An Analysis of the Physicochemical and Energy Parameters of Briquettes Manufactured from Sewage Sludge Mixtures and Selected Organic Additives

Abstract

1. Introduction

2. Materials and Methods

2.1. Selection of the Most Advantageous Mixture

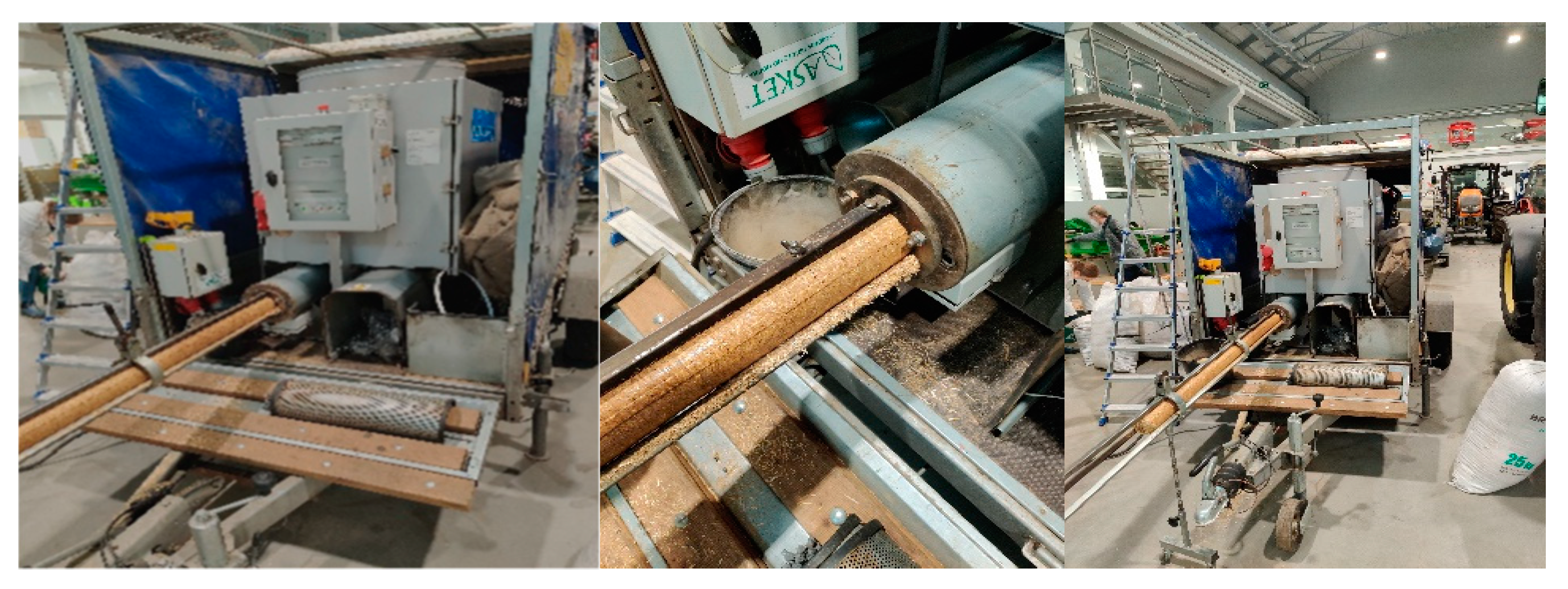

2.2. Briquetting

2.3. Physicochemical Analyses

2.3.1. Moisture Content and Organic Dry Matter Content of Mixtures

2.3.2. Analysis of the Composition of Briquettes and Exhaust Gases

2.4. Strength Tests of Briquettes

3. Results

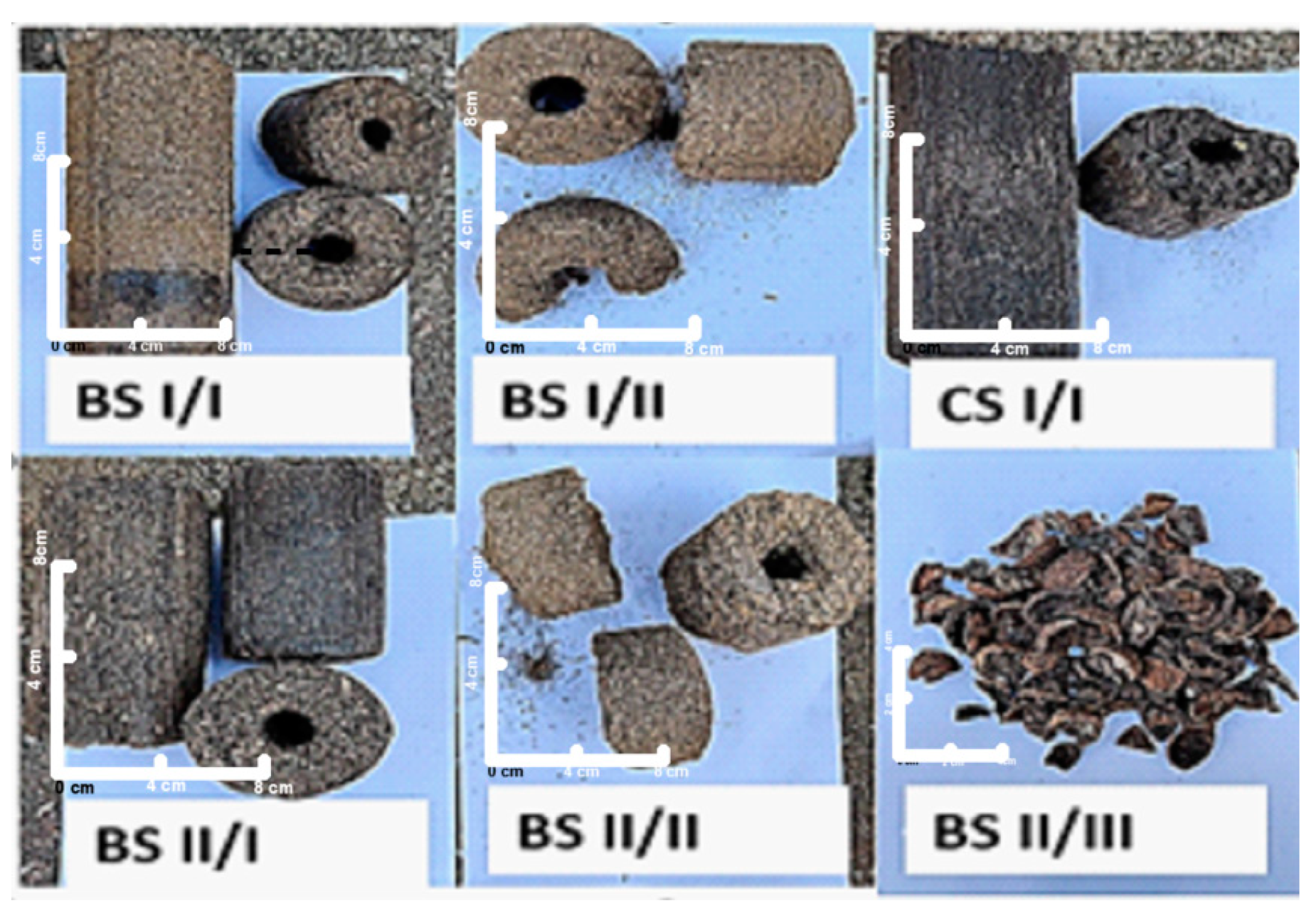

3.1. Briquetting

3.2. Physical and Chemical Properties

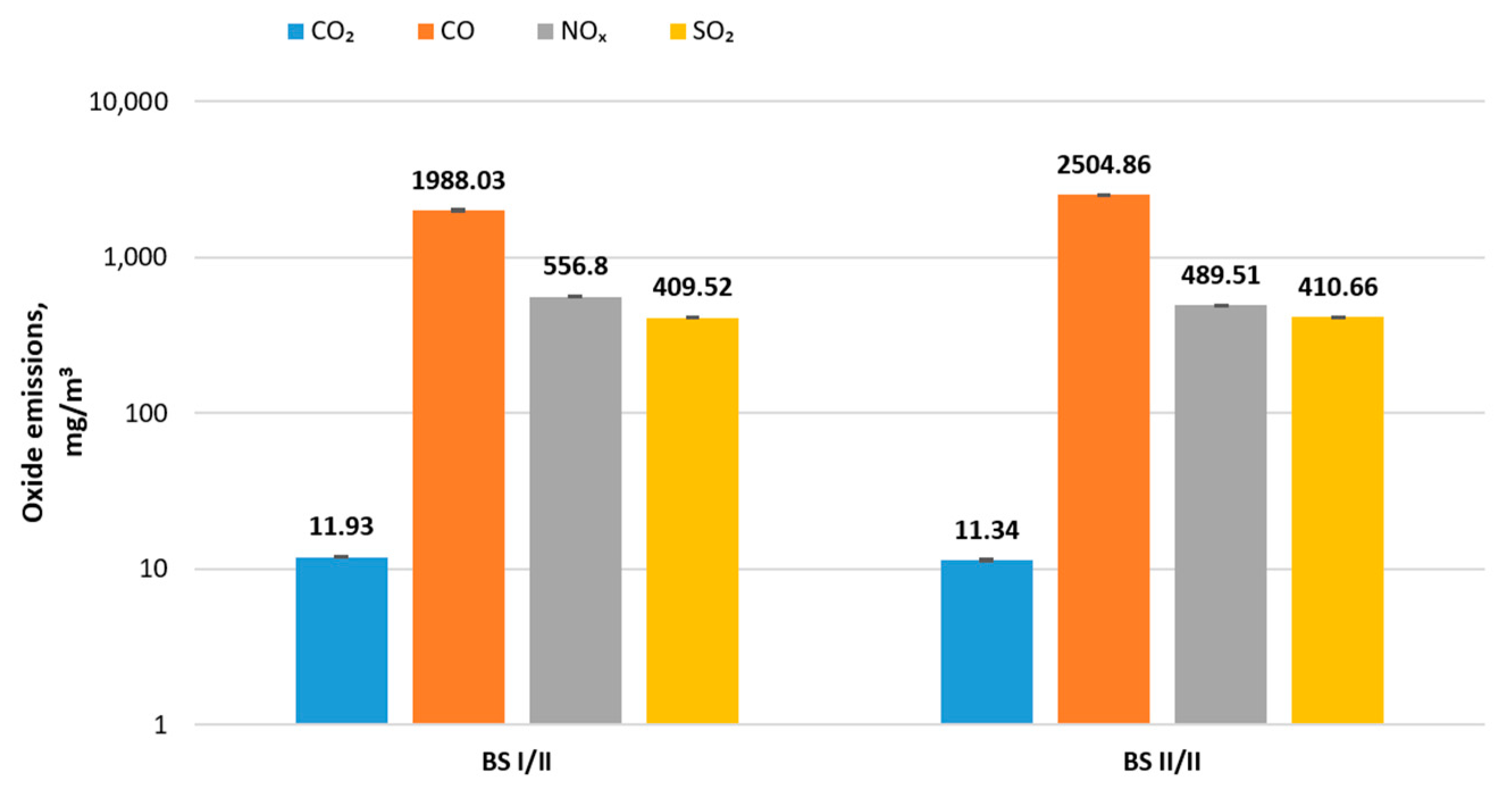

3.3. Flue Gas Analysis

3.4. Strength Tests

4. Discussion

5. Conclusions

6. Patents

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- García-Salirrosas, E.E.; Escobar-Farfán, M.; Gómez-Bayona, L.; Moreno-López, G.; Valencia-Arias, A.; Gallardo-Canales, R. Influence of environmental awareness on the willingness to pay for green products: An analysis under the application of the theory of planned behavior in the Peruvian market. Front. Psychol. 2023, 14, 1282383. [Google Scholar] [CrossRef] [PubMed]

- Masalimova, A.R.; Krokhina, J.A.; Sokolova, N.L.; Melnik, M.; Kutepova, O.S.; Duran, M. Trends in environmental education: A systematic review. Eurasia J. Math. Sci. Technol. Edu. 2023, 19, 2228. [Google Scholar] [CrossRef] [PubMed]

- Melo, G.; Barcellos, T.; Ribeiro, R.; Couto, R.; Gusmão, B.; Cyrino Oliveira, F.L.; Maçaira, P.; Fanzeres, B.; Souza, R.C.; Bet, O. Renewable energy sources spatio-temporal scenarios simulation under influence of climatic phenomena. Electr. Power Syst. Res. 2024, 235, 110725. [Google Scholar] [CrossRef]

- Arzaghi, M.; Squalli, J. The environmental impact of fossil fuel subsidy policies. Energy Econom. 2023, 126, 106980. [Google Scholar] [CrossRef]

- Pochwatka, P.; Rozakis, S.; Kowalczyk-Juśko, A.; Czekała, W.; Qiao, W.; Nägele, H.J.; Janczak, D.; Mazurkiewicz, J.; Mazur, A.; Dach, J. The energetic and economic analysis of demand-driven biogas plant investment possibility in dairy farm. Energy 2023, 283, 129165. [Google Scholar] [CrossRef]

- Milani, S.J.; Nabi Bidhendi, G. Biogas and photovoltaic solar energy as renewable energy in wastewater treatment plants: A focus on energy recovery and greenhouse gas emission mitigation. Water Sci. Eng. 2024, 17, 283–291. [Google Scholar] [CrossRef]

- Ndi, F.A. Land acquisition renewable energy development and livelihood transformation in rural Kenya: The case of the Kipeto wind energy project. Energy Res. Soc. Sci. 2024, 112, 103530. [Google Scholar] [CrossRef]

- Kałuża, T.; Hämmerling, M.; Zawadzki, P.; Czekała, W.; Kasperek, R.; Sojka, M.; Mokwa, M.; Ptak, M.; Szkudlarek, A.; Czechlowski, M.; et al. The hydropower sector in Poland: Historical development and current status. Renew. Sustain. Energy Rev. 2022, 158, 112150. [Google Scholar] [CrossRef]

- Montesdeoca-Martínez, F.; Velázquez-Medina, S. Geothermal energy exploitation in an island-based 100% renewables strategy. Case study of Tenerife (Spain). J. Clean. Prod. 2023, 426, 139139. [Google Scholar] [CrossRef]

- Jadlovec, M.; Výtisk, J.; Honus, S.; Pospišilík, V.; Bassel, N. Pollutants production. energy recovery and environmental impact of sewage sludge co-incineration with biomass pellets. Environ. Technol. Innov. 2023, 32, 103400. [Google Scholar] [CrossRef]

- Posligua, P.; Peñaherrera, M.; Villegas, E.; Banchón, C. Gravimetric Evolution During Sewage Sludge Biostabilization. J. Ecol. Eng. 2018, 195, 76–85. [Google Scholar] [CrossRef] [PubMed]

- Możdżer, E. Effect of Fertilization with Sludge-Ash Granulates on the Activity of Selected Soil Enzymes. J. Ecol. Eng. 2022, 234, 137–144. [Google Scholar] [CrossRef]

- Hajji, S.; Ben-Haddad, M.; Rida Abelouah, M.; De-la-Torre, G.E.; Ait Alla, A. Sludge drying and dewatering processes influence the abundance and characteristics of microplastics in wastewater treatment plants. Chemosphere 2023, 339, 139743. [Google Scholar] [CrossRef]

- Kosiński, P.; Kask, B.; Franus, M.; Piłat-Rożek, M.; Szulżyk-Cieplak, J.; Łagód, G. The Possibility of Using Sewage Sludge Pellets as Thermal Insulation. Adv. Sci. Technol. Res. J. 2023, 172, 161–172. [Google Scholar] [CrossRef]

- Khan, R.; Shukla, S.; Kumar, M.; Zuorro, A.; Pandey, A. Sewage sludge derived biochar and its potential for sustainable environment in circular economy: Advantages and challenges. J. Chem. Eng. 2023, 471, 144495. [Google Scholar] [CrossRef]

- Mehrdadi, N.; Joshi, S.G.; Nasrabadi, T.; Hoveidi, H. Aplication of solar energy for drying of sludge from pharmaceutical industrial waste water and probable reuse. Int. J. Environ. Res. 2007, 1, 42–48. [Google Scholar]

- Yusuf, H.H.; Roddick, F.; Jegatheesan, V.; Gao, L.; Pramanik, B.K. Tackling fat. oil. and grease FOG build-up in sewers: Insights into deposit formation and sustainable in-sewer management techniques. Sci. Total Environ. 2023, 904, 166761. [Google Scholar] [CrossRef]

- Cesaro, A.; Pirozzi, F.; Zafırakou, A.; Alexandraki, A. Microplastics in sewage sludge destined to anaerobic digestion: The potential role of thermal pretreatment. Chemosphere 2022, 309, 136669. [Google Scholar] [CrossRef]

- Zhen, G.; Lu, X.; Kato, H.; Zhao, Y.; Li, Y.Y. Overview of pretreatment strategies for enhancing sewage sludge disintegration and subsequent anaerobic digestion: Current advances. full-scale application and future perspectives. Renew. Sustain. Energy Rev. 2017, 69, 559–577. [Google Scholar] [CrossRef]

- Castro-Fernandez, A.; Taboada-Santos, A.; Balboa, S.; Lema, J.M. Thermal hydrolysis pre-treatment has no positive influence on volatile fatty acids production from sewage sludge. Bioresour. Technol. 2023, 376, 128839. [Google Scholar] [CrossRef]

- Đurđević, D.; Žiković, S.; Blecich, P. Sustainable Sewage Sludge Management Technologies Selection Based on Techno-Economic-Environmental Criteria: Case Study of Croatia. Energies 2022, 15, 3941. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhai, Y.; Li, S.; Liu, X.; Wang, B.; Liu, X.; Fan, Y.; Shi, H.; Li, C.; Zhu, Y. Thermal treatment of sewage sludge: A comparative review of the conversion principle. recovery methods and bioavailability-predicting of phosphorus. Chemosphere 2022, 291, 133053. [Google Scholar] [CrossRef]

- Jat Baloch, M.Y.; Zhang, W.; Sultana, T.; Akram, M.; Shoumik, B.A.; Khan, M.Z.; Farooq, M.A. Utilization of sewage sludge to manage saline–alkali soil and increase crop production: Is it safe or not? Environ. Technol. Innov. 2023, 32, 103266. [Google Scholar] [CrossRef]

- Fan, Z.; Zhou, X.; Peng, Z.; Wan, S.; Gao, Z.F.; Deng, S.; Tong, L.; Han, W.; Chen, X. Co-pyrolysis technology for enhancing the functionality of sewage sludge biochar and immobilizing heavy metals. Chemosphere 2023, 317, 137929. [Google Scholar] [CrossRef] [PubMed]

- An-nori, A.; el Fels, L.; Ezzariai, A.; el Gharous, M.; el Mejahed, K.; Hafidi, M. Effects of solar drying on heavy metals availability and phytotoxicity in municipal sewage sludge under semi-arid climate. Environ. Technol. Innov. 2020, 19, 101039. [Google Scholar] [CrossRef]

- Syed-Hassan, S.S.A.; Wang, Y.; Hu, S.; Su, S.; Xiang, J. Thermochemical processing of sewage sludge to energy and fuel: Fundamentals. challenges and considerations. Renew. Sustain. Energy Rev. 2017, 80, 888–913. [Google Scholar] [CrossRef]

- Krawczyk, P. Numerical Modeling of Simultaneous Heat and Moisture Transfer During Sewage Sludge Drying in Solar Dryer. Procedia Eng. 2016, 157, 230–237. [Google Scholar] [CrossRef]

- Boguniewicz-Zablocka, J.; Klosok-Bazan, I.; Capodaglio, A.G. Sustainable management of biological solids in small treatment plants: Overview of strategies and reuse options for a solar drying facility in Poland. Environ. Sci. Pollut. Res. Int. 2021, 2819, 24680. [Google Scholar] [CrossRef]

- Smol, M. Inventory of Wastes Generated in Polish Sewage Sludge Incineration Plants and Their Possible Circular Management Directions. Resources 2020, 9, 91. [Google Scholar] [CrossRef]

- Tańczuk, M.; Kostowski, W.; Karaś, M. Applying waste heat recovery system in a sewage sludge dryer—A technical and economic optimization. Energy Convers. Manag. 2016, 125, 121–132. [Google Scholar] [CrossRef]

- Krawczyk, P. Control strategy for ventilation system of sewage sludge solar dryer. J. Power Technol. 2016, 96, 145–148. [Google Scholar]

- Czekała, W.; Dach, J.; Janczak, D.; Smurzyńska, A.; Kwiatkowska, A.; Kozłowski, K. Influence of maize straw content with sewage sludge on composting process. J. Water Land Dev. 2016, 301, 43–49. [Google Scholar] [CrossRef]

- Gao, P.; Bai, Z.; Zhang, T.; Jia, Y.; Hou, Y.; Li, W.; Chen, J.; Guo, Z.; Kong, L.; Bai, J.; et al. Optimization of briquetting conditions and influencing factors of high-strength sludge briquette. J. Clean. Prod. 2023, 432, 139749. [Google Scholar] [CrossRef]

- Makowska, M.; Kujawiak, S.; Pawlak, M.; Sowińska, A. Energy use of a biomixture based on sewage sludge. Assessment of sewage and sludge management. In Poland. Report. PAN Monographs of the Environmental Engineering Committee, 1st ed.; Bień, J., Gromiec, M., Pawłowski, L., Eds.; Environmental Engineering Committee Polish Academy of Sciences: Lublin, Poland, 2020. [Google Scholar]

- Czekała, W.; Nowak, M.; Piechota, G. Sustainable management and recycling of anaerobic digestate solid fraction by composting: A review. Bioresour. Technol. 2023, 375, 128813. [Google Scholar] [CrossRef] [PubMed]

- Matias Gonçalves, L.; Mendoza-Martinez, C.; Alves Rocha, E.P.; Coutinho de Paula, E.; Cardoso, M. Solar Drying of Sludge from a Steel-Wire-Drawing Industry. Energies 2023, 16, 6314. [Google Scholar] [CrossRef]

- Kizito, S.; Jjagwe, J.; Ssewaya, B.; Nekesa, L.; Tumutegyereize, P.; Zziwa, A.; Komakech, A.J. Biofuel characteristics of non-charred briquettes from dried fecal sludge blended with food market waste: Suggesting a waste-to-biofuel enterprise as a win–win strategy to solve energy and sanitation problems in slums settlements. Waste Manag. 2022, 140, 173–182. [Google Scholar] [CrossRef] [PubMed]

- Wzorek, M. Solar drying of granulated waste blends for dry biofuel production. Environ. Sci. Pollut. Res. 2021, 2826, 34290–34299. [Google Scholar] [CrossRef]

- Drobíková, K.; Plachá, D.; Motyka, O.; Gabor, R.; Kutláková, K.M.; Vallová, S.; Seidlerová, J. Recycling of blast furnace sludge by briquetting with starch binder: Waste gas from thermal treatment utilizable as a fuel. Waste Manag. 2016, 48, 471–477. [Google Scholar] [CrossRef]

- Ferronato, N.; Calle Mendoza, I.J.; Gorritty Portillo, M.A.; Conti, F.; Torretta, V. Are waste-based briquettes alternative fuels in developing countries? A critical review. Energy Sustain. Dev. 2022, 68, 220–241. [Google Scholar] [CrossRef]

- Fang, J.; He, J.; Hong, Y.; Luo, Z.; Ke, H.; Fan, Z.; Tang, O.; Diao, Z.; Chen, D.; Lingjun, K. Coupling effect of the refuse and sludge on the physical and combustible properties of the densified pellets for energy production. Renew. Energy 2023, 216, 119081. [Google Scholar] [CrossRef]

- Yilmaz, E.; Wzorek, M.; Akçay, S. Co-pelletization of sewage sludge and agricultural wastes. J. Environ. Manag. 2018, 216, 169–175. [Google Scholar] [CrossRef] [PubMed]

- Olorunnisola, A. Production of fuel briquettes from waste paper and coconut husk admixtures. Agric. Eng. Int. CIGR Ejournal 2007, IX, 1–11. [Google Scholar]

- García, R.; González-Vázquez, M.P.; Rubiera, F.; Pevida, C.; Gil, M. Co-pelletization of pine sawdust and refused derived fuel (RDF) to high-quality waste-derived pellets. J. Clean. Prod. 2021, 328, 129635. [Google Scholar] [CrossRef]

- Li, Y.; Williams, P.T. Waste derived ash as catalysts for the pyrolysis-catalytic steam reforming of waste plastics for hydrogen-rich syngas production. J. Anal. Appl. Pyrol. 2024, 177, 106374. [Google Scholar] [CrossRef]

- Haydary, J.; Rapčanová, E.; Škulec, M. Purification of syngas from Refuse-Derived Fuel (RDF) gasification: Techno-economic analysis. Therm. Sci. Eng. Prog. 2023, 44, 102024. [Google Scholar] [CrossRef]

- Yank, A.; Ngadi, M.; Kok, R. Physical properties of rice husk and bran briquettes under low pressure densification for rural applications. Biomass Bioenergy 2016, 84, 22–30. [Google Scholar] [CrossRef]

- Lela, B.; Barišić, M.; Nižetić, S. Cardboard/sawdust briquettes as biomass fuel: Physical–mechanical and thermal characteristics. Waste Manag. 2016, 47, 236–245. [Google Scholar] [CrossRef]

- Stolarski, M.J.; Szczukowski, S.; Tworkowski, J.; Krzyżaniak, M.; Gulczyński, P.; Mleczek, M. Comparison of quality and production cost of briquettes made from agricultural and forest origin biomass. Renew. Energy 2013, 57, 20–26. [Google Scholar] [CrossRef]

- Rozporządzenie Ministra Środowiska z dnia 1 Marca 2018 r. w Sprawie Standardów Emisyjnych dla Niektórych Rodzajów Instalacji. Źródeł Spalania Paliw oraz Urządzeń Spalania lub Współspalania Odpadów. Available online: https://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=WDU20180000680 (accessed on 22 August 2024).

- Council Directive 87/217/EEC of 19 March 1987 on the Prevention and Reduction of Environmental Pollution by Asbestos. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX%3A52016PC0789 (accessed on 22 August 2024).

- Directive 2010/75/EU of the European Parliament and of the Council of 24 November 2010 on Industrial Emissions (Integrated Pollution Prevention and Control) (Recast) (Text with EEA Relevance). Available online: https://eur-lex.europa.eu/eli/dir/2010/75/oj (accessed on 22 August 2024).

- Directive (EU) 2015/2193 of the European Parliament and of the Council of 25 November 2015 on the limitation of Emissions of Certain Pollutants into the Air from Medium Combustion Plants (Text with EEA Relevance). Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A32015L2193 (accessed on 22 August 2024).

- PN-EN ISO 16559:2022; Solid Biofuels—Vocabulary. Polski Komitet Normalizacyjny: Warszawa, Poland, 2022.

- PN-EN ISO 17225-1:2021; Solid Biofuels—Fuel Specifications and Classes. Polski Komitet Normalizacyjny: Warszawa, Poland, 2021.

- PN-EN ISO 16994:2016; Solid Biofuels—Determination of Total Content of Sulfur and Chlorine. Polish Committee for Standarization: Warsaw, Poland, 2016.

- PN-EN ISO 18134-1; Solid Biofuels—Determination of Moisture Content—Oven Dry Method—Part 1: Total Moisture—Reference Method. Polski Komitet Normalizacyjny: Warszawa, Poland, 2016.

- PN-EN ISO 21663:2021-06; Solid Recovered Fuels—Determination of Total Content of Carbon. Hydrogen and Nitrogen. Polski Komitet Normalizacyjny: Warszawa, Poland, 2021.

- PN-EN ISO 21656:2021; Solid Recovered Fuels—Determination of Ash Content. Polski Komitet Normalizacyjny: Warszawa, Poland, 2021.

- PN-EN ISO 21654:2021-12; Solid Recovered Fuels—Determination of Calorific Value. Polski Komitet Normalizacyjny: Warszawa, Poland, 2021.

- PN-EN ISO 11885:2009; Water Quality—Determination of Selected Elements by Inductively Coupled Plasma Optical Emission Spectrometry (ICP-OES). Polski Komitet Normalizacyjny: Warszawa, Poland, 2009.

- PN-EN ISO 17831-2:2015; Solid Biofuels—Determination of Mechanical Durability of Pellets and Briquettes. Polski Komitet Normalizacyjny: Warszawa, Poland, 2015.

- Rozporządzenie Ministra Środowiska z dnia 6 Lutego 2015 r. w Sprawie Stosowania Komunalnych Osadów Ściekowych. Available online: https://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=WDU20150000257 (accessed on 22 August 2024).

- Council Directive 86/278/EEC of 12 June 1986 on the Protection of the Environment, and in Particular of the Soil, When Sewage Sludge is Used in Agriculture. Available online: https://eur-lex.europa.eu/EN/legal-content/summary/using-sewage-sludge-in-farming.html (accessed on 22 August 2024).

- PN-EN ISO 21640:2021; Solid Recovered Fuels—Specifications and Classes. Polski Komitet Normalizacyjny: Warszawa, Poland, 2021.

- Tripathi, N.; Hills, C.D.; Singh, R.S.; Atkinson, C.J. Biomass waste utilisation in low-carbon products: Harnessing a major potential resource. NPJ Clim. Atmos. Sci. 2019, 2, 35. [Google Scholar] [CrossRef]

- Smoliński, A.; Karwot, J.; Bondaruk, J.; Bąk, A. The bioconversion of sewage sludge to bio-fuel: The environmental and economic benefits. Materials 2019, 12, 2417. [Google Scholar] [CrossRef]

- Fukas-Płonka, Ł.; Janik, M. Plusy i minusy suszenia osadów ściekowych. Forum Eksploatatora 2008, 5, 25–27. [Google Scholar]

| Name | Nitrogen Content [% DM] | Carbon Content [% DM] | Dry Organic Matter Content [% DM org] | Moisture [%] |

|---|---|---|---|---|

| Straw chaff (rye) | 1.22 | 45.98 | 92.92 | 7.97 |

| Tree sawdust (mixture: pine, spruce, and beech) | 1.56 | 52.82 | 97.83 | 7.73 |

| Pine bark (sorted) | 1.13 | 50.06 | 65.01 | 52.05 |

| Beech–alder wood chips | 0.73 | 48.19 | 73.74 | 8.47 |

| Walnut shells | 0.83 | 49.89 | 70.11 | 10.67 |

| Sewage sludge (BSI + BSIII) | 6.57 | 37.08 | 62.25 | 88.13 |

| Series Number | Period Start | Period Completion | Drying Time, Days | Type of Biomix |

|---|---|---|---|---|

| I | 17.05.22 | 29.06.22 | 49 | BSI/I—straw 50%/sewage sludge 50% BSI/II—tree sawdust 50%/sewage sludge 50% |

| II | 07.09.22 | 26.11.22 | 76 | BSII/I—wood pine bark 50%/sewage sludge 50% BSII/II—wood chips 50%/sewage sludge 50% BSII/III—walnut shells 50%/sewage sludge 50% |

| CS | 07.07.22 | 07.09.23 | 63 | CSI/I—sewage sludge 100% |

| Parameter | Unit of Measure | Survey Methodology |

|---|---|---|

| Total chlorine content | % s.m. | PN-EN ISO 16994:2016 [56] |

| Total moisture content | % | PN-EN ISO 18134-1 [57] |

| Total sulphur content | % d.m. | PN-EN ISO 21663:2021-06 [58] |

| Total hydrogen content | % d.m. | PN-EN ISO 21663:2021-06 [58] |

| Total carbon content | % d.m. | PN-EN ISO 21663:2021-06 [58] |

| Ash | % d.m. | PN-EN ISO 21656:2021-08 method A [59] |

| Heat of combustion (dry) | kJ/kg | PN-EN ISO 21654:2021-12 [60] |

| Calorific value (from dry calculations) | kJ/kg | PN-EN ISO 21654:2021-12 [60] |

| Kjeldahl nitrogen | % d.m. | PN-EN ISO 21663:2021-06 [58] |

| Hg, As, Cd, Cr, Cu, Ni, Pb, and Zn | mg/kg d.m. | PN-EN ISO 11885:2009 [61] |

| Trial Name | BSI/I | BSI/II | CSI/I | BSII/I | BSII/II | |

|---|---|---|---|---|---|---|

| Total moisture content | % | 9.6 ± 2.2 * | 8.9 ± 2.0 | 10.1 ± 1.6 | 19.8 ± 3.2 | 8.5 ± 2.9 |

| Total chlorine content | % s.m. | 0.22 ± 0.04 | 0.09 ± 0.015 | 0.16 ± 0.03 | 0.089 ± 0.015 | 0.066 ± 0.01 |

| Total sulphur content | 0.57 ± 0.17 | 0.47 ± 0.14 | 0.71 ± 0.21 | 0.44 ± 0.13 | 0.47 ± 0.14 | |

| Total hydrogen content | 4.16 ± 1.08 | 4.72 ± 1.23 | 5.03 ± 1.31 | 4.69 ± 1.22 | 5.34 ± 1.39 | |

| Total carbon content | 31.3 ± 6.6 | 35.6 ± 7.5 | 35.7 ± 7.5 | 44.1 ± 9.3 | 41.6 ± 8.7 | |

| Ash | 44.37 ± 4.44 | 37.43 ± 3.74 | 36.8 ± 3.68 | 25.78 ± 2.58 | 26.2 ± 2.62 | |

| Kjeldahl nitrogen | 2.86 ± 0.57 | 2.39 ± 0.48 | 4.5 ± 0.9 | 2.37 ± 0.47 | 2.67 ± 0.54 | |

| Heat of combustion | MJ/kg | 11.2 ± 0.28 | 12.6 ± 0.31 | 14.3 ± 0.36 | 16 ± 0.4 | 15.7 ± 0.39 |

| Calorific value | 10.3 ± 0.82 | 11.6 ± 0.93 | 13.2 ± 1.06 | 15 ± 1.2 | 14.6 ± 1.17 | |

| Hg | mg/kg | <0.1 | <0.1 | 0.29 ± 0.06 | 0.1 ± 0.02 | <0.1 |

| As | <5 | <5 | <5 | <5 | <5 | |

| Cd | 0.3 ± 0.05 | 0.27 ± 0.04 | 0.61 ± 0.09 | 0.53 ± 0.08 | 0.35 ± 0.05 | |

| Cr | 7.5 ± 1.5 | 5.1 ± 1.0 | 19 ± 4 | 8.5 ± 1.7 | 9.4 ± 1.9 | |

| Cu | 190 ± 40 | 120 ± 20 | 400 ± 80 | 150 ± 3 0 | 170 ± 30 | |

| Ni | 53 ± 11 | 36 ± 7 | 28 ± 6 | 23 ± 5 | 26 ± 5 | |

| Pb | 4.7 ± 0.79 | 3.7 ± 0.7 | 8.8 ± 1.8 | 6.6 ± 1.3 | 7.1 ± 1.4 | |

| Zn | 310 ± 60 | 200 ± 40 | 630 ± 130 | 280 ± 60 | 280 ± 60 | |

| Classification Characteristic | Class | ||||

|---|---|---|---|---|---|

| BSI/I | BSI/II | CSI/I | BSII/I | BSII/II | |

| Net calorific value (NCV) | 4 | 4 | 4 | 3 | 4 |

| Chlorine (CL) | 2 | 1 | 1 | 1 | 1 |

| Mercury (Hg) | 1 | 1 | 1 | 1 | 1 |

| Origin | 3.3.1 | 3.3.1 | 3.3.1 | 3.3.1 | 3.3.1 |

| Trade form | Briquettes | Briquettes | Briquettes | Briquettes | Briquettes |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kujawiak, S.; Makowska, M.; Janczak, D.; Czekała, W.; Krzesiński, W.; Antonowicz, A.; Kupryaniuk, K. An Analysis of the Physicochemical and Energy Parameters of Briquettes Manufactured from Sewage Sludge Mixtures and Selected Organic Additives. Energies 2024, 17, 4573. https://doi.org/10.3390/en17184573

Kujawiak S, Makowska M, Janczak D, Czekała W, Krzesiński W, Antonowicz A, Kupryaniuk K. An Analysis of the Physicochemical and Energy Parameters of Briquettes Manufactured from Sewage Sludge Mixtures and Selected Organic Additives. Energies. 2024; 17(18):4573. https://doi.org/10.3390/en17184573

Chicago/Turabian StyleKujawiak, Sebastian, Małgorzata Makowska, Damian Janczak, Wojciech Czekała, Włodzimierz Krzesiński, Ariel Antonowicz, and Karol Kupryaniuk. 2024. "An Analysis of the Physicochemical and Energy Parameters of Briquettes Manufactured from Sewage Sludge Mixtures and Selected Organic Additives" Energies 17, no. 18: 4573. https://doi.org/10.3390/en17184573

APA StyleKujawiak, S., Makowska, M., Janczak, D., Czekała, W., Krzesiński, W., Antonowicz, A., & Kupryaniuk, K. (2024). An Analysis of the Physicochemical and Energy Parameters of Briquettes Manufactured from Sewage Sludge Mixtures and Selected Organic Additives. Energies, 17(18), 4573. https://doi.org/10.3390/en17184573