Multi-Factor Carbon Emissions Prediction in Coal-Fired Power Plants: A Machine Learning Approach for Carbon Footprint Management

Abstract

1. Introduction

2. Materials and Methods

2.1. Calculation Model for Coal-Fired Power Plants

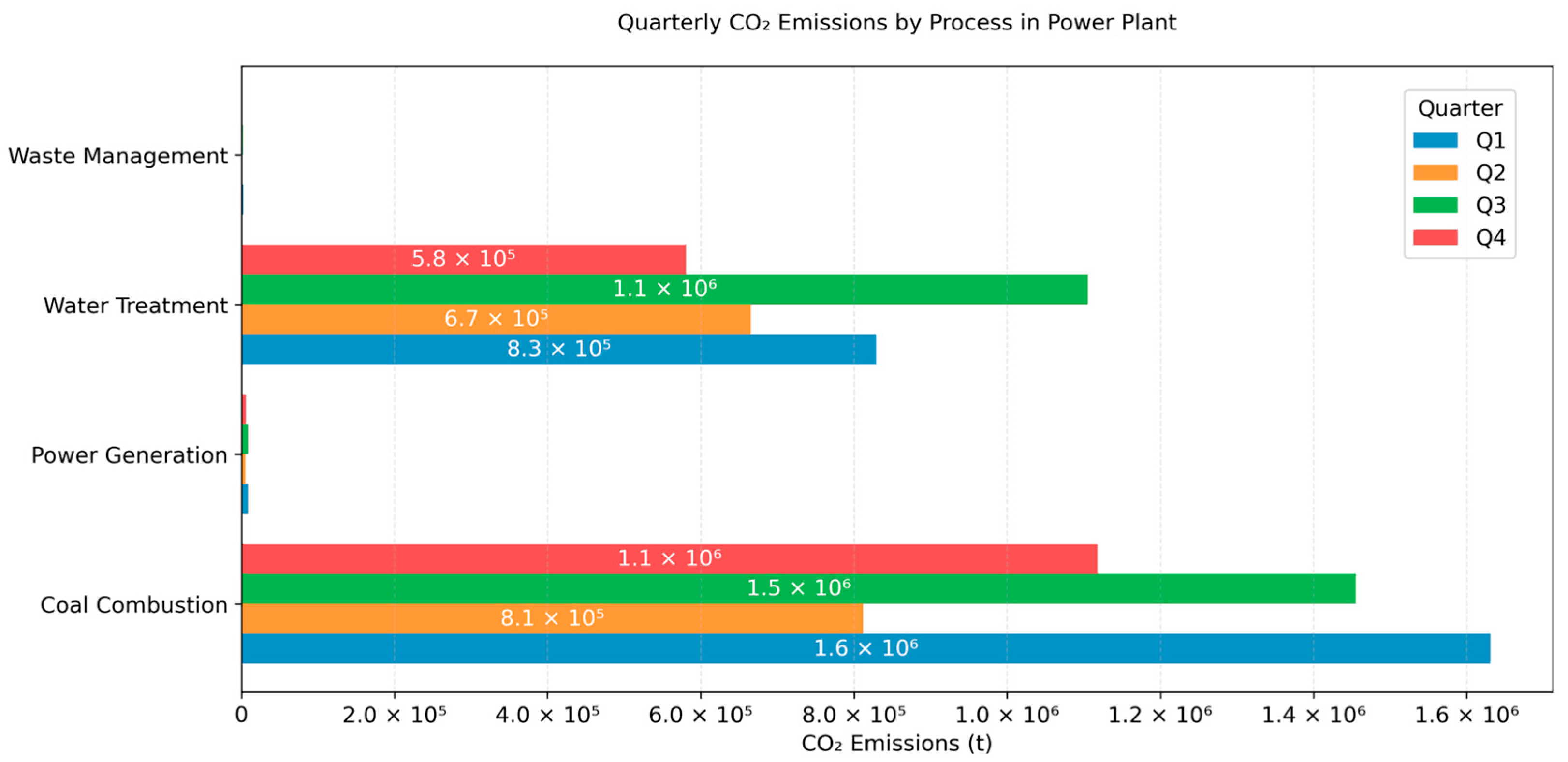

2.1.1. Coal Combustion Emissions

2.1.2. Desulfurization Process Emissions

2.1.3. Ash-Handling Emissions

2.1.4. Comprehensive Efficiency Correction

2.1.5. Total Emissions Calculation

2.2. Data Collection

2.3. Data Preprocessing

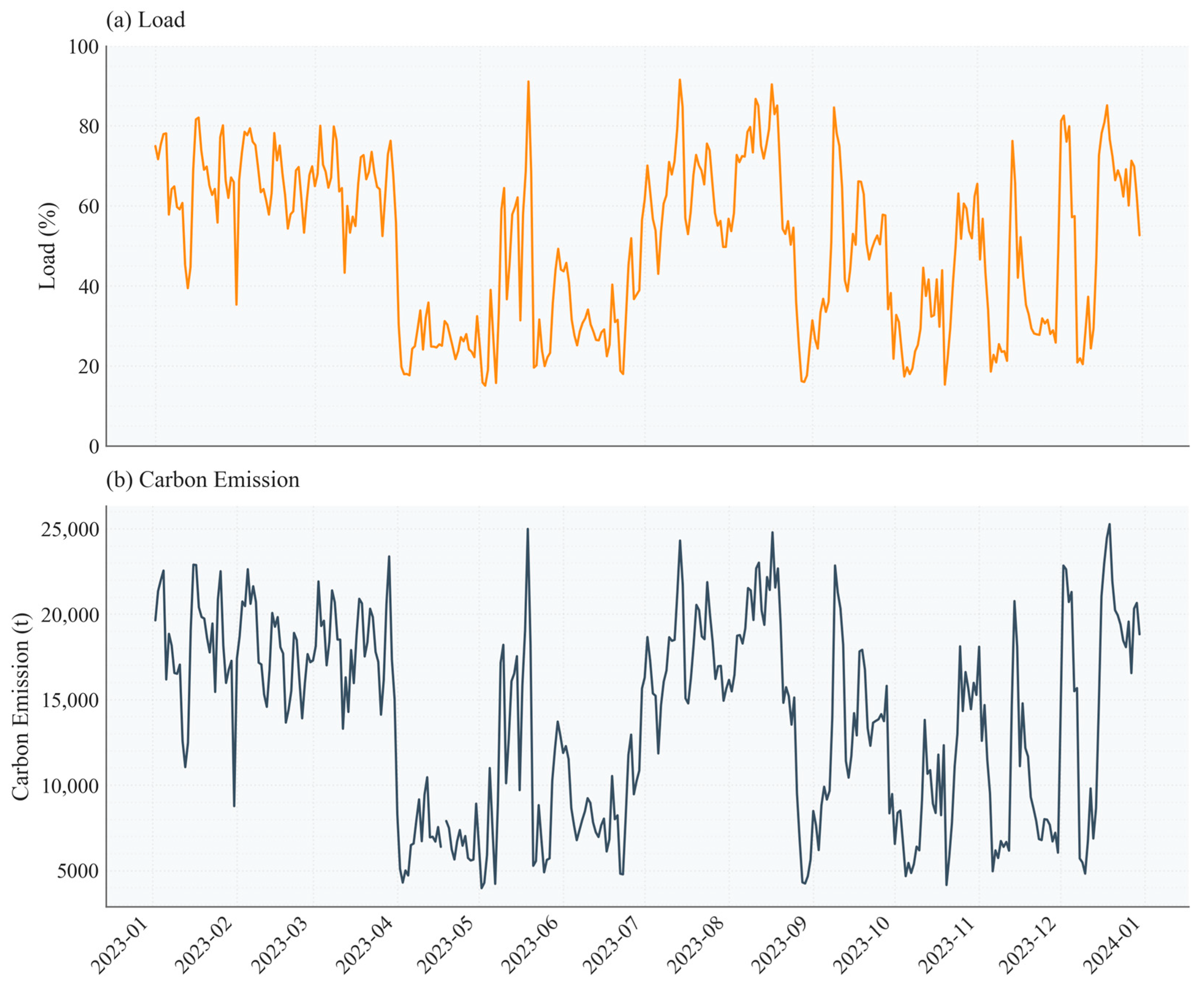

2.4. Exploratory Data Analysis

2.5. Model Development and Evaluation

3. Results

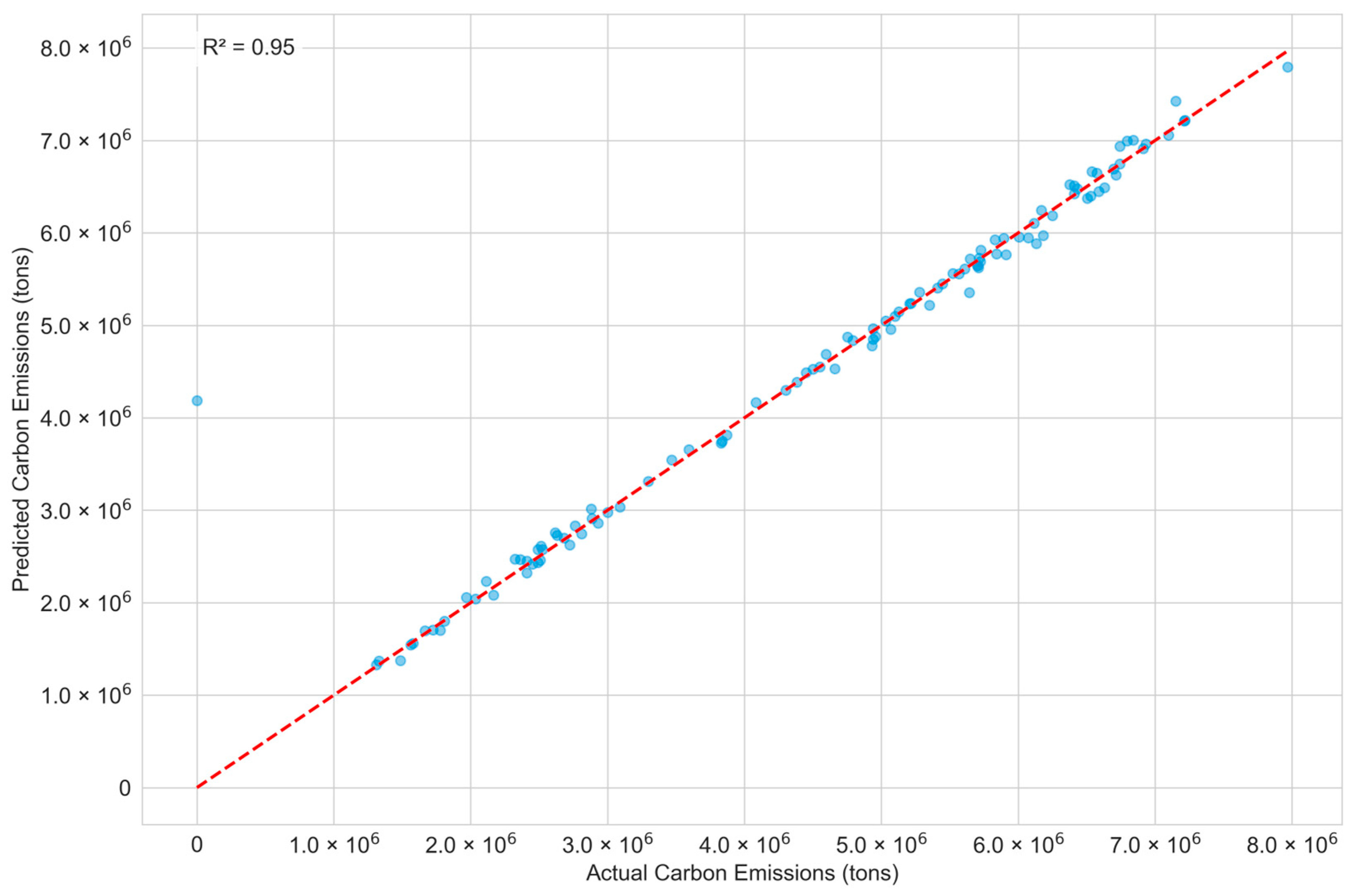

3.1. Model Comparison

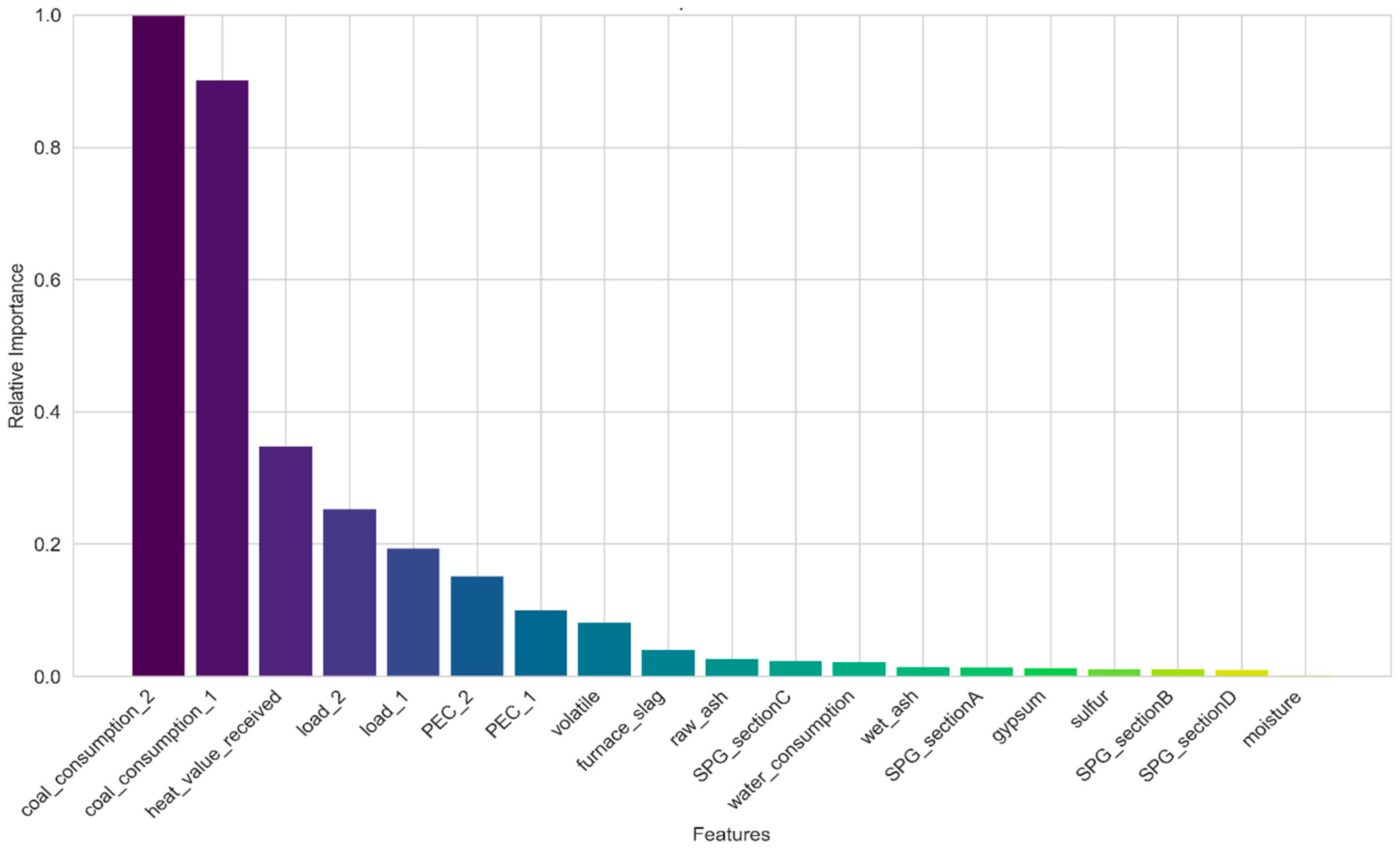

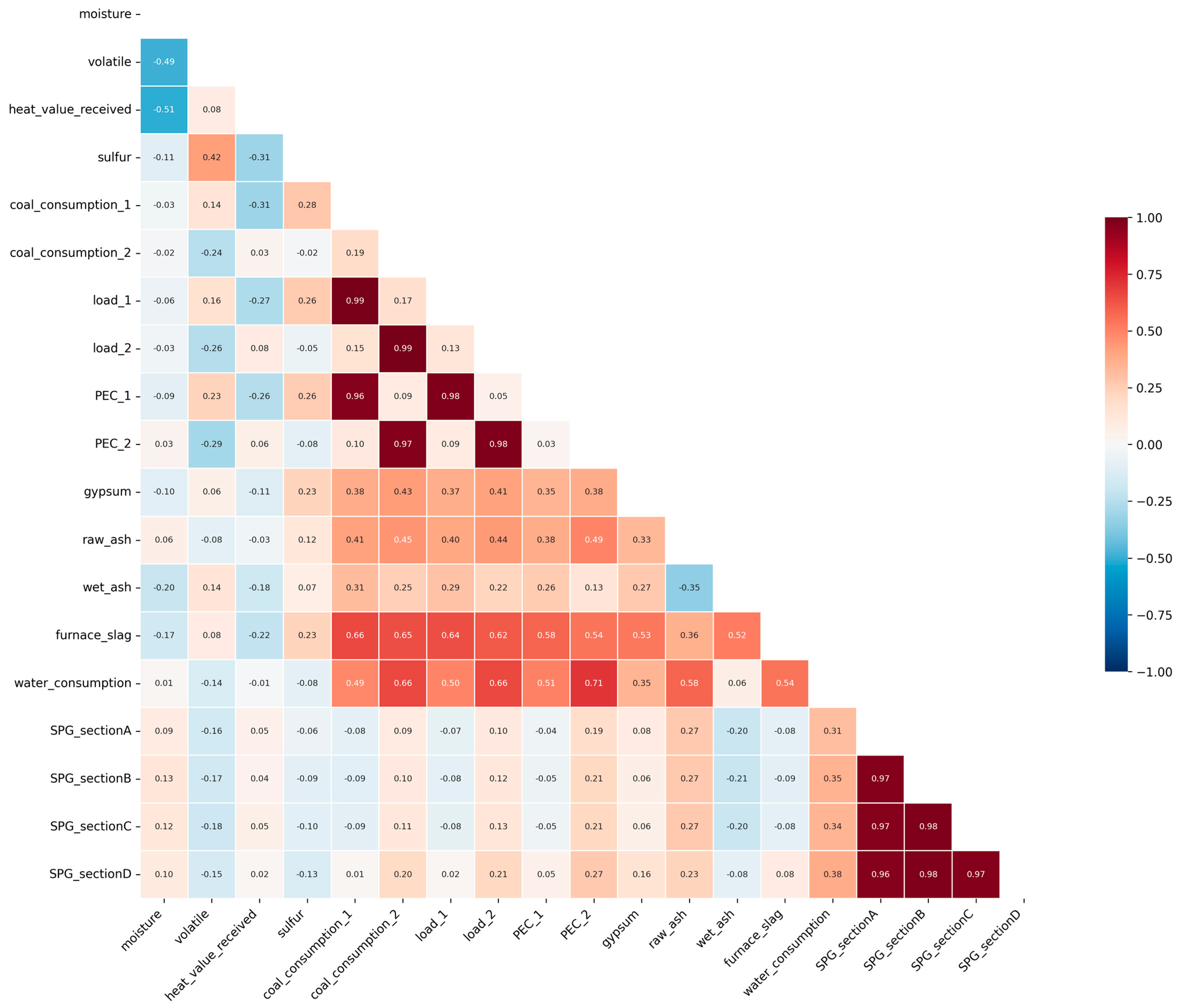

3.2. Feature Correlation Analysis

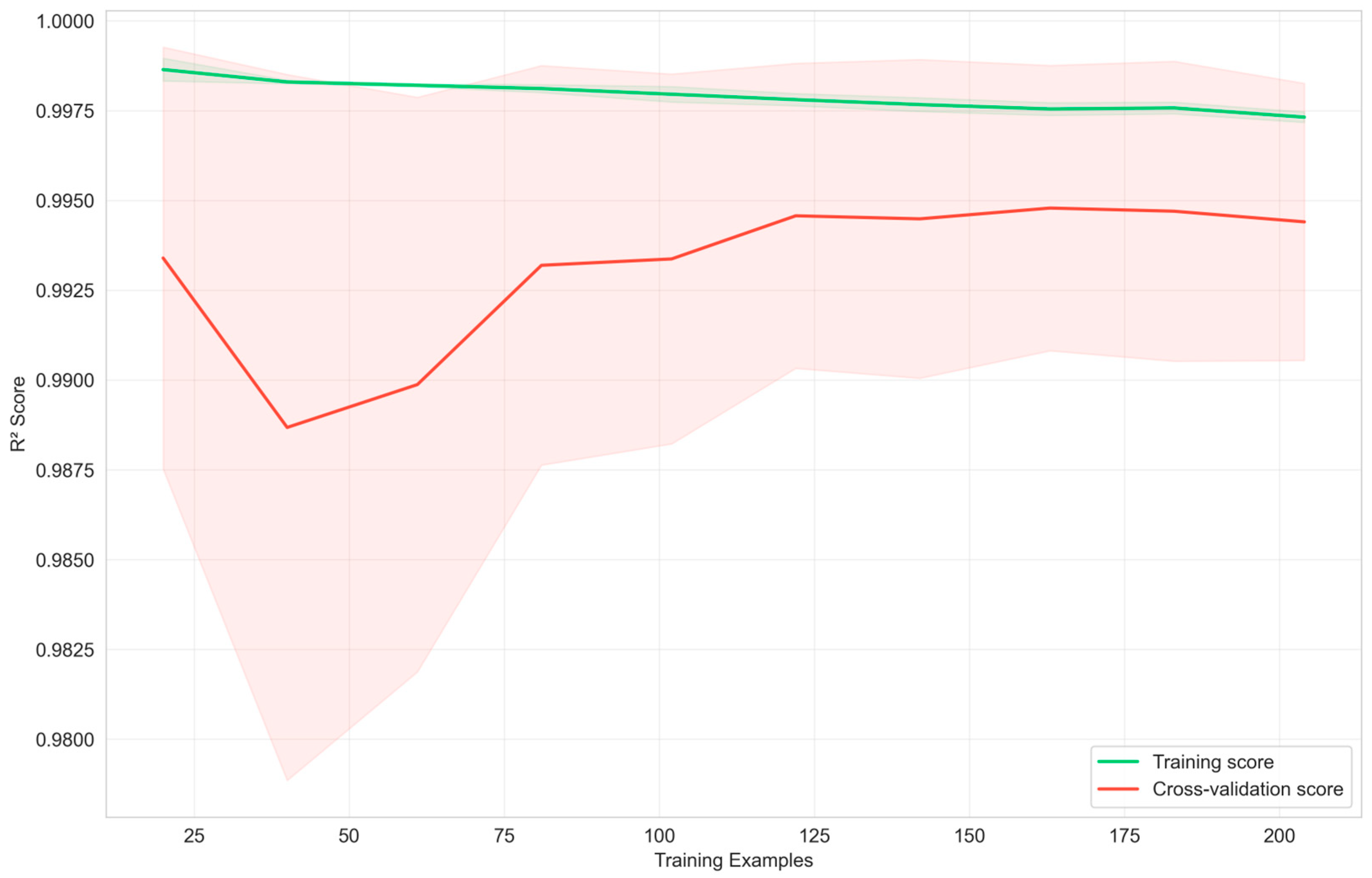

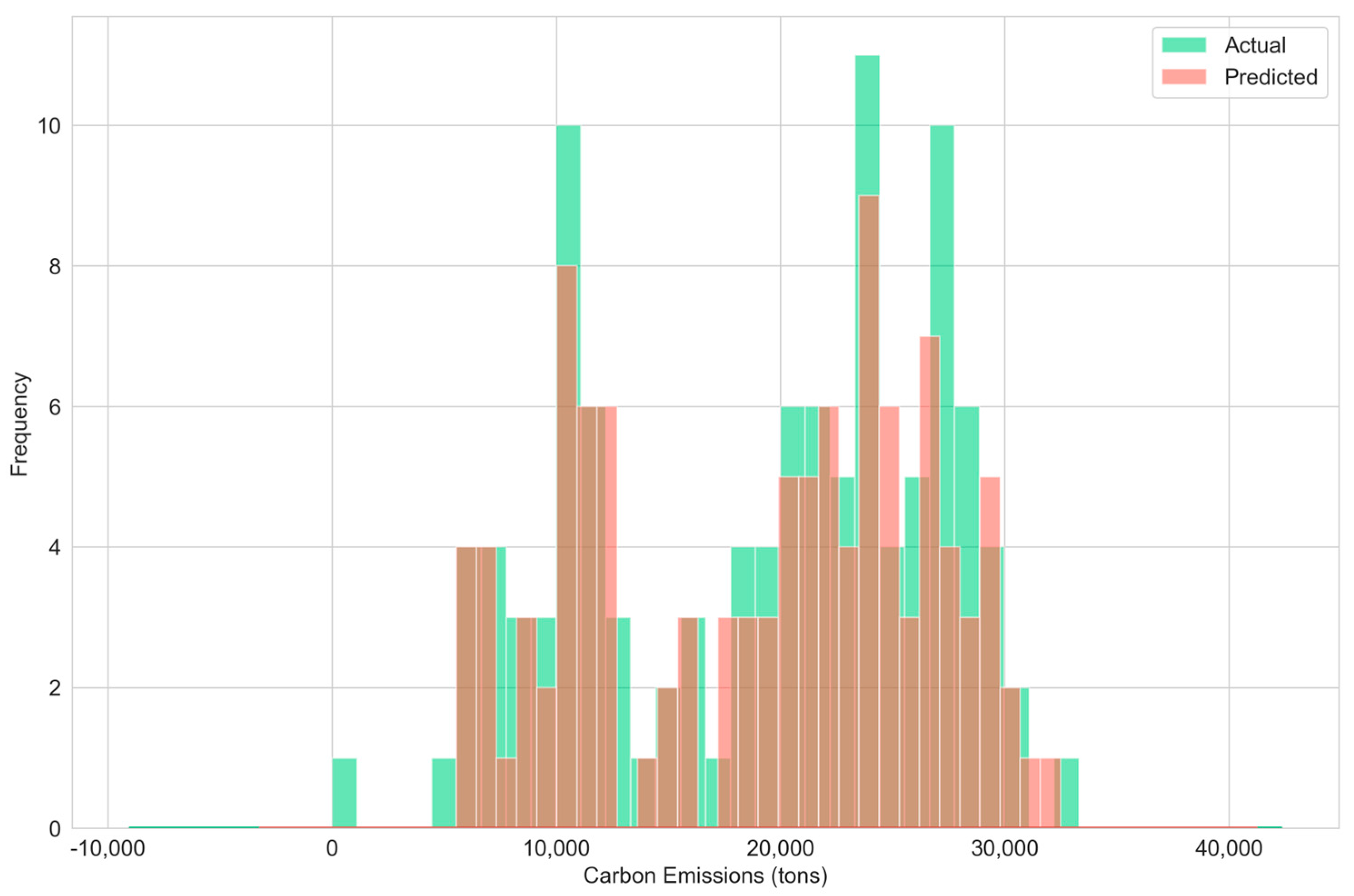

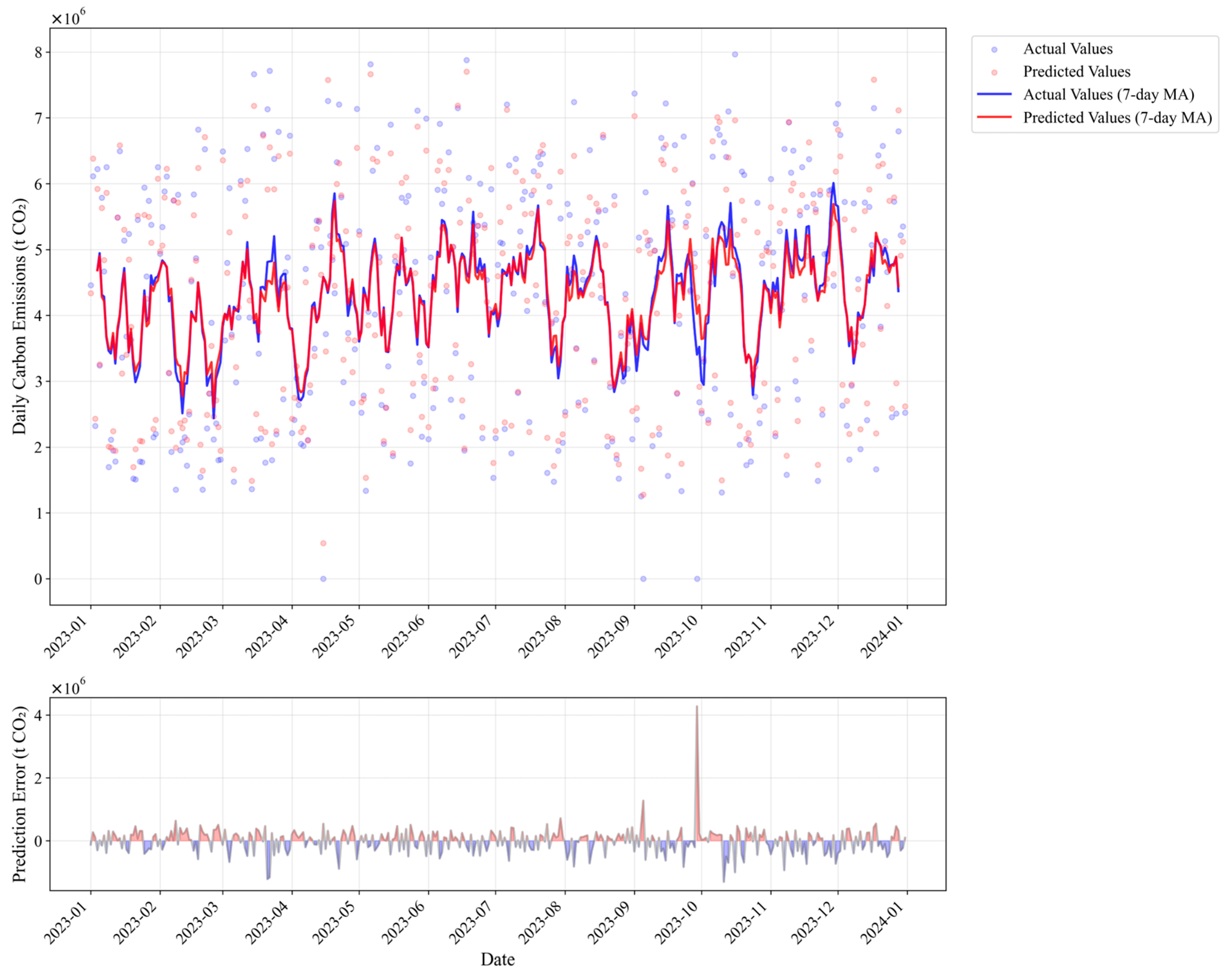

3.3. In-Depth Model Analysis

3.4. Temporal Analysis of Chemical Usage and Costs

3.5. Analysis of Carbon Emissions

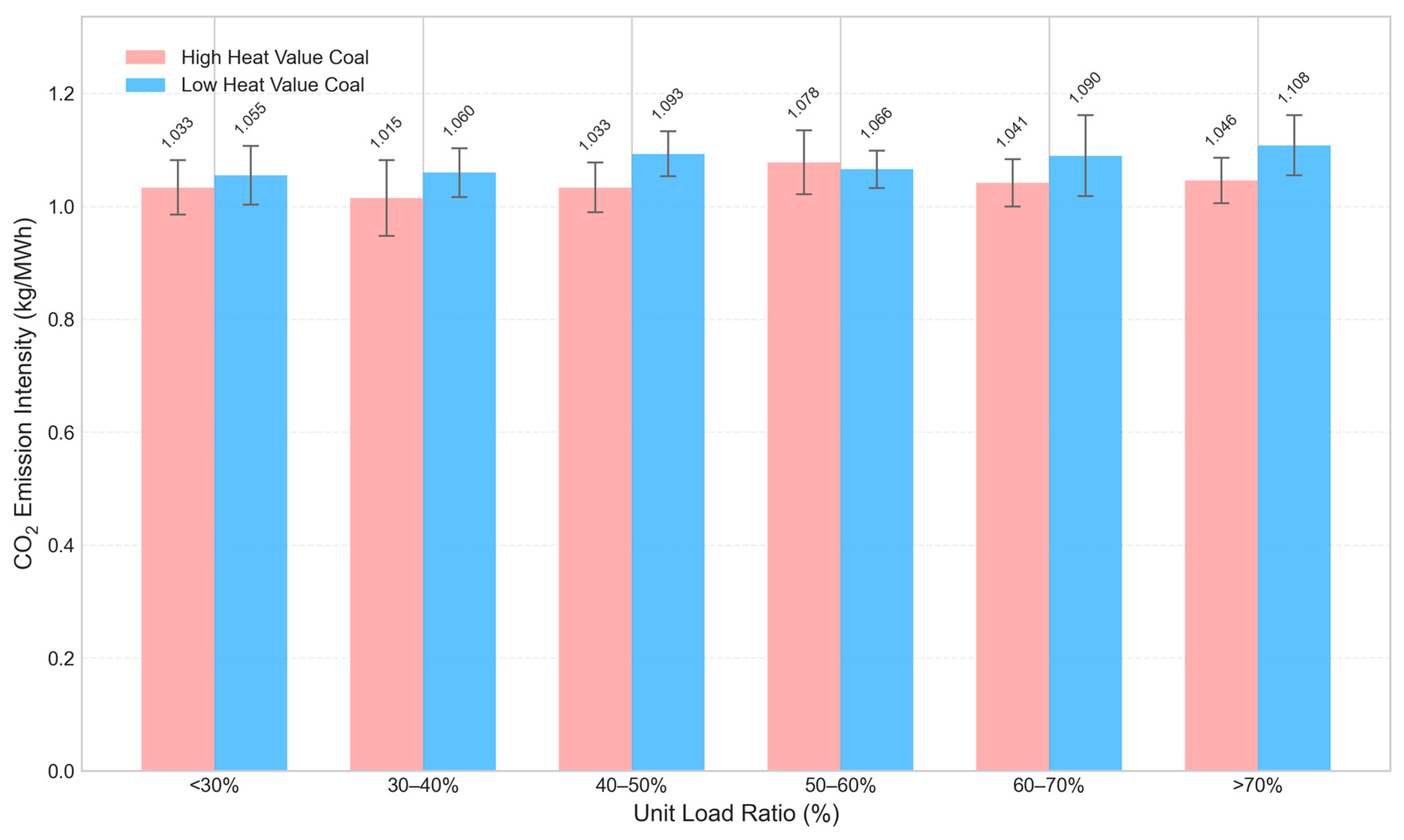

3.6. Model Robustness Analysis

4. Discussion

5. Conclusions

- (1)

- Linear models, especially ElasticNet, showed a high accuracy (R2 > 0.95) for coal plant emissions. Simple models worked well, challenging the need for complexity. Coal quality parameters were key predictors, highlighting the importance of monitoring.

- (2)

- Monthly cost indices varied significantly (2.2–3.2 CNY/10 MWh), linked to coal operations, offering maintenance and resource optimization opportunities.

- (3)

- Chemical correlations in flue gas treatment suggest that coordinated management could improve efficiency. Urea, critical for NOx reduction, was identified as the most variable cost factor, requiring dynamic procurement. Analysis revealed efficiency opportunities in the power generation–cost relationships.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| LCA | Life cycle assessment |

| CO2 | Carbon dioxide |

| CEMS | Continuous emission monitoring systems |

| Coal consumption of unit i | |

| Volatile content of coal | |

| Molecular mass ratio of CO2 to C | |

| Oxidation factor of unit i | |

| Gypsum production | |

| Calcium carbonate conversion coefficient | |

| Molecular mass ratio | |

| Dry ash amount | |

| Wet ash amount | |

| Furnace slag amount | |

| Emission factor for ash handling | |

| Plant electricity consumption rate | |

| Unit load | |

| Moisture correction factor | |

| Heat value correction factor |

References

- Friedlingstein, P.; Andrew, R.M.; Rogelj, J.; Peters, G.P.; Canadell, J.G.; Knutti, R.; Luderer, G.; Raupach, M.R.; Schaeffer, M.; van Vuuren, D.P.; et al. Persistent growth of CO2 emissions and implications for reaching climate targets. Nat. Geosci. 2014, 7, 709–715. [Google Scholar] [CrossRef]

- Uwasu, M.; Jiang, Y.; Saijo, T. On the Chinese Carbon Reduction Target. Sustainability 2010, 2, 1553–1557. [Google Scholar] [CrossRef]

- Ang, J.B. CO2 emissions, research and technology transfer in China. Ecol. Econ. 2009, 68, 2658–2665. [Google Scholar] [CrossRef]

- Zhang, M.; Mu, H.; Ning, Y. Accounting for energy-related CO2 emission in China, 1991–2006. Energy Policy 2009, 37, 767–773. [Google Scholar] [CrossRef]

- Wang, N.; Ren, Y.; Zhu, T.; Meng, F.; Wen, Z.; Liu, G. Life cycle carbon emission modelling of coal-fired power: Chinese case. Energy 2018, 162, 841–852. [Google Scholar] [CrossRef]

- Cobos-Torres, J.-C.; Idrovo-Ortiz, L.-H.; Cobos-Mora, S.L.; Santillan, V. Renewable Energies and Biochar: A Green Alternative for Reducing Carbon Footprints Using Tree Species from the Southern Andean Region of Ecuador. Energies 2025, 18, 1027. [Google Scholar] [CrossRef]

- Zhou, K.; Yang, S.; Shen, C.; Ding, S.; Sun, C.J.R.; Reviews, S.E. Energy conservation and emission reduction of China’s electric power industry. Renew. Sust. Energ. Rev. 2015, 45, 10–19. [Google Scholar] [CrossRef]

- van den Berg, M.; Hof, A.F.; van Vliet, J.; van Vuuren, D.P. Impact of the choice of emission metric on greenhouse gas abatement and costs. Environ. Res. Lett. 2015, 10, 024001. [Google Scholar] [CrossRef]

- Luo, H.; Lin, X. Dynamic Analysis of Industrial Carbon Footprint and Carbon-Carrying Capacity of Zhejiang Province in China. Sustainability 2022, 14, 16824. [Google Scholar] [CrossRef]

- Liu, C.; Tang, X.; Yu, F.; Zhang, D.; Wang, Y.; Li, J. Carbon emission measurement method of regional power system based on LSTM-Attention model. Sci. Tech. Energ. Transit. 2024, 79, 43. [Google Scholar]

- Mariutti, E. The Limits of the Current Consensus Regarding the Carbon Footprint of Photovoltaic Modules Manufactured in China: A Review and Case Study. Energies 2025, 18, 1178. [Google Scholar] [CrossRef]

- Hammond, G.P.; Spargo, J. The prospects for coal-fired power plants with carbon capture and storage: A UK perspective. Energy Convers. Manage. 2014, 86, 476–489. [Google Scholar] [CrossRef]

- Driscoll, C.T.; Buonocore, J.J.; Levy, J.I.; Lambert, K.F.; Burtraw, D.; Reid, S.B.; Fakhraei, H.; Schwartz, J. US power plant carbon standards and clean air and health co-benefits. Nat. Clim. Change 2015, 5, 535–540. [Google Scholar] [CrossRef]

- Agrawal, K.K.; Jain, S.; Jain, A.K.; Dahiya, S. Assessment of greenhouse gas emissions from coal and natural gas thermal power plants using life cycle approach. Int. J. Environ. Sci. Technol. 2014, 11, 1157–1164. [Google Scholar] [CrossRef]

- Hondo, H. Life cycle GHG emission analysis of power generation systems: Japanese case. Energy 2005, 30, 2042–2056. [Google Scholar] [CrossRef]

- Wan, T.; Tao, Y.; Qiu, J.; Lai, S. Internet data centers participating in electricity network transition considering carbon-oriented demand response. Appl. Energy 2023, 329, 120305. [Google Scholar] [CrossRef]

- Hui, J.; Zhu, S.; Zhang, X.; Liu, Y.; Lin, J.; Ding, H.; Su, K.; Cao, X.; Lyu, Q. Experimental study of deep and flexible load adjustment on pulverized coal combustion preheated by a circulating fluidized bed. J. Clean. Prod. 2023, 418, 138040. [Google Scholar] [CrossRef]

- Ma, T.; Li, M.-J.; Xue, X.-D.; Guo, J.-Q.; Wang, W.-Q.; Jiang, T. Study of Peak-load regulation characteristics of a 1000MWe S-CO2 Coal-fired power plant and a comprehensive evaluation method for dynamic performance. Appl. Therm. Eng. 2023, 221, 119892. [Google Scholar] [CrossRef]

- Chen, C.; Zhao, C.; Liu, M.; Wang, C.; Yan, J. Enhancing the load cycling rate of subcritical coal-fired power plants: A novel control strategy based on data-driven feedwater active regulation. Energy 2024, 312, 133627. [Google Scholar] [CrossRef]

- Wang, G.; Deng, J.; Zhang, Y.; Zhang, Q.; Duan, L.; Hao, J.; Jiang, J. Air pollutant emissions from coal-fired power plants in China over the past two decades. Sci. Total Environ. 2020, 741, 140326. [Google Scholar] [CrossRef]

- Du, M.; Zhang, J.; Hou, X. Decarbonization like China: How does green finance reform and innovation enhance carbon emission efficiency? J. Environ. Manag. 2025, 376, 124331. [Google Scholar] [CrossRef]

- Çınarer, G.; Yeşilyurt, M.K.; Ağbulut, Ü.; Yılbaşı, Z.; Kılıç, K. Application of various machine learning algorithms in view of predicting the CO2 emissions in the transportation sector. Sci. Tech. Energ. Transit. 2024, 79, 15. [Google Scholar]

- Płoszaj-Mazurek, M.; Ryńska, E. Artificial Intelligence and Digital Tools for Assisting Low-Carbon Architectural Design: Merging the Use of Machine Learning, Large Language Models, and Building Information Modeling for Life Cycle Assessment Tool Development. Energies 2024, 17, 2997. [Google Scholar] [CrossRef]

- Guo, G.; He, Y.; Jin, F.; Mašek, O.; Huang, Q. Application of life cycle assessment and machine learning for the production and environmental sustainability assessment of hydrothermal bio-oil. Bioresour. Technol. 2023, 379, 129027. [Google Scholar] [CrossRef]

- Romeiko, X.X.; Zhang, X.; Pang, Y.; Gao, F.; Xu, M.; Lin, S.; Babbitt, C. A review of machine learning applications in life cycle assessment studies. Sci. Total Environ. 2024, 912, 168969. [Google Scholar] [CrossRef] [PubMed]

- Guo, G.; Jin, F. The cellulose hydrolysis into glucose with carbon-based solid acid catalyst via machine learning, life cycle assessment and bibliometric analysis. Fuel 2024, 362, 130891. [Google Scholar] [CrossRef]

- Yamacli, D.S.; Tuncsiper, C. Modeling the CO2 Emissions of Turkey Dependent on Various Parameters Employing ARIMAX and Deep Learning Methods. Sustainability 2024, 16, 8753. [Google Scholar] [CrossRef]

- Song, Y.; Yang, K.; Chen, J.; Wang, K.; Sant, G.; Bauchy, M. Machine Learning Enables Rapid Screening of Reactive Fly Ashes Based on Their Network Topology. ACS Sustain. Chem. Eng. 2021, 9, 2639–2650. [Google Scholar] [CrossRef]

- Whitaker, M.; Heath, G.A.; O’Donoughue, P.; Vorum, M. Life Cycle Greenhouse Gas Emissions of Coal-Fired Electricity Generation. J. Ind. Ecol. 2012, 16, S53–S72. [Google Scholar] [CrossRef]

- Córdoba, P. Status of Flue Gas Desulphurisation (FGD) systems from coal-fired power plants: Overview of the physic-chemical control processes of wet limestone FGDs. Fuel 2015, 144, 274–286. [Google Scholar] [CrossRef]

- Gupta, R.K.; Majumdar, D.; Trivedi, J.V.; Bhanarkar, A.D. Particulate matter and elemental emissions from a cement kiln. Fuel Process. Technol. 2012, 104, 343–351. [Google Scholar] [CrossRef]

- Tarroja, B.; AghaKouchak, A.; Samuelsen, S. Quantifying climate change impacts on hydropower generation and implications on electric grid greenhouse gas emissions and operation. Energy 2016, 111, 295–305. [Google Scholar] [CrossRef]

| Model | MAE | R2 Score | Explained Variance |

|---|---|---|---|

| Linear Regression | 403.95 | 0.9493 | 0.9499 |

| Ridge Regression | 406.96 | 0.9492 | 0.9499 |

| Lasso Regression | 406.72 | 0.9491 | 0.9498 |

| ElasticNet | 435.42 | 0.9514 | 0.9517 |

| Random Forest | 869.36 | 0.8935 | 0.8939 |

| Gradient Boosting | 725.37 | 0.9084 | 0.9088 |

| Neural Network | 713.23 | 0.9197 | 0.9207 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Yu, H.; Liu, H.; Sun, Z. Multi-Factor Carbon Emissions Prediction in Coal-Fired Power Plants: A Machine Learning Approach for Carbon Footprint Management. Energies 2025, 18, 1715. https://doi.org/10.3390/en18071715

Liu X, Yu H, Liu H, Sun Z. Multi-Factor Carbon Emissions Prediction in Coal-Fired Power Plants: A Machine Learning Approach for Carbon Footprint Management. Energies. 2025; 18(7):1715. https://doi.org/10.3390/en18071715

Chicago/Turabian StyleLiu, Xiaopan, Haonan Yu, Hanzi Liu, and Zhiqiang Sun. 2025. "Multi-Factor Carbon Emissions Prediction in Coal-Fired Power Plants: A Machine Learning Approach for Carbon Footprint Management" Energies 18, no. 7: 1715. https://doi.org/10.3390/en18071715

APA StyleLiu, X., Yu, H., Liu, H., & Sun, Z. (2025). Multi-Factor Carbon Emissions Prediction in Coal-Fired Power Plants: A Machine Learning Approach for Carbon Footprint Management. Energies, 18(7), 1715. https://doi.org/10.3390/en18071715