Abstract

Digestate is a product with valuable fertilizing properties, remaining after the anaerobic fermentation process. An essential feature of the substance in question is its high water content of up to 97%. To improve the fertilizer value of the digestate, it is necessary to dehydrate it to produce a concentrated product. This paper determined the possibility of dewatering the digestate using an innovative reactor design. The study, conducted on a laboratory scale, used digestate from a Polish biogas plant. The dewatering technique described in the paper is based on the evaporation and condensation of water vapor on the inner surface of the reactor dome. The condensate accumulated on the leach trough and was directed to a storage tank. During the weeks of testing, 11.5 kg of condensate was separated from the initial weight of the digestate (32 kg), with a dry weight of 6.11%. The resulting condensate from dehydration had an average pH value of 9.0 and an average ammonium nitrogen content of 2.07 g∙kg−1. The economic calculations made in the paper allowed for estimating the expected savings associated with the management of digestate in Poland. The research showed the proposed technology’s high potential for dewatering digestate under laboratory conditions.

1. Introduction

The increase in the number of biogas plants in both Poland and EU countries is a result of increased demand for renewable energy and new subsidy projects for such solutions. There is also a proposed economic transition toward a closed loop for all waste generated in the EU [1,2]. This waste also indirectly contributes to global warming. When manure is stored in piles, uncontrolled processes of matter decomposition occur, resulting in methane and other greenhouse gas emissions. Methane is a high-energy compound that can produce electricity and thermal energy [3,4]. The energetic use of CH4 extracted from waste is much more beneficial than the uncontrolled atmospheric emissions resulting from its storage [5,6]. Although carbon dioxide is emitted during the methane combustion process, biogas substrates such as maize silage assimilate it through photosynthesis, thus creating an example of a closed loop. This situation prevents the need for expensive technologies that capture and store carbon dioxide [7].

To ensure the continuity of biogas production, it is necessary to plan and direct an appropriate amount of feedstock into the digester of the biogas plant each day, which involves the removal of some of the digestate. It can be assumed that its amount is usually a few or several percent less than the mass used as feedstock. This depends primarily on the type of substrates used for biogas production and their susceptibility to decomposition. The energy potential of biogas from available biomass in Europe is projected to range from 1.2·103 to 2.3·103 PJy−1 in 2030 [8]. To maintain the continuity of the process, biogas plants install storage tanks in which the digestate pulp is stored. These tanks can take the form of open lagoons or closed silos. It is common practice to use a secondary digester, the second phase of fermentation, followed by a final tank, a storage tank for digestate. In Poland, the required storage time for digestate is due to legal considerations, which prohibit manure distribution on fields between 30 November and 1 March [9,10].

In addition to the production of biogas, which is the primary purpose of a biogas plant, a byproduct, the digestate, is also produced [11,12]. Depending on the input substances used, this product is characterized by high hydration. The average water content of the fresh mass of the product in question ranges from 85% to as much as 97% for biogas plants operating on pig manure [13]. This fact means that biogas plants with a capacity of 1 MWe generate tens of thousands of tons of digestate per year, the fertilizer management of which is mainly associated with distribution on fields. In addition, methods are also used to separate the digestate into liquid and solid fractions using separation techniques [14,15]. The resulting digestate pulp has valuable fertilizer properties due to its high content of numerous mineral compounds. These are yield-forming elements such as nitrogen, phosphorus, and potassium, characterized by their easily assimilable form for plants. Numerous studies have confirmed the beneficial effect of digestate on increasing crop yields of various plant species [16,17]. In addition to mineral compounds, digestate pulp contains organic matter, which increases humus levels, thereby increasing soil fertility [18,19]. Using fresh digestate for fertilizer is a frequently practiced method but is highly energy-intensive due to the substance’s low fertilizer value of 1 m3. The water contained in the pulp is often transported to fields tens of kilometers away, even though it does not have the intended fertilizing effect. Separation and dehydration of the digestate solve the described problem of high hydration. Dewatering is tantamount to an increase in fertilizer concentration, thus minimizing the costs associated with transportation and distribution to agricultural fields [20,21].

Water separation from the digestate can be carried out using various techniques. The current technologies used for digestate separation are not enough, as they require the purchase of additional equipment such as screw presses. In addition, so far no effective and efficient methods of water recovery have been developed, which would be characterized by sufficiently low energy and cost intensity, because the evaporators used most often require the supply of very large amounts of heat, and in the alternative method of ultrafiltration, the slurry from the digestate drastically reduces the life of the membranes [22,23]. Appropriate modification of currently used separation methods or implementation of new technologies would also allow recovery, purification, and ultimate use of water from digestate pulp. The current European Union blue economy dictates the need for such solutions, the main goal of which is to reuse waste as raw materials based on biological processes [24,25]. The impact of the negative way of managing the world’s water resources has been assessed based on ongoing research. Current management is associated with the adverse effect of water stress. This problem is also increasingly affecting the countries of the European Union, where a significant part of the area faces water scarcity and local droughts [26]. The Assembly of the European Commission of 2018 launched an initiative to use nonpotable water, among other things, for agricultural purposes to irrigate crops. Such a solution can significantly contribute to protecting the world’s most important resource—water [27]. The need for new regulations in the European Union countries is also because there are currently no precise legal regulations allowing the use of water separated from digestate. According to the European Parliament and the Council regulation, only information about the minimum requirements that water should meet has been introduced [28,29]. The unification of the legal aspect is a necessary factor that should enable the proper management of the digestate and recovered water. Based on the current law of the Republic of Poland, digestate can be classified as waste (solid or liquid), designated by codes 19 06 05 and 19 06 06. After several chemical composition tests and meeting the requirements, it is possible to sell the digestate in the form of organic fertilizer or an agent that improves the properties of the soil [13,30].

This study aimed to analyze the efficiency and determine the possibility of recovering water from digestate pulp, which can be used as an element to allow proper water management of biogas plants. The digestate was taken from the agricultural biogas plant in Przybroda, Poznan University of Life Sciences (PULS). The research was carried out under laboratory conditions, according to the patent application “Method for digestate dewatering, especially in a biogas plant and a plant for digestate dewatering, especially from a biogas plant” (patent application no. P.436770) on an experimental stand for digestate dewatering made for this purpose. The results obtained in the conducted phases of the experiment are necessary to assess the technological and economic feasibility of implementing the technology at the scale of industrial biogas plants.

2. Materials and Methods

2.1. Subjects of the Study

For the experiments, a fraction of the digestate was used, which was taken from a 499 kW agricultural biogas plant located at the PULS-owned experimental farm in Przybroda (25 km west of Poznań, Poland). The feedstock for this type of plant is biowaste of agricultural origin and from the agrifood industry. After collection from the biogas plant and transport to the Ecotechnology Laboratory, samples of the digestate were stored under anaerobic conditions and a temperature of 4 °C to stop further fermentation and evaporation processes. Then, using a system for mechanical separation, large solid particles above 1 mm were separated from the remaining liquid fraction. For this purpose, a screw press with a sieve with apertures of 1 mm in diameter was used [31]. Table 1 shows the selected parameters of the digestate before the dewatering process.

Table 1.

Selected parameters of the tested digestate.

2.2. Test Stand

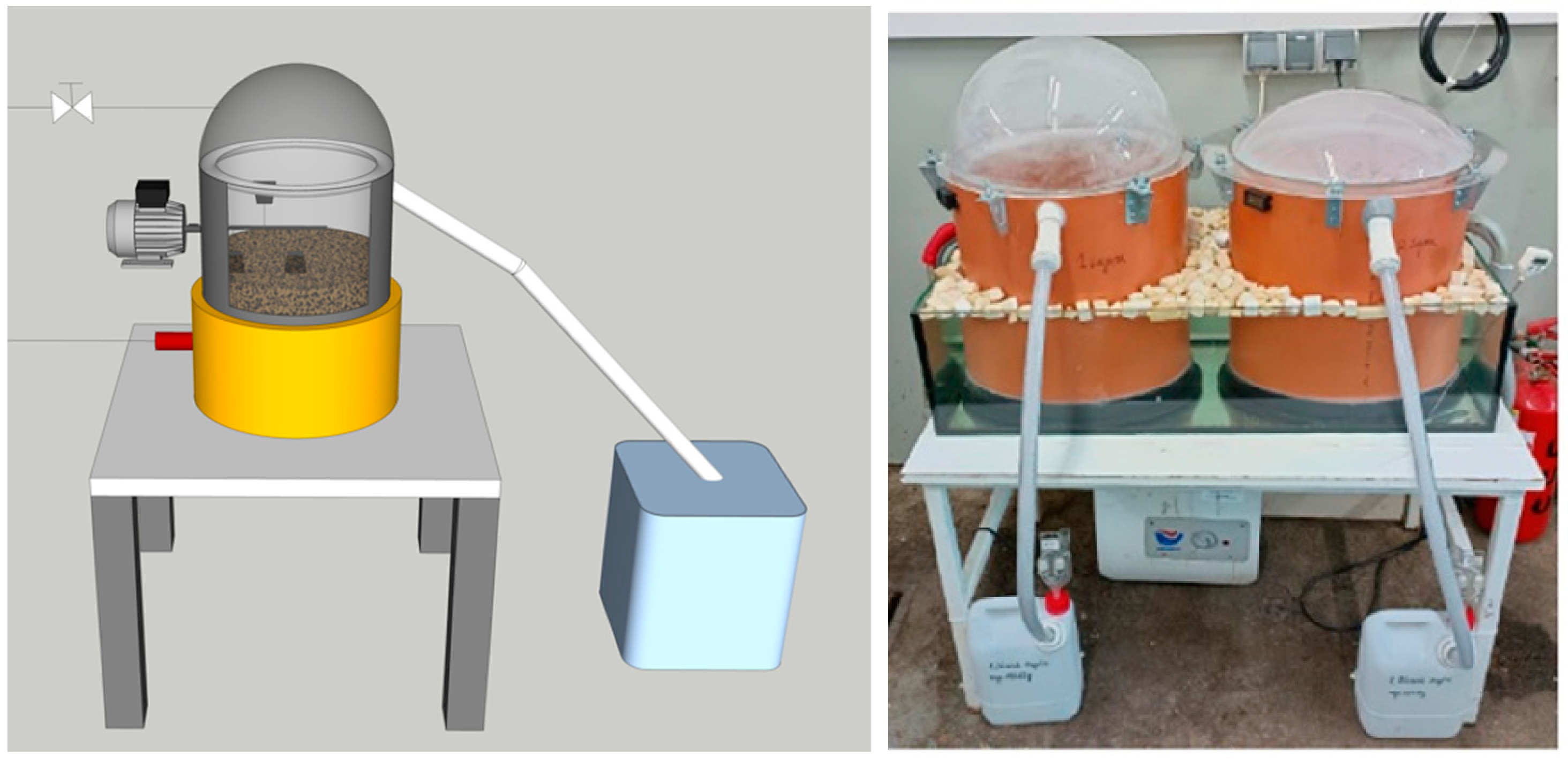

To carry out the experiment, a prototype stand was built to allow dewatering of the digestate. The research was conducted at the Department of Biosystems Engineering of the University of Life Sciences in Poznań. Individual components were installed in the model laboratory stand using materials with properties similar to those used on an industrial scale. The dewatering reactors were made to scale with the research being conducted. Each reactor was made of elements with a diameter and height of 400 mm and a wall thickness of 15.3 mm. The material used for construction is polypropylene, which is resistant to high temperatures and adverse chemical conditions. The bottom of each tank was made of identical material, ensuring a tight connection with the sidewalls. The domes enclosing each reactor were made of 3 mm thick acrylic glass. This material allows observation of the phenomena occurring on the inner surface of each dome. The use of different heights and volumes of the acrylic covers of the reactors was intended to check the variability of the process efficiency depending on the mode of operation of the model biogas plants. The increased convexity of the dome on Reactor 1 is characteristic of biogas plants operating in a peaking system (biogas storage), while Reactor 2 represents a linear operation system. As a result of the correlations introduced, there are differences in the internal surface area, where for the dome of Reactor 1, it is 2443 cm2. In contrast, the internal surface area for the dome in Reactor 2 is 1564 cm2. Both reactors were placed in a water bath simulating a heating system. A flow-through water heater (Regent 10 U EU, Regent part of grupe Ariston Thermo Group, Fabriano, Italy) with a built-in thermostat and a circulating pump (LFP PCO 25/6B, Leszczyńska Fabryka Pomp, Leszno, Poland) responsible for water circulation and equal heating for each reactor were used.

The drainage system comprises a drip trough mounted on the inner perimeter of the reactor and a system of pipes draining the condensate into an external closed tank. The connection between the dome’s surface and the reactor’s top edge was sealed correctly. Conducting Phase I, it was necessary to upgrade the reactors. The modification of the design for Phase II included the adaptation of the laboratory bench to install the stirrer. A DC electric motor was chosen for the drive, along with a gear motor. A PWM speed controller, model CCM96SK (ACS, Warszawa, Poland), was used for smooth speed control capability. On the other hand, the stirrer was constructed from two drilled stainless steel flat bars 20 mm wide, 150 mm long, and 4 mm thick and was mounted at a 45° angle.

2.3. Methodology and Analysis of the Digestate Parameters

The tests were divided into two phases. In Phases I and II of the conducted tests, equal amounts of digestate of 32 kg were placed in the reactors. Standard EN 12880 and APHA 2540 B (ACS, Warszawa, Poland) were used to determine the dry matter parameter. The analysis of the dry mass parameter involves drying the sample in a drying chamber with a set temperature of 105 °C for 24 h. The dried samples were ashed to determine organic and mineral matter. This process was carried out using the glow loss method in a muffle furnace at 550 °C, according to EN 12879 and APHA 2540 E [32]. In addition to the measurements taken, the conductivity and pH were also determined. For both values, 20 g of the digest was weighed in a beaker each time and then topped with distilled water to the appropriate level. After 15 min, measurements were taken with the CX-401 multifunctional device from Elmetron, Zabrze, Poland. Ammonium nitrogen concentration determination was also performed for the condensate generated during dewatering. The concentration values were determined during the distillation test with boric acid (H3BO3) and magnesium oxide (MgO). This process is called the Kiejdahl method and was carried out following ISO 11261, ISO 5663, and APHA 4500-Norg B. Using the samples taken and prepared accordingly, titrations were made with 0.1 N sulfuric acid (H2SO4). Laboratory equipment, i.e., Titator TitoLine 5000 (SI Analytics, Mainz, Germany) and UDK 139 (VELP Scientifica, Usmate Velate, Italy), was used during the research [33].

After being topped off with an equal amount of digestate, each reactor was placed on the bench. Then, the heat of the water was started to achieve the assumed temperature value of 40 °C inside the reactors, corresponding to mesophilic conditions. During the dewatering tests, the water temperature hysteresis value was set at 1 °C. Using PT100 temperature sensors (ALF-SENSOR, Warszawa, Poland), the temperature values of the digestate inside the reactors and the temperature of the water in the aquarium were measured [34]. After condensing on the canopy’s surface, the water vapor flowed into the trough and was then discharged into the storage tank by a system of pipes. The study was conducted for three consecutive weeks: week 1, week 2, and week 3. In each week of the experiment, the amount of condensate obtained was weighed to check the final mass balance. Samples were then taken, allowing monitoring of changes in selected parameters. The schematic of the experimental stand and the actual appearance of the test system are shown in Figure 1.

Figure 1.

Dewatering station and technical schematic of the bench with the equipment used for the separation of liquid fraction of the digestate (own elaboration).

The method and test rig shown in Figure 1 allow for more efficient removal of water from the digestate, without the need for intensive mechanical processes or high temperatures, which reduces energy consumption and the risk of damaging the nutrient structure of the digestate. In addition, the technology promotes more even water removal and minimizes the need for additional chemicals, resulting in a lower environmental impact. A schematic diagram of the test stand is presented in order to understand the process in detail. The stand consists of a cylindrical reactor with a water heating system. The roof of the reactor has a characteristic shape that allows the evaporated fraction of the digestate to condense in its inner part and then condense into a trough located inside the cylindrical tank. The separation process is based on the effects of liquid evaporation and condensation. The process temperature is controlled by a PT100 sensor. The digestate delivered to the tank is mixed, and the reactor dome allows condensation of the liquid fraction, which is then discharged into the condensate tank.

3. Results and Discussion

3.1. Dewatering of Digestate—Phase I

Phase one of the research was conducted to verify the validity of the technological assumptions presented in the methodology. Verification of the correct functioning of the designed stand was performed. After one week of observations, results were obtained that allowed the start of Phase II of the experiments conducted. During the first week of dewatering operation in the reactors without the stirrer system installed, condensate quantities were:

- -

- Reactor 1—2248 g of condensate,

- -

- Reactor 2—1505 g of condensate.

The condensate samples for each reactor were tested for pH and conductivity. The results obtained are shown in Table 2.

Table 2.

Parameters of condensates obtained in the first phase of the experiment.

Phase I was completed after the first week of ongoing experiments on the dewatering system. The results obtained influenced the termination of Phase I due to the formation of an impermeable crust layer on the surface of the digestate. The formed impermeable layer results from a small-scale fermentation process occurring for the entire volume of the digestate, during which the generated gas bubbles lift solid biomass particles to the surface. The formation of the crust negatively affected the efficiency of the evaporation process and, thus, the efficiency of the dewatering plant. Other researchers have also observed the formation of the crust layer. As a result of methane emissions from storage in an open digestate tank, a thin crust layer up to 5 cm thick is formed [35,36].

3.2. Dewatering of Digestate—Phase II

The indicator that determines the effectiveness of the separation is the object (product) subjected to the separation process. If we consider the process of separation and dewatering of digestate, an excellent separator would be characterized by obtaining a solid fraction containing high amounts of dry matter and pure water. In practice, the digestate is often separated into a liquid fraction and a solid fraction [37,38]. In this study, the digestate used, which was subjected to water recovery, had an initial hydration of 93.89%. After the end of the third week of the conducted tests, the digestate was again tested to determine the values of dry and organic matter. The small layer of sludge formed on the bottom was not included in the values obtained. Sedimentation of the heavy sludge fraction concerning the total volume of the liquid fraction of the digestate is insignificant. If the entire volume of the reactor could be thoroughly mixed, it was estimated that the dry matter value would increase by approximately 0.5% for both cases. Table 3 shows the obtained property results for both reactors after dewatering.

Table 3.

Properties of the digestate obtained after the dewatering process for both reactors.

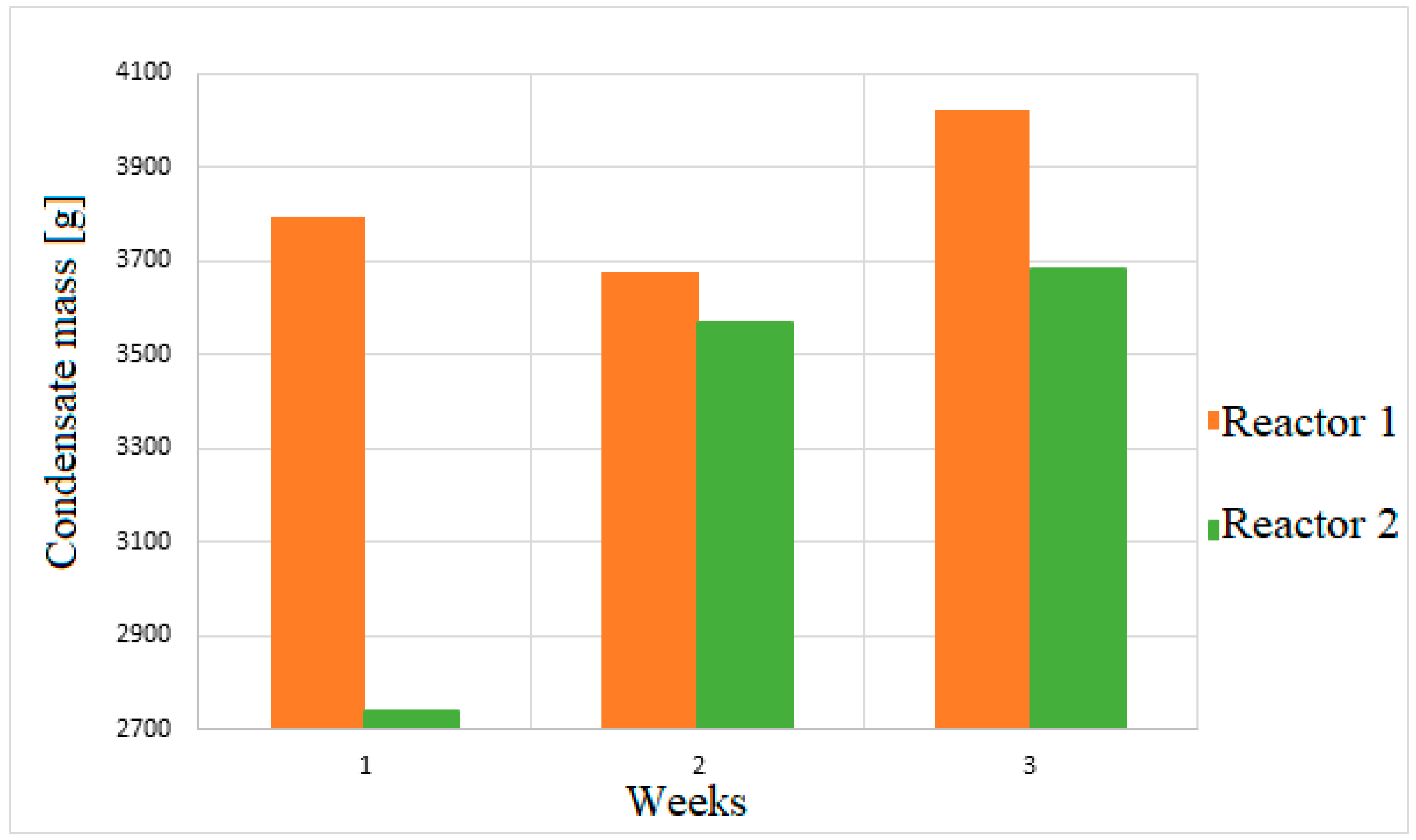

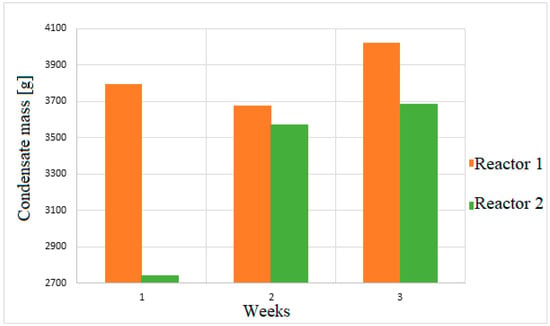

The mass and properties of the resulting condensate were also measured in Phase II of the study. Figure 2 shows the mass values of the discharged condensate for each week of measurements conducted.

Figure 2.

The amount of condensate formed for each week of the dewatering process (own elaboration).

During the first week of testing, the most considerable difference occurred between the amount of condensate discharged and the type of dome used, which was 1053.2 g. During the remaining two weeks, the difference between Reactor 1 and Reactor 2 still occurred, but its value decreased significantly. Invariably, however, a more significant amount of condensate formed on the dome’s surface in Reactor 1. The results’ value is mainly influenced by the fact that the dome used in the peak biogas plants has a proportionally larger internal surface area. In the last week of the study, the highest mass value of the resulting condensate was obtained for each of the reactors. The total amount of recovered condensate for Reactor 1 is 11.5 kg, while for Reactor 2, the value equals 9.99 kg. Obtaining such values for the assumed short testing time demonstrates the high efficiency of the dewatering method used. In comparison, the application of the biosolid drying process studied by Białowiec et al., 2015 is characterized by a 34% weight loss compared to the initial weight of the feedstock [39]. Regarding the dewatering method discussed in the study, this value was 36.6% for Reactor 1 and 31.7% for Reactor 2. The condensates obtained during the conducted studies were also subjected to measurements determining their selected physicochemical parameters, as shown in Table 4 for each week of measurements.

Table 4.

Properties of condensate samples taken from reactors.

Analyzing and comparing the results obtained with the first phase, it was found that the use of the agitator had a positive effect, not only preventing the formation of dross on the surface but also significantly increasing the pH and conductivity values of the condensate during the first week of the study. In subsequent weeks, the measured pH and conductivity values decreased.

The mass balance of the initial substrates introduced to the amount of condensate obtained and the remaining amount of digestate is shown by the following relationships:

- Reactor 1

- 32 kg—initial amount of digestate,

- 20.3 kg—weight of the digest after 3 weeks of dehydration,

- 11.5 kg—total weight of condensate.

Mass balance = 20.3 + 11.5 = 31.8 kg,

- Reactor 2

- 32 kg—initial amount of digestate,

- 21.85 kg—weight of the digest after 3 weeks of dehydration,

- 9.99 kg—total weight of condensate.

Mass balance = 21.85 + 9.99 = 31.84 kg

The difference resulting from the initial amount of the digestate and the mass balance does not exceed the value of 1%.

A new solution for digestate digestion was also analyzed and compared with existing separation and dewatering technologies. The technology of digestion dewatering discussed in the paper can become an alternative to the other analyzed methods used to increase the dry matter content in substances characterized by significant hydration [40,41]. However, a method based on directly dewatering the digestate in a closed storage reactor has not been described. For the most part, the digestate is processed outside the storage tanks or even in plants specialized for this purpose, to which it is transported [9,42].

Analysis of the presented separation process with compatibility with the latest research for the management of digestate showed that the use of dehydration technology can significantly contribute to the reduction of greenhouse gas emissions by reducing the mass of water transported, which can reduce CO2 emissions associated with logistics by up to 20–30% [43]. In addition, technologies such as thermal drying and evaporation are increasingly being implemented in biogas plants to improve efficiency. Research indicates that the implementation of biogas-fueled anaerobic digestion dryers can minimize external energy consumption and reduce the carbon footprint of biogas production. Mechanisms for digestate dehydration, such as solar drying, evaporation, and thermal dehydration, are effective in reducing volume and mass, which has a significant impact on reducing logistics costs and greenhouse gas emissions. In the literature, solar drying with evaporation and biofiltration systems can control emissions of ammonia and other gases [44]. In addition, according to the results of research on water management in the life cycle of products such as digestate, taking into account the dewatering treatment of wastewater, which allows water to be recovered for agricultural or industrial use, leads to a reduction in the use of fresh water resources. Following standards that comply with EU Directive 2018/2001 on environmental protection will maximize the benefits for sustainable development [45].

4. Energy and Economic Analysis

Using an appropriate method that allows comparison and energy and economic evaluation of the dewatering process in question allowed us to justify the validity of conducting further research on the technology presented in the paper. The possibility of making such calculations depends on many variables, such as the type of biogas plant or the properties of the produced digestate [30,46]. The economic aspect also depends on how the digestate is stored in tanks, the feedstock’s properties, and the type of fermentation process carried out (wet or dry). Based on the experience of researchers from the University of Life Sciences in Poznań and data obtained from people in the biogas industry, a comparative method was selected to evaluate the economics of digestate digestion. The primary purpose of the analysis is to compare the amount of water evaporated from the pulp and the outlay of funds required and energy consumed for the export and management of the digestate on agricultural fields. Some literature sources state that the cost of transporting the digestate for a distance of 5 to 10 km is not economically justified because it exceeds its fertilizer value [47,48].

The calculations made were based on the following assumptions:

- -

- Used energy supplied to heat the interior of the lagoon simultaneously allows the evaporation of the water contained in the digestate and is not directly used in the dewatering process under study but in the process of biological desulfurization of biogas and its digestion, using the reactor as an additional phase of fermentation. Due to the use of biological desulfurization and digestion of the digestate, the energy consumption needed to heat the lagoon for dewatering was ignored,

- -

- The digestate in the reactors is stirred to digest it and increase the biogas yield. The use of an agitator is also necessary due to the dross that is formed. The increase in electricity demand by the agitator has been approximated. For the most unfavorable case, the energy consumption used to drive the agitator motor can increase by 50% relative to the initial dry matter value of the mixed digestate,

- -

- The adopted cost of digestate pulp management was considered for a 1 MWel biogas plant, for which the average transport distance resulting from spreading the digestate on agricultural fields is 6.71 km, which translates into costs equal to PLN 390,000 per year. The values are based on the research conducted by [46] for 2011. Converting the annual value to 1 Mg of pulp spread, the cost is PLN 5.76 (2011). Thus, making an economic–energy analysis, the cost of pulp export was increased by 30% to equate to the current prices of equipment, fuel, or the cost of personnel,

- -

- The dry matter value was assumed to be 12% and is based on the fact that typical solutions found in most biogas plants are used, i.e., classic submersible pumps and standard Joskin Quadra-type barrels used for the application of substances to agricultural fields,

- -

- The amount of digestate generated in a 1 MWel agricultural biogas plant is 67,134 Mg per year, according to data [10,46]—it was assumed that the volume of the digestate concerning its mass expressed in Mg is 1:1.

In addition to the assumptions described above, two possible variants for the use of the dewatering system were also adopted, which depend on the initial dry mass value of the digestate in the reactor:

- -

- Variant I, in which the selected biogas plant has a solid–liquid fraction separator and therefore stores the liquid fraction of the digestate for which the average dry matter content is between 3% and 7.5% [49,50], with an intermediate value of 4% DM used in the calculations,

- -

- Variant II, where the solid fraction and the liquid fraction do not undergo a separation process, and in addition, the feedstock mixture used for biogas production is characterized by low hydration. For this type of biogas plant, the average dry matter content of the digestate pulp is 8.5% DM.

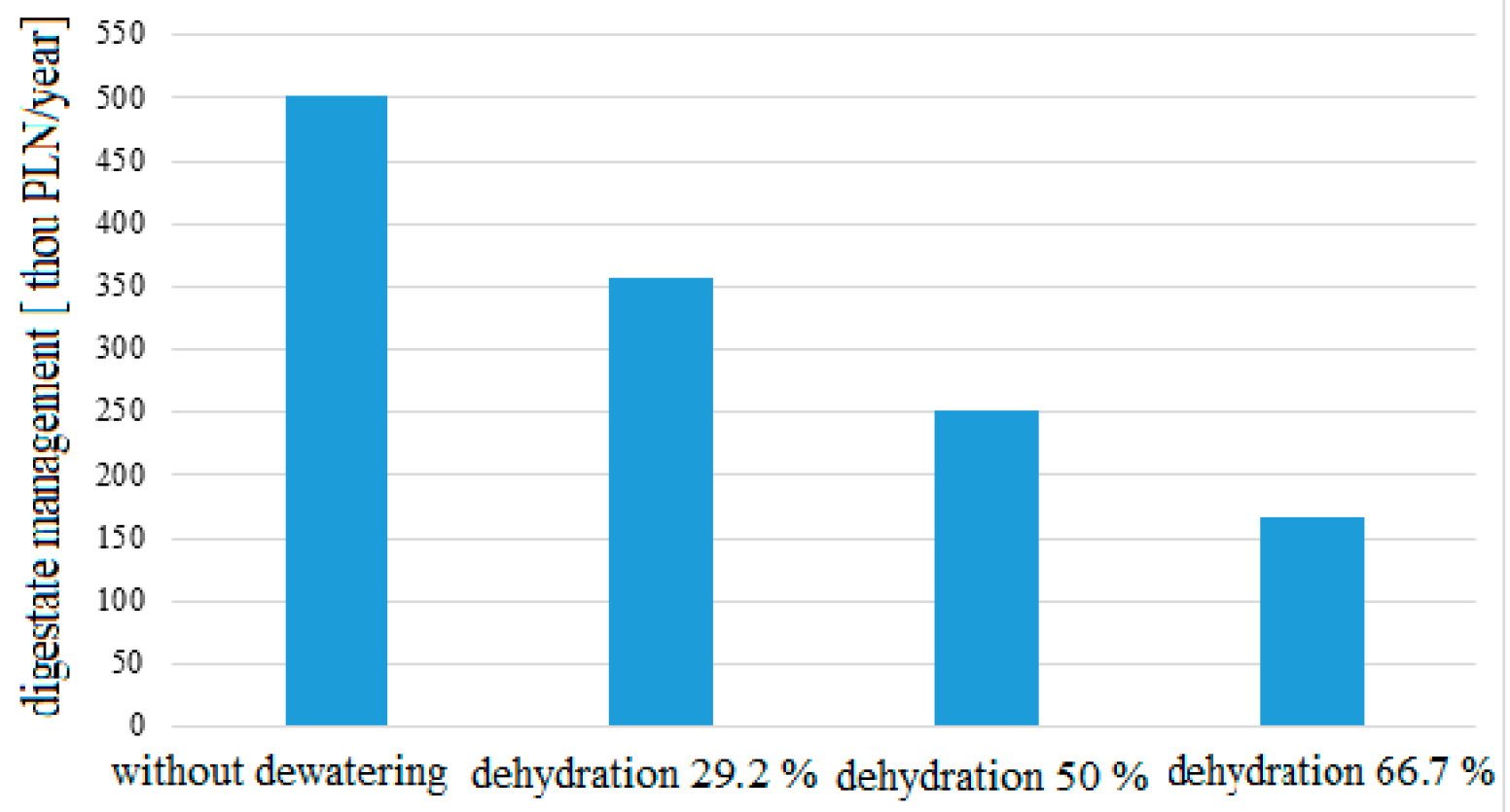

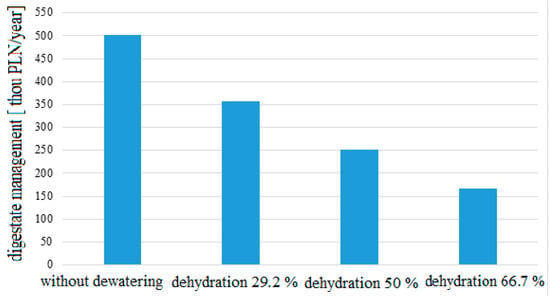

Based on the assumptions, calculations were made to make an economic analysis of the dewatering process. Based on the results obtained, it was calculated that 11.5 kg of condensate was discharged from the initial mass of the digestate in the most favorable variant. Each day, we can evaporate approximately 0.548 kg of condensate from an initial digestate mass of 32 kg with an initial dry weight of 6.11%. The value obtained was scaled for an actual digestate storage reactor installed at a 1 MWel biogas plant. For a 9600 Mg pulp storage tank, the daily evaporation and condensate separation were estimated at 164.4 Mg. Due to the excessive level of compaction occurring in the case of continuous drainage of condensate from the digestate, the process was divided into phases. Each phase depends on the dry matter level of the digestate. The first and most favorable option involves changing the dry weight of the digestate from 4% to 12% by dewatering over 272 days. During this time, 44,716.8 Mg of condensate could be obtained, saving PLN 335,132.5 on transportation and management of the digestate pulp. The study of the pulp dewatering process was divided into four phases. The first phase was presented for the management of digestates without the use of dewatering methods. The next phase considered dehydration at 29.2%. Next, the most favorable variants allowing 50% and 66.7% dewatering were assumed. The values for the percentage of dewatering of the digestate are derived from the number of days during the year on which the dewatering process can be used. The results for each calculation variant are shown in Figure 3.

Figure 3.

Differences in the cost of digestate export depending on the percentage of dewatering (own elaboration).

Analyzing the results, it was noted that low dewatering of the digestate by 29.2% shows gains associated with a reduction in the cost of digestate export during the year by nearly PLN 147,000. In such a developed economic and energy aspect, it is also necessary to consider the increased energy consumption of the agitator placed in the reactor, preventing the formation of crusts. The increased energy consumption results from an increase in the dry weight value of the digestate. Based on the information obtained, it was assumed that most pulp storage tanks use 15 kW agitators, which operate for 45 min per hour with a 15 min technical break. An agitator of this type consumes 270 kWh of electricity each day, which on an annual basis equals a total of 98,550 kWh. As a result of the dewatering process, the electricity consumption by the motor driving the mixer increases. Accordingly, after consultation with the agitator manufacturer, an approximate increase in consumption of 50% relative to the initial dry weight of the mixed pulp was estimated. This means an increase in energy demand of 49,275 kWh, with an assumed cost per kWh for the biogas plant averaging PLN 0.65. Regarding the economic aspect, this translates into an expense of PLN 32,029, which diminishes the final gains from savings on digestate pulp export.

It is essential to emphasize that the increased energy consumption of 50% occurs only for the last variant, in which 66.7% of the pulp water is drained. If the dewatering is only 29.2%, the increased energy consumption of the mixer can be much less. An additional essential aspect of using pulp dewatering is the reduction in CO2 and other elements emitted into the atmosphere by tractor engines as a result of transporting and bottling large quantities of diluted digestate [13,51].

According to a study by Aragon-Briceño et al., 2022, hydrothermal carbonization (HTC) positively affected the efficiency of mechanical recovery of water from the digestate and improved its net energy balance. This means that only a combination of multiple dewatering methods can have the most favorable impact on the final economic balance of a biogas plant where digestion and separation of digestate are carried out [52,53]. HTC is the process used to dry and stabilize the digestate. Both the HTC technology and the method of dewatering the digestate studied in this article allow the provision of an aqueous phase [54,55].

The most recent research indicates that the use of waste substrates for biogas production can make a significant contribution to reducing greenhouse gas emissions. For example, in the Emilia-Romagna region of Italy, emissions from various agricultural residues were analyzed, resulting in a reduction of CO2 emissions at the level of 80% when transported over distances of up to 50 km. Taking into account the application of the presented technological solution in biogas plants, we will certainly reduce emissions associated with the transport of the digestate and improve the eco-efficiency of substrate management. This will bring economic benefits for farmers, as well as for the environment [56].

5. Conclusions

Currently, several methods are on the market to solve the problem of dewatering and separating digestate pulp, but their application requires significant electrical or thermal energy. Separation of digestate into solid and liquid fractions is a popular method; however, it has disadvantages related to the limitation in the separation of pure water. To completely remove bound water, it is necessary to use thermal methods for drying the digestate. The advantage of using such methods on an industrial scale is that the resulting condensate product can allow balancing the water management of the biogas plant and the availability of high amounts of thermal energy. After the denitrification process, it is possible to return the condensate to the digester and use it as process water.

Conducting tests on introducing a new technological method of dewatering confirmed the correctness of the adopted design assumptions and confirmed the validity of this technology’s implementation on a real scale. Analyzing the results obtained within the framework of the conducted research, it was found that the efficiency of dewatering at the level of 0.55 kg of condensate per day is high, taking into account the amount of feedstock of 32 kg.

Analysis of the energy intensity of the discussed process should be further investigated. Using currently available literature data, the gains associated with dewatering the pulp were compared with its management costs for an example of a 1 MWel biogas plant. In the case of using a solid and liquid fraction separator and additionally dewatering the liquid fraction with the dewatering system studied in the paper, the savings associated with the management of the pulp can be up to PLN 330,000 per year, not including the costs associated with the purchase of technology.

For the studies conducted, the short time frame of the experiment may not take into account the long-term effects of the technology’s operation, such as the stability of the evaporation process and the impact of environmental variables such as temperature and moisture content, which can significantly affect process efficiency. In full-scale applications, additional challenges may occur, such as the need to adapt the technology to the diverse parameters of the digestate, which can vary in nutrient content and hydration from one biogas plant to another. By carrying out tests at the laboratory level, the full range of physical and chemical interactions that may occur at the industrial scale were not anticipated. It is planned to continue testing under actual operational conditions at biogas plants to verify the long-term effectiveness of the technology.

The thickening of the pulp and the condensate produced during the dewatering process brings additional benefits. First, the concentrated fertilizer value makes it possible to reduce the costs associated with spreading the fraction on agricultural fields. The resulting condensate product becomes an alternative when irrigating farm fields near an agricultural biogas plant.

6. Patents

“Method for digestate dewatering, especially in a biogas plant and a plant for digestate dewatering, especially from a biogas plant” (patent application no. P.436770).

Author Contributions

Conceptualization, M.N., J.D. and W.C.; methodology, M.N. and J.D.; validation, M.N., W.C. and W.B.; formal analysis, M.N.; investigation, M.N.; resources, M.N. and W.C.; data curation, M.N.; writing—original draft preparation, M.N.; writing—review and editing, M.N., W.C. and W.B.; visualization, M.N.; supervision, M.N., J.D. and W.C.; project administration, M.N. and W.C.; funding acquisition, W.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Sarc, R.; Curtis, A.; Kandlbauer, L.; Khodier, K.; Lorber, K.E.; Pomberger, R. Digitalisation and intelligent robotics in value chain of circular economy oriented waste management—A review. Waste Manag. 2019, 95, 476–492. [Google Scholar] [CrossRef]

- Longo, S.; Cellura, M.; Luu, L.Q.; Nguyen, T.Q.; Rincione, R.; Guarino, F. Circular economy and life cycle thinking applied to the biomass supply chain: A review. Renew. Energy 2024, 220, 119598. [Google Scholar] [CrossRef]

- Siddiqui, S.; Zerhusen, B.; Zehetmeier, M.; Effenberger, M. Distribution of specific greenhouse gas emissions from combined heat-and-power production in agricultural biogas plants. Biomass Bioenergy 2020, 133, 105443. [Google Scholar] [CrossRef]

- Czekała, W.; Janczak, D.; Pochwatka, P.; Nowak, M.; Dach, J. Gases Emissions during Composting Process of Agri-Food Industry Waste. Appl. Sci. 2022, 12, 9245. [Google Scholar] [CrossRef]

- Kucher, O.; Hutsol, T.; Glowacki, S.; Andreitseva, I.; Dibrova, A.; Muzychenko, A.; Szeląg-Sikora, A.; Szparaga, A.; Kocira, S. Energy Potential of Biogas Production in Ukraine. Energies 2022, 15, 1710. [Google Scholar] [CrossRef]

- Stürmer, B.; Leiers, D.; Anspach, V.; Brügging, E.; Scharfy, D.; Wissel, T. Agricultural biogas production: A regional comparison of technical parameters. Renew. Energy 2021, 164, 171–182. [Google Scholar] [CrossRef]

- Almena, A.; Thornley, P.; Chong, K.; Röder, M. Carbon dioxide removal potential from decentralised bioenergy with carbon capture and storage (BECCS) and the relevance of operational choices. Biomass Bioenergy 2022, 159, 106406. [Google Scholar] [CrossRef]

- Meyer, A.K.P.; Ehimen, E.A.; Holm-Nielsen, J.B. Future European biogas: Animal manure, straw and grass potentials for a sustainable European biogas production. Biomass Bioenergy 2018, 111, 154–164. [Google Scholar] [CrossRef]

- Kovačić, Đ.; Lončarić, Z.; Jović, J.; Samac, D.; Popović, B.; Tišma, M. Digestate Management and Processing Practices: A Review. Appl. Sci. 2022, 12, 9216. [Google Scholar] [CrossRef]

- Nowak, M.; Bojarski, W.; Czekała, W. Economic and Energy Efficiency Analysis of the Biogas Plant Digestate Management Methods. Energies 2024, 17, 3021. [Google Scholar] [CrossRef]

- Czekała, W.; Nowak, M.; Piechota, G. Sustainable management and recycling of anaerobic digestate solid fraction by composting: A review. Bioresour. Technol. 2023, 375, 128813. [Google Scholar] [CrossRef] [PubMed]

- Di Maria, F.; Sisani, F. A sustainability assessment for use on land or wastewater treatment of the digestate from bio-waste. Waste Manag. 2019, 87, 741–750. [Google Scholar] [CrossRef] [PubMed]

- Dziedzic, K.; Łapczyńska-Kordon, B.; Jurczyk, M.; Arczewska, M.; Wróbel, M.; Jewiarz, M.; Mudryk, K.; Pająk, T. Solid Digestate—Physicochemical and Thermal Study. Energies 2021, 14, 7224. [Google Scholar] [CrossRef]

- Yamakawa, C.K.; Qin, F.; Mussatto, S.I. Advances and opportunities in biomass conversion technologies and biorefineries for the development of a bio-based economy. Biomass Bioenergy 2018, 119, 54–60. [Google Scholar] [CrossRef]

- Wu, D.; Lü, F.; Shao, L.; He, P. Effect of cycle digestion time and solid-liquid separation on digestate recirculated one-stage dry anaerobic digestion: Use of intact polar lipid analysis for microbes monitoring to enhance process evaluation. Renew. Energy 2017, 103, 38–48. [Google Scholar] [CrossRef]

- Lee, M.-S.; Urgun-Demirtas, M.; Shen, Y.; Zumpf, C.; Anderson, E.K.; Rayburn, A.L.; Lee, D.K. Effect of digestate and digestate supplemented with biochar on switchgrass growth and chemical composition. Biomass Bioenergy 2021, 144, 105928. [Google Scholar] [CrossRef]

- Monfet, E.; Aubry, G.; Ramirez, A.A. Nutrient removal and recovery from digestate: A review of the technology. Biofuels 2018, 9, 247–262. [Google Scholar] [CrossRef]

- Lymperatou, A.; Rasmussen, N.B.; Gavala, H.N.; Skiadas, I.V. Improving the Anaerobic Digestion of Swine Manure through an Optimized Ammonia Treatment: Process Performance, Digestate and Techno-Economic Aspects. Energies 2021, 14, 787. [Google Scholar] [CrossRef]

- Nabel, M.; Schrey, S.D.; Poorter, H.; Koller, R.; Jablonowski, N.D. Effects of digestate fertilization on Sida hermaphrodita: Boosting biomass yields on marginal soils by increasing soil fertility. Biomass Bioenergy 2017, 107, 207–213. [Google Scholar] [CrossRef]

- Lamolinara, B.; Pérez-Martínez, A.; Guardado-Yordi, E.; Guillén Fiallos, C.; Diéguez-Santana, K.; Ruiz-Mercado, G.J. Anaerobic digestate management, environmental impacts, and techno-economic challenges. Waste Manag. 2022, 140, 14–30. [Google Scholar] [CrossRef]

- Logan, M.; Visvanathan, C. Management strategies for anaerobic digestate of organic fraction of municipal solid waste: Current status and future prospects. Waste Manag. Res. 2019, 37, 27–39. [Google Scholar] [CrossRef] [PubMed]

- Borek, K.; Romaniuk, W. Biogas Installations for Harvesting Energy and Utilization of Natural Fertilisers. Agric. Eng. 2020, 24, 1–14. [Google Scholar] [CrossRef]

- Cao, B.; Zhang, T.; Zhang, W.; Wang, D. Enhanced technology based for sewage sludge deep dewatering: A critical review. Water Res. 2021, 189, 116650. [Google Scholar] [CrossRef] [PubMed]

- Ajay, C.M.; Mohan, S.; Dinesha, P. Decentralized energy from portable biogas digesters using domestic kitchen waste: A review. Waste Manag. 2021, 125, 10–26. [Google Scholar] [CrossRef]

- Naddeo, V.; Taherzadeh, M.J. Biomass valorization and bioenergy in the blue circular economy. Biomass Bioenergy 2021, 149, 106069. [Google Scholar] [CrossRef]

- Vanham, D.; Alfieri, L.; Flörke, M.; Grimaldi, S.; Lorini, V.; de Roo, A.; Feyen, L. The number of people exposed to water stress in relation to how much water is reserved for the environment: A global modelling study. Lancet Planet. Health 2021, 5, e766–e774. [Google Scholar] [CrossRef]

- Völker, T.; Kovacic, Z.; Strand, R. Indicator development as a site of collective imagination? The case of European Commission policies on the circular economy. Cult. Organ. 2020, 26, 103–120. [Google Scholar] [CrossRef]

- Kawamoto, R.; Mochizuki, H.; Moriguchi, Y.; Nakano, T.; Motohashi, M.; Sakai, Y.; Inaba, A. Estimation of CO2 Emissions of Internal Combustion Engine Vehicle and Battery Electric Vehicle Using LCA. Sustainability 2019, 11, 2690. [Google Scholar] [CrossRef]

- Shoushtarian, F.; Negahban-Azar, M. Worldwide Regulations and Guidelines for Agricultural Water Reuse: A Critical Review. Water 2020, 12, 971. [Google Scholar] [CrossRef]

- Jurgutis, L.; Šlepetienė, A.; Šlepetys, J.; Cesevičienė, J. Towards a Full Circular Economy in Biogas Plants: Sustainable Management of Digestate for Growing Biomass Feedstocks and Use as Biofertilizer. Energies 2021, 14, 4272. [Google Scholar] [CrossRef]

- Dach, J.; Pulka, J.; Janczak, D.; Lewicki, A.; Pochwatka, P.; Oniszczuk, T. Energetic Assessment of Biogas Plant Projects Based on Biowaste and Maize Silage Usage. IOP Conf. Ser. Earth Environ. Sci. 2020, 505, 012029. [Google Scholar] [CrossRef]

- Drosg, B.; Braun, R.; Bochmann, G.; Al Saedi, T. Analysis and characterisation of biogas feedstocks. In The Biogas Handbook; Elsevier: Amsterdam, The Netherlands, 2013; pp. 52–84. ISBN 978-0-85709-498-8. [Google Scholar] [CrossRef]

- Kumar, H. Advanced Techniques of Analytical Chemistry: Volume 1; Bentham Science Publishers: Oak Par, IL, USA, 2022; ISBN 978-981-5050-24-0. [Google Scholar]

- Prakosa, J.A.; Purwowibowo; Larassati, D. Development of Simple Method for Quality Testing of PT100 Sensors Due to Temperature Coefficient of Resistance Measurement. In Proceedings of the 2021 International Symposium on Electronics and Smart Devices (ISESD), Bandung, Indonesia, 29–30 June 2021; pp. 1–5. [Google Scholar] [CrossRef]

- Baldé, H.; VanderZaag, A.C.; Burtt, S.D.; Wagner-Riddle, C.; Crolla, A.; Desjardins, R.L.; MacDonald, D.J. Methane emissions from digestate at an agricultural biogas plant. Bioresour. Technol. 2016, 216, 914–922. [Google Scholar] [CrossRef] [PubMed]

- Vondra, M.; Touš, M.; Teng, S.Y. Digestate evaporation treatment in biogas plants: A techno-economic assessment by Monte Carlo, neural networks and decision trees. J. Clean. Prod. 2019, 238, 117870. [Google Scholar] [CrossRef]

- Feiz, R.; Carraro, G.; Brienza, C.; Meers, E.; Verbeke, M.; Tonderski, K. Systems analysis of digestate primary processing techniques. Waste Manag. 2022, 150, 352–363. [Google Scholar] [CrossRef] [PubMed]

- Guilayn, F.; Jimenez, J.; Martel, J.-L.; Rouez, M.; Crest, M.; Patureau, D. First fertilizing-value typology of digestates: A decision-making tool for regulation. Waste Manag. 2019, 86, 67–79. [Google Scholar] [CrossRef]

- Białowiec, A.; Wiśniewski, D.; Pulka, J.; Siudak, M.; Jakubowski, B.; Myślak, B. Biosuszenie pofermentu z biogazowni rolniczych. Rocz. Ochr. Sr. 2015, 17, 1554–1568. [Google Scholar]

- Awiszus, S.; Meissner, K.; Reyer, S.; Müller, J. Ammonia and methane emissions during drying of dewatered biogas digestate in a two-belt conveyor dryer. Bioresour. Technol. 2018, 247, 419–425. [Google Scholar] [CrossRef]

- Mudryk, K.; Frączek, J.; Jewiarz, M.; Wróbel, M.; Dziedzic, K. Analysis of Mechanical Dewatering of Digestate. Agric. Eng. 2016, 20, 157–166. [Google Scholar] [CrossRef][Green Version]

- Cathcart, A.; Smyth, B.M.; Lyons, G.; Murray, S.T.; Rooney, D.; Johnston, C.R. Optimising mechanical separation of anaerobic digestate for total solids and nutrient removal. J. Environ. Manag. 2023, 345, 118449. [Google Scholar] [CrossRef]

- Ries, J.; Chen, Z.; Park, Y. Potential Applications of Food-Waste-Based Anaerobic Digestate for Sustainable Crop Production Practice. Sustainability 2023, 15, 8520. [Google Scholar] [CrossRef]

- Morey, L.; Fernández, B.; Tey, L.; Biel, C.; Robles-Aguilar, A.; Meers, E.; Soler, J.; Porta, R.; Cots, M.; Riau, V. Acidification and solar drying of manure-based digestate to produce improved fertilizing products. J. Environ. Manag. 2023, 336, 117664. [Google Scholar] [CrossRef] [PubMed]

- Fina, B.; Auer, H. Economic Viability of Renewable Energy Communities under the Framework of the Renewable Energy Directive Transposed to Austrian Law. Energies 2020, 13, 5743. [Google Scholar] [CrossRef]

- Dach, J.; Pilarski, K.; Janczak, D.; Banasik, P. Koszty zagospodarowania pulpy pofermentacyjnej z biogazowni w kontekście projektu nowej ustawy o nawozach i nawożeniu. In Technika Rolnicza Ogrodnicza Leśna; Przemysłowy Instytut Maszyn Rolniczych: Poznań, Poland, 2011. [Google Scholar]

- Kratzeisen, M.; Starcevic, N.; Martinov, M.; Maurer, C.; Müller, J. Applicability of biogas digestate as solid fuel. Fuel 2010, 89, 2544–2548. [Google Scholar] [CrossRef]

- Wehner, M.; Lichtmannegger, T.; Robra, S.; do Carmo Precci Lopes, A.; Ebner, C.; Bockreis, A. Determination of the dewatered digestate amounts and methane yields from the co-digestion of biowaste as a basis for a cost-benefit analysis. Waste Manag. 2021, 126, 632–642. [Google Scholar] [CrossRef]

- Pilarski, K.; Dach, J.; Janczak, D.; Zbytek, Z. Wpływ odległości transportowej na wydajność pracy agregatów i koszty zagospodarowania pofermentu z biogazowni rolniczej 1 MWel. J. Res. Appl. Agric. Eng. 2011, 56, 109–113. [Google Scholar]

- Naqi, A.; Kuhn, J.N.; Joseph, B. Techno-economic analysis of producing liquid fuels from biomass via anaerobic digestion and thermochemical conversion. Biomass Bioenergy 2019, 130, 105395. [Google Scholar] [CrossRef]

- Ardolino, F.; Parrillo, F.; Arena, U. Biowaste-to-biomethane or biowaste-to-energy? An LCA study on anaerobic digestion of organic waste. J. Clean. Prod. 2018, 174, 462–476. [Google Scholar] [CrossRef]

- Aragon-Briceño, C.; Pożarlik, A.; Bramer, E.; Brem, G.; Wang, S.; Wen, Y.; Yang, W.; Pawlak-Kruczek, H.; Niedźwiecki, Ł.; Urbanowska, A.; et al. Integration of hydrothermal carbonization treatment for water and energy recovery from organic fraction of municipal solid waste digestate. Renew. Energy 2022, 184, 577–591. [Google Scholar] [CrossRef]

- Taufer, N.L.; Benedetti, V.; Pecchi, M.; Matsumura, Y.; Baratieri, M. Coupling hydrothermal carbonization of digestate and supercritical water gasification of liquid products. Renew. Energy 2021, 173, 934–941. [Google Scholar] [CrossRef]

- Roy, U.K.; Radu, T.; Wagner, J.L. Carbon-negative biomethane fuel production: Integrating anaerobic digestion with algae-assisted biogas purification and hydrothermal carbonisation of digestate. Biomass Bioenergy 2021, 148, 106029. [Google Scholar] [CrossRef]

- Rosas-Mendoza, E.S.; Alvarado-Vallejo, A.; Vallejo-Cantú, N.A.; Velasco-Santos, C.; Alvarado-Lassman, A. Valorization of the complex organic waste in municipal solid wastes through the combination of hydrothermal carbonization and anaerobic digestion. Renew. Energy 2024, 231, 120916. [Google Scholar] [CrossRef]

- Kodba, A.; Pukšec, T.; Duić, N. Analysis of Specific Greenhouse Gas Emissions Savings from Biogas Production Based on Agricultural Residues and Industrial By-Products. Energies 2023, 16, 3721. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).