Abstract

Italy ranks among the leading countries in photovoltaic (PV) adoption, having installed 6.80 GW of new PV capacity, bringing the total installed capacity to 37.09 GW in 2024. However, this widespread deployment also leads to a substantial amount of PV waste as systems reach the end of their lifespan. This study aims to estimate the volume of PV waste expected to be generated in Italy due to the decommissioning of end-of-life (EoL) PV panels and to explore landfill and recovery scenarios that could offer the most sustainable management strategies. The findings indicate that 4520 kilotonnes of PV waste will be produced in Italy between 2030 and 2050. Of this, a significant share consists of glass (2704.9 kilotonnes) and aluminum (762.1 kilotonnes). Additionally, Italy will produce 174.6 kt of landfill waste in 2036. In 2049 and 2050, the total composition recovery is predicted to reach 571 kt and 604.7 kt, respectively. To summarize, the main contributions of this work include (1) projections of the EoL of crystalline silicon PV waste by material quantity for 2050, (2) the economic value share of PV module materials based on waste estimates and recovery, and (3) the estimation of the EoL solar compositions generated by 2050.

1. Introduction

Concerns regarding various waste pertain to a broader challenge of managing diverse waste streams, particularly within the realms of agriculture and industry. Agricultural waste, including crop residues and organic byproducts, along with industrial waste, particularly from construction and demolition activities, presents significant environmental risks [1,2]. Agricultural and industrial wastes are increasingly regarded as vital resources for the production of new, high-performance materials, rather than mere disposal challenges, which reflects a trend toward a circular economy. Beyond conventional waste streams, emerging waste types are becoming increasingly prominent environmental concerns. A notable instance is photovoltaic (PV) panel waste, which is garnering substantial attention due to the rapid advancement of solar energy technologies and the imminent mass retirement of panels installed in previous decades. In contrast to traditional waste categories, PV panels present unique challenges stemming from their complex material composition, the presence of hazardous substances, and the difficulties involved in efficient recycling. Addressing these challenges requires targeted research initiatives and the development of specialized policies to promote sustainable management at the end of their life cycle.

Solar PV technology represents a leading solution in the renewable energy sector, thanks to its capacity to generate clean and sustainable electricity. PV is among the most preferred methods for decarbonization, as it significantly reduces greenhouse gas emissions during operation [3]. Over the past decade, global PV capacity has grown rapidly, driven by technological advances, supportive policies, and heightened concern over climate change. Consequently, the shift to renewable energy is considered a necessary step to decrease greenhouse gas emissions and alleviate environmental effects. According to the IEA, global PV production capacity is expected to exceed 1.5 TW by 2035, a critical step toward global decarbonization [4]. However, the rapid increase in PV installations has raised significant concerns over the management of end-of-life (EoL) solar panels. PV panels are long-lived components with an average technical lifetime of 25–30 years and experience significant efficiency degradation at the end of their lifetime. As millions of panels installed in the past two decades near the end of their lifespan, the resulting surge in decommissioned modules poses growing environmental and resource management challenges. According to IRENA, the installed capacity is expected to reach 4500 GW by 2050, which will result in PV waste of 60–78 million tons worldwide [5].

If not properly managed, this waste could lead to resource depletion, environmental contamination, and missed opportunities for material recovery [6,7]. According to the 2024 snapshot of global PV markets, Europe exhibited sustained robust development, installing 61 GW (including 55.8 GW in the EU), spearheaded by a revival in Germany (14.3 GW) and increased installations in Poland (6.0 GW), Italy (5.3 GW), and the Netherlands (4.2 GW), while Spain experienced a minor decline (7.7 GW) [8]. Among European countries, Italy has distinguished itself as a leader in the adoption of solar energy. This rapid growth can be attributed to a combination of favorable government policies, such as feed-in tariffs and tax incentives, and the country’s abundant solar irradiance, which is among the highest in Europe. Thanks to its strategic geographical location and Mediterranean climate, Italy offers ideal conditions for solar power generation, positioning it at the forefront of renewable energy development [9].

The exponential rise in solar PV installations is inevitably leading to a proportional increase in end-of-life (EoL) PV waste. This highlights the urgent need to establish robust strategies for the recycling and recovery of PV waste. The recovery and reuse of secondary materials are becoming increasingly important since PV modules contain valuable materials such as silver, copper, and high-purity silicon, along with glass and aluminum, all of which are suitable for recovery and reintegration into production cycles. Moreover, recycling can help reduce resource depletion and lessen the environmental impacts associated with mining and processing limited natural resources, all while saving energy. The 27 EU member states added around 63.1 gigawatts of solar PV capacity that year [10]. By 2023, Germany, Spain, and Italy were leading the way with the highest cumulative solar PV capacity. Specifically, Germany is expected to generate the most PV waste, around 26,100 tons, while Italy is projected to produce about 1560 tons by 2030. According to the National Energy and Climate Plan (NECP), Italy targets a 40% renewable share in its energy mix and plans to reach 79.9 GW of solar capacity by 2030. However, Italy has the potential to achieve even more. The growth of PV in Italy has been impressive, positioning the country as one of the top solar energy markets in Europe. Yet, with this growth comes the challenge of effectively managing the PV waste that will emerge as these systems reach the end of their lifespan [11].

Addressing the growing number of solar PV panels that have reached their end of life (EoL) in Italy is a pressing issue from environmental, economic, and social perspectives. With the rapid increase in PV installations over the last few decades, Italy is now facing the significant challenge of managing a substantial amount of PV waste, which is expected to skyrocket in the coming years. Effective waste management for these panels is essential to minimize environmental risks, recover valuable materials, and promote a shift toward a circular economy. If PV panels are disposed of improperly, they can cause serious environmental harm due to the presence of materials like lead and other heavy metals, which can leach into water and soil if not handled correctly.

Given the acceleration in solar PV deployment, Italy faces a critical challenge in managing a rapidly increasing volume of PV waste in the coming decades. It is crucial to handle this waste effectively to prevent environmental problems, recover valuable materials, and support the transition to a circular economy. Additionally, solar panels contain valuable materials such as silver, copper, high-purity silicon, glass, and aluminum, all of which can be recycled and repurposed. Studies show that recycling one ton of PV panels can recover up to 80% of these valuable materials, aligning with the EU’s Circular Economy Action Plan to maximize material reuse and resource efficiency [12]. By implementing efficient recycling systems, Italy can decrease its dependence on imported raw materials and enhance resource security. Furthermore, establishing a sustainable recycling and management sector for solar panel waste could create new economic opportunities, including jobs in collection, transportation, processing, and material recovery, with the recycled materials providing an additional revenue stream for manufacturers. This is particularly important for Italy, which aims to strengthen its leadership in renewable energy and sustainable practices. Compliance with the Waste Electrical and Electronic Equipment (WEEE) Directive is mandatory, and failure to meet recovery targets may result in financial penalties and reputational damage. If PV waste is not managed properly, it could result in legal and financial repercussions, including fines and damage to its reputation for not meeting WEEE recycling targets. By implementing advanced waste management systems, Italy can adhere to these regulations and avoid potential liabilities. Thus, addressing the issue of removing PV panels that are nearing the end of their life cycle is a challenge that requires urgent attention. Addressing this issue will not only help Italy protect the environment and recover valuable resources but also create economic opportunities, comply with regulations, conserve energy, and prevent the export of waste to countries with lax regulations. By focusing on establishing recycling facilities and embracing sustainable waste management practices, Italy can enhance its renewable energy goals and take a leading role in the global movement toward sustainability.

In this context, PV waste management must be viewed not only through the lens of national compliance with the WEEE Directive but also as an integral part of the broader European Union Circular Economy Action Plan. This plan emphasizes the transition from a linear “take-make-dispose” model to a circular approach that maximizes material recovery and minimizes waste. Photovoltaic panels, given their valuable and recoverable components such as glass, aluminum, and silver, are specifically highlighted as target products for enhanced circularity. Integrating PV recycling into this EU strategy reinforces its relevance in achieving climate neutrality, resource efficiency, and industrial competitiveness goals across member states [13].

Assessing the environmental and economic impacts of managing EoL PV waste is crucial. Research indicates that recycling PV panels can significantly lower their carbon footprint compared to landfilling, highlighting its significance in sustainable waste management. Estimating solar PV waste will support the formulation of optimal recycling strategies, thereby reducing greenhouse gas emissions and enhancing resource efficiency. Utilizing projections and relying on trustworthy data enable us to gain valuable insights into material quantities, recycling potential, and the economic benefits of end-of-life crystalline solar PV waste. Numerous studies have been conducted to estimate and manage various EoL frameworks for PV technologies to evaluate their overall impact. Recent studies have assessed the environmental and economic implications of PV waste management. For example, Nain et al. compared EU and US regulatory frameworks, estimating the global EoL PV material value at nearly USD 200 billion by 2050 [14].

In a case study on a small Indonesian island, Adiansyah et al. assessed two end-of-life (EoL) management strategies for PV systems: landfilling and recycling. Their analysis revealed that recycling reduced environmental impacts by 25% compared to landfilling, particularly concerning human health and ecological risks. Furthermore, a sensitivity analysis indicated that situating recycling facilities closer to the waste source could further reduce environmental burdens by up to 84%, underscoring the significant influence of transportation on the overall footprint [15]. Daniela-Abigail et al. performed a comprehensive life cycle assessment (LCA) of PV panels using the ReCiPe 2016 methodology and Ecoinvent 3.8 database, comparing two distinct EoL scenarios: recycling and landfilling. The study evaluated both midpoint (e.g., climate change, toxicity) and endpoint (e.g., ecosystem damage) impact categories. The results demonstrated that recycling could reduce environmental burdens across multiple categories, with reductions reaching up to 89% in mineral resource scarcity. The study particularly emphasized the value of recovering strategic materials like silver, given their economic relevance and high extraction costs [16]. In another study, de Wild et al. investigated the life cycle assessment of backsheets used in PV modules. Their research demonstrated that when comparing PET-based backsheets to those made from fluoropolymers, polyolefin (PO)-based backsheets emerged as the superior choice, providing the best energy yield and environmental benefits [17].

Due to the pressing issue of decommissioned solar PV modules and corresponding solar PV waste in Italy in the near future, it is essential to estimate the amount of waste and identify the potential for recycling, recovering, and reusing the materials. This study quantifies not only the amount of recycled and landfilled materials but also the economic value of the Italian solar PV sector when these modules reach their end-of-life (EoL). The information will provide a scientific basis for formulating policies on solar PV development and the waste management of electronic and electrical equipment. Additionally, solar PV developers may refer to this study for planning their businesses related to solar PV deployment, as well as the recycling and reuse of solar PV panels with low environmental impacts, efficient resource consumption, and high economic value.

This study addresses the issue of PV waste in Italy, focusing on mono-crystalline silicon (c-Si) modules, which represent the predominant technology in the national market. The research quantifies projected PV waste volumes through 2050, assesses the recycling potential of constituent materials, and evaluates their associated economic value. By integrating market shares, recycling efficiencies, and material compositions, the study offers a predictive framework for more accurate waste management planning. The results may serve as a reference for other countries aiming to enhance their PV waste recycling strategies and develop more sustainable solar energy infrastructure.

While this study focuses on crystalline silicon (c-Si) modules due to their historical and current market dominance, it is important to acknowledge the rapid development of emerging photovoltaic technologies, such as perovskite-based and tandem silicon–perovskite modules. These next-generation technologies promise higher efficiencies and different material compositions, which may alter the nature and management of PV waste in the future. Future studies should account for their growing market penetration and unique end-of-life challenges as the PV market continues to evolve.

2. Materials and Methods

2.1. PV Analysis in Italy

Italy’s journey in PV deployment began in earnest in 2008, when installed capacity was still below 100 megawatts (MW). A significant shift occurred in 2009, with capacity soaring to over 700 MW, and by 2010, it had tripled, exceeding 2 gigawatts (GW). The true turning point came in 2011, when more than 9 GW of solar power were installed in a single year, which was an unprecedented surge largely driven by the generous “Conto Energia” incentive scheme available at the time.

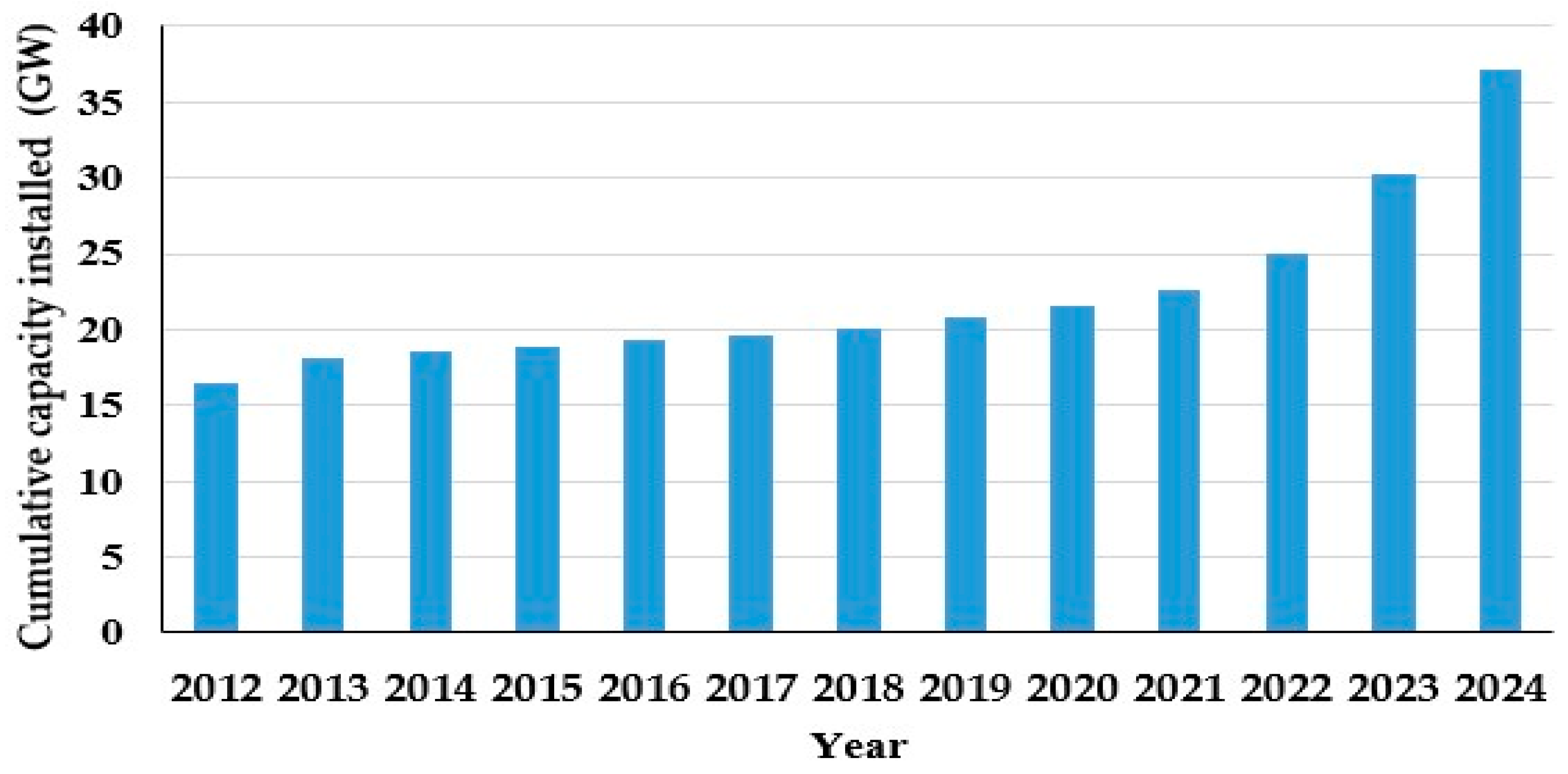

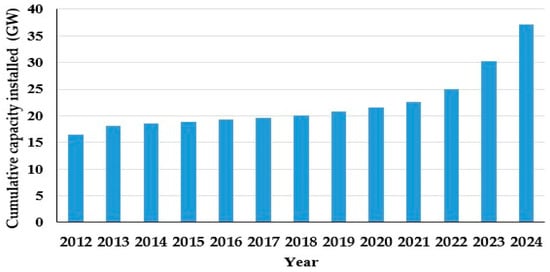

While a more gradual and flexible support mechanism might have ensured steadier long-term growth, the early boom nonetheless established Italy as a major player in the European solar energy market, laying the groundwork for continued expansion and innovation in the sector [18]. By the end of 2020, Figure 1, Italy had established itself as one of the leading countries in solar PV deployment across Europe, boasting a cumulative installed capacity of over 21 GW. Looking ahead, projections suggest that this number will continue to rise significantly, driven by Italy’s goal of achieving 55% renewable energy in electricity generation by 2030 [19]. Italy installed about 3.34 GW of additional solar power capacity in the first half of 2024, as reported by the Italian PV association, Italia Solare. To put that in perspective, during the same period in 2023, the country managed to deploy around 2.3 GW of solar energy. For 2023, the total new PV capacity reached 5.23 GW, which is a significant increase from 2.48 GW in 2022 and just 0.94 GW in 2021. This surge was largely fueled by the connection of 17 plants, each boasting a power output of over 10 MW, contributing a total of 540 MW. These installations were spread across various regions: Lombardy (18 MW), Lazio (215 MW), Friuli-Venezia Giulia (24 MW), Sicily (65 MW), Sardinia (177 MW), and Puglia (38 MW). Recent data confirm that the utility-scale solar PV sector in Italy is gaining strong momentum, as previously approved permits are now materializing into operational plants connected to the national grid. A particularly notable trend is the sharp increase in mid-scale installations (plants ranging from 1 MW to 10 MW), which saw their total capacity increase by 122%, rising from 297 MW in the first half of 2023 to 661 MW in the same period of 2024 [20]. In 2023, approximately 5.3 GW of new PV systems were installed across the country. The northern regions led the expansion, with Lombardy contributing 17.2% of the total, followed by Veneto (13%), Piedmont (10.9%), and Emilia-Romagna (9.9%). In southern Italy, Sicily emerged as the primary contributor, accounting for 7.7% of new capacity [21]. The upward trend continued in 2024. During the first half of the year, six regions (Lombardy, Lazio, Veneto, Emilia-Romagna, Piedmont, and Sardinia) collectively accounted for an impressive 63% of the newly installed solar PV capacity nationwide. Among them, Lombardy emerged as the leading contributor with 554 MW of new capacity, followed by Lazio with 426 MW, Veneto with 329 MW, Emilia-Romagna with 304 MW, Piedmont with 257 MW, and Sardinia with 242 MW. Altogether, these six regions connected a total of 2.11 GW of new capacity in just six months, highlighting the increasingly regionalized momentum behind Italy’s solar expansion.

Figure 1.

Overview of the annual cumulative installed capacity of PV systems in Italy from 2012 to 2024 [22].

From a sectoral perspective, the distribution of newly installed capacity in early 2024 was relatively balanced across market segments. Residential installations accounted for approximately 24%, equivalent to around 515 MW. The commercial and industrial sectors contributed 34%, or 717 MW, while utility-scale projects made up the remaining 42%, corresponding to 880 MW. These figures reflect a healthy diversification in PV deployment across different consumer categories, supporting both decentralized generation and large-scale energy transition goals [20]. Italy ranks among the leading European countries for PV deployment, with consistently high installation rates from 2012 to 2023. After a steady growth phase up to 2020, the sector witnessed accelerated expansion between 2022 and 2024. The country’s total installed PV capacity has grown dramatically from 25 GW in 2022 to over 35 GW by 2024 [22,23,24,25,26,27,28,29,30,31,32,33,34,35,36,37].

This consistent expansion across multiple scales and regions confirms the maturation of Italy’s PV sector and reinforces the need for strategic planning in terms of grid integration, storage solutions, and end-of-life (EoL) management systems.

This study proposes a methodological framework to estimate the projected volume of solar PV waste in Italy, with a specific focus on mono-crystalline silicon (c-Si) technologies, which currently represent the dominant share of both global and national PV markets. The estimation approach is grounded in a systematic review of recent literature and aligns with best practices adopted in state-of-the-art research on end-of-life (EoL) PV module management [38]. In addition, it incorporates relevant policy frameworks, particularly the European Union’s Waste Electrical and Electronic Equipment (WEEE) Directive, along with national-level regulatory guidelines to contextualize the modeling of recovery and landfill scenarios. The methodology aims to quantify the materials embedded in PV systems that are expected to reach end-of-life by 2050 and to assess both their economic market value and recovery potential, reflecting the dual imperative of environmental sustainability and resource efficiency. This approach is consistent with emerging research trends in the field, which emphasize not only the physical mass flow of waste but also the strategic and economic importance of material recovery within a circular economy paradigm.

To implement this methodology, a structured data sheet architecture was designed to systematically organize historical PV installation data, material composition parameters, and degradation profiles. All computational routines, ranging from waste volume estimation and material disaggregation to recovery efficiency and scenario modeling, were developed using Python 3.11. The modeling process is built upon two key assumptions, both of which are well-supported in the current scientific literature. First, it assumes that crystalline silicon technology will continue to dominate the PV market up to 2050, consistent with forecasts by IRENA, the IEA, and leading market analyses. Second, it assumes that the types and relative proportions of raw materials used in PV modules, particularly glass, aluminum, silicon, copper, and silver, will remain relatively constant over time. While this does not fully account for the potential market penetration of emerging technologies such as perovskite or tandem cells, it reflects the characteristics of the installed base and ensures methodological consistency with previous lifecycle and EoL studies.

2.2. PV Waste Material Content and Volume Estimation

To estimate the volume and material composition of future solar PV waste, this study begins with the reconstruction of annual and cumulative PV installations in Italy over the past two decades, specifically from 2005 to 2025. While global PV installation data are available from various international sources, this analysis draws on national-level datasets from the European Photovoltaic Industry Association (EPIA), EurObserv’ER, Italia Solare (the national solar association), the Gestore dei Servizi Energetici (GSE), and the European Union’s annual PV status reports, all of which offer detailed and regionally specific information for the Italian context.

An average operational lifespan of 25 years is assumed for PV modules, in line with international benchmarks and lifecycle analyses. This assumption enables the direct mapping of the year of installation to an expected year of decommissioning, forming the temporal foundation of the end-of-life (EoL) waste estimation model. Given their overwhelming market dominance, constituting approximately 95% of the global installed base, this study focuses exclusively on crystalline silicon (c-Si) modules, which also represent the prevailing technology deployed in Italy [39,40,41,42]. To quantify the material content of PV waste, a typical silicon-based PV module and its material composition were analyzed, with data compiled from the Ecoinvent database. The Ecoinvent database was selected because it is a widely used life cycle inventory resource, providing both qualitative descriptions of the module and quantitative data on its material composition. The module weighs 23 kg, has a peak capacity of 224 Wp, and covers an area of 1.46 m2. The module is based on mono-silicon PV cells, covered with solar glass, and integrated with an aluminum frame and junction box for electrical installation. The detailed material composition of the studied module is summarized in Table 1.

Table 1.

Material composition of crystalline silicon PV panels and their recycling yield.

Equation (1) and the waste composition shown in Table 1 are used to estimate the material content in PV waste. The number of modules is calculated using Equation (2), and once the module number is known, the total mass of PV waste is calculated by multiplying the number of modules by the module weight, as shown in Equation (3).

Here, material content: (kg), installed capacity: (W), composition: (kg/m2), module market share: (%), and module power: (W/m2).

2.3. Economic Value Share of Materials in PV Waste

The economic valuation of materials contained in EoL PV modules was carried out by integrating mass-based composition data with current commodity market prices. The analysis focused on key materials commonly found in crystalline silicon PV modules, namely silicon, silver, aluminum, copper, glass, and polymeric materials, which were selected for their prevalence in module architecture and their strategic or economic relevance. The mass fractions of each material were derived from a combination of peer-reviewed literature, technical datasheets, and industry reports, including the material breakdowns presented in Table 1. This composition data was then used to estimate the total quantities of materials expected to be present in the PV waste stream through 2050.

To ensure consistency and credibility in economic valuation, current market prices were sourced from established and frequently updated databases, such as Trading Economics and Bloomberg Markets [51,52]. These platforms provide real-time commodity pricing, allowing for the integration of temporally accurate and geographically consistent cost data into the modeling framework. By multiplying the projected waste quantities of each material by their respective market prices, the study derived both the gross economic value of the materials present in EoL modules and their recoverable value, factoring in estimated recycling yields.

2.4. Future of EoL Solar Modules (Recovery and Landfill)

As part of the methodological approach adopted in this study, a dedicated analysis was conducted on the regulatory and policy framework governing EoL PV module management in Italy. This analysis was essential to validate the assumptions used in modeling PV waste flows, particularly the proportions of material expected to be recovered versus landfilled. Italy operates under the broader umbrella of the European Union’s Directive 2012/19/EU on Waste Electrical and Electronic Equipment (WEEE) [53], which includes PV modules within its scope and establishes minimum targets for collection, reuse, and recycling. This directive has been formally transposed into national legislation, which outlines the responsibilities of producers, importers, and distributors with regard to the take-back and environmentally sound treatment of EoL PV modules. Producers are obligated to join collective or individual compliance schemes and are financially responsible for managing PV modules placed on the market after 12 April 2014. For systems installed prior to that date, often categorized as “historical WEEE”, responsibility may shift to the owner unless the equipment is being replaced by equivalent new modules. Additional regulatory layers apply to incentivized PV systems, particularly those supported under the Conto Energia programs. In such cases, the Gestore dei Servizi Energetici (GSE) provides operational guidelines detailing the procedures and documentation required for proper decommissioning and waste handling. To support the development of realistic waste management scenarios, this study included a systematic review of Italy’s national legislation, industry-specific compliance structures, and institutional practices. Sources consulted included academic databases, official government portals, and documentation from private organizations and sector consortia. The goal of this regulatory assessment was to establish whether the assumption that all PV waste will be either recovered or landfilled is grounded in current institutional capabilities and legal requirements. Based on this review and in accordance with current EU targets, it was confirmed that at least 85% of the weight of collected PV modules must be recovered and a minimum of 80% must be recycled or prepared for reuse. These regulatory thresholds serve as key reference points in the model’s estimation of recovery rates and landfill volumes. Thus, the regulatory framework analysis constitutes a core element of the study’s methodology, ensuring that material flow scenarios are not only technically accurate but also compliant with the legal and institutional context in which Italy’s PV sector operates.

3. Results and Discussion

3.1. Material Composition and PV Waste Estimation by 2050

The projected future volumes of solar PV waste in Italy have been estimated based on decommissioning assumptions, as summarized in Table 2. The analysis assumes an average operational lifespan of 25 years for PV systems, indicating that installations from 2005 to 2025 are expected to reach end-of-life and begin decommissioning between 2030 and 2050. Over this period, the total number of PV modules reaching end-of-life in Italy is projected to approach 197 million units, corresponding to approximately 4.52 million tonnes of waste.

Table 2.

Expected end-of-life PV modules for Italy and Europe between 2030 and 2050.

The accumulated waste generated from the Italian solar PV sector between 2030 and 2050 will reach 4.52 million tons. The total amount of waste generated, considering all waste from the Italian solar PV sector since the first installation until 2050, is slightly higher at 4.55 million tons. This result is reduced by half compared to the amount of waste estimated 10 years ago by Paiano [54], which was 8.23 million tons. The considerable variance likely originates from the installed capacity of solar PV between 2014 and 2022. Paiano forecasted the projection of solar PV installations in Italy from 2014 to 2022 to be around 29 GW cumulatively. Meanwhile, Italy experienced a decline in solar PV installations since 2014 due to the phasing out of the feed-in tariff in 2013 and the lockdown during the Covid pandemic, leading to only 6 GW of installations between 2014 and 2022. This actual installation was only a fifth of the forecasted number. Similar to this study, Paiano identified the peak of solar PV waste generation in 2036, due to the highest installation in 2011. The amount of waste generated by 2036 differs slightly between the two studies (1 million tons in Paiano and 0.95 million tons in this study).

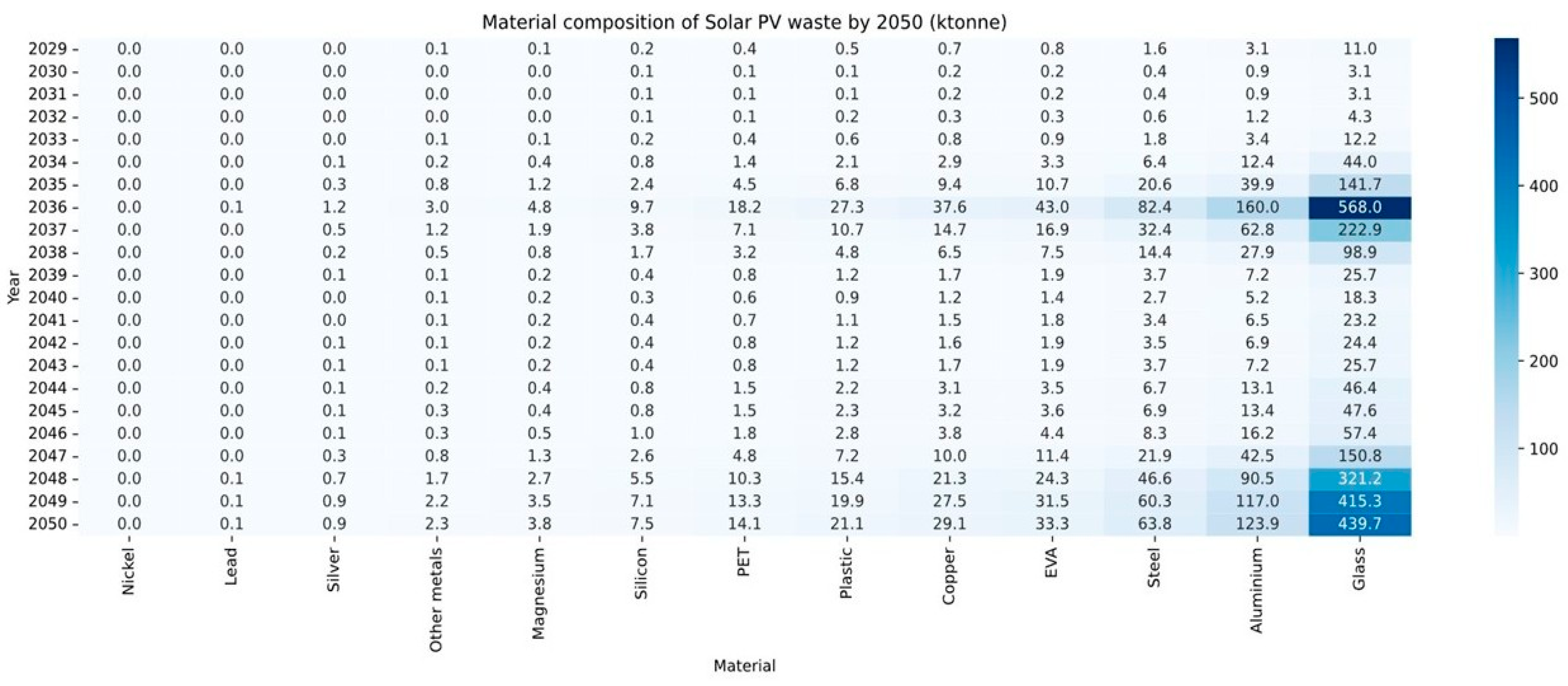

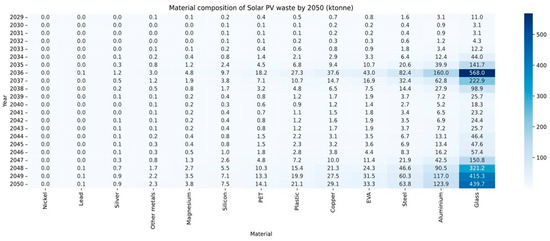

The resulting trends in waste accumulation are visualized in Figure 2, which depicts the projected temporal evolution of PV waste generation and provides key insights into the scale and timing of future waste management needs. According to Figure 2, the projected evolution of solar PV waste in Italy up to 2050 highlights significant trends in both the material composition and volume of end-of-life (EoL) modules. These insights are essential for anticipating future challenges and opportunities related to PV waste management, particularly in designing effective recycling and recovery systems.

Figure 2.

Projected EoL PV modules with material quantities in Italy.

The total mass of PV waste is expected to increase steadily over the coming decades, with a marked acceleration beginning around 2036. This sharp rise corresponds to the decommissioning of early-generation crystalline silicon (c-Si) PV panels, predominantly installed during Italy’s installation boom between 2009 and 2011. By 2050, cumulative PV waste is projected to reach approximately 739.6 kilotonnes (kt), underscoring the critical need for the development of scalable, technologically advanced, and regionally distributed recycling infrastructure.

The material composition of solar PV waste is largely dominated by glass and aluminum, which together constitute the majority of the total waste stream. In the peak year of 2036, glass alone is projected to contribute approximately 568 kilotonnes (kt), while aluminum accounts for an additional 160 kt. These materials are fundamental components of PV modules, used in the front glass cover, frames, and structural supports.

The considerable volume of these materials underscores the strategic importance of developing targeted recycling processes specifically designed for high-volume materials like glass and aluminum, which offer significant potential for reuse in both the PV sector and broader manufacturing applications. Over the entire forecast period from 2030 to 2050, cumulative projections estimate that glass waste will reach 2704.9 kt and aluminum waste will total 762.1 kt. It is expected that technological advancements and evolving module designs will influence both the total waste mass and its material composition in the coming decades. For instance, the increasing adoption of bi-facial PV modules, particularly in non-residential and utility-scale installations, may lead to a higher proportion of glass in future waste streams due to the presence of dual-glass structures [11].

Overall, the substantial quantity of glass and aluminum expected to enter the waste cycle indicates the emergence of a robust end-of-life (EoL) market for PV materials. Anticipating and planning for this waste stream is essential to support circular economy principles and reduce the environmental impact of PV system deployment over time.

In addition to glass and aluminum, several strategic materials, although present in smaller quantities, play a critical role due to their high economic value and importance for resource security. These include copper, magnesium, and especially silver.

By 2050, waste from copper and magnesium in decommissioned PV modules is projected to reach approximately 29.1 kilotonnes (kt) and 3.8 kt, respectively. Although silver is generated in relatively small quantities compared to bulk materials, it is projected to reach 0.9 kt by 2050. Its strategic value, limited global availability, and high market price make it a prime candidate for targeted recovery processes.

The accumulation of silver-containing waste is expected to increase steadily over time, with a noticeable acceleration after 2036, corresponding to the decommissioning of early-generation modules installed during Italy’s solar boom. This trend reflects the critical need for efficient recovery of rare and valuable materials as part of national and European resource circularity strategies. While glass (439.7 kt) and aluminum (123.9 kt) will continue to dominate the material volume in 2050, the inclusion of high-value elements like silver and copper introduces substantial economic opportunities for PV recycling initiatives. Developing recovery processes tailored to these materials can provide both environmental benefits and new revenue streams for the solar sector.

Furthermore, peaks in projected waste volumes, such as 321.2 kt in 2048 and 439.7 kt in 2050, highlight the cyclical nature of PV module decommissioning. These fluctuations stem from the variable rate of past installations and underscore the need for flexible, adaptive waste management systems that can scale responsively over time. Monitoring temporal variations in material intensity and the geographical distribution of PV deployments can also guide the optimal siting and sizing of recycling infrastructure, thereby improving collection efficiency and reducing transportation-related impacts.

Ultimately, the projections of PV waste material composition through 2050 underscore the urgent need for comprehensive, forward-looking recycling strategies. While the dominance of glass and aluminum poses logistical challenges due to their volume, the presence of valuable materials like silver, magnesium, and copper presents significant opportunities for innovation, investment, and sustainability leadership within the PV industry. By fostering collaboration among regulators, industry stakeholders, and technology developers, Italy can strengthen its position in the circular economy and contribute meaningfully to the global energy transition. Although uncertainties related to future legislation and technological advancements in PV systems may affect the accuracy of long-term waste projections, these estimates remain highly valuable for developing a strategic perspective on this critical issue. By anticipating potential waste streams, policymakers and industry stakeholders can proactively design effective management and recycling infrastructures to support a sustainable solar energy future.

Italy’s current PV recycling infrastructure is still evolving and faces significant capacity challenges. While the legal framework is aligned with the EU’s WEEE Directive, actual treatment capacity remains limited. Currently, most decommissioned PV modules are managed through authorized WEEE operators, but dedicated recycling facilities specific to PV panels are scarce. The Italian National Agency for New Technologies, Energy and Sustainable Economic Development (ENEA) has conducted pilot studies and research on advanced recovery processes, particularly for silicon and silver recovery, thereby supporting innovation in this sector. The Italian Ministry for the Environment has also developed national guidelines to support compliance and investment in waste treatment infrastructure. However, significant investments are still needed to scale these efforts to meet the expected volume of PV waste by 2050. This context highlights the importance of aligning technical recovery models with real infrastructure development in the coming years [55,56].

Based on our projections, Italy will require a distributed network of high-capacity recycling facilities by 2050, as peak PV waste volumes are expected to exceed 600,000 tonnes per year. Economically viable recycling plants should ideally process at least 100,000 to 150,000 tonnes annually to achieve cost efficiency through economies of scale. A range of emerging technologies, including thermal delamination, pyrolysis, and chemical etching, can facilitate the high-yield recovery of materials like glass, aluminum, silicon, and especially silver. Optimal locations for these plants would correspond to regions with high PV deployment and strong logistical infrastructure, such as Lombardy, Lazio, Apulia, and Sicily. Aligning infrastructure investment with these regional and technological insights is essential to ensure national readiness for upcoming PV waste flows.

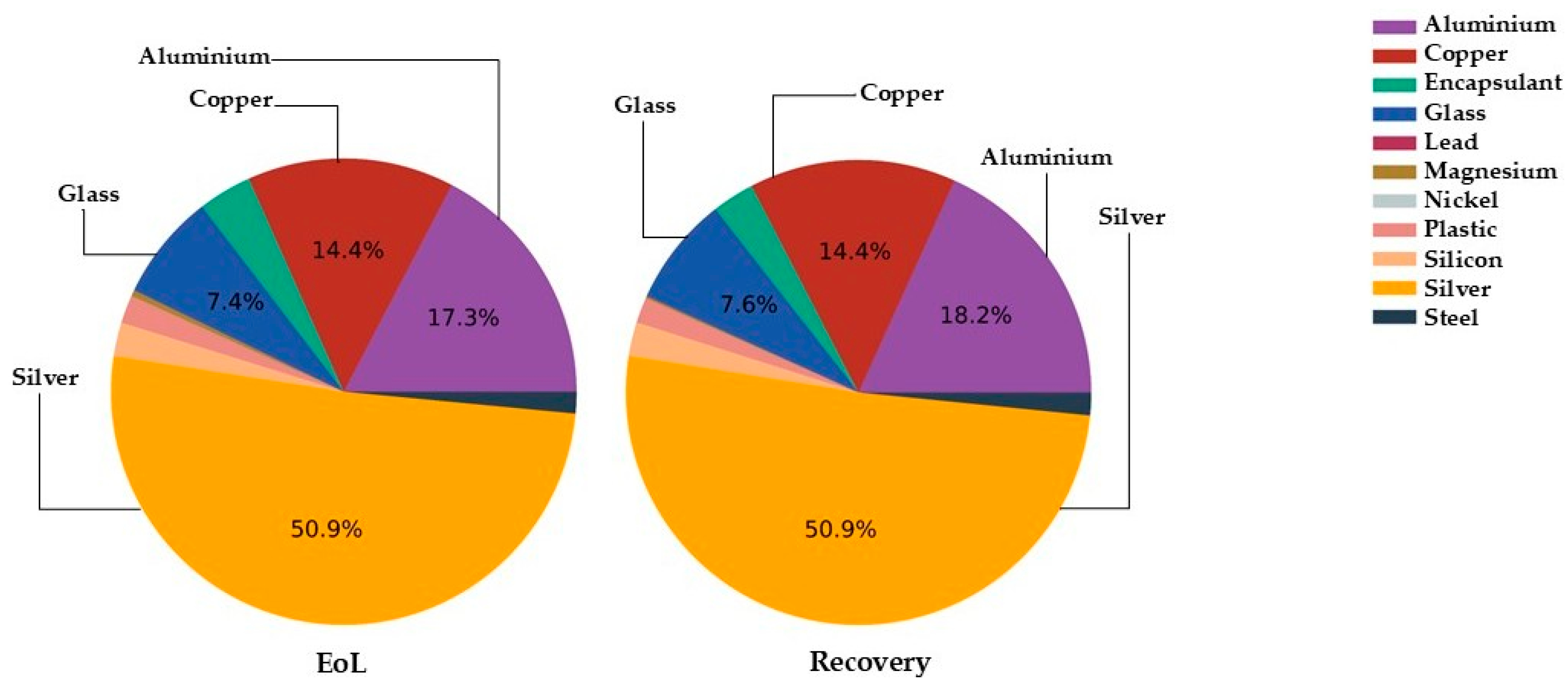

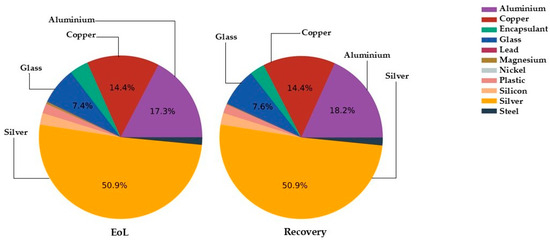

3.2. Market Share of Waste

Figure 3 provides a comparative overview of the economic value distribution of materials contained in EoL PV panels (left) and the recoverable portion after recycling (right), specifically projected for the year 2050.

Figure 3.

Economic value share of PV module materials based on waste estimates (left) and recovery (right).

The EoL value distribution highlights that silver represents the dominant share, accounting for 50.9% of the total economic value embedded in PV waste. This is followed by aluminum (17.3%), copper (14.4%), and glass (7.4%). Other materials, such as silicon, lead, and steel, contribute marginally (<5%) but still play important functional roles in module composition.

On the recovery side, the material value distribution remains remarkably consistent, with silver still comprising 50.9%, indicating that silver maintains a high recovery efficiency and retains its economic value post-recycling. In a PV module, silver is a common material for electrodes. Although it accounts for a small amount of the total waste, at 939 tonnes in 2050, it contributes to more than half of the economic value of the EoL PV module. This is due to the high economic value of this precious metal. As a result, the recycling and recovery of such critical material are crucial for improving the economic value of both the PV modules and the recycled modules, considering their whole life cycle.

Aluminum exhibits a slight increase to 18.2%, reflecting its low loss rates and high recyclability in established industrial processes. Similarly, the glass share rises modestly to 7.6%, suggesting incremental improvements in glass recovery technologies, likely due to advances in lamination separation and glass purity retention.

The near-parity between EoL and recoverable values demonstrates that high-value materials are efficiently retained through modern recycling techniques. This reinforces the strategic role of silver, aluminum, and copper in ensuring the economic feasibility of PV recycling, especially under circular economy principles.

Importantly, materials such as silver, aluminum, copper, and silicon recovered from EoL PV modules can be reintegrated directly into the manufacturing of new PV modules, closing the material loop. Additionally, some materials (e.g., glass, silicon, and encapsulants) have potential cross-sectoral applications in industries like construction (cement, ceramics), electronics, paints, and adhesives, expanding their reuse potential and marketability. The recovery of these resources leads to reduced dependence on primary resource extraction; water and energy savings in production cycles; the minimization of environmental degradation from mining and refining; additional revenue streams for PV manufacturers and recyclers; and lower lifecycle costs of future PV systems.

From a policy and infrastructure perspective, these findings emphasize the necessity of investing in material-specific recovery technologies, especially for high-value metals like silver, to maximize economic returns and minimize resource depletion. Finally, Figure 3 underscores the economic resilience of PV recycling by showing that the value hierarchy of materials is preserved even after processing. This suggests a strong case for further industrial scaling, innovation in separation technologies, and policy incentives targeting the recovery of precious and rare materials from solar waste.

3.3. Future of EoL Solar Modules Generated by 2050

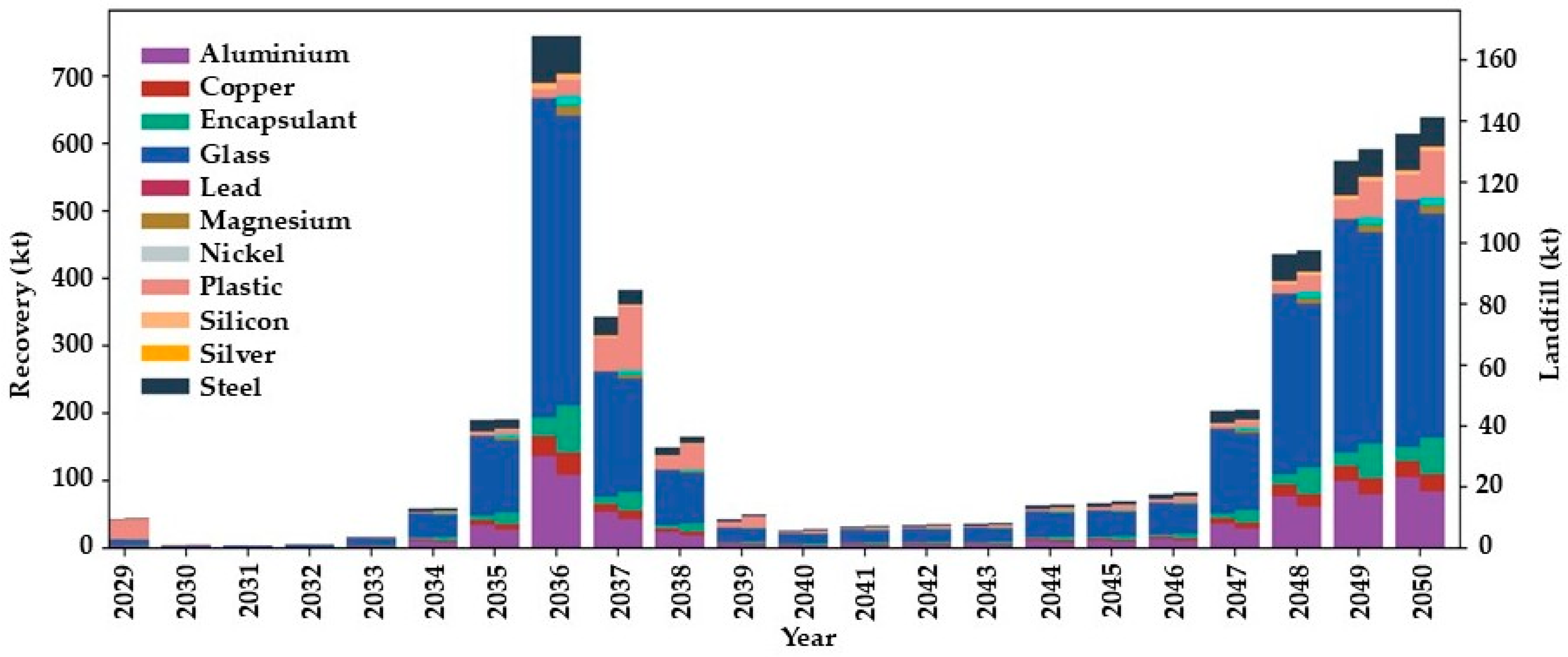

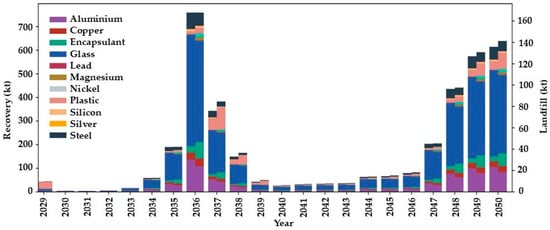

Building upon the economic value analysis of PV materials, it is equally important to examine how these materials are projected to flow through the waste management system over time. Understanding the temporal evolution of both recoverable and landfilled materials is essential for designing efficient, scalable, and future-proof recycling infrastructure.

This dynamic perspective is presented in Figure 4, which illustrates annual recovery and landfill projections for each material class up to the year 2050. Figure 4 presents the projected evolution of material flows from EoL PV modules in terms of recovery (left axis) and landfilling (right axis) up to the year 2050. These estimates are based on PV waste volume and composition data, combined with prevailing European waste management regulations, such as the WEEE Directive, which mandates collection and recovery targets for PV equipment. The recovery and landfill volumes from 2030 to 2050 exhibit a similar pattern to the additional installed capacity from 2005 to 2025. After 25 years of operation, the installed panels reach their end of life, resulting in corresponding amounts of decommissioned panels and materials being recovered and landfilled. A significant spike in both recovery and landfill volumes is observed around 2036. In that year, recovered materials are projected to exceed 760 kilotonnes (kt), while landfilled materials peak at 168 kt, the highest value in the entire projection range. These peaks correspond to the additional installed capacity in 2011, which was 9.3 GW and was also the highest between 2005 and 2025. The late 2040s and 2050 show another period of increased waste flows, with recovery expected to reach 574 kt in 2049 and 615 kt in 2050. Additionally, landfill volumes are projected to reach 141 kt in 2050.

Figure 4.

Estimation of the EoL solar compositions generated by 2050.

Notably, glass and aluminum remain the most dominant materials throughout the entire forecast period, as indicated by their large bar sections. However, valuable metals such as silver, copper, and silicon are also consistently present, emphasizing the long-term importance of establishing selective recovery processes for strategic resources. Among the materials recycled and recovered, glass holds the largest share, comprising about 60% of the total amounts during the 2029 to 2050 period. This is likely attributable to the high mass proportion of glass used in solar PV modules (59.5% of the total module mass) and its impressive recycling yield (98%). A similar explanation applies to the recycling and recovery of aluminum, which makes up 14.7% of the total mass of the module and boasts a 100% recycling yield.

The dual-axis representation underscores that while landfilling persists, the majority of EoL materials are projected to be recovered, reflecting both regulatory compliance and advancements in recycling technologies. This trend supports the notion that solar PV recycling can be a reliable and scalable solution to prevent environmental leakage and recover critical materials. Notably, the data analysis also highlights several key insights: a decline in recovery volumes between 2038 and 2044, likely due to lower installation rates in earlier years; the need for adaptable waste management infrastructure capable of scaling up during peak years such as 2036, 2049, and 2050; and significant opportunities to reduce landfill reliance by improving the recovery of complex or multi-layered materials, including encapsulants and plastics.

Furthermore, it is worth noting that some materials, like magnesium and other metals, are not reflected in the recycling and recovery columns but have a minimal presence in the landfill data. This situation results from the low recycling yields of these metals or the assumption that other metals are not being recycled. Although long-term projections are subject to uncertainties, especially regarding regulatory evolution, technological shifts, and material substitution, the trends strongly support increased investment in high-throughput, modular recycling technologies.

Over the life cycle of solar PV modules, the manufacturing process is the main cause of abiotic depletion potential (or resource use, metal, and mineral), particularly due to the large amounts of glass and aluminum consumed in manufacturing the modules, as well as copper and silver consumed in manufacturing the cells [57]. Therefore, recycling and recovering materials from decommissioned solar PV modules will help reduce the need for virgin materials in similar modules in the future. At the same time, other environmental impacts of the upstream processes (such as extracting and processing virgin materials and manufacturing sub-components) may also be reduced through the use of recovered materials in recycled modules.

The solar PV sector requires some hazardous substances, such as lead. The Directive on the Restriction of Hazardous Substances in Electrical and Electronic Equipment (RoHS) limits the use of lead to less than 0.1% by weight in homogeneous materials for EEE [53]. Lead is mainly used for soldering and accounts for 0.01% of solar PV material composition, which is below the RoHS requirement. However, it is crucial to recover and recycle this substance to prevent any risk to human health and the environment. This is even more important as emerging solar PV cells are based on perovskite material, which contains lead. Further studies should be conducted to limit the use of lead in solar PV modules, as well as to recycle lead when the modules reach their end of life. In summary, Figure 4 reinforces the urgency of developing a resilient PV waste management system that prioritizes recovery, adapts to cyclical waste flows, and aligns with circular economy principles. Recycling remains not only an environmental imperative but also a strategic opportunity for securing material supply chains and reducing reliance on virgin resource extraction.

4. Conclusions

This study provides a comprehensive assessment of projected solar PV waste in Italy, focusing on mono-crystalline silicon (c-Si) technologies, which dominate the national PV market. By combining historical installation data with advanced estimation models, we forecast waste quantities, material composition, and recovery potential through 2050. The results offer detailed insights into the economic market value of recoverable PV materials and highlight the structural characteristics of c-Si modules as a basis for targeted and efficient recycling strategies.

Between 2030 and 2050, Italy is projected to generate approximately 4.52 million tonnes of PV waste. Among the materials, glass and aluminum are the most significant, accounting for 2704.9 kt and 762.1 kt, respectively. Although silver waste represents a small fraction (0.9 kt), its high economic value and critical raw material status make it a strategic priority for recovery. The peak in projected landfill waste in 2036 (174.6 kt) and the subsequent recovery volumes in 2049 and 2050 (571.0 kt and 604.7 kt, respectively) underline the urgent need for scalable, efficient recycling infrastructure and adaptive policy frameworks at the national level.

The key novelty of this work lies in its quantitative integration of material-specific data with end-of-life (EoL) trajectories, filling a critical gap in Italy’s and Europe’s PV waste planning. By incorporating active and proposed regulations into our modeling, we offer projections that are not only data-driven but also policy-relevant. The analyses aim to establish a realistic, forward-looking vision of Italy’s PV waste challenges and opportunities. To summarize, the main contributions of this study are as follows:

- Projections of EoL crystalline silicon PV waste volumes and associated material quantities by 2050;

- Estimations of the economic value share of recyclable materials based on recovery potential

- A breakdown of the expected composition of EoL PV waste to inform waste treatment strategies.

The findings may open a new perspective for PV plant operators, policymakers, and the recycling industry, providing clearer guidance for the development of sustainable and efficient solar waste management strategies. Notably, our analysis draws the following conclusions:

- Recycling will be vital to prevent valuable materials from ending up in landfills and to reintegrate resources into the production cycle. These insights support the creation of circular economy models specific to the solar industry and encourage investment in dedicated recycling facilities and policies;

- Future research should address factors such as unexpected system failures or natural disasters, which can accelerate or delay decommissioning and influence waste management timelines;

- It is essential to account for technological advancements, such as perovskite–silicon tandem modules, that may significantly alter the material profile and recovery potential of PV waste in the coming decades.

Additionally, the possibility of second-life usage or export of used PV panels to emerging markets could delay waste generation in Italy while shifting environmental and regulatory challenges abroad. These alternative EoL routes should be considered in future models to ensure accurate infrastructure planning and international policy coherence.

Author Contributions

Conceptualization, S.K., F.N. and A.L; methodology, S.K., L.Q.L., F.N. and A.L.; software, S.K., L.Q.L. and M.C.; validation, S.K., L.Q.L. and F.N.; formal analysis, S.K., L.Q.L. and F.N.; investigation, S.K., F.N. and A.L.; resources, S.K.; data curation, S.K. and L.Q.L.; writing—original draft preparation, S.K.; writing—review and editing, S.K. and F.N.; visualization, S.K.; supervision, S.K., F.N., A.L. and M.C.; project administration, S.K.; funding acquisition, S.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this article can be obtained from the corresponding authors upon request.

Acknowledgments

The authors would like to acknowledge the support provided by the SECA Laboratory for Energy Sustainability and Control for the technical facilities and assistance throughout the research. Special thanks are given to Eng. Giovanni Terranova and Georgia Whitehouse from Bluefield Group (https://thebluefieldgroup.com) for their valuable insights and support.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| PV | Photovoltaic |

| IRENA | International Renewable Energy Agency |

| EoL | End of Life |

| EU | European Union |

| NECP | National Energy and Climate Plan |

| WEEE | Waste Electrical and Electronic Equipment |

| GSE | Gestore dei Servizi Energetici |

| EPIA | European Photovoltaic Industry Association |

References

- Wang, C.; Liu, J.; Lu, B.; Zhang, Y.; Ma, Z. Stiffness degradation and mechanical behavior of microfiber-modified high-toughness recycled aggregate concrete under constant load cycling. Eng. Fract. Mech. 2024, 312, 110608. [Google Scholar] [CrossRef]

- Ma, Z.; Wang, B.; Zhang, Z.; Zhang, Y.; Wang, C. New insights into the effects of silicate modulus, alkali content and modification on multi-properties of recycled brick powder-based geopolymer. J. Build. Eng. 2024, 97, 110989. [Google Scholar] [CrossRef]

- Sundaram, S.; Benson, D.; Mallick, T.K. Potential Environmental Impacts from Solar Energy Technologies. Sol. Photovolt. Technol. Prod. 2016, 23–45. [Google Scholar] [CrossRef]

- Pv-Magazine. Solar Module Manufacturing Capacity Could Exceed 1.5 TW by 2035, Says IEA. Available online: https://www.pv-magazine.com/2024/10/30/solar-module-manufacturing-capacity-could-exceed-1-5-tw-by-2035-says-iea (accessed on 24 April 2025).

- Mao, D.; Yang, S.; Ma, L.; Ma, W.; Yu, Z.; Xi, F.; Yu, J. Overview of life cycle assessment of recycling end-of-life photovoltaic panels: A case study of crystalline silicon photovoltaic panels. J. Clean. Prod. 2024, 434, 140320. [Google Scholar] [CrossRef]

- Montana, F.; Cellura, M.; Di Silvestre, M.L.; Longo, S.; Luu, L.Q.; Riva Sanseverino, E.; Sciumè, G. Assessing Critical Raw Materials and Their Supply Risk in Energy Technologies—A Literature Review. Energies 2025, 18, 86. [Google Scholar] [CrossRef]

- Riva Sanseverino, E.; Luu, L.Q. Critical Raw Materials and Supply Chain Disruption in the Energy Transition. Energies 2022, 15, 5992. [Google Scholar] [CrossRef]

- IEA-PVPS. Snapshot of Global PV Markets 2024. Available online: https://iea-pvps.org/snapshot-reports/snapshot-2024 (accessed on 24 April 2025).

- Pv-Magazine. Italy Installed 6.8 GW of Solar in 2024. Available online: https://www.pv-magazine.com/2025/02/20/italy-adds-6-8-gw-of-solar-in-2024/ (accessed on 24 April 2025).

- Statista. Cumulative Solar Photovoltaic Capacity in the European Union in 2023, by Country. Available online: https://www.statista.com/statistics/857773/connected-and-cumulated-solar-pv-capacity-in-the-european-union-eu/#statisticContainer (accessed on 24 April 2025).

- Bošnjaković, M.; Galović, M.; Kuprešak, J.; Bošnjaković, T. The End of Life of PV Systems: Is Europe Ready for It? Sustainability 2023, 15, 16466. [Google Scholar] [CrossRef]

- IEA-PVPS. Advances in Photovoltaic Module Recycling Literature Review and Update to Empirical Life Cycle Inventory Data and Patent Review. Available online: https://iea-pvps.org/key-topics/advances-in-module-recycling-literature-review-and-update-to-empirical-lci-data-and-patent-review (accessed on 24 April 2025).

- European Commission. A new Circular Economy Action Plan: For a Cleaner and More Competitive Europe. Brussels: European Union. Available online: https://ec.europa.eu/environment/strategy/circular-economy-action-plan_en (accessed on 24 April 2025).

- Nain, P.; Anctil, A. End-of-life solar photovoltaic waste management: A comparison as per European Union and United States regulatory approaches. Resour. Conserv. Recycl. Adv. 2024, 21, 200212. [Google Scholar] [CrossRef]

- Adiansyah, J.S.; Agusdinata, D.B.; Putra, A.P. Environmental impacts of solar PV energy systems for small-island communities in Indonesia: A life cycle assessment approach. Energy Sustain. Dev. 2025, 85, 101651. [Google Scholar] [CrossRef]

- Daniela-Abigail, H.-L.; Vega-De-Lille, M.I.; Sacramento-Rivero, J.C.; Ponce-Caballero, C.; El-Mekaoui, A.; Navarro-Pineda, F. Life cycle assessment of photovoltaic panels including transportation and two end-of-life scenarios: Shaping a sustainable future for renewable energy. Renew. Energy Focus 2024, 51, 100649. [Google Scholar] [CrossRef]

- de Wild, P.; de Wild-Scholten, M.; Goudswaard, I. Life cycle assessment of photovoltaic module backsheets. Prog. Photovolt. Res. Appl. 2025, 33, 27–39. [Google Scholar] [CrossRef]

- European Commission. The Future of European Competitiveness. Available online: https://commission.europa.eu/document/download/ec1409c1-d4b4-4882-8bdd-3519f86bbb92_en?filename=The%20future%20of%20European%20competitiveness_%20In-depth%20analysis%20and%20recommendations_0.pdf (accessed on 24 April 2025).

- IEA. Energy System of Italy. Available online: https://www.iea.org/countries/italy (accessed on 24 April 2025).

- Pv-Magazine. Italy Adds 3.34 GW of New Solar in H1. Available online: https://www.pv-magazine.com/2024/08/16/italy-adds-3-34-gw-of-new-solar-in-h1 (accessed on 24 April 2025).

- Gestore dei Servizi Energetici (GSE). Document Report. Available online: www.gse.it/documenti_site/Documenti%20GSE/Rapporti%20statistici/Solare%20Fotovoltaico%20-%20Rapporto%20Statistico%202023.pdf (accessed on 24 April 2025).

- Statista. Annual Cumulative Installed Capacity of Photovoltaic (PV) Systems in Italy from 2012 to 2023. Available online: https://www.statista.com/statistics/803279/annual-cumulative-installed-capacity-of-pv-systems-in-italy (accessed on 24 April 2025).

- Gestore dei Servizi Energetici (GSE). Solare Fotovoltaico Rapporto Statistico 2021. Available online: https://www.gse.it/documenti_site/Documenti%20GSE/Rapporti%20statistici/Solare%20Fotovoltaico%20-%20Rapporto%20Statistico%202021.pdf (accessed on 24 April 2025).

- Gestore dei Servizi Energetici (GSE). Solare Fotovoltaico Rapporto Statistico 2011. Available online: https://www.gse.it/documenti_site/Documenti%20GSE/Rapporti%20statistici/Solare%20Fotovoltaico%20Rapporto%20Statistico%202011.pdf (accessed on 24 April 2025).

- Gestore dei Servizi Energetici (GSE). Solare Fotovoltaico Rapporto Statistico 2020. Available online: https://www.gse.it/documenti_site/Documenti%20GSE/Rapporti%20statistici/Solare%20Fotovoltaico%20-%20Rapporto%20Statistico%20GSE%202020.pdf (accessed on 24 April 2025).

- Gestore dei Servizi Energetici (GSE). Solare Fotovoltaico Rapporto Statistico 2022. Available online: https://www.gse.it/documenti_site/Documenti%20GSE/Rapporti%20statistici/GSE%20-%20Solare%20Fotovoltaico%20-%20Rapporto%20Statistico%202022.pdf (accessed on 24 April 2025).

- Gestore dei Servizi Energetici (GSE). Solare Fotovoltaico Rapporto Statistico 2019. Available online: https://www.gse.it/documenti_site/Documenti%20GSE/Rapporti%20statistici/Solare%20Fotovoltaico%20-%20Rapporto%20Statistico%202019.pdf (accessed on 24 April 2025).

- Gestore dei Servizi Energetici (GSE). Solare Fotovoltaico Rapporto Statistico 2018. Available online: https://www.gse.it/documenti_site/Documenti%20GSE/Rapporti%20statistici/Solare%20Fotovoltaico%20-%20Rapporto%20Statistico%202018.pdf (accessed on 24 April 2025).

- Gestore dei Servizi Energetici (GSE). Solare Fotovoltaico Rapporto Statistico 2017. Available online: https://www.gse.it/documenti_site/Documenti%20GSE/Rapporti%20statistici/Solare%20Fotovoltaico%20-%20Rapporto%20Statistico%202017.pdf (accessed on 24 April 2025).

- Gestore dei Servizi Energetici (GSE). Solare Fotovoltaico Rapporto Statistico 2016. Available online: https://www.gse.it/documenti_site/Documenti%20GSE/Rapporti%20statistici/Solare%20Fotovoltaico%20-%20Rapporto%20Statistico%202016.PDF (accessed on 24 April 2025).

- Gestore dei Servizi Energetici (GSE). Solare Fotovoltaico Rapporto Statistico 2015. Available online: https://www.gse.it/documenti_site/Documenti%20GSE/Rapporti%20statistici/Solare%20Fotovoltaico%20-%20Rapporto%20Statistico%202015.pdf (accessed on 24 April 2025).

- Gestore dei Servizi Energetici (GSE). Solare Fotovoltaico Rapporto statistico 2013. Available online: https://www.gse.it/documenti_site/Documenti%20GSE/Rapporti%20statistici/Il%20Solare%20fotovoltaico%202013.pdf (accessed on 24 April 2025).

- Gestore dei Servizi Energetici (GSE). Solare Fotovoltaico Rapporto Statistico 2014. Available online: https://www.gse.it/documenti_site/Documenti%20GSE/Rapporti%20statistici/Il%20Solare%20fotovoltaico%202014.pdf (accessed on 24 April 2025).

- Gestore dei Servizi Energetici (GSE). Solare Fotovoltaico Rapporto Statistico 2010. Available online: https://www.gse.it/documenti_site/Documenti%20GSE/Rapporti%20statistici/Solare%20fotovoltaico%20-%20Rapporto%20Statistico%202010.pdf (accessed on 24 April 2025).

- Gestore dei Servizi Energetici (GSE). Solare Fotovoltaico Rapporto Statistico 2012. Available online: https://www.gse.it/documenti_site/Documenti%20GSE/Rapporti%20statistici/Il%20Solare%20fotovoltaico%202012%20-%20web%20def.pdf (accessed on 24 April 2025).

- Gestore dei Servizi Energetici (GSE). Solare Fotovoltaico Rapporto Statistico 2008. Available online: https://www.gse.it/documenti_site/Documenti%20GSE/Rapporti%20statistici/IL%20fotovoltaico-2008.pdf (accessed on 24 April 2025).

- Gestore dei Servizi Energetici (GSE). Solare Fotovoltaico Rapporto Statistico 2009. Available online: https://www.gse.it/documenti_site/Documenti%20GSE/Rapporti%20statistici/Il-Solare-fotovoltaico-2009.pdf (accessed on 24 April 2025).

- Domínguez, A.; Geyer, R. Photovoltaic waste assessment of major photovoltaic installations in the United States of America. Renew. Energy 2019, 133, 1188–1200. [Google Scholar] [CrossRef]

- Duflou, J.R.; Peeters, J.R.; Altamirano, D.; Bracquene, E.; Dewulf, W. Demanufacturing photovoltaic panels: Comparison of end-of-life treatment strategies for improved resource recovery. CIRP Ann. 2018, 67, 29–32. [Google Scholar] [CrossRef]

- Chen, P.-H.; Chen, W.-S.; Lee, C.-H.; Wu, J.-Y. Comprehensive Review of Crystalline Silicon Solar Panel Recycling: From Historical Context to Advanced Techniques. Sustainability 2024, 16, 60. [Google Scholar] [CrossRef]

- Tan, J.; Jia, S.; Ramakrishna, S. End-of-Life Photovoltaic Modules. Energies 2022, 15, 5113. [Google Scholar] [CrossRef]

- Sica, D.; Malandrino, O.; Supino, S.; Testa, M.; Lucchetti, M.C. Management of end-of-life photovoltaic panels as a step towards a circular economy. Renew. Sustain. Energy Rev. 2018, 82, 2934–2945. [Google Scholar] [CrossRef]

- Dheeraj, S.; Chitra; Sushil, K. Recovery and analysis of valuable materials from a discarded crystalline silicon solar module. Sol. Energy Mater. Sol. Cells 2022, 246, 111908. [Google Scholar] [CrossRef]

- Granata, G.; Altimari, P.; Pagnanelli, F.; De Greef, J. Recycling of solar photovoltaic panels: Techno-economic assessment in waste management perspective. J. Clean. Prod. 2022, 363, 132384. [Google Scholar] [CrossRef]

- Farrell, C.C.; Osman, A.I.; Doherty, R.; Saad, M.; Zhang, X.; Murphy, A.; Harrison, J.; Vennard, A.S.M.; Kumaravel, V.; Al-Muhtaseb, A.H.; et al. Technical challenges and opportunities in realising a circular economy for waste photovoltaic modules. Renew. Sustain. Energy Rev. 2020, 128, 109911. [Google Scholar] [CrossRef]

- Mahmoudi, S.; Huda, N.; Alavi, Z.; Islam, M.T.; Behnia, M. End-of-life photovoltaic modules: A systematic quantitative literature review. Resour. Conserv. Recycl. 2019, 146, 1–16. [Google Scholar] [CrossRef]

- Mahmoudi, S.; Huda, N.; Behnia, M. Critical assessment of renewable energy waste generation in OECD countries: Decommissioned PV panels. Resour. Conserv. Recycl. 2021, 164, 105145. [Google Scholar] [CrossRef]

- Domínguez, A.; Geyer, R. Photovoltaic waste assessment in Mexico. Resour. Conserv. Recycl. 2017, 127, 29–41. [Google Scholar] [CrossRef]

- Corcelli, F.; Ripa, M.; Leccisi, E.; Cigolotti, V.; Fiandra, V.; Graditi, G.; Ulgiati, S. Sustainable urban electricity supply chain–Indicators of material recovery and energy savings from crystalline silicon photovoltaic panels end-of-life. Ecol. Indic. 2018, 94, 37–51. [Google Scholar] [CrossRef]

- Latunussa, C.E.; Ardente, F.; Blengini, G.A.; Mancini, L. Life Cycle Assessment of an innovative recycling process for crystalline silicon photovoltaic panels. Sol. Energy Mater. Sol. cells 2016, 156, 101–111. [Google Scholar] [CrossRef]

- Bloomberg. Available online: https://www.bloomberg.com/europe (accessed on 24 April 2025).

- Trading Economics. Available online: https://tradingeconomics.com (accessed on 24 April 2025).

- European Union. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:02011L0065-20200301 (accessed on 24 April 2025).

- Paiano, A. Photovoltaic waste assessment in Italy. Renew. Sustain. Energy Rev. 2015, 41, 99–112. [Google Scholar] [CrossRef]

- ENEA (National Agency for New Technologies). Energy and Sustainable Economic Development. Technologies for the Recycling of Photovoltaic panels: Recovery of Silicon, Glass and Precious Metals. Available online: https://www.media.enea.it/comunicati-e-news/archivio-anni/anno-2024/ambiente-nuovi-materiali-per-batterie-con-silicio-recuperato-da-pannelli-fotovoltaici.html (accessed on 24 April 2025).

- Ministry of Ecological Transition. National Guidelines for the Management of WEEE from Photovoltaic Modules. Available online: https://www.gse.it/documenti_site/Documenti%20GSE/Servizi%20per%20te/CONTO%20ENERGIA/Regole%20e%20procedure/Istruzioni_operative_RAEE.pdf (accessed on 24 April 2025).

- Cellura, M.; Luu, L.Q.; Guarino, F.; Longo, S. A review on life cycle environmental impacts of emerging solar cells. Sci. Total Environ. 2024, 908, 168019. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).