Enhanced Cycling Stability of LiCuxMn1.95?xSi0.05O4 Cathode Material Obtained by Solid-State Method

Abstract

:1. Introduction

2. Materials and Methods

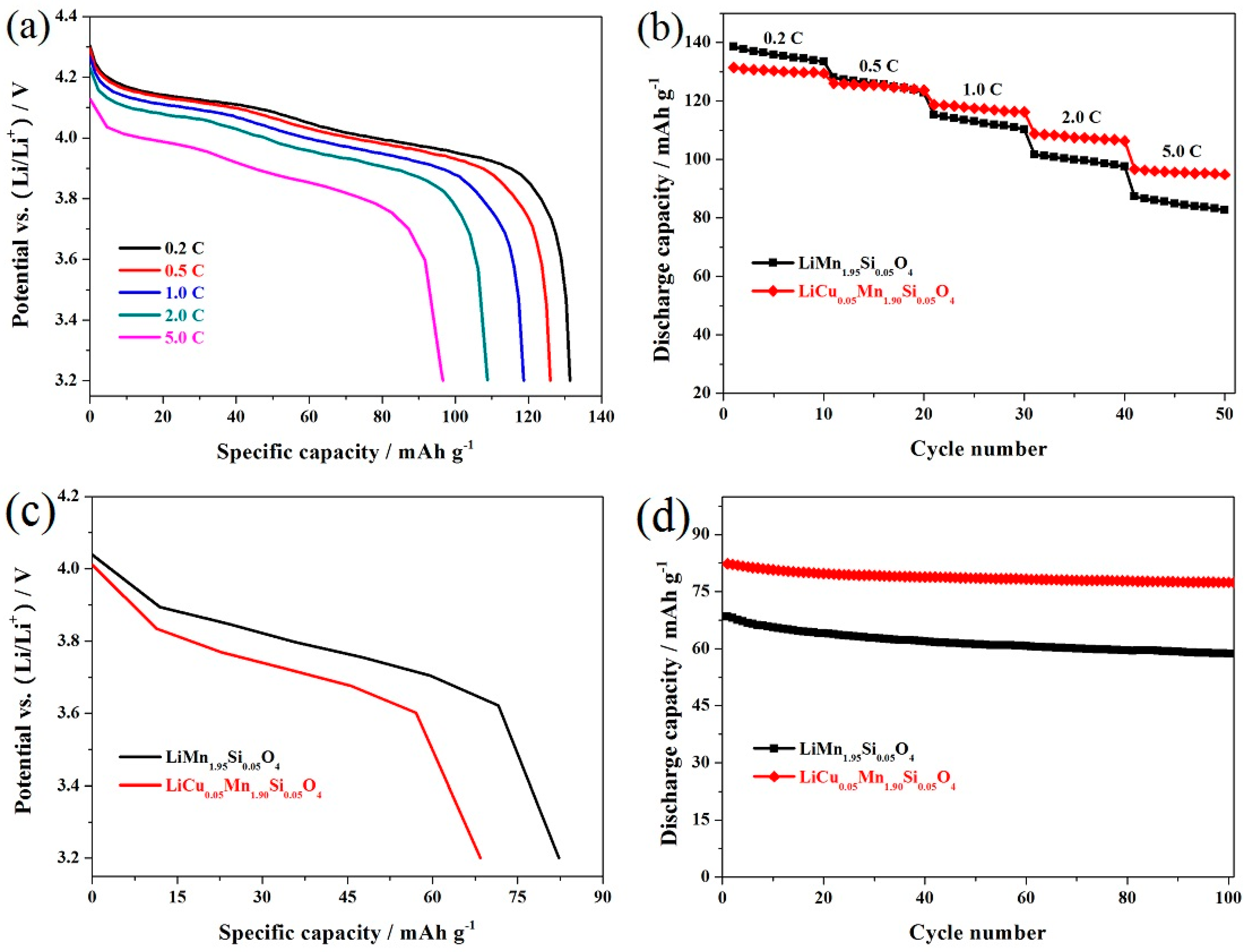

3. Results and Discussion

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Li, W.D.; Song, B.H.; Manthiram, A. High-voltage positive electrode materials for lithium-ion batteries. Chem. Soc. Rev. 2017, 46, 3006–3059. [Google Scholar] [CrossRef] [PubMed]

- Dell’Era, A.; Pasquali, M.; Bauer, E.M.; Vecchio Ciprioti, S.; Scaramuzzo, F.A.; Lupi, C. Synthesis, characterization, and electrochemical behavior of LiMnxFe(1−x)PO4 composites obtained from phenylphosphonate-based organic-inorganic hybrids. Materials 2017, 11, 56. [Google Scholar] [CrossRef] [PubMed]

- Xia, H.; Xia, Q.Y.; Lin, B.H.; Zhu, J.W.; Seo, J.K.; Meng, Y.S. Self-standing porous LiMn2O4 nanowall arrays as promising cathodes for advanced 3D microbatteries and flexible lithium-ion batteries. Nano Energy 2016, 22, 475–482. [Google Scholar] [CrossRef]

- Yoo, K.S.; Kang, Y.H.; Im, K.R.; Kim, C.S. Surface modification of Li(Ni0.6Co0.2Mn0.2)O2 cathode materials by nano-Al2O3 to improve electrochemical performance in lithium-ion batteries. Materials 2017, 10, 1273. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.S.; Zhao, H.Y.; Tan, M.; Hu, Y.Z.; Shu, X.H.; Zhang, M.L.; Chen, B.; Liu, X.Q. Er-doped LiNi0.5Mn1.5O4 cathode material with enhanced cycling stability for lithium-ion batteries. Materials 2017, 10, 859. [Google Scholar] [CrossRef] [PubMed]

- Zhao, H.Y.; Liu, S.S.; Cai, Y.; Wang, Z.W.; Tan, M.; Liu, X.Q. A simple and mass production preferred solid-state procedure to prepare the LiSixMgxMn2−2xO4 (0 ≤ x ≤ 0.10) with enhanced cycling stability and rate capability. J. Alloys Compd. 2016, 671, 304–311. [Google Scholar] [CrossRef]

- Nitta, N.; Wu, F.X.; Lee, J.T.; Yushin, G. Li-ion battery materials: Present and future. Mater. Today 2015, 18, 252–264. [Google Scholar] [CrossRef]

- Yang, S.; Schmidt, D.O.; Khetan, A.; Schrader, F.; Jakobi, S.; Homberger, M.; Noyong, M.; Paulus, A.; Kungl, H.; Eichel, R.A.; et al. Electrochemical and electronic charge transport properties of Ni-doped LiMn2O4 spinel obtained from polyol-mediated synthesis. Materials 2018, 11, 806. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.L.; Li, Z.H.; Yu, S.S.; Xiao, Q.Z.; Lei, G.T.; Ding, Y.H. Carbon-encapsulated LiMn2O4 spheres prepared using a polymer microgel reactor for high-power lithium-ion batteries. J. Power Sources 2016, 301, 376–385. [Google Scholar] [CrossRef]

- Mughal, M.Z.; Amanieu, H.-Y.; Moscatelli, R.; Sebastiani, M. A comparison of microscale techniques for determining fracture toughness of LiMn2O4 particles. Materials 2017, 10, 403. [Google Scholar] [CrossRef] [PubMed]

- Zhao, H.Y.; Liu, S.S.; Wang, Z.W.; Cai, Y.; Tan, M.; Liu, X.Q. Enhanced elevated-temperature performance of LiAlxSi0.05Mg0.05Mn1.90−xO4 (0 ≤ x ≤ 0.08) cathode materials for high-performance lithium-ion batteries. Electrochim. Acta 2016, 199, 18–26. [Google Scholar] [CrossRef]

- Tron, A.; Park, Y.D.; Mun, J.Y. AlF3-coated LiMn2O4 as cathode material for aqueous rechargeable lithium battery with improved cycling stability. J. Power Sources 2016, 325, 360–364. [Google Scholar] [CrossRef]

- Zhang, L.G.; Zhang, Y.R.; Yuan, X.H. Enhanced high-temperature performances of LiMn2O4 cathode by LiMnPO4 coating. Ionics 2014, 21, 37–41. [Google Scholar] [CrossRef]

- Yi, X.; Wang, X.Y.; Ju, B.W.; Wei, Q.L.; Yang, X.K.; Zou, G.S.; Shu, H.B.; Hu, L. Elevated temperature cyclic performance of LiAlxMn2−xO4 microspheres synthesized via co-precipitation route. J. Alloys Compd. 2014, 604, 50–56. [Google Scholar] [CrossRef]

- Prabu, M.; Reddy, M.V.; Selvasekarapandian, S.; Subba Rao, G.V.; Chowdari, B.V.R. (Li, Al)-co-doped spinel, Li(Li0.1Al0.1Mn1.8)O4 as high performance cathode for lithium ion batteries. Electrochim. Acta 2013, 88, 745–755. [Google Scholar] [CrossRef]

- Peng, C.C.; Huang, J.J.; Guo, Y.J.; Li, Q.L.; Bai, H.L.; He, Y.H.; Su, C.W.; Guo, J.M. Electrochemical performance of spinel LiAlxMn2−xO4 prepared rapidly by glucose-assisted solid-state combustion synthesis. Vacuum 2015, 120, 121–126. [Google Scholar] [CrossRef]

- Fang, D.L.; Li, J.C.; Liu, X.; Huang, P.F.; Xu, T.-R.; Qian, M.C.; Zheng, C.H. Synthesis of a Co–Ni doped LiMn2O4 spinel cathode material for high-power Li-ion batteries by a sol-gel mediated solid-state route. J. Alloys Compd. 2015, 640, 82–89. [Google Scholar] [CrossRef]

- Zhang, H.; Xu, Y.L.; Liu, D.; Zhang, X.S.; Zhao, C.J. Structure and performance of dual-doped LiMn2O4 cathode materials prepared via microwave synthesis method. Electrochim. Acta 2014, 125, 225–231. [Google Scholar] [CrossRef]

- Yu, F.D.; Wang, Z.B.; Chen, F.; Wu, J.; Zhang, X.G.; Gu, D.M. Crystal structure and multicomponent effects in Li1+xMn2−x−yAlyO4 cathode materials for Li-ion batteries. J. Power Sources 2014, 262, 104–111. [Google Scholar] [CrossRef]

- Bianchini, M.; Suard, E.; Croguennec, L.; Masquelier, C. Li-rich Li1+xMn2−xO4 spinel electrode materials: An operando neutron diffraction study during Li+ extraction/insertion. J. Phys. Chem. C 2014, 118, 25947–25955. [Google Scholar] [CrossRef]

- Xiang, M.W.; Su, C.W.; Feng, L.L.; Yuan, M.L.; Guo, J.M. Rapid synthesis of high-cycling performance LiMgxMn2−xO4 (x ≤ 0.20) cathode materials by a low-temperature solid-state combustion method. Electrochim. Acta 2014, 125, 524–529. [Google Scholar] [CrossRef]

- Xu, W.Q.; Li, Q.L.; Guo, J.M.; Bai, H.L.; Su, C.W.; Ruan, R.S.; Peng, J.H. Electrochemical evaluation of LiZnxMn2−xO4 (x ≤ 0.10) cathode material synthesized by solution combustion method. Ceram. Int. 2016, 42, 5693–5698. [Google Scholar] [CrossRef]

- Huang, J.J.; Li, Q.L.; Bai, H.L.; Xu, W.Q.; He, Y.H.; Su, C.W.; Peng, J.H.; Guo, J.M. Preparation and electrochemical properties of LiCuxMn2−xO4 (x ≤ 0.10) cathode material by a low-temperature molten-salt combustion method. Int. J. Electrochem. Sci. 2015, 10, 4596–4603. [Google Scholar]

- Zhang, H.; Liu, D.; Zhang, X.S.; Zhao, C.J.; Xu, Y.L. Microwave synthesis of LiMg0.05Mn1.95O4 and electrochemical performance at elevated temperature for lithium-ion batteries. J. Solid State Electrochem. 2014, 18, 569–575. [Google Scholar] [CrossRef]

- Peng, Z.D.; Jiang, Q.L.; Du, K.; Wang, W.G.; Hu, G.R.; Liu, Y.X. Effect of Cr-sources on performance of Li1.05Cr0.04Mn1.96O4 cathode materials prepared by slurry spray drying method. J. Alloys Compd. 2010, 493, 640–644. [Google Scholar] [CrossRef]

- Guo, D.L.; Li, B.; Chang, Z.R.; Tang, H.W.; Xu, X.H.; Chang, K.; Shangguan, E.B.; Yuan, X.Z.; Wang, H.J. Facile synthesis of LiAl0.1Mn1.9O4 as cathode material for lithium ion batteries: Towards rate and cycling capabilities at an elevated temperature. Electrochim. Acta 2014, 134, 338–346. [Google Scholar] [CrossRef]

- Wang, J.L.; Li, Z.H.; Yang, J.; Tang, J.J.; Yu, J.J.; Nie, W.B.; Lei, G.T.; Xiao, Q.Z. Effect of Al-doping on the electrochemical properties of a three-dimensionally porous lithium manganese oxide for lithium-ion batteries. Electrochim. Acta 2012, 75, 115–122. [Google Scholar] [CrossRef]

- Balaji, S.R.K.; Mutharasu, D.; Shanmugan, S.; Subramanian, N.S.; Ramanathan, K. Influence of Sm3+ ion in structural, morphological, and electrochemical properties of LiMn2O4 synthesized by microwave calcination. Ionics 2010, 16, 351–360. [Google Scholar] [CrossRef]

- Iturrondobeitia, A.; Goñi, A.; Palomares, V.; Gil de Muro, I.; Lezama, L.; Rojo, T. Effect of doping LiMn2O4 spinel with a tetravalent species such as Si(iv) versus with a trivalent species such as Ga(iii). Electrochemical, magnetic and ESR study. J. Power Sources 2012, 216, 482–488. [Google Scholar] [CrossRef]

- Wang, M.; Yang, M.; Zhao, X.Y.; Ma, L.Q.; Shen, X.D.; Cao, G.Z. Spinel LiMn2−xSixO4 (x < 1) through Si4+ substitution as a potential cathode material for lithium-ion batteries. Sci. China Mater. 2016, 59, 558–566. [Google Scholar]

- Xiong, L.L.; Xu, Y.L.; Zhang, C.; Zhang, Z.W.; Li, J.B. Electrochemical properties of tetravalent Ti-doped spinel LiMn2O4. J. Solid State Electrochem. 2010, 15, 1263–1269. [Google Scholar] [CrossRef]

- Zhao, H.Y.; Liu, S.S.; Wang, Z.W.; Cai, Y.; Tan, M.; Liu, X.Q. LiSixMn2−xO4 (x ≤ 0.10) cathode materials with improved electrochemical properties prepared via a simple solid-state method for high-performance lithium-ion batteries. Ceram. Int. 2016, 42, 13442–13448. [Google Scholar] [CrossRef]

- Zhao, H.Y.; Liu, X.Q.; Cheng, C.; Li, Q.; Zhang, Z.; Wu, Y.; Chen, B.; Xiong, W.Q. Synthesis and electrochemical characterizations of spinel limn1.94MO4 (M = Mn0.06, Mg0.06, Si0.06, (Mg0.03Si0.03)) compounds as cathode materials for lithium-ion batteries. J. Power Sources 2015, 282, 118–128. [Google Scholar] [CrossRef]

- Xiong, L.L.; Xu, Y.L.; Tao, T.; Goodenough, J.B. Synthesis and electrochemical characterization of multi-cations doped spinel LiMn2O4 used for lithium ion batteries. J. Power Sources 2012, 199, 214–219. [Google Scholar] [CrossRef]

- Zhao, H.Y.; Li, F.; Liu, X.Q.; Cheng, C.; Zhang, Z.; Wu, Y.; Xiong, W.Q.; Chen, B. Effects of equimolar Mg (ii) and Si (iv) co-doping on the electrochemical properties of spinel LiMn2−xMgxSixO4 prepared by citric acid assisted sol-gel method. Electrochim. Acta 2015, 151, 263–269. [Google Scholar] [CrossRef]

- Zhao, H.Y.; Li, F.; Liu, X.Q.; Xiong, W.Q.; Chen, B.; Shao, H.L.; Que, D.Y.; Zhang, Z.; Wu, Y. A simple, low-cost and eco-friendly approach to synthesize single-crystalline LiMn2O4 nanorods with high electrochemical performance for lithium-ion batteries. Electrochim. Acta 2015, 166, 124–133. [Google Scholar] [CrossRef]

- Ding, Y.L.; Xie, J.; Cao, G.S.; Zhu, T.J.; Yu, H.M.; Zhao, X.B. Single-crystalline LiMn2O4 nanotubes synthesized via template-engaged reaction as cathodes for high-power lithium ion batteries. Adv. Funct. Mater. 2011, 21, 348–355. [Google Scholar] [CrossRef]

- de Beeck, J.O.; Labyedh, N.; Sepúlveda, A.; Spampinato, V.; Franquet, A.; Conard, T.; Vereecken, P.M.; Celano, U. Direct imaging and manipulation of ionic diffusion in mixed electronic-ionic conductors. Nanoscale 2018, 10, 12564–12572. [Google Scholar] [CrossRef] [PubMed]

- Balke, N.; Jesse, S.; Morozovska, A.N.; Eliseev, E.; Chung, D.W.; Kim, Y.; Adamczyk, L.; García, R.E.; Dudney, N.; Kalinin, S.V. Nanoscale mapping of ion diffusion in a lithium-ion battery cathode. Nature Nanotechnol. 2010, 5, 749–754. [Google Scholar] [CrossRef] [PubMed]

| Samples | I(311)/I(400) |

|---|---|

| LiMn1.95Si0.05O4 | 0.98 |

| LiCu0.02Mn1.93Si0.05O4 | 1.00 |

| LiCu0.05Mn1.90Si0.05O4 | 1.01 |

| LiCu0.08Mn1.87Si0.05O4 | 1.03 |

| Samples | R2 (Ω cm2) before Cycles | R2 (Ω cm2) after 200 Cycles |

|---|---|---|

| LiMn1.95Si0.05O4 | 93.2 | 158.1 |

| LiCu0.05Mn1.90Si0.05O4 | 70.5 | 116.0 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, H.; Li, F.; Bai, X.; Wu, T.; Wang, Z.; Li, Y.; Su, J. Enhanced Cycling Stability of LiCuxMn1.95?xSi0.05O4 Cathode Material Obtained by Solid-State Method. Materials 2018, 11, 1302. https://doi.org/10.3390/ma11081302

Zhao H, Li F, Bai X, Wu T, Wang Z, Li Y, Su J. Enhanced Cycling Stability of LiCuxMn1.95?xSi0.05O4 Cathode Material Obtained by Solid-State Method. Materials. 2018; 11(8):1302. https://doi.org/10.3390/ma11081302

Chicago/Turabian StyleZhao, Hongyuan, Fang Li, Xiuzhi Bai, Tingting Wu, Zhankui Wang, Yongfeng Li, and Jianxiu Su. 2018. "Enhanced Cycling Stability of LiCuxMn1.95?xSi0.05O4 Cathode Material Obtained by Solid-State Method" Materials 11, no. 8: 1302. https://doi.org/10.3390/ma11081302

APA StyleZhao, H., Li, F., Bai, X., Wu, T., Wang, Z., Li, Y., & Su, J. (2018). Enhanced Cycling Stability of LiCuxMn1.95?xSi0.05O4 Cathode Material Obtained by Solid-State Method. Materials, 11(8), 1302. https://doi.org/10.3390/ma11081302