Winglet Geometries Applied to Rotor Blades of a Hydraulic Axial Turbine Used as a Turbopump: A Parametric Analysis

Abstract

1. Introduction

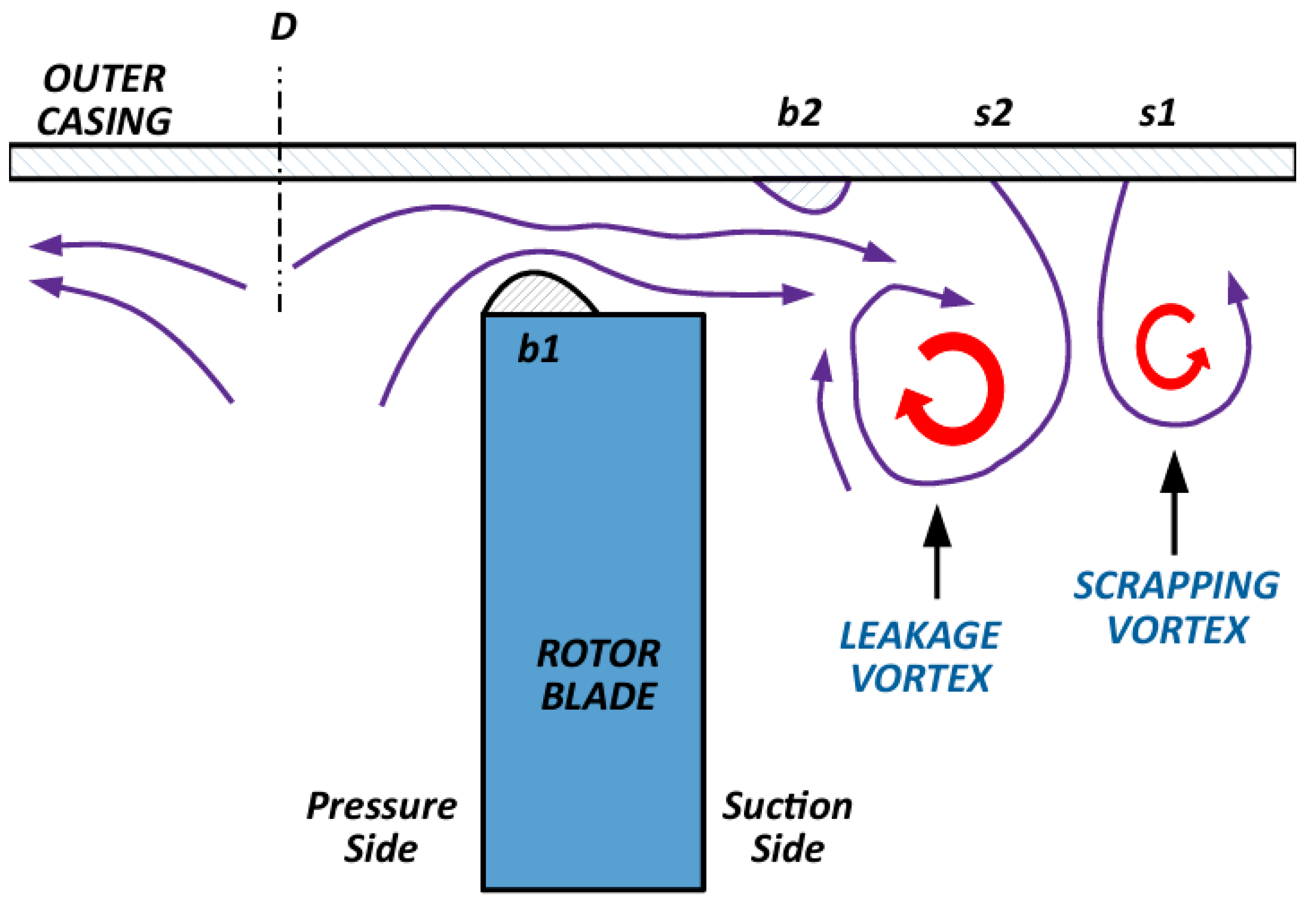

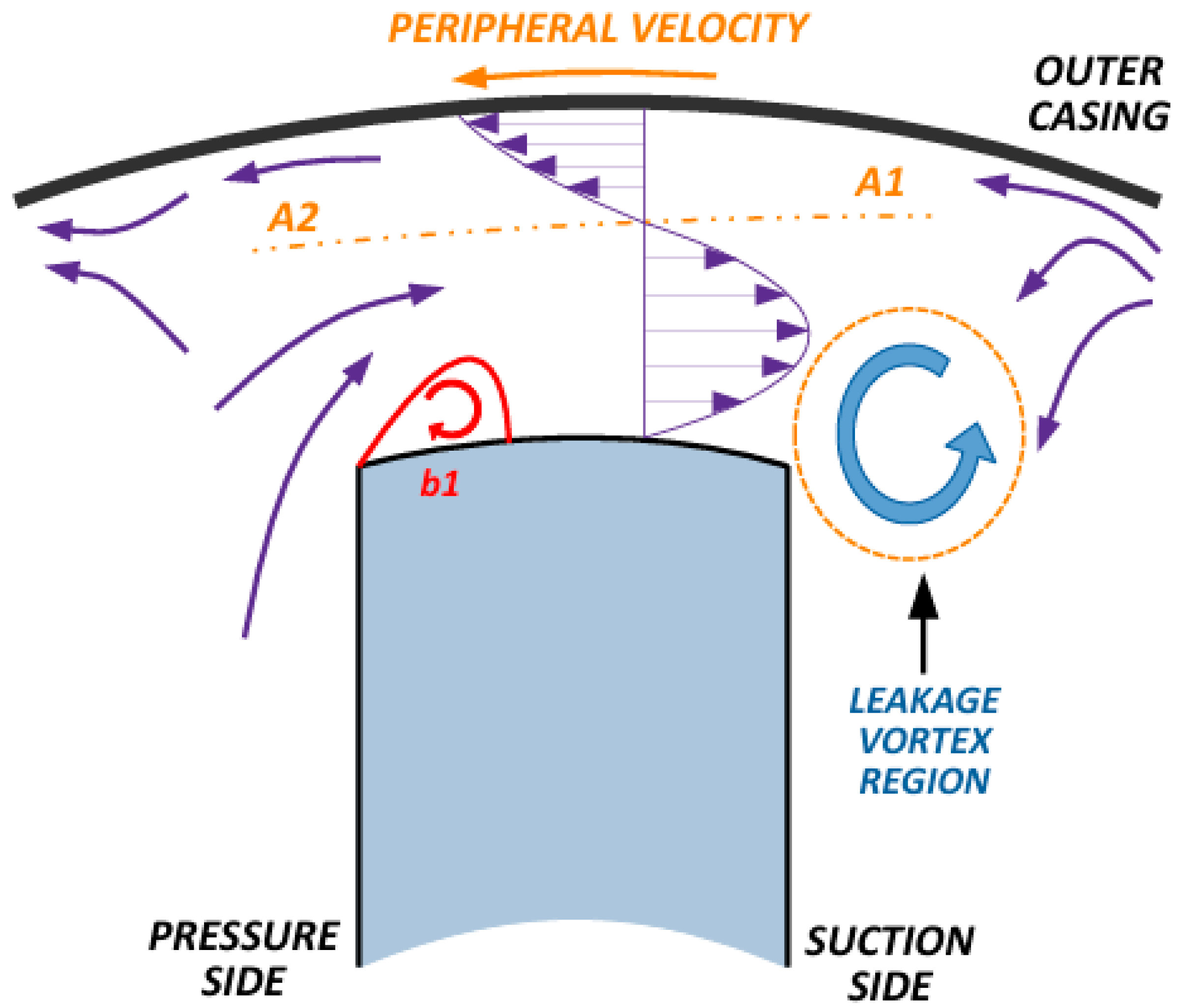

2. Tip Leakage Effects

2.1. Leakage Behavior

2.2. Cavitation

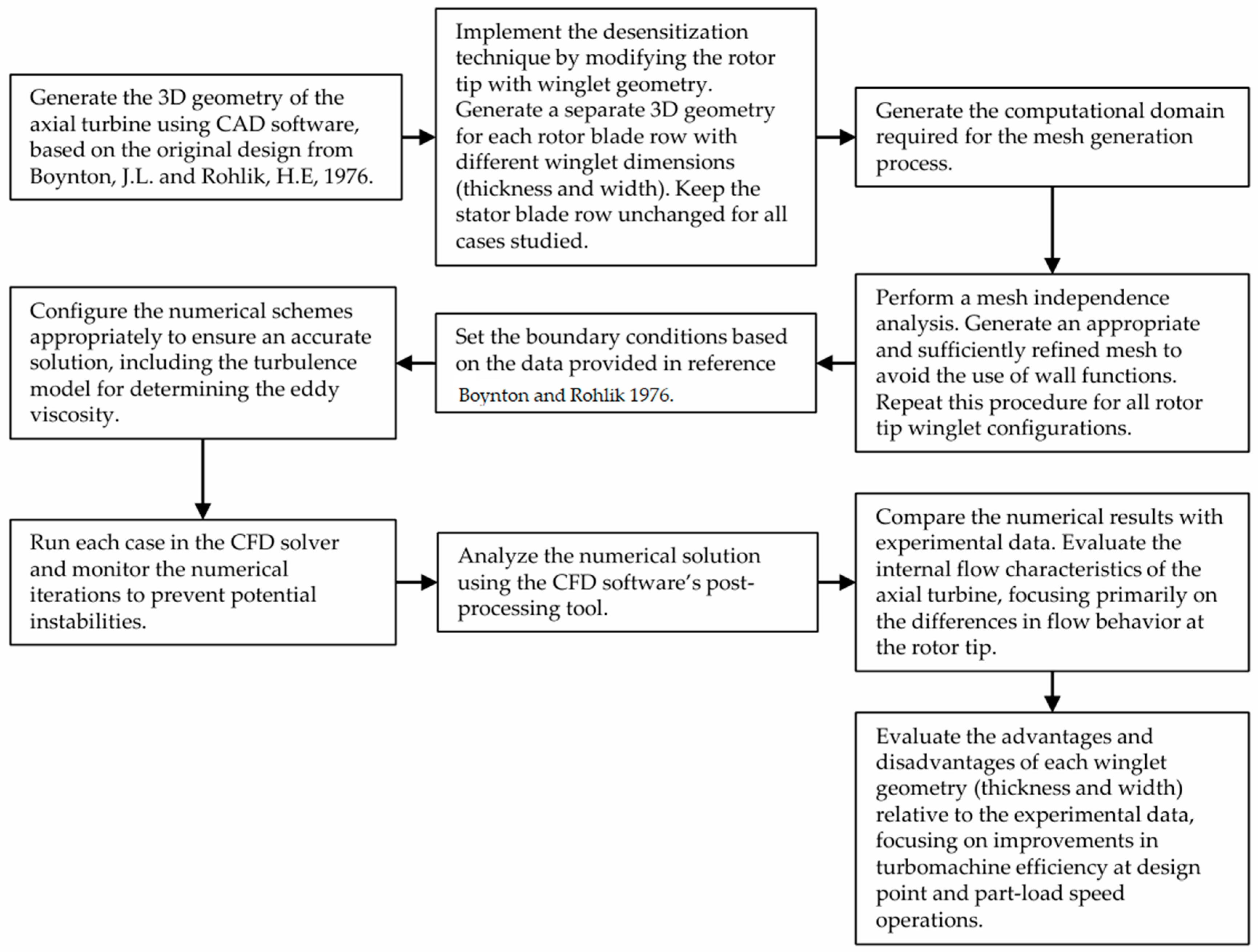

3. SSME LOX Booster Turbopump

4. Desensitization Methods

4.1. General Considerations

4.2. Winglet

5. Computational Fluid Dynamics Considerations

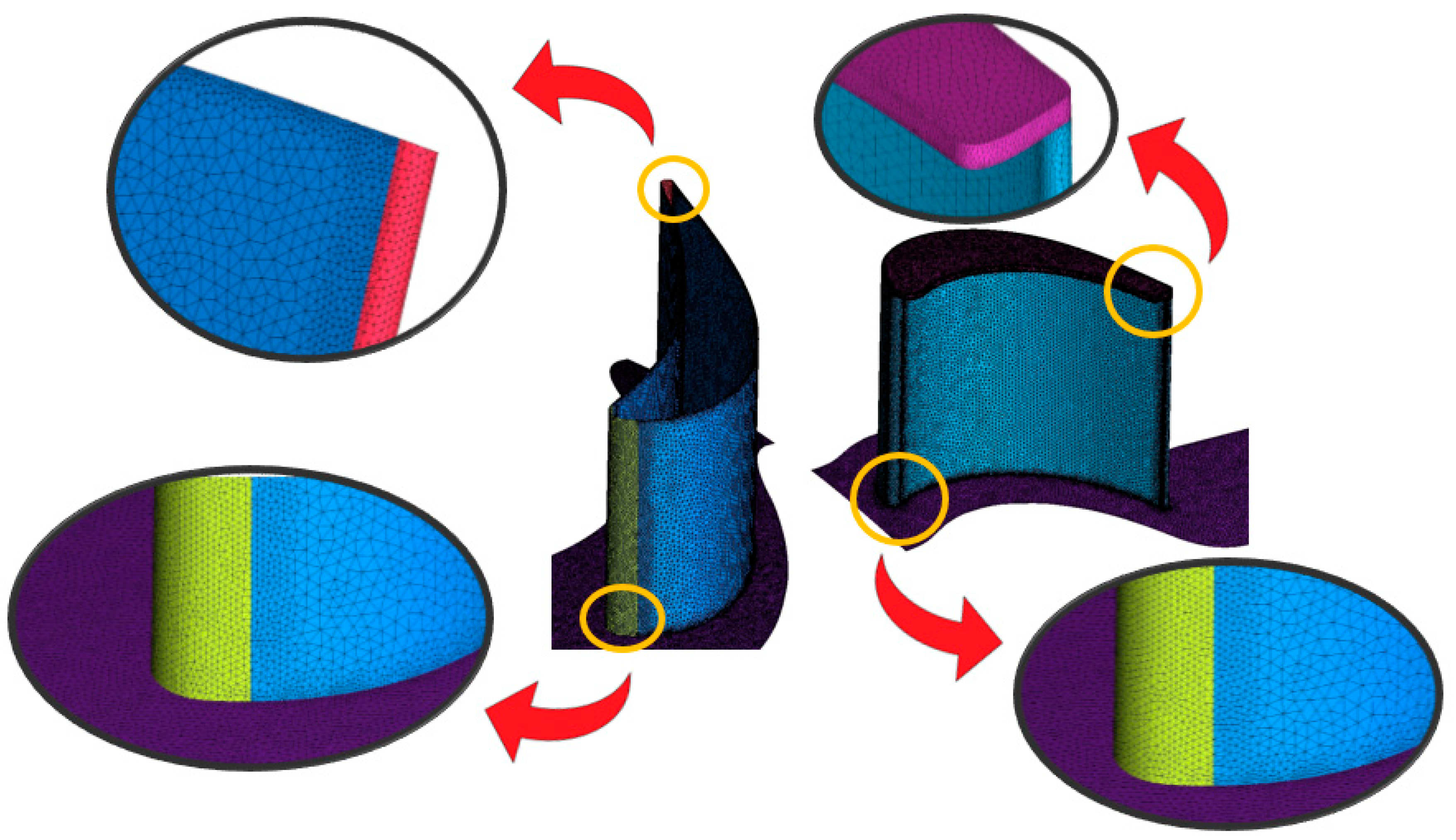

5.1. Mesh Characteristics

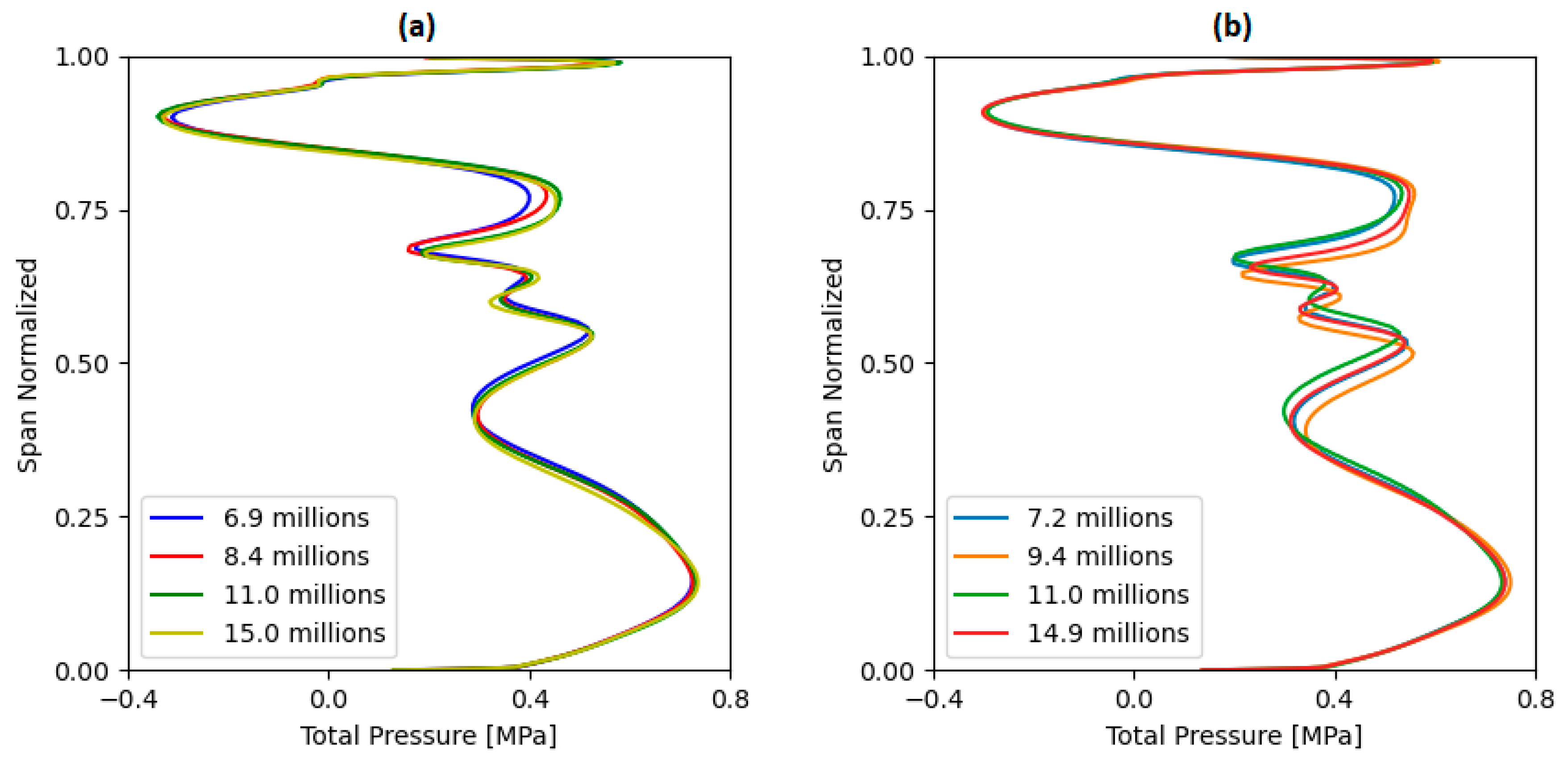

5.2. Independence Analysis

5.3. Initial and Boundary Conditions

- Stage inlet: entry velocity vector, total temperature (294 K), mass flow, and intensity of turbulence (5%);

- Stage outlet: average blade hub static pressure, which varies until reaching the casing, using the radial equilibrium equation;

- Stator–rotor interface: mixing-plane;

- Wall surfaces: non-slip condition;

- Blade-to-blade surfaces: periodicity.

5.4. Numerical Scheme

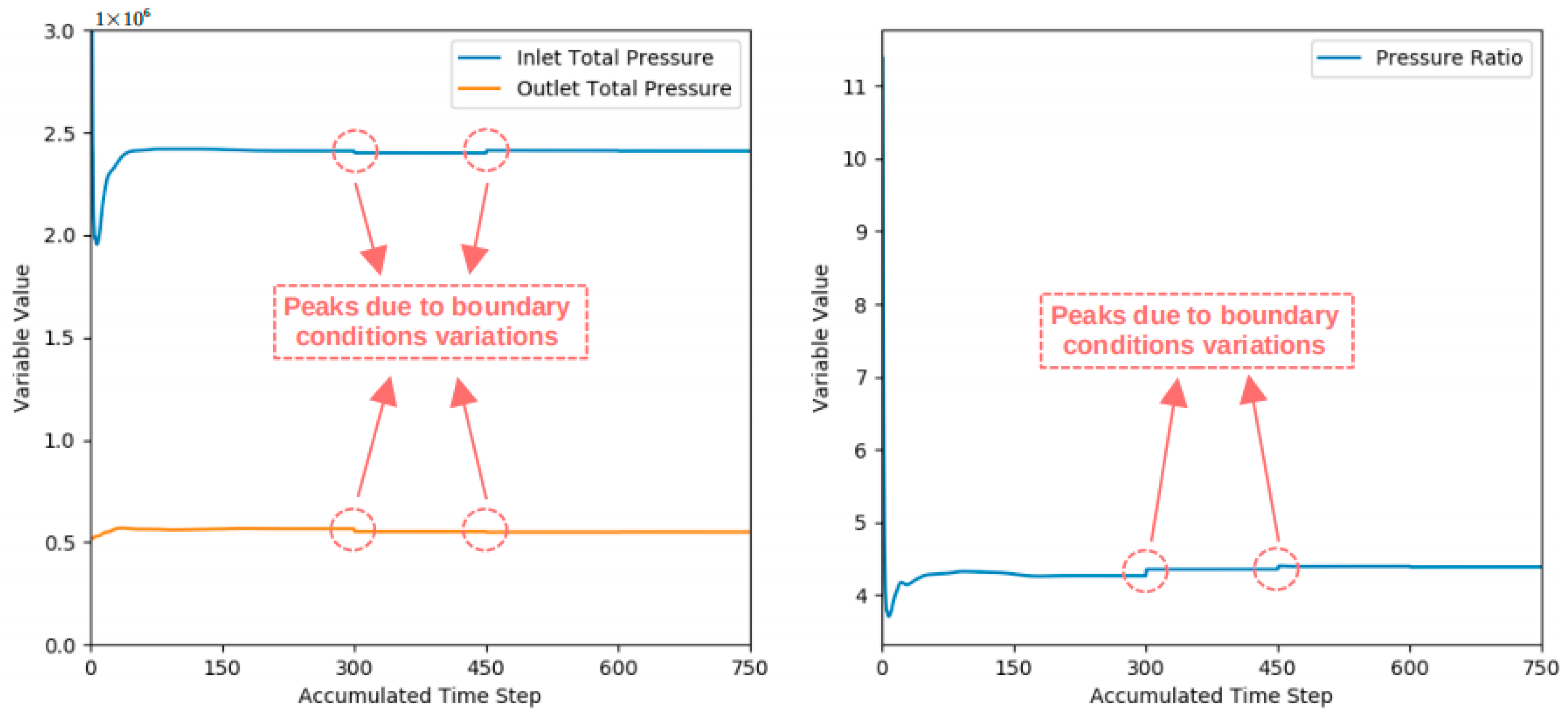

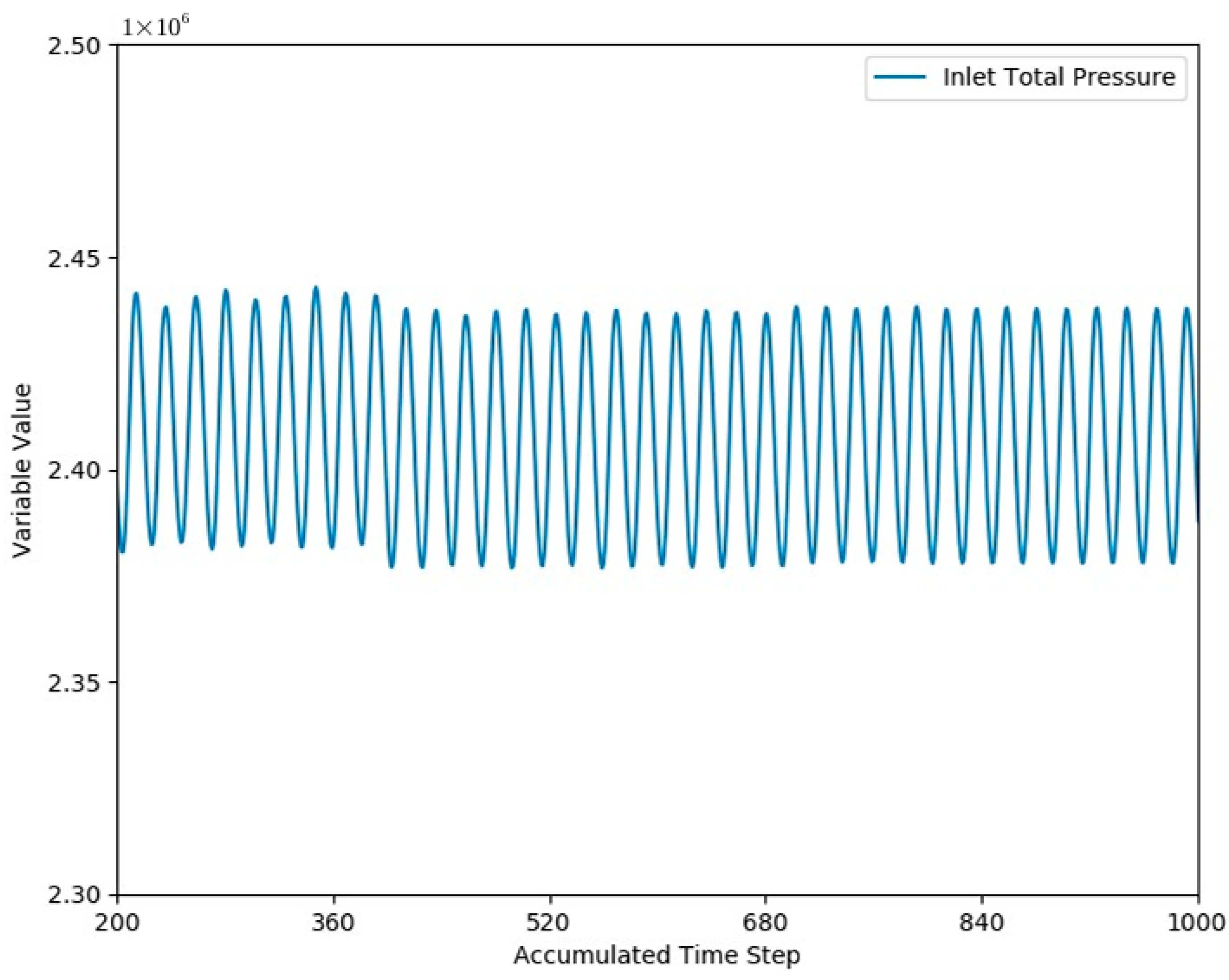

5.5. Residual Evolution

6. Results

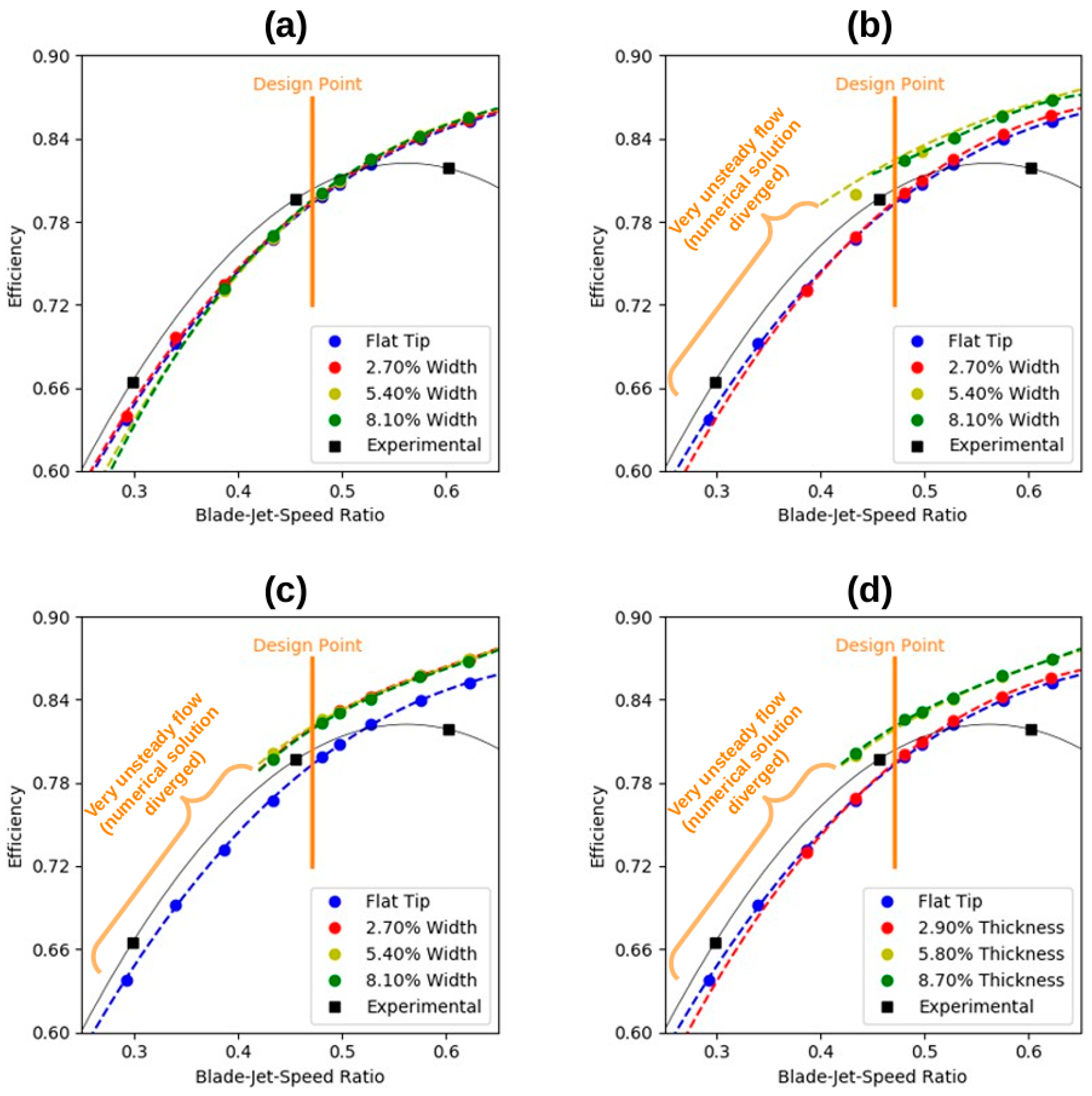

6.1. Stage Efficiency

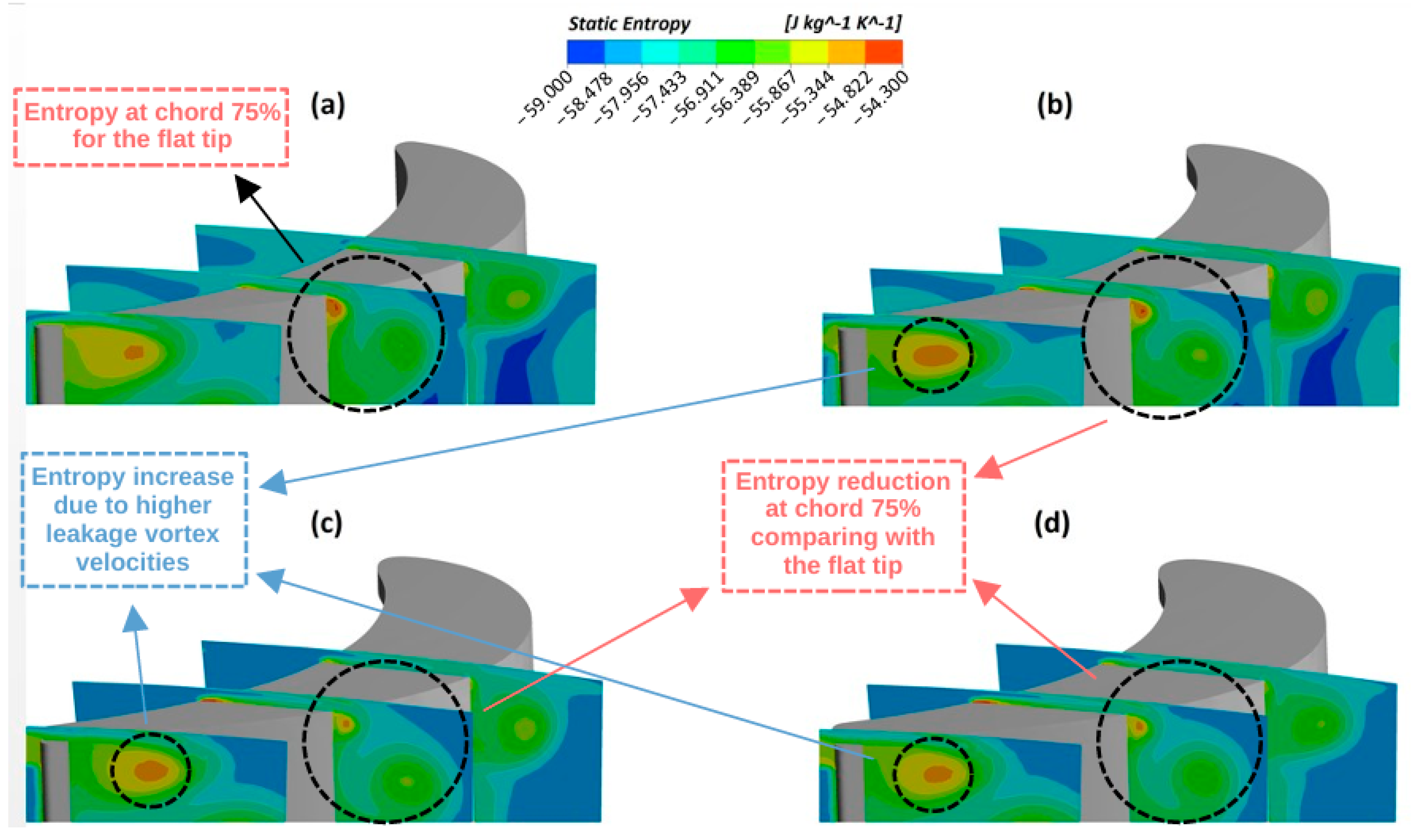

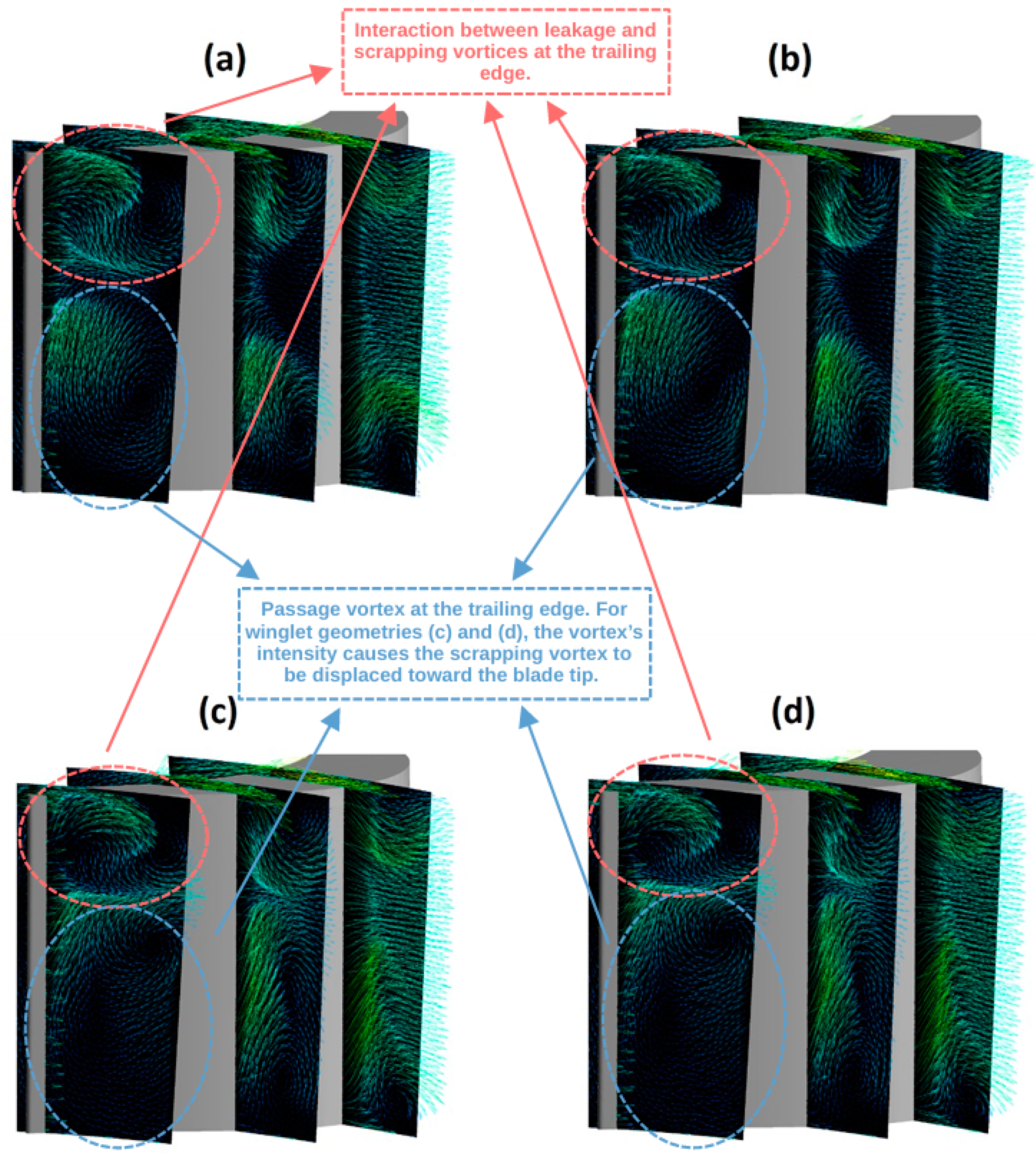

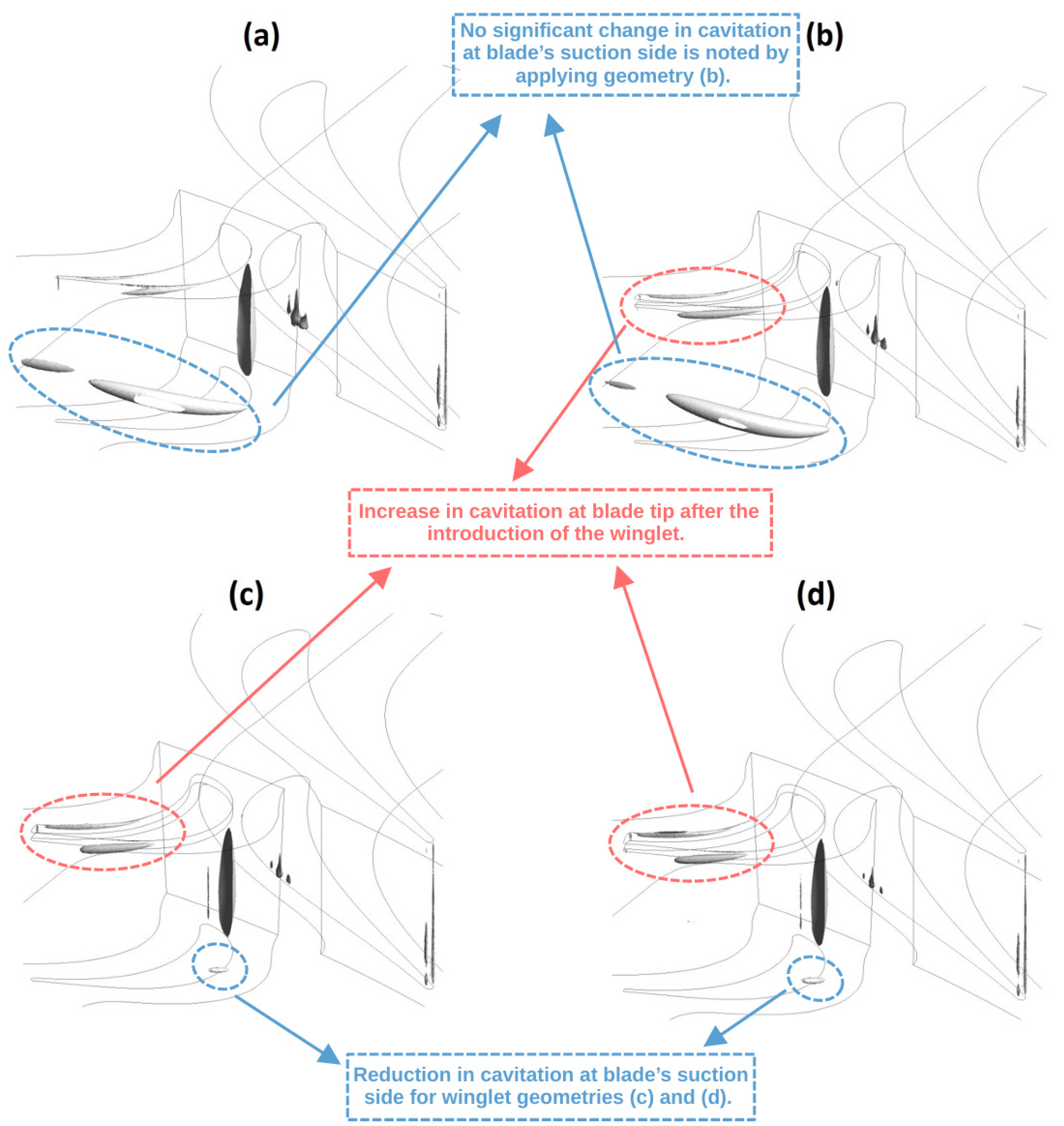

6.2. Effect of Squealer Geometries in the Axial Turbine Flowfield Characteristics

7. Conclusions

- A winglet parametric analysis was performed considering 2.90%, 5.80%, and 8.70% thicknesses and 2.70%, 8.40%, and 8.10% widths. These percentages are all in relation to the blade height. The results of the nine proposed geometries show that increasing the winglet thickness has a positive impact on the turbine’s total efficiency—the greater the winglet thickness, the greater the stage efficiency. However, there is a maximum value for this parameter, beyond which the efficiency remains constant. The winglet geometry with 8.70% thickness and 5.40% width provides the highest stage efficiency average increase (2.00%) over the entire turbine operational range, in comparison with the rotor flat-tip configuration. For reference, the highest average increase in this parameter for the squealer geometries, available in [18], was 1.43%.

- The winglet width dimension almost does not impact the stage efficiency.

- In general, the results found in this work show that the winglet geometries analyzed are able to provide a greater increase in stage efficiency than the squealer geometries evaluated in previous research [18], considering both design and off-design operating conditions. In the case of the squealer, for the design point, the maximum efficiency improvement was 1.62% [18], compared to the current improvement of 2.23% using the winglet desensitization technique.

- Regarding the vortices in the tip region, the same behavior shown in previous works for the flat tip and the squealer geometries was maintained for the winglet modifications: they have a different rotation direction, reducing the losses in the region. However, for the winglet geometries that provide the best performance results, it is noted that the scrapping vortex is displaced in relation to the flat-tip case due to the effects of the leakage and passage vortices.

- The cavitation results obtained with the application of winglet geometries show that it would be possible to reduce the occurrence of this phenomenon at the blade’s suction side for some configurations. However, for these same configurations, there is an increase in the cavitation at the tip region. The effects of these combined changes on the turbine life cycle must be carefully analyzed through structural simulations and tests.

8. Future Research

- All the proposed and evaluated geometries in this work are blade pressure-side winglet geometries along the full blade chord; it would be interesting to also develop analyses for a partial winglet with dimensional variations distributed along the blade chord.

- In order to validate the results obtained by the numerical simulations, the development of experimental tests will be very useful.

- Regarding Figure 17, a more detailed study needs to be conducted based on the simulation of multiphase flows to analyze the effect of the cavitation region on the tip clearance and verify its influence on turbine operating conditions and lifecycle.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| CFD | Computational fluid dynamics |

| ITA | Aeronautics Institute of Technology |

| LH2 | Liquid hydrogen |

| LPOTP | Low-pressure oxidizer turbopump |

| LOX | Liquid oxygen |

| LPREs | Liquid propellant rocket engines |

| NASA | National Aeronautics and Space Administration |

| PDE | Partial differential equations |

| RANS | Reynolds-averaged Navier–Stokes |

| SST | Shear stress transport |

| SSME | Space shuttle main engine |

| TP | Turbopump |

| N | Rotational frequency |

| ṁ | Mass flow |

| p | Pressure |

| i | Inlet condition |

| o | Outlet condition |

| T | Total condition |

| W | Turbine shaft power |

| τ | Turbine torque |

| η | Turbine efficiency |

| ρ | Density |

| UCasing | Peripheral velocity |

| U/C0 | Blade–jet–speed ratio |

| R | Turbine rotor blade tip radius |

References

- De Oliveira Silva, G.P.; Tomita, J.T.; Bringhenti, C.; Whitacker, L.H.L.; Da Silva Tonon, D. Interactive learning platform for the preliminary design of axial turbines and its use for graduate courses. In Proceedings of the ASME Turbo Expo, Rotterdam, Netherlands, 13–17 June 2022; Volume 5. [Google Scholar]

- Oliveira, I.; Silva, G.P.; Tonon, D.; Bringhenti, C.; Tomita, J.T. Interactive learning platform for turbine design using reduced order methods. In Proceedings of the ASME Turbo Expo, Virtual, Online, 21–25 September 2020; Volume 6. [Google Scholar]

- da Silva, L.M.; Tomita, J.T.; Bringhenti, C. Numerical investigation of a HPT with Different rotor tip configurations in terms of pressure ratio and efficiency. Aerosp. Sci. Technol. 2017, 63, 33–40. [Google Scholar] [CrossRef]

- Silva, L.M.; Tomita, J.T.; Barbosa, J.R. A study of the influence of the tip-clearance on the tip-leakage flow using CFD techniques. In Brazilian Congress of Mechanical Engineering—COBEM, Proceedings of the 21st Brazilian Congress of Mechanical Engineering, Natal, RN, Brazil, 24–28 October 2011; Springer: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Schabowski, Z.; Hodson, H.; Giacche, D.; Power, B.; Stokes, M.R. Aeromechanical optimization of a winglet-squealer tip for an axial turbine. J. Turbomach. 2014, 136, 071004. [Google Scholar] [CrossRef]

- Wang, T.; Xuan, Y. A novel approach for suppressing leakage flow through turbine blade tip gaps. Propuls. Power Res. 2022, 11, 431–443. [Google Scholar] [CrossRef]

- Kong, X.; Liu, G.; Liu, Y.; Zheng, L. Experimental testing for the influences of rotation and tip clearance on the labyrinth seal in a compressor stator well. Aerosp. Sci. Technol. 2017, 71, 556–567. [Google Scholar] [CrossRef]

- Gao, Y.; Liu, Y. A flow model for tip leakage flow in turbomachinery using a square duct with a longitudinal slit. Aerosp. Sci. Technol. 2019, 95, 105460. [Google Scholar] [CrossRef]

- Booth, T.C.; Dodge, P.R.; Hepworth, H.K. Rotor-tip leakage: Part I basic methodology. J. Eng. Power 1982, 104, 154–161. [Google Scholar] [CrossRef]

- Krishnababu, S.K.; Newton, P.J.; Dawes, W.N.; Lock, G.D.; Hodson, H.P.; Hannis, J.; Whitney, C. Aerothermal investigations of tip leakage flow in axial flow turbines-part i: Effect of tip geometry and tip clearance gap. J. Turbomach. 2009, 131, 1–14. [Google Scholar] [CrossRef]

- Bringhenti, C.; Barbosa, J.R. Effects of turbine tip clearance on gas turbine performance. In ASME Turbo Expo 2008: Power for Land, Sea, and Air, Berlin, Germany, 9–13 June 2008; ASME, Ed.; ASME: New York, NY, USA, 2009. [Google Scholar]

- Moustapha, H.; Zelesky, M.F.; Baines, N.C.; Japikse, D. Axial and Radial Turbines; Concepts NREC: Vermont, VT, USA, 2003. [Google Scholar]

- Kim, J.; Song, S.J. Visualization of rotating cavitation oscillation mechanism in a turbopump inducer. J. Fluids Eng. Trans. ASME 2019, 141, 091103. [Google Scholar] [CrossRef]

- Kim, D.J.; Sung, H.J.; Choi, C.H.; Kim, J.S. Cavitation instabilities of an inducer in a cryogenic pump. Acta Astronaut. 2017, 132, 19–24. [Google Scholar] [CrossRef]

- Li, L.; Xu, P.; Li, Q.; Zheng, R.; Xu, X.; Wu, J.; He, B.; Bao, J.; Tan, D. A coupled LBM-LES-DEM particle flow modeling for microfluidic chip and ultrasonic-based particle aggregation control method. Appl. Math. Model. 2025, 143, 116025. [Google Scholar] [CrossRef]

- Lindquist Whitacker, L.H.; Tomita, J.T.; Bringhenti, C. An evaluation of the tip clearance effects on turbine efficiency for space propulsion applications considering liquid rocket engine using turbopumps. Aerosp. Sci. Technol. 2017, 70, 55–65. [Google Scholar] [CrossRef]

- Whitacker, L.H.L.; Tomita, J.T.; Bringhenti, C. Turbopump Booster Turbine Performance: Comparison Between Monophase and Multiphase Flows Using CFD; ASME, Ed.; ASME Turbo Expo: Oslo, The Netherlands, 2018; pp. 1–9. [Google Scholar]

- Tonon, D.d.S.; Tomita, J.T.; Garcia, E.C.; Bringhenti, C.; Almeida, L.E.N. A parametric study of squealer tip geometries applied in a hydraulic axial turbine used in a rocket engine turbopump. Aerosp. Sci. Technol. 2022, 122, 107426. [Google Scholar] [CrossRef]

- Saha, A.K.; Acharya, S.; Bunker, R.; Prakash, C. Blade tip leakage flow and heat transfer with pressure-side winglet. Int. J. Rotating Mach. 2006, 2006, 017079. [Google Scholar] [CrossRef]

- Zamiri, A.; Choi, M.; Chung, J.T. Effect of blade squealer tips on aerodynamic performance and stall margin in a transonic centrifugal compressor with vaned diffuser. Aerosp. Sci. Technol. 2022, 123, 107504. [Google Scholar] [CrossRef]

- Chen, Y.; Cai, L.; Jiang, D.; Li, Y.; Du, Z.; Wang, S. Experimental and numerical investigations for turbine aerodynamic performance with different pressure side squealers and incidence angles. Aerosp. Sci. Technol. 2023, 136, 108234. [Google Scholar] [CrossRef]

- He, X.; Zou, Z.; Yao, L.; Fu, C. Refined Flow Organization in Squealer Tip Gap and Its Impact on Turbine Aerodynamic Performance. Aerosp. Sci. Technol. 2023, 138, 108331. [Google Scholar] [CrossRef]

- Tonon, D.D.S.; Tomita, J.T.; Garcia, E.C.; Bringhenti, C.; Díaz, R.B.; Whitacker, L.H.L. Comparative Study Between Structured and Unstructured Meshes Applied in Turbopump’s Hydraulic Turbine. In ASME Turbo Expo 2020: Turbomachinery Technical Conference and Exposition, Virtual, 21–25 September 2020; ASME, Ed.; ASME: New York, NY, USA, 2020; pp. 1–13. [Google Scholar]

- Tonon, D.d.S.; Tomita, J.T.; Garcia, E.C.; Bringhenti, C.; Almeida, L.E.N. Effects of a Squealer-Winglet Geometry on the Aerodynamic Performance of a Hydraulic Axial Turbine Used in Turbopumps. In Proceedings of the 25th International Symposium on Air Breathing Engines (ISABE 2022), Ottawa, ON, Canada, 25–30 September 2022. [Google Scholar]

- Barbosa, D.F.C.; Tonon, D.D.S.; Luiz Henrique, L.W.; Tomita, J.T.; Bringhenti, C. Evaluation of Different Turbulence Models Applied in Turbopump’s Hydraulic Turbine. In Proceedings of the ASME Turbo Expo: Online, 7–11 June 2021; Volume 2C. [Google Scholar]

- Boynton, J.L.; Rohlik, H.E. Effect of Tip Clearance on Performance of Small Axial Hydraulic Turbine; NASA: Cleveland, OH, USA, 1976. [Google Scholar]

- Sieverding, C.H. Recent Progress in the Understanding of Basic Aspects of Secondary Flows in Turbine Blade Passages. J. Eng. Gas Turbines Power 1985, 107, 248–257. [Google Scholar] [CrossRef]

- Langston, L.S. Secondary flows in axial turbines—A review. Ann. N.Y. Acad. Sci. 2001, 934, 11–26. [Google Scholar] [CrossRef]

- Ainley, D.G.; Mathieson, G.C.R. A Method of Performance Estimation for Axial-Flow Turbines; Technical Report No. 2974; Aeronautical Research Council Reports and Memoranda: London, UK, 1951. [Google Scholar]

- Dunham, J.; Came, P.M. Improvements to the Ainley & Mathieson method of turbine performance prediction. Trans. ASME J. Eng. Power 1970, 92, 252–256. [Google Scholar]

- Kacker, S.C.; Okapuu, U. A mean line prediction method for axial flow turbine efficiency. J. Eng. Gas Turbines Power 1982, 104, 111–119. [Google Scholar] [CrossRef]

- Moustapha, H.; Kacker, S.C.; Traemblay, B. An improved incidence losses prediction method for turbine airfoils. J. Turbomach. 1990, 112, 267–276. [Google Scholar] [CrossRef]

- da Silva, L.M. Cálculo Do Escoamento Em Uma Turbina Axial de Alta Pressão Com Diferentes Configurações Na Geometria Do Topo Do Rotor Utilizando Técnicas de CFD; Instituto Tecnológico de Aeronáutica: São José dos Campos, Brazil, 2012. [Google Scholar]

- Lee, S.W.; Jeong, J.S.; Hong, I.H. Chord-wise repeated thermal load change on flat tip of a turbine blade. Int. J. Heat Mass Transf. 2019, 138, 1154–1165. [Google Scholar] [CrossRef]

- Bunker, R.S.; Bailey, J.C.; Ameri, A.A. Heat transfer and flow on the first stage blade tip of a power generation gas turbine part 1: Experimental results. In ASME Turbo Expo, Proceedings of the 44th Gas Turbine and Aeroengine Congress, Indianapolis, IN, USA, 7–10 June 1999; ASME/NASA, Ed.; ASME: New York, NY, USA, 1999; Volume 3. [Google Scholar]

- Han, J.C.; Dutta, S.; Ekkad, S. Gas Turbine Heat Transfer and Cooling Technology, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2013; ISBN 0791835332. [Google Scholar]

- Dey, D.; Camci, C. Aerodynamic Tip Desensitization of an Axial Turbine Rotor Using Tip Platform Extensions. In ASME Turbo Expo 2001: Power for Land, Sea, and Air, New Orleans, LA, USA, 4–7 June 2001; ASME, Ed.; ASME Turbo Expo: New Orleans, LA, USA, 2001. [Google Scholar]

- Rodríguez-Pérez, Á.M.; Pulido-Calvo, I. Analysis and viability of microturbines in hydraulic networks: A case study. J. Water Supply Res. Technol.—AQUA 2019, 68, 474–482. [Google Scholar] [CrossRef]

- Langston, L.S.; Nice, M.L.; Hooper, R.M. Three-dimensional flow within a turbine cascade passage. Am. Soc. Mech. Eng. 1976, 99, 21–28. [Google Scholar] [CrossRef]

- Yamamoto, A. Interaction Mechanisms Between Tip Leakage Flow and the Passage Vortex in a Linear Turbine Rotor Cascade. J. Turbomach. 1988, 110, 329–338. [Google Scholar] [CrossRef]

- Cao, L.; Si, H.; Wang, J.; Li, P. Effects of leakage vortex on aerodynamic performance and loss mechanism of steam turbine. Proc. Inst. Mech. Eng. Part A J. Power Energy 2019, 233, 866–876. [Google Scholar] [CrossRef]

- Passmann, M.; Aus Der Wiesche, S.; Joos, F. An experimental and numerical study of tip-leakage flows in an idealized turbine tip gap at high mach numbers. In ASME Turbo Expo 2018: Turbomachinery Technical Conference and Exposition 2018, Oslo, Norway, 11–15 June 2018; ASMR: New York, NY, USA, 2018; Volume V02BT41A023, p. 12. [Google Scholar] [CrossRef]

- Arakeri, V.H. Contributions to Some Cavitation Problems in Turbomachinery. Sadhana—Acad. Proc. Eng. Sci. 1999, 24, 453–483. [Google Scholar] [CrossRef]

- Whitacker, L.H.L. Determinação Da Influência Da Folga de Topo Na Eficiência de Uma Turbina Axial Multiestágio Utilizada Em Booster de Motor Foguete Para Operação Com LOX; Instituto Tecnológico de Aeronáutica: São José dos Campos, Brazil, 2017. [Google Scholar]

- Acosta, A.J. An experimental study of cavitating inducers. In Proceedings of the 2nd Symposium on Naval Hydrodynamics, Hydrodynamic Noise, Cavity Flow, Washington, WA, USA, 25–29 August 1958; pp. 25–29. [Google Scholar]

- Whitacker, L.H.L.; Tomita, J.T.; Bringhenti, C. Effect of tip clearance on cavitating flow of a hydraulic axial turbine applied in turbopump. Int. J. Mech. Sci. 2022, 213, 106855. [Google Scholar] [CrossRef]

- Lindau, R.F.; Kunz, J.W.; Venkateswaran, S.; Boger, D.A. Application of preconditioned, multiple-species, navier-stokes models to cavitating flows. In Proceedings of the CAV 2001: Fourth International Symposium on Cavitation, Pasedena, CA, USA, 20–23 June 2001; pp. 1–14. [Google Scholar]

- Pinho, J.; Peveroni, L.; Vetrano, M.R.; Buchlin, J.M.; Steelant, J.; Strengnart, M. Experimental and numerical study of a cryogenic valve using liquid nitrogen and water. Aerosp. Sci. Technol. 2019, 93, 105331. [Google Scholar] [CrossRef]

- Piscaglia, F.; Giussani, F.; Hèlie, J.; Lamarque, N.; Aithal, S.M. Vortex flow and cavitation in liquid injection: A comparison between high-fidelity cfd simulations and experimental visualizations on transparent nozzle replicas. Int. J. Multiph. Flow 2021, 138, 103605. [Google Scholar] [CrossRef]

- Balz, R.; Nagy, I.G.; Weisser, G.; Sedarsky, D. Experimental and numerical investigation of cavitation in marine diesel injectors. Int. J. Heat Mass Transf. 2021, 169, 120933. [Google Scholar] [CrossRef]

- Chen, M.; Li, L.; Lin, Z.; Zhang, J.; Li, F. Investigation of splashing characteristics during spray impingement using VOF–DPM approach. Water 2025, 17, 394. [Google Scholar] [CrossRef]

- Tu, Y.; Zhao, X.; Lu, L.; Zhou, W.; Li, S.; Dai, J.; Wang, Z.; Zheng, Y.; Yang, C. Flow Characteristics and Pressure pulsation analysis of cavitation induced in a double-volute centrifugal pump. Water 2025, 17, 445. [Google Scholar] [CrossRef]

- Pouffary, B.; Patella, R.F.; Reboud, J.L.; Lambert, P.A. Numerical simulation of 3D cavitating flows: Analysis of cavitation head drop in turbomachinery. J. Fluids Eng. Trans. ASME 2008, 130, 10. [Google Scholar] [CrossRef]

- Rossetti, A.; Pavesi, G.; Ardizzon, G.; Santolin, A. Numerical analyses of cavitating flow in a pelton turbine. J. Fluids Eng. Trans. ASME 2014, 136, 081304. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, L. Numerical simulation of cavitating turbulent flow in a high head francis turbine at part load operation with OpenFOAM. Procedia Eng. 2012, 31, 156–165. [Google Scholar] [CrossRef]

- Sun, L.; Guo, P.; Luo, X. Numerical investigation of inter-blade cavitation vortex for a francis turbine at part load conditions. IET Renew. Power Gener. 2021, 15, 1163–1177. [Google Scholar] [CrossRef]

- Ghenaiet, A.; Bakour, M. Hydrodynamic characterization of small-size kaplan turbine. J. Hydraul. Eng. 2021, 147, 06020019. [Google Scholar] [CrossRef]

- Sivolella, D. The Space Shuttle Program; Springer: Cham, Switzerland, 2017; ISBN 9783319549446. [Google Scholar]

- United States. Main Propulsion System; Boeing: Arlington, VA, USA; NASA: Washington, WA, USA; United Space Alliance: Houston, TX, USA, 1998. [Google Scholar]

- United States. Space transportation system training data. In Reviews in Space Shuttle Main Engine Orientation; Boeing: Arlington, VA, USA, 1998. [Google Scholar]

- You, Y.; Ding, L. Numerical investigation of unsteady film cooling on turbine blade squealer tip with pressure side coolant. Int. Commun. Heat Mass Transf. 2023, 143, 106720. [Google Scholar] [CrossRef]

- Huang, M.; Li, Z.; Li, J. Investigations on the aerothermal performance of the turbine blade winglet squealer tip within an uncertainty framework. Aerosp. Sci. Technol. 2022, 123, 107506. [Google Scholar] [CrossRef]

- Bi, S.; Mao, J.; Chen, P.; Han, F.; Wang, L. Effect of multiple cavities and tip injection on the aerothermal characteristics of the squealer tip in turbine stage. Appl. Therm. Eng. 2023, 220, 119631. [Google Scholar] [CrossRef]

- Kim, J.H.; Lee, S.Y.; Chung, J.T. Numerical analysis of the aerodynamic performance & heat transfer of a transonic turbine with a partial squealer Tip. Appl. Therm. Eng. 2019, 152, 878–889. [Google Scholar] [CrossRef]

- Harvey, N.W.; Newman, D.A.; Haselbach, F.; Willer, L. An investigation into a novel turbina rotor winglet part 1: Design and model rig test results. In ASME Turbo Expo 2006: Power for Land, Sea, and Air, Barcelona, Spain, 8–11 May; ASME, Ed.; ASME: New York, NY, USA, 2006. [Google Scholar]

- Lee, S.W.; Choi, M.Y. Tip gap height effects on the aerodynamic performance of a cavity squealer tip in a turbine cascade in comparison with plane tip results: Part 2-aerodynamic losses. Exp. Fluids 2010, 49, 713–723. [Google Scholar] [CrossRef]

- da Silva Tonon, D.; Tomita, J.T.; Bringhenti, C.; Barbosa, D.F.C.; Whitacker, L.H.L.; Almeida, L.E.N. Effects of two winglet tip geometries on the flow and aerodynamic performance of a hydraulic axial turbine. In Proceedings of the 33rd Congress of the International Council of the Aeronautical Sciences ICAS 2022, Stockholm, Sweden, 4–9 September 2022; pp. 2402–2418. [Google Scholar]

- Camci, C.; Dey, D.; Kavurmacioglu, L. Tip Leakage Flows Near Partial Squealer Rims in an Axial Flow Turbine Stage; ASME, Ed.; ASME Turbo Expo: Atlanta, GE, USA, 2003. [Google Scholar]

- Zhou, C.; Hodson, H.; Tibbott, I.; Stokes, M. Effects of winglet geometry on the aerodynamic performance of tip leakage flow in a turbine cascade. J. Turbomach. 2013, 135, 051009. [Google Scholar] [CrossRef]

- Seo, Y.C.; Lee, S.W. Tip gap flow and aerodynamic loss generation in a turbine cascade equipped with suction-side winglets. J. Mech. Sci. Technol. 2013, 27, 703–712. [Google Scholar] [CrossRef]

- Jeong, J.S.; Bong, S.W.; Lee, S.W. An efficient winglet coverage for aeroengine turbine blade flat tip and its loss map. Energy 2022, 260, 125153. [Google Scholar] [CrossRef]

- Chen, S.; Li, W. Effects of combined sweeping jet actuator and winglet tip on aerodynamic performance in a turbine cascade. Aerosp. Sci. Technol. 2022, 131, 107956. [Google Scholar] [CrossRef]

- O’Dowd, D.O.; Zhang, Q.; He, L.; Oldfield, M.L.G.; Ligrani, P.M.; Cheong, B.C.Y.; Tibbott, I. Aerothermal performance of a winglet at engine representative mach and reynolds numbers. J. Turbomach. 2011, 133, 041026. [Google Scholar] [CrossRef]

- Cheon, J.H.; Lee, S.W. Winglet geometry effects on tip leakage loss over the plane tip in a turbine cascade. J. Mech. Sci. Technol. 2018, 32, 1633–1642. [Google Scholar] [CrossRef]

- Coull, J.D.; Atkins, N.R.; Hodson, H.P. Winglets for improved aerothermal performance of high pressure turbines. J. Turbomach. 2014, 136, 091007. [Google Scholar] [CrossRef]

- Cevik, M.; Vo, H.D.; Yu, H. Casing treatment for desensitization of compressor performance and stability to tip clearance. J. Turbomach. 2016, 138, 121008. [Google Scholar] [CrossRef]

- Zhou, C.; Zhong, F. A Novel suction-side winglet design philosophy for high-pressure turbine rotor tips. J. Turbomach. 2017, 139, 111002. [Google Scholar] [CrossRef]

- Garg, A.; Vadlamani, N.R.; Srinivasan, B. Aerothermal performance of axially varying winglet-squealer blade tips. J. Turbomach. 2023, 145, 071009. [Google Scholar] [CrossRef]

- Jo, S.H.; Jeon, Y.; Baek, S.; Song, J.; You, D.; Hwang, W. Effects of turbine blade tip pressure side winglet and cavity rim on aerodynamic performance. In Proceeding of the Turbo Expo 2023Turbomachinery Technical Conference & Exposition, Boston, MA, USA, 26–30 June 2023; Volume 13B, pp. 1–13. [Google Scholar] [CrossRef]

- Rhie, C.M.; Allison, D.D.; Asme, A.; Thermoph, J.; Louis, S. A Numerical Study of the Turbulent Flow Past an Isolated Airfoil with Trailing Edge Separation. In Proceedings of the 3rd Joint Thermophysics, Fluids, Plasma and Heat Transfer Conference, St. Louis, MO, USA; 1982. [Google Scholar] [CrossRef]

- da Silva, L.M.; Tomita, J.T.; Bringhenti, C.; Whitacker, L.H.L.; Almeida, L.E.N.; Cavalca, D.F. A Small Jet Engine Preliminary Design and Its Performance Calculations. In Proceedings of the 24th International Symposium on Air Breathing Engines (ISABE 2019), Canberra, Australia, 22–27 September 2019. [Google Scholar]

- Aulich, M.; Goinis, G.; Voß, C. Data-driven AI model for turbomachinery compressor aerodynamics enabling rapid approximation of 3D flow solutions. Aerospace 2024, 11, 723. [Google Scholar] [CrossRef]

- Zou, Z.; Xu, P.; Chen, Y.; Yao, L.; Fu, C. Application of Artificial Intelligence in Turbomachinery Aerodynamics: Progresses and Challenges; Springer: Berlin/Heidelberg, Germany, 2024; Volume 57, ISBN 0123456789. [Google Scholar]

- Hammond, J.; Pepper, N.; Montomoli, F.; Michelassi, V. Machine learning methods in CFD for turbomachinery: A review. Int. J.; Turbomach. Propuls. Power 2022, 7, 16. [Google Scholar] [CrossRef]

| Thickness (%) | Width (%) | Mesh 1 | Mesh 2 | Mesh 3 | Mesh 4 |

|---|---|---|---|---|---|

| 2.90 | 2.70 | 7.2 | 9.4 | 11.0 | 14.9 |

| 2.90 | 5.40 | 7.2 | 8.2 | 10.7 | 15.8 |

| 2.90 | 8.10 | 6.9 | 8.2 | 11.3 | 15.1 |

| 5.80 | 2.70 | 6.6 | 8.9 | 11.6 | 15.7 |

| 5.80 | 5.40 | 7.1 | 8.9 | 11.6 | 15.2 |

| 5.80 | 8.10 | 8.6 | 11.0 | 13.1 | 18.3 |

| 8.70 | 2.70 | 7.7 | 9.6 | 11.6 | 15.5 |

| 8.70 | 5.40 | 6.9 | 8.4 | 11.0 | 15 |

| 8.70 | 8.10 | 8.7 | 11.0 | 13.5 | 17.7 |

| Thickness [%] | Width [%] | A | B | C | D |

|---|---|---|---|---|---|

| 2.90 | 2.70 | 1.0339 | −2.8360 | 2.5599 | 0.1098 |

| 2.90 | 5.40 | 1.1505 | −3.1993 | 2.8677 | 0.0330 |

| 2.90 | 8.10 | 2.3079 | −4.9466 | 3.7219 | −0.1012 |

| 5.80 | 2.70 | 0.9700 | −2.9132 | 2.7195 | 0.05874 |

| 5.80 | 5.40 | 1.1260 | −2.5565 | 2.1145 | 0.2718 |

| 5.80 | 8.10 | −4.0937 | 6.2653 | −2.8493 | 1.2008 |

| 8.70 | 2.70 | 4.3434 | −7.9066 | 5.0558 | −0.2616 |

| 8.70 | 5.40 | 3.2998 | −6.0235 | 3.9295 | −0.0389 |

| 8.70 | 8.10 | 4.2550 | −7.7215 | 4.9318 | −0.2362 |

| Percentage Variations Compared to the Flat Tip [%] | ||||

|---|---|---|---|---|

| Parameters | U/C0 | 2.70% Width | 5.40% Width | 8.10% Width |

| Average | - | 0.1624 | 0.1760 | 0.2403 |

| DP | 0.4706 | 0.1708 | 0.1483 | 0.2909 |

| Experimental | 0.2983 | 0.2898 | - | - |

| 0.4559 | 0.1803 | 0.0899 | 0.2610 | |

| 0.6017 | 0.1315 | 0.3600 | 0.2898 | |

| 0.3860 | 0.2307 | −0.3068 | −0.1352 | |

| 0.4193 | 0.2060 | −0.0921 | 0.1143 | |

| 0.4526 | 0.1825 | 0.0757 | 0.2522 | |

| 0.4859 | 0.1617 | 0.2006 | 0.3084 | |

| 0.5192 | 0.1450 | 0.2868 | 0.3125 | |

| 0.5525 | 0.1340 | 0.3384 | 0.2943 | |

| 0.5858 | 0.1303 | 0.3595 | 0.2836 | |

| Percentage Variations Compared to the Flat Tip [%] | ||||

|---|---|---|---|---|

| Parameters | U/C0 | 2.70% Width | 5.40% Width | 8.10% Width |

| Average | - | 0.3504 | 2.0292 | 2.0485 |

| DP | 0.4706 | 0.2025 | 2.5643 | 2.8442 |

| Experimental | 0.2983 | - | - | - |

| 0.4559 | 0.1431 | 2.7607 | 3.2627 | |

| 0.6017 | 0.4431 | 1.6614 | 1.5760 | |

| 0.4500 | 0.1174 | 2.8446 | 3.4556 | |

| 0.4726 | 0.2100 | 2.5390 | 2.7937 | |

| 0.4953 | 0.2875 | 2.2759 | 2.3189 | |

| 0.5179 | 0.3491 | 2.0586 | 2.0000 | |

| 0.5405 | 0.3953 | 1.8871 | 1.7997 | |

| 0.5632 | 0.4262 | 1.7621 | 1.6824 | |

| 0.5858 | 0.4415 | 1.6857 | 1.6140 | |

| Percentage Variations Compared to the Flat Tip [%] | ||||

|---|---|---|---|---|

| Parameters | U/C0 | 2.70% Width | 5.40% Width | 8.10% Width |

| Average | - | 2.2178 | 2.2336 | 2.0803 |

| DP | 0.4706 | 2.6896 | 2.7865 | 2.5686 |

| Experimental | 0.2983 | - | - | - |

| 0.4559 | 2.8038 | 2.9793 | 2.6967 | |

| 0.6017 | 1.6917 | 1.6386 | 1.5419 | |

| 0.4300 | 2.9451 | 3.3082 | 2.8694 | |

| 0.4560 | 2.8031 | 2.9780 | 2.6959 | |

| 0.4819 | 2.5902 | 2.6389 | 2.4604 | |

| 0.5079 | 2.3405 | 2.3129 | 2.1955 | |

| 0.5339 | 2.0901 | 2.0258 | 1.9368 | |

| 0.5598 | 1.8755 | 1.8031 | 1.7197 | |

| 0.5858 | 1.7304 | 1.6676 | 1.5771 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tonon, D.d.S.; Tomita, J.T.; Garcia, E.C.; Bringhenti, C.; de Almeida, L.E.N.; Kapat, J.; Vesely, L. Winglet Geometries Applied to Rotor Blades of a Hydraulic Axial Turbine Used as a Turbopump: A Parametric Analysis. Energies 2025, 18, 2099. https://doi.org/10.3390/en18082099

Tonon DdS, Tomita JT, Garcia EC, Bringhenti C, de Almeida LEN, Kapat J, Vesely L. Winglet Geometries Applied to Rotor Blades of a Hydraulic Axial Turbine Used as a Turbopump: A Parametric Analysis. Energies. 2025; 18(8):2099. https://doi.org/10.3390/en18082099

Chicago/Turabian StyleTonon, Daniel da Silva, Jesuino Takachi Tomita, Ezio Castejon Garcia, Cleverson Bringhenti, Luiz Eduardo Nunes de Almeida, Jayanta Kapat, and Ladislav Vesely. 2025. "Winglet Geometries Applied to Rotor Blades of a Hydraulic Axial Turbine Used as a Turbopump: A Parametric Analysis" Energies 18, no. 8: 2099. https://doi.org/10.3390/en18082099

APA StyleTonon, D. d. S., Tomita, J. T., Garcia, E. C., Bringhenti, C., de Almeida, L. E. N., Kapat, J., & Vesely, L. (2025). Winglet Geometries Applied to Rotor Blades of a Hydraulic Axial Turbine Used as a Turbopump: A Parametric Analysis. Energies, 18(8), 2099. https://doi.org/10.3390/en18082099