Google Scholar] [CrossRef]

- Kalbitz, R. Keep the Balance–Balancing of Supercapacitors; Würth Elektronik eiSos GmbH & Co.: Waldenburg, Germany, 2021; Available online: https://www.we-online.com/components/media/o671684v410%20ANP090a_EN.pdf (accessed on 12 May 2024).

- Pathak, M.; Bhatt, D.; Bhatt, R.C.; Bohra, B.S.; Tatrari, G.; Rana, S.; Arya, M.C.; Sahoo, N.G. High Energy Density Supercapacitors: An Overview of Efficient Electrode Materials, Electrolytes, Design, and Fabrication. Chem. Rec. 2024, 24, e202300236. [Google Scholar] [CrossRef] [PubMed]

- Redondo, E.; Fevre, L.W.L.; Fields, R.; Todd, R.; Forsyth, A.J.; Dryfe, R.A.W. Enhancing supercapacitor energy density by mass-balancing of graphene composite electrodes. Electrochim. Acta 2020, 360, 136957. [Google Scholar] [CrossRef]

- Shang, W.; Yu, W.; Xiao, X.; Ma, Y.; He, Y.; Zhao, Z.; Tan, P. Insight into the self-discharge suppression of electrochemical capacitors: Progress and challenges. Adv. Powder Mater. 2023, 2, 100075. [Google Scholar] [CrossRef]

- Zhou, W.; Liu, Z.; Chen, W.; Sun, X.; Luo, M.; Zhang, X.; Li, C.; An, Y.; Song, S.; Wang, K.; et al. A Review on Thermal Behaviors and Thermal Management Systems for Supercapacitors. Batteries 2023, 9, 128. [Google Scholar] [CrossRef]

- He, X.; Zhang, X. A comprehensive review of supercapacitors: Properties, electrodes, electrolytes and thermal management systems based on phase change materials. J. Energy Storage 2022, 56, 106023. [Google Scholar] [CrossRef]

- Roy, P.K.S.; Karayaka, H.B.; He, J.; Yu, Y.H. Economic Comparison between Battery and Supercapacitor for Hourly Dispatching Wave Energy Converter Power. In Proceedings of the 2020 52nd North American Power Symposium (NAPS), Tempe, AZ, USA, 11–13 April 2021; pp. 1–6. [Google Scholar]

- Sirimanne, D.C.U.; Kularatna, N.; Arawwawala, N. Electrical Performance of Current Commercial Supercapacitors and Their Future Applications. Electronics 2023, 12, 2465. [Google Scholar] [CrossRef]

- Shi, C.; Zhao, Q.; Li, H.; Liao, Z.-M.; Yu, D. Low cost and flexible mesh-based supercapacitors for promising large-area flexible/wearable energy storage. Nano Energy 2014, 6, 82–91. [Google Scholar] [CrossRef]

| Characteristics | Capacitors |  | Supercapacitors |  | Batteries |  |

|---|---|---|---|---|---|---|

| Power density (W/kg) | >106 | 60,000 | <3000 | |||

| Energy density (Wh/kg) | <0.1 | 1 to 73 | 10 to 250 | |||

| Equivalent series resistance | Typically, in mΩ range | Typically, in mΩ range | Fractional Ω to few Ω | |||

| Charge time (s) | 10−3 to 10−6 | 0.3 to 60 | 3600 to 18,000 | |||

| Discharge time (s) | 10−3 to 10−6 | 0.1 to 1800 | 600 to 10,800 | |||

| Lifetime cycles | 106 | 50,000 to 1,100,000 | 500 to 18,000 | |||

| Typical lifetime (years) | 30 | 30 | 5–20 | |||

| Operating temperature range (°C) | −40 to +125 | −40 to +70 | −20 to +65 | |||

| Energy Harvesting Technique | Advantages | Disadvantages |

|---|---|---|

| Photovoltaic | High energy availability and good energy conversion efficiency | Intermittent supply |

| Environmentally friendly | Space requirement | |

| Scalability | Requirement for maintenance and cleaning | |

| Small-scale wind | High power potential | Intermittent and fluctuating supply |

| Scalability | Regular maintenance required | |

| Mechanical | Ubiquitous sources | Intermittent nature |

| Compact size | Complexity of energy conversion | |

| Thermal | Continuous supply | Low conversion efficiency |

| Easy to install | Material degradation at high temperatures | |

| Radio frequency | Minimal maintenance | Interference issues |

| Ubiquitous availability | Distance limitation |

| Supercapacitor Type | Typical Stored Energy Range (J) | ||||

|---|---|---|---|---|---|

| Photovoltaic | Small-Scale Wind | Mechanical | Thermal | Radio Frequency | |

| Electric Double-Layer Capacitors | 200–400 | 20–50 | 20–50 | 50–100 | 10–30 |

| Hybrid Supercapacitors | 500–1000 | 100–200 | 100–200 | 200–400 | 50–100 |

| Pseudocapacitors | 300–600 | 50–100 | 50–100 | 100–200 | 30–50 |

| Converter Type | Study | Hardware | Applications | Role of Supercapacitors |

|---|---|---|---|---|

| Piezoelectric | Energy harvesting and storage with ceramic piezoelectric transducers coupled with an ionic liquid-based supercapacitor [27] | Integrated piezoelectric unit, ionic liquid-based micro-SC, and a bridge rectifier | Wearable electronics | To reduce the charge times and overall system volume |

| Piezoelectric-driven self-powered supercapacitor for wearable device applications [43] | LTC3588-1 (from Analog Devices, Wilmington, NC, USA) based circuit designs which combine a low-loss full-wave bridge rectifier with a high-efficiency buck converter | Wearable electronics | Energy storage element with low leakage current | |

| Analysis of batteries or supercapacitor as energy storage device for a sound energy harvester system [44] | Q220-A4-503YB (from https://piezo.com/, Woburn, MA, USA) piezoelectric energy transducer, 0.22 F SC, voltage multiplier, voltage regulator | Low-power electronic devices, LEDs | More efficient energy storage device due to their better charging and discharging characteristics | |

| Self-charging piezo-supercapacitor: one-step mechanical energy conversion and storage [37] | Fabricated piezoelectric driven self-charging SC | Portable electronic devices | To harvest sporadic mechanical energy, convert it to electrical energy, and simultaneously store energy | |

| Electromagnetic | A portable high-efficiency electromagnetic energy harvesting system using supercapacitors for renewable energy applications in railroads [45] | Mechanical transmission system, regulating circuit, SCs | Safety facilities/standby power supplies for rail-side equipment | To permit the storage of energy from rapidly changing transient currents and act as a steady power supply for external loads |

| Maximum power transfer tracking for ultralow-power electromagnetic energy harvesters [46] | Rectifier, boost rectifier, voltage regulators, controller with MPTT, SCs | Resistive loads | The low output power and large storage capacitance of SCs enable the MPTT control to rely solely on output current measurement. | |

| Ultralow power, fully autonomous boost rectifier for electromagnetic energy harvesters [47] | Full-wave boost rectifier, SC | Wireless sensor nodes | Energy storage element which is fed by a boost rectifier | |

| Electrostatic | A flexible all-solid-state micro supercapacitor and its application in electrostatic energy management system [32] | Flexible micro-SC, rectifier, buck-boost converter, low-dropout regulator, controller | Wearable electronics | Flexible energy storage element |

| Triboelectric | Wearable self-charging power textile based on flexible yarn supercapacitors and fabric nanogenerators [48] | Rectifier, SC, circuit to switch between the SC and the load | Wearable electronics | Lightweight energy storage element |

| Triboelectric nanogenerator/supercapacitor in-one self-powered textile based on PTFE yarn wrapped PDMS/MnO2NW hybrid elastomer [6] | Rectifier, SC, circuit to switch between the SC and the load | Wearable electronics and versatile pressure sensing | Energy storage element with high volumetric energy density and excellent cyclic stability |

| Study | Hardware | Applications | Role of Supercapacitors |

|---|---|---|---|

| Wind energy harvesting system powered wireless sensor networks for structural health monitoring [51] | Wind turbine, rectifier, DC–DC boost converter, SCs as energy storage | Sensors, wireless modules | Alternative energy storage device which eliminates the complication of replacing the batteries at regular intervals results in the developing a sustainable power management system for wireless sensor nodes |

| Instantaneous charging and discharging cycle analysis of a novel supercapacitor-based energy harvesting circuit [52] | Vertical axis turbine, battery–SC combined energy storage, rectifier, DC–DC boost converter, Arduino-based controller | Low-power electronic devices with improved charging efficiency in the energy storage | Supportive energy storage unit which increases the longevity of the battery pack in use. |

| Wind energy harvesting for autonomous wireless sensor networks [53] | Wind turbine, rectifier, DC–DC converter, SCs as energy storage | Wireless sensor networks | Energy storage device |

| Study | Hardware | Applications | Role of Supercapacitors |

|---|---|---|---|

| Powering a low-power wireless sensor in a harsh industrial environment: energy recovery with a thermoelectric generator and storage on supercapacitors [54] | Eureca TEG1-30-30-8.5/200 TEG module, commercial energy harvesting IC (The BQ25504 (Texas Instruments, Dallas, TX, USA), SC storage, TPS610995 (Texas Instruments, Dallas, TX, USA) boost converter and TPS71533 (Texas Instruments, Dallas, TX, USA) low-dropout regulator | Battery-free autonomous power supply, wireless sensor networks | Battery-free energy storage that operates at temperatures of up to 80 °C |

| High-efficient energy harvesting architecture for self-powered thermal-monitoring wireless sensor node based on a single thermoelectric generator [3] | Thermoelectric generator, DC–DC boost converter with MPPT, 30 mF SC energy storage, microcontroller | Wireless sensor nodes | Energy storage module |

| Wearable thermoelectric power generators combined with flexible supercapacitor for low-power human diagnosis devices [56] | Wearable thermoelectric generator, flexible SC | Low-power human diagnosis devices, sensor nodes | Flexible energy storage element to realize the combination of renewable energy and wearable devices. |

| A laterally designed all-in-one energy device using a thermoelectric generator-coupled micro supercapacitor [57] | A thermoelectric generator-coupled micro SC | Self-powered electronic devices | All-in-one energy devices with space efficacy |

| Carbon nanotube-based thermoelectric generator and graphite nanoparticle-based supercapacitor for smart wearable sensors [58] | Nanoparticle-based thermoelectric generator and SC, DC–DC boost converter | Self-powered wearable sensors | Stabilize the voltage output of the TEG and power out the loads under different conditions |

| Study | Frequency Range | Hardware | Applications | Role of Supercapacitors |

|---|---|---|---|---|

| Radiofrequency energy harvesting and storing in supercapacitors for wearable sensors [62] | Digital terrestrial television frequency (DTT) band: 750–758 MHz | SCs, N-stage Dickson voltage multiplier PCBs | Low-power electronic devices | Energy storage device which can cope with the receiver energy fluctuations |

| Ultralow power RF energy harvesting system using a supercapacitor as an energy reservoir for an IoT node [61] | 2.45 GHz | RF-to-DC converter, a storage SC, and a DC–DC boost converter. | IoT sensor nodes | Energy reservoir |

| Performance of printable supercapacitors in an RF energy harvesting circuit [23] | 13.56 MHz | Printed loop antenna and half-wave organic diode rectifier, pair of SCs (0.45 F and 0.21 F), voltage regulator | Sensors and small indicator display | Printable supercapacitors as energy storage devices |

| Radio-frequency energy harvesting for wearable sensors [63] | GSM 900/1800 MHz cellular and 700 MHz DTT | Rectenna, buck-boost converter, SC energy storage and Arduino-based controller | Wearable biomedical sensors | Battery-free energy storage for low maintenance and precise estimation of remaining energy |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Subasinghage, K.; Gunawardane, K. Supercapacitor-Assisted Energy Harvesting Systems. Energies 2024, 17, 3853. https://doi.org/10.3390/en17153853

Subasinghage K, Gunawardane K. Supercapacitor-Assisted Energy Harvesting Systems. Energies. 2024; 17(15):3853. https://doi.org/10.3390/en17153853

Chicago/Turabian StyleSubasinghage, Kasun, and Kosala Gunawardane. 2024. "Supercapacitor-Assisted Energy Harvesting Systems" Energies 17, no. 15: 3853. https://doi.org/10.3390/en17153853