Hybrid Power System Design and Dynamic Modeling for Enhanced Reliability in Remote Natural Gas Pipeline Control Stations

Abstract

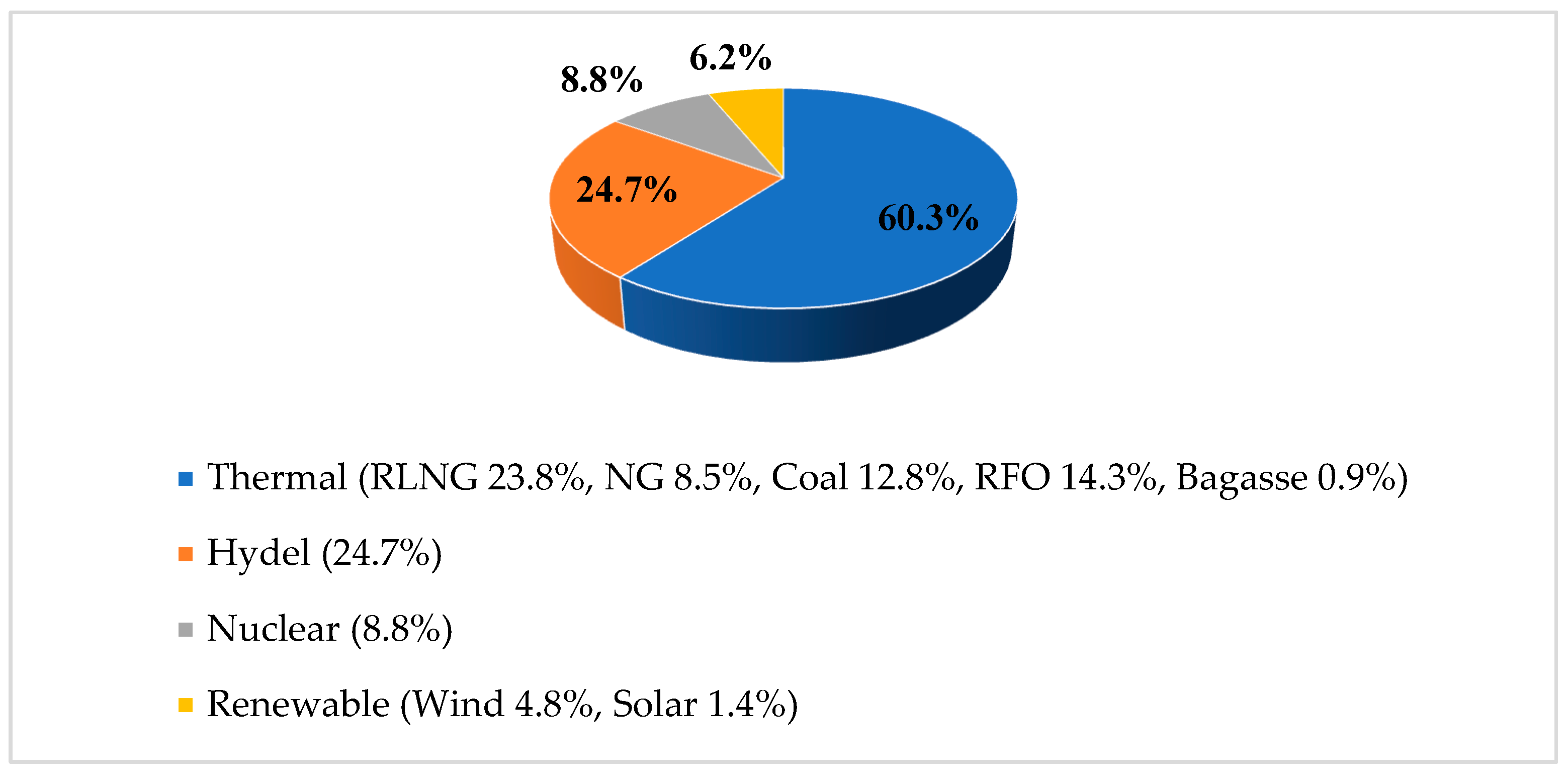

:1. Introduction

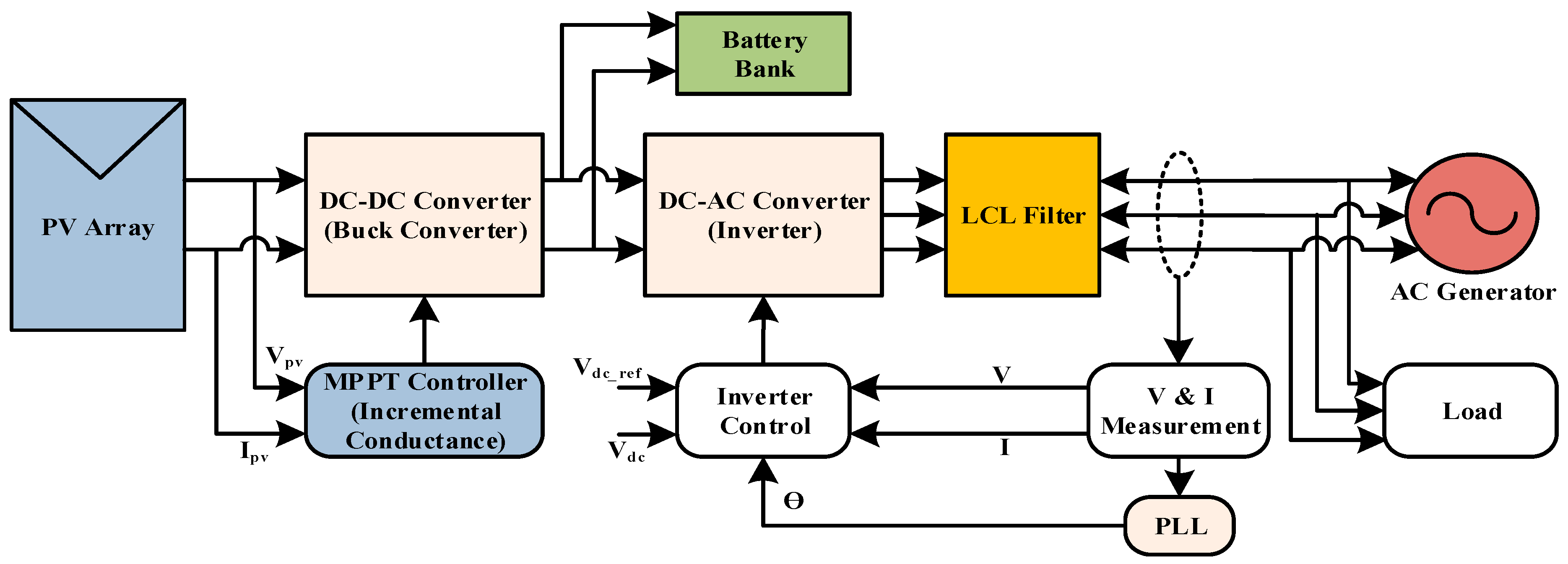

- It designs and sizes the proposed HPS using HOMER Pro, which involves determining the optimal capacity and configuration of components to meet the energy demands of a specific application. This process includes analyzing the load profile, assessing renewable resource availability, incorporating energy storage, determining the generator capacity, and implementing a control system.

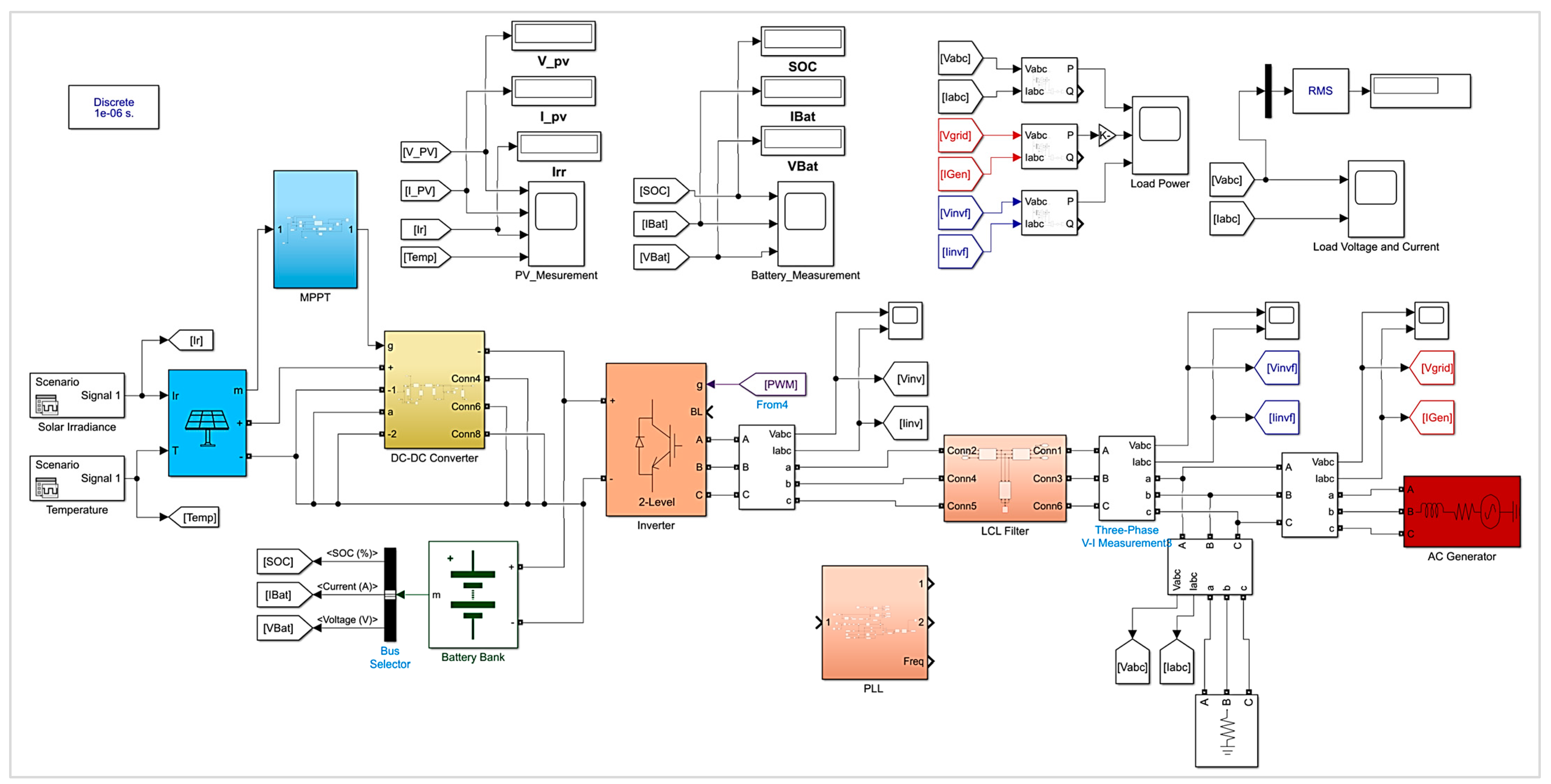

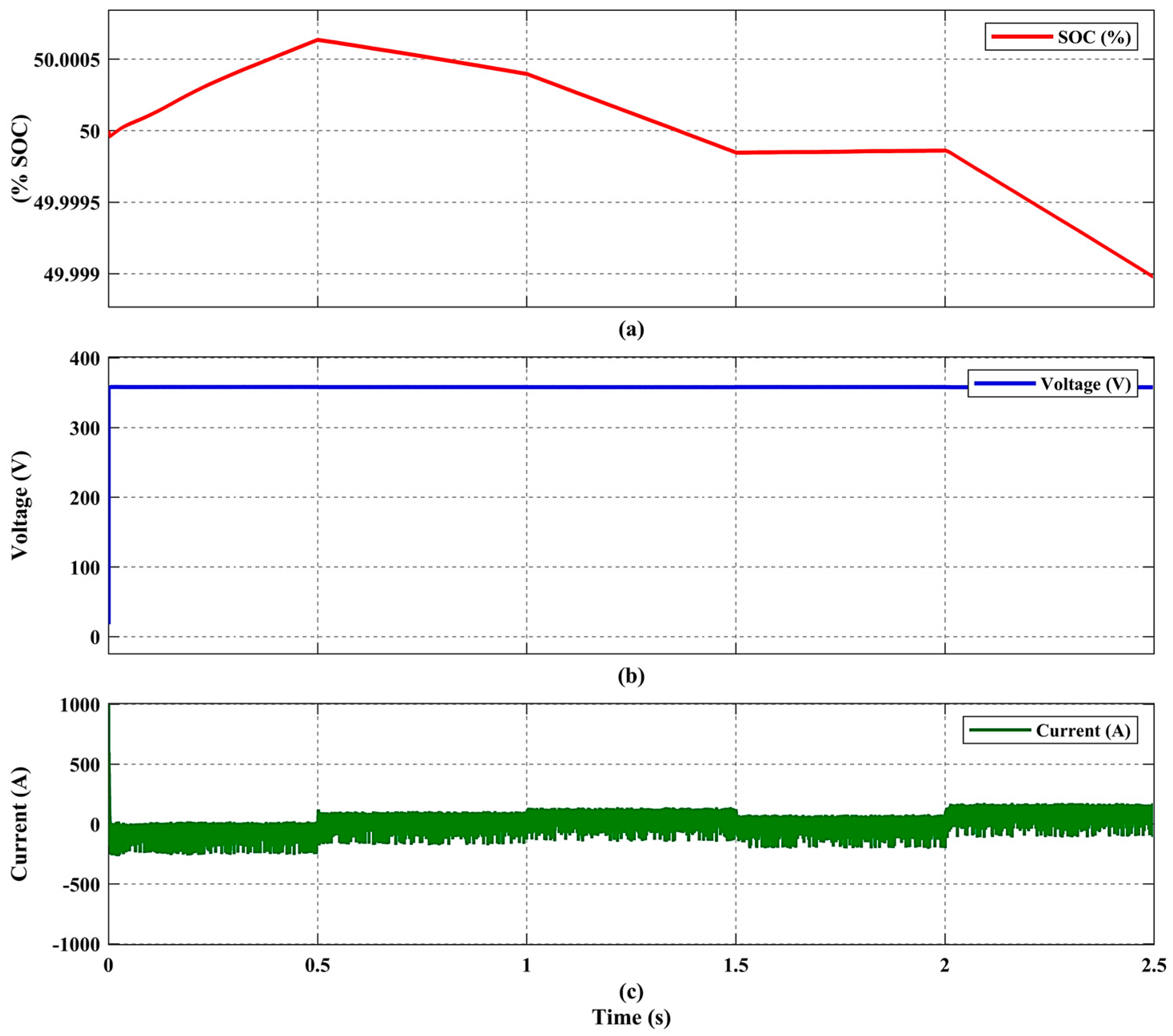

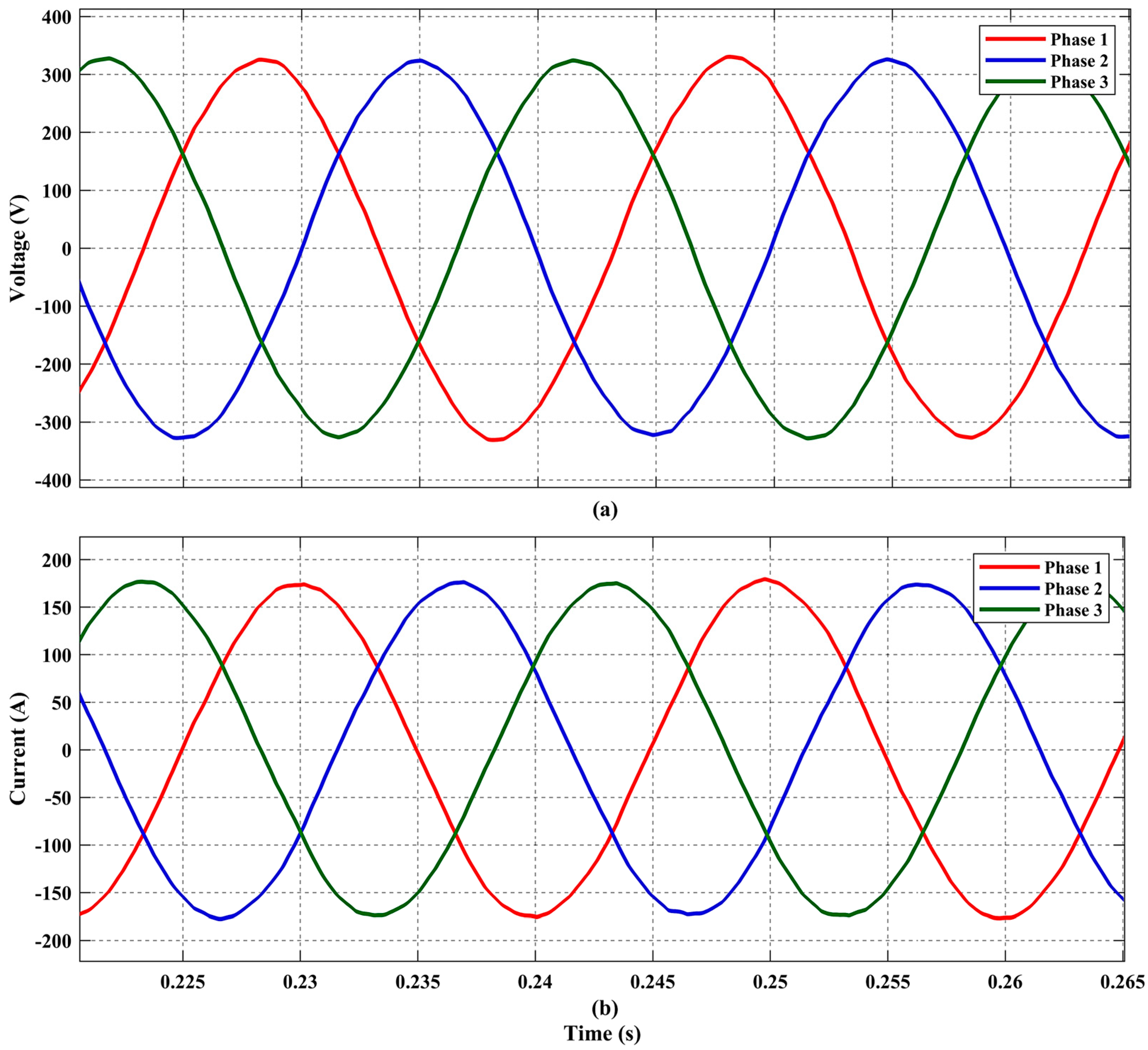

- It carries out dynamic modeling of the proposed hybrid power system using MATLAB Simulink to analyze the system’s response, voltage transients, load impact, and power quality under diverse conditions, which are specifically related to the control station under consideration.

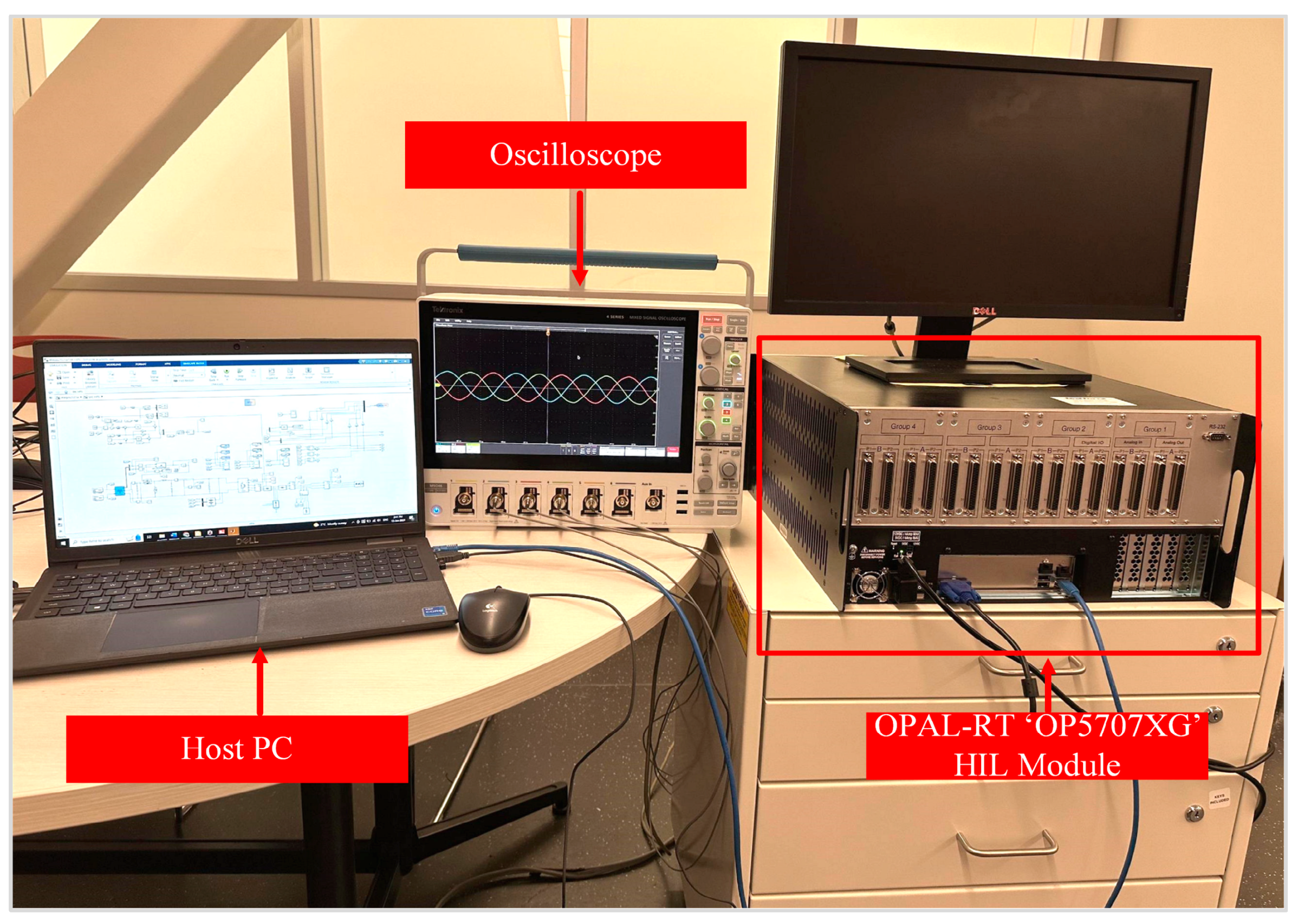

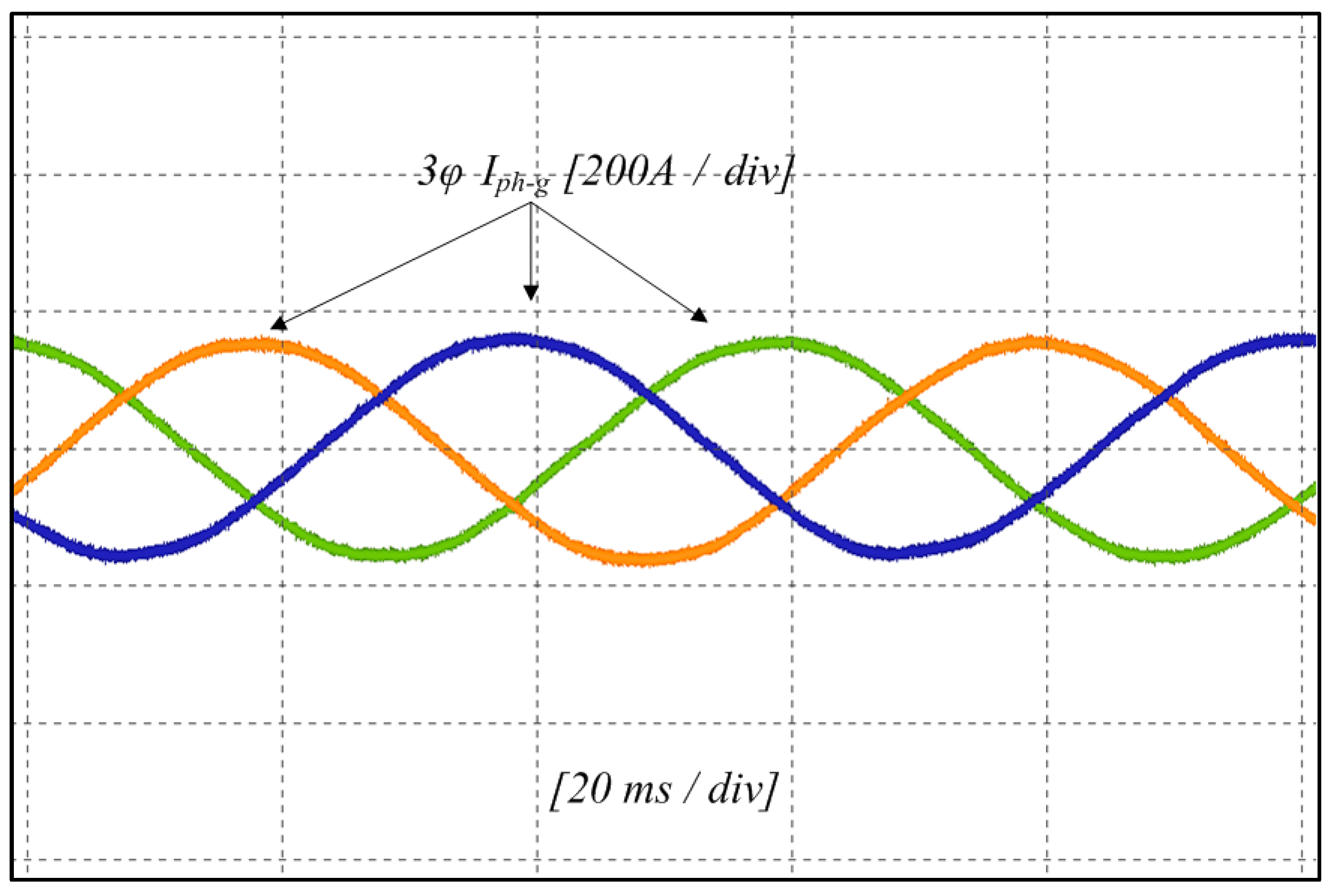

- The experimental validation of the proposed hybrid power system (HPS) is carried out using hardware in the loop (HIL), and the real-time OPAL-RT Technologies’ OP5707XG simulator (OPAL-RT, Montreal, QC, Canada) is used to confirm the systems’ robustness and overall performance.

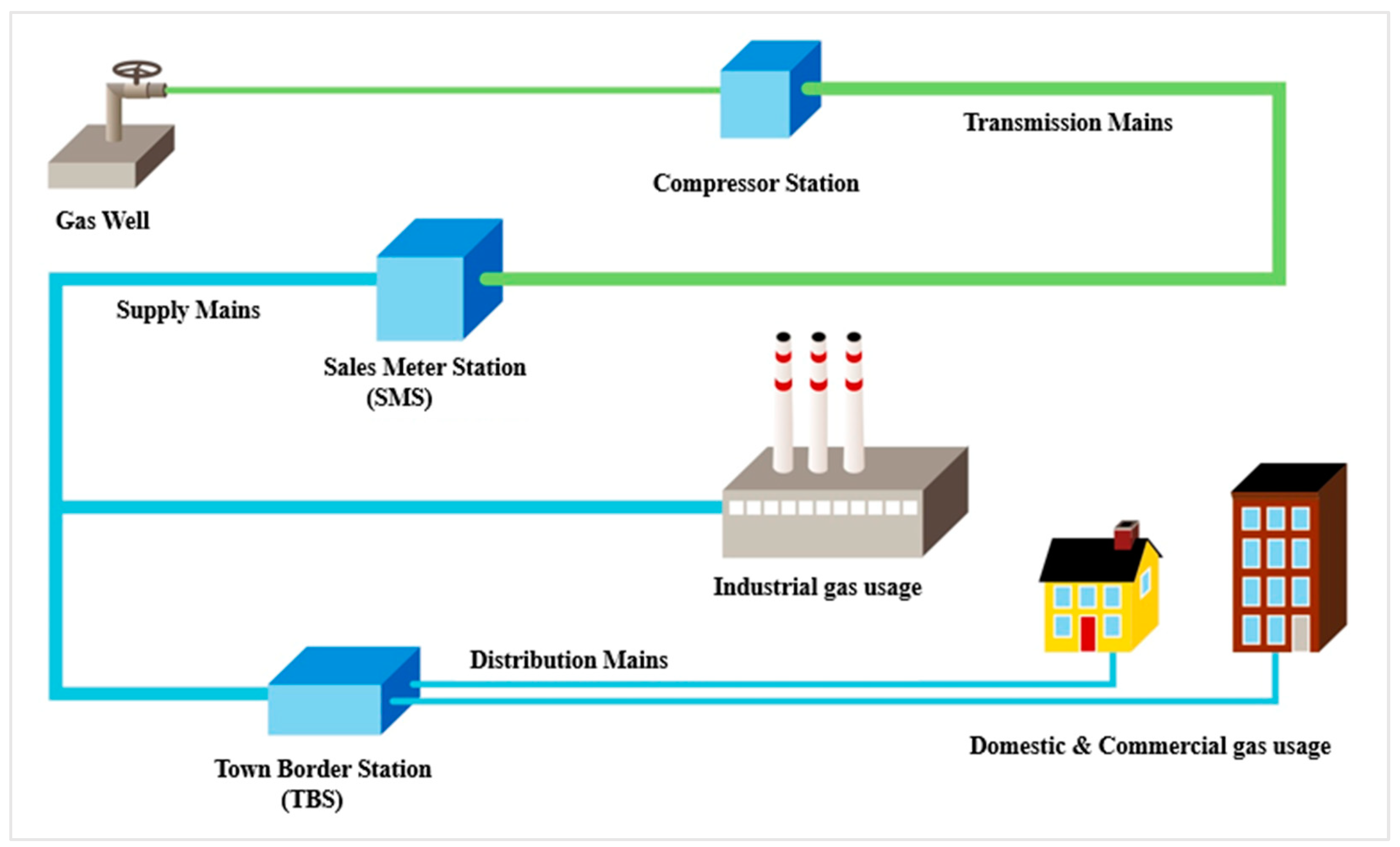

2. Site Selection

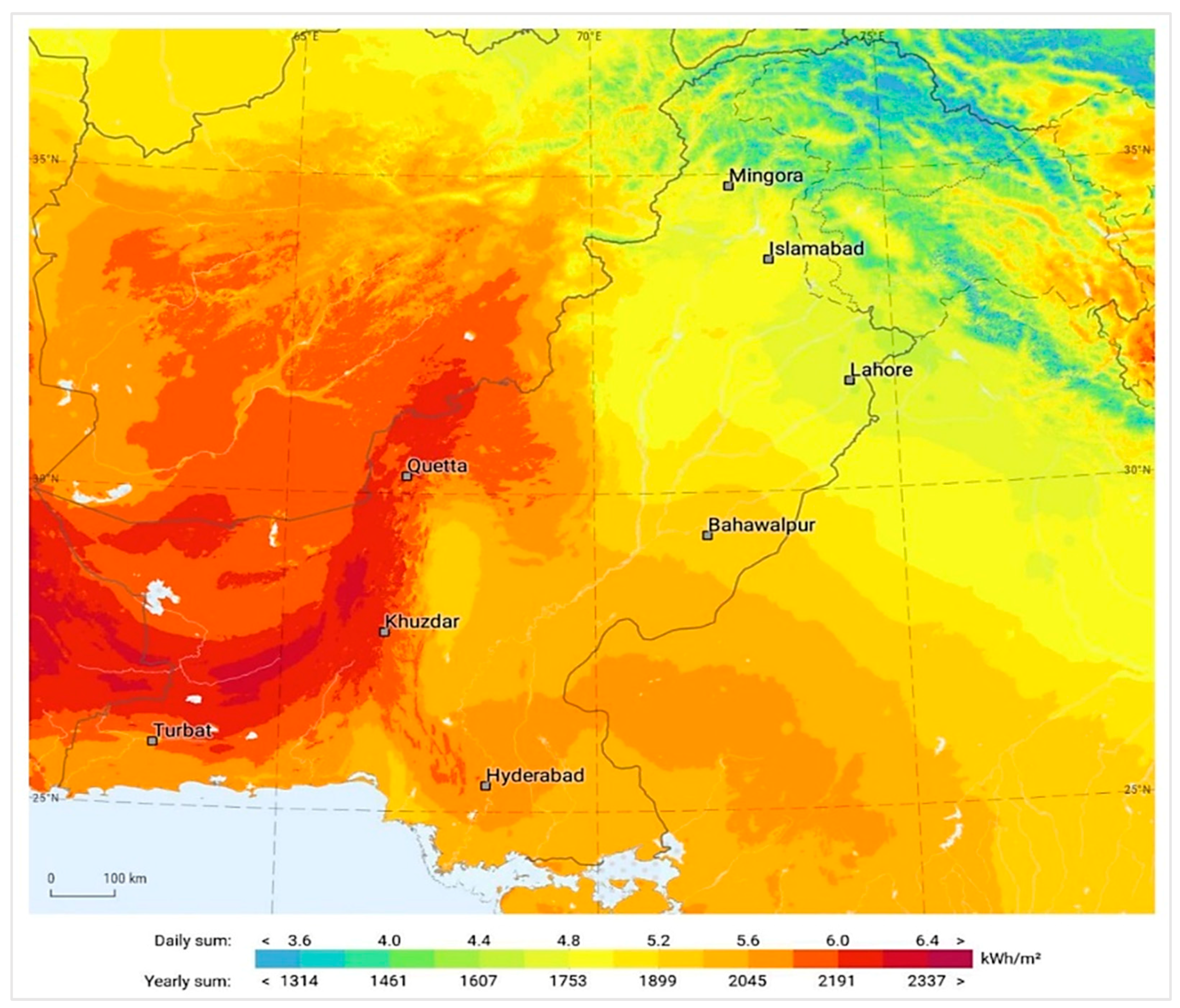

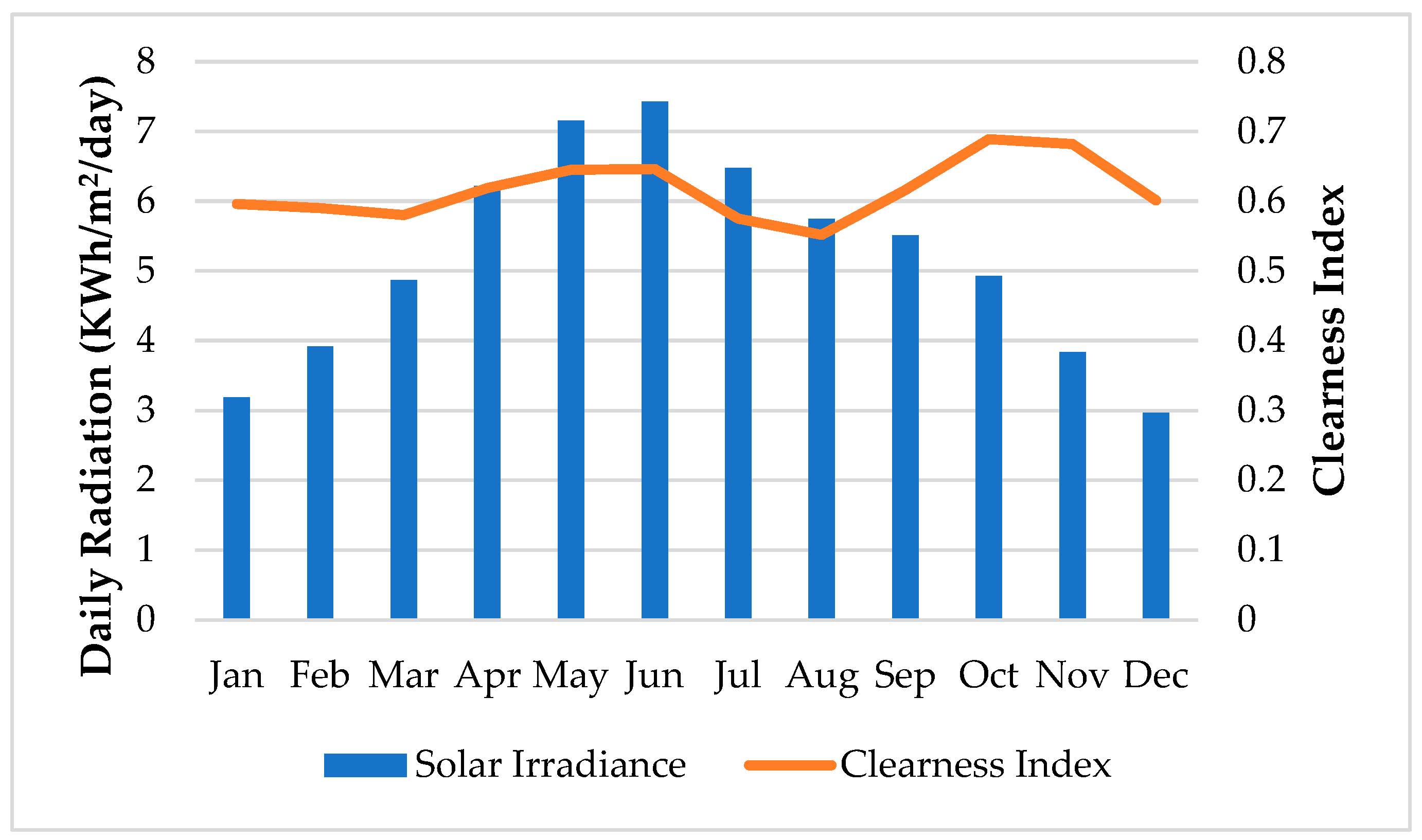

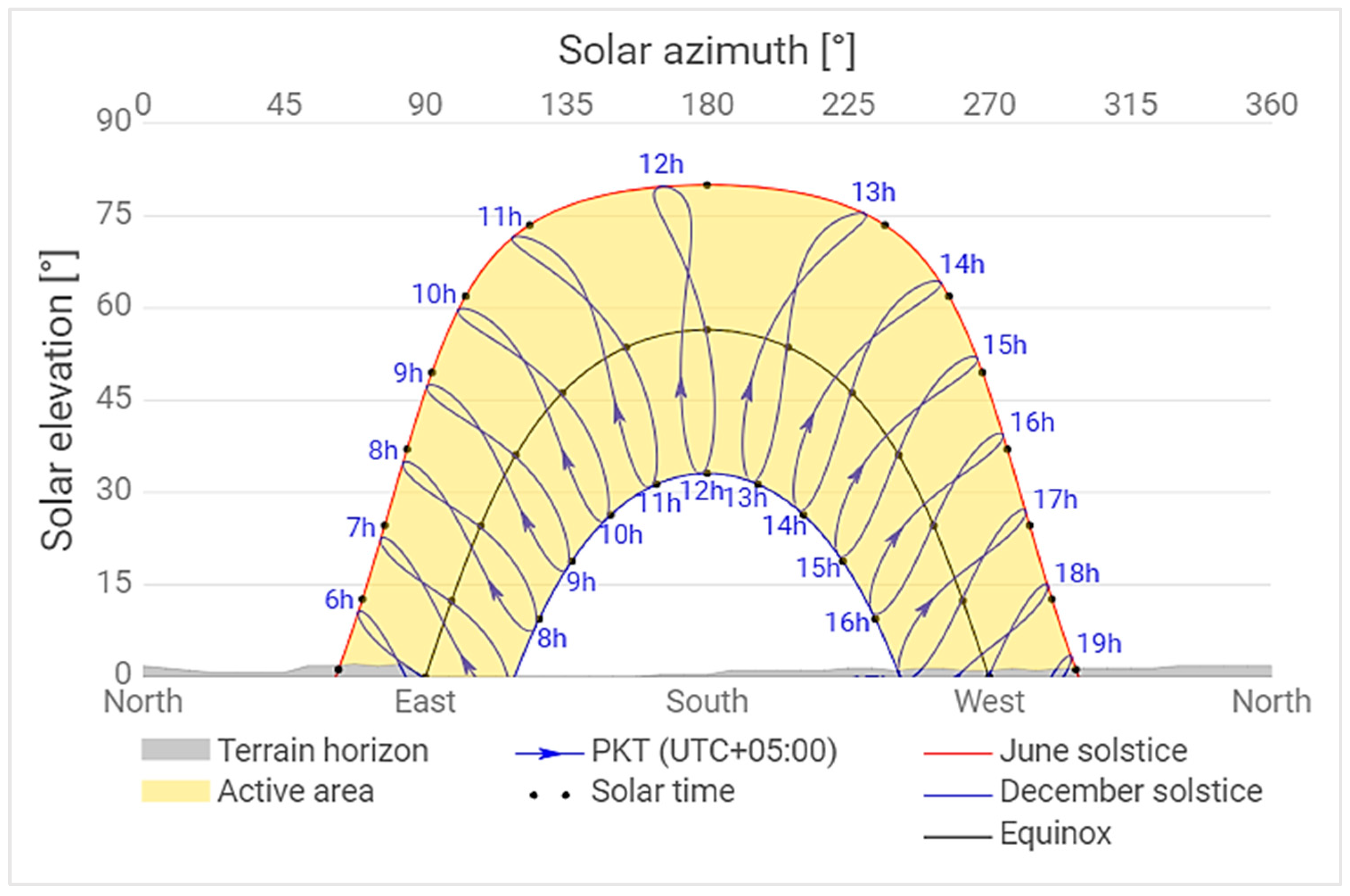

2.1. Global Horizontal Irradiance (GHI)

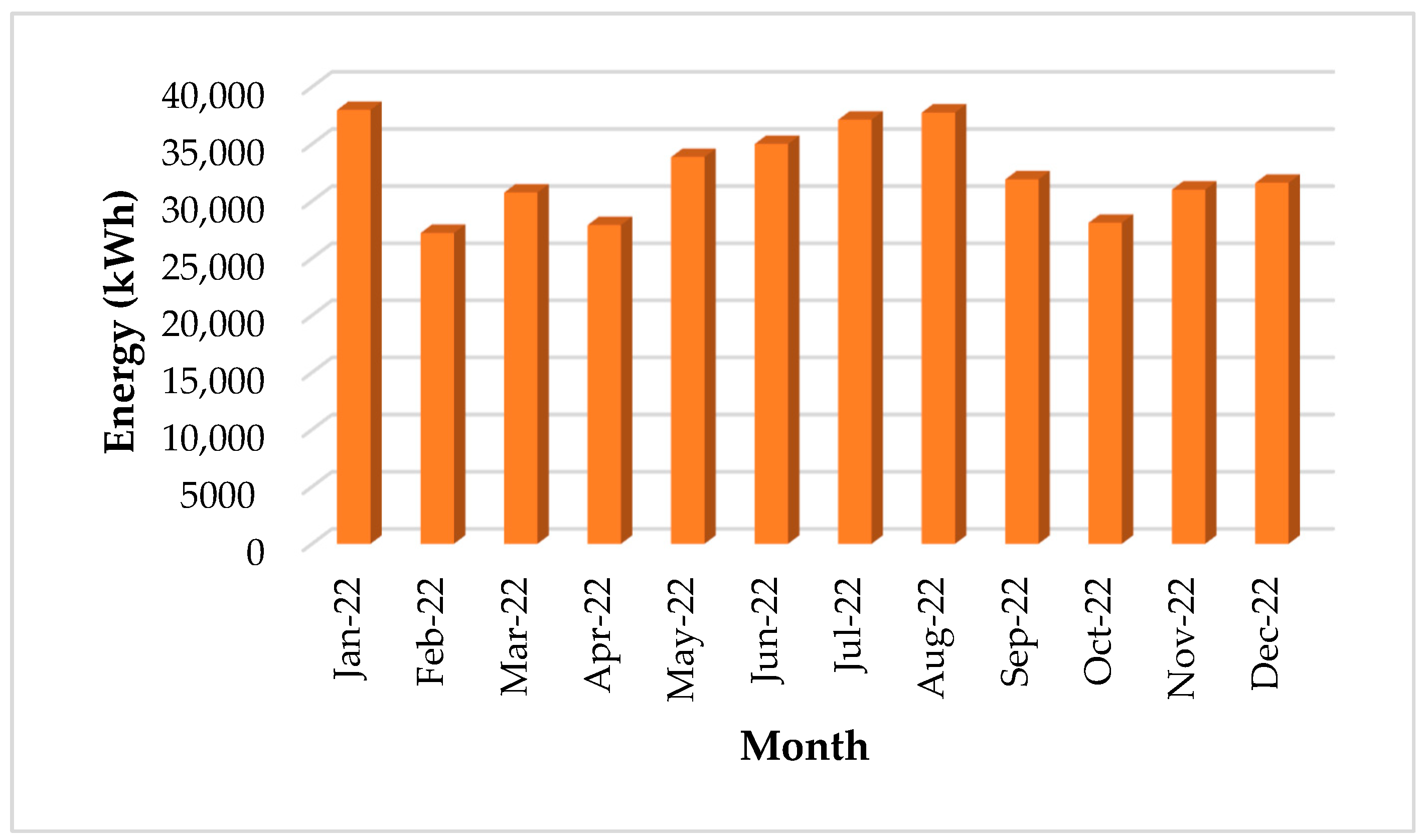

2.2. Electrical Load Analysis

2.3. Diversity Factor

3. Proposed Hybrid Power System (HPS)

3.1. Mathematical Modeling of Proposed HPS Components

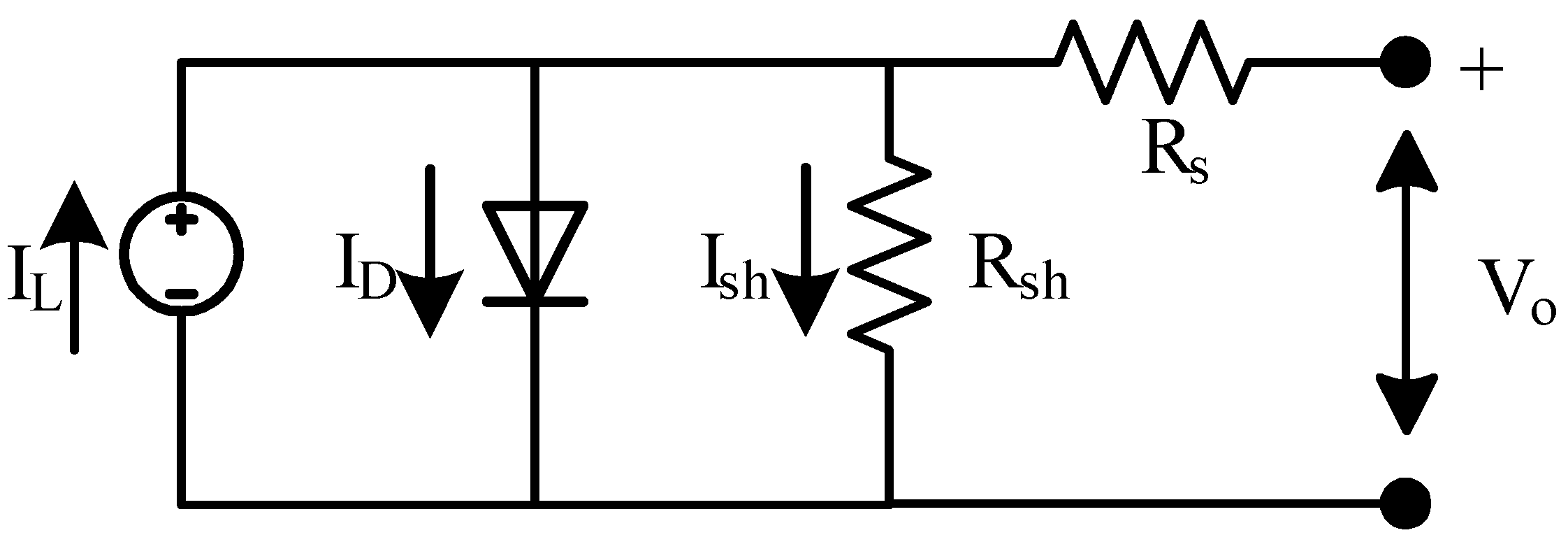

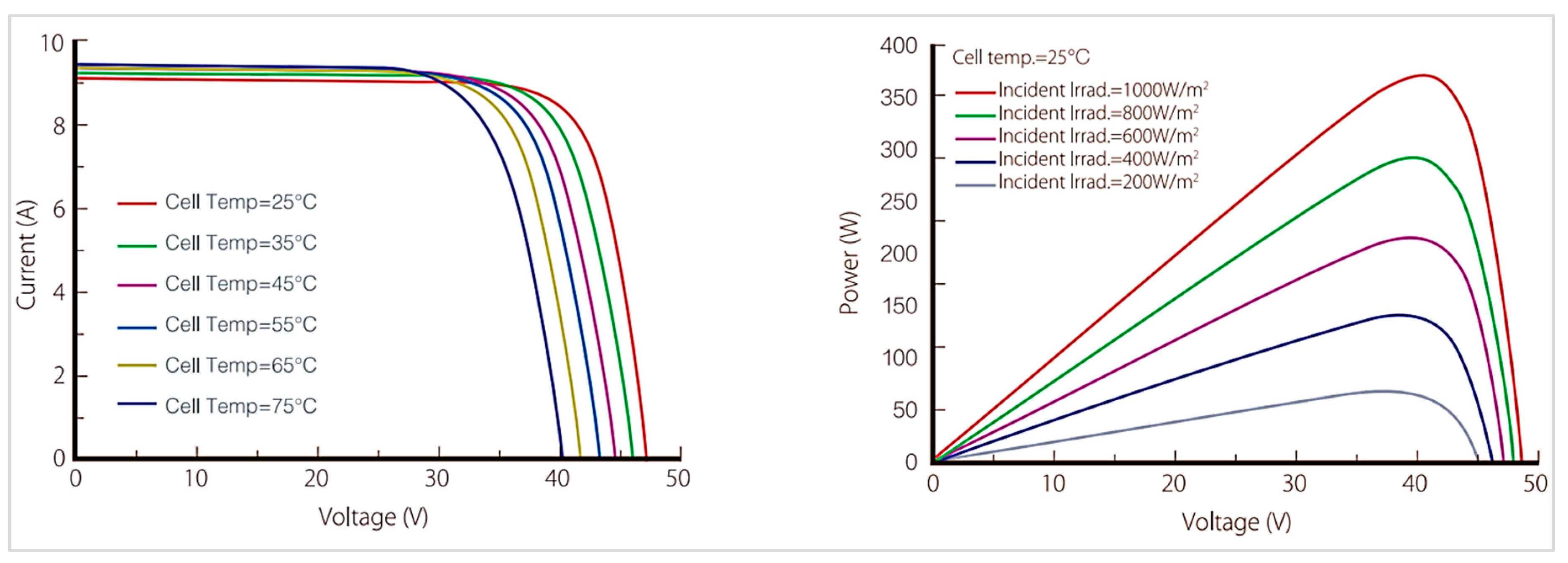

3.1.1. Photovoltaic System

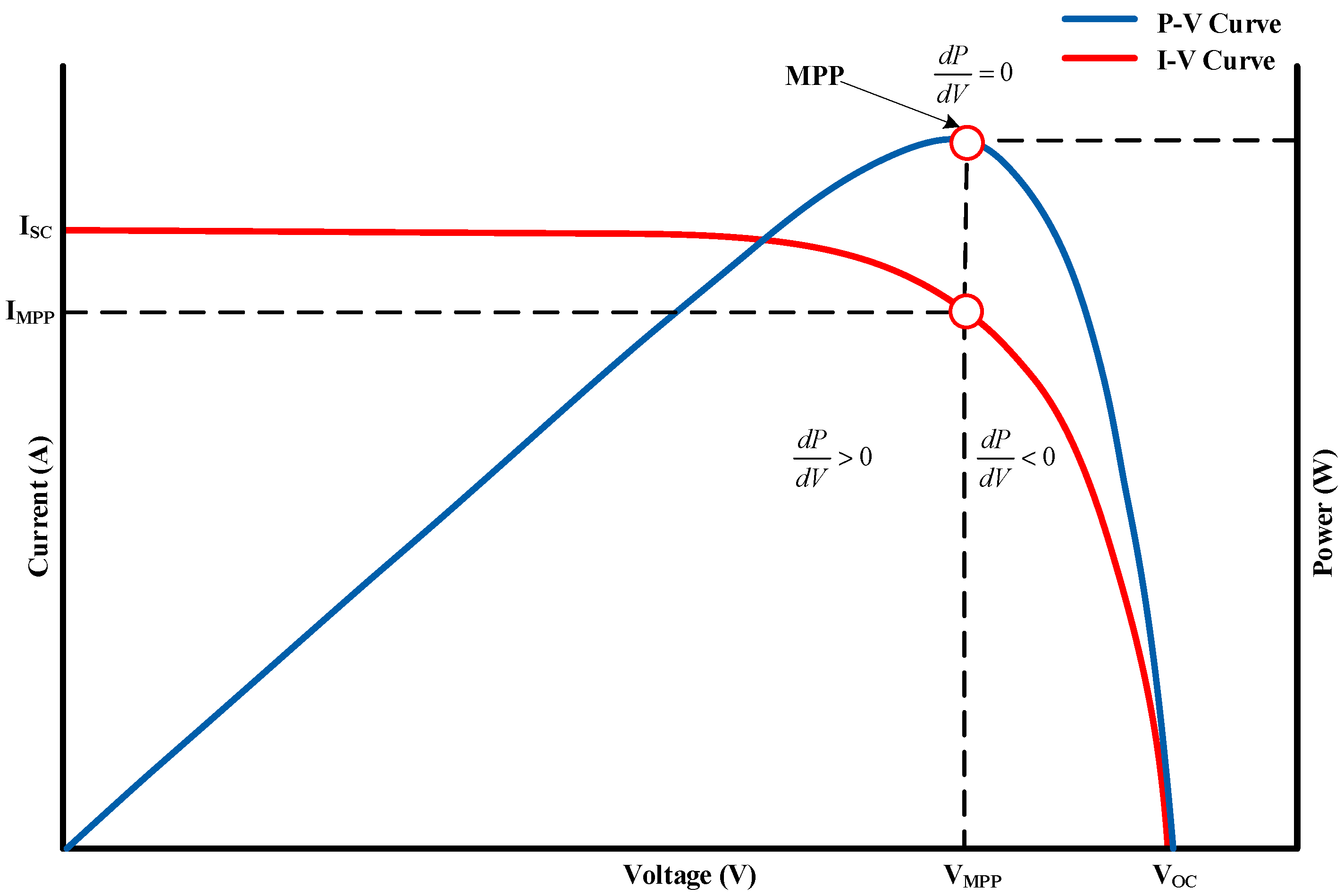

3.1.2. Maximum Power Point Tracking (MPPT) Control

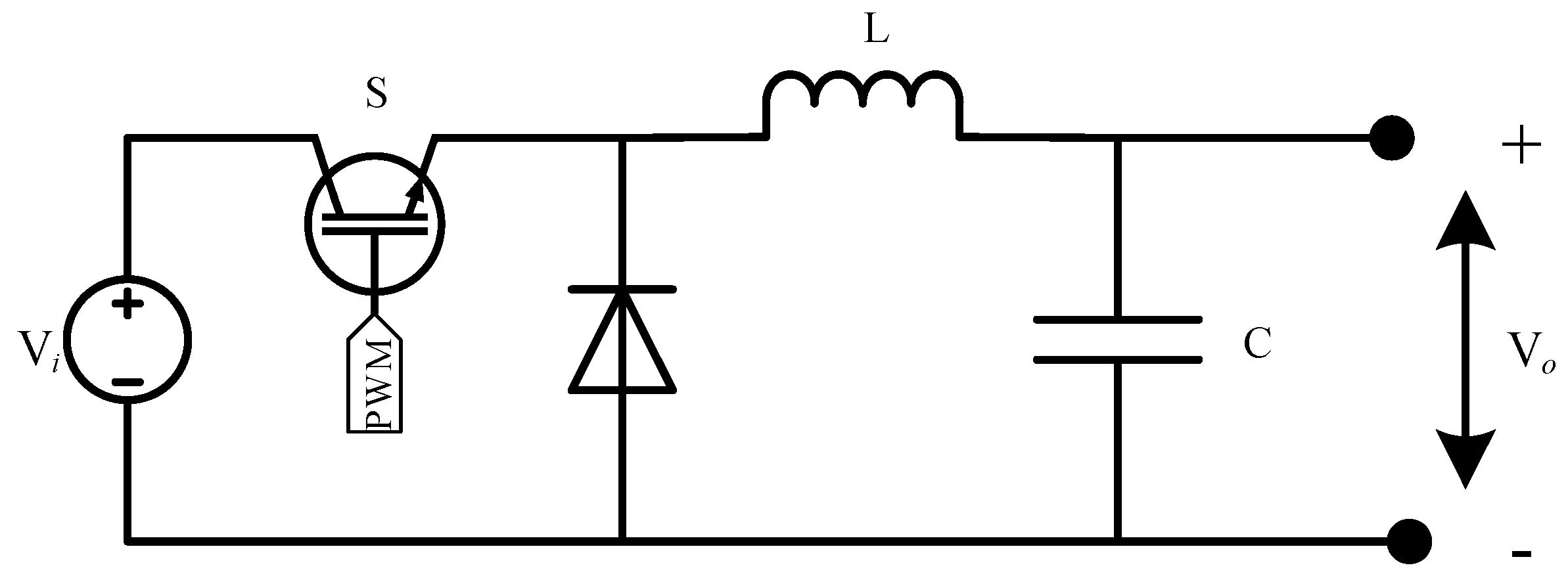

3.1.3. DC−DC Buck Converter

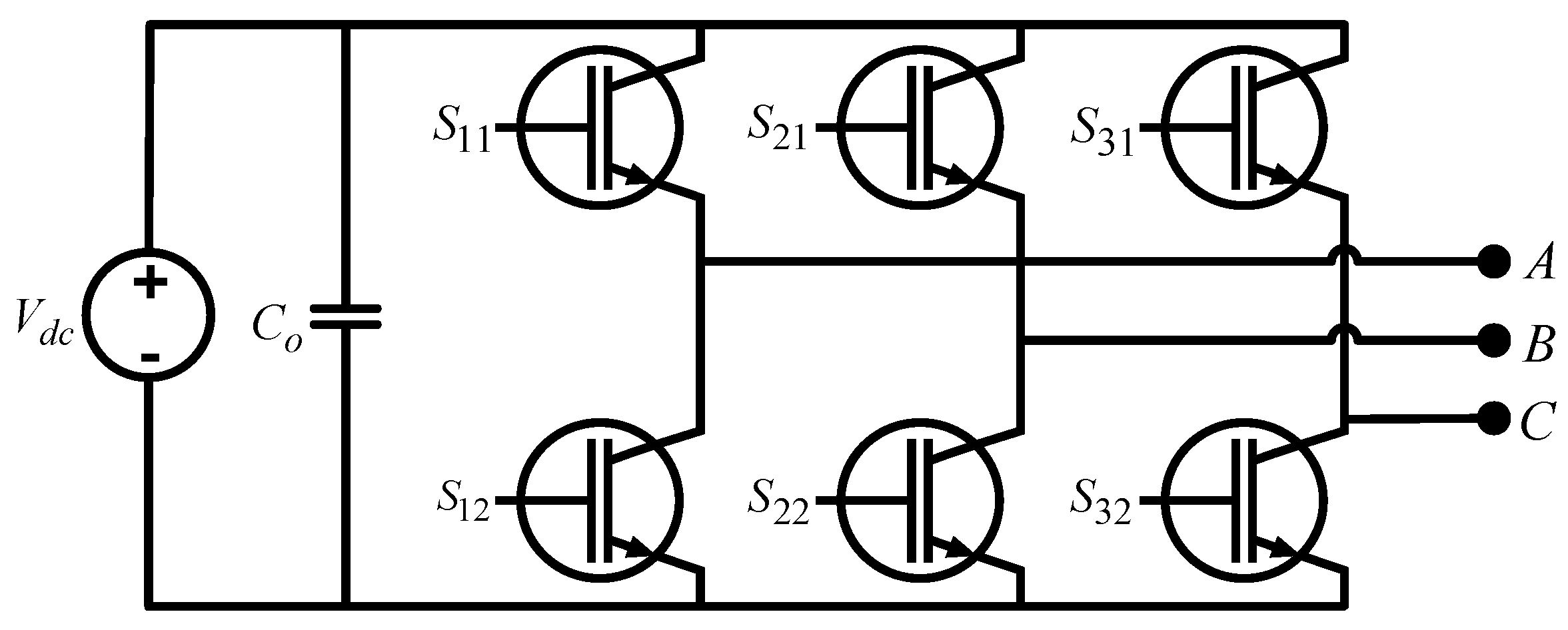

3.1.4. DC-AC Inverter

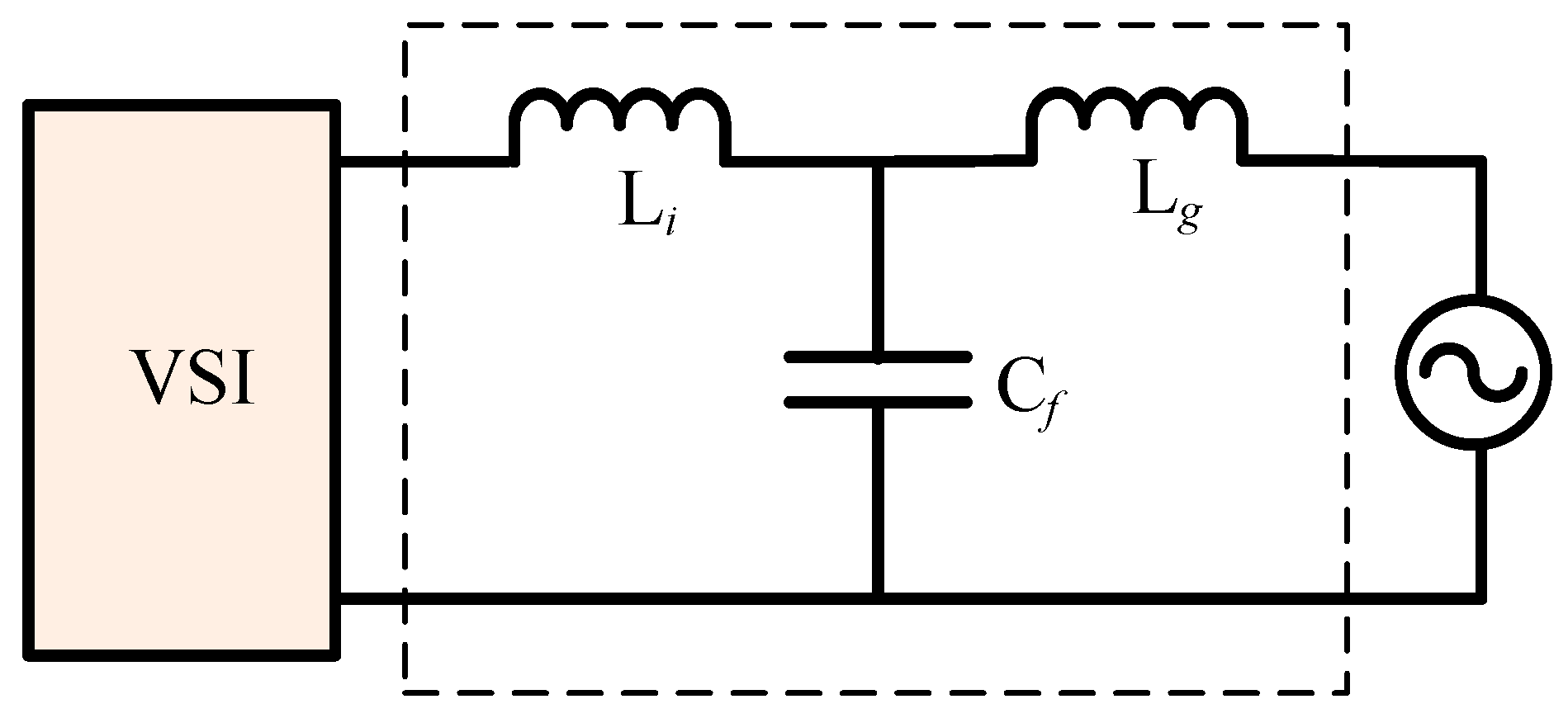

3.1.5. LCL Filter

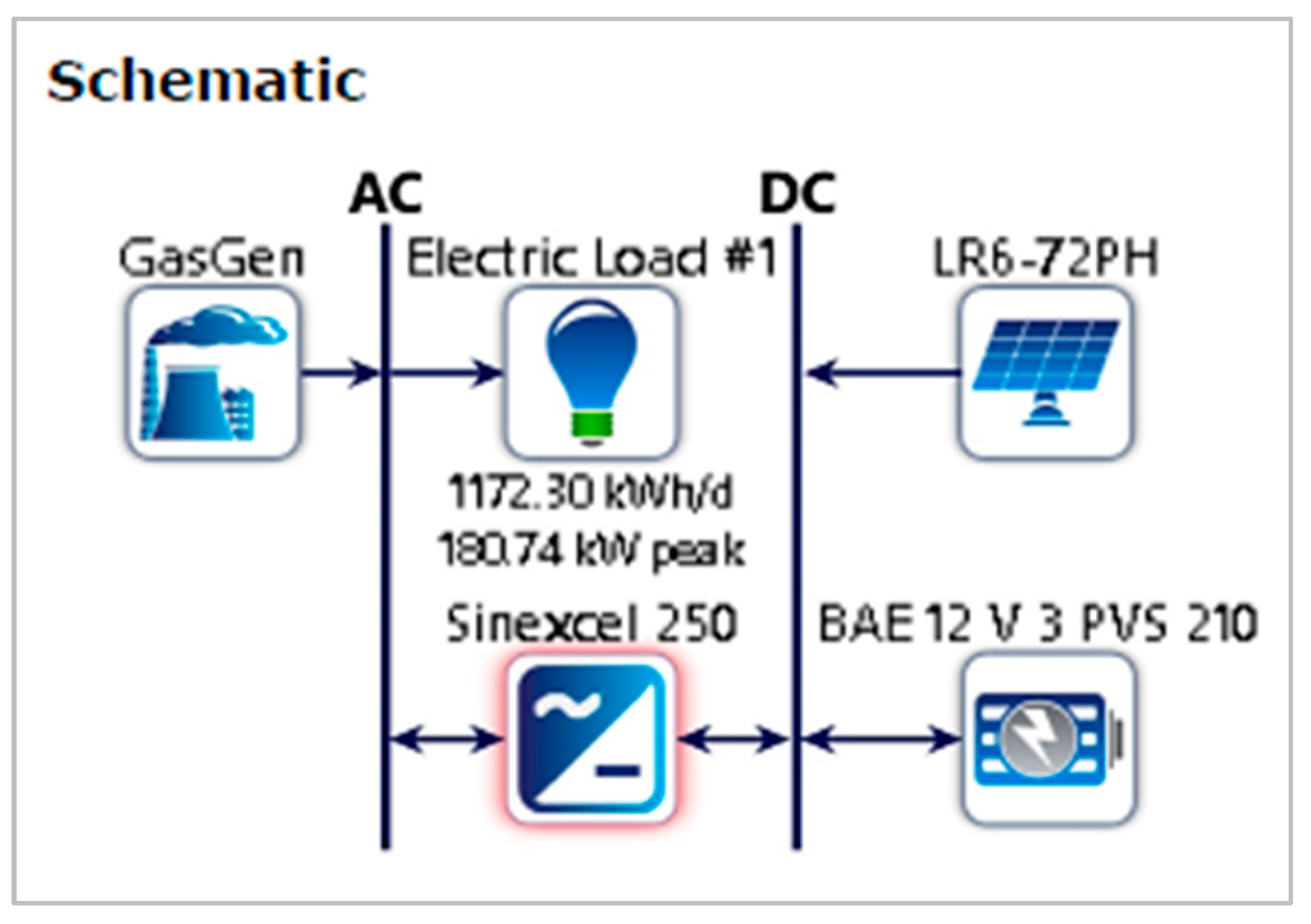

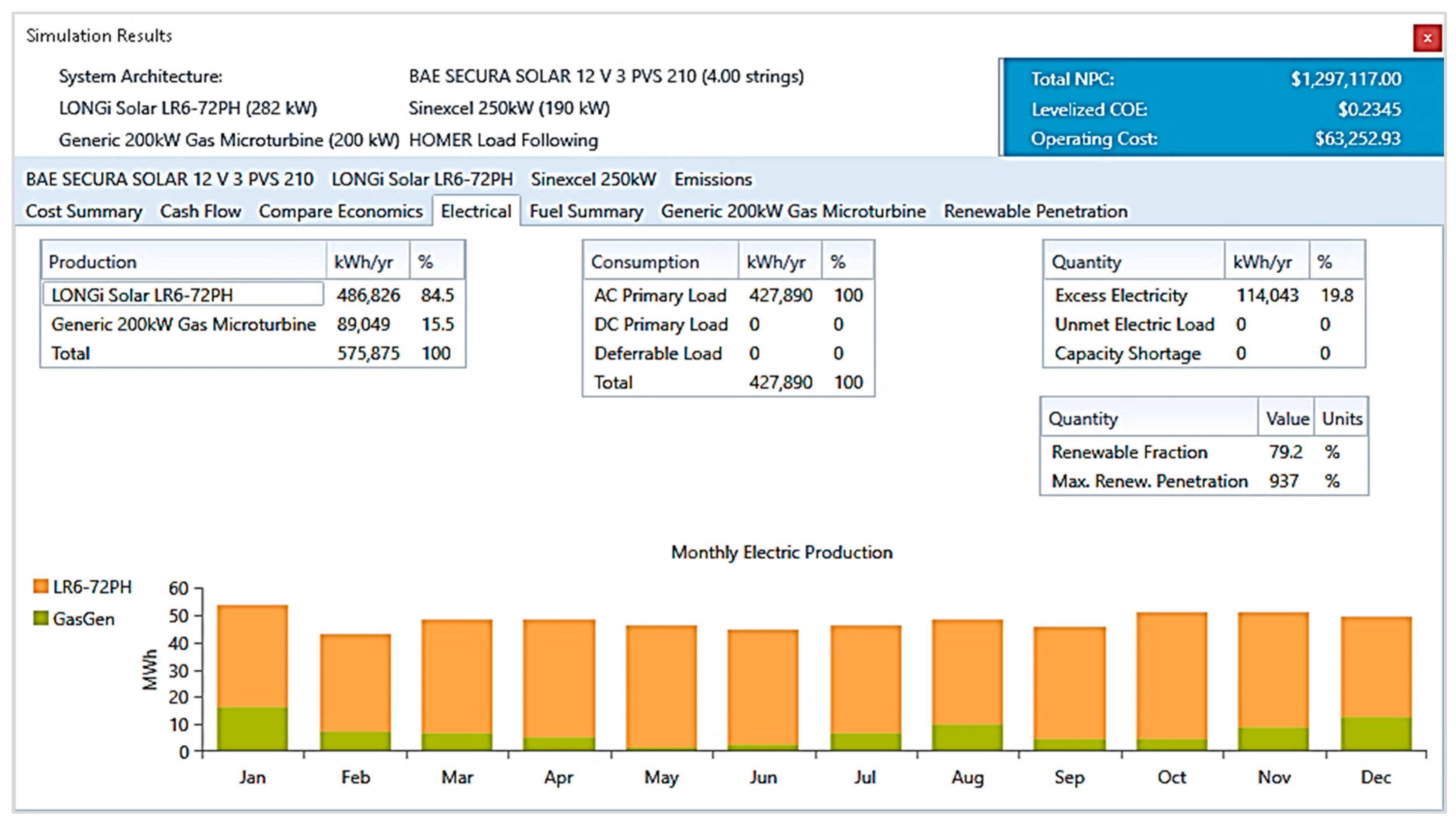

4. Optimization of Proposed HPS Using HOMER Pro

5. Dynamic Modeling of Proposed HPS in MATLAB/SIMULINK

6. Experimental Results and Discussion

7. Conclusions

- Given the abundant solar global horizontal irradiance resource in Pakistan, solar photovoltaic systems play a predominant role in contributing to the hybrid power system’s electricity supply. It addresses the unique energy demands of these facilities and underscores the financial benefits while aligning with broader energy sustainability goals.

- HOMER Pro performed a total of 892 simulations, and the designed optimal system features a 79.2% renewable energy fraction, reducing the non-renewable fraction from the prior 100% to only 20.8%, thereby addressing cost inefficiencies.

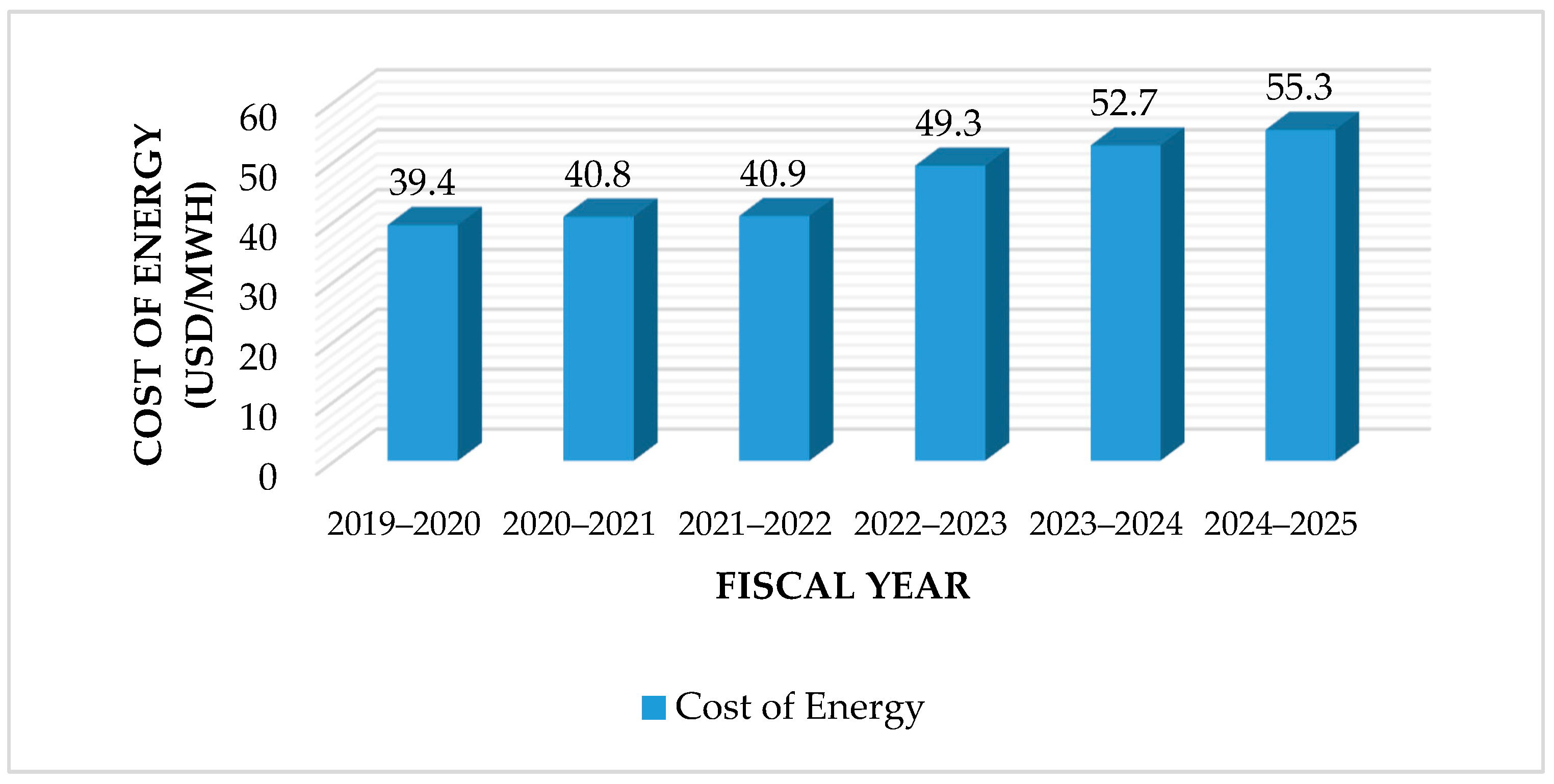

- The designed hybrid power system provides a cost of energy of USD 0.234, presenting noteworthy cost savings of USD 0.148 when compared to the current actual cost of energy, which stands at USD 0.382. Likewise, with an annual operating cost of USD 63,253, the system achieves significant savings of USD 87,321 compared to the current actual cost of USD 150,574.

- The dynamic modeling of an HPS coupled with experimental validation through Hardware-in-the-Loop and OPAL-RT Technologies’ high-performance real-time OP5707XG simulator substantiates the comprehensive performance of the proposed system. This validation confirms the designed system’s capability to supply reliable and consistent power and affirms the HPS’s capability to fully satisfy the energy demands of control stations in remote areas, promising environmentally friendly and economical energy while contributing to the enhanced sustainability of energy infrastructure.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, Q.; Wang, F.; Wang, Y.; Bai, B.; Zhang, J.; Lili, C.; Sun, Q.; Wang, Y.; Forson, K. Adsorption behavior and mechanism analysis of siloxane thickener for CO2 fracturing fluid on shallow shale soil. J. Mol. Liq. 2023, 376, 121394. [Google Scholar] [CrossRef]

- Ali, S.; Yan, Q.; Sajjad Hussain, M.; Irfan, M.; Ahmad, M.; Razzaq, A.; Dagar, V.; Işık, C. Evaluating Green Technology Strategies for the Sustainable Development of Solar Power Projects: Evidence from Pakistan. Sustainability 2021, 13, 12997. [Google Scholar] [CrossRef]

- Wang, F.; Xiao, Z.; Li, X.; Ren, J.; Xing, T.; Li, Z.; Li, X.; Chen, Y. Strategic design of cellulose nanofibers@zeolitic imidazolate frameworks derived mesoporous carbon-supported nanoscale CoFe2O4/CoFe hybrid composition as trifunctional electrocatalyst for Zn-air battery and self-powered overall water-splitting. J. Power Sources 2022, 521, 230925. [Google Scholar] [CrossRef]

- Anwar, J. Analysis of energy security, environmental emission and fuel import costs under energy import reduction targets: A case of Pakistan. Renew. Sustain. Energy Rev. 2016, 65, 1065–1078. [Google Scholar] [CrossRef]

- Bergasse, E.; Paczynski, W.; Dabrowski, M.; De Wulf, L. The Relationship between Energy and Socio-Economic Development in the Southern and Eastern Mediterranean. SSRN Electron. J. 2013. [Google Scholar] [CrossRef]

- Etokakpan, M.U.; Solarin, S.A.; Yorucu, V.; Bekun, F.V.; Sarkodie, S.A. Modeling natural gas consumption, capital formation, globalization, CO2 emissions and economic growth nexus in Malaysia: Fresh evidence from combined cointegration and causality analysis. Energy Strategy Rev. 2020, 31, 100526. [Google Scholar] [CrossRef]

- Akhtar, T.; Rehman, A.U.; Jamil, M.; Gilani, S.O. Impact of an Energy Monitoring System on the Energy Efficiency of an Automobile Factory: A Case Study. Energies 2020, 13, 2577. [Google Scholar] [CrossRef]

- Shar, A.M. Natural Gas Potential of Pakistan an Important Parameter in Mitigating Greenhouse Gas Emissions. Pak. J. Anal. Environ. Chem. 2020, 21, 209–218. [Google Scholar] [CrossRef]

- IEA. Energy Statistics Data Browser—Data Tools. Available online: https://www.iea.org/data-and-statistics/data-tools/energy-statistics-databrowser?country=PAK&fuel=Energy%20supply&indicator=CoalProdByType (accessed on 31 March 2024).

- Guo, B.; Ghalambor, A. Natural Gas Engineering Handbook; Gulf Publishing Company: Houston, TX, USA, 2012; pp. 277–279. [Google Scholar]

- Fetisov, V.; Ilyushin, Y.V.; Vasiliev, G.G.; Leonovich, I.A.; Müller, J.; Riazi, M.; Mohammadi, A.H. Development of the automated temperature control system of the main gas pipeline. Sci. Rep. 2023, 13, 3092. [Google Scholar] [CrossRef]

- Gudmundsson, J. Hydrate Non-Pipeline Technology for Transport of Natural Gas. Available online: https://citeseerx.ist.psu.edu/document?repid=rep1&type=pdf&doi=cd54d345cdfb6b6fab99a9a93a095dccd9837709 (accessed on 28 January 2024).

- Da Lio, L.; Lazzaretto, A. Remote Power Generation for Applications to Natural Gas Grid: A Comprehensive Market Review of Techno-Energetic, Economic and Environmental Performance. Energies 2022, 15, 5065. [Google Scholar] [CrossRef]

- World Bank. Access to Electricity (% of Population)|Data. Worldbank.org. 2018. Available online: https://data.worldbank.org/indicator/eg.elc.accs.zs (accessed on 30 November 2023).

- Muqeet, H.A.; Munir, H.M.; Javed, H.; Shahzad, M.; Jamil, M.; Guerrero, J.M. An Energy Management System of Campus Microgrids: State-of-the-Art and Future Challenges. Energies 2021, 14, 6525. [Google Scholar] [CrossRef]

- Energy and Economy. Available online: https://www.finance.gov.pk/survey/chapter_22/PES14-ENERGY.pdf (accessed on 30 November 2023).

- ieefa.org. Rising LNG Dependence in Pakistan is a Recipe for High Costs, Financial Instability, and Energy Insecurity. Available online: https://ieefa.org/resources/rising-lng-dependence-pakistan-recipe-high-costs-financial-instability-and-energy (accessed on 15 December 2023).

- Javed, H.; Muqeet, H.A.; Shehzad, M.; Jamil, M.; Khan, A.A.; Guerrero, J.M. Optimal Energy Management of a Campus Microgrid Considering Financial and Economic Analysis with Demand Response Strategies. Energies 2021, 14, 8501. [Google Scholar] [CrossRef]

- IEA. Annual Average Price of Electricity in Pakistan, 2019–2025—Charts—Data & Statistics. Available online: https://www.iea.org/data-and-statistics/charts/annual-average-price-of-electricity-in-pakistan-2019-2025 (accessed on 15 December 2023).

- Ahsan, L.; Iqbal, M. Dynamic Modeling of an Optimal Hybrid Power System for a Captive Power Plant in Pakistan. Jordan J. Electr. Eng. 2022, 8, 195. [Google Scholar] [CrossRef]

- Agajie, T.F.; Ali, A.; Fopah-Lele, A.; Amoussou, I.; Khan, B.; Velasco, C.L.R.; Tanyi, E. A Comprehensive Review on Techno-Economic Analysis and Optimal Sizing of Hybrid Renewable Energy Sources with Energy Storage Systems. Energies 2023, 16, 642. [Google Scholar] [CrossRef]

- Hussain, F.; Maeng, S.-J.; Cheema, M.J.M.; Anjum, M.N.; Afzal, A.; Azam, M.; Wu, R.-S.; Noor, R.S.; Umair, M.; Iqbal, T. Solar Irrigation Potential, Key Issues and Challenges in Pakistan. Water 2023, 15, 1727. [Google Scholar] [CrossRef]

- Deveci, M.; Cali, U.; Pamucar, D. Evaluation of criteria for site selection of solar photovoltaic (PV) projects using fuzzy logarithmic additive estimation of weight coefficients. Energy Rep. 2021, 7, 8805–8824. [Google Scholar] [CrossRef]

- Herrería-Alonso, S.; Suárez-González, A.; Rodríguez-Pérez, M.; Rodríguez-Rubio, R.F.; López-García, C. A Solar Altitude Angle Model for Efficient Solar Energy Predictions. Sensors 2020, 20, 1391. [Google Scholar] [CrossRef]

- Solar Azimuth Angle—An Overview|ScienceDirect Topics. Available online: https://www.sciencedirect.com/topics/engineering/solar-azimuth-angle (accessed on 2 January 2024).

- apps.solargis.com. Solargis Prospect. Available online: https://apps.solargis.com/prospect/detail/scRwdD0kCL2vzMj1/info (accessed on 4 November 2023).

- Heydt, G.T. Distribution Transformer Loading:Probabilistic Modeling and Diversity Factor. IEEE Trans. Power Deliv. 2022, 38, 842–849. [Google Scholar] [CrossRef]

- Kahani, R.; Jamil, M.; Iqbal, M.T. An Improved Perturb and Observed Maximum Power Point Tracking Algorithm for Photovoltaic Power Systems. J. Mod. Power Syst. Clean Energy 2023, 11, 1165–1175. [Google Scholar] [CrossRef]

- Solaris. Longi Solar HiMO1 LR6-72PH-365M 365w Mono Solar Panel. Available online: https://www.solaris-shop.com/longi-solar-himo1-lr6-72ph-365m-365w-mono-solar-panel/ (accessed on 27 March 2024).

- Martin, L.; Vladislav, P.; Pavel, K. Temperature changes of I-V characteristics of photovoltaic cells as a consequence of the Fermi energy level shift. Res. Agric. Eng. 2017, 63, 10–15. [Google Scholar] [CrossRef]

- Cai, Y.; He, Y.; Zhou, H.; Liu, J. Design Method of LCL Filter for Grid-Connected Inverter Based on Particle Swarm Optimization and Screening Method. IEEE Trans. Power Electron. 2021, 36, 10097–10113. [Google Scholar] [CrossRef]

- Reznik, A.; Simoes, M.G.; Al-Durra, A.; Muyeen, S.M. LCL Filter Design and Performance Analysis for Grid-Interconnected Systems. IEEE Trans. Ind. Appl. 2013, 50, 1225–1232. [Google Scholar] [CrossRef]

- Aghenta, L.O.; Iqbal, M.T. Design and Dynamic Modelling of a Hybrid Power System for a House in Nigeria. Int. J. Photoenergy 2019, 2019, 6501785. [Google Scholar] [CrossRef]

- ‘Flagship Real-Time Digital Simulator|Simulation Tools|OP5707XG’, OPAL-RT. Available online: https://www.opal-rt.com/simulator-platform-op5707/ (accessed on 22 January 2024).

| Mode of Transportation | Capacity (bcm) | Distance (km) |

|---|---|---|

| LNG (Liquefied Natural Gas) | 1.0–10.0 | 1000–10,000 |

| Gas to Liquid (GTL) | 0.1–1.0 | 5000–10,000 |

| CNG (Compressed Natural Gas) | 0.1–1.0 | 100–5000 |

| Pipeline | 1.0–10.0 | 100–1000 |

| NGH (Natural Gas Hydrates) | 0.1–1.0 | 100–5000 |

| GTW (Gas to Wire) | 0.1–1.0 | 100–5000 |

| System Description | Number of Units | Rated Power of Unit Load Installed | Total Connected Load | |||

|---|---|---|---|---|---|---|

| hp | kW | hp | kW | |||

| Discharge Gas Cooling (DGC) System | Fan Motors | 4 | 25 | 18.65 | 100 | 74.6 |

| Fan Motors | 2 | 40 | 29.84 | 80 | 59.68 | |

| Pump Motors | 0 | 0 | 0 | 30 | 22.38 | |

| Turbine Package | Lube Oil Tank Heater | 0 | 0 | 0 | 0 | 0 |

| Evaporative Cooling Pump Motor | 2 | 0.75 | 0.5595 | 1.5 | 1.119 | |

| Turbine Shed | Inlet Fan Motors | 0 | 0 | 0 | 0 | 0 |

| Exhaust Fan Motor | 0 | 0 | 0 | 0 | 0 | |

| Raw Water Pump | Pump Motor #1 | 2 | 15 | 11.19 | 30 | 22.38 |

| Air system | Air Compressor Motors | 2 | 15 | 11.19 | 30 | 22.38 |

| Power House | Radiator Fan Motor | 1 | 0.75 | 0.5595 | 0.75 | 0.5595 |

| Water Circulating Pump Motor | 1 | 1 | 0.746 | 1 | 0.746 | |

| Auxiliary Load | Residential Load | 75 | 0 | 75 | ||

| Total Connected Load | 278.84 KW | |||||

| Condition | Constraint | Description |

|---|---|---|

| If P = MPP | MPP achieved | |

| If P < MPP | Operating point is left to MPP | |

| If P > MPP | Operating point is right to MPP |

| System Architecture | PV (kW) | Gas Genset (kW) | ESS (No. of Batteries) | Converter (kW) | NPC (USD) | COE (USD) | Operating Cost (USD/Year) | Initial Capital (USD) |

|---|---|---|---|---|---|---|---|---|

| PV-Genset-ESS-Converter | 282 | 200 | 280 | 190 | 1.30 M | 0.234 | 63,253 | 479,414 |

| Genset-ESS-Converter | 200 | 140 | 66.8 | 1.85 M | 0.335 | 125,403 | 229,611 | |

| Genset | 200 | 2.11 M | 0.382 | 150,574 | 165,350 | |||

| PV-ESS-Converter | 582 | 1260 | 201 | 2.12 M | 0.383 | 95,462 | 881,476 | |

| PV-Genset-Converter | 6.11 | 200 | 1.42 | 2.12 M | 0.383 | 150,989 | 169,402 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Waqas, M.; Jamil, M.; Khan, A.A. Hybrid Power System Design and Dynamic Modeling for Enhanced Reliability in Remote Natural Gas Pipeline Control Stations. Energies 2024, 17, 1763. https://doi.org/10.3390/en17071763

Waqas M, Jamil M, Khan AA. Hybrid Power System Design and Dynamic Modeling for Enhanced Reliability in Remote Natural Gas Pipeline Control Stations. Energies. 2024; 17(7):1763. https://doi.org/10.3390/en17071763

Chicago/Turabian StyleWaqas, Muhammad, Mohsin Jamil, and Ashraf Ali Khan. 2024. "Hybrid Power System Design and Dynamic Modeling for Enhanced Reliability in Remote Natural Gas Pipeline Control Stations" Energies 17, no. 7: 1763. https://doi.org/10.3390/en17071763

APA StyleWaqas, M., Jamil, M., & Khan, A. A. (2024). Hybrid Power System Design and Dynamic Modeling for Enhanced Reliability in Remote Natural Gas Pipeline Control Stations. Energies, 17(7), 1763. https://doi.org/10.3390/en17071763