Simulation of the Multi-Wake Evolution of Two Sandia National Labs/National Rotor Testbed Turbines Operating in a Tandem Layout

Abstract

1. Introduction

2. The Common ODE Framework (CODEF)

2.1. Blade Structure Model

2.2. Rotor Flow Model

2.3. Farm-Flow Model

3. Numerical Experiments and Analysis of Results

3.1. Aeroelastic Response of the SNL-NRT Rotor Operating in a Waked Condition

3.2. Twin-Turbine Wake Characteristics of the SNL-NRT Rotor Operating in a Tandem Layout

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Dykes, K.L.; Veers, P.S.; Lantz, E.J.; Holttinen, H.; Carlson, O.; Tuohy, A.; Sempreviva, A.M.; Clifton, A.; Rodrigo, J.S.; Berry, D.S.; et al. IEA Wind TCP: Results of IEA Wind TCP Workshop on a Grand Vision for Wind Energy Technology; Technical Report NREL/TP-5000-72437; National Renewable Energy Laboratory: Golden, CO, USA, 2019. [Google Scholar]

- Veers, P.; Dykes, K.; Lantz, E.; Barth, S.; Bottasso, C.L.; Carlson, O.; Clifton, A.; Green, J.; Green, P.; Holttinen, H.; et al. Grand challenges in the science of wind energy. Science 2019, 366, eaau2027. [Google Scholar] [CrossRef]

- Meneveau, C. Big wind power: Seven questions for turbulence research. J. Turbul. 2019, 20, 2–20. [Google Scholar] [CrossRef]

- IEC. Wind Turbine Generator Systems—Part 1: Design Requirements; Technical Report IEC 61400-1:2019; International Electrotechnical Commission (IEC): Geneva, Switzerland, 2019. [Google Scholar]

- Gebraad, P.M.; Teeuwisse, F.W.; Van Wingerden, J.; Fleming, P.A.; Ruben, S.D.; Marden, J.R.; Pao, L.Y. Wind plant power optimization through yaw control using a parametric model for wake effects—A CFD simulation study. Wind Energy 2016, 19, 95–114. [Google Scholar] [CrossRef]

- Ekaterinaris, J.A. Numerical simulation of incompressible two-blade rotor flowfields. J. Propuls. Power 1998, 14, 367–374. [Google Scholar] [CrossRef]

- Duque, E.; Van Dam, C.; Hughes, S. Navier-Stokes simulations of the NREL combined experiment phase II rotor. In Proceedings of the 37th Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 11–14 January 1999; p. 37. [Google Scholar]

- Sorensen, N. Aerodynamic predictions for the unsteady aerodynamics experiment phase-II rotor at the National Renewable Energy Laboratory. In Proceedings of the 2000 ASME Wind Energy Symposium, Reno, NV, USA, 10–13 January 2000; p. 37. [Google Scholar]

- Hansen, M.; Sorensen, J.; Michelsen, J.; Sorensen, N.; Hansen, M.; Sorensen, J.; Michelsen, J.; Sorensen, N. A global Navier-Stokes rotor prediction model. In Proceedings of the 35th Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 6–9 January 1997; p. 970. [Google Scholar]

- Maronga, B.; Gryschka, M.; Heinze, R.; Hoffmann, F.; Kanani-Sühring, F.; Keck, M.; Ketelsen, K.; Letzel, M.O.; Sühring, M.; Raasch, S. The Parallelized Large-Eddy Simulation Model (PALM) version 4.0 for atmospheric and oceanic flows: Model formulation, recent developments, and future perspectives. Geosci. Model Dev. 2015, 8, 2515–2551. [Google Scholar] [CrossRef]

- Churchfield, M.; Lee, S.; Moriarty, P.; Martinez, L.; Leonardi, S.; Vijayakumar, G.; Brasseur, J. A large-eddy simulation of wind-plant aerodynamics. In Proceedings of the 50th AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exposition, Nashville, TN, USA, 9–12 January 2012; p. 537. [Google Scholar]

- Domino, S. Sierra Low Mach Module: Nalu Theory Manual 1.0; Sandia National Laboratories: Albuquerque, NM, USA, 2015. [Google Scholar]

- Sprague, M.A.; Ananthan, S.; Vijayakumar, G.; Robinson, M. ExaWind: A multifidelity modeling and simulation environment for wind energy. J. Phys. Conf. Ser. 2020, 1452, 012071. [Google Scholar] [CrossRef]

- Van Bussel, G.J. The Aerodynamics of Horizontal Axis Wind Turbine Rotors Explored with Asymptotic Expansion Methods. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 1995. [Google Scholar]

- Doubrawa, P.; Quon, E.W.; Martinez-Tossas, L.A.; Shaler, K.; Debnath, M.; Hamilton, N.; Herges, T.G.; Maniaci, D.; Kelley, C.L.; Hsieh, A.S.; et al. Multimodel validation of single wakes in neutral and stratified atmospheric conditions. Wind Energy 2020, 23, 2027–2055. [Google Scholar] [CrossRef]

- Lignarolo, L.E.; Mehta, D.; Stevens, R.J.; Yilmaz, A.E.; van Kuik, G.; Andersen, S.J.; Meneveau, C.; Ferreira, C.J.; Ragni, D.; Meyers, J.; et al. Validation of four LES and a vortex model against stereo-PIV measurements in the near wake of an actuator disc and a wind turbine. Renew. Energy 2016, 94, 510–523. [Google Scholar] [CrossRef]

- Manwell, J.F.; McGowan, J.G.; Rogers, A.L. Wind Energy Explained: Theory, Design and Application; Wiley: Chichester, UK, 2009. [Google Scholar]

- Burton, T.; Sharpe, D.; Jenkins, N.; Bossanyi, E. Wind Energy Handbook; Wiley: Chichester, UK, 2001. [Google Scholar]

- Ponta, F.L.; Otero, A.D.; Lago, L.I.; Rajan, A. Effects of rotor deformation in wind-turbine performance: The Dynamic Rotor Deformation Blade Element Momentum model (DRD–BEM). Renew. Energy 2016, 92, 157–170. [Google Scholar] [CrossRef]

- Hodges, D.H. Nonlinear Composite Beam Theory; AIAA: Reston, VA, USA, 2006. [Google Scholar]

- Yu, W.; Hodges, D.H.; Volovoi, V.; Cesnik, C.E.S. On Timoshenko-like modeling of initially curved and twisted composite beams. Int. J. Sol. Struct. 2002, 39, 5101–5121. [Google Scholar] [CrossRef]

- Otero, A.D.; Ponta, F.L. Structural Analysis of Wind-Turbine Blades by a Generalized Timoshenko Beam Model. J. Sol. Energy Eng. 2010, 132, 011015. [Google Scholar] [CrossRef]

- Baruah, A.; Ponta, F. Analysis of Wind Turbine Wake Dynamics by a Gaussian-Core Vortex Lattice Technique. Dynamics 2024, 4, 97–118. [Google Scholar] [CrossRef]

- Herges, T.; Maniaci, D.C.; Naughton, B.T.; Mikkelsen, T.; Sjöholm, M. High resolution wind turbine wake measurements with a scanning lidar. J. Phys. Conf. Ser. 2017, 854, 012021. [Google Scholar] [CrossRef]

- Batchelor, G.K. An Introduction to Fluid Dynamics; Cambridge University Press: Cambridge, UK, 2000. [Google Scholar]

- Ponta, F.L.; Jacovkis, P.M. A vortex model for Darrieus turbine using finite element techniques. Renew. Energy 2001, 24, 1–18. [Google Scholar] [CrossRef]

- Ponta, F.L. Vortex decay in the Kármán eddy street. Phys. Fluids 2010, 22, 093601. [Google Scholar] [CrossRef]

- Strickland, J.H.; Webster, B.T.; Nguyen, T. A Vortex Model of the Darrieus Turbine: An Analytical and Experimental Study. J. Fluids Eng. 1979, 101, 500–505. [Google Scholar] [CrossRef]

- Cottet, G.H.; Koumoutsakos, P.D. Vortex Methods: Theory and Practice; Cambridge University Press: London, UK, 2000. [Google Scholar]

- Karamcheti, K. Principles of Ideal-Fluid Aerodynamics; Wiley: New York, NY, USA, 1966. [Google Scholar]

- Lamb, H. Hydrodynamics, 6th ed.; Cambridge University Press: Cambridge, UK, 1932. [Google Scholar]

- Trieling, R.R.; van Wesenbeeck, J.M.A.; van Heijst, G.J.F. Dipolar vortices in a strain flow. Phys. Fluids 1998, 10, 144–159. [Google Scholar] [CrossRef]

- Flór, J.B.; van Heijst, G.J.F. An experimental study of dipolar structures in a stratified fluid. J. Fluid Mech. 1994, 279, 101–133. [Google Scholar] [CrossRef]

- Hooker, S.G. On the action of viscosity in increasing the spacing ration of a vortex street. Proc. R. Soc. Lond. 1936, 154, 67–89. [Google Scholar]

- Kelley, C.L. Aerodynamic Design of the National Rotor Testbed; Technical Report SAND2015-8989; Sandia National Lab.: Albuquerque, NM, USA, 2015. [Google Scholar]

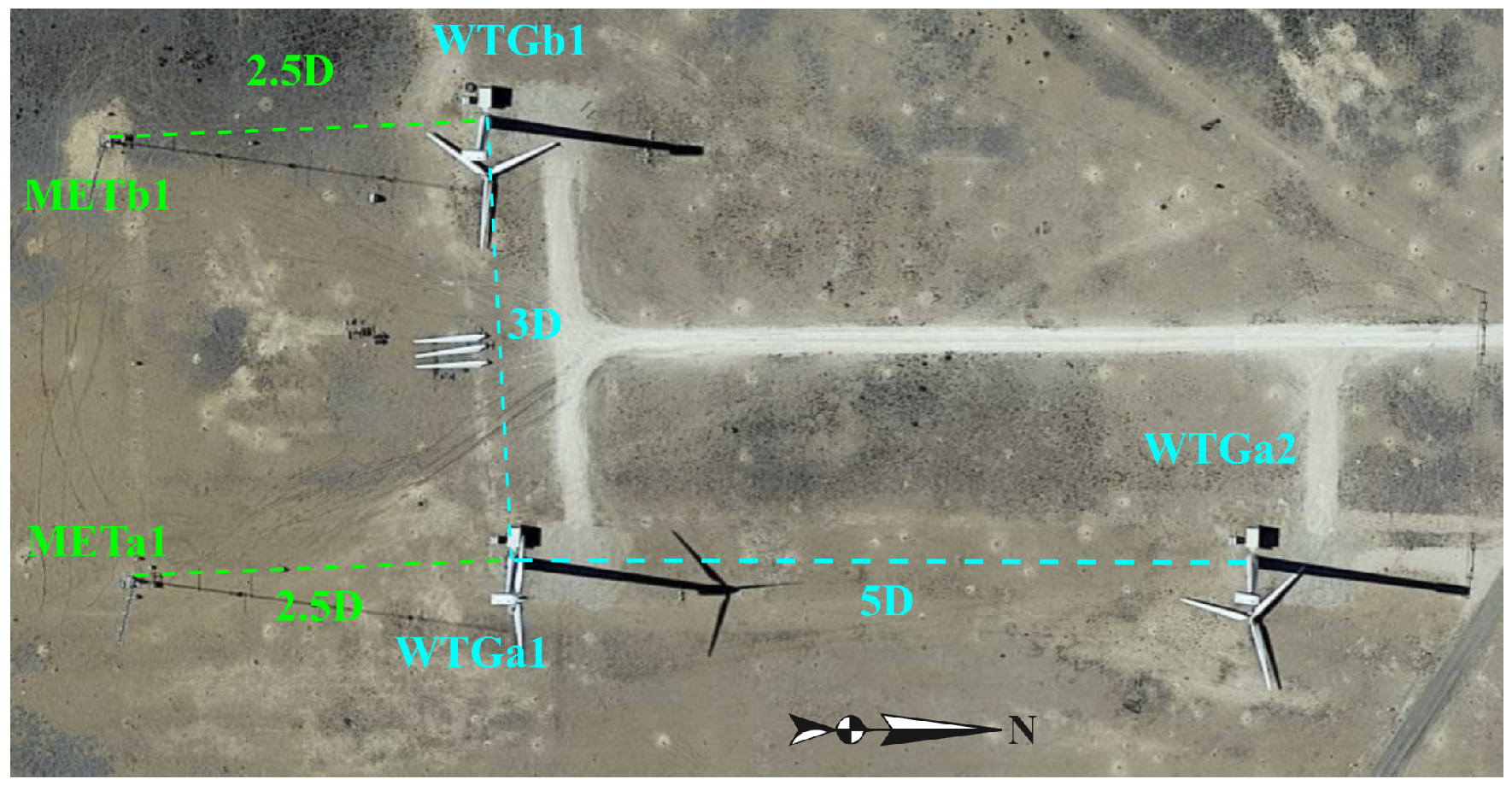

- Berg, J.; Bryant, J.; LeBlanc, B.; Maniaci, D.C.; Naughton, B.; Paquette, J.A.; Resor, B.R.; White, J.; Kroeker, D. Scaled wind farm technology facility overview. In Proceedings of the 32nd ASME Wind Energy Symposium, National Harbor, MD, USA, 13–17 January 2014; p. 1088. [Google Scholar]

- Kelley, C.; Naughton, B. Surface Meteorological Station—SWiFT Southwest—METa1—Reviewed Data. 2021. Available online: https://www.osti.gov/biblio/1349888 (accessed on 10 December 2023).

- Kelley, C.; Naughton, B. Lidar—DTU SpinnerLidar—Reviewed Data. 2021. Available online: https://www.osti.gov/biblio/1349890 (accessed on 10 December 2023).

- Barone, M.F.; White, J. DOE/SNL-TTU Scaled wind Farm Technology Facility; Technical Report SAND2011-6522; Sandia National Lab.: Albuquerque, NM, USA, 2011. [Google Scholar]

- Jonkman, J.; Butterfield, S.; Musial, W.; Scott, G. Definition of a 5-MW Reference Wind Turbine for Offshore System Development; Technical Report NREL/TP-500-38060; National Renewable Energy Laboratory: Golden, CO, USA, 2009. [Google Scholar]

- Su, K.; Bliss, D. A numerical study of tilt-based wake steering using a hybrid free-wake method. Wind Energy 2020, 23, 258–273. [Google Scholar] [CrossRef]

- Porté-Agel, F.; Bastankhah, M.; Shamsoddin, S. Wind-Turbine and Wind-Farm Flows: A Review. Bound.-Layer Meteorol. 2020, 174, 1–59. [Google Scholar] [CrossRef]

- Abkar, M.; Sørensen, J.N.; Porté-Agel, F. An Analytical Model for the Effect of Vertical Wind Veer on Wind Turbine Wakes. Energies 2018, 11, 1838. [Google Scholar] [CrossRef]

- Ponta, F.L.; Aref, H. Numerical experiments on vortex shedding from an oscillating cylinder. J. Fluids Struct. 2006, 22, 327–344. [Google Scholar] [CrossRef]

- Williamson, C.H.K.; Roshko, A. Vortex formation in the wake of an oscillating cylinder. J. Fluids Struct. 1988, 2, 355–381. [Google Scholar] [CrossRef]

- Williamson, C.H.K.; Prasad, A. A new mechanism for oblique wave resonance in the natural far wake. J. Fluid Mech. 1993, 256, 269–313. [Google Scholar] [CrossRef]

- Govardhan, R.; Williamson, C.H.K. Modes of vortex formation and frequency response of a freely vibrating cylinder. J. Fluid Mech. 2000, 420, 85–130. [Google Scholar] [CrossRef]

- Griffin, O.M.; Ramberg, S.E. The vortex street wakes of vibrating cylinders. J. Fluid Mech. 1974, 66, 553–576. [Google Scholar] [CrossRef]

- Meneghini, J.R.; Bearman, P.W. Numerical simulation of high amplitude oscillatory flow about a circular cylinder. J. Fluids Struct. 1995, 9, 435–455. [Google Scholar] [CrossRef]

- Aref, H.; Siggia, E. Evolution and breakdown of a vortex street in two dimensions. J. Fluid Mech. 1981, 109, 435–463. [Google Scholar] [CrossRef]

- Cimbala, J.M.; Nagib, H.M.; Roshko, A. Large structure in the far wakes of two-dimensional bluff bodies. J. Fluid Mech. 1988, 190, 265–298. [Google Scholar] [CrossRef]

- Inoue, O.; Yamazaki, T. Secondary vortex streets in Two-dimensional cylinder wakes. Fluid Dyn. Res. 1999, 25, 1–18. [Google Scholar] [CrossRef]

- Matsui, T.; Okude, M. Formation of the secondary vortex street in the wake of a circular cylinder. In Proceedings of the IUTAM Symposium on Structures of Compressible Turbulent Shear Flows, Marseille, France, 31 August–3 September 1983; Springer: Berlin/Heidelberg, Germany, 1983; pp. 156–164. [Google Scholar]

- Meiburg, E. On the role of subharmonic perturbations in the far wake. J. Fluid Mech. 1987, 177, 83–107. [Google Scholar] [CrossRef]

- Taneda, S. Downstream development of the wakes behind cylinders. J. Phys. Soc. Jpn. 1959, 14, 843–848. [Google Scholar] [CrossRef]

- Ponta, F.L.; Aref, H. Vortex synchronization regions in shedding from an oscillating cylinder. Phys. Fluids 2005, 17, 011703. [Google Scholar] [CrossRef]

| Scenario | Wind Speed [m/s] | Alpha | TSR | Yaw Offset [deg] |

|---|---|---|---|---|

| NRTD1 | 6 | 0.06 | 9 | 0° |

| NRTD2 | 6 | 0.06 | 9 | 10° |

| NRTN1 | 6 | 0.30 | 9 | 0° |

| NRTN2 | 6 | 0.30 | 9 | 10° |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baruah, A.; Ponta, F.; Farrell, A. Simulation of the Multi-Wake Evolution of Two Sandia National Labs/National Rotor Testbed Turbines Operating in a Tandem Layout. Energies 2024, 17, 1000. https://doi.org/10.3390/en17051000

Baruah A, Ponta F, Farrell A. Simulation of the Multi-Wake Evolution of Two Sandia National Labs/National Rotor Testbed Turbines Operating in a Tandem Layout. Energies. 2024; 17(5):1000. https://doi.org/10.3390/en17051000

Chicago/Turabian StyleBaruah, Apurva, Fernando Ponta, and Alayna Farrell. 2024. "Simulation of the Multi-Wake Evolution of Two Sandia National Labs/National Rotor Testbed Turbines Operating in a Tandem Layout" Energies 17, no. 5: 1000. https://doi.org/10.3390/en17051000

APA StyleBaruah, A., Ponta, F., & Farrell, A. (2024). Simulation of the Multi-Wake Evolution of Two Sandia National Labs/National Rotor Testbed Turbines Operating in a Tandem Layout. Energies, 17(5), 1000. https://doi.org/10.3390/en17051000