Pore Structure Characteristics of Shale Oil Reservoirs with Different Lithofacies and Their Effects on Mobility of Movable Fluids: A Case Study of the Chang 7 Member in the Ordos Basin, China

Abstract

:1. Introduction

2. Geological Background

3. Samples and Methods

4. Results

4.1. Reservoir Petrological Characteristics and Petrophysical Properties

4.2. Pore Types

4.3. Quantitative Pore Parameter Characterization

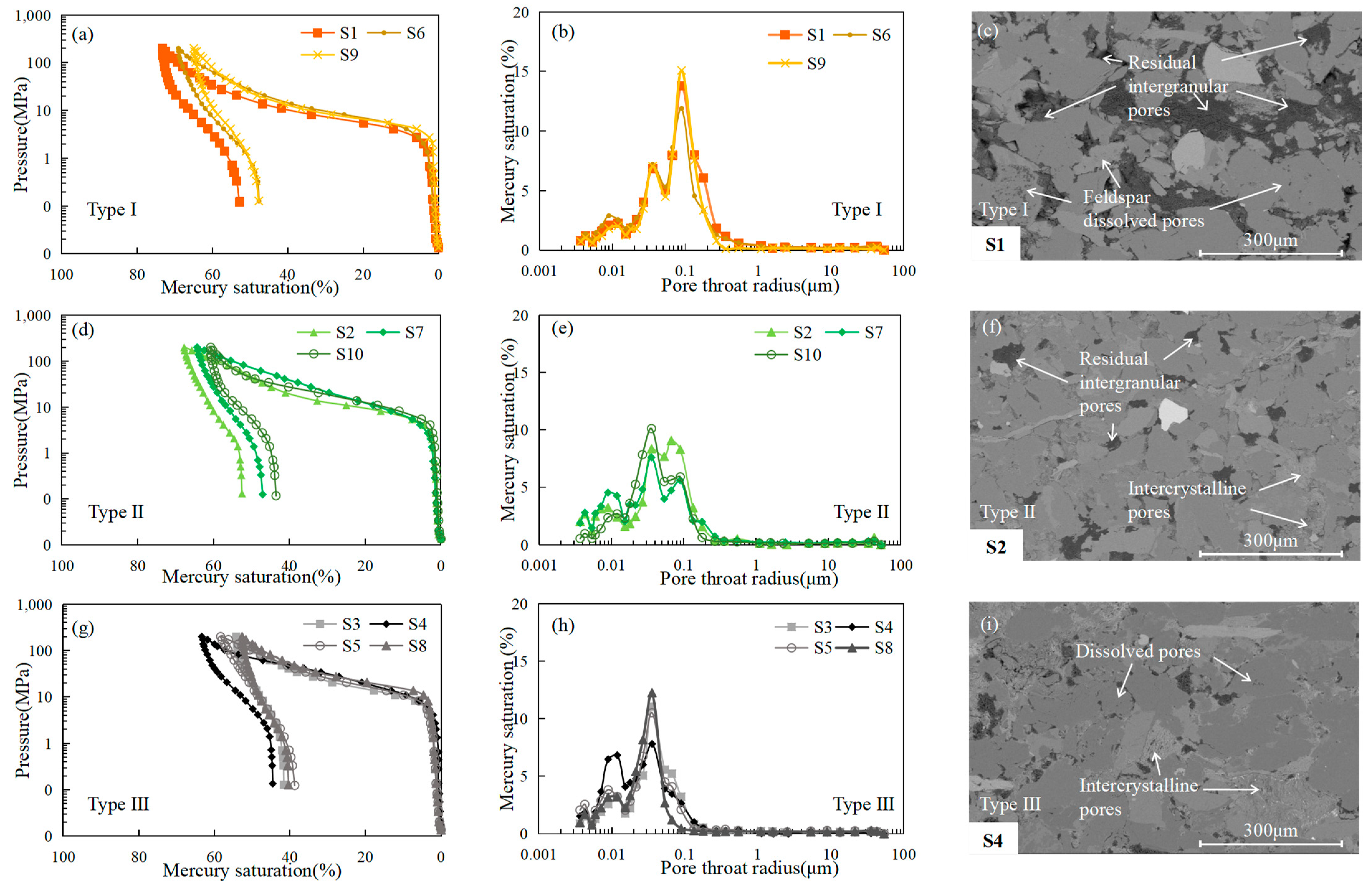

4.3.1. HPMI Curve

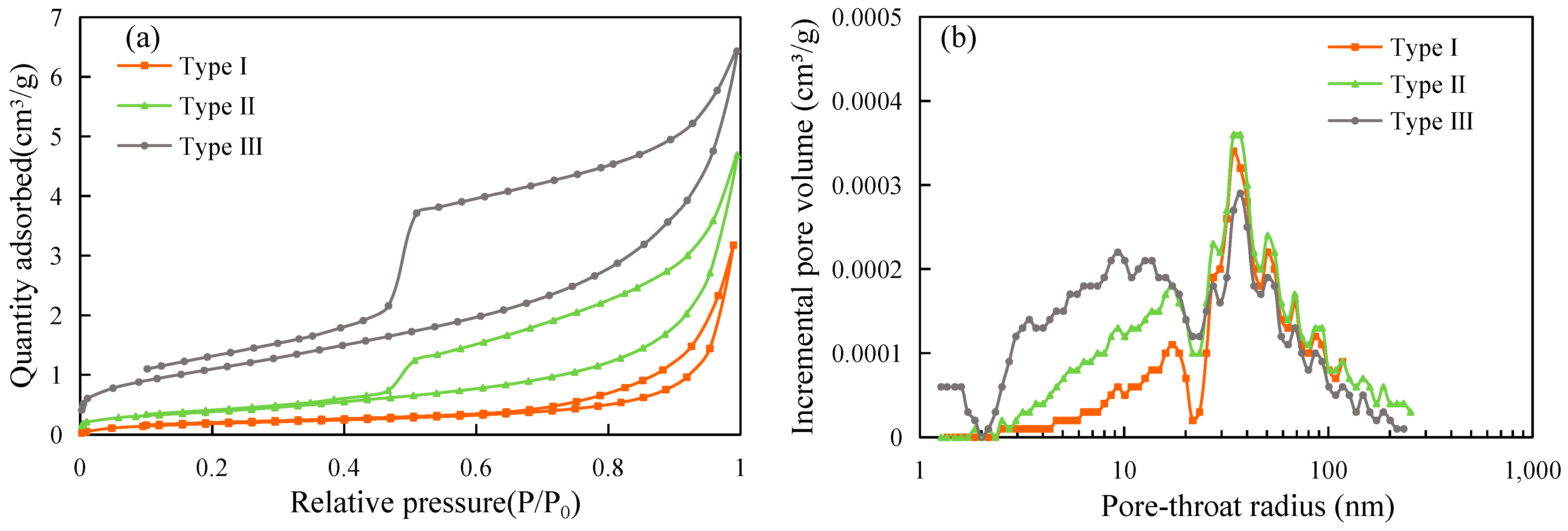

4.3.2. N2 Adsorption Isotherms

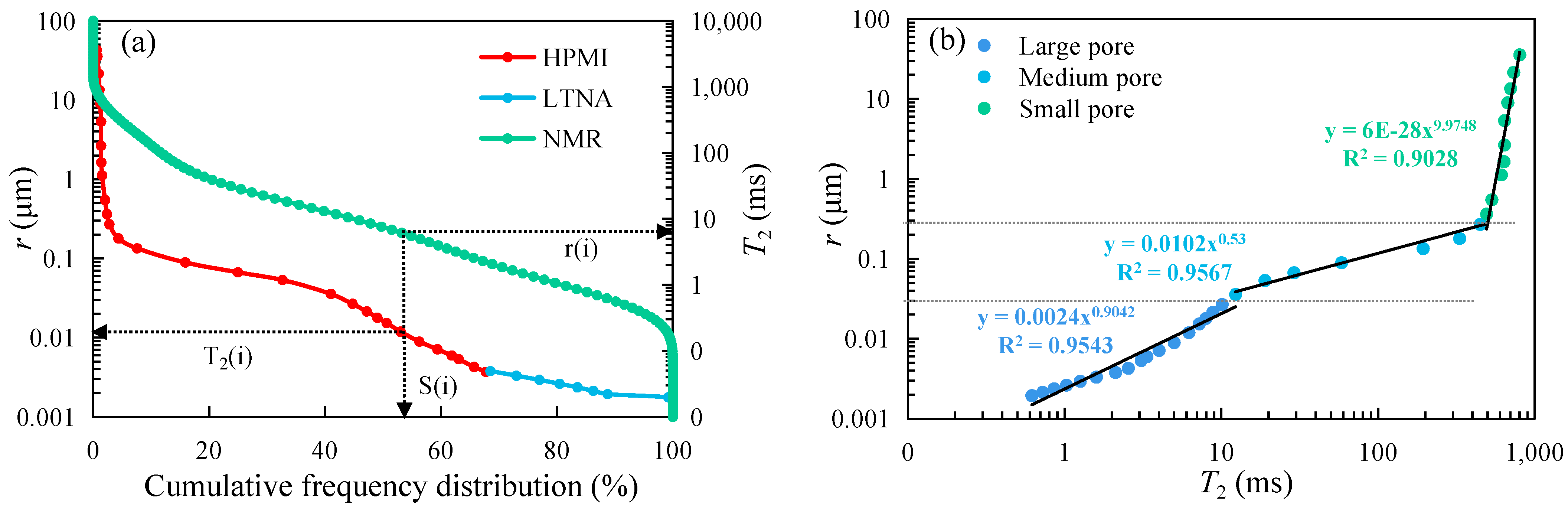

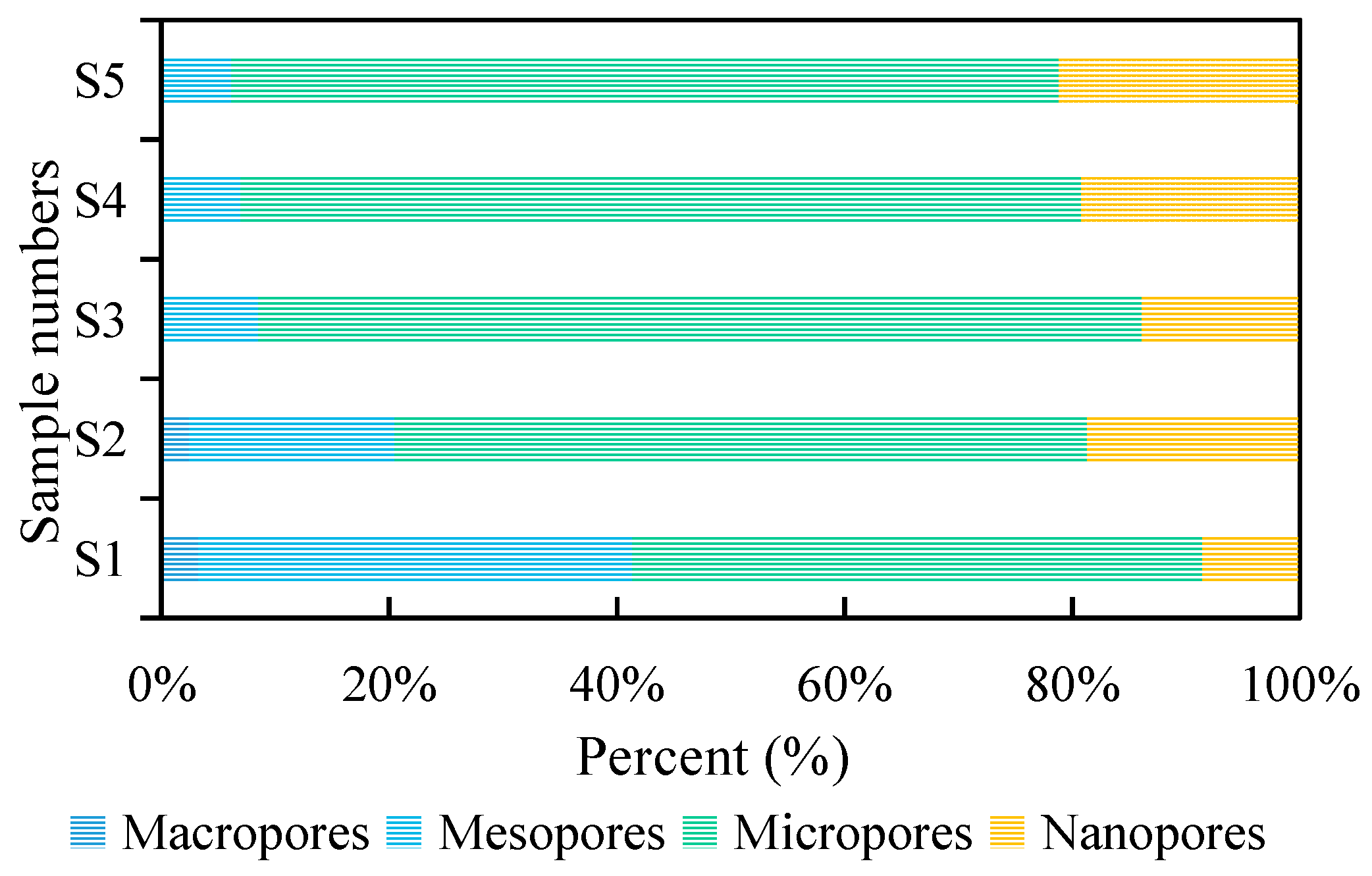

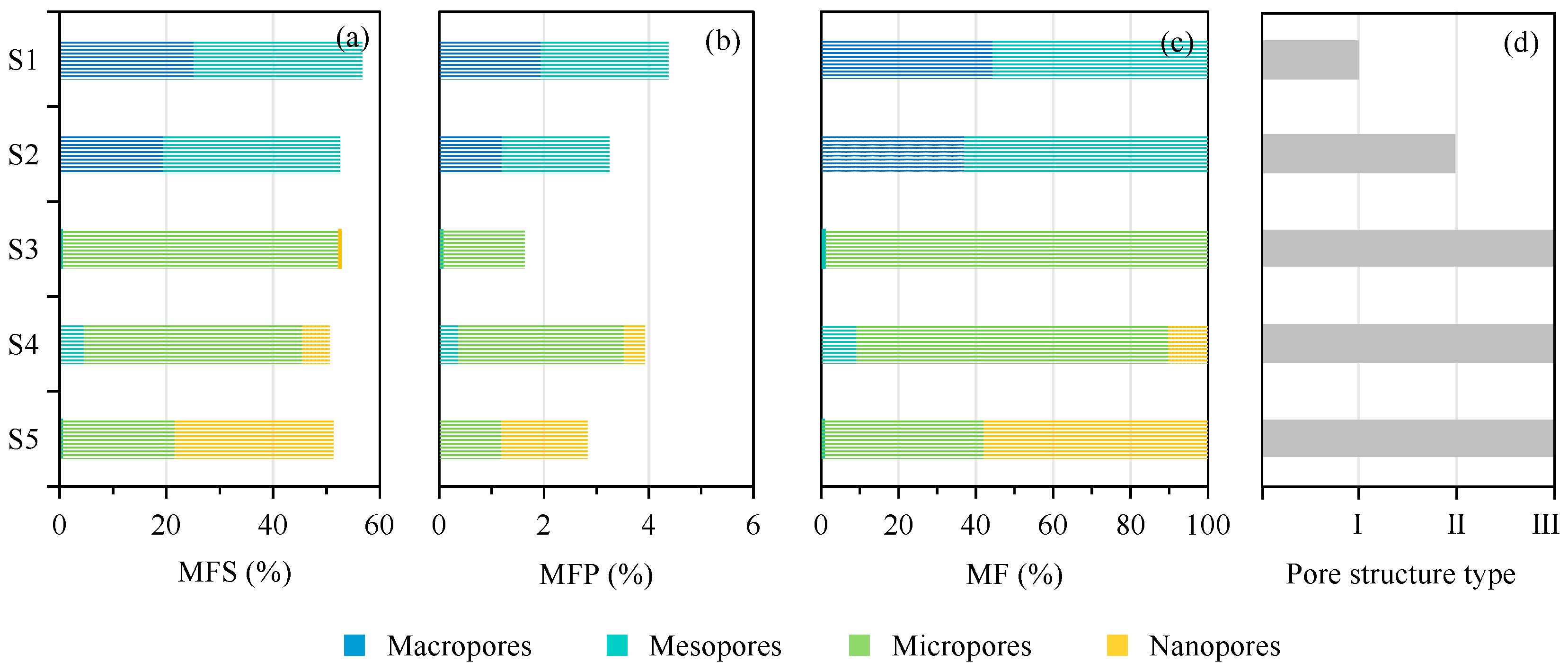

4.4. Complete Pore Dispersion on a Full Scale

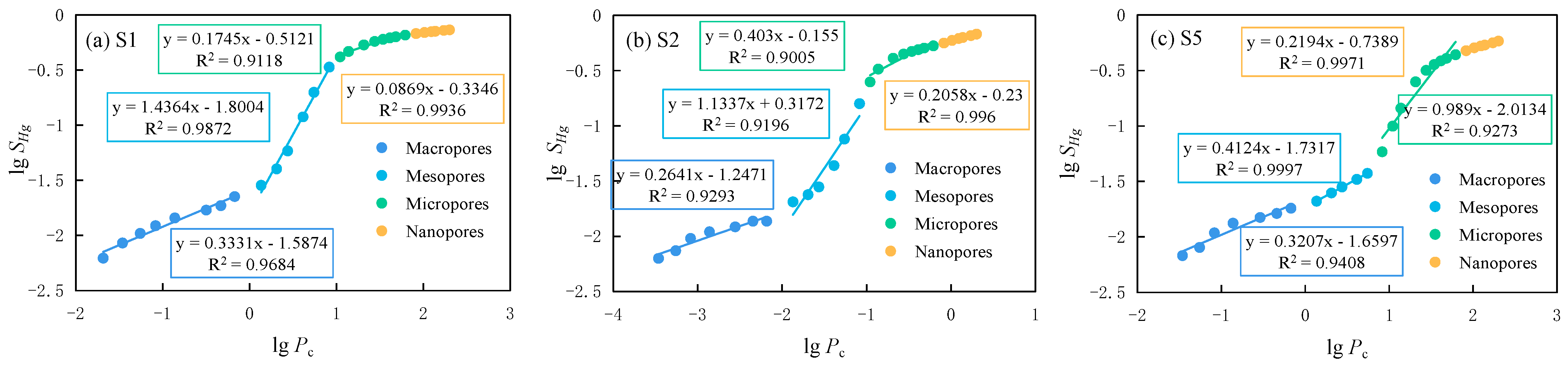

4.5. Fractal Characteristics of Pore Structure

4.6. Distribution of Mobile Fluids

5. Discussion

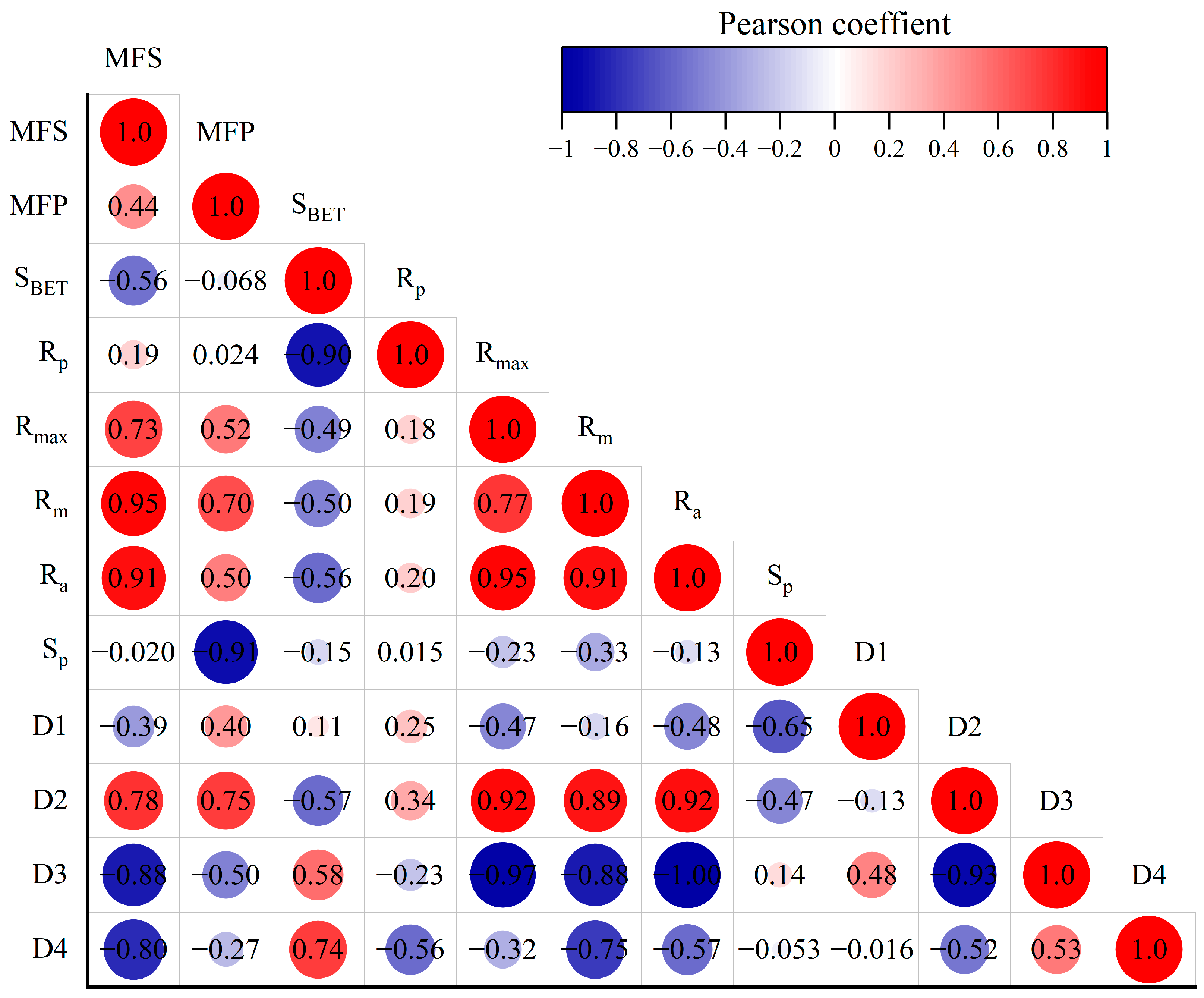

5.1. Connection between Fluid Mobility and the Pore Structures

5.2. Effect of Heterogeneity in Pore Structure on Fluid Mobility

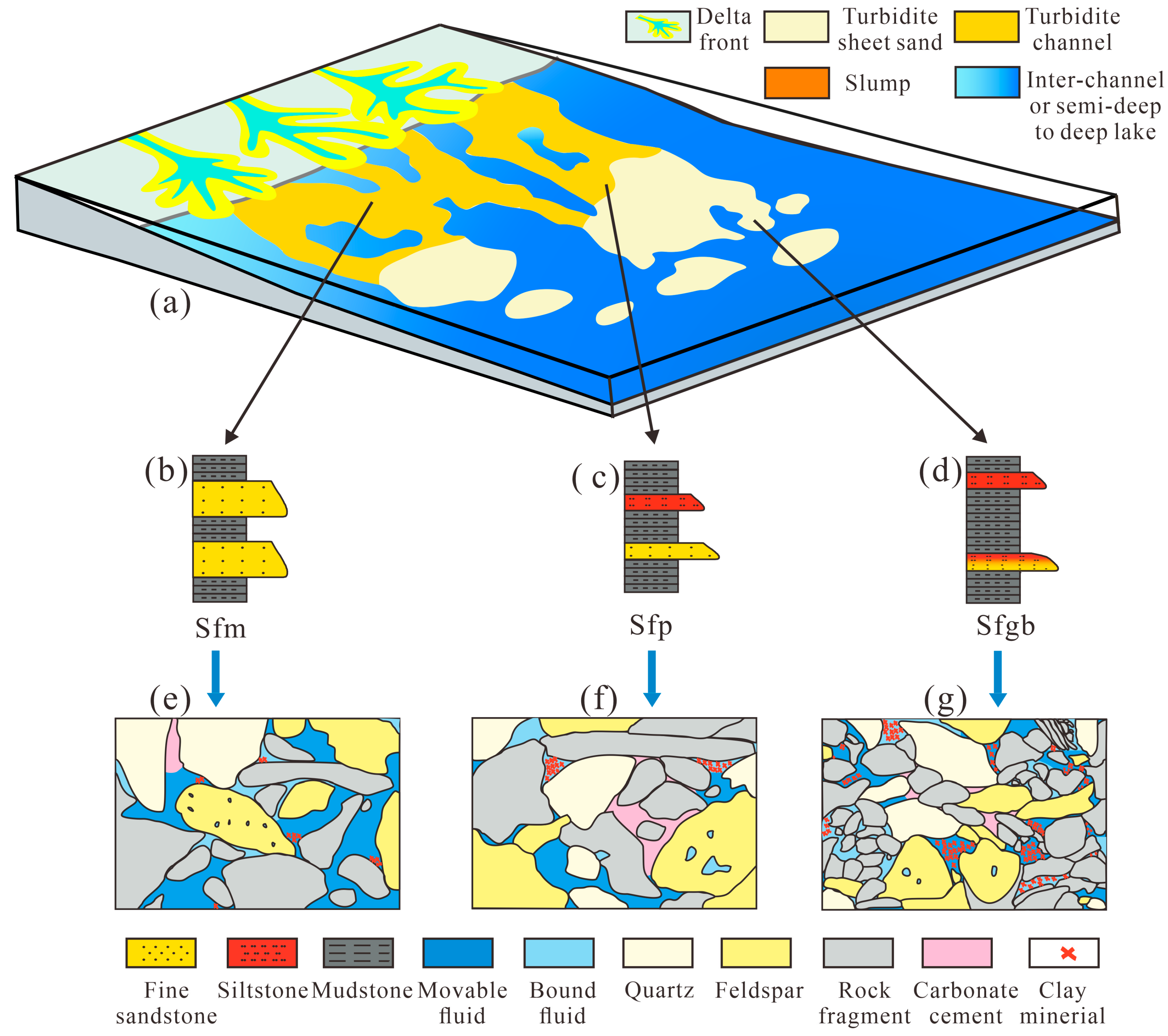

5.3. Relationships between Lithofacies and Fluid Mobility

6. Conclusions

- (1)

- Following a comprehensive examination of the pore structure in the Chang 7 shale oil reservoirs, it was observed that three distinct types exist. Type I mainly developed residual intergranular pores and feldspar dissolution pores, manifesting bimodal pore diameter curves with the highest MFS and MFP values. The curves of the pore size distribution in Type II displays unimodal characteristics indicating good pore connectivity, with higher fluid mobility. Type III is mainly dominated by dissolved pores and intercrystalline pores, showcasing an inadequate relationship in the configuration of pores, consequently leading to the lowest fluid mobility.

- (2)

- The pore structure of the Chang 7 shale oil reservoir plays a significant role in controlling fluid mobility. High fluid flowability is attributed to favorable petrophysical properties and large pores. Mesopores mainly control MFS and MFP, and micropores primarily dictate the shift from bound fluid to movable fluid. The pronounced heterogeneity of mesopores significantly impairs the fluidity of reservoir fluids.

- (3)

- The lithofacies in the Chang 7 shale oil reservoirs exhibit various fluid mobilities. The lithofacies characterized by massive fine-grained sandstone (Sfm) exhibit the highest fluid mobility due to the large proportion of macropores and mesopores. In contrast, graded bedding and silt-fine sandstone lithofacies (Sfgb) have lower fluid mobility due to the abundance of micropores. The decrease in the proportion of macropores in the parallel bedding and silt-fine sandstone (Sfp) lithofacies leads to medium fluid mobility.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sun, L.D.; Zou, C.N.; Jia, A.L.; Wei, Y.S.; Zhu, R.K.; Wu, S.T.; Guo, Z. Development Characteristics and Orientation of Tight Oil and Gas in China. Pet. Explor. Dev. 2019, 46, 1015–1026. [Google Scholar] [CrossRef]

- Pang, Y.D.; Liu, Y.L.; Zhang, L.; Xi, N.; Yuan, L.; Chen, C. Micro-Pore Structure and Fluid Mobility of Tight Sandstone Reservoirs of Chang 8 Member in Huachi Area in Ordos Basin. Pet. Geol. Oilfield Dev. Daqing 2023, 42, 1–10. [Google Scholar] [CrossRef]

- Wang, G.P.; Jin, Z.J.; Zhang, Q.; Zhu, R.; Tang, X.; Liu, K.; Dong, L. Effects of Clay Minerals and Organic Matter on Pore Evolution of the Early Mature Lacustrine Shale in the Ordos Basin, Chi-Na. J. Asian Earth Sci. 2022, 246, 105516. [Google Scholar] [CrossRef]

- Fu, J.H.; Liu, X.Y.; Li, S.X.; Guo, Q.; Zhou, X.; Yang, W. Discovery and Resource Potential of Shale Oil of Chang 7 Member, Triassic Yanchang Formation, Ordos Basin. China Pet. Explor. 2021, 26, 1–11. [Google Scholar] [CrossRef]

- Fu, J.; Niu, X.; Dan, W.; Liang, X.; Xin, H.; You, Y. The Geological Characteristics and the Progress on Exploration and Development of Shale Oil in Chang7 Member of Mesozoic Yanchang Formation, Ordos Basin. China Pet. Explor. 2019, 24, 601–614. [Google Scholar]

- Wang, Q.; Tao, S.; Guan, P. Progress in Research and Exploration & Development of Shale Oil in Continental Basins in China. Nat. Gas Geosci. 2020, 31, 417–427. [Google Scholar]

- Fu, S.; Jin, Z.; Fu, J.; Li, S.; Yang, W. Transformation of Understanding from Tight Oil to Shale Oil in the Member 7 of Yanchang Formation in Ordos Basin and Its Significance of Exploration and Development. Acta Pet. Sin. 2021, 42, 561–569. [Google Scholar]

- Xu, J.; Ge, Y.; He, Y.; Pu, R.; Liu, L.; Duan, L.; Du, K. Quantitative Characterization and Dynamic Evolution of Pore Structure in Shale Reservoirs of Chang 7 Oil Layer Group in Yanchang Area, Ordos Basin. Oil Gas Geol. 2023, 44, 292–307. [Google Scholar]

- Zang, Q.; Liu, C.; Awan, R.S.; Yang, X.; Li, G.; Wu, Y.; Lu, Z.; Feng, D. Occurrence Characteristics of the Movable Fluid in Heterogeneous Sandstone Reservoir Based on Fractal Analysis of NMR Data: A Case Study of the Chang 7 Member of Ansai Block, Ordos Basin, China. J. Pet. Sci. Eng. 2022, 214, 110499. [Google Scholar] [CrossRef]

- Zhang, Q.; Liu, Y.; Wang, B.; Ruan, J.; Yan, N.; Chen, H.; Wang, Q.; Jia, G.; Wang, R.; Liu, H.; et al. Effects of Pore-Throat Structures on the Fluid Mobility in Chang 7 Tight Sandstone Reservoirs of Longdong Area, Ordos Basin. Mar. Pet. Geol. 2022, 135, 105407. [Google Scholar] [CrossRef]

- Gao, H.; Zhou, X.; Wen, Z.; Guo, W.; Tian, W.; Li, S.; Fan, Y.; Luo, Y. Classification and Evaluation of Shale Oil Reservoirs of the Chang 71-2 Sub-Member in the Longdong Area. Energies 2022, 15, 5364. [Google Scholar] [CrossRef]

- Feng, D.; Liu, C.; Feng, X.; Wang, X.; Awan, R.S.; Yang, X.; Xu, N.; Wu, Y.; Wu, Y.; Zang, Q. Movable Fluid Evaluation of Tight Sandstone Reservoirs in Lacustrine Delta Front Setting: Occurrence Characteristics, Multiple Control Factors, and Prediction Model. Mar. Pet. Geol. 2023, 155, 106393. [Google Scholar] [CrossRef]

- Meng, Z.; Sun, W.; Liu, Y.; Luo, B.; Zhao, M. Effect of Pore Networks on the Properties of Movable Fluids in Tight Sandstones from the Perspective of Multi-Techniques. J. Pet. Sci. Eng. 2021, 201, 108449. [Google Scholar] [CrossRef]

- Wang, W.R.; Yue, D.L.; Eriksson, K.A.; Liu, X.Y.; Liang, X.W.; Qu, X.F.; Xie, Q.C. Qualitative and Quantitative Characterization of Multiple Factors That Influence Movable Fluid Saturation in Lacustrine Deep-Water Gravity-Flow Tight Sandstones from the Yanchang Formation, Southern Ordos Basin, China. Mar. Pet. Geol. 2020, 121, 104625. [Google Scholar] [CrossRef]

- Tian, W.; Lu, S.; Huang, W.; Wang, S.; Gao, Y.; Wang, W.; Li, J.; Xu, J.; Zhan, Z. Study on the Full-Range Pore Size Distribution and the Movable Oil Distribution in Glutenite. Energy Fuels 2019, 33, 7028–7042. [Google Scholar] [CrossRef]

- Zhao, X.; Yang, Z.; Lin, W.; Xiong, S.; Luo, Y.; Liu, X.; Xia, D. Fractal Study on Pore Structure of Tight Sandstone Based on Full-Scale Map. Int. J. Oil Gas Coal Technol. 2019, 22, 123–139. [Google Scholar] [CrossRef]

- Yue, Q.; Shan, X.; Zhang, X.; Xu, C.; Yi, J.; Fu, M. Quantitative Characterization, Classification, and Influencing Factors of the Full Range of Pores in Weathering Crust Volcanic Reservoirs: Case Study in Bohai Bay Basin, China. Nat. Resour. Res. 2021, 30, 1347–1365. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, G.; Torsaeter, O.; Tao, S.; Jiang, M.; Li, G.; Zhang, S. Pore-Throat Structure Characteristics and Its Effect on Flow Behavior in Gaotaizi Tight Siltstone Reservoir, Northern Songliao Basin. Mar. Pet. Geol. 2020, 122, 104651. [Google Scholar] [CrossRef]

- Wu, M.; Qin, Y.; Wang, X.; Li, G.; Zhu, C.; Zhu, S. Fluid Mobility and Its Influencing Factors of Tight Sandstone Reservoirs in China. J. Jilin Univ. Earth Sci. Ed. 2021, 51, 35–51. [Google Scholar]

- Nie, R.-S.; Zhou, J.; Chen, Z.; Liu, J.; Pan, Y. Pore Structure Characterization of Tight Sandstones via a Novel Integrated Method: A Case Study of the Sulige Gas Field, Ordos Basin (Northern China). J. Asian Earth Sci. 2021, 213, 104739. [Google Scholar] [CrossRef]

- Wang, M.; Guan, Y.; Li, C.; Liu, Y.; Liu, J.; Xu, J.; Li, Z.; Lu, S. Qualitative Description and Full-Pore-Size Quantitative Evaluation of Pores in Lacustrine Shale Reservoir of Shahejie Formation, Jiyang Depression. Oil Gas Geol. 2018, 39, 1107–1119. [Google Scholar]

- Xiao, D.; Zhao, R.; Yang, X.; Fang, D.; Li, B.; Kong, X. Characterization, Classification and Contribution of Marine Shale Gas Reservoirs. Oil Gas Geol. 2019, 40, 1215–1225. [Google Scholar]

- Zhu, R.; Wu, S.; Su, L.; Cui, J.; Mao, Z.; Zhang, X. Problems and Future Works of Porous Texture Characterization of Tight Reservoirs in China. Acta Pet. Sin. 2016, 37, 1323–1336. [Google Scholar]

- Yang, W.; Wang, Y.; Xie, M.; Li, Y.; Gao, Y.; Deng, Y.; Xu, C.; Qin, J.; Peng, S.; Yang, L.; et al. Effect of Lithofacies on Differential Movable Fluid Behaviors of Saline Lacustrine Fine-Grained Mixed Sedimentary Sequences in the Jimusar Sag, Junggar Basin, NW China: Forcing Mechanisms and Multi-Scale Models. Mar. Pet. Geol. 2023, 150, 106150. [Google Scholar] [CrossRef]

- Zeng, H.; Wang, F.; Luo, J.; Tao, T.; Wu, S. Characteristics of Pore Structure of Intersalt Shale Oil Reservoir by Low Temperature Nitrogen Adsorption and High Pressure Mercury Pressure Methods in Qianjiang Sag. Bull. Geol. Sci. Technol. 2021, 40, 242–252. [Google Scholar]

- Xu, H.; Tang, D.; Zhao, J.; Li, S. A Precise Measurement Method for Shale Porosity with Low-Field Nuclear Magnetic Resonance: A Case Study of the Carboniferous-Permian Strata in the Linxing Area, Eastern Ordos Basin, China. Fuel 2015, 143, 47–54. [Google Scholar] [CrossRef]

- Cao, S.; Li, S.; Dang, H.; Xing, H.; Zhang, L.; Zhang, T.; Bai, P. Pore Characteristics and Controlling Factors of Chang 7 Shale in Southeastern Ordos Basin. Xinjiang Pet. Geol. 2022, 43, 11–17. [Google Scholar]

- Wu, J.; Yang, S.; Gan, B.; Cao, Y.; Zhou, W.; Kou, G.; Wang, Z.; Li, Q.; Dong, W.; Zhao, B. Pore Structure and Movable Fluid Characteristics of Typical Sedimentary Lithofacies in a Tight Conglomerate Reservoir, Mahu Depression, Northwest China. ACS Omega 2021, 6, 23243–23261. [Google Scholar] [CrossRef] [PubMed]

- Bai, Y.-B.; Luo, J.-L.; Wang, S.-F.; Yang, Y.; Tang, L.-P.; Fu, X.-Y.; Zheng, H. The Distribution of Chang-8 Tight Sandstone Oil Reservoir of Yanchang Formation in Wubao Area, Central-South of Ordos Basin. Geol. China 2013, 40, 1159–1168. [Google Scholar]

- Bai, Y.B.; Zhao, J.Z.; Zhao, Z.L.; Yin, Y.Y.; Tong, J.N. Accumulation Conditions and Characteristics of the Chang 7 Tight Oil Reservoir of the the Yanchang Formation in Zhidan Area, Ordos Basin. Oil Gas Geol. 2012, 34, 22–28. [Google Scholar] [CrossRef]

- Bai, Y.B.; Luo, J.L.; Zhang, T.J.; Liu, Z.; Feng, X. Characteristics and Evaluation of Source Rocks of Yanchang Formation in Wubao Area, Ordos Basin. J. Lanzhou Univ. Sci. 2012, 48, 22–28. [Google Scholar] [CrossRef]

- Zang, Q.; Liu, C.; Awan, R.S.; Yang, X.; Lu, Z.; Li, G.; Wu, Y.; Feng, D.; Ran, Y. Comparison of Pore Size Distribution, Heterogeneity and Occurrence Characteristics of Movable Fluids of Tight Oil Reservoirs Formed in Different Sedimentary Environments: A Case Study of the Chang 7 Member of Ordos Basin, China. Nat. Resour. Res. 2022, 31, 415–442. [Google Scholar] [CrossRef]

- Xi, K.; Cao, Y.; Liu, K.; Wu, S.; Yuan, G.; Zhu, R.; Kashif, M.; Zhao, Y. Diagenesis of Tight Sandstone Reservoirs in the Upper Triassic Yanchang Formation, Southwestern Ordos Basin, China. Mar. Pet. Geol. 2019, 99, 548–562. [Google Scholar] [CrossRef]

- SY/T 6385-2016; Porosity and Permeability Measurement under Overburden Pressure. Petroleum Industry Press: Beijing, China, 2016.

- SY/T 5163-2018; Analysis Method for Clay Minerals and Ordinary Non-Clay Minerals in Sedimentary Rocks by the X-ray Diffraction. Petroleum Industry Press: Beijing, China, 2018.

- GB/T 29171-2012; Rock Capillary Pressure Measurement. China Standards Press: Beijing, China, 2012.

- GB/T 21650.2-2008; Pore Size Distribution and Porosity of Solid Materials by Mercury Porosimetry and Gas Adsorption—Part 2: Analysis of Mesopores and Macropores by Gas Adsorption. China Standards Press: Beijing, China, 2008.

- SY/T 6490-2014; Specification for Mmeasurement of Rock NMR Parameter in Laboratory. Petroleum Industry Press: Beijing, China, 2014.

- Qu, Y.; Sun, W.; Tao, R.; Luo, B.; Chen, L.; Ren, D. Pore-Throat Structure and Fractal Characteristics of Tight Sandstones in Yanchang Formation, Ordos Basin. Mar. Pet. Geol. 2020, 120, 104573. [Google Scholar] [CrossRef]

- Huang, H.; Sun, W.; Ji, W.; Zhang, R.; Du, K.; Zhang, S.; Ren, D.; Wang, Y.; Chen, L.; Zhang, X. Effects of Pore-Throat Structure on Gas Permeability in the Tight Sandstone Reservoirs of the Upper Triassic Yanchang Formation in the Western Ordos Basin, China. J. Pet. Sci. Eng. 2018, 162, 602–616. [Google Scholar] [CrossRef]

- Fang, T.; Zhang, L.K.; Liu, N.G.; Zhang, L.Q.; Wang, W.M.; Yu, L.; Li, C.; Lei, Y.H. Quantitative Characterization of Pore Structure of Tight Gas Sandstone Reservoirs by NMR T2 Spectrum Technology: A Case Study of Carboniferous-Permian Tight Sandstone Reservoir in Linqing Depression. Acta Pet. Sin. 2017, 38, 902–915. [Google Scholar] [CrossRef]

- Liu, T.; Ma, Z.; Fu, R. Analysis of Rock Pore Structure with NMR Spectra. Prog. Geophys. 2003, 18, 737–742. [Google Scholar]

- Li, J.; Yin, J.; Zhang, Y.; Lu, S.; Wang, W.; Li, J.; Chen, F.; Meng, Y. A Comparison of Experimental Methods for Describing Shale Pore Features—A Case Study in the Bohai Bay Basin of Eastern China. Int. J. Coal Geol. 2015, 152, 39–49. [Google Scholar] [CrossRef]

- Xiao, D.; Lu, S.; Lu, Z.; Huang, W.; Gu, M. Combining Nuclear Magnetic Resonance and Rate-Controlled Porosimetry to Probe the Pore-Throat Structure of Tight Sandstones. Pet. Explor. Dev. 2016, 43, 961–970. [Google Scholar] [CrossRef]

- Zhao, H.; Ning, Z.; Zhao, T.; Zhang, R.; Wang, Q. Effects of Mineralogy on Petrophysical Properties and Permeability Estimation of the Upper Triassic Yanchang Tight Oil Sandstones in Ordos Basin, Northern China. Fuel 2016, 186, 328–338. [Google Scholar] [CrossRef]

- Li, K. Analytical Derivation of Brooks-Corey Type Capillary Pressure Models Using Fractal Geometry and Evaluation of Rock Heterogeneity. J. Pet. Sci. Eng. 2010, 73, 20–26. [Google Scholar] [CrossRef]

- Wu, Y.; Liu, C.; Ouyang, S.; Luo, B.; Zhao, D.; Sun, W.; Awan, R.S.; Lu, Z.; Li, G.; Zang, Q. Investigation of Pore-Throat Structure and Fractal Characteristics of Tight Sandstones Using HPMI, CRMI, and NMR Methods: A Case Study of the Lower Shihezi Formation in the Sulige Area, Ordos Basin. J. Pet. Sci. Eng. 2022, 210, 110053. [Google Scholar] [CrossRef]

- Li, P.; Zheng, M.; Bi, H.; Wu, S.; Wang, X. Pore Throat Structure and Fractal Characteristics of Tight Oil Sandstone: A Case Study in the Ordos Basin, China. J. Pet. Sci. Eng. 2017, 149, 665–674. [Google Scholar] [CrossRef]

- Zhang, F.; Jiang, Z.; Sun, W.; Li, Y.; Zhang, X.; Zhu, L.; Wen, M. A Multiscale Comprehensive Study on Pore Structure of Tight Sandstone Reservoir Realized by Nuclear Magnetic Resonance, High Pressure Mercury Injection and Constant-Rate Mercury Injection Penetration Test. Mar. Pet. Geol. 2019, 109, 208–222. [Google Scholar] [CrossRef]

- Sing, S.W.; Everett, R.A.; Haul, L.; Moscou, N.; Pierotti, R.A.; Rouquerol, J.; France, & Siemieniewska, T. International Union of Pure and Applied Chemistry Physical Chemistry Division Commission on Colloid and Surface Chemistry including Catalysis* Reporting Physisorption Data for Gas/solid Systems with Special Reference to the Determination of Surface Area and Porosity Reporting Physisorption Data for. Available online: https://publications.iupac.org/pac/contact.html (accessed on 21 December 2023).

- Budaeva, A.D.; Zoltoev, E.V. Porous Structure and Sorption Properties of Nitrogen-Containing Activated Carbon. Fuel 2010, 89, 2623–2627. [Google Scholar] [CrossRef]

- Li, K.; Home, R. Fractal Modeling of Capillary Pressure Curves for the Geysers Rocks. Geothermics 2006, 35, 198–207. [Google Scholar] [CrossRef]

- Wang, J.; Wu, S.; Li, Q.; Guo, Q. An Investigation into Pore Structure Fractal Characteristics in Tight Oil Reservoirs: A Case Study of the Triassic Tight Sandstone with Ultra-Low Permeability in the Ordos Basin, China. Arab. J. Geosci. 2020, 13, 961. [Google Scholar] [CrossRef]

- Dou, W.; Liu, L.; Jia, L.; Xu, Z.; Wang, M.; Du, C. Pore Structure, Fractal Characteristics and Permeability Prediction of Tight Sandstones: A Case Study from Yanchang Formation, Ordos Basin, China. Mar. Pet. Geol. 2021, 123, 104737. [Google Scholar] [CrossRef]

- Lai, J.; Wang, G.; Fan, Z.; Zhou, Z.; Chen, J.; Wang, S. Fractal Analysis of Tight Shaly Sandstones Using Nuclear Magnetic Resonance Measurements. AAPG Bull. 2018, 102, 175–193. [Google Scholar] [CrossRef]

- Yang, L.; Wang, S.; Jiang, Q.; You, Y.; Gao, J. Effects of Microstructure and Rock Mineralogy on Movable Fluid Saturation in Tight Reservoirs. Energy Fuels 2020, 34, 14515–14526. [Google Scholar] [CrossRef]

- Bouma, A.H.; Kuenen, P.H.; Shepard, F.P. Sedimentology of Some Flysch Deposits: A Graphic Approach to Facies Interpretation; Elsevier: Amsterdam, The Netherlands, 1962. [Google Scholar]

- Talling, P.J.; Masson, D.G.; Sumner, E.J.; Malgesini, G. Subaqueous Sediment Density Flows: Depositional Processes and Deposit Types. Sedimentology 2012, 59, 1937–2003. [Google Scholar] [CrossRef]

| Sample ID | Well | Depth (m) | Porosity (%) | Permeability (mD) | Mineral Composition of XRD Whole-Rock Analysis (%) | Clay Composition of XRD Clay Analysis (%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Quartz | Feldspar | Calcite | Ankerite | Dolomite | Clay | Kaolinite | Chlorite | Illite | I/S | |||||

| S1 | W4223 | 1992.7 | 7.877 | 0.0618 | 41 | 26.5 | 0.6 | 0 | 11.8 | 17.6 | 3.04 | 6 | 4.42 | 4.14 |

| S2 | W4227 | 1938.6 | 5.85 | 0.0219 | 28.5 | 40.2 | 0.4 | 0 | 7.7 | 23.2 | 2.13 | 4.27 | 10.16 | 6.64 |

| S3 | W4227 | 1946.6 | 3.646 | 0.0025 | 18.1 | 19.5 | 1.7 | 47.2 | 0 | 11.2 | 0.16 | 0.26 | 6.82 | 3.96 |

| S4 | W4227 | 1961.3 | 7.298 | 0.0041 | 37.7 | 35.3 | 0.3 | 0 | 9.2 | 17.5 | 2.47 | 8.72 | 3.55 | 2.77 |

| S5 | W4227 | 1980.2 | 3.579 | 0.0024 | 15.8 | 17.4 | 0 | 0 | 1.2 | 64.1 | 2.24 | 4.1 | 37.82 | 19.94 |

| S6 | W4223 | 1987.5 | 5.83 | 0.0655 | 27.8 | 39.1 | 1.9 | 0 | 8.7 | 22.5 | 9 | 27.1 | 30.9 | 33 |

| S7 | W4223 | 2016.62 | 6.558 | 0.0217 | 34.9 | 40.3 | 1.1 | 0 | 7.7 | 14.3 | 11.8 | 37.4 | 24.5 | 26.3 |

| S8 | W4227 | 1929.66 | 3.925 | 0.003 | 22.1 | 31.2 | 30.3 | 0 | 6.3 | 10.1 | 13.5 | 34.6 | 30.7 | 21.2 |

| S9 | W4227 | 1960.13 | 5.483 | 0.0629 | 36.2 | 33.9 | 2.9 | 0 | 0.4 | 26.6 | 14.8 | 40.2 | 24.6 | 20.4 |

| S10 | W4227 | 2005.84 | 3.883 | 0.0531 | 30.6 | 29.2 | 0.9 | 0 | 1.1 | 37 | 12.3 | 28.5 | 23 | 36.2 |

| Average | 5.3929 | 0.02989 | 29.27 | 31.26 | 4.01 | 4.72 | 5.41 | 24.41 | 7.144 | 19.115 | 19.647 | 17.455 | ||

| Lithofacies and Samples | Core Photos | CTS | Lithological Characteristics |

|---|---|---|---|

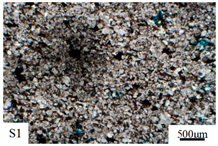

| Massive fine-grained sandstone (Sfm); (Samples: S1, S2, S7, S9, S10) |  |  | Grey, homogeneous, structureless, with low mud content; sharp contact at the lower or upper parts; high charcoal content. |

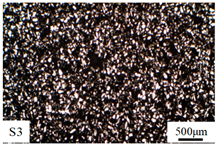

| Silt-fine sandstone with graded bedding (Sfgb); (Samples: S3, S5, S8) |  |  | Grey and grey-brown; high carbonate content or high mud content; graded bedding, the Bouma Sequence (Ta division). |

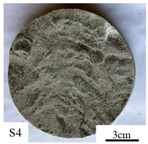

| Silt-fine sandstone with parallel bedding (Sfp); (Samples: S4, S6) |  |  | Grey-white; low mud content; parallel bedding, the Bouma Sequence (Tb division). |

| Type | Sample ID | HPMI | LTNA | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Pt (MPa) | Rmax (μm) | Ra (μm) | Rm (μm) | Smax (%) | We(%) | Sp | SBET (m2/g) | Vads (cm3/g) | Rp (nm) | ||

| I | S1 | 2.738 | 0.268 | 0.072 | 0.043 | 73.199 | 27.86 | 1.658 | 0.705 | 0.002 | 11.054 |

| S6 | 2.736 | 0.269 | 0.064 | 0.027 | 69.001 | 30.984 | 1.669 | 1.416 | 0.004 | 3.325 | |

| S9 | 2.733 | 0.269 | 0.073 | 0.03 | 64.906 | 26.548 | 1.491 | 0.764 | 0.002 | 6.483 | |

| Average | 2.736 | 0.269 | 0.07 | 0.033 | 69.035 | 28.464 | 1.606 | 0.962 | 0.003 | 6.954 | |

| II | S2 | 2.725 | 0.27 | 0.057 | 0.016 | 67.744 | 25.526 | 1.717 | 1.374 | 0.004 | 4.368 |

| S7 | 2.733 | 0.269 | 0.047 | 0.01 | 64.317 | 26.854 | 1.772 | 0.637 | 0.002 | 13.145 | |

| S10 | 4.117 | 0.179 | 0.045 | 0.017 | 60.744 | 28.361 | 1.316 | 4.427 | 0.008 | 2.669 | |

| Average | 3.191 | 0.239 | 0.05 | 0.014 | 64.268 | 26.914 | 1.602 | 2.146 | 0.004 | 6.727 | |

| III | S3 | 5.499 | 0.134 | 0.036 | 0.007 | 54.244 | 23.295 | 1.978 | 0.773 | 0.002 | 6.522 |

| S4 | 5.479 | 0.134 | 0.029 | 0.01 | 63.33 | 29.651 | 1.533 | 1.993 | 0.006 | 6.733 | |

| S5 | 5.496 | 0.134 | 0.032 | 0.007 | 58.347 | 30.605 | 1.762 | 4.092 | 0.007 | 2.772 | |

| S8 | 11.017 | 0.067 | 0.024 | 0.005 | 52.652 | 23.356 | 1.135 | 3.127 | 0.006 | 4.454 | |

| Average | 6.873 | 0.117 | 0.03 | 0.008 | 57.143 | 26.727 | 1.602 | 2.496 | 0.005 | 5.12 | |

| Sample ID | Small Pore Area | Medium Pore Area | Large Pore Area | ||||||

|---|---|---|---|---|---|---|---|---|---|

| C | n | R2 | C | n | R2 | C | n | R2 | |

| S1 | 0.0031 | 1.7963 | 0.9688 | 0.0013 | 1.0289 | 0.9985 | 7 × 10−35 | 0.0720 | 0.955 |

| S2 | 0.0024 | 1.1060 | 0.9543 | 0.0102 | 2.2287 | 0.9567 | 6 × 10−28 | 0.1003 | 0.9028 |

| S3 | 0.0011 | 1.1438 | 0.9992 | 0.002 | 1.9201 | 0.9405 | 4 × 10−39 | 0.0844 | 0.9602 |

| S4 | 0.0033 | 1.2381 | 0.998 | 0.0116 | 2.2336 | 0.9887 | 6 × 10−23 | 0.1160 | 0.9149 |

| S5 | 7 × 10−5 | 0.6598 | 0.9986 | 0.0023 | 2.2573 | 0.9992 | 3 × 10−13 | 0.2419 | 0.9772 |

| Type | Sample ID | Macropores (>1 μm) | Mesopores (0.1~1 μm) | Micropores (0.01~0.1 μm) | Nanopores (<0.01 μm) | ||||

|---|---|---|---|---|---|---|---|---|---|

| D1 | R2 | D2 | R2 | D3 | R2 | D4 | R2 | ||

| I | S1 | 2.333 | 0.968 | 3.436 | 0.987 | 2.175 | 0.912 | 2.087 | 0.994 |

| S6 | 2.344 | 0.961 | 3.056 | 0.980 | 2.394 | 0.917 | 2.114 | 0.986 | |

| S9 | 2.421 | 0.931 | 3.588 | 0.900 | 2.330 | 0.910 | 2.083 | 0.998 | |

| Average | 2.366 | 0.953 | 3.360 | 0.956 | 2.300 | 0.913 | 2.095 | 0.992 | |

| II | S2 | 2.264 | 0.929 | 3.134 | 0.920 | 2.403 | 0.901 | 2.206 | 0.996 |

| S7 | 2.311 | 0.945 | 2.851 | 0.958 | 2.623 | 0.968 | 2.236 | 0.993 | |

| S10 | 2.287 | 0.967 | 2.742 | 0.879 | 2.784 | 0.944 | 2.082 | 0.989 | |

| Average | 2.287 | 0.947 | 2.909 | 0.919 | 2.603 | 0.937 | 2.175 | 0.993 | |

| III | S3 | 2.311 | 0.958 | 2.471 | 0.951 | 2.892 | 0.905 | 2.139 | 0.993 |

| S4 | 2.559 | 0.908 | 2.758 | 0.966 | 3.020 | 0.972 | 2.177 | 0.967 | |

| S5 | 2.321 | 0.941 | 2.412 | 0.997 | 2.989 | 0.927 | 2.219 | 0.997 | |

| S8 | 2.344 | 0.957 | 2.242 | 0.993 | 3.365 | 0.937 | 2.170 | 0.988 | |

| Average | 2.384 | 0.941 | 2.471 | 0.977 | 3.067 | 0.935 | 2.176 | 0.986 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, Y.; Ye, Z.; Wang, H.; Yang, H.; Mu, N.; Ji, X.; Zhao, H. Pore Structure Characteristics of Shale Oil Reservoirs with Different Lithofacies and Their Effects on Mobility of Movable Fluids: A Case Study of the Chang 7 Member in the Ordos Basin, China. Energies 2024, 17, 862. https://doi.org/10.3390/en17040862

Xiao Y, Ye Z, Wang H, Yang H, Mu N, Ji X, Zhao H. Pore Structure Characteristics of Shale Oil Reservoirs with Different Lithofacies and Their Effects on Mobility of Movable Fluids: A Case Study of the Chang 7 Member in the Ordos Basin, China. Energies. 2024; 17(4):862. https://doi.org/10.3390/en17040862

Chicago/Turabian StyleXiao, Yufang, Zhengqin Ye, Hongliang Wang, Hailong Yang, Nana Mu, Xinyuan Ji, and He Zhao. 2024. "Pore Structure Characteristics of Shale Oil Reservoirs with Different Lithofacies and Their Effects on Mobility of Movable Fluids: A Case Study of the Chang 7 Member in the Ordos Basin, China" Energies 17, no. 4: 862. https://doi.org/10.3390/en17040862

APA StyleXiao, Y., Ye, Z., Wang, H., Yang, H., Mu, N., Ji, X., & Zhao, H. (2024). Pore Structure Characteristics of Shale Oil Reservoirs with Different Lithofacies and Their Effects on Mobility of Movable Fluids: A Case Study of the Chang 7 Member in the Ordos Basin, China. Energies, 17(4), 862. https://doi.org/10.3390/en17040862