Micro Photosynthetic Power Cell Array for Energy Harvesting: Bio-Inspired Modeling, Testing and Verification

Abstract

1. Introduction

2. µPSC Operation and Fabrication

3. µPSC Fabrication

4. Modeling the Electrical Equivalent Circuit of a Single µ-PSC

| R | Universal gas constant (8.31447 J/mol-K) |

| T | Operating temperature (Room temperature, (298.15 K) |

| F | Faraday’s constant (96,486 C/mol) |

| n | Number of transferred electrons/reactions (4 mol) |

| Limiting current density (0.1818 mA/cm2) | |

| Equilibrium exchange current density (10−8 A/cm2) | |

| Ohmic resistance (Ω) |

5. Modeling Array Configurations of µ-PSCs

5.1. SA6 Configuration

5.2. PA6 Configuration

5.3. Combinatory Configuration (CC-1)

5.4. Combinatory Configuration (CC-2)

6. Results and Discussion

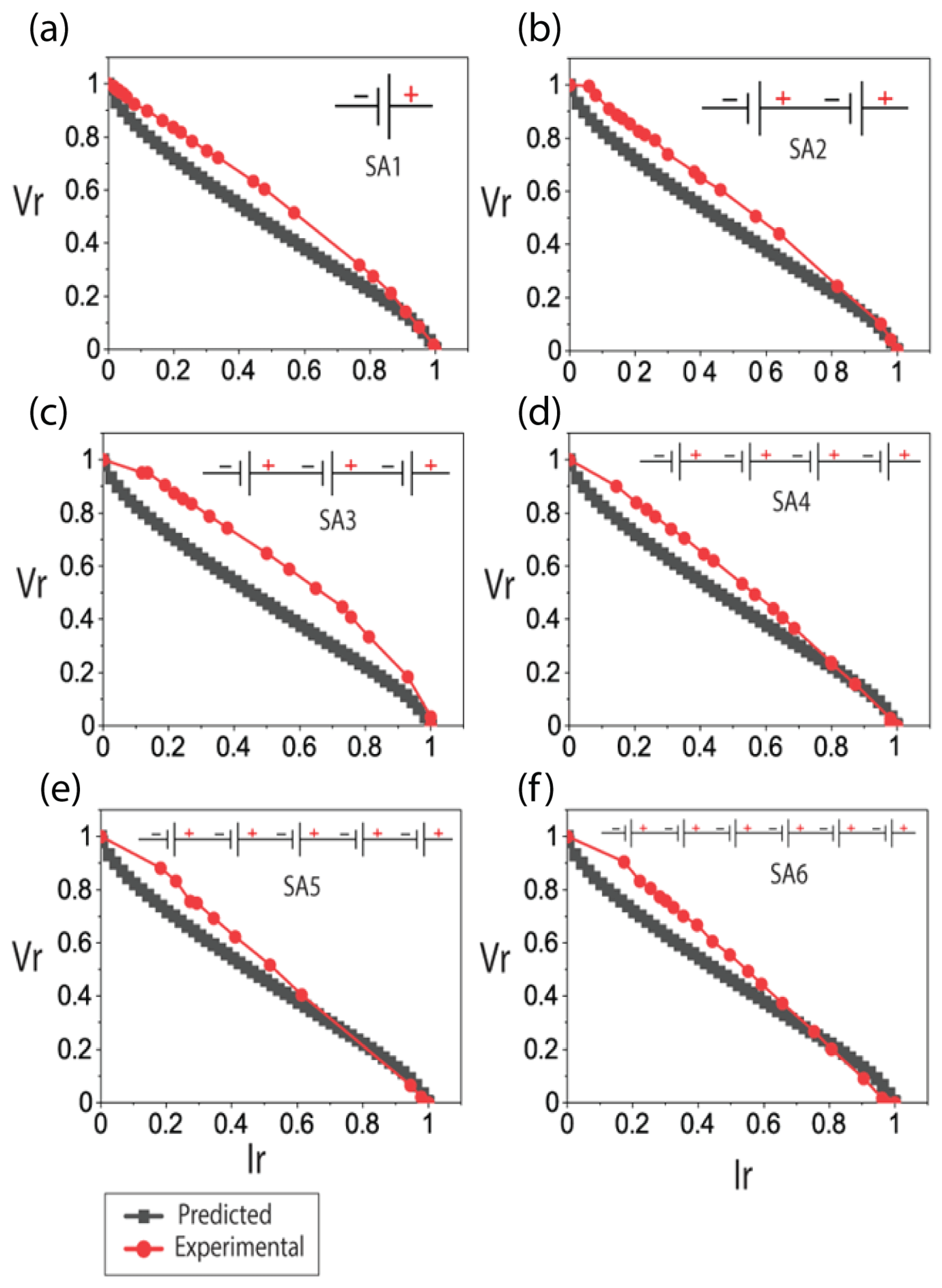

6.1. Polarization (I-V) Characteristics of SA6 Configuration

6.2. Polarization (I-V) Characteristics of PA6 Configuration

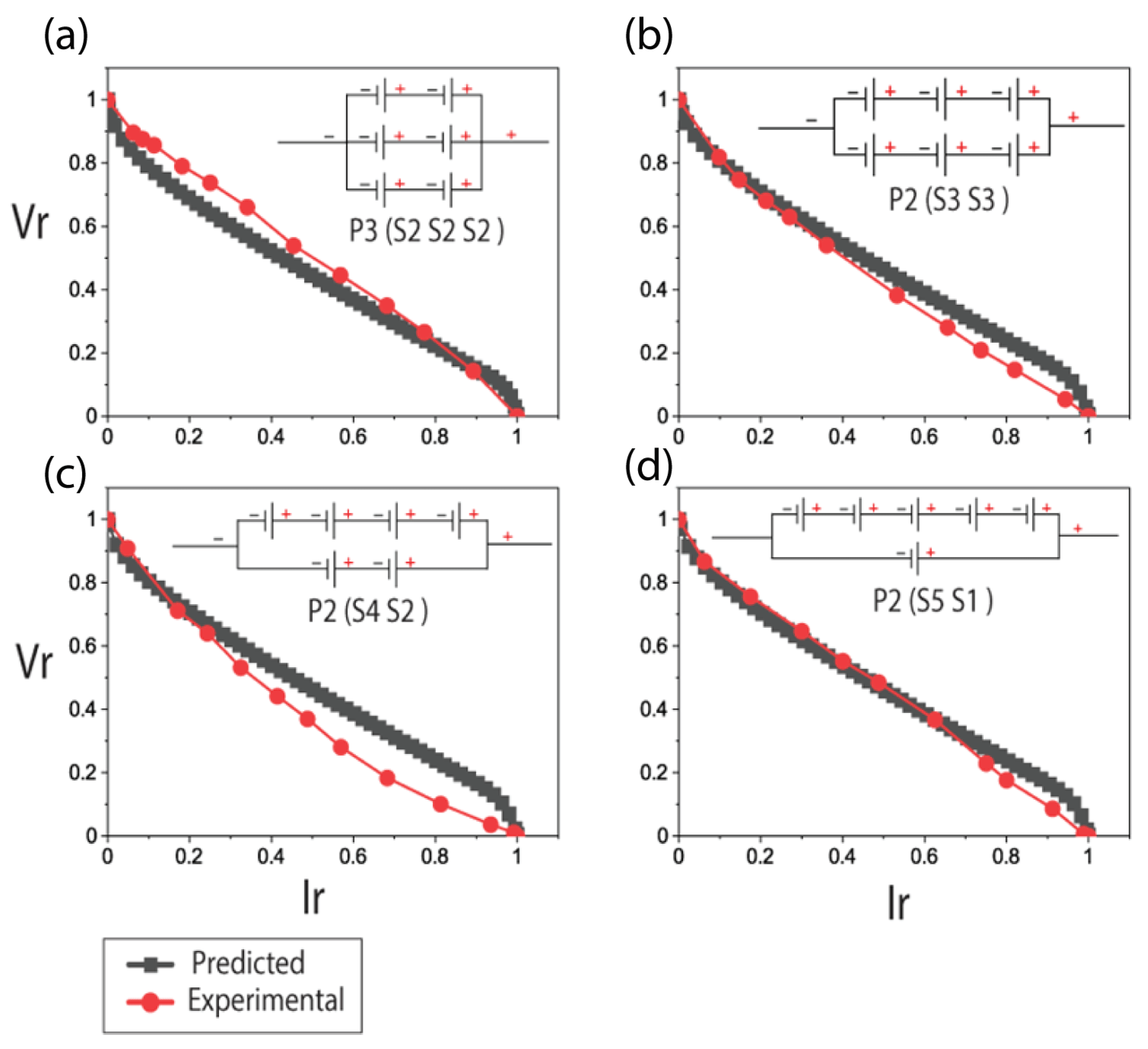

6.3. Polarization (I-V) Characteristics of CC-1 Configuration

6.4. Polarization (I-V) Characteristics of CC-2 Configuration

6.5. I-P Characteristics

6.6. I-P Characteristics of SA6 Configuration

6.7. I-P Characteristics of PA6 Configuration

6.8. I-P Characteristics of CC-1 Configuration

6.9. I-P Characteristics of CC-2 Configuration

6.10. Variation of Open-Circuit Voltage (Voc), Short Circuit Current (Isc), Load Voltage (VL), and Load Current (IL)

6.10.1. Variation of Open-Circuit Voltage (Voc)

6.10.2. Variation of Short Circuit Current (Isc)

6.10.3. Variation of Load Voltage (VL) and Current (IL) at 1 kΩ

6.10.4. Variation of Maximum Power (Pmp) of Array Configurations

6.11. Fill Factor (FF)

7. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dresselhaus, M.S.; Thomas, I.L. Alternative energy technologies. Nature 2001, 414, 332–337. [Google Scholar] [CrossRef] [PubMed]

- Kuruvinashetti, K.; Guoqing, G.; Haobin, J.; Packirisamy, M. Perspective—Application of Micro Photosynthetic Power Cells for IoT in Automotive Industry. J. Electrochem. Soc. 2020, 167, 037545. [Google Scholar] [CrossRef]

- Tanneru, H.K.; Kuruvinashetti, K.; Pillay, P.; Rengaswamy, R.; Packirisamy, M. Perspective—Micro photosynthetic power cells. J. Electrochem. Soc. 2019, 166, B3012. [Google Scholar] [CrossRef]

- Saar, K.L.; Bombelli, P.; Lea-Smith, D.J.; Call, T.; Aro, E.M.; Müller, T.; Howe, C.J.; Knowles, T.P. Enhancing power density of biophotovoltaics by decoupling storage and power delivery. Nat. Energy 2018, 3, 75–81. [Google Scholar] [CrossRef]

- Sawa, M.; Fantuzzi, A.; Bombelli, P.; Howe, C.J.; Hellgardt, K.; Nixon, P.J. Electricity generation from digitally printed cyanobacteria. Nat. Commun. 2017, 8, 1327. [Google Scholar] [CrossRef]

- Bombelli, P.; Müller, T.; Herling, T.W.; Howe, C.J.; Knowles, T.P.J. A High Power-Density, Mediator-Free, Microfluidic Biophotovoltaic Device for Cyanobacterial Cells. Adv. Energy Mater. 2015, 5, 1401299. [Google Scholar] [CrossRef]

- McCormick, A.J.; Bombelli, P.; Bradley, R.W.; Thorne, R.; Wenzel, T.; Howe, C.J. Biophotovoltaics: Oxygenic photosynthetic organisms in the world of bioelectrochemical systems. Energy Environ. Sci. 2015, 8, 1092–1109. [Google Scholar] [CrossRef]

- Ramanan, A.V.; Pakirisamy, M.; Williamson, S.S. Advanced Fabrication, Modeling, and Testing of a Microphotosynthetic Electrochemical Cell for Energy Harvesting Applications. IEEE Trans. Power Electron. 2015, 30, 1275–1285. [Google Scholar] [CrossRef]

- Ravi, S.K.; Yu, Z.; Swainsbury, D.J.; Ouyang, J.; Jones, M.R.; Tan, S.C. Enhanced output from biohybrid photoelectrochemical transparent tandem cells integrating photosynthetic proteins genetically modified for expanded solar energy harvesting. Adv. Energy Mater. 2017, 7, 1601821. [Google Scholar] [CrossRef]

- Driver, A.; Bombelli, P. Biophotovoltaics. Catalyst. 2011, 13–15. [Google Scholar]

- Bradley, R.W.; Bombelli, P.; Rowden, S.J.; Howe, C.J. Biological photovoltaics: Intra-and extra-cellular electron transport by cyanobacteria. Biochem. Soc. Trans. 2012, 40, 1302–1307. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Gobeze, H.B.; D’Souza, F.; Jankowiak, R.; Li, J. Plasmonic enhancement of biosolar cells employing light harvesting complex II incorporated with core–shell metal@ TiO2 nanoparticles. Adv. Mater. Interfaces 2016, 3, 1600371. [Google Scholar] [CrossRef]

- Robinson, M.T.; Armbruster, M.E.; Gargye, A.; Cliffel, D.E.; Jennings, G.K. Photosystem I multilayer films for photovoltage enhancement in natural dye-sensitized solar cells. ACS Appl. Energy Mater. 2018, 1, 301–305. [Google Scholar]

- Wey, L.T.; Bombelli, P.; Chen, X.; Lawrence, J.M.; Rabideau, C.M.; Rowden, S.J.; Zhang, J.Z.; Howe, C.J. The development of biophotovoltaic systems for power generation and biological analysis. ChemElectroChem 2019, 6, 5375–5386. [Google Scholar] [CrossRef] [PubMed]

- Kuruvinashetti, K.; Pakkiriswami, S.; Packirisamy, M. Gold Nanoparticle interaction in algae enhancing quantum efficiency and power generation in microphotosynthetic power cells. Adv. Energy Sustain. Res. 2022, 3, 2100135. [Google Scholar] [CrossRef]

- Lam, K.B.; Irwin, E.F.; Healy, K.E.; Lin, L. Bioelectrocatalytic self-assembled thylakoids for micro-power and sensing applications. Sens. Actuators B Chem. 2006, 117, 480–487. [Google Scholar] [CrossRef]

- Firoozabadi, H.; Mardanpour, M.M.; Motamedian, E. A system-oriented strategy to enhance electron production of Synechocystis sp. PCC6803 in bio-photovoltaic devices: Experimental and modeling insights. Sci. Rep. 2021, 11, 12294. [Google Scholar] [CrossRef]

- Ng, F.-L.; Phang, S.-M.; Periasamy, V.; Beardall, J.; Yunus, K.; Fisher, A.C. Algal biophotovoltaic (BPV) device for generation of bioelectricity using Synechococcus elongatus (Cyanophyta). J. Appl. Phycol. 2018, 30, 2981–2988. [Google Scholar] [CrossRef]

- Kim, M.J.; Bai, S.J.; Youn, J.R.; Song, Y.S. Anomalous power enhancement of biophotovoltaic cell. J. Power Sources 2019, 412, 301–310. [Google Scholar] [CrossRef]

- Park, S.H.; Song, Y.S. Carbon nanofluid flow based biophotovoltaic cell. Nano Energy 2021, 81, 105624. [Google Scholar] [CrossRef]

- Carbas, B.B.; Güler, M.; Yücel, K.; Yildiz, H.B. Construction of novel cyanobacteria-based biological photovoltaic solar cells: Hydrogen and photocurrent generated via both photosynthesis and respiratory system. J. Photochem. Photobiol. Chem. 2023, 442, 114764. [Google Scholar] [CrossRef]

- Choi, D. Developing Sustainable Water and Electricity for Impoverished Regions using Algae-based Bio-Photovoltaics. Available online: https://www.gcrsef.org/wp-content/uploads/formidable/13/State-Research-Paper_Dorothy-Choi.pdf (accessed on 2 October 2023).

- Chin, J.-C.; Khor, W.-H.; Chong, W.W.F.; Wu, Y.-T.; Kang, H.-S. Effects of anode materials in electricity generation of microalgal-biophotovoltaic system—Part I: Natural biofilm from floating microalgal aggregation. Mater. Today Proc. 2022, 65, 2970–2978. [Google Scholar] [CrossRef]

- Amjadian, S.; Esmaeilzadeh, M.; Ajeian, R.; Riazi, G.; Ramakrishna, S. Efficiency Enhancement of Biophotovoltaic Solid-State Solar Cells. Energy Technol. 2023, 11, 2300337. [Google Scholar] [CrossRef]

- Lee, S.J.; Song, J.J.; Lee, H.J.; Jeong, H.Y.; Song, Y.S. Enhanced energy harvesting in a bio-photovoltaic cell by integrating silver nanoparticles. J. Korean Phys. Soc. 2022, 80, 420–426. [Google Scholar] [CrossRef]

- Liu, L.; Choi, S. Self-sustainable, high-power-density bio-solar cells for lab-on-a-chip applications. Lab. Chip 2017, 17, 3817–3825. [Google Scholar] [CrossRef] [PubMed]

- Indro, M.N.; Maddu, A.; Eviana, E. Utilization of cyanobacteria in photovoltaic technology. IOP Conf. Ser. Earth Environ. Sci. 2019, 299, 012064. [Google Scholar] [CrossRef]

- Tanneru, H.K.; Suresh, R.; Rengaswamy, R. On modeling and optimization of micro-photosynthetic power cells. Comput. Chem. Eng. 2017, 107, 284–293. [Google Scholar] [CrossRef]

- Masadeh, M.A.; Kuruvinashetti, K.; Shahparnia, M.; Pillay, P.; Packirisamy, M. Electrochemical Modeling and Equivalent Circuit Representation of a Microphotosynthetic Power Cell. IEEE Trans. Ind. Electron. 2017, 64, 1561–1571. [Google Scholar] [CrossRef]

- Kuruvinashetti, K.; Tanneru, H.K.; Pillay, P.; Packirisamy, M. Review on Microphotosynthetic Power Cells—A Low-Power Energy-Harvesting Bioelectrochemical Cell: From Fundamentals to Applications. Energy Technol. 2021, 9, 2001002. [Google Scholar] [CrossRef]

| Array | (Voc) mV | (Isc) µA | (Pmp) µW | |||

|---|---|---|---|---|---|---|

| Predicted | Experimental | Predicted | Experimental | Predicted | Experimental | |

| SA1 | 848.6 | 780 | 800 | 820 | 180 | 186 |

| SA2 | 1697 | 1404 | 800 | 500 | 314 | 202 |

| SA3 | 2545 | 2101 | 800 | 370 | 472 | 271 |

| SA4 | 3394 | 3000 | 800 | 340 | 629 | 285 |

| SA5 | 4243 | 3700 | 800 | 334 | 786 | 330 |

| SA6 | 5091 | 4200 | 800 | 410 | 944 | 474 |

| Array | (Voc) mV | (Isc) µA | (Pmp) µW | |||

|---|---|---|---|---|---|---|

| Predicted | Experimental | Predicted | Experimental | Predicted | Experimental | |

| PA1 | 848.6 | 780 | 800 | 820 | 180 | 186 |

| PA2 | 848.6 | 725 | 1600 | 880 | 314 | 183.96 |

| PA3 | 848.6 | 765 | 2400 | 1480 | 472 | 308.7 |

| PA4 | 848.6 | 675 | 3200 | 1700 | 629 | 256 |

| PA5 | 848.6 | 736 | 4000 | 2400 | 786 | 496.2 |

| PA6 | 848.6 | 730 | 4800 | 2600 | 944 | 412.5 |

| CC-1 | (Voc) mV | (Isc) µA | (Pmp) µW | |||

|---|---|---|---|---|---|---|

| P | E | P | E | P | E | |

| P3 (S2,S2,S2) | 1839 | 1550 | 2400 | 1760 | 985 | 616 |

| P2 (S3,S3) | 2741 | 2430 | 1600 | 1220 | 1026 | 624 |

| P2 (S4,S2) | 2438 | 2800 | 1600 | 1230 | 912 | 396 |

| P2 (S5,S1) | 1526 | 1302 | 1600 | 800 | 570 | 246 |

| CC-2 | (Voc) | (Isc) | (Pmp) | |||

|---|---|---|---|---|---|---|

| P | E | P | E | P | E | |

| S3 (P2, P2, P2) | 2741 | 2300 | 1600 | 1390 | 1026 | 869 |

| S2 (P3, P3) | 1839 | 1475 | 2400 | 2100 | 985 | 926 |

| S2 (P4, P2) | 1833 | 1680 | 1600 | 1820 | 887 | 777 |

| S2 (P5, P1) | 1826 | 1530 | 800 | 960 | 561 | 141 |

| Array | FF | Array | FF |

|---|---|---|---|

| SA1 | 0.267 | PA1 | 0.267 |

| SA2 | 0.245 | PA2 | 0.233 |

| SA3 | 0.236 | PA3 | 0.234 |

| SA4 | 0.238 | PA4 | 0.234 |

| SA5 | 0.233 | PA5 | 0.233 |

| SA6 | 0.236 | PA6 | 0.234 |

| S3 (P2, P2, P2) | 0.237 | P3 (S2, S2, S2) | 0.228 |

| S2 (P3, P3) | 0.228 | P2 (S3, S3) | 0.237 |

| S2 (P4, P2) | 0.307 | P2 (S4, S2) | 0.237 |

| S2 (P5, P1) | 0.389 | P2 (S5, S1) | 0.237 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kuruvinashetti, K.; Pakkiriswami, S.S.; M. Panneerselvam, D.; Packirisamy, M. Micro Photosynthetic Power Cell Array for Energy Harvesting: Bio-Inspired Modeling, Testing and Verification. Energies 2024, 17, 1749. https://doi.org/10.3390/en17071749

Kuruvinashetti K, Pakkiriswami SS, M. Panneerselvam D, Packirisamy M. Micro Photosynthetic Power Cell Array for Energy Harvesting: Bio-Inspired Modeling, Testing and Verification. Energies. 2024; 17(7):1749. https://doi.org/10.3390/en17071749

Chicago/Turabian StyleKuruvinashetti, Kirankumar, Shanmuga Sundaram Pakkiriswami, Dhilippan M. Panneerselvam, and Muthukumaran Packirisamy. 2024. "Micro Photosynthetic Power Cell Array for Energy Harvesting: Bio-Inspired Modeling, Testing and Verification" Energies 17, no. 7: 1749. https://doi.org/10.3390/en17071749

APA StyleKuruvinashetti, K., Pakkiriswami, S. S., M. Panneerselvam, D., & Packirisamy, M. (2024). Micro Photosynthetic Power Cell Array for Energy Harvesting: Bio-Inspired Modeling, Testing and Verification. Energies, 17(7), 1749. https://doi.org/10.3390/en17071749