Research Progress of Thermoelectric Materials—A Review

Abstract

1. Introduction

2. Optimization of Thermoelectric Material Performance

| Materials | Strategies | ZT | T(K) | Ref. |

|---|---|---|---|---|

| Cu2CoTi3S8 | carrier concentration | 0.2 | 670 | [16] |

| Cu3Sb0.92Mn0.06Sn0.02Se4 | carrier concentration | 0.74 | 673 | [17] |

| Ti0.3Zr0.35Hf0.35CoSb1−xSnx | carrier concentration | 0.8 | 380 | [18] |

| dithienothiophene | phonon engineering | 1.48 | 300 | [19] |

| CuxBi0.5Sb1.5Te3 | phonon engineering | 1.34 | 400 | [20] |

| Nb0.8Ti0.2FeSb | phonon engineering | 0.9 | 973 | [21] |

| FeNb1−xTixSb | band engineering | 1.1 | 1100 | [22] |

| α-MgAgSb | band engineering | 2.0 | 575 | [23] |

| Al0.04Sn0.96Se | band engineering | 0.84 | 823 | [24] |

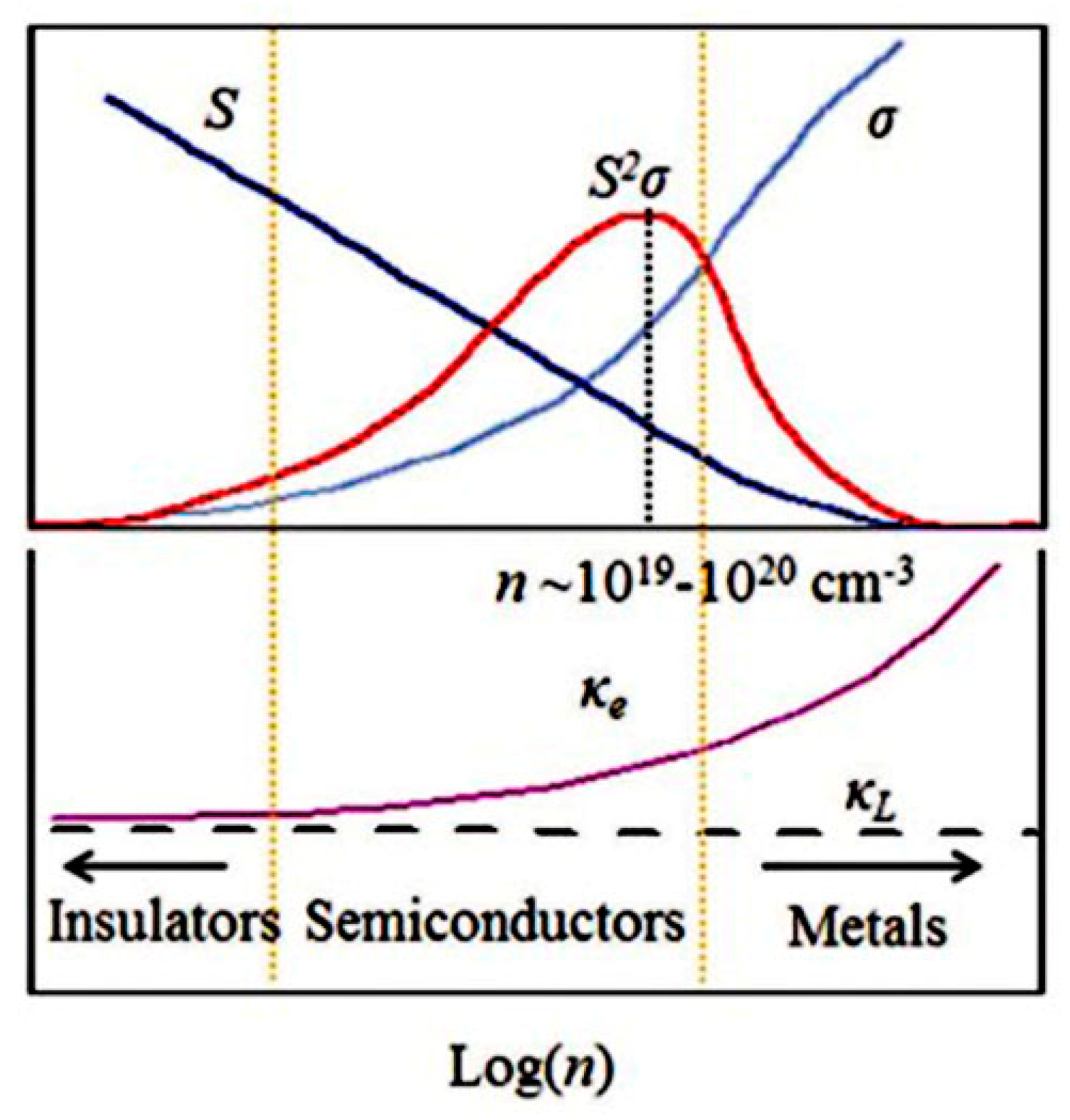

2.1. Optimization of Carrier Concentration

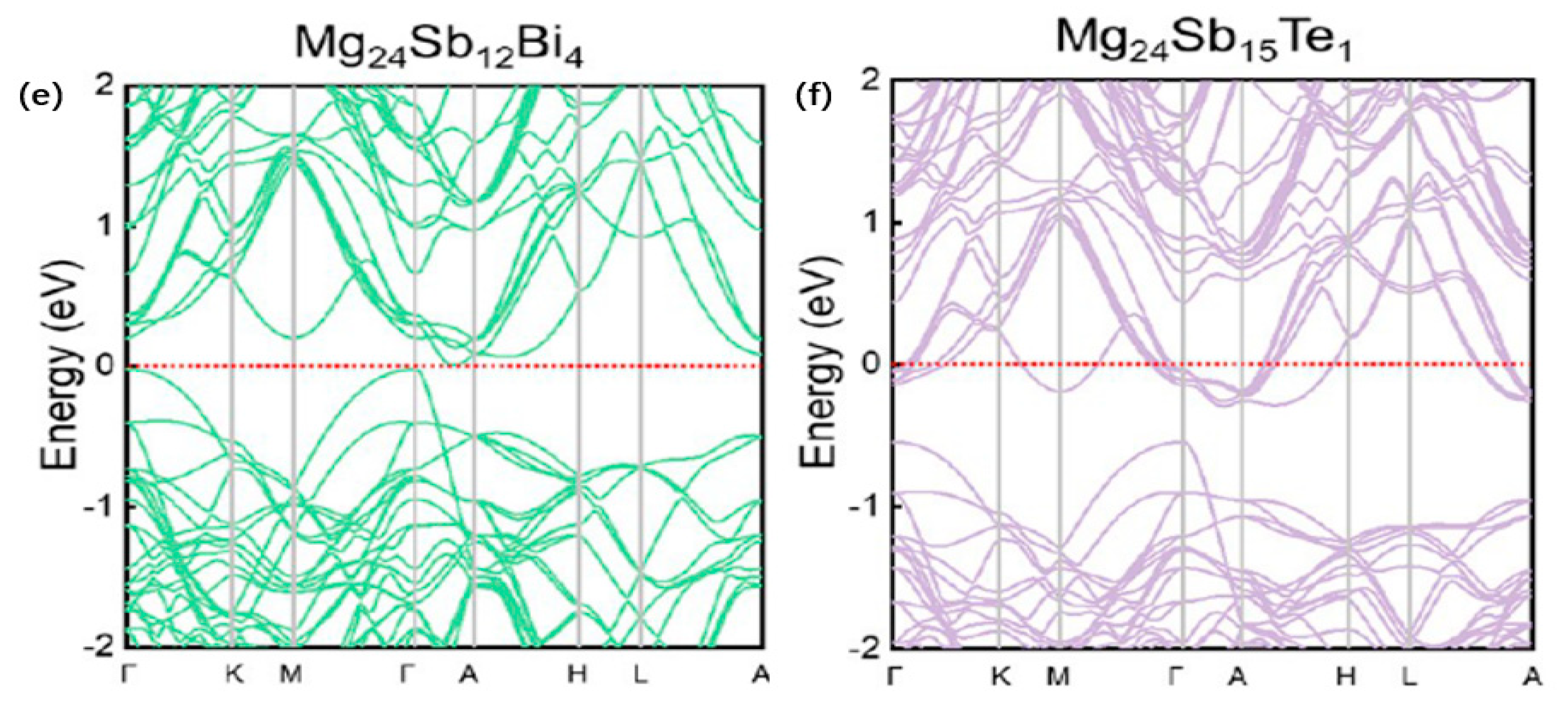

2.2. Band Engineering

2.3. Phonon Engineering

3. Classification and Fabrication Techniques of Thermoelectric Materials

| Samples | T (K) | ZT | Ref. |

|---|---|---|---|

| SnSeS | 700 | 3.07 | [51] |

| (Ca0.85Ba0.15)0.995Na0.005Mg1.85Cd0.15Bi2 | 873 | 1.30 | [52] |

| Ge0.93Bi0.03Pb0.04Te | 670 | 2.14 | [31] |

| Ge0.93Ti0.01Bi0.06Te0.01Cu | 623 | 2.30 | [53] |

| CoGe2/Ge0.85Sb0.10Te | 775 | 2.20 | [54] |

| (Ge0.89Pb0.08Bi0.03Te)0.97(HgTe)0.03 | 650 | 2.30 | [55] |

| Bi2(Te,Se)3 | 375 | 1.20 | [56] |

| AgSbTe2 | 643 | 1.70 | [57] |

| Cu3SbS4 | 773 | 1.30 | [58] |

| Na0.99Cd0.995Ag0.005Sb | 673 | 1.41 | [59] |

| CuIn7Se11 | 873 | 1.23 | [60] |

| PbSnS2 | 473 | 1.20 | [61] |

| Sn0.71Ge0.2Mn0.07In0.02Te | 873 | 1.64 | [62] |

| EMIM:DCA | 330 | 3.10 | [63] |

| Sn0.78Sb0.16Te(MgB2)0.09 | 850 | 1.22 | [64] |

| Mg3.2Bi1.998−xSbxTe0.002Cu0.005 | 348 | 1.10 | [65] |

| GeSb2Te4 | 673 | 1.00 | [66] |

| Mg3(Sb,Bi)2 | 773 | 1.82 | [67] |

| AgMnGePbSbTe5 | 750 | 2.64 | [68] |

| Nb0.75Ti0.25FeSb | 973 | 1.21 | [69] |

| (Nb, Hf)FeSb | 973 | 1.47 | [70] |

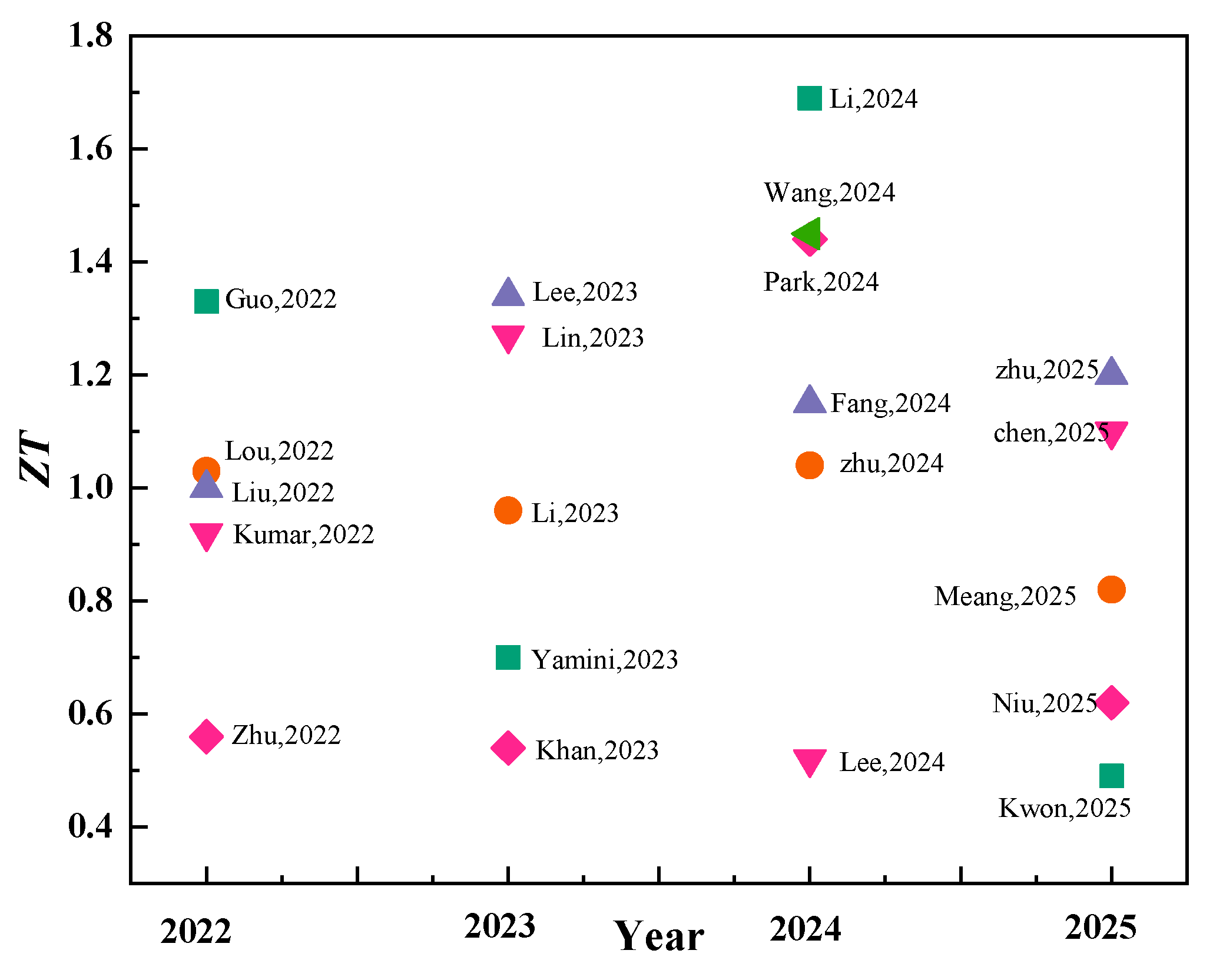

3.1. Classical Thermoelectric Materials

3.2. Novel Thermoelectric Materials

3.3. Techniques for Material Preparation

3.3.1. Solid-State Reaction Technique

3.3.2. Vapor Deposition Technique

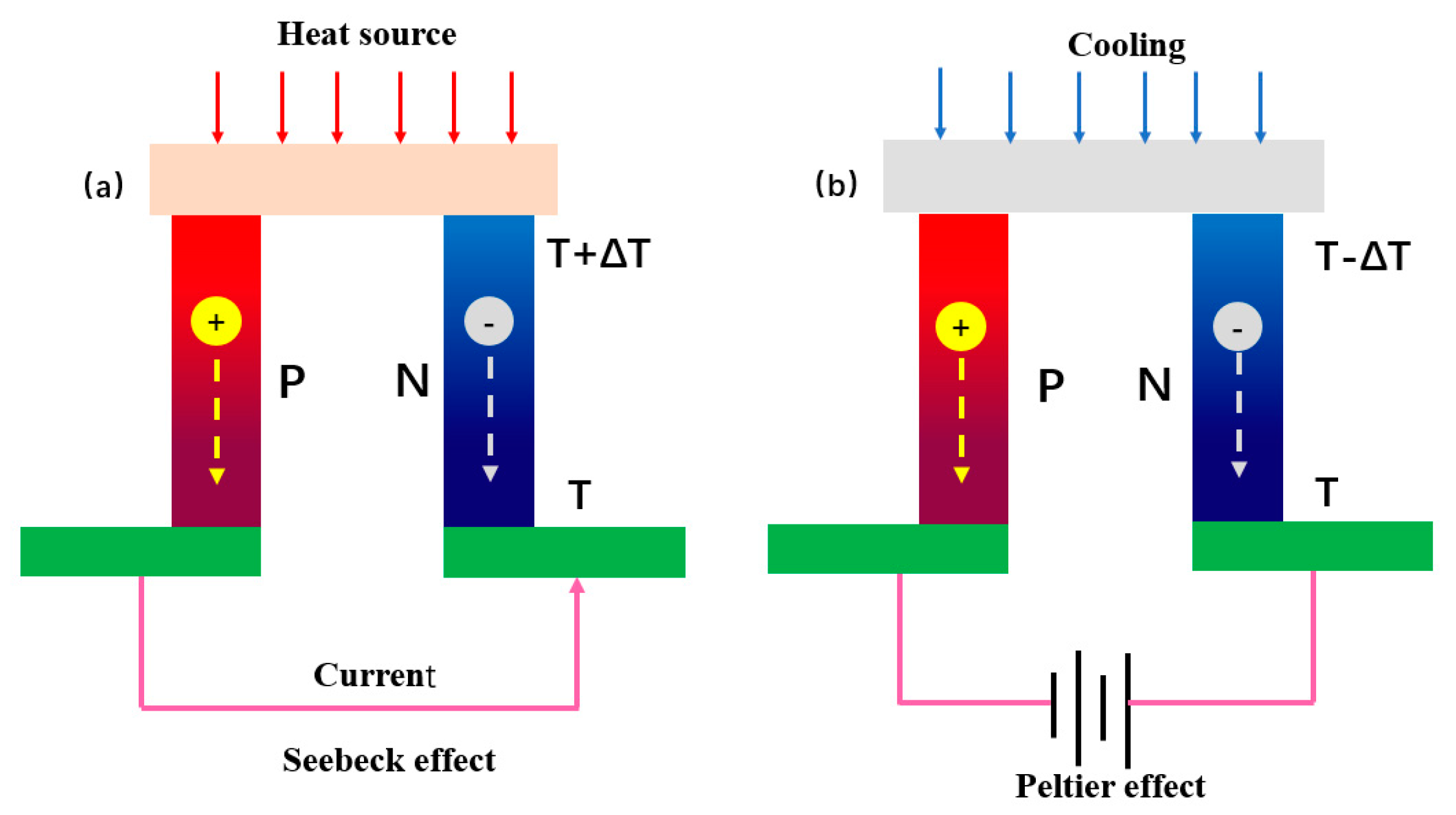

4. Principles and Applications of Thermoelectric Conversion Technologies

4.1. Thermoelectric Power Generation

4.2. Thermoelectric Refrigeration

4.3. Applications

4.3.1. Waste Heat Recovery

4.3.2. Solid-State Refrigeration

5. Conclusions and Challenges

- Lower conversion efficiency. The conversion efficiency of thermoelectric materials is a critical issue, and the relatively low efficiency exhibited by current thermoelectric materials significantly restricts their broader application. Currently, although some thermoelectric materials exhibit an excellent performance within specific temperature ranges, the overall conversion efficiency has not yet reached a practical level.

- Poor high-temperature performance. Thermoelectric materials for high-temperature use typically have larger bandgaps, which complicates the balance between electrical conductivity and thermal conductivity. Most existing materials exhibit a poor performance in high-temperature environments, limiting their application in high-temperature conditions. However, a wider bandgap also results in a more complicated coupling effect between electrical transport properties (electrical conductivity and carrier mobility) and thermal transport properties (electronic and lattice thermal conductivities). This interaction makes the optimization of material properties more challenging; furthermore, most existing materials exhibit an inadequate performance at elevated temperatures due to insufficient thermal stability, decreased carrier mobility, and degradation of lattice structures, thus restricting their practical applications.

- The challenge of multicriteria optimization. The parameters governing the performance of thermoelectric materials are interdependent, requiring that multiple criteria (thermal conductivity, electrical conductivity, and Seebeck coefficient) be simultaneously satisfied during the design process. Optimizing material properties while simultaneously satisfying these criteria remains a complex theoretical and practical challenge, and the existing theoretical models and experimental approaches have not yet provided comprehensive solutions.

- Difficulty in converting technology. Although progress has been made in the basic research, translating these findings into practical applications remains challenging. Many promising thermoelectric materials perform well under laboratory conditions, but ensuring their consistency and repeatability in industrial production remains a challenge.

Author Contributions

Funding

Conflicts of Interest

References

- Yang, L.; Chen, Z.; Dargusch, M.S.; Zou, J. High performance thermoelectric materials: Progress and their applications. Adv. Energy Mater. 2018, 8, 1701797. [Google Scholar] [CrossRef]

- Deng, T.; Qiu, P.; Yin, T.; Li, Z.; Yang, J.; Wei, T.; Shi, X. High-Throughput Strategies in the Discovery of Thermoelectric Materials. Adv. Mater. 2024, 36, e2311278. [Google Scholar] [CrossRef]

- Tritt, T.M. Holey and unholey semiconductors. Science 1999, 283, 804–805. [Google Scholar] [CrossRef]

- Tian, Z.; Jiang, Q.; Li, J.; Kang, H.; Chen, Z.; Guo, E.; Wang, T. Achieving n-and p-type thermoelectric materials with the identical chemical composition BiSbTe1.5Se1.5 by defect structure engineering. Chem. Eng. J. 2024, 494, 152954. [Google Scholar] [CrossRef]

- Ivanov, A.A.; Kaplar, E.P.; Prilepo, Y.P.; Murav’ev, V.V.; Ustinov, V.S. Progress in the Research on Promising High-Performance Thermoelectric Materials. Nanobiotechnol. Rep. 2021, 16, 268–281. [Google Scholar] [CrossRef]

- Hou, Z.H.; Qian, X.; Cui, Q.J.; Wang, S.F.; Zhao, L.D. Strategies to advance thermoelectric performance of PbSe and PbS materials. Rare Met. 2024, 43, 4099–4114. [Google Scholar] [CrossRef]

- Zhang, D.; Zhong, R.; Gao, S.; Yang, L.; Xu, F.; He, P.; Liu, G.; San, X.; Yang, J.; Luo, Y.; et al. Reinforcing bond covalency for high thermoelectric performance in Cu3SbSe4-based thermoelectric material. Sci. China Mater. 2023, 66, 3644–3650. [Google Scholar] [CrossRef]

- Hu, L.; Zhang, Q.; Shan, Z.; Wang, L.; Zheng, Y.; Fan, J. Synergy of grain size and texture effect for high-performance Mg3Sb2-based thermoelectric materials. Scr. Mater. 2023, 235, 115629. [Google Scholar] [CrossRef]

- Jiang, Q.; Li, G.; Wang, X.; Kang, H.; Chen, Z.; Guo, E.; Wang, T. Enhanced thermoelectric properties for eco-friendly CaTiO3 by band sharpening and atomic-scale defect phonon scattering. Mater. Today Energy 2024, 44, 101655. [Google Scholar] [CrossRef]

- Anita; Gupta, V.; Pandey, A. Improvement in thermoelectric properties of Bi-Mg co-doped SnTe via band engineering and nanostructuring. J. Mater. Sci. Mater. Electron. 2024, 35, 1–16. [Google Scholar] [CrossRef]

- Jiang, Q.; Long, H.; Zeng, X.; Wang, B.; Yang, B.; Yi, J.; Luo, Y.; Yang, J.; Ye, H.; Liu, Y. A simple in-situ PZT oxide’s decomposition: Realizing synergistic tailoring of electrical and thermal transport properties of BiCuSeO thermoelectric ceramics through band and phonon engineering. Ceram. Int. 2024, 50, 35985–35992. [Google Scholar] [CrossRef]

- Vijay, V.; Harish, S.; Archana, J.; Navaneethan, M. Synergistic effect of grain boundaries and phonon engineering in Sb substituted Bi2Se3 nanostructures for thermoelectric applications. J. Colloid Interface Sci. 2022, 612, 97–110. [Google Scholar] [CrossRef] [PubMed]

- Li, J.W.; Liu, W.; Xu, W.; Zhuang, H.L.; Han, Z.; Jiang, F.; Zhang, P.; Hu, H.; Gao, H.; Jiang, Y.; et al. Bi-deficiency leading to high-performance in Mg3(Sb, Bi)2-based thermoelectric materials. Adv. Mater. 2023, 35, 2209119. [Google Scholar] [CrossRef] [PubMed]

- Tang, Q.; Jiang, B.; Wang, K.; Wang, W.; Jia, B.; Ding, T.; Huang, Z.; Lin, Y.; He, J. High-entropy thermoelectric materials. Joule 2024, 8, 1641–1666. [Google Scholar] [CrossRef]

- Lu, N.; Li, L.; Liu, M. A review of carrier thermoelectric-transport theory in organic semiconductors. Phys. Chem. Chem. Phys. 2016, 18, 19503–19525. [Google Scholar] [CrossRef]

- Hashikuni, K.; Suekuni, K.; Watanabe, K.; Bouyrie, Y.; Ohta, M.; Ohtaki, M.; Takabatake, T. Carrier concentration tuning in thermoelectric thiospinel Cu2CoTi3S8 by oxidative extraction of copper. J. Solid State Chem. 2018, 259, 5–10. [Google Scholar] [CrossRef]

- Wei, S.; Yu, L.; Zhang, Z.; Ji, Z.; Luo, S.; Liang, J.; Song, W.; Zheng, S. Enhancing the effective mass and covalent bond strength of Cu3SbSe4-based thermoelectric materials by Mn/Sn co-doping. Mater. Today Phys. 2023, 38, 101260. [Google Scholar] [CrossRef]

- Rausch, E.; Balke, B.; Deschauer, T.; Ouardi, S.; Felser, C. Charge carrier concentration optimization of thermoelectric p-type half-Heusler compounds. APL Mater. 2015, 3, 041516. [Google Scholar] [CrossRef]

- Mi, X.Y.; Yu, X.; Yao, K.L.; Huang, X.; Yang, N.; Lu, J.T. Enhancing the thermoelectric figure of merit by low-dimensional electrical transport in phonon-glass crystals. Nano Lett. 2015, 15, 5229–5234. [Google Scholar] [CrossRef]

- Yoon, J.S.; Song, J.M.; Rahman, J.U.; Lee, S.; Seo, W.S.; Lee, K.H.; Kim, S.; Kim, H.S.; Kim, S.I.; Shin, W.H. High thermoelectric performance of melt-spun CuxBi0.5Sb1.5Te3 by synergetic effect of carrier tuning and phonon engineering. Acta Mater. 2018, 158, 289–296. [Google Scholar] [CrossRef]

- Tan, C.; Wang, H.; Yao, J.; Chen, T.; Wang, L.; Sun, Y.; Khan, M.; Wang, H.; Wang, C. Synchronously enhanced thermoelectric and mechanical properties of Ti doped NbFeSb based half-heusler alloys by carrier regulation and phonon engineering. J. Eur. Ceram. Soc. 2022, 42, 7010–7016. [Google Scholar] [CrossRef]

- Fu, C.; Zhu, T.; Liu, Y.; Xie, H.; Zhao, X. Band engineering of high performance p-type FeNbSb based half-Heusler thermoelectric materials for figure of merit zT > 1. Energy Environ. Sci. 2015, 8, 216–220. [Google Scholar] [CrossRef]

- Tan, X.; Wang, L.; Shao, H.; Yue, S.; Xu, J.; Liu, G.; Jiang, H.; Jiang, J. Improving Thermoelectric Performance of α-MgAgSb by Theoretical Band Engineering Design. Adv. Energy Mater. 2017, 7, 1700076. [Google Scholar] [CrossRef]

- Xin, N.; Li, Y.; Shen, H.; Shen, L.; Tang, G. Realizing high thermoelectric performance in hot-pressed polycrystalline AlxSn1-xSe through band engineering tuning. J. Mater. 2022, 8, 475–488. [Google Scholar] [CrossRef]

- Li, X.; Liu, M.; Guo, M.; Niu, C.; He, H.; Liu, Z.; Zhu, Y.; Dong, X.; Cai, W.; Guo, F.; et al. Tailoring band structure and Ge precipitates through Er and Sb/Bi co-doping to realize high thermoelectric performance in GeTe. Chem. Eng. J. 2023, 474, 145820. [Google Scholar] [CrossRef]

- Kim, S.; Kihoi, S.K.; Kim, H.; Kahiu, J.N.; Lee, H.S. Synergetic effect of Bi and Al co-doping in GeTe-based thermoelectric materials leading to optimized carrier concentration tuning and high ZT. J. Alloys Compd. 2024, 970, 172574. [Google Scholar] [CrossRef]

- Cui, S.; Wang, C.; Hao, M.; Huang, X.; Wang, C.; Wang, X.; Wang, Y. Enhancing thermoelectric performance of p-type BixSb2−xTe3 by optimizing carrier concentration. J. Eur. Ceram. Soc. 2025, 45, 116942. [Google Scholar] [CrossRef]

- Dharmaiah, P.; Heo, M.; Nagarjuna, C.; Jung, S.-J.; Won, S.O.; Lee, K.H.; Kim, S.K.; Kim, J.-S.; Ahn, B.; Kim, H.-S.; et al. Enhancement of thermoelectric properties in p-type ZnSb alloys through Cu-doping. J. Alloys Compd. 2024, 1004, 175739. [Google Scholar] [CrossRef]

- Ren, Y.; Jiang, Q.; Yang, J.; Luo, Y.; Zhang, D.; Cheng, Y.; Zhou, Z. Enhanced thermoelectric performance of MnTe via Cu doping with optimized carrier concentration. J. Mater. 2016, 2, 172–178. [Google Scholar] [CrossRef]

- Liu, R.; Lan, J.-L.; Tan, X.; Liu, Y.-C.; Ren, G.-K.; Liu, C.; Zhou, Z.-F.; Nan, C.-W.; Lin, Y.-H. Carrier concentration optimization for thermoelectric performance enhancement in n-type Bi2O2Se. J. Eur. Ceram. Soc. 2018, 38, 2742–2746. [Google Scholar] [CrossRef]

- Liu, M.; Guo, M.; Zhu, J.; Zeng, X.; Chen, H.; Yuan, D.; Zhang, Q.; Cai, F.; Guo, F.; Zhu, Y.; et al. High-Performance CaMg2Bi2-Based Thermoelectric Materials Driven by Lattice Softening and Orbital Alignment via Cadmium Doping. Adv. Funct. Mater. 2024, 34, 2316075. [Google Scholar] [CrossRef]

- Pei, Y.; May, A.F.; Snyder, G.J. Self-Tuning the carrier concentration of PbTe/Ag2Te composites with excess ag for high thermoelectric performance. Adv. Energy Mater. 2011, 1, 291–296. [Google Scholar] [CrossRef]

- Zhu, T.; Liu, Y.; Fu, C.; Heremans, J.P.; Snyder, J.G.; Zhao, X. Compromise and synergy in high-efficiency thermoelectric materials. Adv. Mater. 2017, 29, 1605884. [Google Scholar] [CrossRef] [PubMed]

- Pei, Y.; LaLonde, A.D.; Heinz, N.A.; Snyder, G.J. High thermoelectric figure of merit in PbTe alloys demonstrated in PbTe–CdTe. Adv. Energy Mater. 2012, 2, 670–675. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, R.; Cheng, N.; Zhang, Y.; Yang, J.; Uher, C.; Shi, X.; Chen, L.; Zhang, W. High-performance pseudocubic thermoelectric materials from non-cubic chalcopyrite compounds. Adv. Mater. 2014, 26, 3848–3853. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Gibbs, Z.M.; Takagiwa, Y.; Snyder, G.J. Tuning bands of PbSe for better thermoelectric efficiency. Energy Environ. Sci. 2014, 7, 804–811. [Google Scholar] [CrossRef]

- Tan, G.; Shi, F.; Hao, S.; Chi, H.; Bailey, T.P.; Zhao, L.D.; Uher, C.; Wolverton, C.; Dravid, V.P.; Kanatzidis, M.G.; et al. Valence Band Modification and High Thermoelectric Performance in SnTe Heavily Alloyed with MnTe. J. Am. Chem. Soc. 2015, 137, 11507–11516. [Google Scholar] [CrossRef] [PubMed]

- Li, A.; Hu, C.; He, B.; Yao, M.; Fu, C.; Wang, Y.; Zhao, X.; Felser, C.; Zhu, T. Demonstration of valley anisotropy utilized to enhance the thermoelectric power factor. Nat. Commun. 2021, 12, 1–9. [Google Scholar] [CrossRef]

- Qian, X.; Guo, H.R.; Lyu, J.X.; Ding, B.F.; San, X.Y.; Zhang, X.; Wang, J.L.; Wang, S.F. Enhancing thermoelectric performance of p-type SnTe through manipulating energy band structures and decreasing electronic thermal conductivity. Rare Met. 2024, 43, 3232–3241. [Google Scholar] [CrossRef]

- Yu, L.; Shi, X.L.; Mao, Y.; Liu, W.D.; Ji, Z.; Wei, S.; Zhang, Z.; Song, W.; Zheng, S.; Chen, Z.G. Simultaneously boosting thermoelectric and mechanical properties of n-type Mg3Sb1.5Bi0.5-based zintls through energy-band and defect engineering. ACS Nano 2024, 18, 1678–1689. [Google Scholar] [CrossRef]

- Pei, Y.; Shi, X.; LaLonde, A.; Wang, H.; Chen, L.; Snyder, G.J. Convergence of electronic bands for high performance bulk thermoelectrics. Nature 2011, 473, 66–69. [Google Scholar] [CrossRef] [PubMed]

- Mao, J.; Liu, Z.; Zhou, J.; Zhu, H.; Zhang, Q.; Chen, G.; Ren, Z. Advances in thermoelectrics. Adv. Phys. 2018, 67, 69–147. [Google Scholar] [CrossRef]

- Heremans, J.P.; Jovovic, V.; Toberer, E.S.; Saramat, A.; Kurosaki, K.; Charoenphakdee, A.; Yamanaka, S.; Snyder, G.J. Enhancement of thermoelectric efficiency in PbTe by distortion of the electronic density of states. Science 2008, 321, 554–557. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Wang, H.; Liu, W.; Wang, H.; Yu, B.; Zhang, Q.; Tian, Z.; Ni, G.; Lee, S.; Esfarjani, K.; et al. Enhancement of thermoelectric figure-of-merit by resonant states of aluminium doping in lead selenide. Energy Environ. Sci. 2012, 5, 5246–5251. [Google Scholar] [CrossRef]

- Jaworski, C.M.; Kulbachinskii, V.; Heremans, J.P. Resonant level formed by tin in Bi2Te3 and the enhancement of room-temperature thermoelectric power. Phys. Rev. B-Condens. Matter Mater. Phys. 2009, 80, 233201. [Google Scholar] [CrossRef]

- Zhang, Q.; Liao, B.; Lan, Y.; Lukas, K.; Liu, W.; Esfarjani, K.; Opeil, C.; Broido, D.; Chen, G.; Ren, Z. High thermoelectric performance by resonant dopant indium in nanostructured SnTe. Proc. Natl. Acad. Sci. USA 2013, 110, 13261–13266. [Google Scholar] [CrossRef]

- Callaway, J.; von Baeyer, H.C. Effect of Point Imperfections on Lattice Thermal Conductivity. Phys. Rev. B 1960, 120, 1149–1154. [Google Scholar] [CrossRef]

- Wang, L.; Shi, X.; Li, L.; Hong, M.; Lin, B.; Miao, P.; Ding, J.; Yuan, N.; Zheng, S.; Chen, Z. Zinc Doping Induces Enhanced Thermoelectric Performance of Solvothermal SnTe. Chem.–Asian J. 2024, 19, e202400130. [Google Scholar] [CrossRef]

- Klemens, P.G. Thermal resistance due to point defects at high temperatures. Phys. Rev. B 1960, 119, 507–509. [Google Scholar] [CrossRef]

- Chen, Z.; Jian, Z.; Li, W.; Chang, Y.; Ge, B.; Hanus, R.; Yang, J.; Chen, Y.; Huang, M.; Snyder, G.J.; et al. Lattice dislocations enhancing thermoelectric PbTe in addition to band convergence. Adv. Mater. 2017, 29, 1606768. [Google Scholar] [CrossRef]

- Chen, Z.; Ge, B.; Li, W.; Lin, S.; Shen, J.; Chang, Y.; Hanus, R.; Snyder, G.J.; Pei, Y. Vacancy-induced dislocations within grains for high-performance PbSe thermoelectrics. Nat. Commun. 2017, 8, 13828. [Google Scholar] [CrossRef] [PubMed]

- Zhu, B.C.; Bao, L.; Zeng, L.; Fang, W.Y.; Liu, C.J. First-principles calculations of the thermoelectric properties of 2D SnSeS thermoelectric materials. Mater. Today Commun. 2025, 42, 111593. [Google Scholar] [CrossRef]

- Zhang, M.; Gao, Z.; Lou, Q.; Zhu, Q.; Wang, J.; Han, Z.; Fu, C.; Zhu, T. Achieving High Carrier Mobility And Thermal Stability in Plainified Rhombohedral GeTe Thermoelectric Materials with ZT > 2. Adv. Funct. Mater. 2023, 34, 2307864. [Google Scholar] [CrossRef]

- Yin, L.C.; Liu, W.D.; Li, M.; Wang, D.Z.; Wu, H.; Wang, Y.; Zhang, L.; Shi, X.L.; Liu, Q.; Chen, Z.G. Interstitial Cu: An effective strategy for high carrier mobility and high thermoelectric performance in GeTe. Adv. Funct. Mater. 2023, 33, 2301750. [Google Scholar] [CrossRef]

- Hu, M.H.; Li, M.; Wang, D.Z.; Yin, L.C.; Wu, H.; Liu, W.D.; Shi, X.L.; Wang, Y.; Liu, Q.; Chen, Z.G. Revisiting Cobalt Dopability in GeTe System to Design Modulation-Doped Thermoelectrics. Adv. Funct. Mater. 2025, 2421837. [Google Scholar] [CrossRef]

- Guo, Z.; Wu, G.; Yuan, M.; Li, H.; Tan, X.; Cai, J.; Zhang, Z.; Shuai, J.; Liu, G.; Jiang, J. High Thermoelectric Performance and Energy Conversion in Hg-doped GeTe. Adv. Funct. Mater. 2024, 2419431. [Google Scholar] [CrossRef]

- Zhu, H.; Deng, Z.; Qu, Y.; He, P.; Geng, H. Cu-In Co-Doping and Layered Directional Sintering for High Thermoelectric Efficiency and Mechanical Strength in Bi2 (Te,Se)3. Adv. Funct. Mater. 2025, 2422007. [Google Scholar] [CrossRef]

- Kim, J.H.; Yun, J.H.; Cha, S.; Byeon, S.; Park, J.; Jin, H.; Kim, S.; Kim, S.J.; Park, J.; Jang, J. Enhancement of Phase Stability and Thermoelectric Performance of Meta-Stable AgSbTe2 by Thermal Cycling Process. Adv. Funct. Mater. 2024, 34, 2404886. [Google Scholar] [CrossRef]

- Zhang, D.; Wang, X.; Wu, H.; Huang, Y.; Zheng, S.; Zhang, B.; Fu, H.; Cheng, Z.; Jiang, P.; Han, G.; et al. High Thermoelectric Performance in Earth-Abundant Cu3SbS4 by Promoting Doping Efficiency via Rational Vacancy Design. Adv. Funct. Mater. 2023, 33, 2214163. [Google Scholar] [CrossRef]

- Liu, K.; Chen, C.; Cheng, J.; Ma, X.; Li, J.; Bao, X.; Li, H.; Zhang, Q.; Chen, Y. Realizing a High Thermoelectric Conversion Efficiency in Zintl-phase NaCdSb via Suppressing the Intrinsic Carrier Excitation. Adv. Funct. Mater. 2024, 2419145. [Google Scholar] [CrossRef]

- Yang, Z.; Zi, P.; Liu, K.; Luo, H.; Bai, H.; Chen, S.; Wu, J.; Su, X.; Uher, C.; Zhang, Q.; et al. Ultralow Lattice Thermal Conductivity and Extraordinary Thermoelectric Performance in Highly Disordered CuIn7Se11 Layered Compound. Adv. Funct. Mater. 2024, 34, 2306849. [Google Scholar] [CrossRef]

- Zhan, S.; Bai, S.; Qin, B.; Zhu, Y.; Wang, S.; Liu, D.; Hong, T.; Gao, X.; Zheng, L.; Wen, Y.; et al. High Carrier Mobility Promotes In-Plane Thermoelectric Performance of n-Type PbSnS2 Crystals. Adv. Funct. Mater. 2024, 34, 2406428. [Google Scholar] [CrossRef]

- Moshwan, R.; Zhang, M.; Li, M.; Liu, S.; Li, N.; Cao, T.; Liu, W.; Shi, X.; Chen, Z. Compromising Configurational Entropy Leading to Exceptional Thermoelectric Properties in SnTe-Based Materials. Adv. Funct. Mater. 2024, 2418291. [Google Scholar] [CrossRef]

- Qian, Q.; Cheng, H.; Le, Q.; Ouyang, J. Great Enhancement in the Thermopower of Ionic Liquid by a Metal-Organic Framework. Adv. Funct. Mater. 2023, 33, 2303311. [Google Scholar] [CrossRef]

- Yang, H.; Wu, L.; Feng, X.; Huang, X.; Wang, H.; Duan, B.; Li, G.; Zhai, P.; Zhang, Q. Constructing Coated Grain Nanocomposites and Intracrystalline Precipitates to Simultaneously Improve the Thermoelectric and Mechanical Properties of SnTe by MgB2 and Sb Co-Doping. Adv. Funct. Mater. 2024, 34, 2316344. [Google Scholar] [CrossRef]

- Cho, H.; Back, S.Y.; Sato, N.; Liu, Z.; Gao, W.; Wang, L.; Nguyen, H.D.; Kawamoto, N.; Mori, T. Outstanding Room-Temperature Thermoelectric Performance of n-type Mg3Bi2-Based Compounds Through Synergistically Combined Band Engineering Approaches. Adv. Funct. Mater. 2024, 34, 2407017. [Google Scholar] [CrossRef]

- Chen, P.; Wu, H.; Zhang, B.; Zhou, Z.; Zheng, S.; Dai, L.; Huo, Y.; Zhang, D.; Yan, Y.; Peng, K.; et al. Intrinsically Low Lattice Thermal Conductivity and Anisotropic Thermoelectric Performance in In-doped GeSb2Te4 Single Crystals. Adv. Funct. Mater. 2023, 33, 2211281. [Google Scholar] [CrossRef]

- Ma, Z.; Luo, Y.; Dong, J.; Liu, Y.; Zhang, D.; Li, W.; Li, C.; Wei, Y.; Jiang, Q.; Li, X.; et al. Synergistic Performance of Thermoelectric and Mechanical in Nanotwinned High-Entropy Semiconductors AgMnGePbSbTe5. Adv. Mater. 2024, 36, e2407982. [Google Scholar] [CrossRef]

- Chen, J.; Dong, Z.; Li, Q.; Ge, B.; Zhang, J.; Zhang, Y.; Luo, J. Enhanced Thermoelectric Performance in Vacancy-Filling Heuslers due to Kondo-Like Effect. Adv. Mater. 2024, 36, 2405858. [Google Scholar] [CrossRef]

- Li, W.; Poudel, B.; Kishore, R.A.; Nozariasbmarz, A.; Liu, N.; Zhang, Y.; Priya, S. Toward high conversion efficiency of thermoelectric modules through synergistical optimization of layered materials. Adv. Mater. 2023, 35, e2210407. [Google Scholar] [CrossRef]

- Solco, S.F.D.; Saglik, K.; Zhang, D.; Tan, X.Y.; Zhu, Q.; Liu, H.; Suwardi, A.; Cao, J. Thermoelectric performance enhancement of Mg2Si-based silicides synthesized in nitrogen atmosphere. Mater. Res. Express 2024, 11, 125505. [Google Scholar] [CrossRef]

- Kuroda, K.; Ye, M.; Kimura, A.; Eremeev, S.V.; Krasovskii, E.E.; Chulkov, E.V.; Ueda, Y.; Miyamoto, K.; Okuda, T.; Shimada, K.; et al. Experimental Realization of a Three-Dimensional Topological Insulator Phase in Ternary Chalcogenide TlBiSe2. Phys. Rev. Lett. 2010, 105, 146801. [Google Scholar] [CrossRef] [PubMed]

- Zhu, T.; Hu, L.; Zhao, X.; He, J. New insights into intrinsic point defects in V2VI3 thermoelectric materials. Adv. Sci. 2016, 3, 1600004. [Google Scholar] [CrossRef] [PubMed]

- Shi, Q.; Li, J.; Zhao, X.; Chen, Y.; Zhang, F.; Zhong, Y.; Ang, R. Comprehensive insight into p-type Bi2Te3-based thermoelectrics near room temperature. ACS Appl. Mater. Interfaces 2022, 14, 49425–49445. [Google Scholar] [CrossRef] [PubMed]

- Shi, Y.C.; Yang, J.; Wang, Y.; Li, Z.G.; Zhong, T.Y.; Ge, Z.H.; Feng, J.; He, J. Highly effective solid solution towards high thermoelectric and mechanical performance in Bi–Sb–Te alloys via Trojan doping. Energy Environ. Sci. 2024, 17, 2326–2335. [Google Scholar] [CrossRef]

- Fanguo, L. Preparation and Thermoelectric Properties of Cux/Bi2Te3 Composites. Compos. Mech. Comput. Appl. Int. J. 2024, 15, 35–43. [Google Scholar] [CrossRef]

- Fang, W.; Wu, F. The impact of varying EDTA dosage on the flower-like morphology and thermoelectric properties of Ce-doped Bi2Te3. Sci. Rep. 2024, 14, 21855. [Google Scholar]

- Lee, N.; Ye, S.W.; Park, J.; Seo, S.; Kang, M.; Kim, H.-S.; Kim, S.-I.; Cho, J.Y.; Nam, W.H.; Roh, J.W. The Electrical Conduction-Type Transition in Se-Free Bi2Te3 Thermoelectric Materials by Decoration of Ni Nanoparticles. ACS Appl. Energy Mater. 2024, 7, 8807–8813. [Google Scholar] [CrossRef]

- Lee, S.; Park, G.M.; Kim, Y.; Lee, S.H.; Jung, S.J.; Hong, J.; Kim, S.C.; Won, S.O.; Lee, A.S.; Chung, Y.J.; et al. Unlocking the potential of porous Bi2Te3-based thermoelectrics using precise interface engineering through atomic layer deposition. ACS Appl. Mater. Interfaces 2024, 16, 17683–17691. [Google Scholar] [CrossRef]

- Wang, X.; Shang, H.; Gu, H.; Chen, Y.; Zhang, Z.; Zou, Q.; Zhang, L.; Feng, C.; Li, G.; Ding, F. High-Performance p-Type Bi2Te3-Based Thermoelectric Materials Enabled via Regulating Bi–Te Ratio. ACS Appl. Mater. Interfaces 2024, 16, 11678–11685. [Google Scholar] [CrossRef]

- Aminorroaya Yamini, S.; Santos, R.; Fortulan, R.; Gazder, A.A.; Malhotra, A.; Vashaee, D.; Serhiienko, I.; Mori, T. Room-temperature thermoelectric performance of n-type multiphase pseudobinary Bi2Te3–Bi2S3 compounds: Synergic effects of phonon scattering and energy filtering. ACS Appl. Mater. Interfaces 2023, 15, 19220–19229. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.Z.; Zhang, Q.; Liu, K.; Lin, Y.J.; Lin, N.; Yu, Y.; Liu, F.; Zhao, X.B.; Ge, B.H. Multi-scale hierarchical microstructure modulation towards high room temperature thermoelectric performance in n-type Bi2Te3-based alloys. Mater. Today Nano 2023, 22, 100340. [Google Scholar] [CrossRef]

- Lee, S.; Jung, S.J.; Park, G.M.; Na, M.Y.; Kim, K.C.; Hong, J.; Lee, A.S.; Baek, S.H.; Kim, H.; Park, T.J.; et al. Selective Dissolution-Derived Nanoporous Design of Impurity-Free Bi2Te3 Alloys with High Thermoelectric Performance. Small 2023, 19, 2205202. [Google Scholar] [CrossRef] [PubMed]

- Lin, F.H.; Liu, C.J. Reaction mechanism of room-temperature synthesized n-Bi2Te3 and high thermoelectric performance p-(Bi,Sb)2Te3–Te using nanosized precursor methods: A novel and energy-efficient production method. Ceram. Int. 2023, 49, 26077–26083. [Google Scholar] [CrossRef]

- Khan, J.S.; Akram, R.; Shah, A.A.; Hussain, M.; Rafique, S.; ur Rehman, A.; Khurshid, T.; Karim, K. Enhanced zT due to non-stoichiometric induced defects for bismuth telluride thermoelectric materials. Kuwait J. Sci. 2023, 50, 231–237. [Google Scholar] [CrossRef]

- Kwon, O.; Kim, M.; Lee, J.; Lee, S.; Kim, J.; Kim, M.; Kim, J. High Thermoelectric Performance of Bi0.3Sb1.7Te3/PEDOT: PSS Flexible Composite via Cation Cross-Linking. J. Alloys Compd. 2025, 1014, 178789. [Google Scholar] [CrossRef]

- Meang, E.J.; Shin, Y.J.; Park, K.H.; Chung, J.; Kim, H.; Lee, H.S. Scalable synthesis and enhanced thermoelectric properties of Cu-doped and Se-substituted Bi2Te3-based materials via high-pressure sintering. Mater. Today Commun. 2025, 111830. [Google Scholar] [CrossRef]

- Chen, S.; Luo, T.; Li, J.; Liao, L.; Liu, Y.; Yang, Z.; Zhong, S.; Wu, J.; Su, X.; Yan, Y.; et al. Synergistic regulation of texture and low-angle grain boundaries enables mechanically robust p-type Bi2Te3-based compounds with superior thermoelectric performance. Mater. Today Energy 2025, 48, 101788. [Google Scholar] [CrossRef]

- Niu, X.; Li, Z.; Fan, Z.; Wu, X.; Zhao, Q.; Wang, S.; Zhu, H.; Li, G.; Zhao, H. Vacancy Regulation to Achieve N-Type High Thermoelectric Performance PbSe through Titanium-Incorporation. Mater. Today Phys. 2025, 101675. [Google Scholar] [CrossRef]

- Guo, F.; Sun, Y.; Qin, H.; Zhu, Y.; Ge, Z.; Liu, Z.; Cai, W.; Sui, J. BiSbTe alloy with high thermoelectric and mechanical performance for power generation. Scr. Mater. 2022, 218, 114801. [Google Scholar] [CrossRef]

- Lou, L.Y.; Yang, J.; Zhu, Y.K.; Liang, H.; Zhang, Y.X.; Feng, J.; He, J.; Ge, Z.H.; Zhao, L.D. Tunable electrical conductivity and simultaneously enhanced thermoelectric and mechanical properties in n-type Bi2Te3. Adv. Sci. 2022, 9, 2203250. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Gao, W.; Oshima, H.; Nagase, K.; Lee, C.-H.; Mori, T. Maximizing the performance of n-type Mg3Bi2 based materials for room-temperature power generation and thermoelectric cooling. Nat. Commun. 2022, 13, 1–9. [Google Scholar] [CrossRef]

- Kumar Choudhary, K.; Rathore, V.; Chandra Dixit, R.; Kaurav, N. Phonon Scattering Mechanism for Size-Dependent Thermoelectric Properties of Bi2Te3 Nanoparticles. ChemistrySelect 2022, 7, e202202503. [Google Scholar] [CrossRef]

- Zhu, B.; Su, X.; Shu, S.; Luo, Y.; Tan, X.Y.; Sun, J.; Sun, D.; Zhang, H.; Zhang, Q.; Suwardi, A.; et al. Cold-sintered Bi2Te3-based materials for engineering nanograined thermoelectrics. ACS Appl. Energy Mater. 2022, 5, 2002–2010. [Google Scholar] [CrossRef]

- Androulakis, J.; Todorov, I.; Chung, D.-Y.; Ballikaya, S.; Wang, G.; Uher, C.; Kanatzidis, M. Thermoelectric enhancement in PbTe with K or Na codoping from tuning the interaction of the light- and heavy-hole valence bands. Phys. Rev. B 2010, 82, 115209. [Google Scholar] [CrossRef]

- Yu, X.; Li-Dong, Z. Charge and phonon transport in PbTe-based thermoelectric materials. Npj Quantum Mater. 2018, 3, 55. [Google Scholar]

- Shtern, Y.; Sherchenkov, A.; Shtern, M.; Rogachev, M.; Pepelyaev, D. Challenges and perspective recent trends of enhancing the efficiency of thermoelectric materials on the basis of PbTe. Mater. Today Commun. 2023, 37, 107083. [Google Scholar] [CrossRef]

- Shtern, M.; Sherchenkov, A.; Shtern, Y.; Borgardt, N.; Rogachev, M.; Yakubov, A.; Babich, A.; Pepelyaev, D.; Voloshchuk, I.; Zaytseva, Y.; et al. Mechanical properties and thermal stability of nanostructured thermoelectric materials on the basis of PbTe and GeTe. J. Alloys Compd. 2023, 946, 169364. [Google Scholar] [CrossRef]

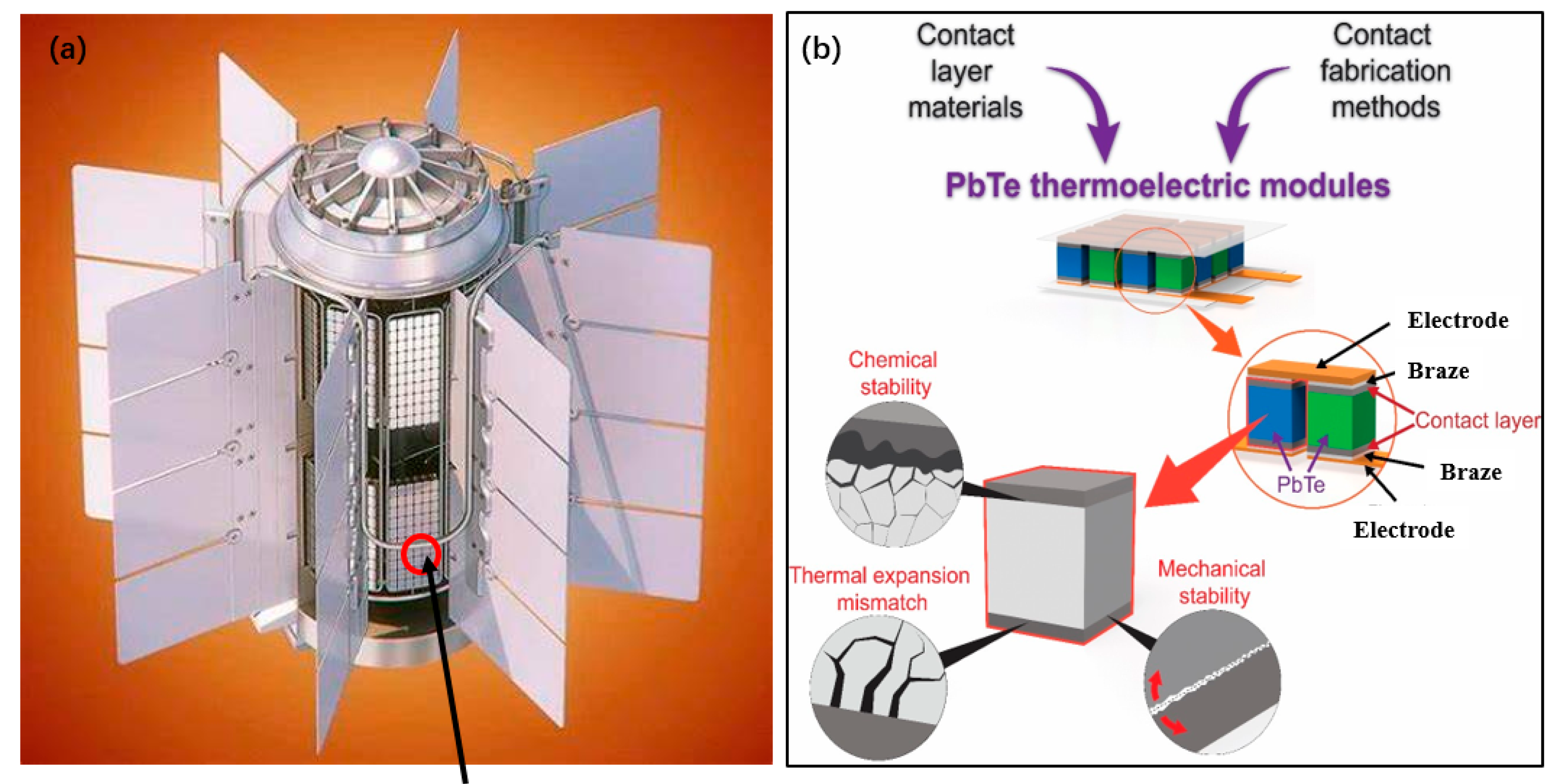

- Sauerschnig, P.; Jood, P.; Ohta, M. Challenges and Progress in Contact Development for PbTe-based Thermoelectrics. Chemnanomat 2023, 9, e2200560. [Google Scholar] [CrossRef]

- Bathula, S.; Jayasimhadri, M.; Singh, N.; Srivastava, A.K.; Pulikkotil, J.; Dhar, A.; Budhani, R.C. Enhanced thermoelectric figure-of-merit in spark plasma sintered nanostructured n-type SiGe alloys. Appl. Phys. Lett. 2012, 101, 213902. [Google Scholar] [CrossRef]

- Yu, B.; Zebarjadi, M.; Wang, H.; Lukas, K.; Wang, H.; Wang, D.; Opeil, C.; Dresselhaus, M.; Chen, G.; Ren, Z. Enhancement of thermoelectric properties by modulation-doping in silicon germanium alloy nanocomposites. Nano Lett. 2012, 12, 2077–2082. [Google Scholar] [CrossRef] [PubMed]

- Lee, Y.; Pak, A.J.; Hwang, G.S. What is the thermal conductivity limit of silicon germanium alloys? Phys. Chem. Chem. Phys. 2016, 18, 19544–19548. [Google Scholar] [CrossRef]

- Hussain, T.; Li, X.; Danish, M.H.; Rehman, M.U.; Zhang, J.; Li, D.; Chen, G.; Tang, G. Realizing high thermoelectric performance in eco-friendly SnTe via synergistic resonance levels, band convergence and endotaxial nanostructuring with Cu2Te. Nano Energy 2020, 73. [Google Scholar] [CrossRef]

- Hong, M.; Chen, Z.G. Chemistry in advancing thermoelectric GeTe materials. Acc. Chem. Res. 2022, 55, 3178–3190. [Google Scholar] [CrossRef] [PubMed]

- Samanta, M.; Ghosh, T.; Arora, R.; Waghmare, U.V.; Biswas, K. Realization of both n- and p-type GeTe thermoelectrics: Electronic structure modulation by AgBiSe2 alloying. J. Am. Chem. Soc. 2019, 141, 19505–19512. [Google Scholar] [CrossRef]

- Sales, B.C.; Mandrus, D.; Williams, R.K. Filled skutterudite antimonides: A new class of thermoelectric materials. Science 1996, 272, 1325–1328. [Google Scholar] [CrossRef]

- Nayak, P.; Srivastava, P.; Gupta, D.C. Theoretical exploration of inherent electronic, structural, mechanical, thermoelectric, and thermophysical response of KRu4Z12 (Z = As12, Sb12) filled skutterudite materials. RSC Adv. 2023, 13, 27873–27886. [Google Scholar] [CrossRef]

- Li, H.; Tang, X.; Zhang, Q.; Uher, C. High performance InxCeyCo4Sb12 thermoelectric materials with in situ forming nanostructured InSb phase. Appl. Phys. Lett. 2009, 94, 102114. [Google Scholar] [CrossRef]

- Shi, X.; Yang, J.; Salvador, J.R.; Chi, M.; Cho, J.Y.; Wang, H.; Bai, S.; Yang, J.; Zhang, W.; Chen, L. Multiple-filled skutterudites: High thermoelectric figure of merit through separately optimizing electrical and thermal transports. J. Am. Chem. Soc. 2011, 133, 7837–7846. [Google Scholar] [CrossRef]

- Sharp, J.W.; Poon, S.J.; Goldsmid, H.J. Boundary scattering and the thermoelectric figure of merit. Phys. Status Solidi A 2001, 187, 507–516. [Google Scholar] [CrossRef]

- Yu, C.; Zhu, T.J.; Shi, R.Z.; Zhang, Y.; Zhao, X.B.; He, J. High-performance half-Heusler thermoelectric materials Hf1−x ZrxNiSn1−ySby prepared by levitation melting and spark plasma sintering. Acta Mater. 2009, 57, 2757–2764. [Google Scholar] [CrossRef]

- Fu, C.; Zhu, T.; Pei, Y.; Xie, H.; Wang, H.; Snyder, G.J.; Liu, Y.; Liu, Y.; Zhao, X. High band degeneracy contributes to high thermoelectric performance in p-type half-heusler compounds. Adv. Energy Mater. 2014, 4, 1400600. [Google Scholar] [CrossRef]

- Pei, Y.; LaLonde, A.D.; Wang, H.; Snyder, G.J. Low effective mass leading to high thermoelectric performance. Energy Environ. Sci. 2012, 5, 7963–7969. [Google Scholar] [CrossRef]

- Teunis, M.B.; Jana, A.; Dutta, P.; Johnson, M.A.; Mandal, M.; Muhoberac, B.B.; Sardar, R. Mesoscale growth and assembly of bright luminescent organolead halide perovskite quantum wires. Chem. Mater. 2016, 28, 5043–5054. [Google Scholar] [CrossRef]

- Liu, W.; Chang, A.Y.; Schaller, R.D.; Talapin, D.V. Colloidal insb nanocrystals. J. Am. Chem. Soc. 2012, 134, 20258–20261. [Google Scholar] [CrossRef] [PubMed]

- Zhao, C.; Wang, M.; Liu, Z. Research Progress on Preparation Methods of Skutterudites. Inorganics 2022, 10, 106. [Google Scholar] [CrossRef]

- Dey, T.K. Electrical conductivity, thermoelectric power and figure of merit of doped Bi-Sb tapes produced by melt spinning technique. Pramana 1990, 34, 243–248. [Google Scholar] [CrossRef]

- Chen, H.Y.; Zhao, X.B.; Lu, Y.F.; Mueller, E.; Mrotzek, A. Microstructures and thermoelectric properties of Fe0.92Mn0.08Six alloys prepared by rapid solidification and hot pressing. J. Appl. Phys. 2003, 94, 6621–6626. [Google Scholar] [CrossRef]

- Purushottam Bhat, C.; Anusha; Ani, A.; Shanubhogue, U.D.; Poornesh, P.; Rao, A.; Chattopadhyay, S. Investigations on Bi Doped Cu2Se Prepared by Solid State Reaction Technique for Thermoelectric Applications. Energies 2023, 16, 3010. [Google Scholar] [CrossRef]

- Qin, B.K.; Zhang, L.; Ji, Y.H.; Bai, Z.L.; Zhao, D.; Sun, C. Enhanced thermoelectric properties of FeTe2 by Sb doping prepared by solid-state reaction. Mater. Sci. Semicond. Process. 2024, 174, 108212. [Google Scholar] [CrossRef]

- Bai, Z.; Ji, Y.; Qin, B. Microstructure and thermoelectric properties of marcasite-type compounds XTe2 (X = Fe, Co, Ni) prepared by solid-state reaction. J. Mater. Sci. Mater. Electron. 2023, 34, 461. [Google Scholar] [CrossRef]

- Jin, M.; Tang, Z.; Jiang, J.; Zhang, R.; Zhou, L.; Zhao, S.; Chen, Y.; Chen, Y.; Wang, X.; Li, R. Growth of SnSe single crystal via vertical vapor deposition method and characterization of its thermoelectric performance. Mater. Res. Bull. 2020, 126, 110819. [Google Scholar] [CrossRef]

- Chuai, Y.H.; Wang, Y.F.; Bai, Y. Structural, Optical, Electrical, and Thermoelectric Properties of Bi2Se3 Films Deposited at a High Se/Bi Flow Rate. Nanomaterials 2023, 13, 2785. [Google Scholar] [CrossRef] [PubMed]

- Son, J.S.; Choo, S.; Lee, J.; Sisik, B.; Jung, S.J.; Kim, K.; Yang, S.E.; Jo, S.; Nam, C.; Ahn, S.; et al. Geometric design of Cu2Se-based thermoelectric device for enhancing power generation. Res. Sq. 2023. [Google Scholar] [CrossRef]

- Bharti, M.; Singh, A.; Samanta, S.; Aswal, D. Conductive polymers for thermoelectric power generation. Prog. Mater. Sci. 2018, 93, 270–310. [Google Scholar] [CrossRef]

- Singh, R.; Dogra, S.; Dixit, S.; Vatin, N.I.; Bhardwaj, R.; Sundramoorthy, A.K.; Perera, H.; Patole, S.P.; Mishra, R.K.; Arya, S. Advancements in thermoelectric materials for efficient waste heat recovery and renewable energy generation. Hybrid Adv. 2024, 5, 100176. [Google Scholar] [CrossRef]

- Palaporn, D.; Tanusilp, S.-A.; Sun, Y.; Pinitsoontorn, S.; Kurosaki, K. Thermoelectric materials for space explorations. Mater. Adv. 2024, 5, 5351–5364. [Google Scholar] [CrossRef]

- Summerer, L.; Roux, J.P.; Pustovalov, A.; Gusev, V.; Rybkin, N. Technology-based design and scaling for RTGs for space exploration in the 100 W range. Acta Astronaut. 2011, 68, 873–882. [Google Scholar] [CrossRef]

- Dai, Y.; Wang, H.; Qi, K.; Ma, X.; Wang, M.; Ma, Z.; Wang, Z.; Yang, Y.; Ramakrishna, S.; Ou, K. Electrode-dependent thermoelectric effect in ionic hydrogel fiber for self-powered sensing and low-grade heat harvesting. Chem. Eng. J. 2024, 497, 154970. [Google Scholar] [CrossRef]

- Sajid, M.; Hassan, I.; Rahman, A. An overview of cooling of thermoelectric devices. Renew. Sustain. Energy Rev. 2017, 78, 15–22. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, X.; Hou, S.; Wu, Z.; Wang, J.; Mao, J.; Zhang, Q.; Liu, Z.; Cao, F. Scalable-produced 3D elastic thermoelectric network for body heat harvesting. Nat. Commun. 2023, 14, 1–8. [Google Scholar] [CrossRef] [PubMed]

- He, Y.; Li, R.; Fan, Y.; Zheng, Y.; Chen, G. Study on the performance of a solid-state thermoelectric refrigeration system equipped with ionic wind fans for ultra-quiet operation. Int. J. Refrig. 2021, 130, 441–451. [Google Scholar] [CrossRef]

- Qamar, A.; Kanwal, A.; Amjad, M.; Farooq, M.; Munir, A.; Ahmad, S.; Abdollahian, M. Advancing sustainable cooling: Performance analysis of a solar-driven thermoelectric refrigeration system for eco-friendly solutions. Case Stud. Therm. Eng. 2024, 60, 104781. [Google Scholar] [CrossRef]

- Twaha, S.; Zhu, J.; Yan, Y.; Li, B. A comprehensive review of thermoelectric technology: Materials, applications, modelling and performance improvement. Renew. Sustain. Energy Rev. 2016, 65, 698–726. [Google Scholar] [CrossRef]

- Soleimani, Z.; Zoras, S.; Ceranic, B.; Shahzad, S.; Cui, Y. A review on recent developments of thermoelectric materials for room-temperature applications. Sustain. Energy Technol. Assess. 2020, 37, 100604. [Google Scholar] [CrossRef]

- Hendricks, T.; Caillat, T.; Mori, T. Keynote Review of Latest Advances in Thermoelectric Generation Materials, Devices, and Technologies 2022. Energies 2022, 15, 7307. [Google Scholar] [CrossRef]

- Yazawa, K.; Bahk, J.-H.; Shakouri, A. Thermoelectric Energy Conversion Devices and Systems; World Scientific Pub Co Pte Ltd.: Singapore, 2021; ISBN 9789811218262. [Google Scholar]

- Zheng, L.J.; Lim, S.; Kim, N.K.; Kang, D.H.; Youn, Y.J.; Lee, W.; Kang, H.W. Experimental study of a thin water-film evaporative cooling system to enhance the energy conversion efficiency of a thermoelectric device. Energy 2020, 211, 119040. [Google Scholar] [CrossRef]

- Singh, B.S.B. Thermoelectric Generators: Design, Operation, and Applications. In New Materials and Devices for Thermoelectric Power Generation; IntechOpen: London, UK, 2023. [Google Scholar]

- Mastsuura, K.; Rowe, D.M.; Tsvyoshi, A.; Min, G. Large scale thermoelectric generator’s of low grade heat. In Proceedings of the 10th International Conference on Thermoelectric, Cardiff, UK, 10–12 September 1991; pp. 9–12. [Google Scholar]

- Meng, F.; Chen, L.; Xie, Z.; Ge, Y. Thermoelectric generator with air-cooling heat recovery device from wastewater. Therm. Sci. Eng. Prog. 2017, 4, 106–112. [Google Scholar] [CrossRef]

- Telkes, M. Solar thermoelectric generators. J. Appl. Phys. 1954, 25, 765–777. [Google Scholar] [CrossRef]

- Guo, J.; Huai, X. Maximizing Electric Power through Spectral-Splitting Photovoltaic-Thermoelectric Hybrid System Integrated with Radiative Cooling. Adv. Sci. 2023, 10, 2206575. [Google Scholar] [CrossRef]

- Lamba, R.; Kaushik, S. Modeling and performance analysis of a concentrated photovoltaic–thermoelectric hybrid power generation system. Energy Convers. Manag. 2016, 115, 288–298. [Google Scholar] [CrossRef]

- Ge, M.; Zhao, Y.; Li, Y.; He, W.; Xie, L.; Zhao, Y. Structural optimization of thermoelectric modules in a concentration photovoltaic–thermoelectric hybrid system. Energy 2022, 244 Pt B, 123202. [Google Scholar] [CrossRef]

- Ying, P.; He, R.; Mao, J.; Zhang, Q.; Reith, H.; Sui, J.; Ren, Z.; Nielsch, K.; Schierning, G. Towards tellurium-free thermoelectric modules for power generation from low-grade heat. Nat. Commun. 2021, 12, 1121. [Google Scholar] [CrossRef] [PubMed]

- Huang, B.; Shen, Z.G. Performance assessment of annular thermoelectric generators for automobile exhaust waste heat recovery. Energy 2022, 246, 123375. [Google Scholar] [CrossRef]

- Siddique, A.R.M.; Bozorgi, M.; Venkateshwar, K.; Tasnim, S.; Mahmud, S. Phase change material-enhanced solid-state thermoelectric cooling technology for food refrigeration and storage applications. J. Energy Storage 2023, 60, 106569. [Google Scholar] [CrossRef]

- Ab Rahman, R.; Mohamad, M.A.H.; Kaamin, M.; Batcha, M.F.M.; Mazlan, M.D.A.; Rosli, M.L.; Aziz, M.A.A.C. Experimental study of peltier-based thermoelectric cooling box system. J. Adv. Res. Appl. Mech. 2022, 94, 1–6. [Google Scholar] [CrossRef]

- Wu, X.; Wang, Z.; Liu, Y.; Sun, X.; Xu, Y.; Tian, Y.; Wang, B.; Sang, X.; Shi, J.; Xiong, R. Enhanced performance of Bi2Te3-based thermoelectric materials by incorporating Bi2Fe4O9 magnetic nanoparticles. J. Alloys Compd. 2022, 904, 163933. [Google Scholar] [CrossRef]

- Liu, C.; Liang, D.; Chen, T.; Ye, X.; He, D.; Zhu, W.; Nie, X.; Wei, P.; Zhao, W.; Zhang, Q. Optimizing Room-Temperature Thermoelectric and Magnetocaloric Performance via Constructing Multi-Scale Interfacial Phases in LaFeSi/BiSbTe Thermo-Electro-Magnetic Refrigeration Materials. Adv. Funct. Mater. 2024, 35, 2415368. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Yin, Y.; Che, C.; Cui, M. Research Progress of Thermoelectric Materials—A Review. Energies 2025, 18, 2122. https://doi.org/10.3390/en18082122

Wang J, Yin Y, Che C, Cui M. Research Progress of Thermoelectric Materials—A Review. Energies. 2025; 18(8):2122. https://doi.org/10.3390/en18082122

Chicago/Turabian StyleWang, Jun, Yonggao Yin, Chunwen Che, and Mengying Cui. 2025. "Research Progress of Thermoelectric Materials—A Review" Energies 18, no. 8: 2122. https://doi.org/10.3390/en18082122

APA StyleWang, J., Yin, Y., Che, C., & Cui, M. (2025). Research Progress of Thermoelectric Materials—A Review. Energies, 18(8), 2122. https://doi.org/10.3390/en18082122