Research on the Law of Layered Fracturing in the Composite Roof Strata of Coal Seams via Hydraulic Fracturing

Abstract

:1. Introduction

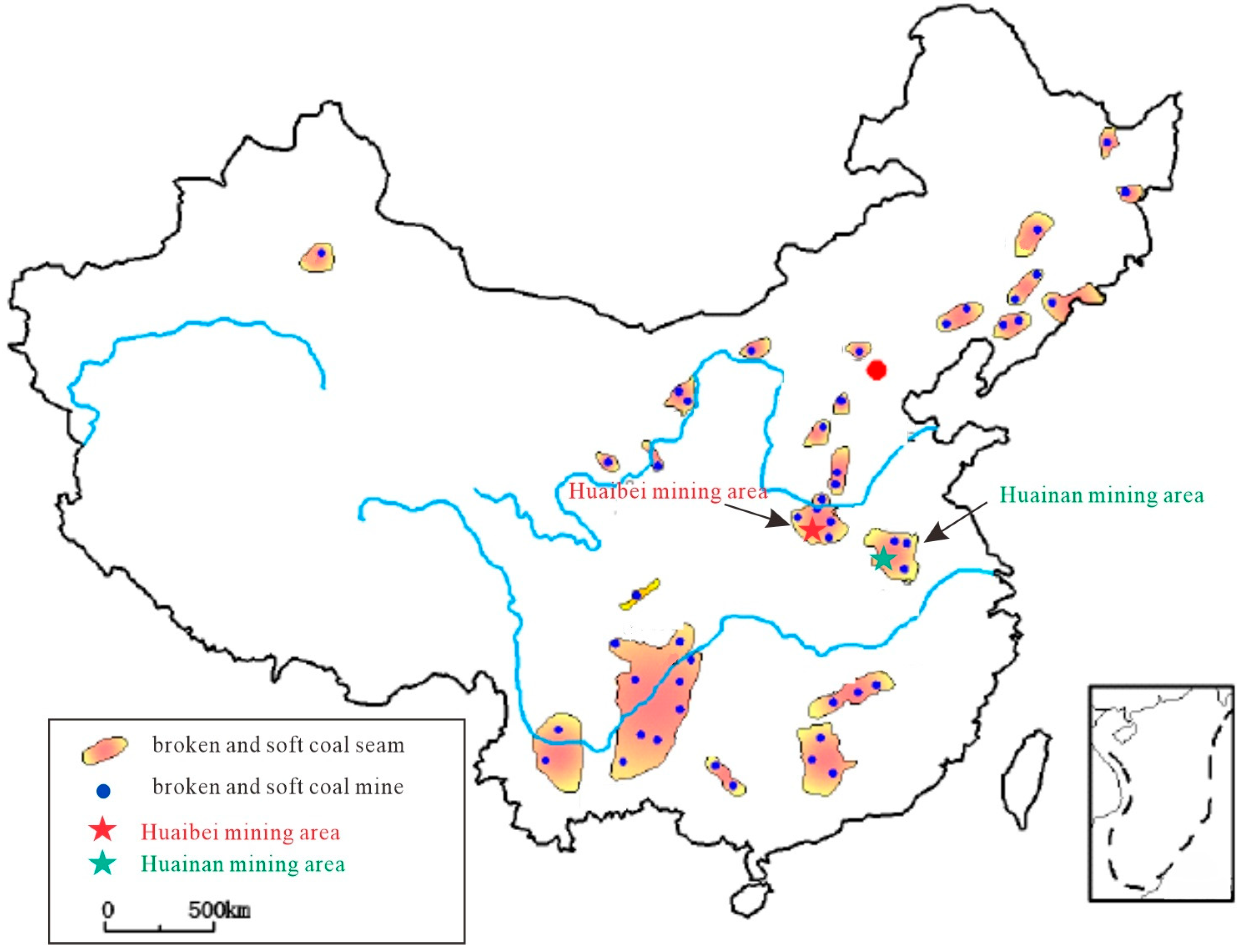

2. Engineering Background

2.1. Geological Background

2.2. The Gas Extraction Model of Sectional Hydraulic Fracturing in the Rock of the Coal Seam Roof

3. Numerical Model

3.1. Model Parameter Settings

3.2. Numerical Simulation Results

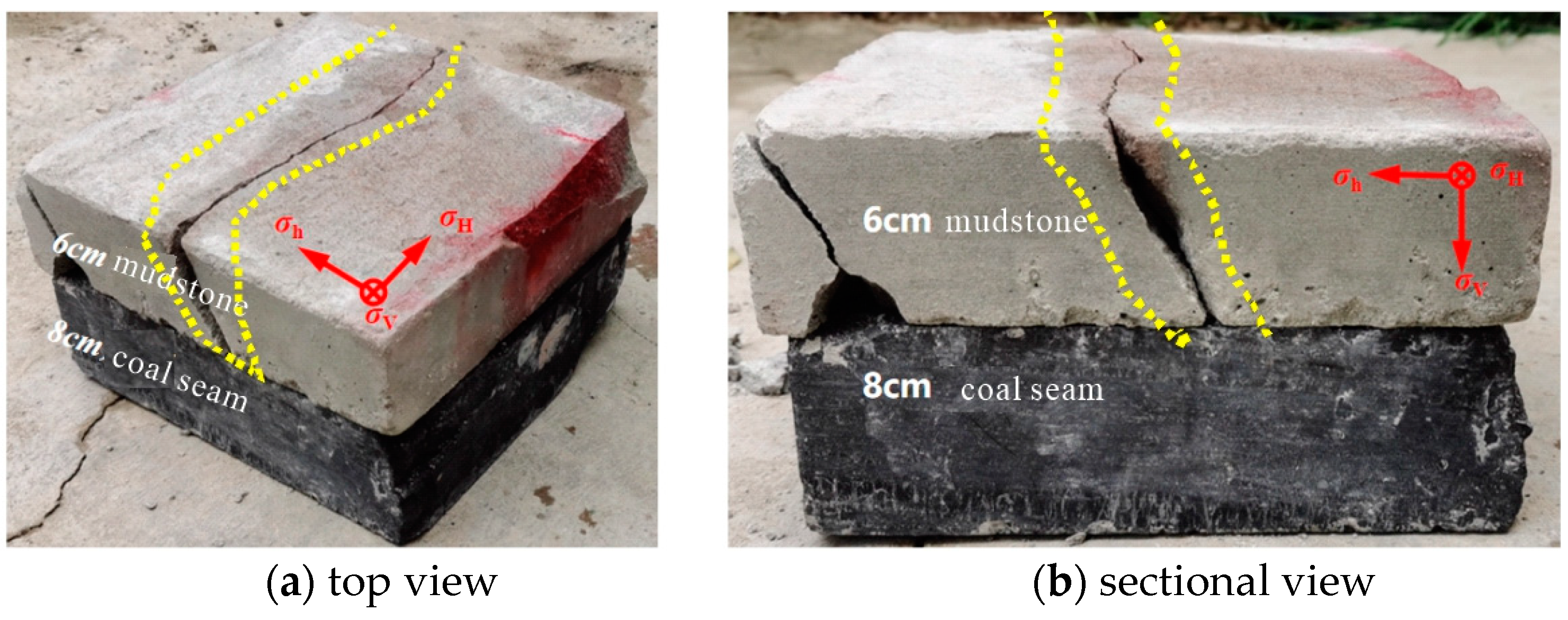

4. Physical Similarity Models

4.1. The Fabrication of Physical Similarity Models

4.2. Quality Control and Uncertainty Discussion

- (1)

- Different bonding strengths between the rock layers’ interfaces may have subtle effects on the expansion of fractures crossing the interface. Therefore, during model preparation, the pouring procedure and method were ensured to be identical, and the coal and sandstone original rock samples were taken from the same location. The bonding materials used were strictly uniform, and the thickness of the Baiyun adhesive was kept consistent to eliminate differences in interface bonding strength.

- (2)

- The nonverticality of the horizontal wellbore with respect to the specimen boundary may affect the distance between the horizontal well fracture point and the coal seam, thereby affecting the test results. Thus, during wellbore processing, efforts were made to ensure that the wellbore was completely vertical with respect to the specimen boundary, reducing the influence of wellbore inclination. Variations in the length of the cut when precutting the fractures for inducing hydraulic fracturing may also affect the test results. Therefore, the same cutting method and procedure were employed for manually precutting the fractures to ensure that the precut length of the specimens was consistent.

- (3)

- The application of confining pressure was achieved through triaxial loading plates. Due to the uneven surface treatment of the specimens, the force actually applied to the specimen surface may be unevenly distributed, leading to stress concentration and affecting the test results. Hence, after the completion of horizontal wellbore processing, each face of the specimen was polished to smoothness to eliminate the influence of local stress.

4.3. Physical Simulation Experimental Conditions and Parameters

4.4. Physical Similarity Simulation Experiment Procedure

- (1)

- 1# piece

- (2)

- 2# piece

4.5. The Results of the Physical Similarity Model

5. Engineering Application

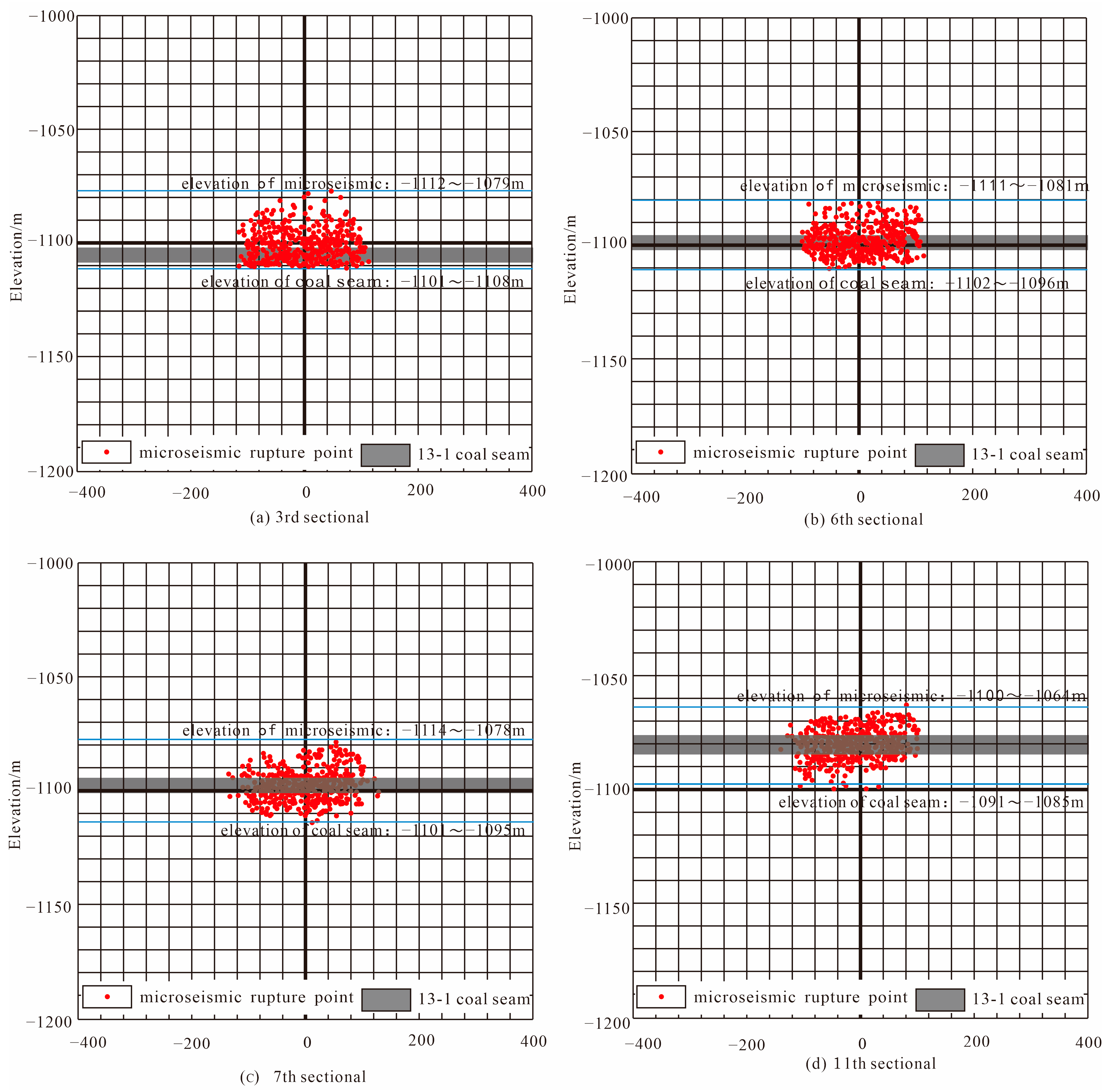

5.1. Panxie Coal Mine of Huainan Mine Area

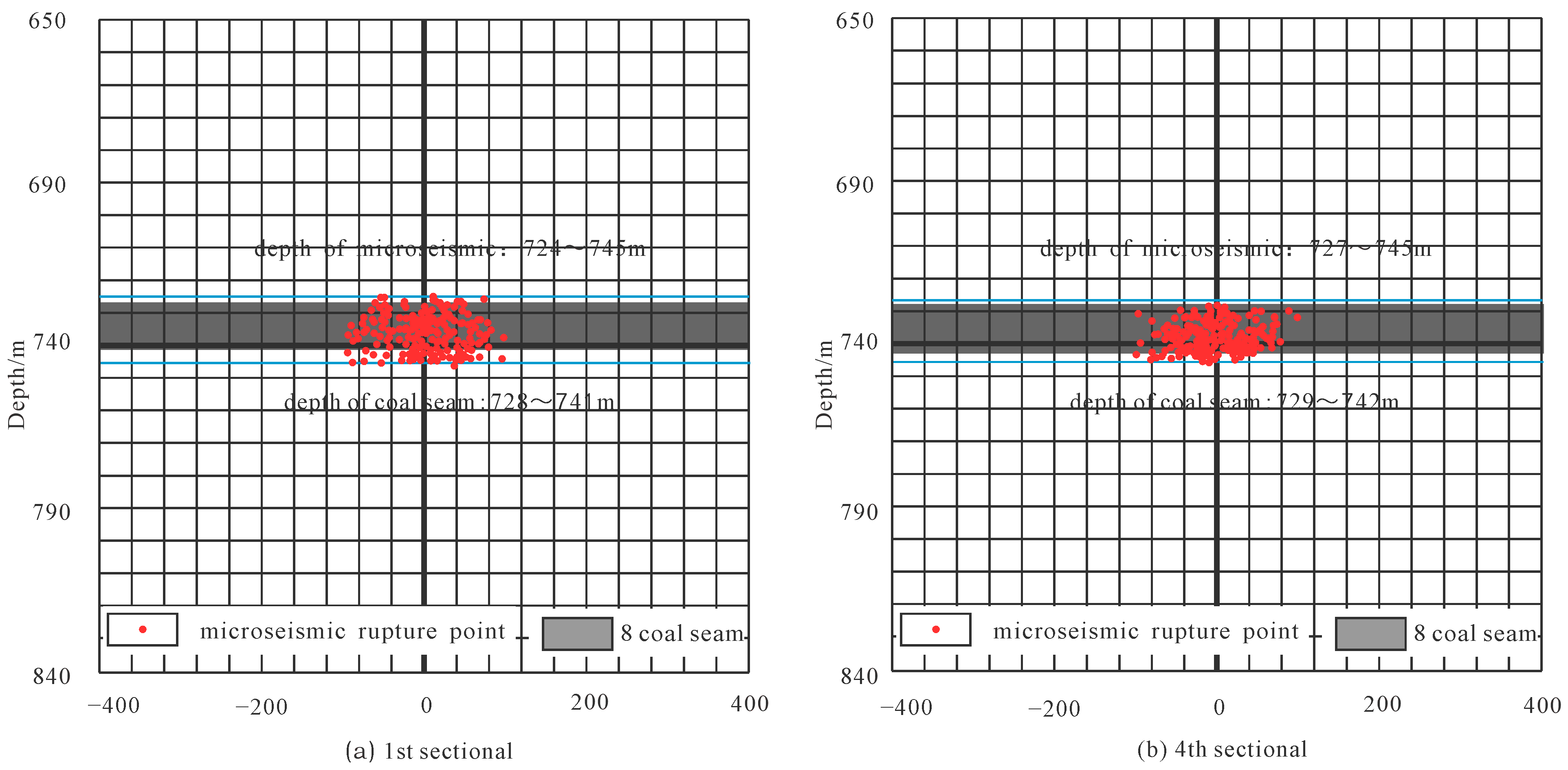

5.2. Luling Coal Mine of Huanbei Mine Area

5.3. Comparative Analysis

- (1)

- The main reasons for this difference lie in the geological conditions. The coal seam thickness in the Luling parameter well of Huaibei coalfield was 13.50 m, belonging to the stable ultra-thick coal seam in the entire region. In contrast, the coal seam thickness in Huainan coal mine was only 6.70 m, with significant variations in coal thickness.

- (2)

- Furthermore, based on the statistical data of the gas storage ratio from the parameter wells, the average gas storage ratio in the Panxie coal mine of Huainan was only around 0.55, while the average gas storage ratio in the Luling coal mine of Huaibei was around 0.64, reflecting the relatively low gas saturation of coal seams in the Huainan coalfield. From the permeability data of coal seams in the Huainan coalfield, it can be observed that the permeability of coal seams was low, with a maximum measured permeability of only 0.011 md, indicating extremely poor permeability of coal seams. Although the permeability of the No. 8 coal seam in Luling coal mine was also low, ranging from 0.18 to 0.99 md, it was much higher than that of the Panxie coal mine in Huainan.

- (3)

- Finally, due to the shallower burial depth, the bottom depth of Luling coal mine in Huaibei was approximately 742 m, while the burial depth of Panxie coal mine in Huainan was deeper, averaging around 1100 m. This resulted in increased pumping pressure for fracturing operations in Huainan, making it difficult to increase the displacement. The displacement in Luling coal mine in Huaibei generally exceed 10 m3/min, while the average displacement in Panxie coal mine in Huainan was around 8.2 m3/min.

6. Conclusions

- (1)

- The numerical simulation method simulated the penetration and extension law of fracture at the boundary of coal-rock after fracturing in the roof stratum. It was proven that the fracture in the roof stratum can extend to the coal seam. The fracture within the coal can spread rapidly and the fracture width of the coal seam was wider than that of the roof stratum.

- (2)

- With the increase in the false mudstone roof thickness and under the condition of constant fracturing volume, the width of fractures in the coal seam decreased. The reason was that the fracturing process consumed certain kinetic energy in the fracture of the mudstone pseudo roof, leading to a reduction in pore pressure when the fractures extended into the coal seam, and consequently, a decrease in fracture width. The width of fractures in the coal seam roof initially increased rapidly and then slowed down, with the final fracturing width showing a negative correlation with the thickness of the false mudstone roof. The reason was that the initiation time of the fracture at the interface between the immediate roof and the pseudo roof (sandstone-mudstone interface) increased during the fracturing process, resulting in initially larger widths of roof fractures. After the fracture of the mudstone pseudo roof, the energy loss caused a rapid decrease in the growth rate of fracture width in the later stage.

- (3)

- Considering the development of the false roof in the mudstone, physical similarity simulation was employed to simulate the expansion fracture. The results indicated that with horizontal boreholes placed within the sandy mudstone of the fractured soft coal seam roof, under reasonable vertical distance and high-volume fracturing fluid construction, and if the coal seam had a relatively thin false roof of mudstone, the fracture can penetrate through the direct roof-false roof interface (sandy mudstone-mudstone interface) and the false roof-coal seam interface (mudstone-coal seam interface), extending into the underlying coal seam. The fracture then extended to form a curved and irregular stepped pattern, demonstrating that hydraulic fracturing can achieve the goal of fracturing and increasing production in both soft and hard coal seams. However, when the coal seam developed a thicker false roof of mudstone, the mudstone created a blocking effect on hydraulic fracturing, making it difficult for the fracture to open the underlying coal seam. It was evident that the thick false mudstone roof was a detrimental factor for hydraulic fracturing and production enhancement of the coal seam roof. Therefore, it is recommended to increase the construction volume in areas where the false mudstone roof is well developed.

- (4)

- The engineering verification conducted at the Panxie coal mine and the Luling coal mine showed that by utilizing a construction drainage rate of 7.5 cubic meters per minute at Panxie coal mine, the maximum fracture length reached 218.3 m, with a maximum fracture height of 36.8 m. The maximum daily gas production of a single well reached 1450 cubic meters per day, with a total gas extraction volume of 43.62 × 104 cubic meters over two years. At Luling coal mine, utilizing a construction drainage rate of 10 cubic meters per minute, the maximum fracture length reached 169.1 m, with a maximum fracture height of 20.5 m. The maximum daily gas production of a single well reached 10,775 cubic meters per day, with a total gas extraction volume of 590 × 104 cubic meters for 1090 days. This indicated that the fracture within the roof can penetrate the composite roof of coal seams and extended to the interior of the coal seams, achieving the purpose of transforming fractured and low-permeability coal seams and providing an effective mode of gas extraction.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, W.; Cui, C.; Zhang, Z.; Wei, M.; Ma, X. Optimization of Gas Drainage Parameters for Large-Diameter Drilling in Low-Permeability Coal Seam. Coal Technol. 2024, 43, 195–199. [Google Scholar] [CrossRef]

- Chen, B.; Yuan, L.; Xue, S.; Jiang, W.; Yang, K.; Zhou, T.; Li, D.; Wu, J. Study on segmented fracturing and horizontal well drainage technology for coal seam roof in Huainan mining area. Coal Sci. Technol. 2024, 1–11. Available online: http://kns.cnki.net/kcms/detail/11.2402.td.20240327.1504.003.html (accessed on 18 April 2024).

- Wang, E.; Zhang, G.; Zhang, C.; Li, Z. Preventionand control of coal and gas outburst in China Progress and prospect of theoretical and technical research. J. Coal 2022, 47, 297–322. [Google Scholar]

- Ding, Y.; Zhu, B.; Li, S.; Lin, H.; Wei, Z.; Li, L.; Long, H.; Yi, Y. Accurate identification and efficient extraction of pressure relief gas in goaf of high outburst mines. J. Coal Ind. 2021, 46, 3565–3577. [Google Scholar]

- Chai, J.; Liu, Y.; Wang, Z.; Lei, W.; Zhang, D.; Ouyang, Y.; Sun, K.; Weng, M.; Zhang, Y.; Ding, G.; et al. Pressure relief effect and optical fiber monitoring of coal and rock underlying protected layer mining. J. Coal Sci. 2022, 47, 2896–2906. [Google Scholar]

- Wu, D.; Li, S. Research on regional gas drainage technology using holes instead of roadways in a single medium thick coal seam. Coal Technol. 2021, 40, 58–62. [Google Scholar]

- Li, Q.; Ye, S.; Jin, X. Application of hole protection technology and equipment for bedding hole screen tubes in soft coal seams. Coal Sci. Technol. 2017, 45, 147–151. [Google Scholar]

- Tang, Y.; Li, P.; Zhu, G.; Chen, J.; Chen, D.; Feng, A.; Tang, Z.; Yang, Y.; Ye, M. Application of ultra-high pressure hydraulic cutting technology in medium hardness and low permeability coal seams. Coal Sci. Technol. 2022, 50, 43–49. [Google Scholar]

- Zhou, L.; Peng, Y.; Lu, Y.; Xia, B. Numerical simulation study on hydraulic slotting, pressure relief, desorption, and permeability enhancement of deep coalbed methane based on the material point method. J. Coal Sci. 2022, 47, 3298–3309. [Google Scholar]

- Liu, W.; Xu, X.; Han, J.; Wang, B.; Li, Z.; Yan, Y. Trend model and key technologies for methane emission reduction in coal mines under carbon neutrality goals. J. China Coal Soc. 2022, 47, 470–479. [Google Scholar] [CrossRef]

- Li, S.; Zhang, J.; Lin, H.; Ding, Y.; Bai, Y.; Zhou, Y.; Zhu, B.; Dai, Z. Reflections on the development path of coalbed methane co-production technology in the dual carbon strategy. Coal Sci. Technol. 2024, 52, 138–153. [Google Scholar]

- Jia, J.; Chen, C.; Dong, K.; Wu, Y.; Wu, M. Research on staged fracturing and efficient extraction of coalbed methane from horizontal wells in fractured soft and low-permeability coal seams. Nat. Gas Geosci. 2017, 28, 1873–1881. [Google Scholar]

- Zhang, Q.; Jiang, W.; Jiang, Z.; Sun, S.; Li, B.; Du, X.; Wu, X.; Zhao, J.; Fan, Y.; Fan, Z.; et al. Current status and technological research progress of coalbed methane surface development in China’s coal mining areas. Coal Geol. Explor. 2023, 51, 139–158. [Google Scholar]

- Xu, Y.; Zhang, P.; Fan, Z.; Xu, J.; Zhu, W.; Wang, J. Analysis of layer fracturing and crack propagation laws and sensitive factors of horizontal well drilling in crushed soft coal seam roof. J. Min. Saf. Eng. 2023, 40, 420–428. [Google Scholar] [CrossRef]

- Wu, X. Research on the Law and Mechanism of Fracture Propagation in Horizontal Well Staged Fracturing in Fractured Soft and Low-Permeability Coal Seam Roof. Ph.D. Thesis, General Institute of Coal Science Research, Beijing, China, 2017. [Google Scholar]

- Jiang, Z.; Li, H.; Xu, Y.; Zhang, Q.; Li, G.; Fan, Y.; Jiang, W.; Shu, J.; Pang, T.; Cheng, B. Geological adaptability analysis and construction parameter optimization of segmented fracturing horizontal wells in coal seam roof. Coal Geol. Explor. 2022, 50, 183–192. [Google Scholar]

- Zhang, Q.; Ge, C.; Li, W.; Jiang, Z.; Chen, J.; Li, B.; Wu, J.; Wu, X.; Liu, J. High efficiency extraction model of fractured coalbed methane from horizontal wells in fractured soft and low-permeability coal seams. J. Coal Ind. 2018, 43, 150–159. [Google Scholar]

- Xu, C. Study on the Controlling Effect of Geological Structure on Coal Seam Gas Occurrence and Prevention and Control Technology in the Huaibei Mining Area. Ph.D. Thesis, China University of Mining & Technology, Beijing, China, 2023. [Google Scholar]

- Hu, Q.; Liu, J.; Li, Q.; Zhang, Y.; Song, M.; Sun, W.; Song, J. Experimental study on stress and crack evolution of segmented hydraulic fracturing in coal seam roof. J. China Univ. Min. Technol. 2023, 52, 1084–1095+1202. [Google Scholar] [CrossRef]

- Pang, T.; Jiang, Z.; Yang, J. The influence of the spatial location of horizontal wells in the roof of fractured soft coal seams on the expansion of fracturing fractures. J. Coal Sci. 2022, 47, 196–203. [Google Scholar]

- Jiang, Z.; Li, H.; Fang, L.; Fan, Z. Fracture extension machine for horizontal wells adjacent to the roof of fractured soft coal seams. J. Coal Ind. 2020, 45, 922–931. [Google Scholar]

- Li, Q.; Deng, Y.; Hu, Q.; Wu, X.; Wang, X.; Jiang, Z.; Liu, Y.; Qian, Y.; Song, M. Overview and prospect of physical test research on hydraulic fracturing of coal and rock. Coal Sci. Technol. 2022, 50, 62–72. [Google Scholar]

- Xu, Y.; Guo, S. Staged fracturing technology and application of coalbed methane horizontal wells combined with soft and hard coal. J. Coal Ind. 2019, 44, 1169–1177. [Google Scholar]

- Zhu, Q.; Yang, Y.; Wang, Y.; Shao, G. Optimization model and application of efficient development engineering technology for high-rank coalbed methane. Nat. Gas Ind. 2017, 37, 27–34. [Google Scholar]

- DB/T 14-2018; Specification of Hydraulic Fracturing and Overcoring Method for In-Situ Stress Measurement. The China Earthquake Administration: Beijing, China, 2018.

- Xu, Y.; Zhu, Y.; Zhang, P. Technology for developing coalbed methane in horizontal wells in roof strataadjacent to fractured and soft coal seams. Nat. Gas Ind. 2018, 38, 70–75. [Google Scholar]

- Li, W.; Bai, J.; Cheng, J.; Peng, S.; Liu, H. Determination of coal-rock interface strength by laboratory direct shear-tests under constantnormal load. Int. J. Rock Mech. Min. Sci. 2015, 77, 60–67. [Google Scholar] [CrossRef]

- Zou, J.; Chen, W.; Yuan, J.; Yang, D.; Yang, J. 3-D numerical simulation of hydraulic fracturing in a CBM reservoir. J. Nat. Gas Sci. Eng. 2017, 37, 386–396. [Google Scholar] [CrossRef]

- Juan, G. Geo-Stress Condition of Coalbed Methane Extraction in Coalmining Area and Its Influence on Productivity of Coalbed Methane Wells. Ph.D. Thesis, China University of Mining & Technology, Beijing, China, 2016. [Google Scholar]

- Hou, B.; Chang, Z.; Wu, A.; Elsworth, D. Simulation of competitive propagation of multi-fractures on shale oil reservoir multi-clustered fracturing in Jimsar sag. Acta Pet. Sin. 2022, 43, 75–90. [Google Scholar]

- Chang, Z.; Hou, B.; Ding, J. Competitive propagation simulation of multi-clustered fracturing in a cracked shale oil reservoir. Geomech. Geophys. Geo-Energy Geo-Resour. 2022, 8, 1–19. [Google Scholar] [CrossRef]

- Lau, H.C.; Li, H.; Huang, S. Challenges and Opportunities of Coalbed Methane Development in China. Energy Fuels 2017, 31, 4588–4602. [Google Scholar] [CrossRef]

- Fang, L.; Li, G.; Li, D.; Li, H.; Liu, J. Analysis of coalbed methane extraction effect of coal seam roof horizontal wells in the Luling Coal Mine, Huaibei. Coal Geol. Explor. 2020, 48, 155–160+169. [Google Scholar]

| Rock Name | Depth/m | Thickness/m | Permeability/mD | Gas Content/m3·t−1 | |

|---|---|---|---|---|---|

| Panxie Coal Mine (Huainan mine area) | Siltstone | 1100.30 | 4.00 | 0.015 | \ |

| Mudstone | 1101.30 | 1.00 | 0.003 | \ | |

| 13-1 Coal seam | 1108.00 | 6.70 | 0.011 | 15.28 | |

| Luling Coal Mine (Huaibei mine area) | Siltstone | 727.75 | 3.20 | 0.015 | \ |

| Mudstone | 728.50 | 0.55 | 0.005 | \ | |

| 8 Coal seam | 742.00 | 13.50 | 0.360 | 8.50 | |

| Rock | Fine-Grained Sandstone | Siltstone | Mudstone | Coal Seam | Mudstone |

|---|---|---|---|---|---|

| Elastic modulus/GPa | 20.00 | 15.50 | 11.80 | 5.10 | 11.80 |

| Poisson’s ratio | 0.23 | 0.25 | 0.28 | 0.33 | 0.28 |

| Tensile strength/MPa | 4.50 | 2.42 | 1.75 | 0.50 | 1.75 |

| Density/(kg·m−3) | 2.54 | 2.05 | 1.85 | 1.35 | 1.85 |

| Permeability/10−3 μm2 | 2 × 10−3 | 10−2 | 10−3 | 10−2 | 10−3 |

| Vertical stress/MPa | 17.74 | 17.74 | 17.74 | 17.74 | 17.74 |

| Stress of Maximum horizontal principal/MPa | 16.30 | 16.30 | 16.30 | 16.30 | 16.30 |

| Stress of Minimum horizontal principal/MPa | 14.00 | 13.50 | 13.00 | 10.00 | 14.00 |

| Physical Rock Parameters of Test Specimens | Immediate Roof | Mudstone Pseudo-Roof | Coal Seam | |||

|---|---|---|---|---|---|---|

| 1# Piece | 2# Piece | 1# Piece | 2# Piece | 1# Piece | 2# Piece | |

| Elastic Modulus/GPa | 17.90 | 18.40 | 15.00 | 15.50 | 1.00 | 1.10 |

| Poisson’s Ratio | 0.20 | 0.20 | 0.20 | 0.18 | 0.28 | 0.25 |

| Tensile Strength/MPa | 3.50 | 3.50 | 2.20 | 2.10 | 0.50 | 0.50 |

| Section Sequence | Hydraulic Fracturing Liquid Volume/m3 | Sand Total/m3 | Average Pump Pressure/MPa | Average Sand Ratio/% | Average Displacement/m3·min−1 |

|---|---|---|---|---|---|

| 1 | 1131 | 35.0 | 22.4 | 6.7 | 7.3 |

| 2 | 1001 | 45.1 | 33.4 | 8.2 | 8.2 |

| 3 | 967 | 45.5 | 39.3 | 8.4 | 8.0 |

| 4 | 1011 | 55.2 | 44.7 | 9.2 | 5.7 |

| 5 | 985 | 60.9 | 47.6 | 10.4 | 7.1 |

| 6 | 625 | 31.2 | 29.1 | 10.5 | 7.4 |

| 7 | 601 | 25.9 | 34.5 | 8.4 | 7.0 |

| 8 | 1028 | 40.8 | 33.8 | 7.3 | 7.7 |

| 9 | 1181 | 46.7 | 34.2 | 6.9 | 8.0 |

| 10 | 902 | 47.3 | 33.0 | 8.1 | 8.0 |

| 11 | 1059 | 79.3 | 30.4 | 11.6 | 7.8 |

| 12 | 504 | 21.7 | 25.4 | 7.2 | 8.0 |

| Section Sequence | Orientation/° | Total Fracture Length/m | East Wing Fracture Length/m | West Wing Fracture Length/m | Height/m | Inclination Angle/° |

|---|---|---|---|---|---|---|

| 3 | 71.7 | 205.1 | 112.2 | 92.9 | 31.5 | 3 |

| 6 | 74.9 | 197.7 | 108.2 | 89.5 | 30.0 | 5 |

| 7 | 80.6 | 191.5 | 92.9 | 98.6 | 36.8 | 3 |

| 11 | 77.9 | 218.3 | 104.8 | 113.5 | 36.8 | 1 |

| Section Sequence | Hydraulic Fracturing Liquid Volume/m3 | Sand Total/m3 | Average Pump Pressure/MPa | Average Sand Ratio/% | Average Displacement/m3·min−1 |

|---|---|---|---|---|---|

| 1 | 979 | 63.8 | 30.9 | 9.27 | 10.0 |

| 2 | 976 | 65.5 | 24.4 | 9.77 | 10.0 |

| 3 | 927 | 78.8 | 22.9 | 13.19 | 10.0 |

| 4 | 920 | 80.0 | 21.8 | 13.37 | 9.50 |

| 5 | 1019 | 86.9 | 26.7 | 12.48 | 10.0 |

| 6 | 972 | 83.4 | 22.4 | 12.66 | 10.0 |

| 7 | 834 | 82.9 | 20.8 | 15.48 | 9.60 |

| Section Sequence | Orientation/° | Total Fracture Length/m | East Wing Fracture Length/m | West Wing Fracture Length/m | Height/m | Inclination Angle/° |

|---|---|---|---|---|---|---|

| 1 | 45.2 | 169.1 | 90.5 | 78.6 | 20.5 | 2 |

| 4 | 46.1 | 163.2 | 89.8 | 73.4 | 17.6 | 3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, B.; Hou, E.; Ma, L.; Liu, Z.; Fan, T.; Gong, Z.; Gao, Y.; Du, W.; Liu, Q.; Ma, B. Research on the Law of Layered Fracturing in the Composite Roof Strata of Coal Seams via Hydraulic Fracturing. Energies 2024, 17, 1941. https://doi.org/10.3390/en17081941

Wang B, Hou E, Ma L, Liu Z, Fan T, Gong Z, Gao Y, Du W, Liu Q, Ma B. Research on the Law of Layered Fracturing in the Composite Roof Strata of Coal Seams via Hydraulic Fracturing. Energies. 2024; 17(8):1941. https://doi.org/10.3390/en17081941

Chicago/Turabian StyleWang, Bo, Enke Hou, Liang Ma, Zaibin Liu, Tao Fan, Zewen Gong, Yaoquan Gao, Wengang Du, Qiang Liu, and Bingzhen Ma. 2024. "Research on the Law of Layered Fracturing in the Composite Roof Strata of Coal Seams via Hydraulic Fracturing" Energies 17, no. 8: 1941. https://doi.org/10.3390/en17081941

APA StyleWang, B., Hou, E., Ma, L., Liu, Z., Fan, T., Gong, Z., Gao, Y., Du, W., Liu, Q., & Ma, B. (2024). Research on the Law of Layered Fracturing in the Composite Roof Strata of Coal Seams via Hydraulic Fracturing. Energies, 17(8), 1941. https://doi.org/10.3390/en17081941