Thermal and Mechanical Interfacial Behaviors of Graphene Oxide-Reinforced Epoxy Composites Cured by Thermal Latent Catalyst

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Synthesis of GO and HMTA-GO

2.3. Synthesis of Epoxy Composites

2.4. Characterization

3. Results

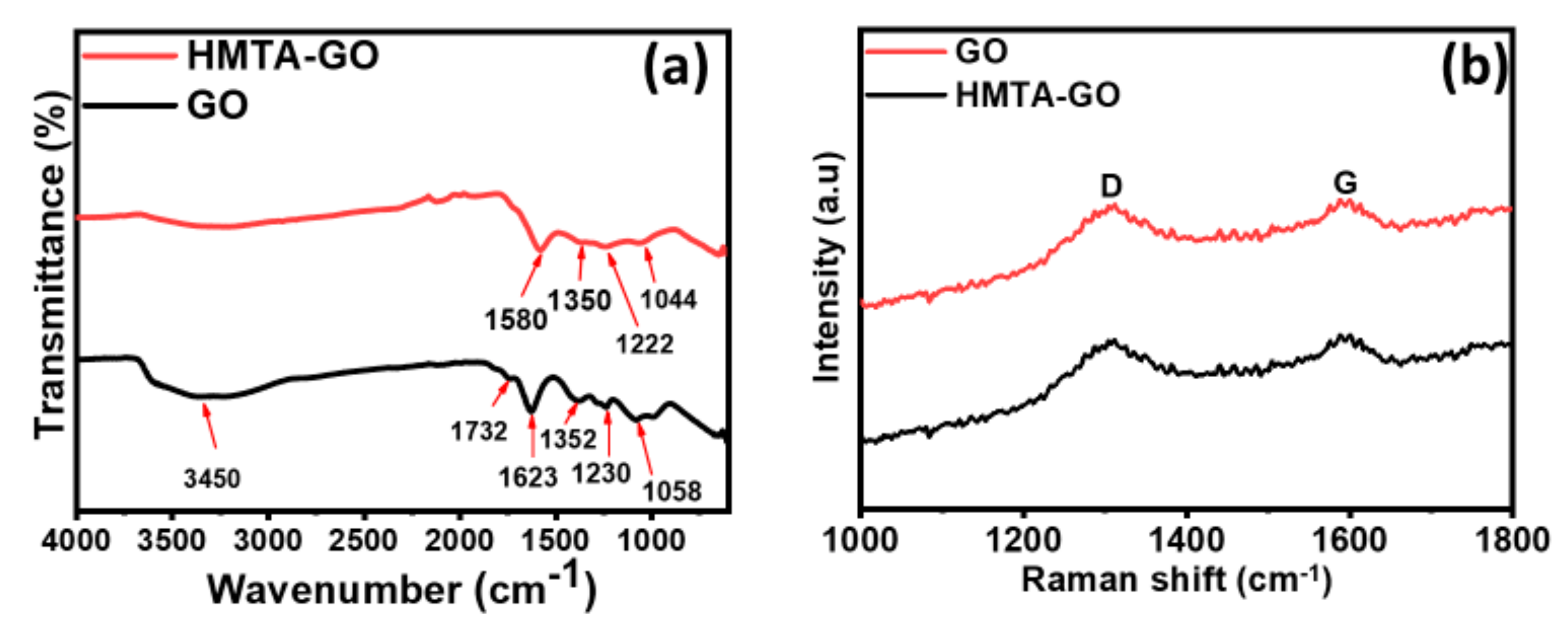

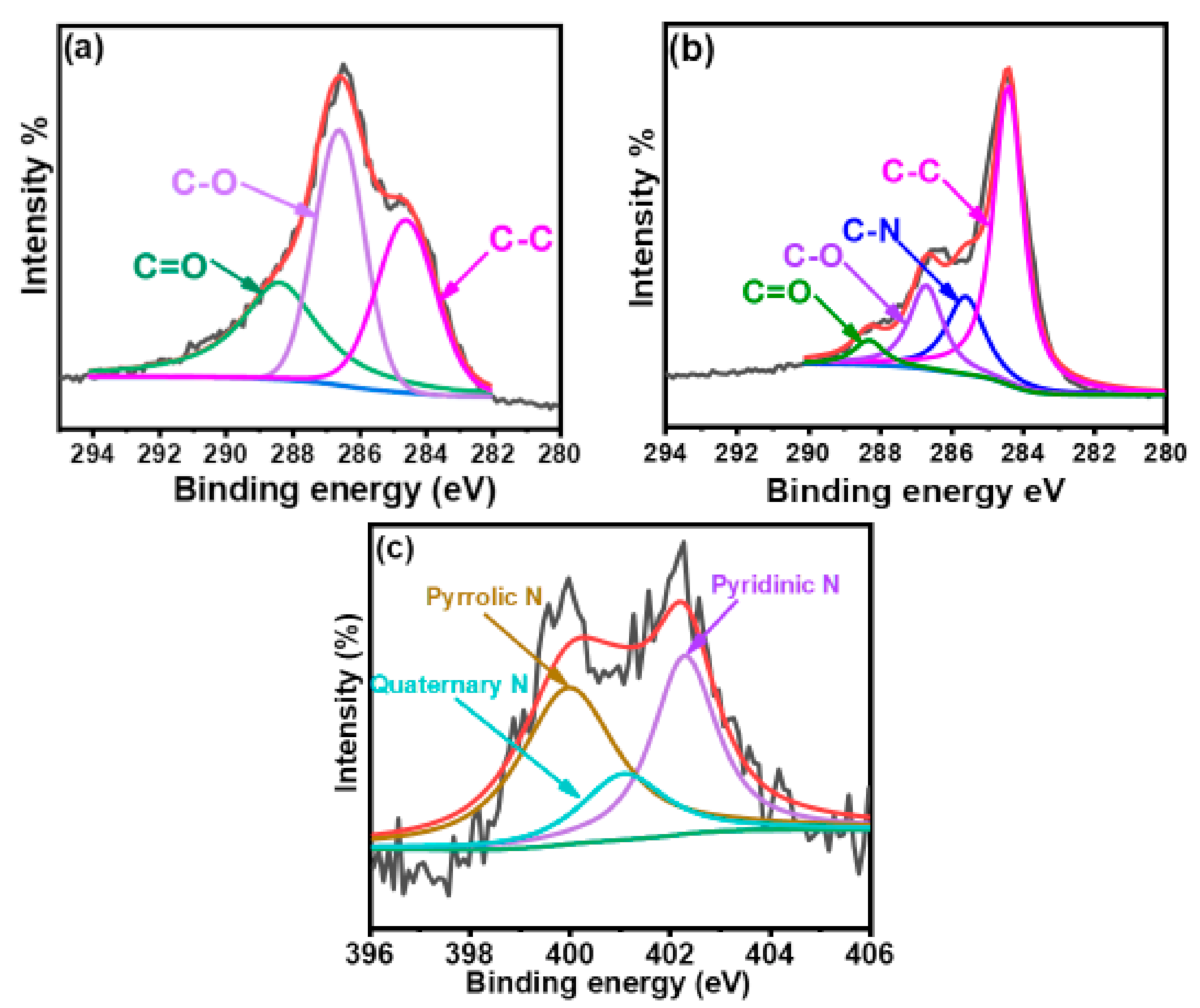

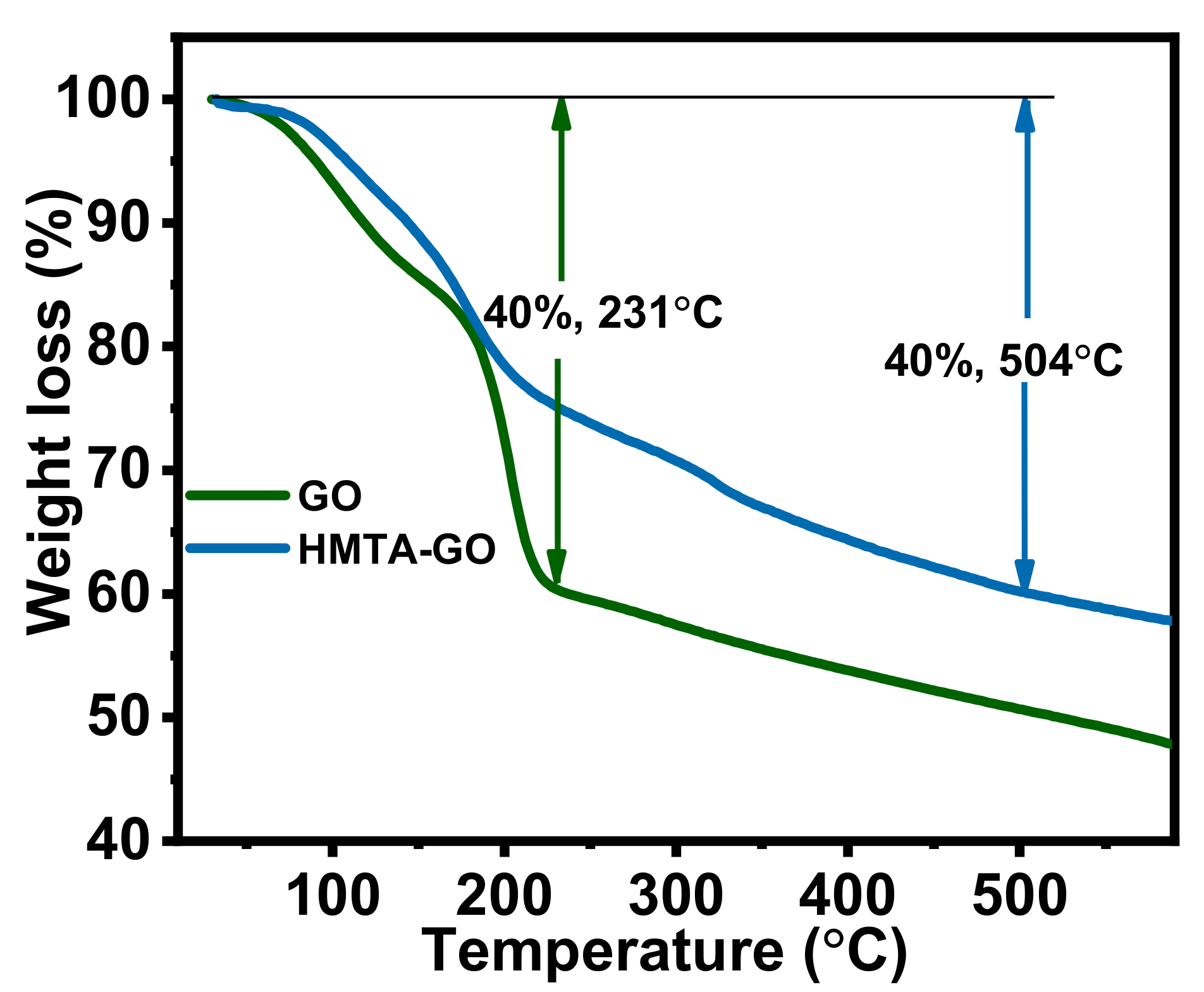

3.1. Characterization of Filler

3.2. XRD of Epoxy Composites

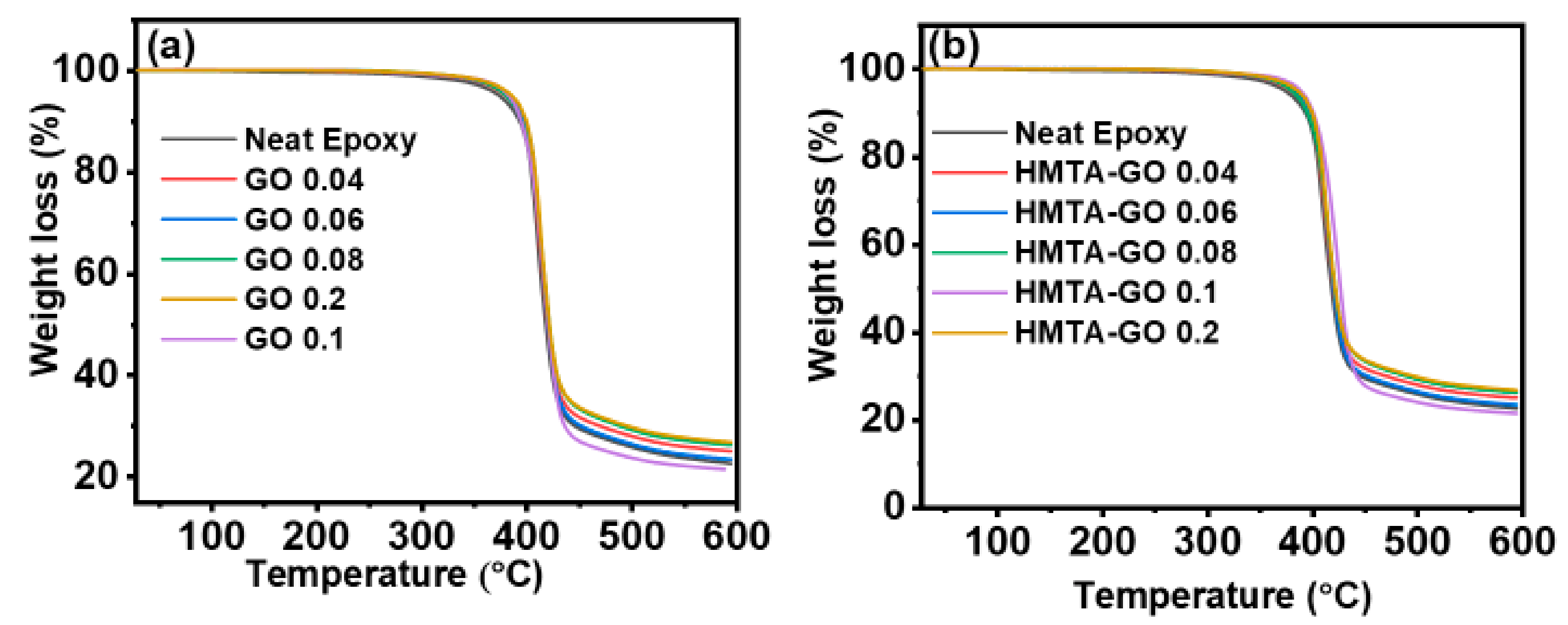

3.3. Thermal Stability and Degradation Kinetics of Epoxy Composites

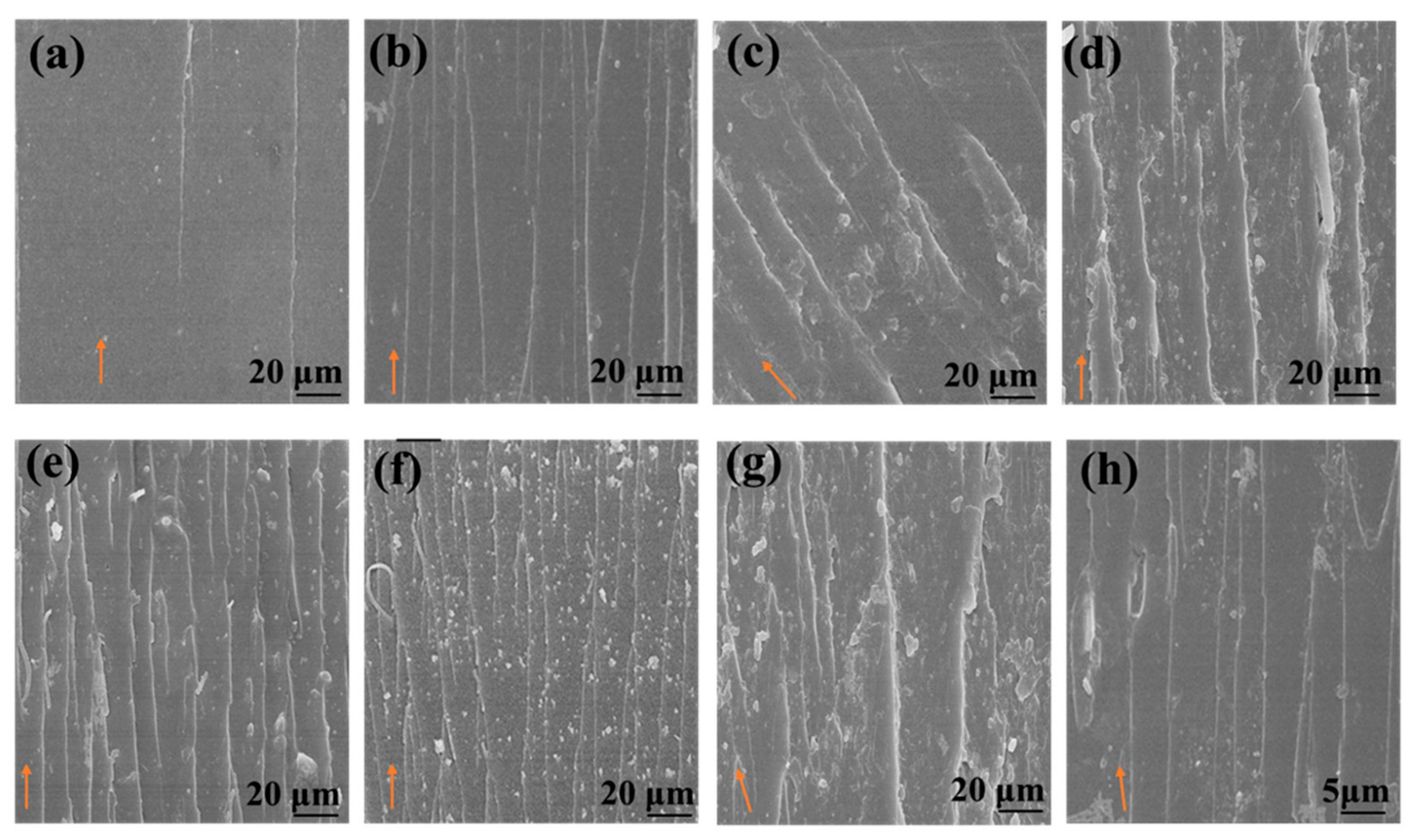

3.4. Mechanical Properties of Epoxy Composites

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Zhao, Y.; Barrera, E.V. Asymmmetric Diamino Functionalization of Nanotubes Assisted by BOC Protection and Their Epoxy Nanocomposites. Adv. Funct. Mater. 2010, 20, 3039–3044. [Google Scholar] [CrossRef]

- Stoddart, A. Polymers: Colour in the cracks. Nat. Rev. Mater. 2016, 1, 16004. [Google Scholar] [CrossRef]

- Chruściel, J.J.; Leśniak, E. Modification of epoxy resins with functional silanes, polysiloxanes, silsesquioxanes, silica and silicates. Prog. Sci. 2015, 41, 67–121. [Google Scholar] [CrossRef]

- Zhang, Y.; Rhee, K.Y.; Park, S.-J. Nanodiamond nanocluster-decorated graphene oxide/epoxy nanocomposites with enhanced mechanical behavior and thermal stability. Compos. Part B Eng. 2017, 114, 111–120. [Google Scholar] [CrossRef]

- Wang, F.; Drzal, L.T.; Qin, Y.; Huang, Z. Mechanical properties and thermal conductivity of graphene nanoplatelet/epoxy composites. J. Mater. Sci. 2015, 50, 1082–1093. [Google Scholar] [CrossRef]

- Liu, Y.-L.; Liu, Y.-L.; Chang, G.-P.; Wu, C.-S.; Liu, Y.; Chang, G.; Wu, C. Halogen-free flame retardant epoxy resins from hybrids of phosphorus- or silicon-containing epoxies with an amine resin. J. Appl. Sci. 2006, 102, 1071–1077. [Google Scholar] [CrossRef]

- Qing, Y.; Zhou, W.; Luo, F.; Zhu, D. Epoxy-silicone filled with multi-walled carbon nanotubes and carbonyl iron particles as a microwave absorber. Carbon 2010, 48, 4074–4080. [Google Scholar] [CrossRef]

- Yu, X.; Cheng, H.; Zhang, M.; Zhao, Y.; Qu, L.; Shi, G. Graphene-based smart materials. Nat. Rev. Mater. 2017, 2, 17046. [Google Scholar] [CrossRef]

- Zhu, Y.; James, D.K.; Tour, J.M. New Routes to Graphene, Graphene Oxide and Their Related Applications. Adv. Mater. 2012, 24, 4924–4955. [Google Scholar] [CrossRef]

- Kuzhir, P.; Paddubskaya, A.; Plyushch, A.; Volynets, N.; Maksimenko, S.; Macutkevic, J.; Kranauskaite, I.; Banys, J.; Ivanov, E.; Kotsilkova, R.; et al. Epoxy composites filled with high surface area-carbon fillers: Optimization of electromagnetic shielding, electrical, mechanical, and thermal properties. J. Appl. Phys. 2013, 114, 164304. [Google Scholar] [CrossRef]

- Spitalsky, Z.; Tasis, D.; Papagelis, K.; Galiotis, C. Carbon nanotube–polymer composites: Chemistry, processing, mechanical and electrical properties. Prog. Sci. 2010, 35, 357–401. [Google Scholar] [CrossRef]

- Yang, Z.; McElrath, K.; Bahr, J.; D’Souza, N.A. Effect of matrix glass transition on reinforcement efficiency of epoxy-matrix composites with single walled carbon nanotubes, multi-walled carbon nanotubes, carbon nanofibers and graphite. Compos. Part B Eng. 2012, 43, 2079–2086. [Google Scholar] [CrossRef]

- Potts, J.R.; Dreyer, D.R.; Bielawski, C.W.; Ruoff, R.S. Graphene-based polymer nanocomposites. Polymer 2011, 52, 5–25. [Google Scholar] [CrossRef] [Green Version]

- Renteria, J.D.; Ramirez, S.; Malekpour, H.; Alonso, B.; Centeno, A.; Zurutuza, A.; Cocemasov, A.I.; Nika, D.L.; Balandin, A.A. Strongly Anisotropic Thermal Conductivity of Free-Standing Reduced Graphene Oxide Films Annealed at High Temperature. Adv. Funct. Mater. 2015, 25, 4664–4672. [Google Scholar] [CrossRef]

- Stankovich, S.; Dikin, D.A.; Dommett, G.H.B.; Kohlhaas, K.M.; Zimney, E.J.; Stach, E.A.; Piner, R.D.; Nguyen, S.T.; Ruoff, R.S. Graphene-based composite materials. Nature 2006, 442, 282. [Google Scholar] [CrossRef]

- Balandin, A.A. Thermal properties of graphene and nanostructured carbon materials. Nat. Mater. 2011, 10, 569–581. [Google Scholar] [CrossRef] [Green Version]

- Ramirez, S.; Chan, K.; Hernandez, R.; Recinos, E.; Hernandez, E.; Salgado, R.; Khitun, A.; Garay, J.; Balandin, A. Thermal and magnetic properties of nanostructured densified ferrimagnetic composites with graphene—graphite fillers. Mater. Des. 2017, 118, 75–80. [Google Scholar] [CrossRef]

- Feng, L.; Shi, X.; Tan, X.; Liu, Z.; Yang, X.; Peng, R.; Wang, J. Polyethylene Glycol and Polyethylenimine Dual-Functionalized Nano-Graphene Oxide for Photothermally Enhanced Gene Delivery. Small 2013, 9, 1989–1997. [Google Scholar] [CrossRef]

- Liu, P.; Gong, K.; Xiao, P.; Xiao, M. Preparation and characterization of poly(vinyl acetate)-intercalated graphite oxide nanocomposite. J. Mater. Chem. 2000, 10, 933–935. [Google Scholar] [CrossRef]

- Kovtyukhova, N.I.; Ollivier, P.J.; Martin, B.R.; Mallouk, T.E.; Chizhik, S.A.; Buzaneva, E.V.; Gorchinskiy, A.D. Layer-by-Layer Assembly of Ultrathin Composite Films from Micron-Sized Graphite Oxide Sheets and Polycations. Chem. Mater. 1999, 11, 771–778. [Google Scholar] [CrossRef]

- Yang, Y.; Rigdon, W.; Huang, X.; Li, X. Enhancing graphene reinforcing potential in composites by hydrogen passivation induced dispersion. Sci. Rep. 2013, 3, 3. [Google Scholar] [CrossRef] [PubMed]

- Hu, Y.; Shen, J.; Li, N.; Ma, H.; Shi, M.; Yan, B.; Huang, W.; Wang, W.; Ye, M. Comparison of the thermal properties between composites reinforced by raw and amino-functionalized carbon materials. Compos. Sci. Technol. 2010, 70, 2176–2182. [Google Scholar] [CrossRef]

- Zhang, H.-X.; Park, J.-H.; Ko, E.-B.; Moon, Y.-K.; Lee, D.-h.; Hu, Y.-M.; Zhang, X.-Q.; Yoon, K.-B. Comparison of the properties of graphene-and graphene oxide-based polyethylene nanocomposites prepared by an in situ polymerization method. RSC Adv. 2016, 6, 73013–73019. [Google Scholar] [CrossRef]

- Kargar, F.; Barani, Z.; Balinskiy, M.; Magana, A.S.; Lewis, J.S.; Balandin, A.A. Dual-Functional Graphene Composites for Electromagnetic Shielding and Thermal Management. Adv. Electron. Mater. 2019, 5, 1800558. [Google Scholar] [CrossRef]

- Kuila, T.; Bose, S.; Mishra, A.K.; Khanra, P.; Kim, N.H.; Lee, J.H. Chemical functionalization of graphene and its applications. Prog. Mater. Sci. 2012, 57, 1061–1105. [Google Scholar] [CrossRef]

- Naebe, M.; Wang, J.; Amini, A.; Khayyam, H.; Hameed, N.; Li, L.H.; Chen, Y.; Fox, B. Mechanical Property and Structure of Covalent Functionalised Graphene/Epoxy Nanocomposites. Sci. Rep. 2014, 4, 4375. [Google Scholar] [CrossRef]

- Rourke, J.P.; Pandey, P.A.; Moore, J.J.; Bates, M.; Kinloch, I.A.; Young, R.J.; Wilson, N.R. The Real Graphene Oxide Revealed: Stripping the Oxidative Debris from the Graphene-like Sheets. Angew. Chem. 2011, 123, 3231–3235. [Google Scholar] [CrossRef]

- Gao, W. The Chemistry of Graphene Oxide. In Graphene Oxide; Springer: Berlin, Germany, 2015; pp. 61–95. [Google Scholar]

- Malekpour, H.; Chang, K.-H.; Chen, J.-C.; Lu, C.-Y.; Nika, D.L.; Novoselov, K.S.; Balandin, A.A. Thermal Conductivity of Graphene Laminate. Nano Lett. 2014, 14, 5155–5161. [Google Scholar] [CrossRef]

- Ramezanzadeh, B.; Niroumandrad, S.; Ahmadi, A.; Mahdavian, M.; Moghadam, M.M.; Mahdavian-Ahadi, M. Enhancement of barrier and corrosion protection performance of an epoxy coating through wet transfer of amino functionalized graphene oxide. Corros. Sci. 2016, 103, 283–304. [Google Scholar] [CrossRef]

- Ribeiro, H.; Da Silva, W.M.; Neves, J.C.; Calado, H.D.R.; Paniago, R.; Seara, L.M.; Camarano, D.D.M.; Silva, G.G. Multifunctional nanocomposites based on tetraethylenepentamine-modified graphene oxide/epoxy. Polym. Test. 2015, 43, 182–192. [Google Scholar] [CrossRef]

- Jang, E.S.; Khan, S.B.; Seo, J.; Akhtar, K.; Nam, Y.H.; Seo, K.W.; Han, H. Preparation of cationic latent initiators containing imidazole group and their effects on the properties of DGEBA epoxy resin. Macromol. Res. 2011, 19, 989–997. [Google Scholar] [CrossRef]

- Isarn, I.; Massagués, L.; Ramis, X.; Serra, À.; Ferrando, F. New BN-epoxy composites obtained by thermal latent cationic curing with enhanced thermal conductivity. Compos. Part A Appl. Sci. Manuf. 2017, 103, 35–47. [Google Scholar] [CrossRef]

- Nakano, S.; Endo, T. Thermal cationic curing by benzylpyridinium salts. Prog. Org. Coat. 1994, 23, 379–385. [Google Scholar] [CrossRef]

- Park, S.-J.; Heo, G.-Y.; Suh, D.-H. Thermal properties and fracture toughness of epoxy resins cured by phosphonium and pyrazinium salts as latent cationic initiators. J. Polym. Sci. Part A: Chem. 2003, 41, 2393–2403. [Google Scholar] [CrossRef]

- Toneri, T.; Watanabe, K.-i.; Sanda, F.; Endo, T. Synthesis and the initiator activity of fluorenyltriphenylphosphonium salts in the cationic polymerization of epoxide. Novel thermally latent initiators. Macromolecules 1999, 32, 1293–1296. [Google Scholar] [CrossRef]

- Sanda, F.; Kaizuka, T.; Sudo, A.; Endo, T. A Novel Thermally Latent Anionic Initiator. Polymerization of Epoxide with Hydroxylamide Based on Thermal Dissociation. Macromolecules 2003, 36, 967–968. [Google Scholar] [CrossRef]

- Ma, L.; Meng, L.; Fan, D.; He, J.; Yu, J.; Qi, M.; Chen, Z.; Huang, Y. Interfacial enhancement of carbon fiber composites by generation 1–3 dendritic hexamethylenetetramine functionalization. Appl. Surf. Sci. 2014, 296, 61–68. [Google Scholar] [CrossRef]

- Kang, M.-J.; Jin, F.-L.; Park, S.-J. Effect of Ozone Treatment on Fracture Toughness of Single-Walled Carbon Nanotubes-Reinforced Epoxy Resin Initiated by a Thermal Latent Catalyst. Macromol. Res. 2018, 26, 1048–1051. [Google Scholar] [CrossRef]

- Manjunath, G.; Bharath, K.; Ganesh, D.; Kumar, D.R.; Shivprakash, P.; Harsha, H. ANOVA and Response Surface Methodology for the Optimization of Fracture Toughness parameters on Jute Fabric-Epoxy composites using SENB specimens. Mater. Today Proc. 2017, 4, 11285–11291. [Google Scholar] [CrossRef]

- Shelly, D.; Nanda, T.G.; Mehta, R.G. Effect of Nanoclay Addition on the Mechanical Properties of Glass Fibre Reinforced Epoxy Nanocomposites Processed through VARIM. Master’s Thesis, Department of Mechanical Engineering, Punjab, India, 2016. [Google Scholar]

- Lee, J.W.; Ko, J.M.; Kim, J.-D. Hydrothermal preparation of nitrogen-doped graphene sheets via hexamethylenetetramine for application as supercapacitor electrodes. Electrochim. Acta 2012, 85, 459–466. [Google Scholar] [CrossRef]

- Ferreira, F.; Brito, F.; Franceschi, W.; Simonetti, E.; Cividanes, L.; Chipara, M.; Lozano, K. Functionalized graphene oxide as reinforcement in epoxy based nanocomposites. Surf. Interfaces 2018, 10, 100–109. [Google Scholar] [CrossRef]

- Pant, B.; Park, M.; Park, S.-J. Synthesis, characterization, and photocatalytic performances of electrospun cadmium titanate nanofibers immobilized into the reduced graphene oxide sheets. Mater. Lett. 2018, 228, 365–368. [Google Scholar] [CrossRef]

- Seong, D.B.; Son, Y.-R.; Park, S.-J. A study of reduced graphene oxide/leaf-shaped TiO2 nanofibers for enhanced photocatalytic performance via electrospinning. J. Solid State Chem. 2018, 266, 196–204. [Google Scholar] [CrossRef]

- Yang, D.; Velamakanni, A.; Bozoklu, G.; Park, S.; Stoller, M.; Piner, R.D.; Stankovich, S.; Jung, I.; Field, D.A.; Ventrice Jr, C.A. Chemical analysis of graphene oxide films after heat and chemical treatments by X-ray photoelectron and Micro-Raman spectroscopy. Carbon 2009, 47, 145–152. [Google Scholar] [CrossRef]

- Yu, B.; Wang, X.; Qian, X.; Xing, W.; Yang, H.; Ma, L.; Lin, Y.; Jiang, S.; Song, L.; Hu, Y. Functionalized graphene oxide/phosphoramide oligomer hybrids flame retardant prepared via in situ polymerization for improving the fire safety of polypropylene. RSC Adv. 2014, 4, 31782–31794. [Google Scholar] [CrossRef]

- Barman, B.K.; Nanda, K.K. Hexamethylenetetramine mediated simultaneous nitrogen doping and reduction of graphene oxide for a metal-free SERS substrate. RSC Adv. 2014, 4, 44146–44150. [Google Scholar] [CrossRef]

- Szabó, T.; Berkesi, O.; Forgó, P.; Josepovits, K.; Sanakis, Y.; Petridis, D.; Dékány, I. Evolution of Surface Functional Groups in a Series of Progressively Oxidized Graphite Oxides. Chem. Mater. 2006, 18, 2740–2749. [Google Scholar] [CrossRef]

- Wan, Y.-J.; Gong, L.-X.; Tang, L.-C.; Wu, L.-B.; Jiang, J.-X. Mechanical properties of epoxy composites filled with silane-functionalized graphene oxide. Compos. Part A: Appl. Sci. Manuf. 2014, 64, 79–89. [Google Scholar] [CrossRef]

- Qi, B.; Yuan, Z.; Lu, S.; Liu, K.; Li, S.; Yang, L.; Yu, J. Mechanical and thermal properties of epoxy composites containing graphene oxide and liquid crystalline epoxy. Fibers Polym. 2014, 15, 326–333. [Google Scholar] [CrossRef]

- Yan, Z.; Nika, D.L.; Balandin, A.A. Thermal properties of graphene and few-layer graphene: Applications in electronics. IET Circuits, Devices Syst. 2015, 9, 4–12. [Google Scholar] [CrossRef]

- Qu, H.; Wu, W.; Wu, H.; Jiao, Y.; Xu, J. Thermal degradation and fire performance of wood treated with various inorganic salts. Fire Mater. 2011, 35, 569–576. [Google Scholar] [CrossRef]

- Demir, P.; Düşükcan, İ.Y. Thermal decomposition kinetics and dielectric properties of polyurethane grafted onto PEMA-co-PHEMA. Polym. Bull. 2018, 75, 4037–4053. [Google Scholar] [CrossRef]

- Reghunadhan, A.; Stranskowski, M.; Datta, J.; Kalarikkal, N.; Thomas, S. Recycled Polyurethane as a Second Phase in Thermoset Blends and Its Effect on Thermal Degradation Kinetics Studies. In Proceed. Macromol. Symp. 2018, 381, 1800112. [Google Scholar] [CrossRef]

- Rafiee, M.A.; Rafiee, J.; Wang, Z.; Song, H.; Yu, Z.-Z.; Koratkar, N. Enhanced Mechanical Properties of Nanocomposites at Low Graphene Content. ACS Nano 2009, 3, 3884–3890. [Google Scholar] [CrossRef]

- Chandrasekaran, S.; Sato, N.; Tölle, F.; Mülhaupt, R.; Fiedler, B.; Schulte, K. Fracture toughness and failure mechanism of graphene based epoxy composites. Compos. Sci. Technol. 2014, 97, 90–99. [Google Scholar] [CrossRef]

- Tang, L.-C.; Wan, Y.-J.; Yan, D.; Pei, Y.-B.; Zhao, L.; Li, Y.-B.; Wu, L.-B.; Jiang, J.-X.; Lai, G.-Q. The effect of graphene dispersion on the mechanical properties of graphene/epoxy composites. Carbon 2013, 60, 16–27. [Google Scholar] [CrossRef]

- Rafiee, M.A.; Rafiee, J.; Srivastava, I.; Wang, Z.; Song, H.; Yu, Z.-Z.; Koratkar, N. Fracture and Fatigue in Graphene Nanocomposites. Small 2010, 6, 179–183. [Google Scholar] [CrossRef]

- Park, Y.T.; Qian, Y.; Chan, C.; Suh, T.; Nejhad, M.G.; Macosko, C.W.; Stein, A. Epoxy toughening with low graphene loading. Adv. Funct. Mater. 2015, 25, 575–585. [Google Scholar] [CrossRef]

- Declet-Perez, C.; Redline, E.M.; Bates, F.S.; Francis, L.F. Role of Localized Network Damage in Block Copolymer Toughened Epoxies. ACS Macro Lett. 2012, 1, 338–342. [Google Scholar] [CrossRef]

- Lian, G.; Tuan, C.-C.; Jiao, S.; Cui, D.; Li, L.; Wang, Q.; Moon, K.-S.; Wong, C.-P. Vertically Aligned and Interconnected Graphene Networks for High Thermal Conductivity of Epoxy Composites with Ultralow Loading. Chem. Mater. 2016, 28, 6096–6104. [Google Scholar] [CrossRef]

| Samples | A* | K* | A*. K* | IPDT (°C) | IDT (°C) (5% Weight Loss) | Te (°C) |

|---|---|---|---|---|---|---|

| Neat Epoxy | 0.703 | 1.597 | 1.123 | 664 | 381 | 428 |

| GO 0.04 HMTA-GO 0.04 | 0.705 | 1.601 | 1.129 | 668 | 382 | 428 |

| 0.708 | 1.605 | 1.136 | 672 | 383 | 440 | |

| GO 0.06 HMTA-GO 0.06 | 0.706 | 1.603 | 1.132 | 669 | 382 | 431 |

| 0.709 | 1.609 | 1.141 | 675 | 384 | 442 | |

| GO 0.08 HMTA-GO 0.08 | 0.709 | 1.613 | 1.144 | 676 | 383 | 431 |

| 0.711 | 1.614 | 1.148 | 678 | 385 | 446 | |

| GO 0.1 HMTA-GO 0.1 | 0.711 | 1.615 | 1.148 | 679 | 387 | 439 |

| 0.715 | 1.618 | 1.157 | 684 | 390 | 450 | |

| GO 0.2 HMTA-GO 0.2 | 0.714 | 1.615 | 1.153 | 682 | 387 | 431 |

| 0.719 | 1.619 | 1.164 | 688 | 391 | 448 |

| Samples | E (J/mol) | R2 |

|---|---|---|

| Neat epoxy | 127 | 0.998 |

| GO 0.04 HMTA-GO 0.04 | 132 | 0.998 |

| 136 | 0.997 | |

| GO 0.06 HMTA-GO 0.06 | 135 | 0.994 |

| 141 | 0.996 | |

| GO 0.08 HMTA-GO 0.08 | 143 | 0.993 |

| 161 | 0.999 | |

| GO 0.1 HMTA-GO 0.1 | 152 | 0.983 |

| 179 | 0.996 | |

| GO 0.2 HMTA-GO 0.2 | 147 | 0.997 |

| 162 | 0.997 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Riaz, S.; Park, S.-J. Thermal and Mechanical Interfacial Behaviors of Graphene Oxide-Reinforced Epoxy Composites Cured by Thermal Latent Catalyst. Materials 2019, 12, 1354. https://doi.org/10.3390/ma12081354

Riaz S, Park S-J. Thermal and Mechanical Interfacial Behaviors of Graphene Oxide-Reinforced Epoxy Composites Cured by Thermal Latent Catalyst. Materials. 2019; 12(8):1354. https://doi.org/10.3390/ma12081354

Chicago/Turabian StyleRiaz, Shahina, and Soo-Jin Park. 2019. "Thermal and Mechanical Interfacial Behaviors of Graphene Oxide-Reinforced Epoxy Composites Cured by Thermal Latent Catalyst" Materials 12, no. 8: 1354. https://doi.org/10.3390/ma12081354

APA StyleRiaz, S., & Park, S.-J. (2019). Thermal and Mechanical Interfacial Behaviors of Graphene Oxide-Reinforced Epoxy Composites Cured by Thermal Latent Catalyst. Materials, 12(8), 1354. https://doi.org/10.3390/ma12081354