Enhancing Performance of Permanent Magnet Motor Drives through Equivalent Circuit Models Considering Core Loss

Abstract

1. Introduction

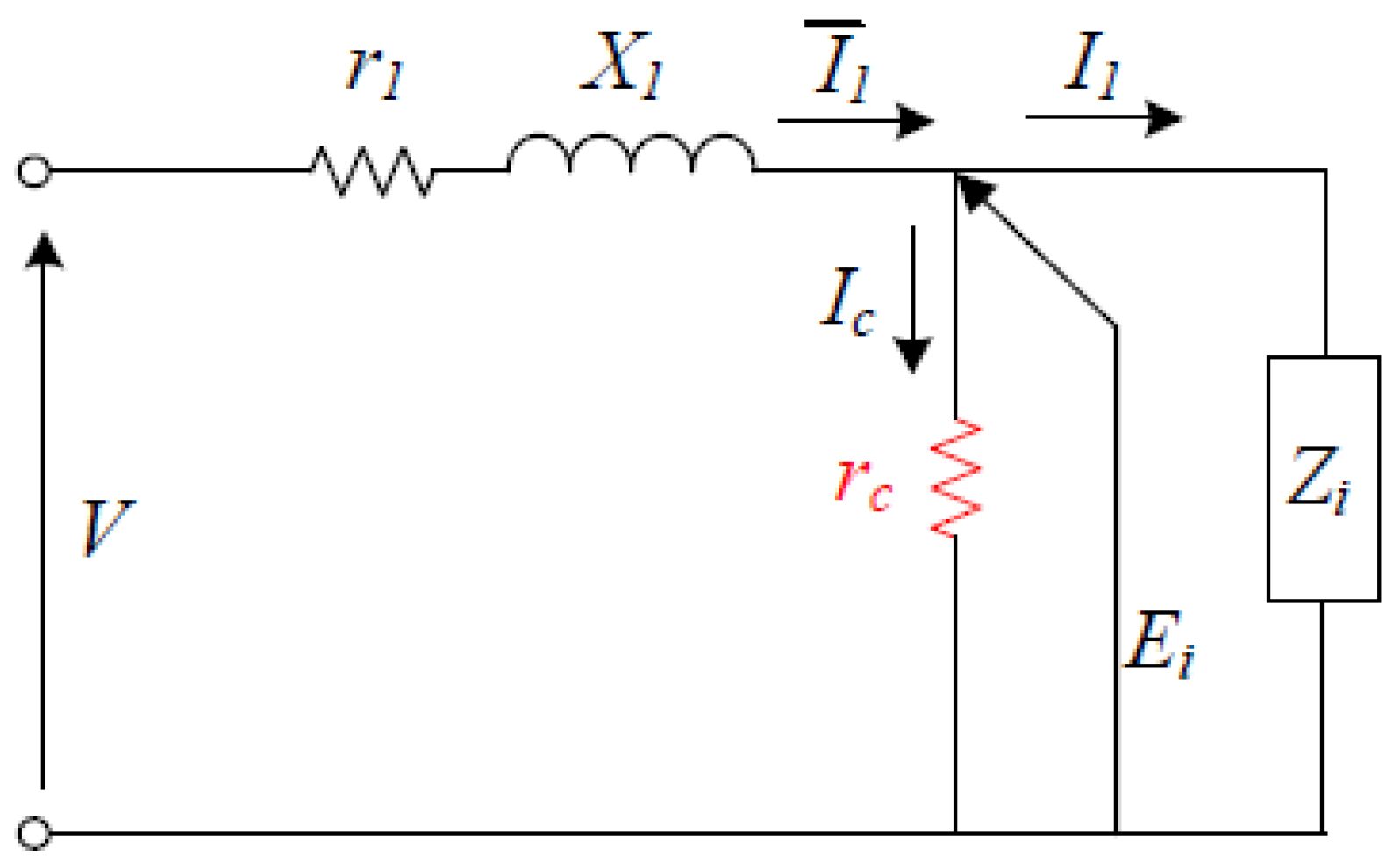

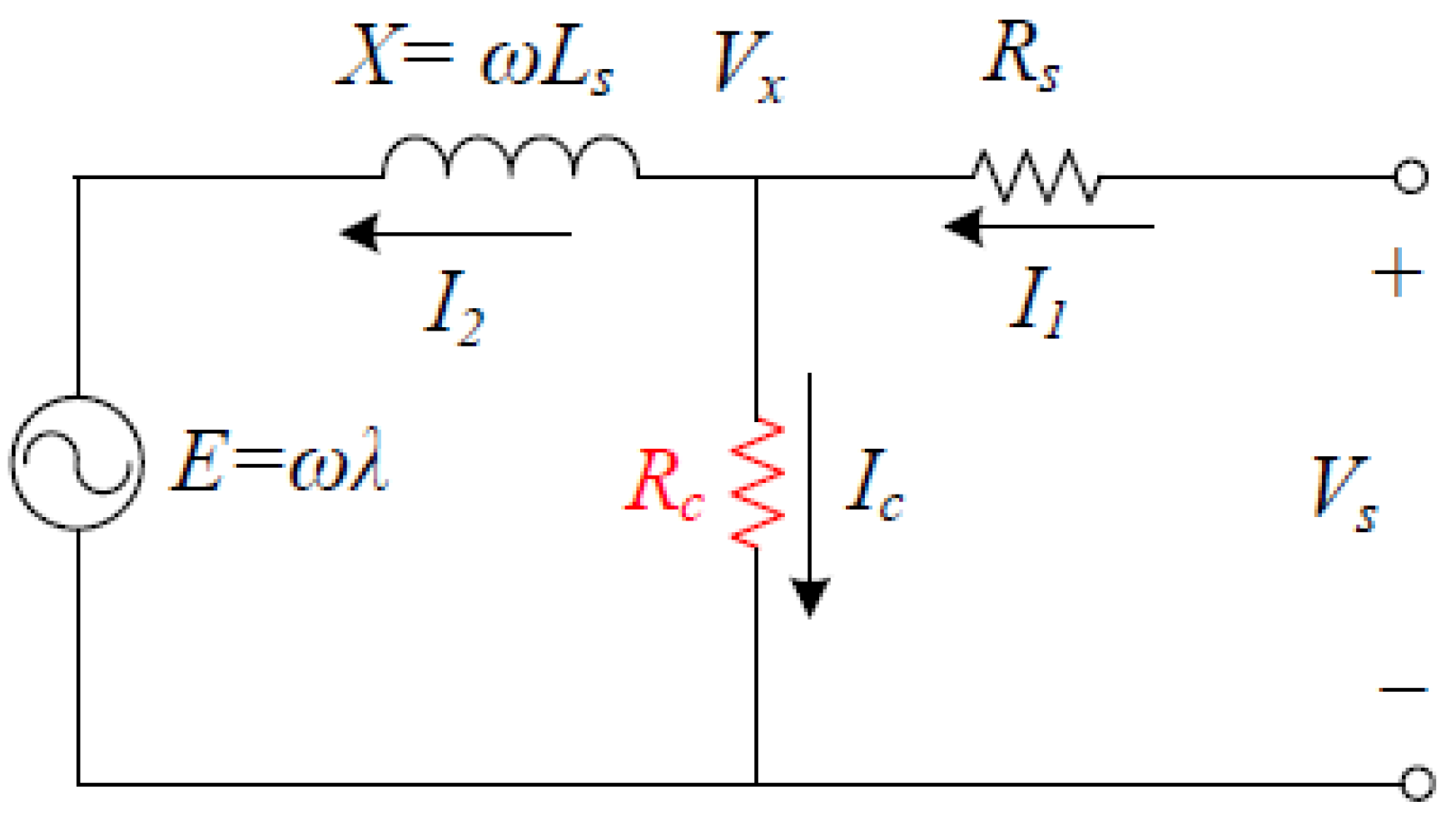

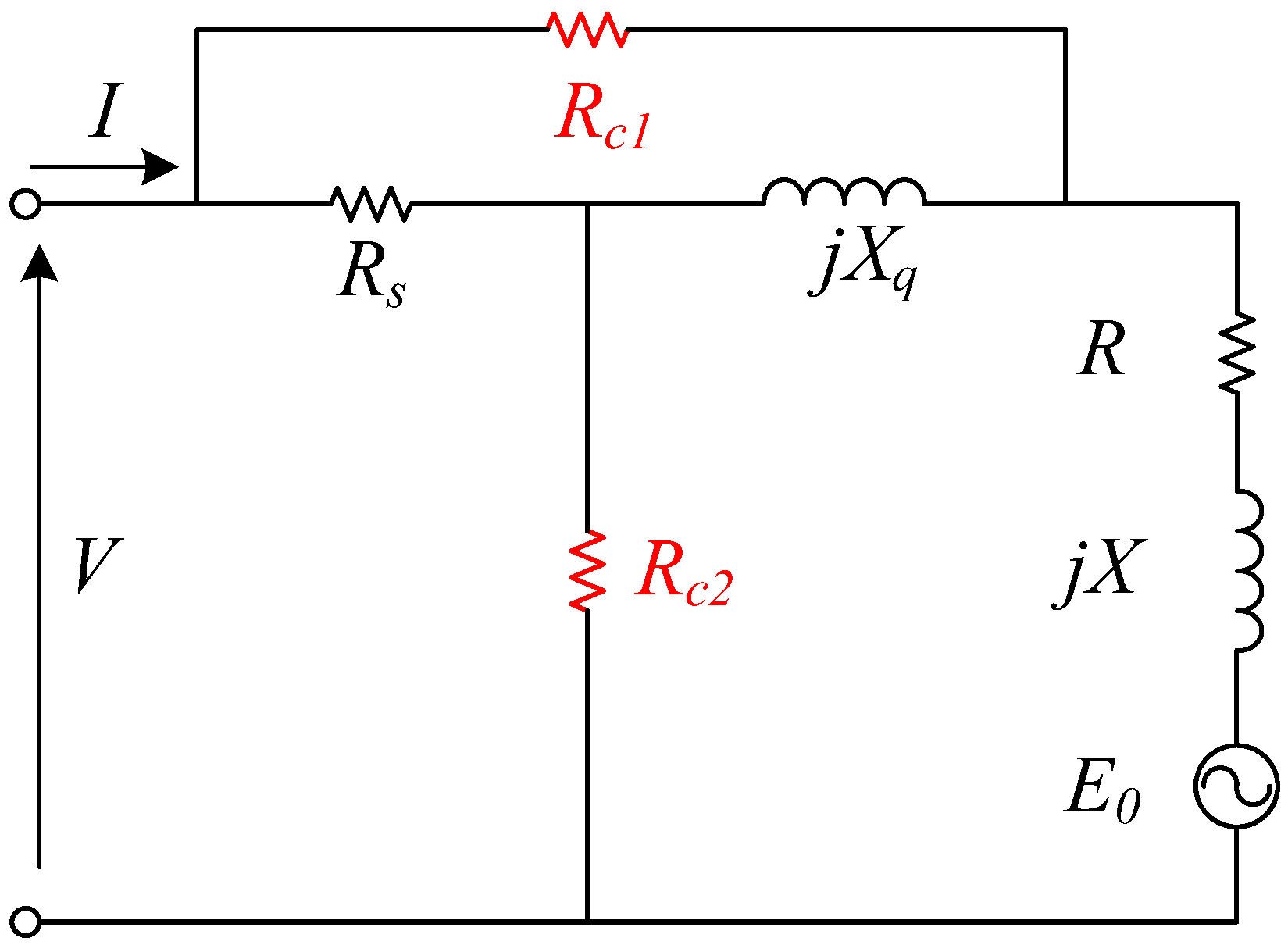

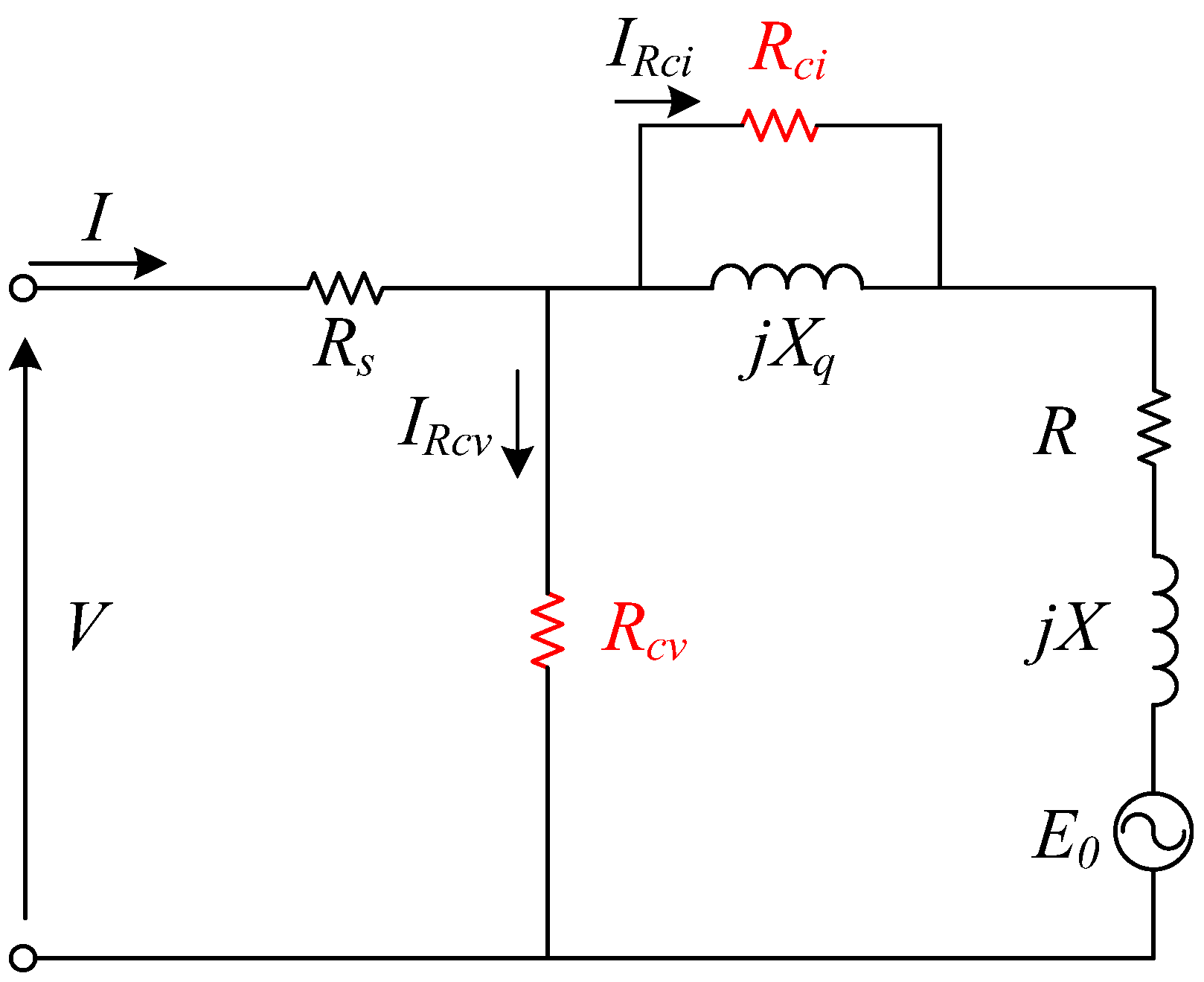

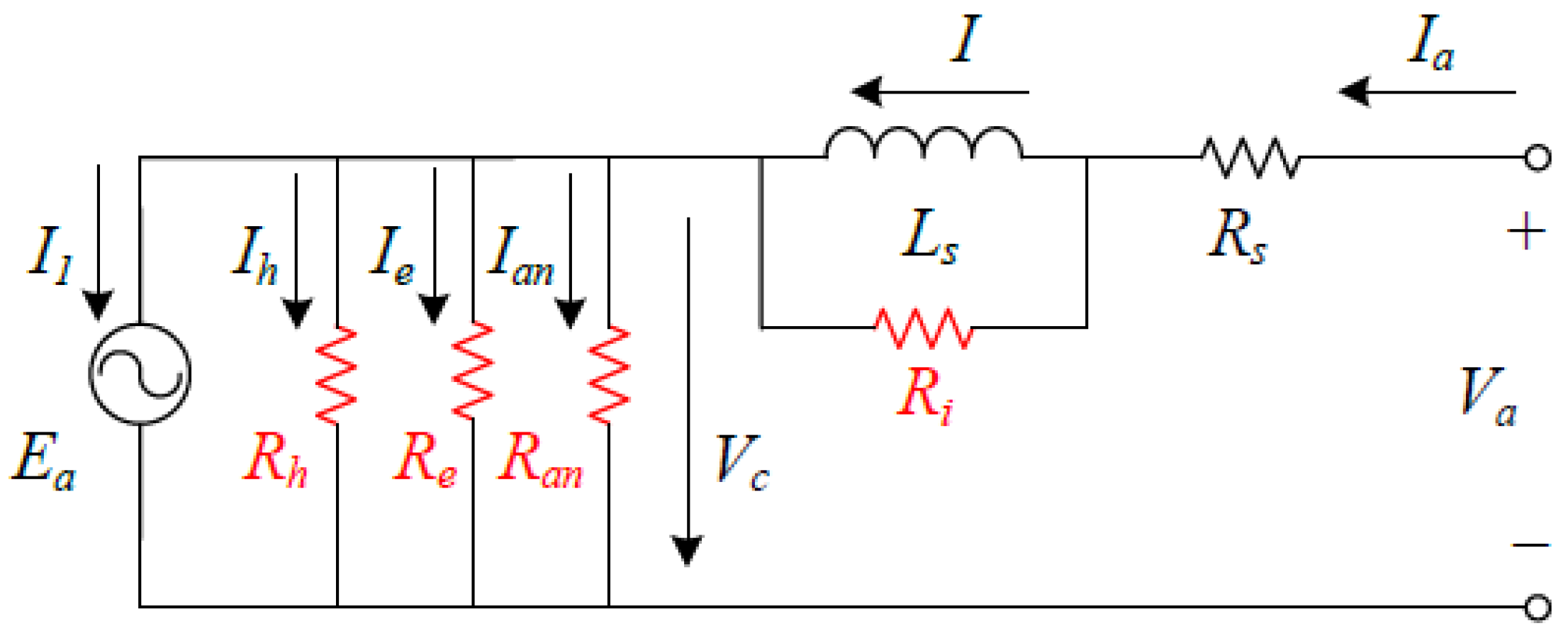

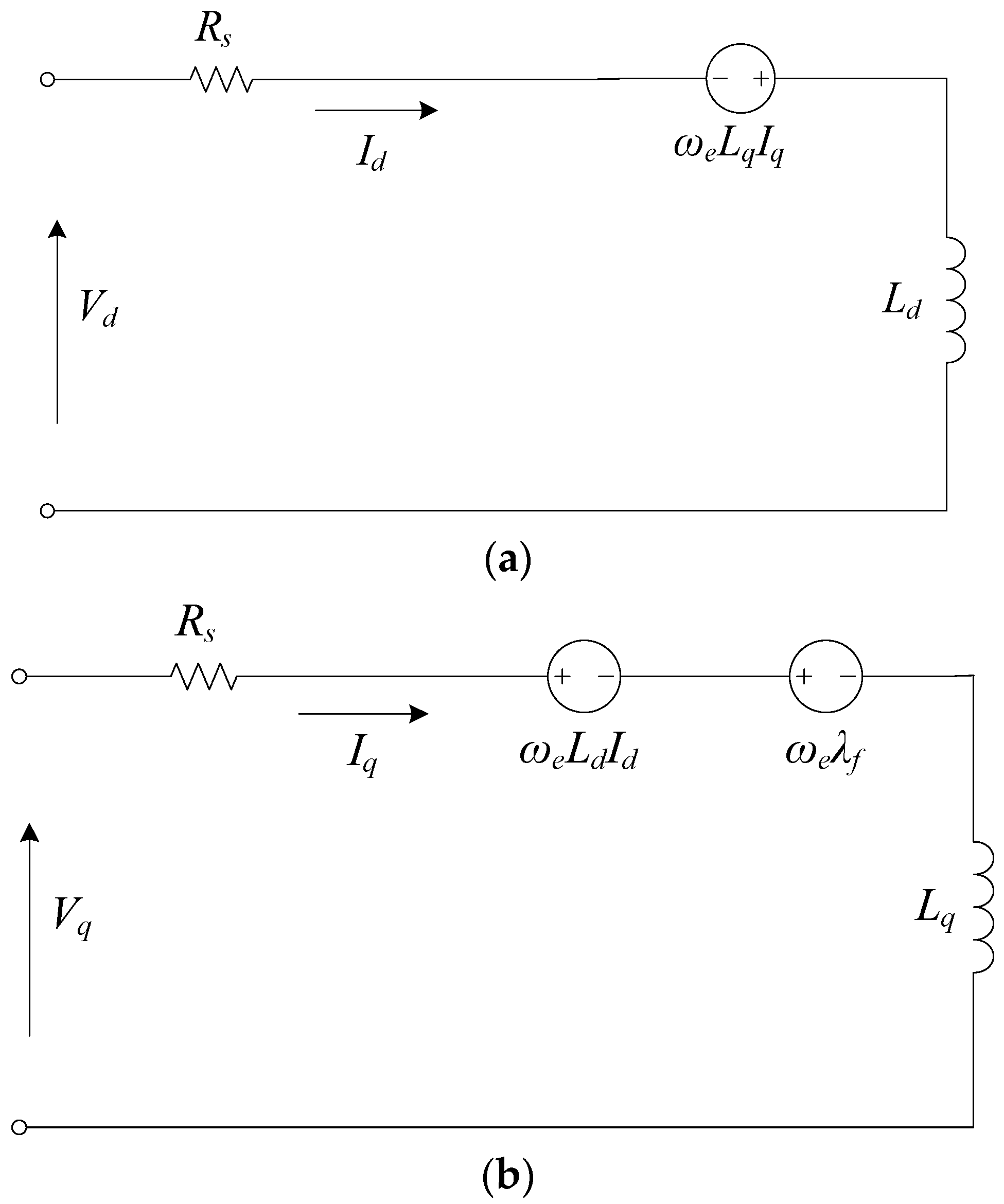

2. Development of PMM Equivalent Circuit Models Considering Core Loss

3. Performance Enhancement via Improved Design and Analysis Based on the Core Loss ECM

4. Performance Enhancement via Improved Control Based on the Core Loss ECM

5. Discussion and Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zhu, Z.Q.; Howe, D. Electrical Machines and Drives for Electric, Hybrid, and Fuel Cell Vehicles. Proc. IEEE 2007, 95, 746–765. [Google Scholar] [CrossRef]

- Chan, C.; Chau, K.; Jiang, J.; Xia, W.; Zhu, M.; Zhang, R. Novel Permanent Magnet Motor Drives for Electric Vehicles. IEEE Trans. Ind. Electron. 1996, 43, 331–339. [Google Scholar] [CrossRef]

- Su, W.; Rahimi-Eichi, H.; Zeng, W.; Chow, M.-Y. A Survey on the Electrification of Transportation in a Smart Grid Environment. IEEE Trans. Ind. Inform. 2012, 8, 1–10. [Google Scholar] [CrossRef]

- Viswanath, A.; Farid, A.M. A Hybrid Dynamic System Model for the Assessment of Transportation Electrification. In Proceedings of the 2014 American Control Conference, Portland, OR, USA, 4–6 June 2014; pp. 4617–4623. [Google Scholar]

- Bilgin, B.; Emadi, A. Electric Motors in Electrified Transportation: A Step toward Achieving a Sustainable and Highly Efficient Transportation System. IEEE Power Electron. Mag. 2014, 1, 10–20. [Google Scholar] [CrossRef]

- Tan, D. Transportation Electrification: Challenges and Opportunities. IEEE Power Electron. Mag. 2016, 3, 50–52. [Google Scholar] [CrossRef]

- Fernandes, J.F.P.; Bhagubai, P.P.C.; Branco, P.J.C. Recent Developments in Electrical Machine Design for the Electrification of Industrial and Transportation Systems. Energies 2022, 15, 6390. [Google Scholar] [CrossRef]

- Guo, Y.; Liu, L.; Ba, X.; Lu, H.; Lei, G.; Yin, W.; Zhu, J. Designing High-Power-Density Electric Motors for Electric Vehicles with Advanced Magnetic Materials. World Electr. Veh. J. 2023, 14, 114. [Google Scholar] [CrossRef]

- Ueno, S.; Enokizono, M.; Mori, Y.; Yamazaki, K. Vector Magnetic Characteristics of Ultra-Thin Electrical Steel Sheet for Development of High-Efficiency High-Speed Motor. IEEE Trans. Magn. 2017, 53, 6300604. [Google Scholar] [CrossRef]

- Pei, R.; Zeng, L.; Gao, L. Studies of Core Loss of Thin Non-oriented Electrical Steel for Electrical Vehicle Traction Motors. In Proceedings of the 2018 21st International Conference on Electrical Machines and Systems (ICEMS), Jeju, Republic of Korea, 7–10 October 2018; pp. 2715–2718. [Google Scholar]

- Huynh, T.; Hsieh, M.-F. Performance Evaluation of Thin Electrical Steels Applied to Interior Permanent Magnet Motor. In Proceedings of the 2016 19th International Conference on Electrical Machines and Systems (ICEMS), Chiba, Japan, 13–16 November 2016; pp. 1–6. [Google Scholar]

- Hasegawa, M.; Tanaka, N.; Chiba, A.; Fukao, T. The Operation Analysis and Efficiency Improvement of Switched Reluctance Motors with High Silicon Steel. In Proceedings of the Power Conversion Conference-Osaka 2002 (Cat. No.02TH8579), Osaka, Japan, 2–5 April 2002; pp. 981–986. [Google Scholar]

- Ou, J.; Liu, Y.; Breining, P.; Gietzelt, T.; Gietzelt, T.; Wunsch, T.; Doppelbauer, M. Study of the Electromagnetic and Mechanical Properties of a High-silicon Steel for a High-speed Interior PM Rotor. In Proceedings of the 2019 22nd International Conference on Electrical Machines and Systems (ICEMS), Harbin, China, 11–14 August 2019; pp. 1–4. [Google Scholar]

- Ma, D.; Li, J.; Tian, B.; Zhang, H.; Li, M.; Pei, R. Studies on Loss of a Motor Iron Core with High Silicon Electrical Steel Considering Temperature and Compressive Stress Factors. In Proceedings of the 2022 IEEE 5th International Electrical and Energy Conference (CIEEC), Nanjing, China, 27–29 May 2022; pp. 4243–4248. [Google Scholar]

- Jensen, C.C.; Profumo, F.; Lipo, T.A. A Low-Loss Permanent-Magnet Brushless dc Motor Utilizing Tape Wound Amorphous Iron. IEEE Trans. Ind. Appl. 1992, 28, 646–651. [Google Scholar] [CrossRef]

- Wang, Z.; Enomoto, Y.; Ito, M.; Masaki, R.; Morinaga, S.; Itabashi, H.; Tanigawa, S. Development of a Permanent Magnet Motor Utilizing Amorphous Wound Cores. IEEE Trans. Magn. 2010, 46, 570–573. [Google Scholar] [CrossRef]

- Wang, L.; Li, J.; Li, S.; Zhang, G.; Huang, S. Development of the New Energy-Efficient Amorphous Iron Based Electric Motor. In Proceedings of the 2011 International Conference on Computer Distributed Control and Intelligent Environmental Monitoring, Changsha, China, 19–20 February 2011; pp. 2059–2061. [Google Scholar]

- Fan, T.; Li, Q.; Wen, X. Development of a High Power Density Motor Made of Amorphous Alloy Cores. IEEE Trans. Ind. Electron. 2014, 61, 4510–4518. [Google Scholar] [CrossRef]

- Tomioka, T.; Akatsu, K. Study of High-Speed SRM with Amorphous Steel Sheet for EV. In Proceedings of the 2016 19th International Conference on Electrical Machines and Systems (ICEMS), Chiba, Japan, 13–16 November 2016; pp. 1–6. [Google Scholar]

- Fan, Z.; Yi, H.; Xu, J.; Xie, K.; Qi, Y.; Ren, S.; Wang, H. Performance Study and Optimization Design of High-Speed Amorphous Alloy Induction Motor. Energies 2021, 14, 2468. [Google Scholar] [CrossRef]

- Guo, Y.; Liu, L.; Yin, W.; Lu, H.; Lei, G.; Zhu, J. Designing High-Power-Density Electromagnetic Devices with Nanocrystalline and Amorphous Magnetic Materials. Nanomaterials 2023, 13, 1963. [Google Scholar] [CrossRef]

- Persson, M.; Jansson, P.; Jack, A.G.; Mecrow, B.C. Soft Magnetic Composite Materials—Use for Electrical Machines. In Proceedings of the 1995 Seventh International Conference on Electrical Machines and Drives (Conf. Publ. No. 412), Durham, UK, 11–13 September 1995; pp. 242–246. [Google Scholar]

- Jack, A.G.; Mecrow, B.C.; Maddison, C.P. Combined Radial and Axial Magnet Motors Using Soft Magnetic Composites. In Proceedings of the 1999 Ninth International Conference on Electrical Machines and Drives (Conf. Publ. No. 468), Canterbury, UK, 1–3 September 1999; pp. 25–29. [Google Scholar]

- Cvetkovski, G.; Petkovska, L.; Cundev, M.; Gair, S. Improved Design of a Novel PM Disk Motor by Using Soft Magnetic Composite Material. IEEE Trans. Magn. 2002, 38, 3165–3167. [Google Scholar] [CrossRef]

- Qu, R.; Kliman, G.B.; Carl, R. Split-Phase Claw-Pole Induction Machines with Soft Magnetic Composite Cores. In Proceedings of the 39th IAS Annual Meeting, Seattle, WA, USA, 3–7 October 2004; pp. 2514–2519. [Google Scholar]

- Guo, Y.; Zhu, J.G.; Dorrell, D.G. Design and Analysis of a Claw Pole Permanent Magnet Motor with Molded SMC Core. IEEE Trans. Magn. 2009, 45, 4582–4585. [Google Scholar]

- Zhu, J.G.; Guo, Y.G.; Lin, Z.W.; Li, Y.J.; Huang, Y.K. Development of PM Transverse Flux Motors with Soft Magnetic Composite Cores. IEEE Trans. Magn. 2011, 47, 4376–4383. [Google Scholar] [CrossRef]

- Doering, J.; Steinborn, G.; Hofmann, W. Torque, Power, Losses, and Heat Calculation of a Transverse Flux Reluctance Machine with Soft Magnetic Composite Materials and Disk-Shaped Rotor. IEEE Trans. Ind. Appl. 2015, 51, 1494–1504. [Google Scholar] [CrossRef]

- Liu, C.; Lei, G.; Ma, B.; Wang, Y.; Guo, Y.; Zhu, J. Development of a New Low-Cost 3-D Flux Transverse Flux FSPMM with Soft Magnetic Composite Cores and Ferrite Magnets. IEEE Trans. Magn. 2017, 53, 8109805. [Google Scholar] [CrossRef]

- Ahmed, N.; Atkinson, G.J. A Review of Soft Magnetic Composite Materials and Applications. In Proceedings of the 2022 International Conference on Electrical Machines (ICEM), Valencia, Spain, 5–8 September 2022; pp. 551–557. [Google Scholar]

- Guo, Y.; Ba, X.; Liu, L.; Lu, H.; Lei, G.; Yin, W.; Zhu, J. A Review of Electric Motors with Soft Magnetic Composite Cores for Electric Drives. Energies 2023, 16, 2053. [Google Scholar] [CrossRef]

- Snitchler, G.; Gamble, B.; Kalsi, S.S. The Performance of a 5 MW High Temperature Superconductor Ship Propulsion Motor. IEEE Trans. Appl. Supercond. 2005, 15, 2206–2209. [Google Scholar] [CrossRef]

- Gonzalez-Parada, A.; Espinosa-Loza, F.J.; Castaneda-Miranda, A.; Bosch-Tous, R.; Granados-Garcia, X. Application of HTS BSCCO Tapes in an Ironless Axial Flux Superconductor Motor. IEEE Trans. Appl. Supercond. 2012, 22, 5201004. [Google Scholar] [CrossRef]

- Jin, J.X.; Zheng, L.H.; Guo, Y.G.; Grantham, C.; Sorrell, C.C.; Xu, W. High-Temperature Superconducting Linear Synchronous Motors Integrated with HTS Magnetic Levitation Components. IEEE Trans. Appl. Supercond. 2012, 22, 5202617. [Google Scholar]

- Moon, H.; Kin, Y.-C.; Park, H.-J.; Park, M.; Yu, I.-K. Development of a MW-Class 2G HTS Ship Propulsion Motor. IEEE Trans. Appl. Supercond. 2016, 26, 5203805. [Google Scholar] [CrossRef]

- Liu, B.; Badcock, R.; Shu, H.; Tan, L.; Fang, J. Electromagnetic Characteristic Analysis and Optimization Design of a Novel HTS Coreless Induction Motor for High-Speed Operation. IEEE Trans. Appl. Supercond. 2018, 28, 5202405. [Google Scholar] [CrossRef]

- Lee, J.-Y.; Nam, G.-D.; Yu, I.-K.; Park, M. Design and Characteristic Analysis of an Axial Flux High-Temperature Superconducting Motor for Aircraft Propulsion. Materials 2023, 16, 3587. [Google Scholar] [CrossRef]

- Guo, Y.G.; Zhu, J.G.; Lin, Z.W.; Zhong, J.J.; Wu, W. Measurement and Modeling of Core Losses of Soft Magnetic Composites Under 3-D Magnetic Excitations in Rotating Motors. IEEE Trans. Magn. 2005, 41, 3925–3927. [Google Scholar]

- Sievert, J. Two-dimensional Magnetic Measurement-History and the Achievements of the Workshop. Przeg. Elektrot. 2011, 87, 2–10. [Google Scholar]

- Guo, Y.; Liu, L.; Ba, X.; Lu, H.; Lei, G.; Sarker, P.; Zhu, J. Characterization of Rotational Magnetic Properties of Amorphous Metal Materials for Advanced Electrical Machine Design and Analysis. Energies 2022, 15, 7798. [Google Scholar] [CrossRef]

- Guo, Y.; Liu, L.; Ba, X.; Lu, H.; Lei, G.; Yin, W.; Zhu, J. Measurement and Modeling of Magnetic Materials under 3D Vectorial Magnetization for Advanced Electrical Machine Design and Analysis. Energies 2023, 16, 417. [Google Scholar] [CrossRef]

- Soomro, W.A.; Guo, Y.; Lu, H.; Jin, J.X.; Shen, B.; Zhu, J.G. AC Loss in High-Temperature Superconducting Bulks Subjected to Alternating and Rotating Magnetic Fields. Materials 2023, 16, 633. [Google Scholar] [CrossRef]

- Sun, X.; Shi, Z.; Cai, Y.; Lei, G.; Guo, Y.; Zhu, J. Driving-Cycle-Oriented Design Optimization of a Permanent Magnet Hub Motor Drive System for a Four-Wheel-Drive Electric Vehicle. IEEE Trans. Transp. Electrif. 2020, 6, 1115–1125. [Google Scholar] [CrossRef]

- Lei, G.; Wang, T.; Zhu, J.; Guo, Y.; Wang, S. System-Level Design Optimization Method for Electrical Drive Systems—Robust Approach. IEEE Trans. Ind. Electron. 2015, 62, 4702–4713. [Google Scholar] [CrossRef]

- Salimi, A.; Lowther, D.A. On the Role of Robustness in Multi-Objective Robust Optimization: Application to an IPM Motor Design Problem. IEEE Trans. Magn. 2016, 52, 8102304. [Google Scholar] [CrossRef]

- Zhu, X.; Shu, Z.; Quan, L.; Xiang, Z.; Pan, X. Multi-Objective Optimization of an Outer-Rotor V-Shaped Permanent Magnet Flux Switching Motor Based on Multi-Level Design Method. IEEE Trans. Magn. 2016, 52, 8205508. [Google Scholar] [CrossRef]

- Ma, B.; Lei, G.; Zhu, J.; Guo, Y.; Liu, C. Application-Oriented Robust Design Optimization Method for Batch Production of Permanent-Magnet Motors. IEEE Trans. Ind. Electron. 2018, 65, 1728–1739. [Google Scholar] [CrossRef]

- Lei, G.; Bramerdorfer, G.; Ma, B.; Guo, Y.; Zhu, J. Robust Design Optimization of Electrical Machines: Multi-Objective Approach. IEEE Trans. Energy Convers. 2021, 36, 390–401. [Google Scholar] [CrossRef]

- Liu, C.-T.; Chiang, T.; Zamora, J.; Lin, S. Field-Oriented Control Evaluations of a Single-Sided Permanent Magnet Axial-Flux Motor for an Electric Vehicle. IEEE Trans. Magn. 2003, 39, 3280–3282. [Google Scholar]

- Men, X.; Guo, Y.; Wu, G.; Chen, S.; Shi, C. Implementation of an Improved Motor Control for Electric Vehicles. Energies 2022, 15, 4833. [Google Scholar] [CrossRef]

- Zhang, L.; Fan, Y.; Cui, R.; Lorenz, R.D.; Cheng, M. Fault-Tolerant Direct Torque Control of Five-Phase FTFSCW-IPM Motor Based on Analogous Three-Phase SVPWM for Electric Vehicle Applications. IEEE Trans. Veh. Technol. 2018, 67, 910–919. [Google Scholar] [CrossRef]

- Sun, X.; Diao, K.; Lei, G.; Guo, Y.; Zhu, J. Direct Torque Control Based on a Fast Modeling Method for a Segmented-Rotor Switched Reluctance Motor in HEV Application. IEEE J. Emerg. Sel. Top. Power Electron. 2019, 9, 232–241. [Google Scholar] [CrossRef]

- Wang, T.; Liu, C.; Lei, G.; Guo, Y.; Zhu, J. Model Predictive Direct Torque Control of Permanent Magnet Synchronous Motors with Extended Set of Voltage Space Vectors. IET Electr. Power Appl. 2017, 11, 1376–1382. [Google Scholar] [CrossRef]

- Wu, H.; Si, Z.; Li, Z. Trajectory Tracking Control for Four-Wheel Independent Drive Intelligent Vehicle Based on Model Pre-dictive Control. IEEE Access 2020, 8, 73071–73081. [Google Scholar] [CrossRef]

- Machacek, D.T.; Barhoumi, K.; Ritzmann, J.M.; Huber, T.; Onder, C.H. Multi-Level Model Predictive Control for the Energy Management of Hybrid Electric Vehicles Including Thermal Derating. IEEE Trans. Veh. Technol. 2022, 71, 10400–10414. [Google Scholar] [CrossRef]

- Ba, X.; Gong, Z.; Guo, Y.; Zhang, C.; Zhu, J. Development of Equivalent Circuit Models of Permanent Magnet Synchronous Motors Considering Core Loss. Energies 2022, 15, 1995. [Google Scholar] [CrossRef]

- Guo, Y.; Ba, X.; Liu, L.; Hou, L.; Lei, G.; Zhu, J. Performance Enhancement of Permanent Magnet Synchronous Motors Based on Improved Circuit Models. In Proceedings of the 25th International Conference on Electrical Machines and Systems (ICEMS), Chiang Mai, Thailand, 29 November–2 November 2023; pp. 1–6. [Google Scholar]

- Fiorillo, F.; Novikov, A. An Improved Approach to Power Losses in Magnetic Laminations under Nonsinusoidal Induction Waveform. IEEE Trans. Magn. 1990, 26, 2904–2910. [Google Scholar] [CrossRef]

- Guo, Y.; Zhu, J.; Zhong, J.; Wu, W. Core Losses in Claw Pole Permanent Magnet Machines with Soft Magnetic Composite Core. IEEE Trans. Magn. 2003, 39, 3199–3201. [Google Scholar]

- Ionel, D.M.; Poescu, M.; McGilp, M.I.; Miller, T.J.E.; Dellinger, S.J.; Heidman, R.J. Computation of Core Losses in Electrical Machines Using Improved Models for Laminated Steel. IEEE Trans. Ind. Appl. 2007, 43, 1554–1564. [Google Scholar] [CrossRef]

- Brix, W.; Hempel, K.A.; Schulte, F.J. Improved Method for the Investigations of the Rotational Magnetization Process in Electrical Steel Sheets. IEEE Trans. Magn. 1984, 20, 1708–1710. [Google Scholar] [CrossRef]

- Sievert, J. Recent Advances in the One- and Two-dimensional Magnetic Measurement Technique for Electrical Sheet Steel. IEEE Trans. Magn. 1990, 26, 2553–2558. [Google Scholar] [CrossRef]

- Bertotti, G.; Boglietti, A.; Chiampi, M.; Chiarabaglio, D.; Fiorillo, F.; Lazzari, M. An Improved Estimation of Iron Losses in Rotating Machines. IEEE Trans. Magn. 1991, 27, 5007–5009. [Google Scholar] [CrossRef]

- Stranges, N.; Findlay, R.D. Importance of Rotational Iron Loss Data for Accurate Prediction of Rotating Machine Core Losses. In Proceedings of the 29th IEEE Industry Applications Society Annual Meeting (IAS), Denver, CO, USA, 2–6 October 1994; pp. 123–127. [Google Scholar]

- Enokizono, M.; Tanabe, I. Studies on a New Simplified Rotational Loss Tester. IEEE Trans. Magn. 1997, 33, 4020–4022. [Google Scholar] [CrossRef]

- Zhu, J.G.; Ramsden, V.S. Improved Formulations for Rotational Core Losses in Rotating Electrical Machines. IEEE Trans. Magn. 1998, 34, 2234–2242. [Google Scholar]

- Guo, Y.; Zhu, J.G.; Zhong, J.; Lu, H.; Jin, J.X. Measurement and Modeling of Rotational Core Losses of Soft Magnetic Materials Used in Electrical Machines: A Review. IEEE Trans. Magn. 2008, 44, 279–291. [Google Scholar]

- Guo, Y.; Zhu, J.; Lu, H.; Lin, Z.; Li, Y. Core Loss Calculations for Soft Magnetic Composite Electrical Machines. IEEE Trans. Magn. 2012, 48, 3112–3115. [Google Scholar] [CrossRef]

- Li, J.; Zhang, Y.; Zhang, D.; Ren, Z.; Koh, C.S. Analysis of Rotational Hysteresis Property in a Transformer Core Based on an Inverse Jiles-Atherton Hysteresis Model Coupled with Finite Element Method. In Proceedings of the 23rd International Conference on Electrical Machines and Systems (ICEMS), Hamamastsu, Japan, 24–27 November 2020; pp. 1027–1030. [Google Scholar]

- Sarker, P.C.; Guo, Y.; Lu, H.Y.; Zhu, J.G. Measurement and Modeling of Rotational Core Loss of Fe-Based Amorphous Magnetic Material Under 2-D Magnetic Excitation. IEEE Trans. Magn. 2021, 57, 8402008. [Google Scholar] [CrossRef]

- Yan, J.; Di, C.; Bao, X.; Zhu, Q. Iron Loss Model for Induction Machines Considering the Influence of Rotational Iron Losses. IEEE Trans. Energy Convers. 2023, 38, 971–981. [Google Scholar] [CrossRef]

- Honsinger, V. Performance of Polyphase Permanent Magnet Machines. IEEE Trans. Power App. Syst. 1980, PAS-99, 1510–1518. [Google Scholar] [CrossRef]

- Colby, R.S.; Novotny, D.W. Efficient Operation of Surface-Mounted PM Synchronous Motors. IEEE Trans. Ind. Appl. 1987, IA-23, 1048–1054. [Google Scholar] [CrossRef]

- Ba, X.; Guo, Y.; Zhu, J.G.; Zhang, C. An Equivalent Circuit Model for Predicting the Core Loss in a Claw-Pole Permanent Magnet Motor with Soft Magnetic Composite Core. IEEE Trans. Magn. 2018, 54, 8206706. [Google Scholar] [CrossRef]

- Lee, J.Y.; Lee, S.H.; Lee, G.H.; Hong, J.P.; Hur, J. Determination of Parameters Considering Magnetic Nonlinearity in an Interior Permanent Magnet Synchronous Motor. IEEE Trans. Magn. 2006, 42, 1303–1306. [Google Scholar]

- Hur, J. Characteristic Analysis of Interior Permanent-Magnet Synchronous Motor in Electrohydraulic Power Steering systems. IEEE Trans. Ind. Electron. 2008, 55, 2316–2323. [Google Scholar]

- Rachev, S.; Stefanov, D.; Dimitrov, L.; Koeva, D. Evaluation of Electric Power Losses of an Induction Motor Driving a Compact Electric Vehicles at Change of Parameters and Loads. In Proceedings of the Electric Vehicles International Conference & Show (EV2019), Bucuresti, Romania, 3–4 October 2019; pp. 1–5. [Google Scholar]

- Guo, Y.; Zhu, J.G.; Watterson, P.A.; Wu, W. Development of a PM Transverse Flux Motor with Soft Magnetic Composite Core. IEEE Trans. Energy Convers. 2006, 21, 426–434. [Google Scholar] [CrossRef]

- Tao, D.; Zhou, K.L.; Lv, F.; Dou, Q.; Wu, J.; Sun, Y.; Zou, J. Magnetic Field Characteristics and Stator Core Losses of High-Speed Permanent Magnet Synchronous Motors. Energies 2020, 13, 535. [Google Scholar] [CrossRef]

- Consoli, A.; Renna, G. Interior Type Permanent Magnet Synchronous Motor Analysis by Equivalent Circuits. IEEE Trans. Energy Convers. 1989, 4, 681–689. [Google Scholar] [CrossRef]

- Consoli, A.; Raciti, A. Analysis of Permanent Magnet Synchronous Motors. IEEE Trans. Ind. Appl. 1991, 27, 350–354. [Google Scholar] [CrossRef]

- Guo, Y.; Zhu, J.; Lu, H.; Li, Y.; Jin, J. Core Loss Computation in a Permanent Magnet Transverse Flux Motor with Rotating Fluxes. IEEE Trans. Magn. 2014, 50, 6301004. [Google Scholar] [CrossRef]

- Hou, L.; Guo, Y.; Ba, X.; Lei, G.; Zhu, J. Efficiency Improvement of Permanent Magnet Synchronous Motors Using Model Predictive Control Considering Core Loss. Energies 2024, 17, 773. [Google Scholar] [CrossRef]

- Li, Y.; Gerling, D.; Ma, J.; Liu, J.; Yu, Q. The Comparison of Control Strategies for the Interior PMSM Drive used in the Electric Vehicle. World Electr. Veh. J. 2010, 4, 648–654. [Google Scholar] [CrossRef]

- Wang, Z.; Chen, J.; Cheng, M.; Chau, K.T. Field-Oriented Control and Direct Torque Control for Paralleled VSIs Fed PMSM Drives with Variable Switching Frequencies. IEEE Trans. Power Electron. 2016, 31, 2417–2428. [Google Scholar] [CrossRef]

- Yan, Y.; Wang, S.; Xia, C.; Wang, H.; Shi, T. Hybrid Control Set-Model Predictive Control for Field-Oriented Control of VSI-PMSM. IEEE Trans. Energy Convers. 2016, 31, 1622–1633. [Google Scholar] [CrossRef]

- Farah, N.; Lei, G.; Zhu, J.; Guo, Y. Two-Vector Dimensionless Model Predictive Control of PMSM Drives Based on Fuzzy Decision Making. CES Trans. Electr. Mach. Syst. 2022, 6, 393–403. [Google Scholar] [CrossRef]

- Li, T.; Sun, X.; Lei, G.; Yang, Z.; Guo, Y.; Zhu, J. Finite-Control-Set Model Predictive Control of Permanent Magnet Synchronous Motor Drive Systems—An Overview. IEEE/CAA J. Autom. Sin. 2022, 9, 2087–2105. [Google Scholar] [CrossRef]

- Wang, H.; Wu, T.; Guo, Y.; Lei, G.; Wang, X. Predictive Current Control of Sensorless Linear Permanent Magnet Synchronous Motor. Energies 2023, 16, 628. [Google Scholar] [CrossRef]

- Uddin, M.N.; Nam, S.W. New Online Loss-Minimization-Based Control of an Induction Motor Drive. IEEE Trans. Power Electron. 2008, 23, 926–933. [Google Scholar] [CrossRef]

- Yu, J.; Pei, W.; Zhang, C. A Loss-Minimization Port-Controlled Hamilton Scheme of Induction Motor for Electric Vehicles. IEEE/ASEM Trans. Mechatron. 2015, 20, 2645–2653. [Google Scholar] [CrossRef]

- Eftekhari, S.R.; Davari, S.A.; Naderi, P.; Carcia, C.; Rodriguez, J. Robust Loss Minimization for Predictive Direct Torque and Flux Control of an Induction Motor with Electrical Circuit Model. IEEE Trans. Power Electron. 2020, 35, 5417–5426. [Google Scholar] [CrossRef]

- Xiao, X.; Xu, W.; Tang, Y.; Li, W.; Dong, D.; Shangguan, Y.; Huang, S. Improved Loss Minimization Control Based on Time-Harmonic Equivalent Circuit for Linear Induction Motors Adopted to Linear Metro. IEEE Trans. Veh. Technol. 2023, 72, 8601–8612. [Google Scholar] [CrossRef]

- Morimoto, S.; Tong, Y.; Takeda, Y.; Hirasa, T. Loss Minimization Control of Permanent Magnet Synchronous Motor Drives. IEEE Trans. Ind. Electron. 1994, 41, 511–517. [Google Scholar] [CrossRef]

- Mademlis, C.; Margaris, N. Loss Minimization in Vector-Controlled Interior Permanent-Magnet Synchronous Motor Drives. IEEE Trans. Ind. Electron. 2002, 49, 1344–1347. [Google Scholar] [CrossRef]

- Xie, W.; Wang, X.; Wang, F.; Xu, W.; Kennel, R.; Gerling, D. Dynamic Loss Minimization of Finite Control Set-Model Predictive Torque Control for Electric Drive System. IEEE Trans. Power Electron. 2016, 31, 849–860. [Google Scholar] [CrossRef]

- Li, X.; Lu, K.; Zhao, Y.; Chen, D.; Yi, P.; Hua, W. Incorporating Harmonic-Analysis-Based Loss Minimization into MPTC for Efficiency Improvement of FCFMPM Motor. IEEE Trans. Ind. Electron. 2023, 70, 6540–6550. [Google Scholar] [CrossRef]

- Fernandez-Bernal, F.; Carcia-Cerrada, A.; Faure, R. Model-Based Loss Minimization for DC and AC Vector-Controlled Motors Including Core Saturation. IEEE Trans. Ind. Appl. 2000, 36, 755–763. [Google Scholar] [CrossRef]

| Speed (rpm) | Core Loss (W) |

|---|---|

| 200 | 4.2 |

| 400 | 9.3 |

| 600 | 15.3 |

| 800 | 22.1 |

| 1000 | 29.8 |

| 1200 | 38.4 |

| 1400 | 47.9 |

| 1600 | 58.2 |

| 1800 | 69.4 |

| Sa | Sb | Sc | Voltage Vector V |

|---|---|---|---|

| 0 | 0 | 0 | |

| 1 | 0 | 0 | |

| 1 | 1 | 0 | |

| 0 | 1 | 0 | |

| 0 | 1 | 1 | |

| 0 | 0 | 1 | |

| 1 | 0 | 1 | |

| 1 | 1 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, Y.; Yu, Y.; Lu, H.; Lei, G.; Zhu, J. Enhancing Performance of Permanent Magnet Motor Drives through Equivalent Circuit Models Considering Core Loss. Energies 2024, 17, 1837. https://doi.org/10.3390/en17081837

Guo Y, Yu Y, Lu H, Lei G, Zhu J. Enhancing Performance of Permanent Magnet Motor Drives through Equivalent Circuit Models Considering Core Loss. Energies. 2024; 17(8):1837. https://doi.org/10.3390/en17081837

Chicago/Turabian StyleGuo, Youguang, Yunfei Yu, Haiyan Lu, Gang Lei, and Jianguo Zhu. 2024. "Enhancing Performance of Permanent Magnet Motor Drives through Equivalent Circuit Models Considering Core Loss" Energies 17, no. 8: 1837. https://doi.org/10.3390/en17081837

APA StyleGuo, Y., Yu, Y., Lu, H., Lei, G., & Zhu, J. (2024). Enhancing Performance of Permanent Magnet Motor Drives through Equivalent Circuit Models Considering Core Loss. Energies, 17(8), 1837. https://doi.org/10.3390/en17081837