Discrete Element Simulation of the Effect of Roller-Spreading Parameters on Powder-Bed Density in Additive Manufacturing

Abstract

1. Introduction

2. Materials and Methods

2.1. Discrete Element Method

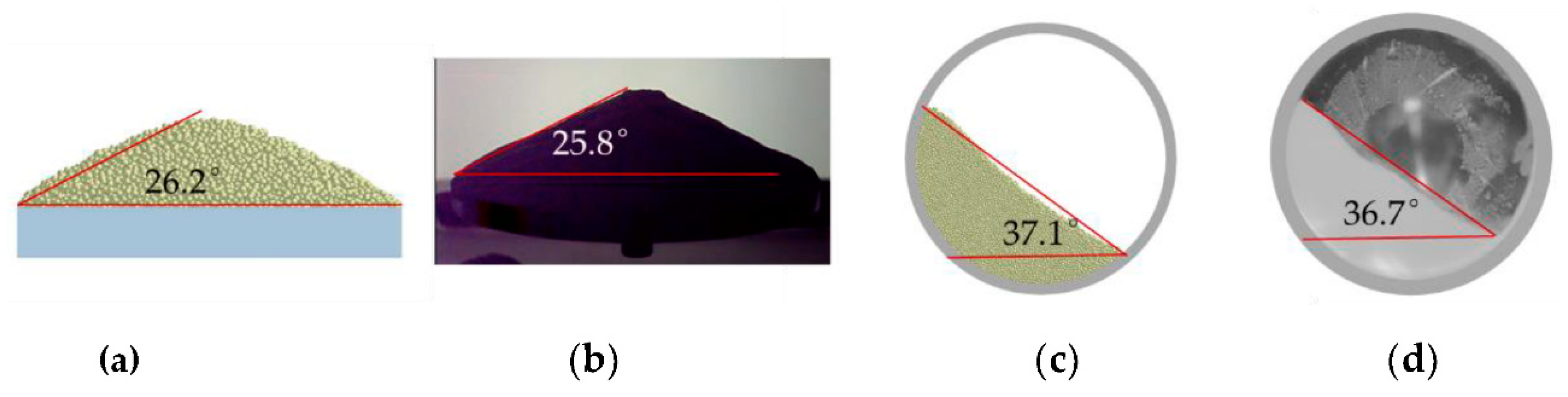

2.2. Calibration of DEM Parameters

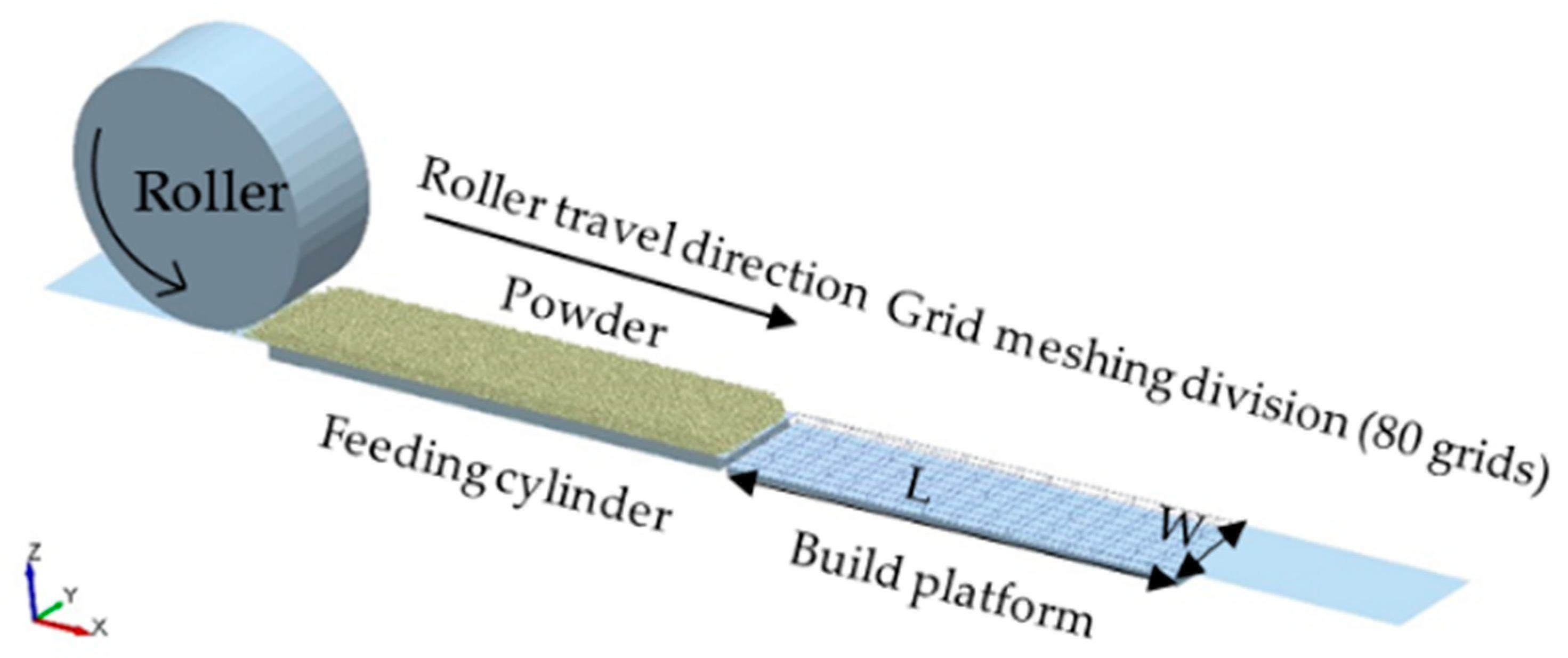

2.3. Simulation Conditions

2.4. Characterization of Powder-Bed Density

3. Results and Discussion

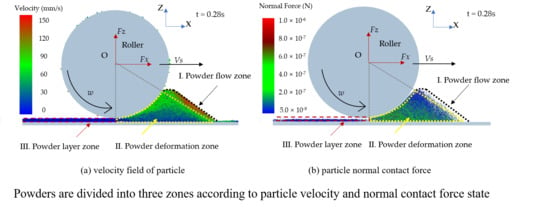

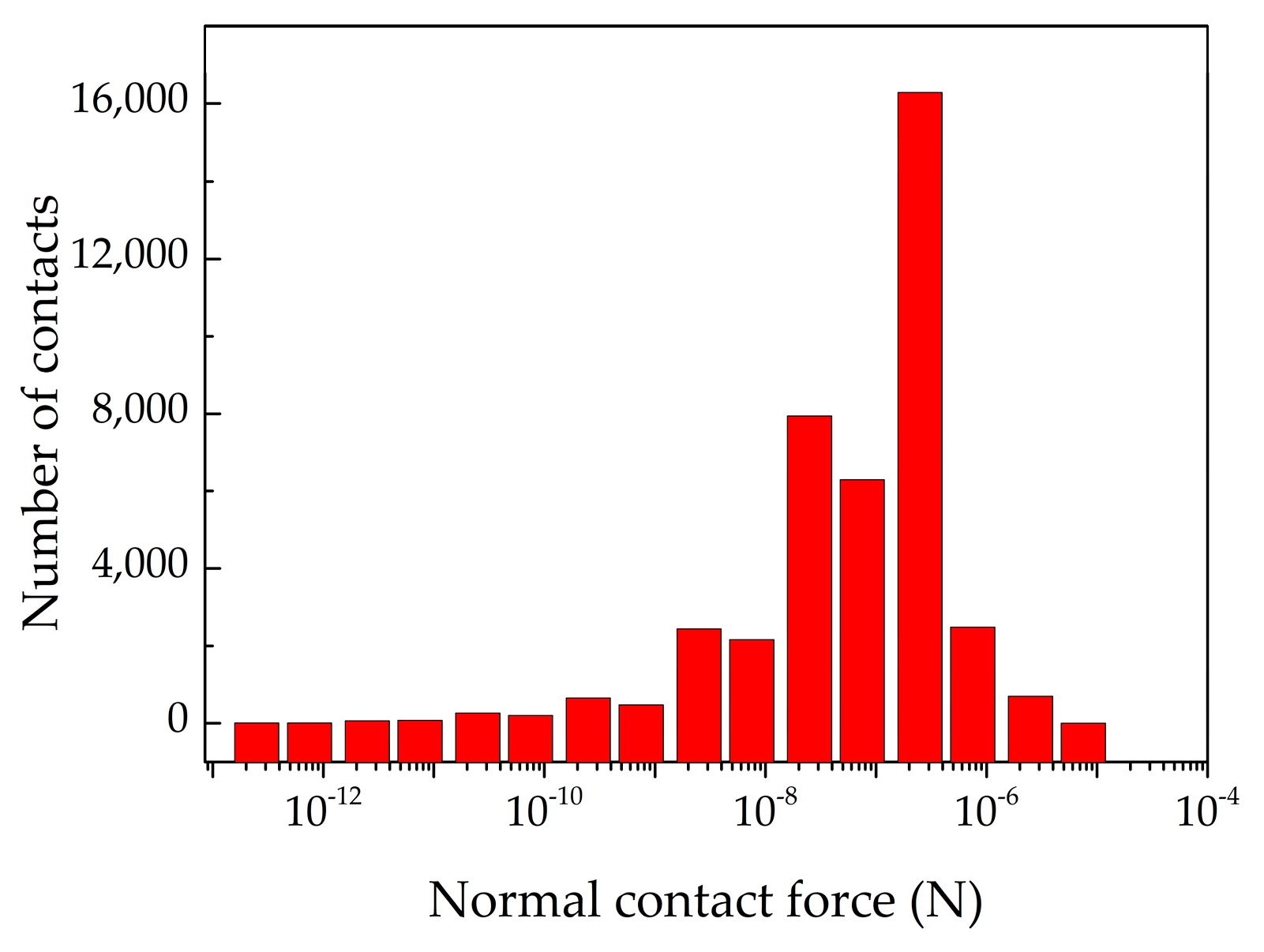

- (1)

- Powder free-flow zone: the powder flow under the action of weight force and external force exerted by roller. The normal contact forces between particles are weak, but particles velocities are relatively higher in this zone. The particles in the zone that will fall into the build platform to form powder layer.

- (2)

- Powder compression zone: the powder-bed is compressed and deformed forming a considerably dense powder layer by roller. The particle normal contact force is strong and particles below the roller are squeezed in this zone with low velocity.

- (3)

- Powder layer zone: powder layer underneath the surface of the roller is formed and flattened by the translation motion of the roller. The particles in this zone keep stable.

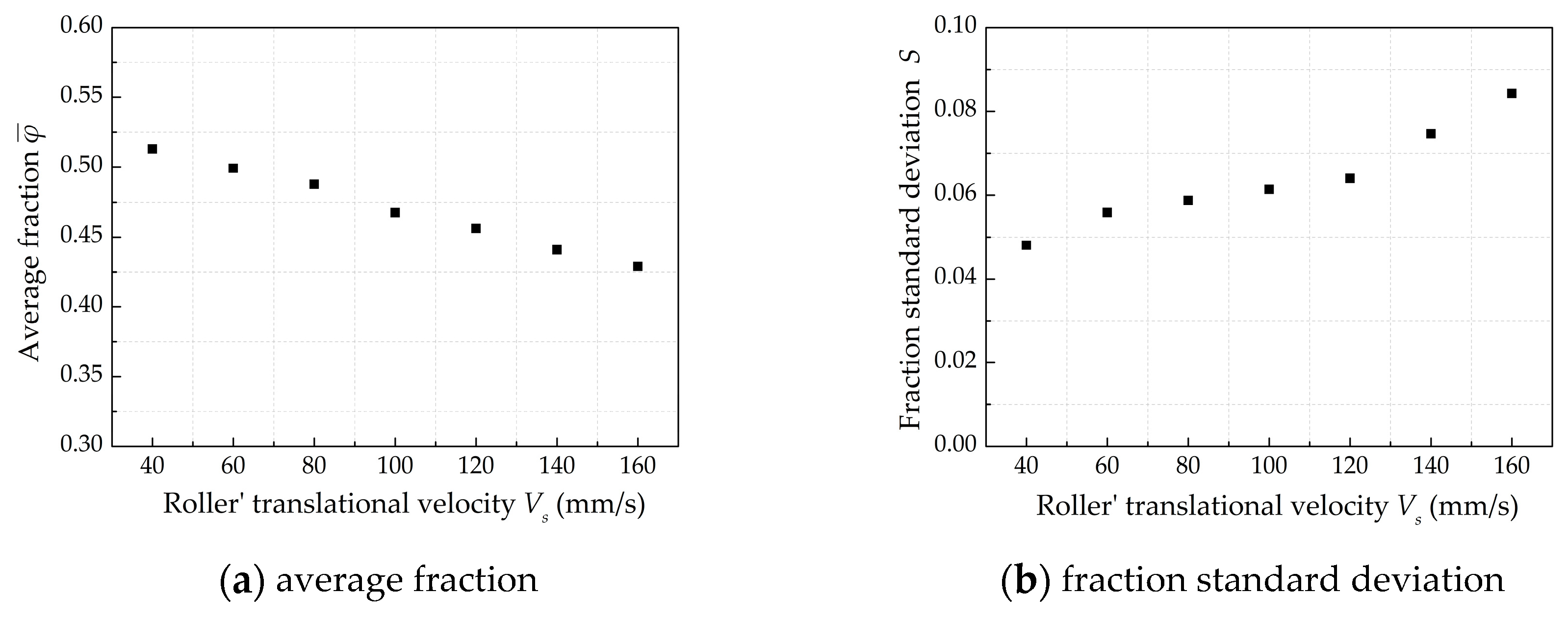

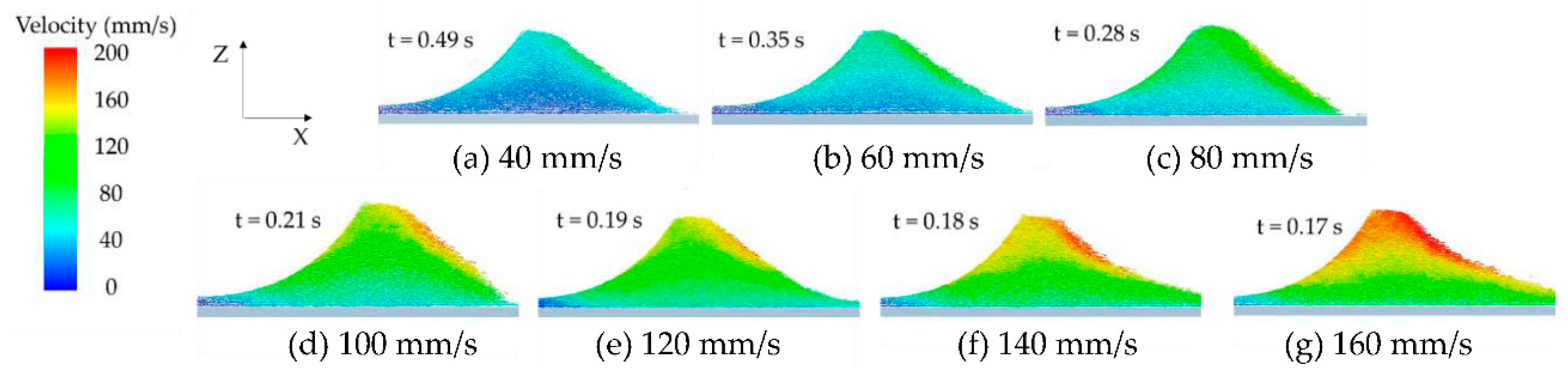

3.1. The Effect of Roller’s Translational Velocity on Powder-Bed Density

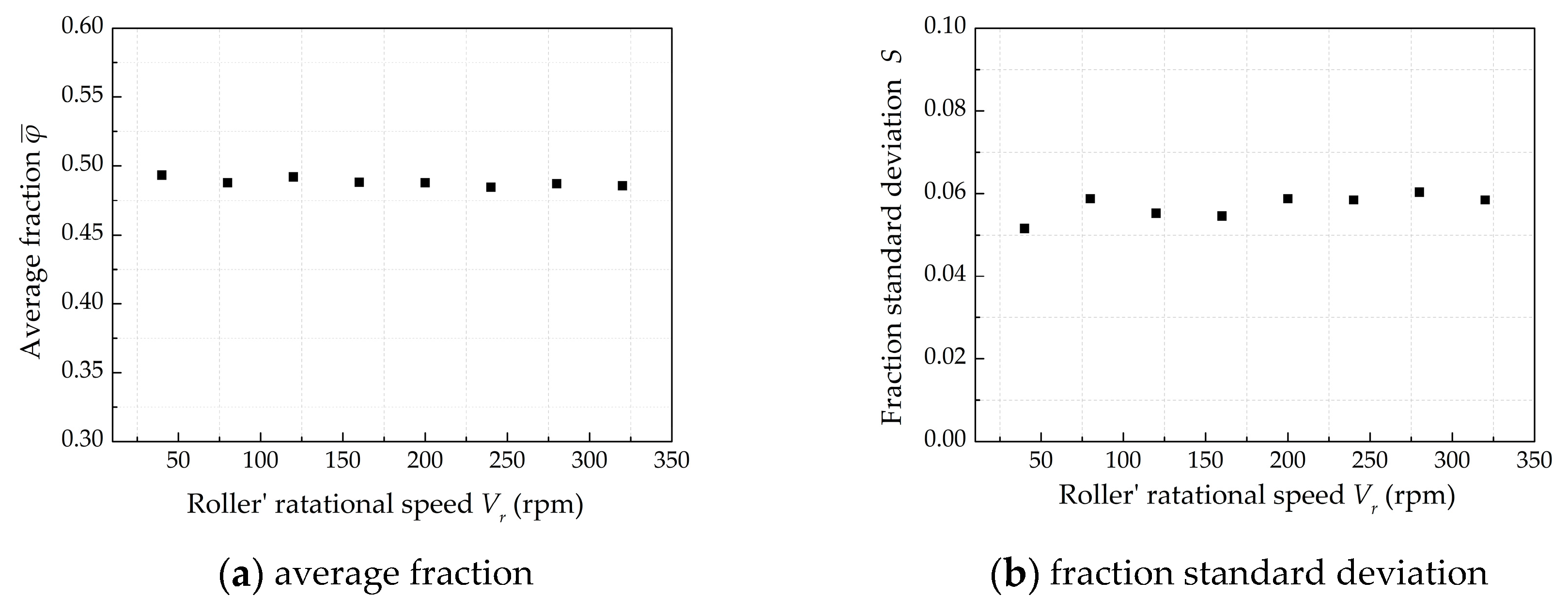

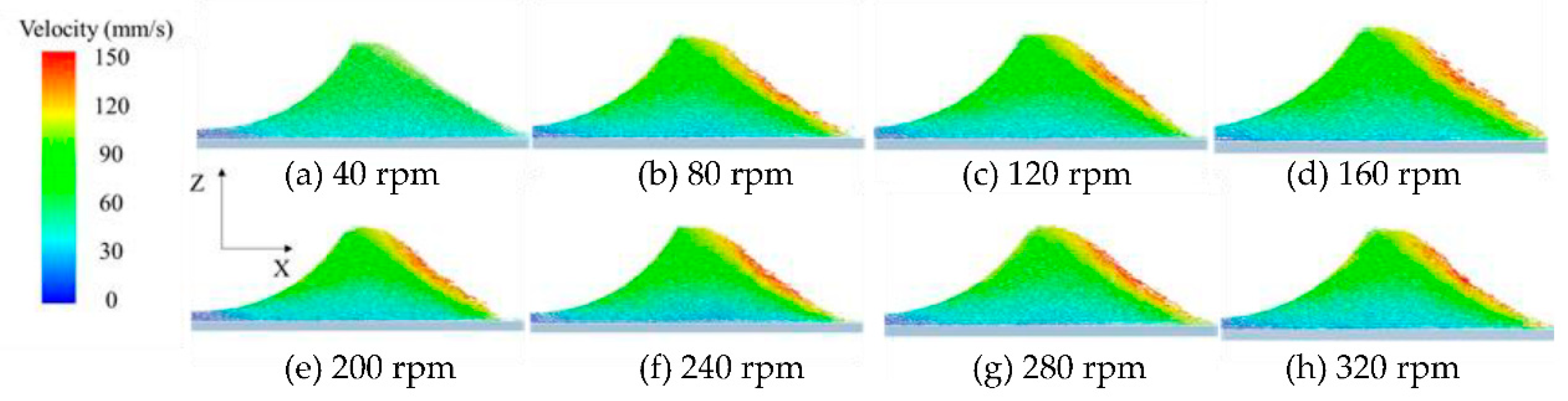

3.2. The Effect of Roller’s Rotational Speed on Powder-Bed Density

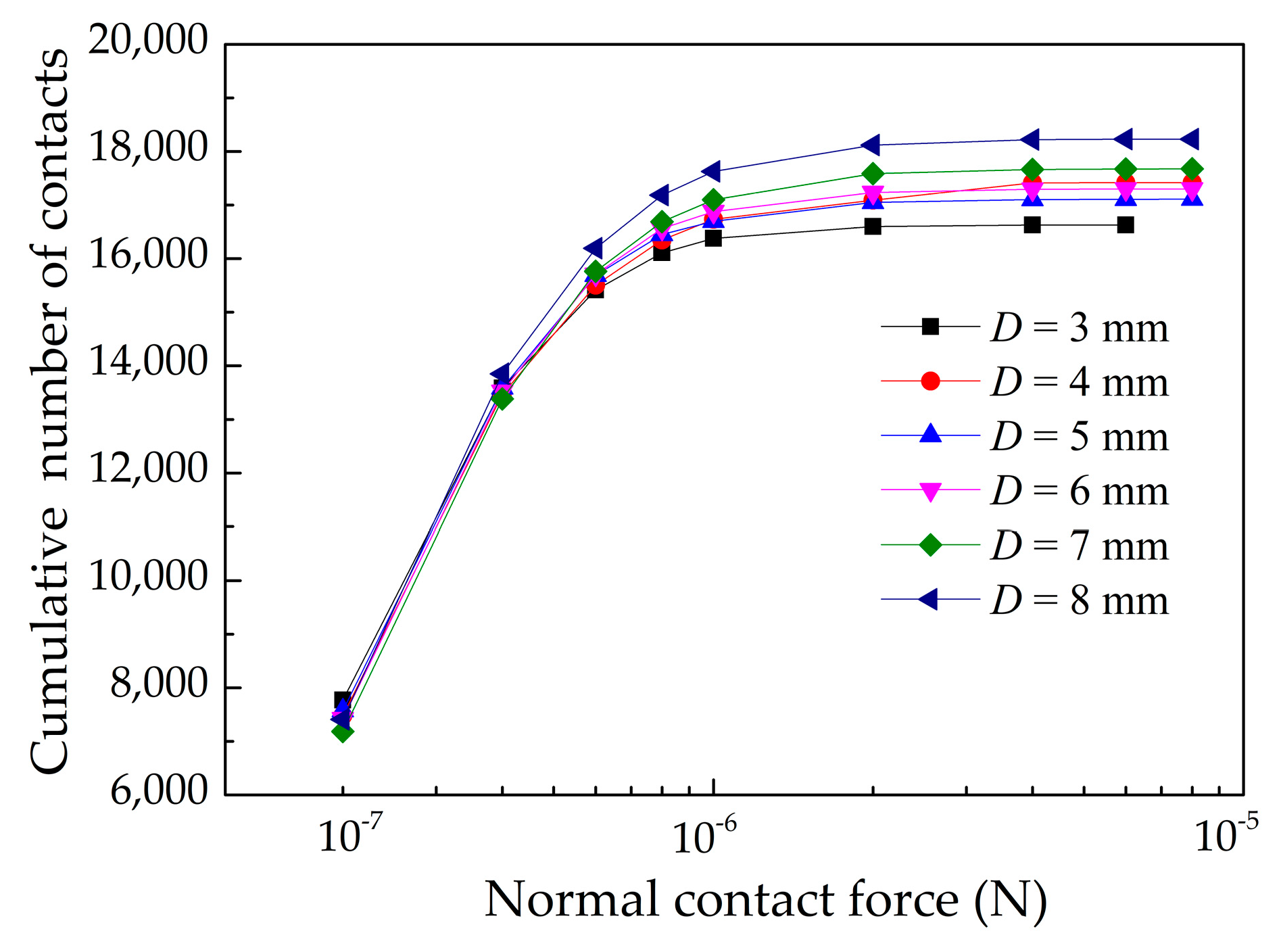

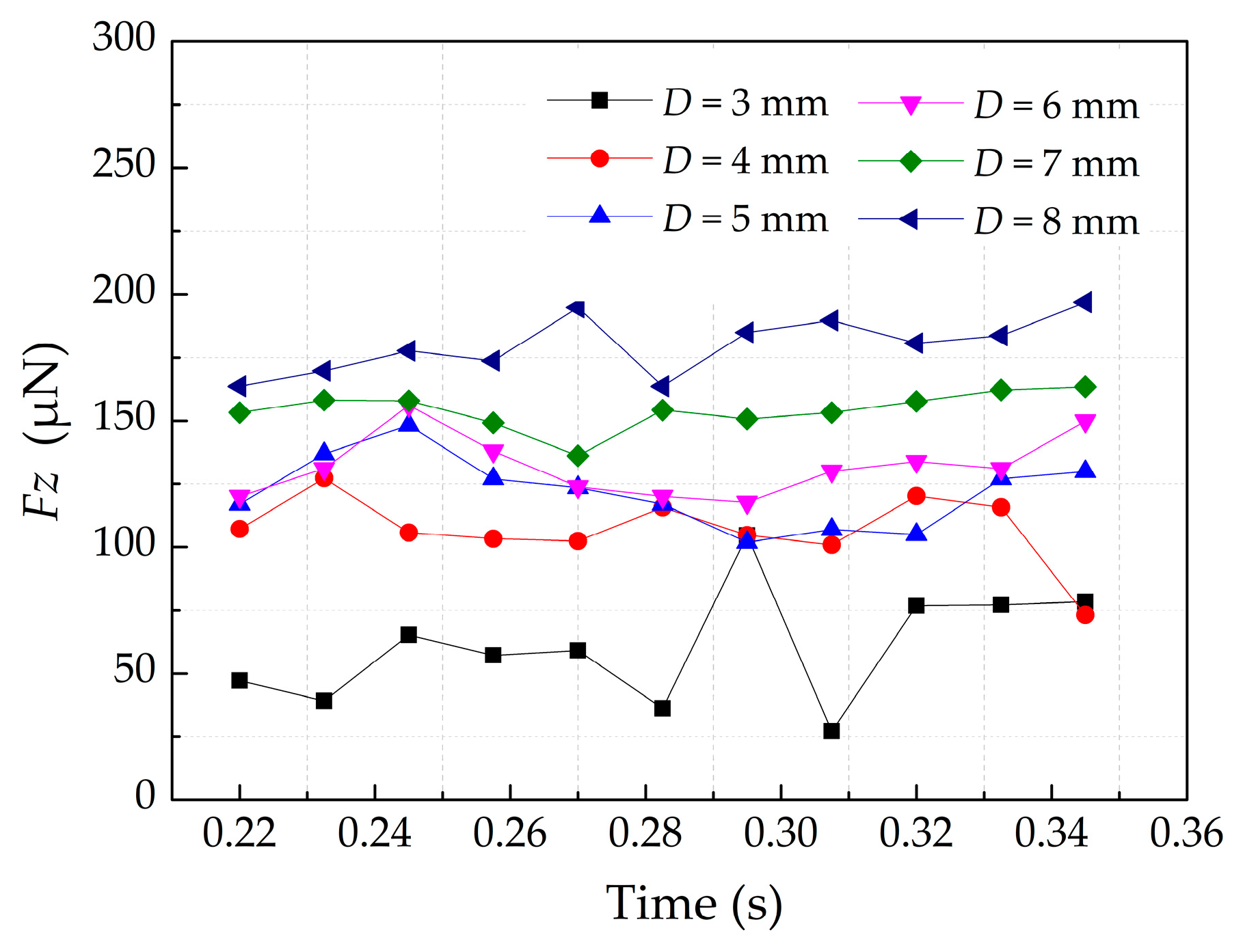

3.3. The Effect of Roller’s Diameter on Powder-Bed Density

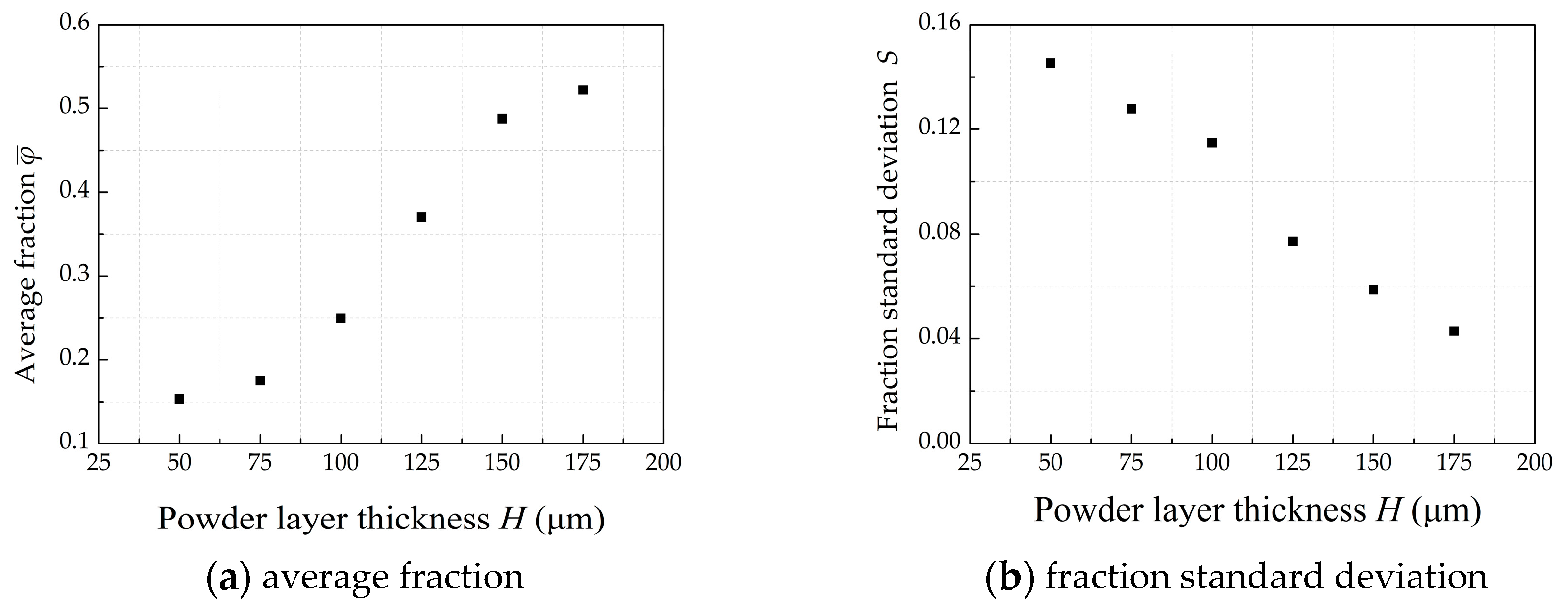

3.4. The Effect of Powder Layer Thickness on Powder-Bed Density

4. Conclusions

- (1)

- The increased roller’s translational velocity lead to a reduced number of particles in powder layer zone. This will lead to poor powder-bed density. The roller’s rotational speed has little effect on the powder-bed density.

- (2)

- When the roller’s diameter increases, more particles are in the powder compression zone. The normal contact force becomes strong, which enhances densification of powder-bed.

- (3)

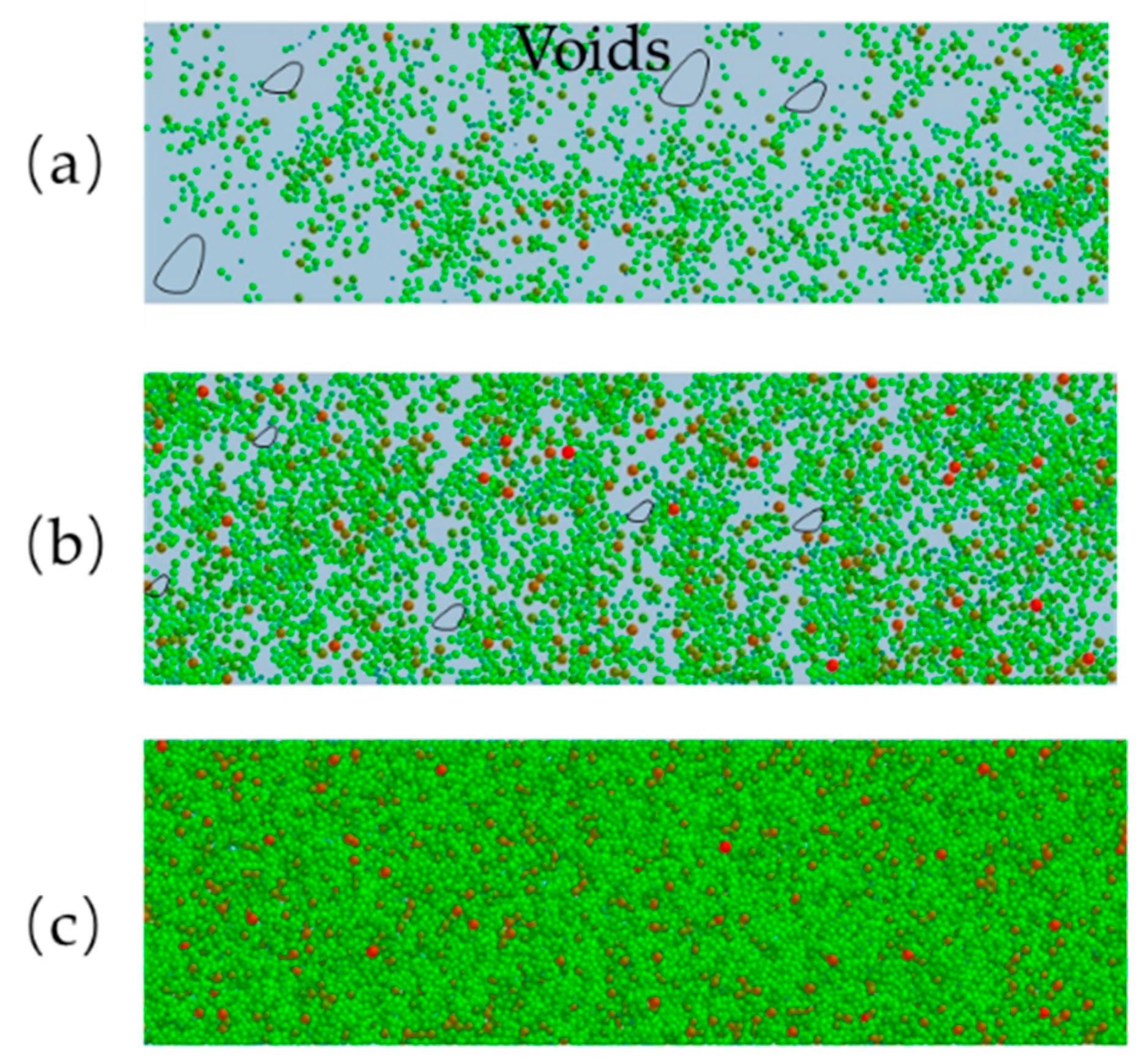

- Layer thickness is the most significant influencing factor on powder-bed density. When the layer thickness is 50 μm, most of the particles are pushed out of the build platform, forming a lot of voids. However, when the layer thickness is greater than 150 μm, the powder-bed becomes more uniform and denser.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Brandão, A.; Gerard, R.; Gumpinger, J.; Beretta, S.; Makaya, A.; Pambaguian, L.; Ghidini, T. Challenges in Additive Manufacturing of Space Parts: Powder Feedstock Cross-Contamination and its Impact on End Products. Materials 2017, 10, 522. [Google Scholar] [CrossRef] [PubMed]

- Rausch, A.; Küng, V.; Pobel, C.; Markl, M.; Körner, C. Predictive Simulation of Process Windows for Powder Bed Fusion Additive Manufacturing: Influence of the Powder Bulk Density. Materials 2017, 10, 1117. [Google Scholar] [CrossRef]

- Ali, U.; Mahmoodkhani, Y.; Imani Shahabad, S.; Esmaeilizadeh, R.; Liravi, F.; Sheydaeian, E.; Huang, K.Y.; Marzbanrad, E.; Vlasea, M.; Toyserkani, E. On the Measurement of Relative Powder-Bed Compaction Density in Powder-Bed Additive Manufacturing Processes. Mater. Des. 2018, 155, 495–501. [Google Scholar] [CrossRef]

- Zocca, A.; Colombo, P.; Gomes, C.M.; Günster, J. Additive Manufacturing of Ceramics: Issues, Potentialities, and Opportunities. J. Am. Ceram. Soc. 2015, 98, 1983–2001. [Google Scholar] [CrossRef]

- Wischeropp, T.M.; Emmelmann, C.; Brandt, M.; Pateras, A. Measurement of Actual Powder Layer Height and Packing Density in a Single Layer in Selective Laser Melting. Addit. Manuf. 2019, 28, 176–183. [Google Scholar] [CrossRef]

- Chen, H.; Wei, Q.; Wen, S.; Li, Z.; Shi, Y. Flow Behavior of Powder Particles in Layering Process of Selective Laser Melting: Numerical Modeling and Experimental Verification Based on Discrete Element Method. Int. J. Mach. Tools Manuf. 2017, 123, 146–159. [Google Scholar] [CrossRef]

- Zohdi, T.I. A Direct Particle-Based Computational Framework for Electrically Enhanced Thermo-Mechanical Sintering of Powdered Materials. Math. Mech. Solids 2013, 19, 93–113. [Google Scholar] [CrossRef]

- Zohdi, T.I. Additive Particle Deposition and Selective Laser Processing-A Computational Manufacturing Framework. Comput. Mech. 2014, 54, 171–191. [Google Scholar] [CrossRef]

- Steuben, J.C.; Iliopoulos, A.P.; Michopoulos, J.G. Discrete Element Modeling of Particle-Based Additive Manufacturing Processes. Comput. Method. Appl. M. 2016, 305, 537–561. [Google Scholar] [CrossRef]

- Haeri, S. Optimisation of Blade Type Spreaders for Powder Bed Preparation in Additive Manufacturing Using DEM Simulations. Powder Technol. 2017, 321, 94–104. [Google Scholar] [CrossRef]

- Lee, Y.S.; Nandwana, P.; Zhang, W. Dynamic Simulation of Powder Packing Structure for Powder Bed Additive Manufacturing. Int. J. Adv. Manuf. Technol. 2018, 96, 1–14. [Google Scholar] [CrossRef]

- Nan, W.; Ghadiri, M. Jamming during particle spreading in additive manufacturing. Powder Technol. 2018, 338, 253–262. [Google Scholar] [CrossRef]

- Parteli, E.J.R.; Pöschel, T. Particle-Based Simulation of Powder Application in Additive Manufacturing. Powder Technol. 2016, 288, 96–102. [Google Scholar] [CrossRef]

- Chen, H.; Wei, Q.; Zhang, Y.; Chen, F.; Shi, Y.; Yan, W. Powder-spreading mechanisms in powder-bed-based additive manufacturing: Experiments and computational modeling. Acta Mater. 2019, 179, 158–171. [Google Scholar] [CrossRef]

- Han, Q.; Gu, H.; Setchi, R. Discrete Element Simulation of Powder Layer Thickness in Laser Additive Manufacturing. Powder Technol. 2019, 352, 91–102. [Google Scholar] [CrossRef]

- Haeri, S.; Wang, Y.; Ghita, O.; Sun, J. Discrete Element Simulation and Experimental Study of Powder Spreading Process in Additive Manufacturing. Powder Technol. 2017, 306, 45–54. [Google Scholar] [CrossRef]

- Meier, C.; Weissbach, R.; Weinberg, J.; Wall, W.A.; John Hart, A. Modeling and Characterization of Cohesion in Fine Metal Powders with a Focus on Additive Manufacturing Process Simulations. Powder Technol. 2019, 343, 855–866. [Google Scholar] [CrossRef]

- Tan, Y.; Xiao, X.; Zhang, J.; Jiang, S. Determination of discrete element model contact parameters of nylon powder at SLS preheating temperature and its flow characteristics. Chin. J. Theor. Appl. Mech. 2019, 51, 56–63. [Google Scholar]

- Nan, W.; Pasha, M.; Ghadiri, M. Numerical simulation of particle flow and segregation during roller spreading process in additive manufacturing. Powder Technol. 2020, 364, 811–821. [Google Scholar] [CrossRef]

- Cundall, P.A.; Strack, O.D.L. Discussion: A discrete numerical model for granular assemblies. Géotechnique 1980, 30, 331–336. [Google Scholar] [CrossRef]

- Johnson, K.; Kendall, K. Surface Energy and the Contact of Elastic Solids. Proceedings of the Royal Society A: Mathematical. Phys. Eng. Sci. 1971, 324, 301–313. [Google Scholar]

- Di Renzo, A.; Di Maio, F.P. Comparison of Contact-Force Models for the Simulation of Collisions in DEM-based Granular Flow Codes. Chem. Eng. Sci. 2004, 59, 525–541. [Google Scholar] [CrossRef]

- Cleary, P.W. Predicting Charge Motion, Power Draw, Segregation and Wear in Ball Mills Using Discrete Element Methods. Miner. Eng. 1998, 11, 1061–1080. [Google Scholar] [CrossRef]

- Gilabert, F.A.; Roux, J.; Castellanos, A. Computer Simulation of Model Cohesive Powders: Influence of Assembling Procedure and Contact Laws on Low Consolidation States. Phys. Rev. E Stat. Nonlinear Soft Matter Phys. 2007, 75, 011303. [Google Scholar] [CrossRef] [PubMed]

- Mindlin, R.D. Vibrations of doubly-rotated-cut quartz plates with monoclinic symmetry. Int. J. Solids Struct. 1985, 21, 597–607. [Google Scholar] [CrossRef]

- Xiao, X.; Tan, Y.; Zhang, H.; Deng, R.; Jiang, S. Experimental and DEM studies on the Particle Mixing Performance in Rotating Drums: Effect of Area Ratio. Powder Technol. 2017, 314, 182–194. [Google Scholar] [CrossRef]

- Coetzee, C.J. Review: Calibration of the discrete element method. Powder Technol. 2017, 310, 104–142. [Google Scholar] [CrossRef]

- Peng, Z.; Luo, X.; Xie, Z.; An, D.; Yang, M. Effect of print path process on sintering behavior and thermal shock resistance of Al2O3 ceramics fabricated by 3D inkjet-printing. Ceram. Int. 2018, 44, 16766–16772. [Google Scholar] [CrossRef]

- Wu, D.; Liu, H.; Lu, F.; Ma, G.; Yan, S.; Niu, F.; Guo, D. Al2O3-YAG eutectic ceramic prepared by laser additive manufacturing with water-cooled substrate. Ceram. Int. 2019, 45, 4119–4122. [Google Scholar] [CrossRef]

- Hu, Y.; Ning, F.; Cong, W.; Li, Y.; Wang, X.; Wang, H. Ultrasonic Vibration-Assisted Laser Engineering Net Shaping of ZrO2-Al2O3 Bulk Parts: Effects on Crack Suppression, Microstructure, and Mechanical Properties. Ceram. Int. 2018, 44, 2752–2760. [Google Scholar] [CrossRef]

- Tahir, A.; Rasche, S.; Könke, C. Discrete Element Model Development of ZTA Ceramic Granular Powder Using Micro Computed Tomography. Adv. Powder Technol. 2018, 29, 3471–3482. [Google Scholar] [CrossRef]

- Hanley, K.J.; O’Sullivan, C. Analytical Study of the Accuracy of Discrete Element Simulations. Int. J. Numer. Meth. Eng. 2017, 109, 29–51. [Google Scholar] [CrossRef]

- ASTM_International. ASTM D6773-08, Standard Shear Test Method for Bulk Solids Using the Schulze Ring Shear Tester; ASTM_International: West Conshohocken, PA, USA, 2008. [Google Scholar]

- International Standardisation Organisation. ISO 4490:2014—Metallic Powders—Determination of Flow Rate by Means of a Calibrated Funnel (Hall Flowmeter); ISO: Geneva, Switzerland, 2014. [Google Scholar]

- Chen, H.; Chen, Y.; Liu, Y.; Wei, Q.; Shi, Y.; Yan, W. Packing quality of powder layer during counter-rolling-type powder spreading process in additive manufacturing. Int. J. Mach. Tools Manuf. 2020, 153, 103553. [Google Scholar] [CrossRef]

- Zheng, Y.; Zhang, K.; Liu, T.T.; Liao, W.H.; Zhang, C.D.; Shao, H. Cracks of Alumina Ceramics by Selective Laser Melting. Ceram. Int. 2019, 45, 175–184. [Google Scholar] [CrossRef]

| Parameter | Equations |

|---|---|

| Normal stiffness constant | |

| Damping ratio | |

| Tangential stiffness | |

| Equivalent shear modulus | |

| Equivalent Young’s Modulus | |

| Equivalent mass | |

| Equivalent radius |

| Parameter | Value |

|---|---|

| Particle density (kg/m3) | 3820 |

| Particle size D (50) (μm) | 48 |

| Particle shear modulus (GPa) | 3 |

| Particle Poisson’s ratio | 0.3 |

| Roller density (kg/m3) | 7800 |

| Roller shear modulus (GPa) | 80 |

| Roller Poisson’s ratio | 0.3 |

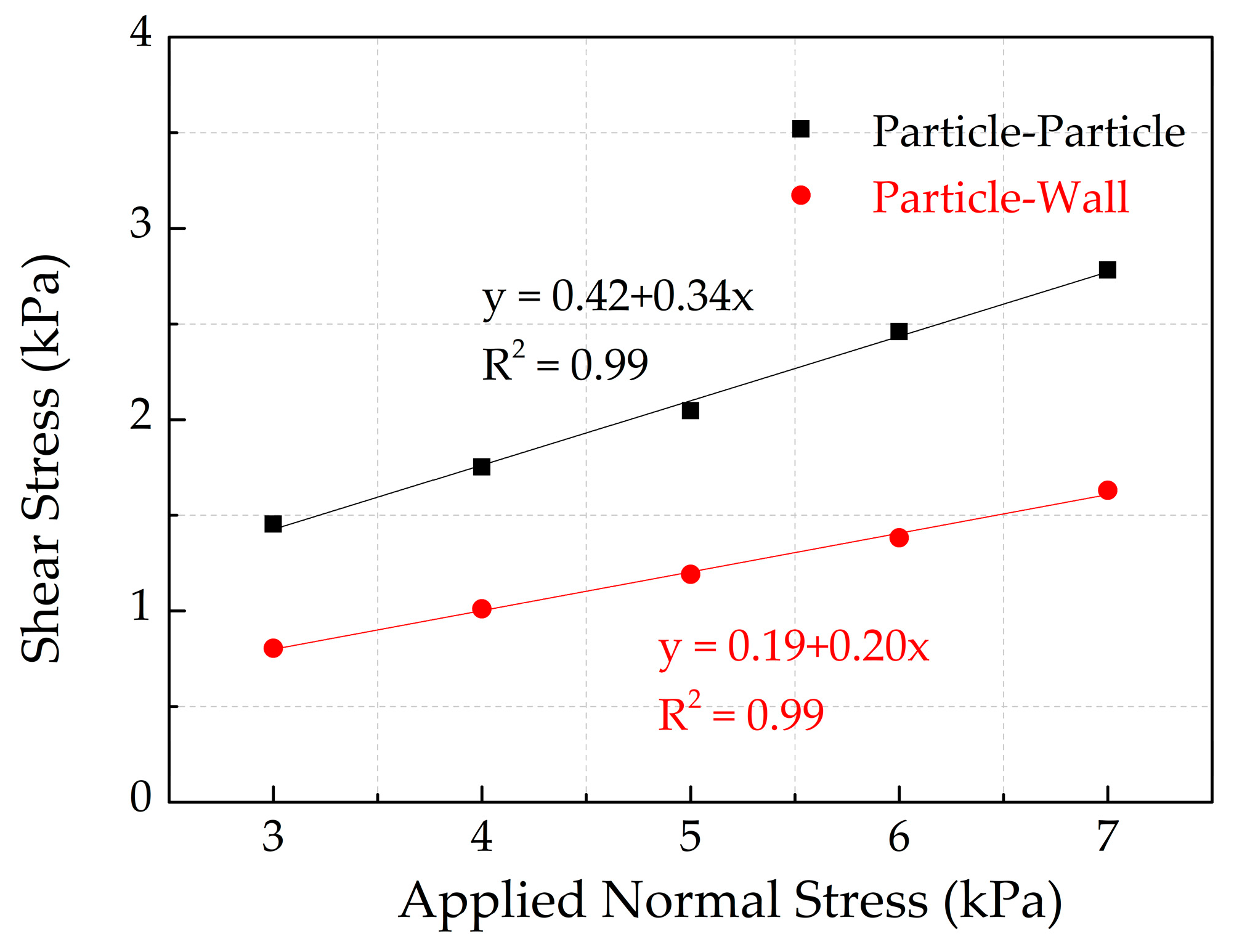

| Static friction coefficient of particle-wall | 0.20 |

| Rolling friction coefficient of particle-wall | 0.05 |

| Restitution coefficient of particle-wall | 0.52 |

| Surface energy density of particle-wall (mJ/m2) | 0.17 |

| Static friction coefficient of particle-particle | 0.34 |

| Rolling friction coefficient of particle-particle | 0.05 |

| Restitution coefficient of particle-particle | 0.50 |

| Surface energy density of particle-particle (mJ/m2) | 0.15 |

| Parameters | Value |

|---|---|

| Roller’s translational velocity Vs (mm/s) | 40/60/80/100/120/140/160 |

| Roller’s rotational velocity ω (rpm) | 40/80/120/160/200/240/280/320 |

| Roller’s diameter D (mm) | 3/4/5/6/7/8 |

| Powder layer thickness H (μm) | 50/75/100/125/150/175 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Tan, Y.; Bao, T.; Xu, Y.; Xiao, X.; Jiang, S. Discrete Element Simulation of the Effect of Roller-Spreading Parameters on Powder-Bed Density in Additive Manufacturing. Materials 2020, 13, 2285. https://doi.org/10.3390/ma13102285

Zhang J, Tan Y, Bao T, Xu Y, Xiao X, Jiang S. Discrete Element Simulation of the Effect of Roller-Spreading Parameters on Powder-Bed Density in Additive Manufacturing. Materials. 2020; 13(10):2285. https://doi.org/10.3390/ma13102285

Chicago/Turabian StyleZhang, Jiangtao, Yuanqiang Tan, Tao Bao, Yangli Xu, Xiangwu Xiao, and Shengqiang Jiang. 2020. "Discrete Element Simulation of the Effect of Roller-Spreading Parameters on Powder-Bed Density in Additive Manufacturing" Materials 13, no. 10: 2285. https://doi.org/10.3390/ma13102285

APA StyleZhang, J., Tan, Y., Bao, T., Xu, Y., Xiao, X., & Jiang, S. (2020). Discrete Element Simulation of the Effect of Roller-Spreading Parameters on Powder-Bed Density in Additive Manufacturing. Materials, 13(10), 2285. https://doi.org/10.3390/ma13102285