Blending In Situ Polyurethane-Urea with Different Kinds of Rubber: Performance and Compatibility Aspects

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Cure Characteristics

2.2.2. Mechanical Testing

2.2.3. Scanning Electron Microscopy (SEM) Coupled with Energy Dispersive X-ray Analysis (EDX)

2.2.4. Energy Filtered Transmission Electron Microscopy (EFTEM)

2.2.5. Dynamic Mechanical Analysis

2.2.6. Preparation of Rubber/PUU Blends

3. Results and Discussion

3.1. Curing Study

3.2. Performance of Blends Based on Polar Rubbers

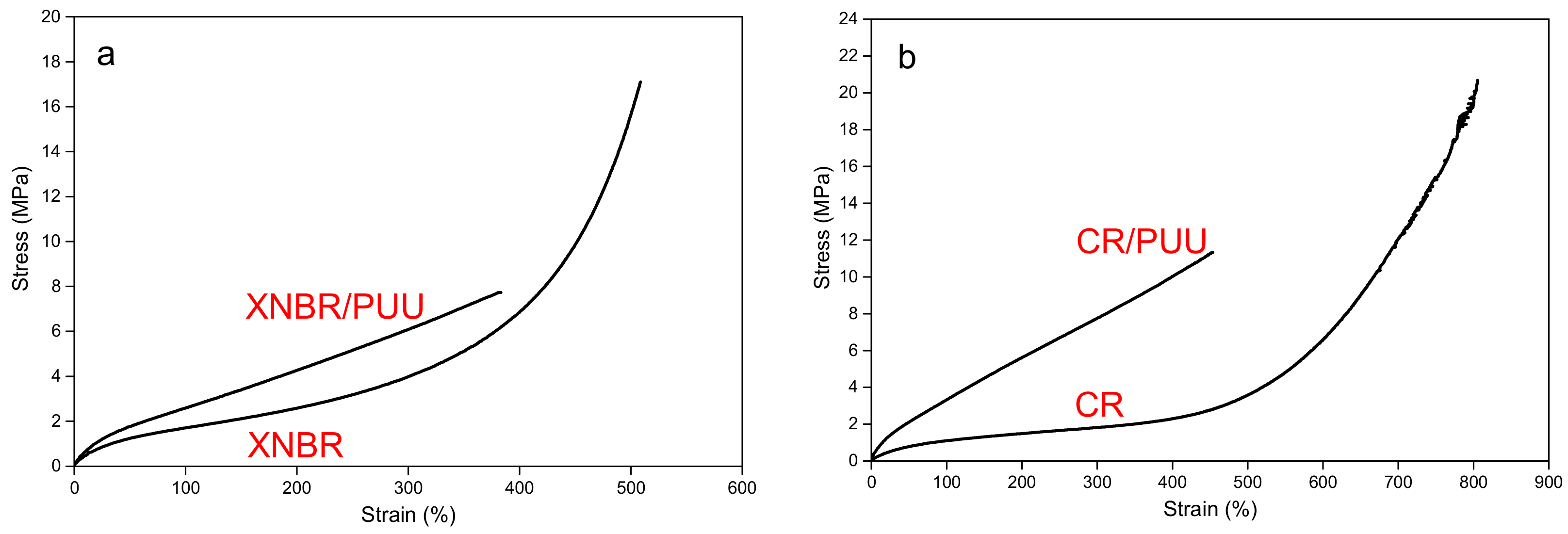

3.2.1. Stress-Strain Response

3.2.2. Dynamic Temperature Sweep Study

3.3. Performance of Blends Based on Nonpolar Rubbers

3.3.1. Stress-Strain Response

3.3.2. Dynamic Temperature Sweep Study

3.4. Evidence of Compatibility in Rubber/PUU Blends

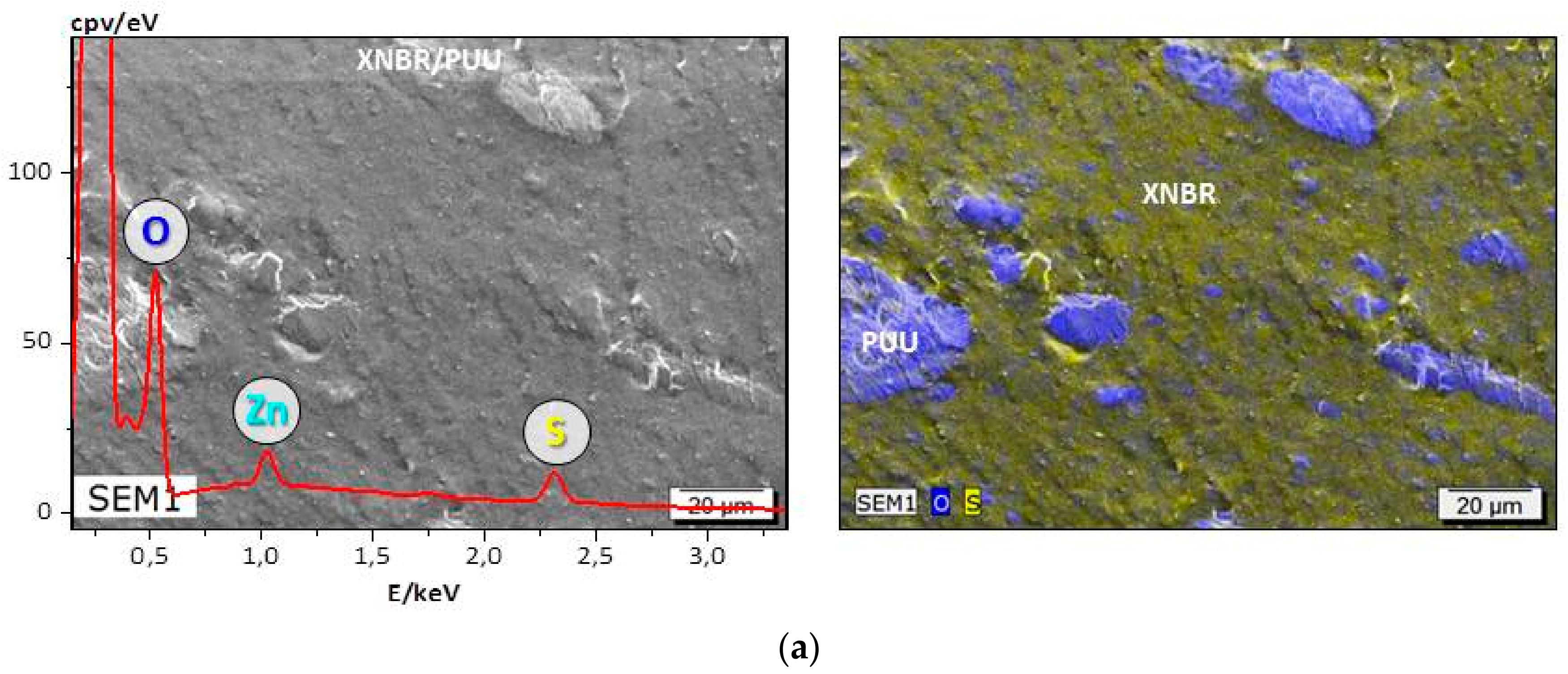

3.4.1. SEM-EDX Analysis

3.4.2. Energy-Filtered Transmission Electron Microscopy

4. Conclusions

5. Patents

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Utracki, L.A. Commercial Polymer Blends, 1st ed.; Utracki, L.A., Ed.; Springer: New York, NY, USA, 1998. [Google Scholar]

- Utracki, L.A. Polymer Blends Handbook; Kluwer Academic Publishers: Dordrecht, The Netherlands, 2002. [Google Scholar]

- Moore, J.W.; Stanitski, C.L.; Jurs, P.C. Chemistry: The Molecular Science, 4th ed.; Cengage Learning: Boston, MA, USA, 2010. [Google Scholar]

- Giancola, G.; Lehman, R.L.; Idol, J.D. Melt processing and domain morphology of PMMA/HDPE polymer blends prepared from powder precursors. Powder Technol. 2012, 218, 18–22. [Google Scholar] [CrossRef]

- Sperling, L.H. Interpenetrating Polymer Networks and Related Materials, 1st ed.; Springer: New York, NY, USA, 1981. [Google Scholar]

- Bonner, J.G.; Hope, P.S. Polymer Blends and Alloys; Springer: Dordrecht, The Netherlands, 1993. [Google Scholar]

- Utraki, L.A. History of commercial polymer alloys and blends (from a perspective of the patent literature). Polym. Eng. Sci. 1995, 35, 2–17. [Google Scholar] [CrossRef]

- Dimitrievski, I.; Susteric, Z.; Marinovic, T. Advances in Polymer Blends and Alloys Technology; Finlayson, K., Ed.; Technomic Publishing Co.: Lancester, UK, 1993; pp. 11–28. [Google Scholar]

- Tang, T.; Hu, C.P.; Ying, S.K.; Zhang, Y.X. Advances in Polymer Blends and Alloys Technology; Finlayson, K., Ed.; Technomic Publishing Co.: Lancester, UK, 1993; pp. 1–10. [Google Scholar]

- Xu, D.; Karger-Kocsis, J. Unlubricated rolling and sliding wear against steel of carbon-black-reinforced and in situ cured polyurethane containing ethylene/propylene/diene rubber compounds. J. Appl. Polym. Sci. 2010, 115, 1651–1662. [Google Scholar] [CrossRef]

- Karger-Kocsis, J.; Felhös, D.; Xu, D. Mechanical and tribological properties of rubber blends composed of HNBR and in situ produced polyurethane. Wear 2010, 268, 464–472. [Google Scholar] [CrossRef]

- Tan, J.H.; Wang, X.P.; Tai, J.J.; Luo, Y.F.; Jia, D.M. Novel blends of acrylonitrile butadiene rubber and polyurethane-silica hybrid networks. Express Polym. Lett. 2012, 6, 588–600. [Google Scholar] [CrossRef]

- Varghese, S.; Gatos, K.G.; Apostolov, A.A.; Karger-Kocsis, J. Morphology and mechanical properties of layered silicate reinforced natural and polyurethane rubber blends produced by latex compounding. J. Appl. Polym. Sci. 2004, 92, 543–551. [Google Scholar] [CrossRef]

- Psarras, G.C.; Gatos, K.G.; Karger-Kocsis, J. Dielectric properties of layered silicate-reinforced natural and polyurethane rubber nanocomposites. J. Appl. Polym. Sci. 2007, 106, 1405–1411. [Google Scholar] [CrossRef]

- Mahmood, N.; Khan, A.U.; Ali, Z.; Khan, M.S.; Haq, A.U.; Stöckelhuber, K.W.; Gohs, U.; Heinrich, G. Preparation and characterization of thermoplastic polyurethane–urea and carboxylated acrylonitrile butadiene rubber blend nanocomposites. J. Appl. Polym. Sci. 2012, 123, 3635–3643. [Google Scholar] [CrossRef]

- Mahmood, N.; Khan, A.U.; Stöckelhuber, K.W.; Das, A.; Jehnichen, D.; Heinrich, G. Carbon Nanotubes-Filled Thermoplastic polyurethane-urea and carboxylated acrylonitrile butadiene rubber blend nanocomposites. J. Appl. Polym. Sci. 2014, 131, 40341. [Google Scholar] [CrossRef]

- Berezkin, Y.; Urick, M. Modern polyurethanes: Overview of structure property relationship. ACS Symp. Ser. 2013, 1148, 65–81. [Google Scholar]

- Oertal, G. Polyurethane Handbook; Hanser Publishers: New York, NY, USA, 1994. [Google Scholar]

- Petrovic, Z.S. Handbook of Polymer Synthesis, 2nd ed.; Kricheldorf, H.R., Nuyken, O., Swift, G., Eds.; Marcel Dekker, Inc.: New York, NY, USA, 2005. [Google Scholar]

- Woods, G. The ICI Polyurethane Book, 2nd ed.; John Wiley & Sons: Hoboken, NJ, USA, 1987. [Google Scholar]

- Noshay, A.; McGrath, J.E. Block Copolymers: Overview and Critical Survey; Academic Press: New York, NY, USA, 1977. [Google Scholar]

- Prisacariu, C. Polyurethane Elastomers: From Morphology to Mechanical Aspects; Springer: New York, NY, USA, 2011. [Google Scholar]

- Tahir, M.; Stöckelhuber, K.W.; Mahmood, N.; Komber, H.; Heinrich, G. Reactive blending of nitrile butadiene rubber and in situ synthesized thermoplastic polyurethane-urea: Novel preparation method and characterization. Macromol. Mater. Eng. 2015, 300, 242–250. [Google Scholar] [CrossRef]

- Tahir, M.; Stöckelhuber, K.W.; Mahmood, N.; Komber, H.; Formanek, P.; Wießner, S.; Heinrich, G. Highly reinforced blends of nitrile butadiene rubber and in-situ synthesized polyurethane-urea. Eur. Polym. J. 2015, 73, 75–87. [Google Scholar] [CrossRef]

- Pike, M.; Watson, W.F. Mastication of rubber, I. Mechanism of plasticizing by cold mastication. J. Polym. Sci. 1952, 9, 229–251. [Google Scholar] [CrossRef]

- Whelan, T. Polymer Technology Dictionary; Chapman & Hall: London, UK, 1994. [Google Scholar]

- Dimier, F.; Vergnes, B.; Vincent, M. Relationships between mastication conditions and rheological behavior of a natural rubber. Rheol. Acta 2004, 43, 196–202. [Google Scholar] [CrossRef]

- Tanaka, Y. Recent advances in structural characterization of elastomers. Rubber Chem. Technol. 1991, 64, 325. [Google Scholar] [CrossRef]

- Chattaraj, P.P.; Mukhopadhyay, R.; Tripathy, D.K. Effect of high crystalline trans-polyoctenylene (TOR) on different cure systems of NR compounds. J. Elastom. Plast 1994, 26, 74–92. [Google Scholar] [CrossRef]

- Ibarra, L.; Marcos-Fernández, A.; Alzorriz, M. Mechanistic approach to the curing of carboxylated nitrile rubber (XNBR) by zinc peroxide/zinc oxide. Polymer 2002, 43, 1649–1655. [Google Scholar] [CrossRef]

- Hird, B.; Eisenberg, A. Sizes and stabilities of multiplets and clusters in carboxylated and sulfonated styrene ionomers. Macromolecules 1992, 25, 6466–6474. [Google Scholar] [CrossRef]

- Brown, H.P. Crosslinking reactions of carboxylic elastomers. Rubber Chem. Technol. 1963, 36, 931–962. [Google Scholar] [CrossRef]

- Chakraborty, S.K.; Bhowmick, A.K.; De, S.K. Structure-property relations of carboxylated nitrile rubbers. J. Appl. Polym. Sci. 1981, 26, 4011–4020. [Google Scholar] [CrossRef]

- Zakharov, N.D. Vulcanization of carboxylic rubbers. Rubber Chem. Technol. 1963, 36, 568–574. [Google Scholar] [CrossRef]

- Basu, D.; Das, A.; Stöckelhuber, K.W.; Jehnichen, D.; Formanek, P.; Sarlin, E.; Vuorinen, J.; Heinrich, G. Evidence for an in situ developed polymer phase in ionic elastomers. Macromolecules 2014, 47, 3436–3450. [Google Scholar] [CrossRef]

- Sorenson, W.R. Reaction of an Isocyanate and a Carboxylic Acid in Dimethyl Sulfoxide. J. Org. Chem. 1959, 24, 978–980. [Google Scholar] [CrossRef]

- Franta, I. Elastomers and Rubber Compounding Materials; Elsevier: Prague, Czechoslovakia, 1989. [Google Scholar]

- Karak, N. Fundamentals of Polymers: Raw Materials to Finish Products; PHI Publishers: Dehli, India, 2009. [Google Scholar]

- Maynard, J.T.; Mochel, W.E. The structure of neoprene. VI. crystallization. J. Polm. Sci. A Polym. Chem. 1954, XIII, 235–250. [Google Scholar]

- Erman, B.; Mark, J.E.; Roland, C.M. The Science and Technology of Rubber; Academic Press: Oxford, UK, 2013. [Google Scholar]

- Mandal, U.K.; Tripathy, D.K.; De, S.K. Effect of carbon black fillers on dynamic mechanical properties of ionic elastomer based on carboxylated nitrile rubber. Plast Rubber Comp. Proc. Appl. 1995, 24, 19–25. [Google Scholar]

- Toki, S.; Fujimaki, T.; Okuyama, M. Strain-induced crystallization of natural rubber as detected real-time by wide-angle X-ray diffraction technique. Polymer 2000, 41, 5423–5429. [Google Scholar] [CrossRef]

- Brüning, K.; Schneider, K.; Roth, S.V.; Heinrich, G. Kinetics of strain-induced crystallization in natural rubber studied by WAXD: Dynamic and impact tensile experiments. Macromolecules 2012, 45, 7914–7919. [Google Scholar] [CrossRef]

- Brüning, K.; Schneider, K.; Roth, S.V.; Heinrich, G. Strain-induced crystallization around a crack tip in natural rubber under dynamic load. Polymer 2013, 54, 6200–6205. [Google Scholar] [CrossRef]

- Stricher, A.M.; Rinaldi, R.G.; Barres, C.; Ganachaud, F.; Chazeau, L. How I met your elastomers: From network topology to mechanical behaviours of conventional silicone materials. RSC Adv. 2015, 5, 53713–53725. [Google Scholar] [CrossRef]

- Mattia, J.; Painter, P. A Comparison of hydrogen bonding and order in a polyurethane and Poly(urethane−urea) and their blends with Poly(ethylene glycol). Macromolecules 2007, 40, 1546–1554. [Google Scholar] [CrossRef]

- Coleman, M.M.; Lee, K.L.; Skrovanek, D.J.; Painter, P.C. Hydrogen bonding in polymers. 4. Infrared temperature studies of a simple polyurethane. Macromolecules 1986, 19, 2149–2157. [Google Scholar] [CrossRef]

- Coleman, M.M.; Sobkowiak, M.; Pehlert, G.J.; Painter, P.C. Infrared temperature studies of a simple polyuria. Macromol. Chem. Phys. 1997, 198, 117–136. [Google Scholar] [CrossRef]

- Coleman, M.M.; Skrovanek, D.J.; Hu, J.; Painter, P.C. Hydrogen bonding in polymer blends. 1. FTIR studies of urethane-ether blends. Macromolecules 1988, 21, 59–65. [Google Scholar] [CrossRef]

- Yilgör, E.; Burgaz, E.; Yurtsever, E.; Yilgör, I. Comparison of hydrogen bonding in polydimethylsiloxane and polyether based urethane and urea copolymers. Polymer 2000, 41, 849–857. [Google Scholar] [CrossRef]

| Ingredients | Rubbers | Rubber/PUU Blends | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| NR | sSBR | XNBR | CR | EPDM | NR/PUU | sSBR/PUU | XNBR/PUU | CR/PUU | EPDM/PUU | |

| Rubber | 100 | 100 | 100 | 100 | 100 | 70 | 70 | 70 | 70 | 70 |

| Premix | - | - | - | - | - | 30 | 30 | 30 | 30 | 30 |

| ZnO | 3 | 3 | 3 | 5 | - | 2.1 | 2.1 | 2.1 | 3.5 | - |

| Stearic Acid | 2 | 2 | 2 | - | - | 1.4 | 1.4 | 1.4 | - | - |

| DPG | 2 | 2 | 2 | - | - | 1.4 | 1.4 | 1.4 | - | - |

| CBS | 1.5 | 1.5 | 1.5 | - | - | 1.1 | 1.1 | 1.1 | - | - |

| Sulfur | 1.5 | 1.5 | 1.5 | - | - | 1.1 | 1.1 | 1.1 | - | - |

| MgO | - | - | - | 4 | - | - | - | - | 2.8 | - |

| Peroxide | - | - | - | - | 3 | - | - | - | - | 2.1 |

| Coagent | - | - | - | - | 2 | - | - | - | - | 1.4 |

| Compound | Young’s Modulus (MPa) | Modulus at 100% Elongation (MPa) | Tensile Strength (MPa) | Elongation at Break (%) |

|---|---|---|---|---|

| NR | 1.33 ± 0.17 | 0.83 ± 0.01 | 14.43 ± 1.20 | 570 ± 8 |

| NR/PUU | 3.30 ± 0.15 | 1.26 ± 0.01 | 11.04 ± 0.09 | 595 ± 4 |

| XNBR | 4.79 ± 0.12 | 1.71 ± 0.01 | 20.64 ± 5.01 | 525 ± 24 |

| XNBR/PUU | 6.81 ± 0.53 | 2.63 ± 0.05 | 7.08 ± 0.08 | 373 ± 14 |

| sSBR | 1.63 ± 0.01 | 0.69 ± 0.01 | 2.48 ± 0.28 | 403 ± 16 |

| sSBR/PUU | 3.89 ± 0.44 | 1.20 ± 0.01 | 2.00 ± 0.03 | 425 ± 10 |

| CR | 2.72 ± 0.10 | 1.10 ± 0.02 | 20.68 ± 2.10 | 805 ± 18 |

| CR/PUU | 8.75 ± 0.25 | 3.31 ± 0.03 | 11.72 ± 0.54 | 470 ± 23 |

| EPDM | 2.43 ± 0.17 | 1.08 ± 0.01 | 1.65 ± 0.10 | 205 ± 18 |

| EPDM/PUU | 5.12 ± 0.10 | 2.16 ± 0.02 | 3.16 ± 0.10 | 154 ± 7 |

| Compound | Glass Transition Temperature of Rubber Tg,rubber (°C) | tan δ Peak Height at Tg,rubber | Storage Modulus at 25 °C (MPa) |

|---|---|---|---|

| NR | −47 | 2.7 | 1.7 |

| NR/PUU | −46 | 1.6 | 3.6 |

| XNBR | −1 | 1.2 | 6.5 |

| XNBR/PUU | −4 | 0.9 | 10.2 |

| sSBR | −3 | 2.3 | 1.9 |

| sSBR/PUU | −3 | 1.2 | 4.8 |

| CR | −27 | 2.4 | 2.8 |

| CR/PUU | −27 | 1.1 | 8.0 |

| EPDM | −43 | 1.9 | 3.1 |

| EPDM/PUU | −43 | 1.4 | 6.4 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tahir, M.; Heinrich, G.; Mahmood, N.; Boldt, R.; Wießner, S.; Stöckelhuber, K.W. Blending In Situ Polyurethane-Urea with Different Kinds of Rubber: Performance and Compatibility Aspects. Materials 2018, 11, 2175. https://doi.org/10.3390/ma11112175

Tahir M, Heinrich G, Mahmood N, Boldt R, Wießner S, Stöckelhuber KW. Blending In Situ Polyurethane-Urea with Different Kinds of Rubber: Performance and Compatibility Aspects. Materials. 2018; 11(11):2175. https://doi.org/10.3390/ma11112175

Chicago/Turabian StyleTahir, Muhammad, Gert Heinrich, Nasir Mahmood, Regine Boldt, Sven Wießner, and Klaus Werner Stöckelhuber. 2018. "Blending In Situ Polyurethane-Urea with Different Kinds of Rubber: Performance and Compatibility Aspects" Materials 11, no. 11: 2175. https://doi.org/10.3390/ma11112175

APA StyleTahir, M., Heinrich, G., Mahmood, N., Boldt, R., Wießner, S., & Stöckelhuber, K. W. (2018). Blending In Situ Polyurethane-Urea with Different Kinds of Rubber: Performance and Compatibility Aspects. Materials, 11(11), 2175. https://doi.org/10.3390/ma11112175