Micromachining of Biolox Forte Ceramic Utilizing Combined Laser/Ultrasonic Processes

Abstract

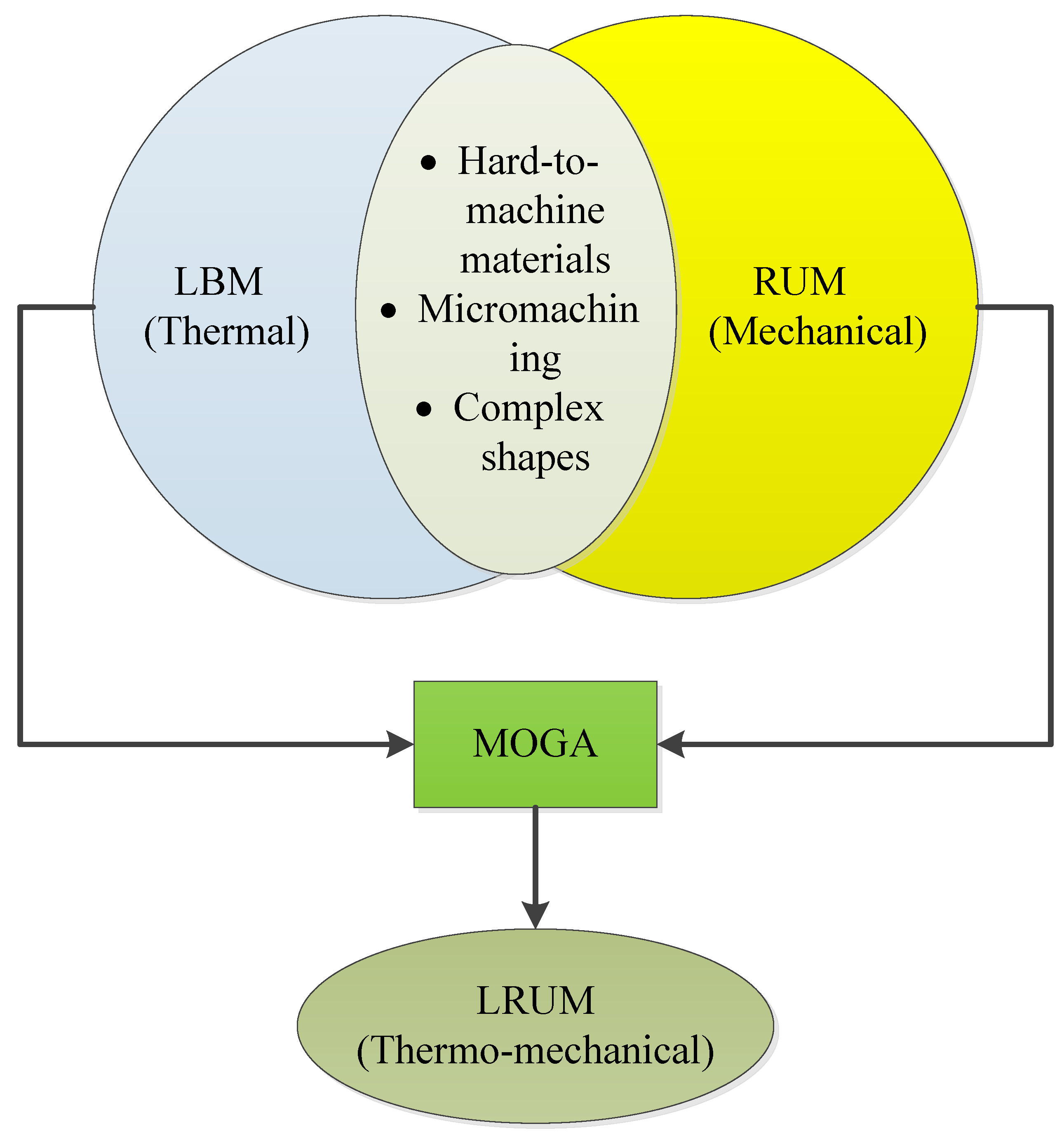

:1. Introduction

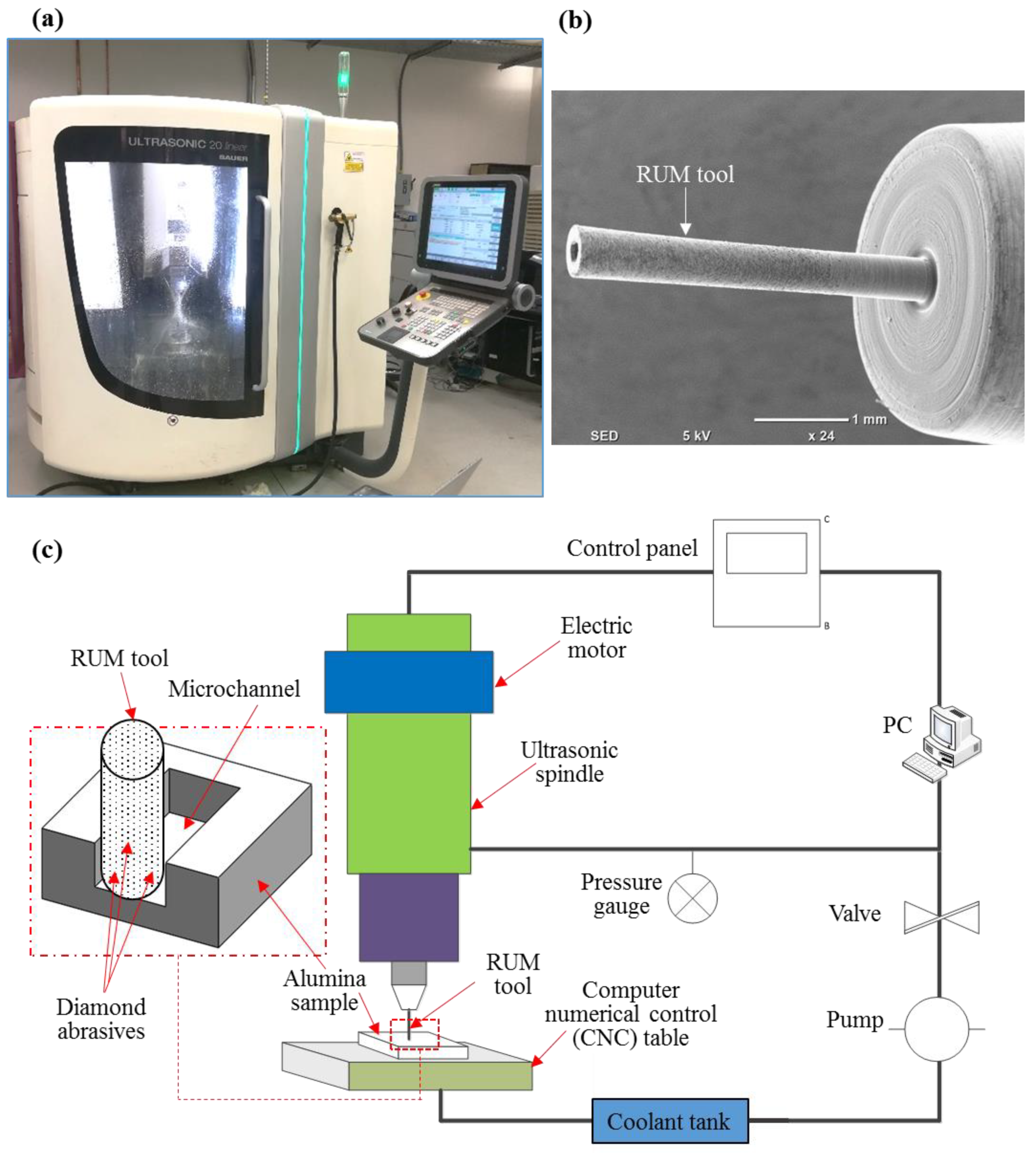

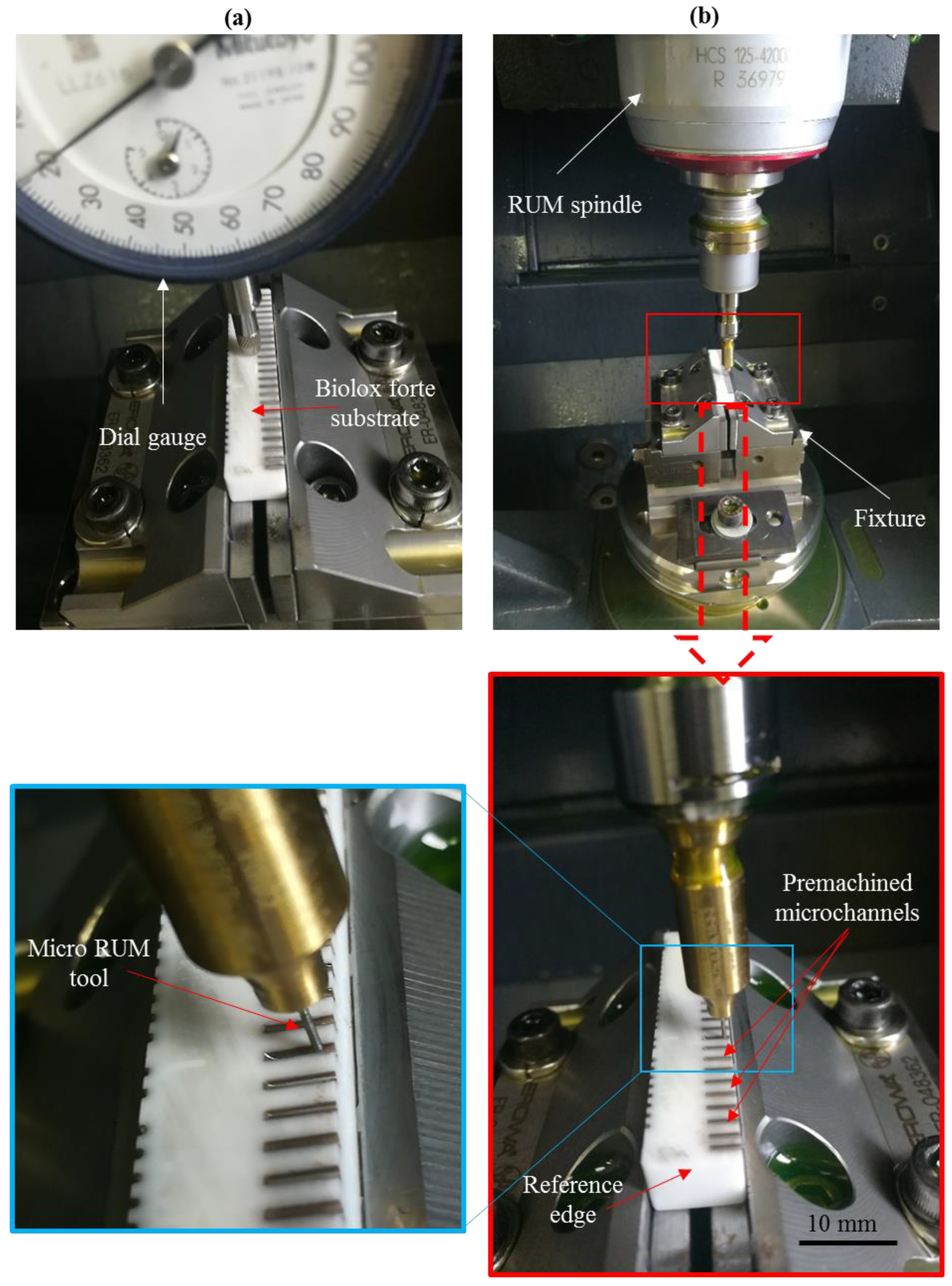

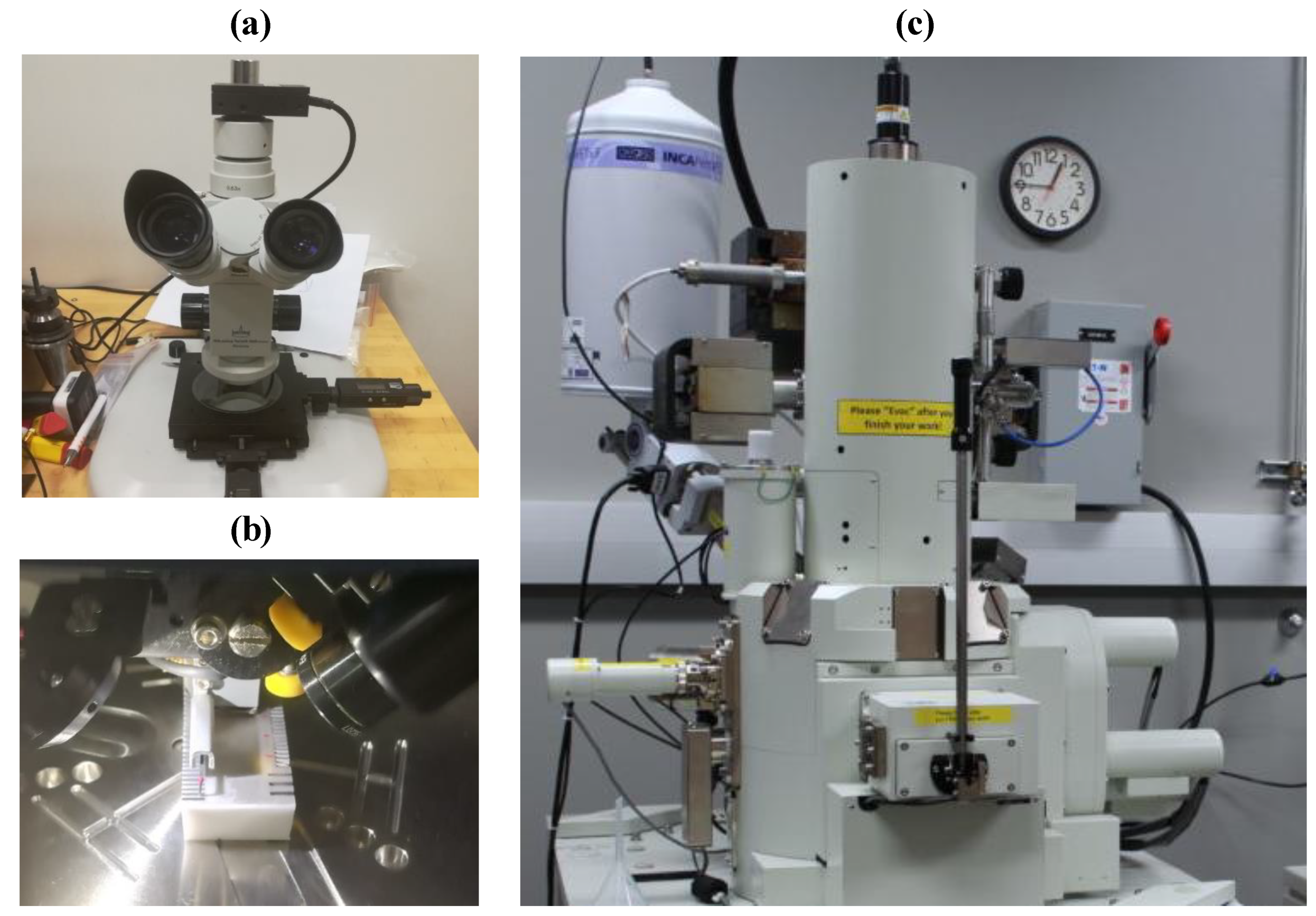

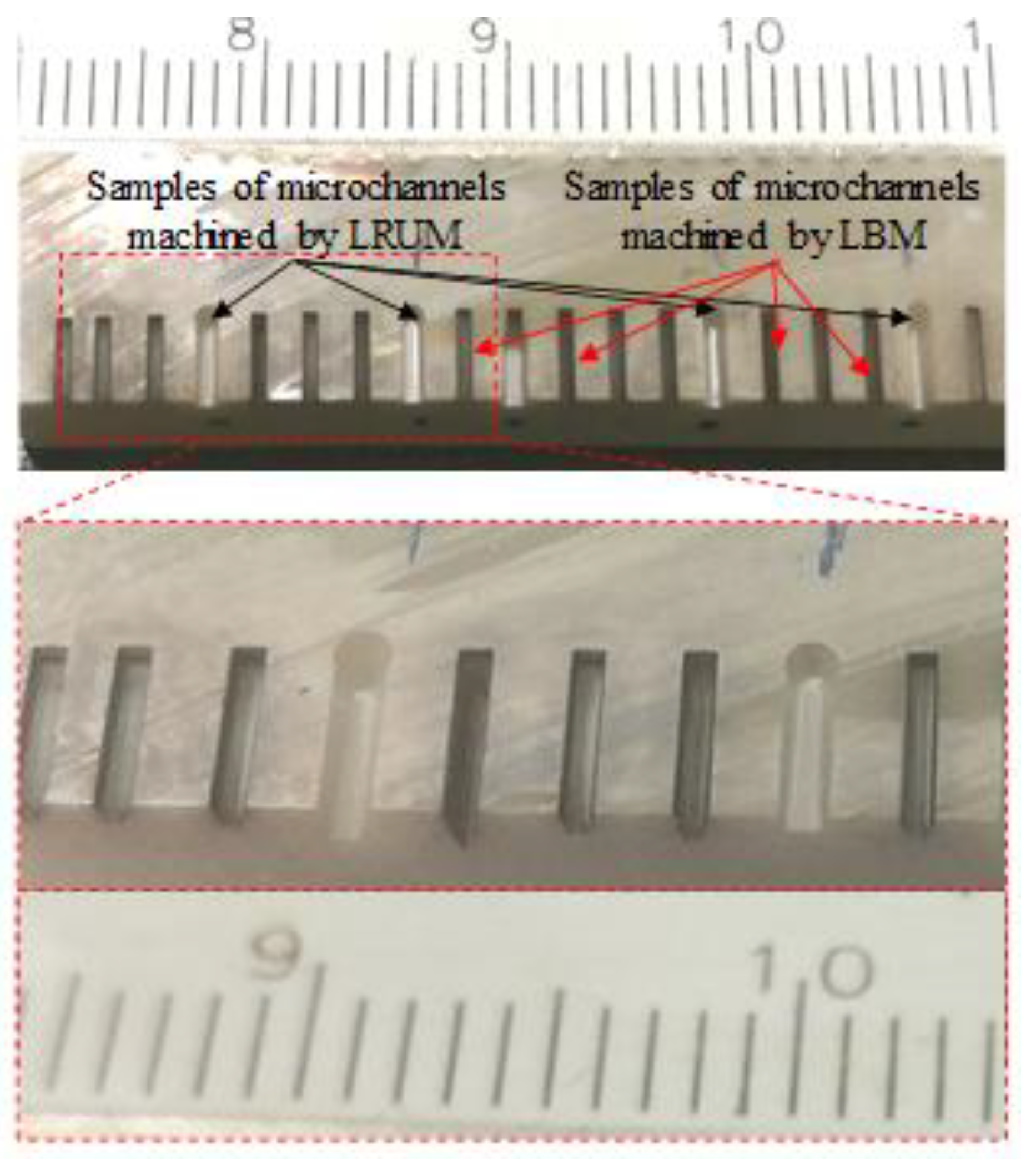

2. Material and Method

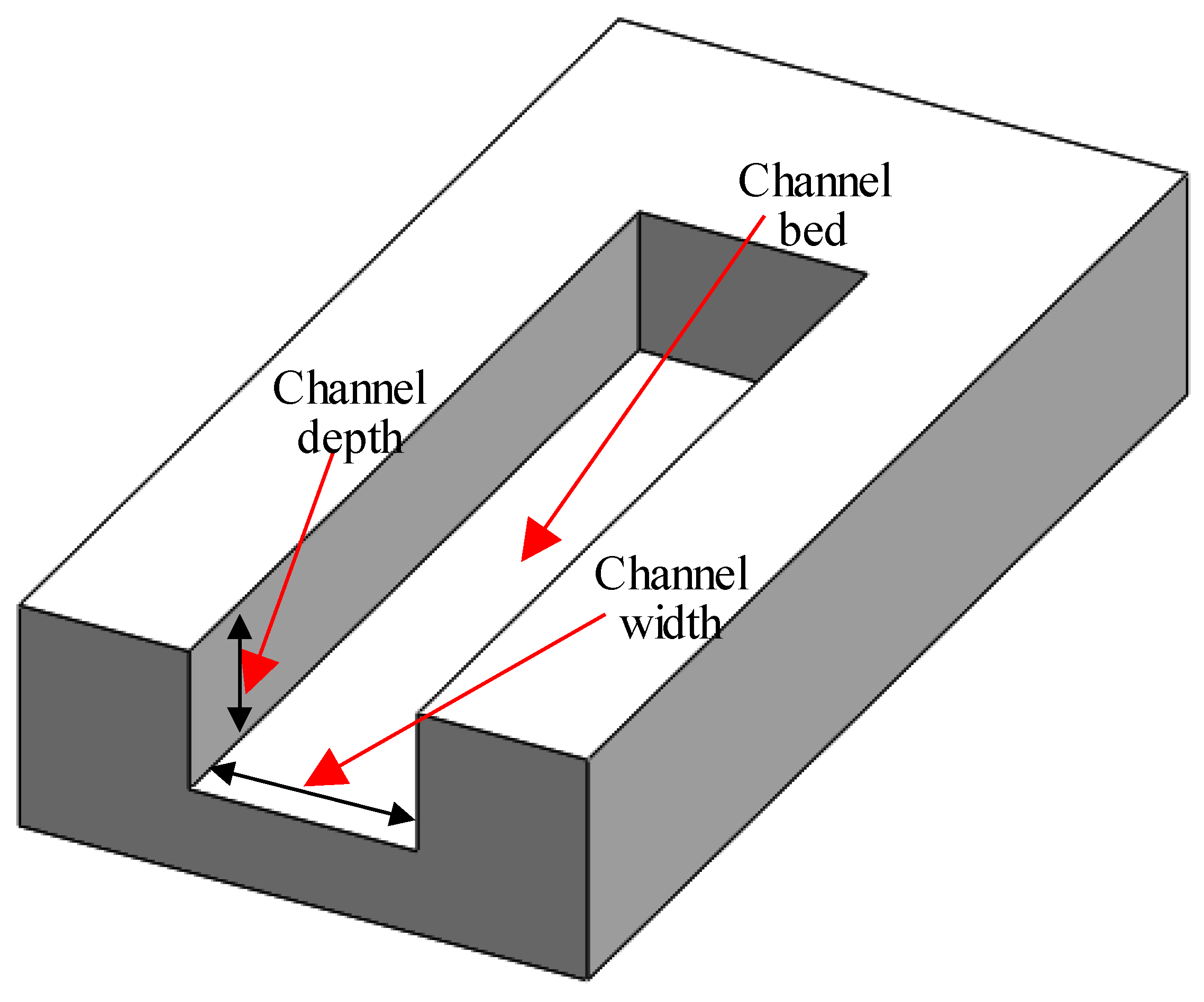

2.1. Machining Conditions

2.2. Multi-Objective Genetic Algorithm

2.3. Measurement Method

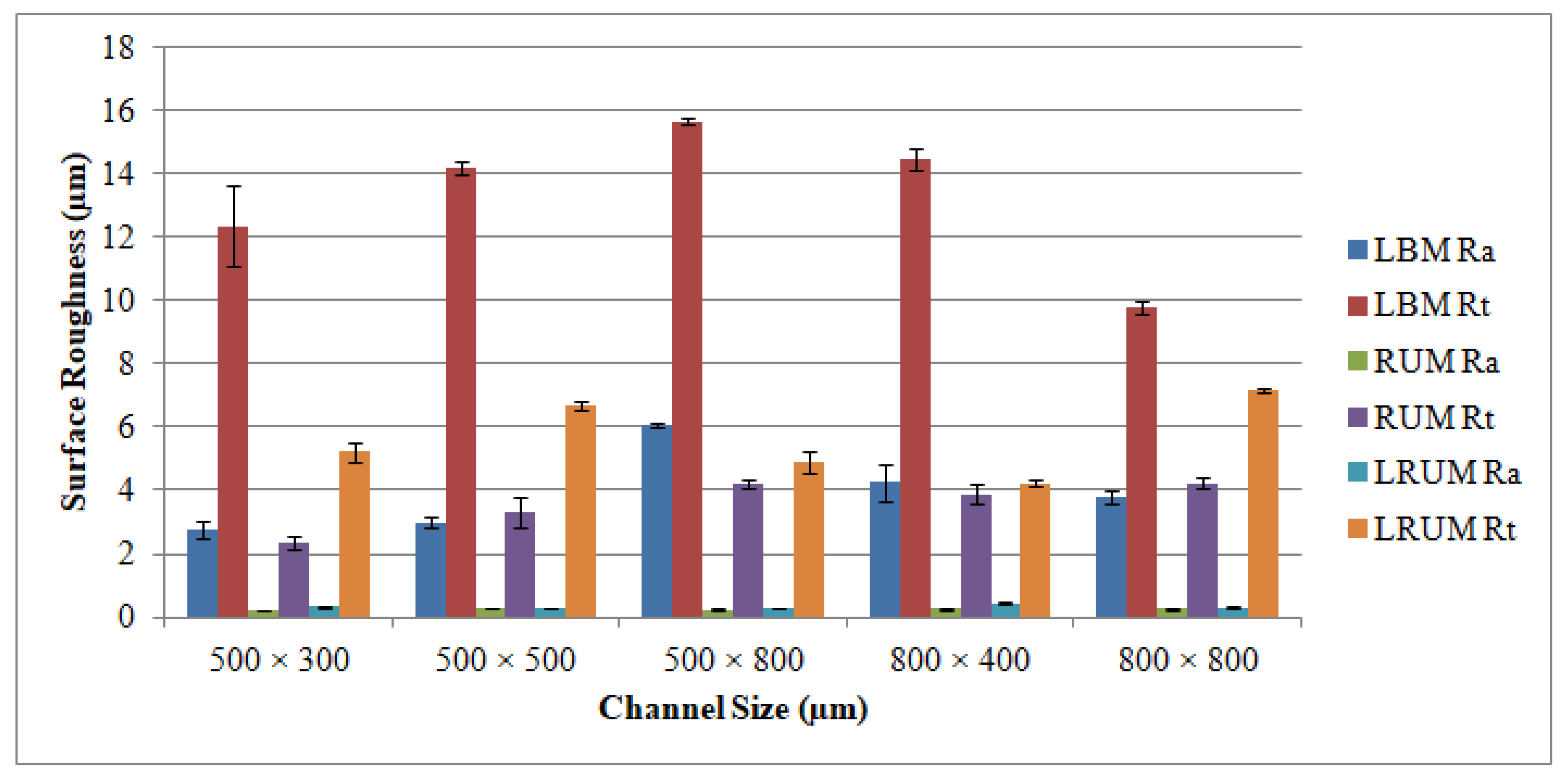

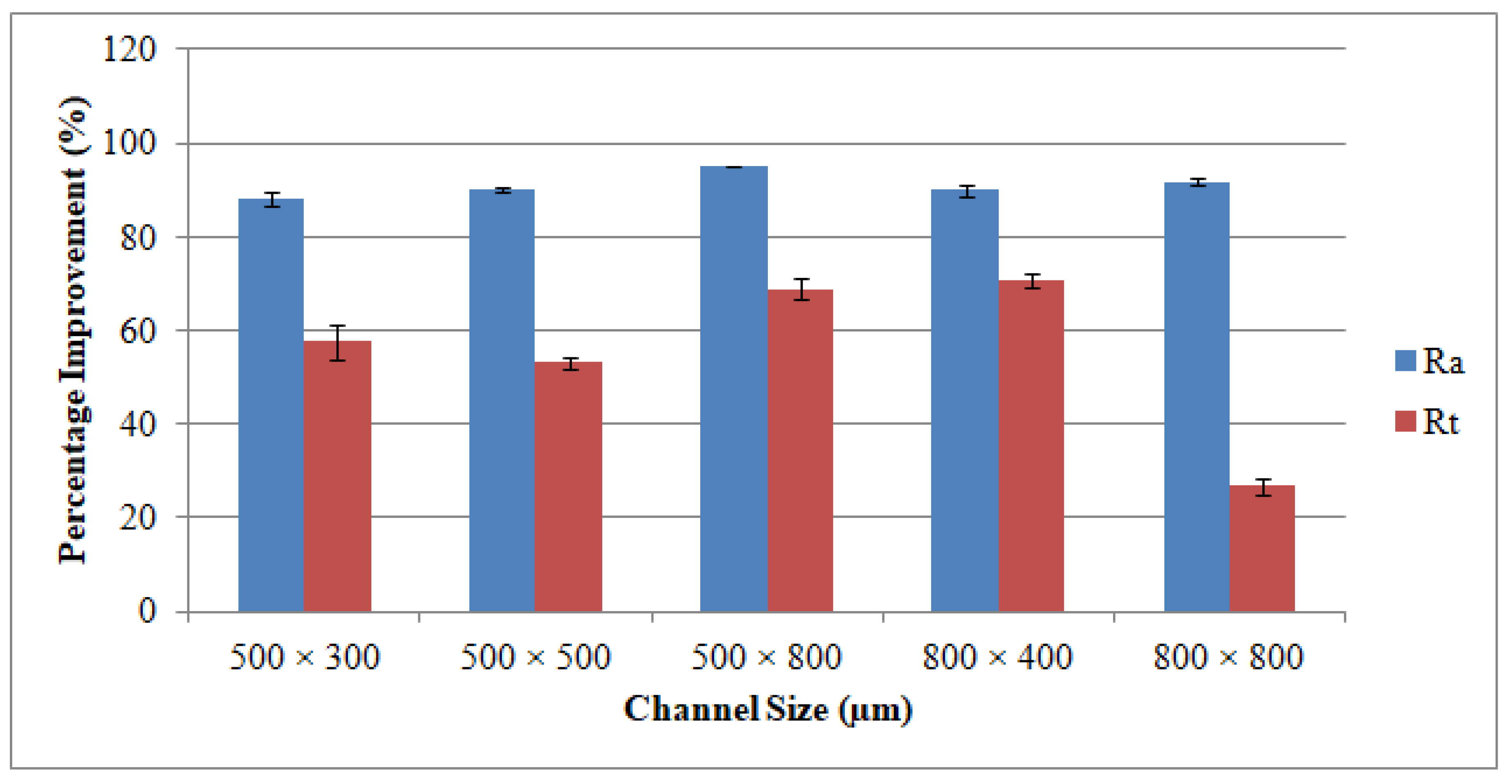

3. Results and Analysis

3.1. Surface Roughness

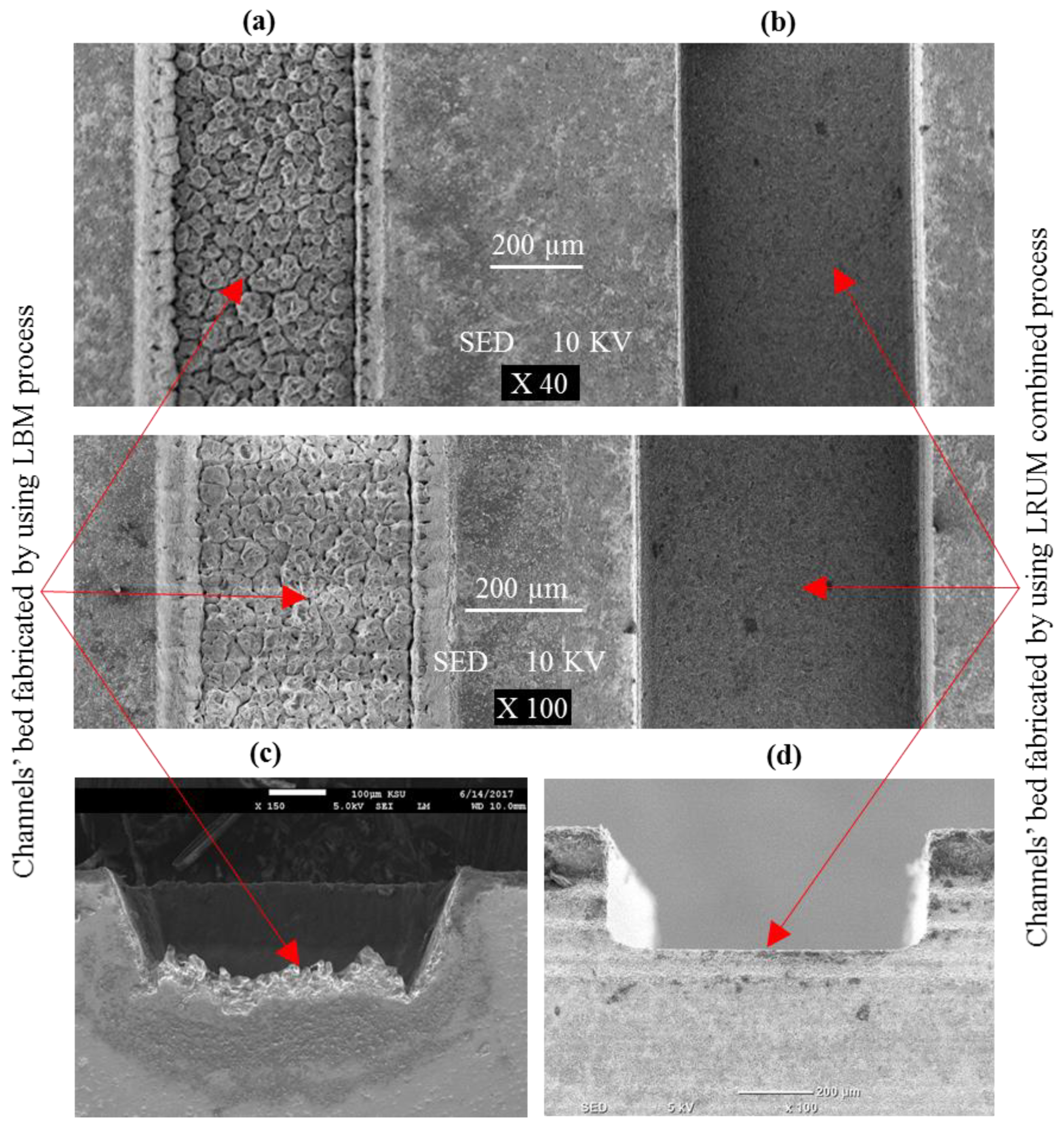

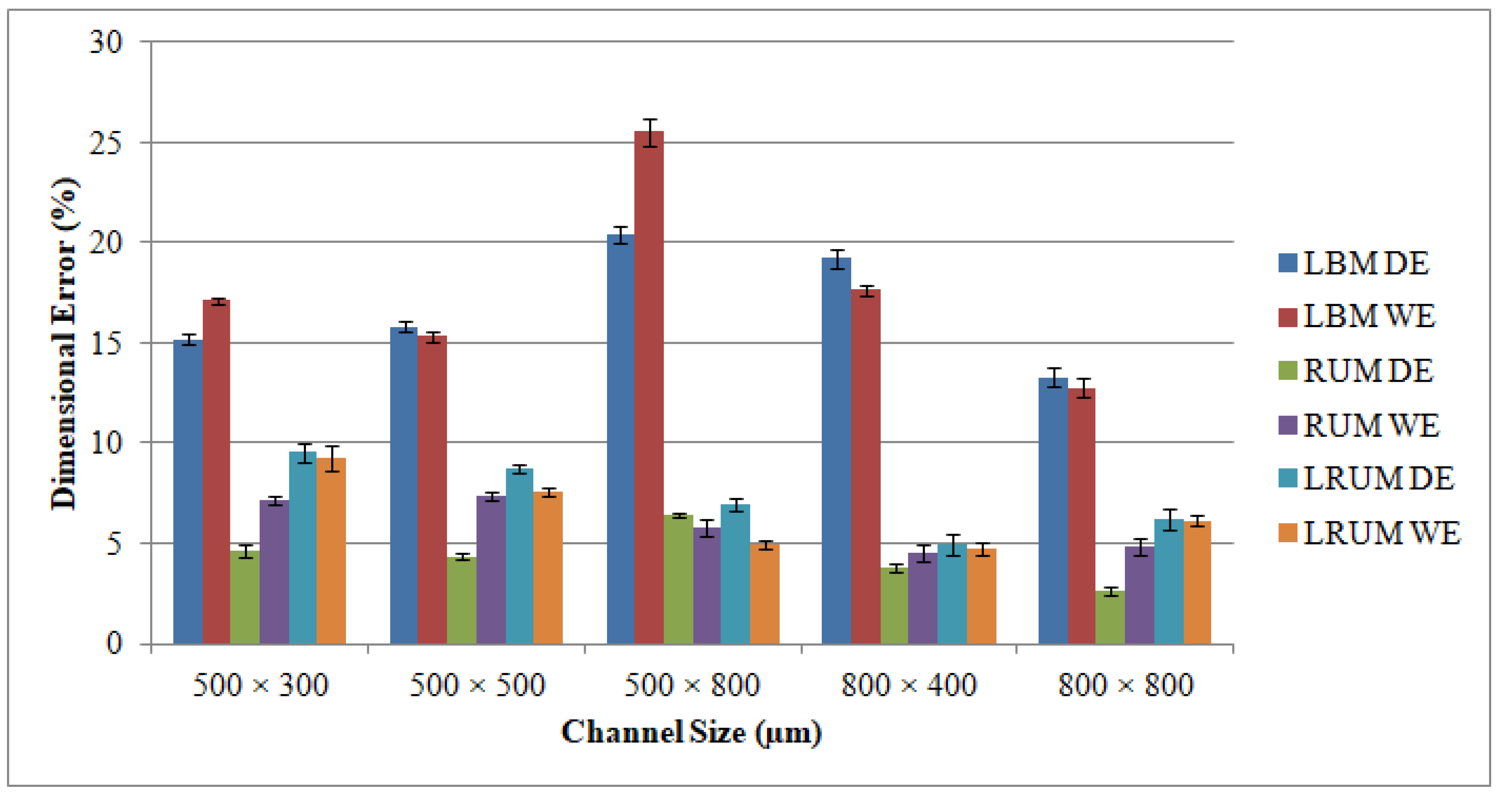

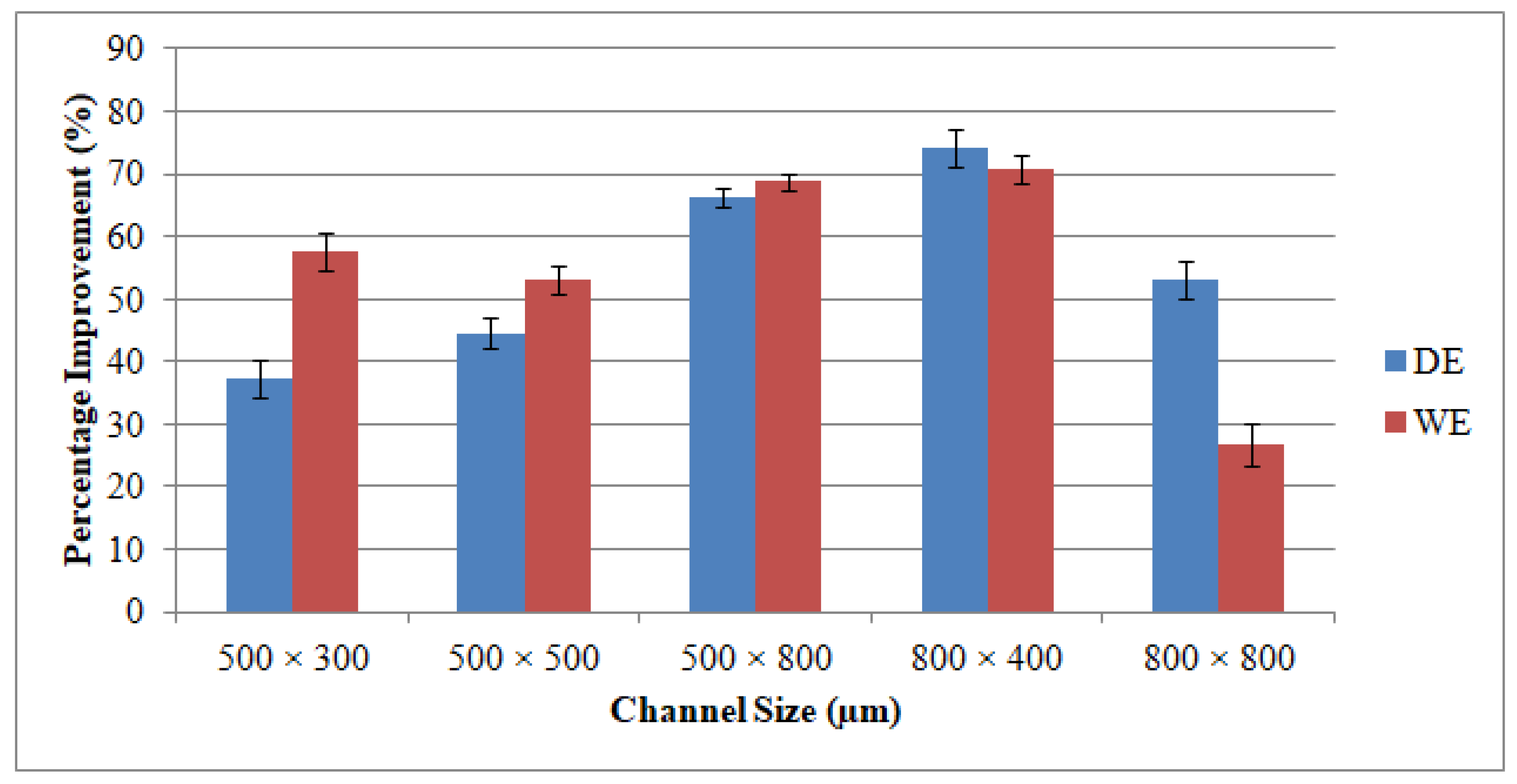

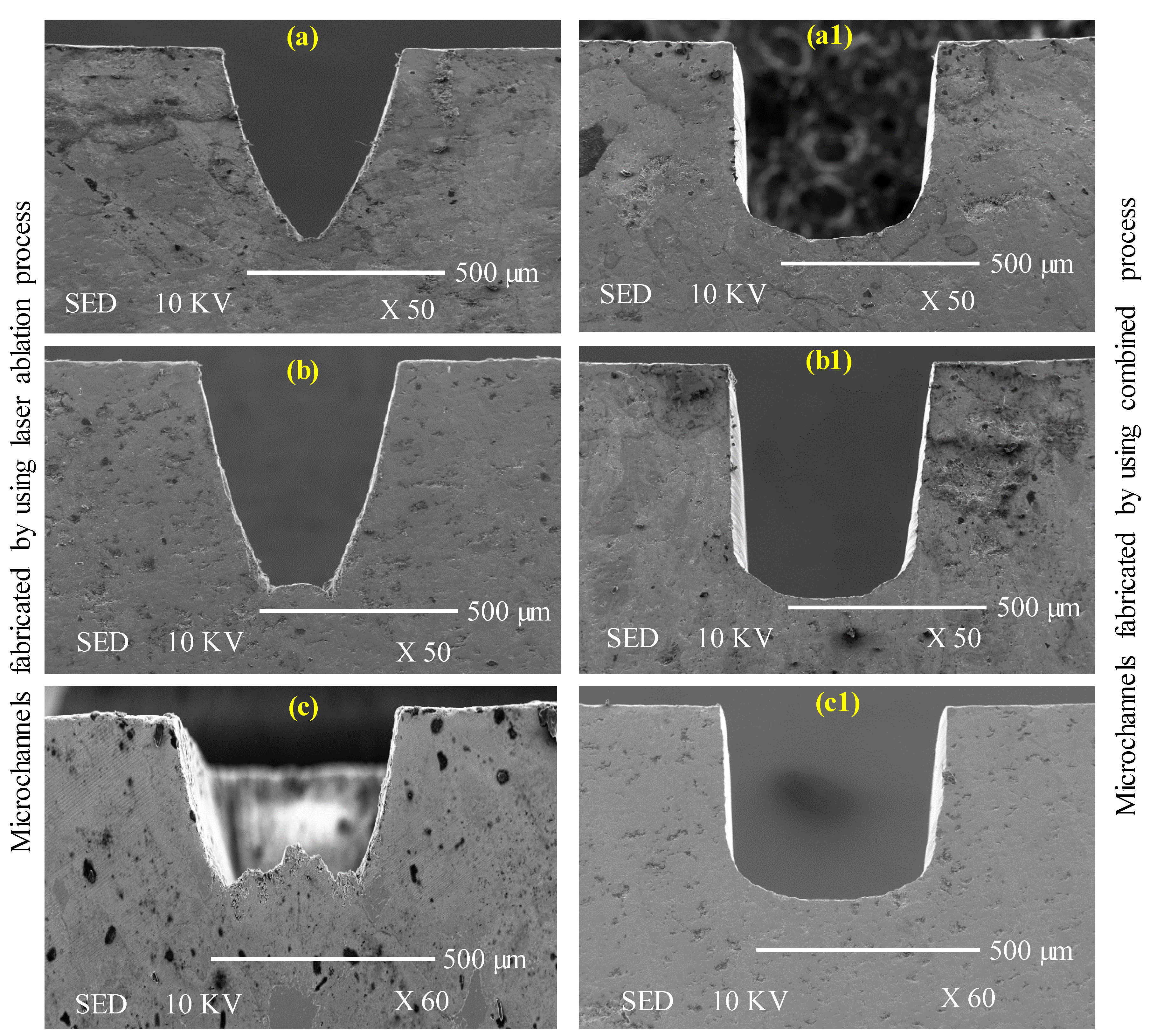

3.2. Dimensional Accuracy

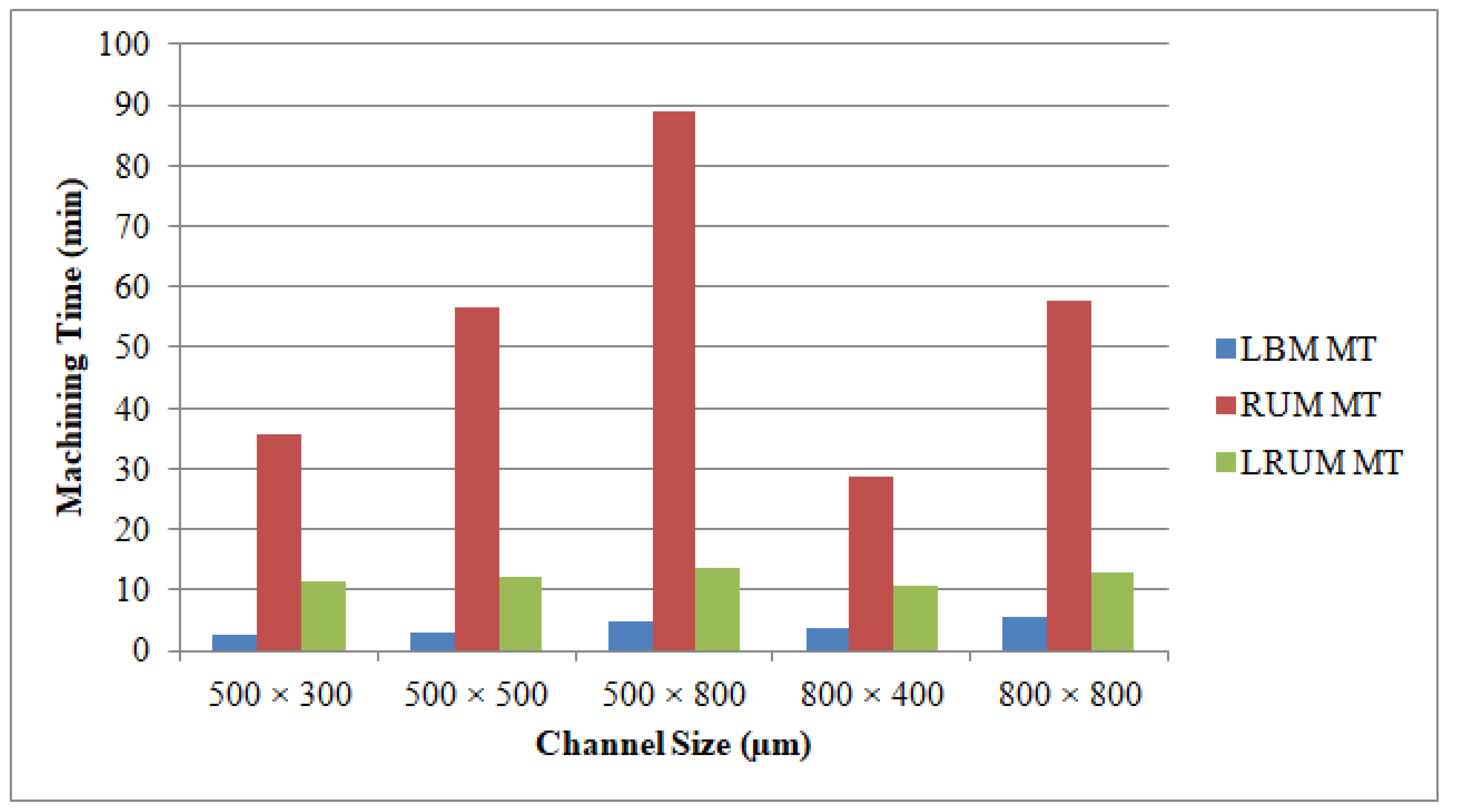

3.3. Machining Time

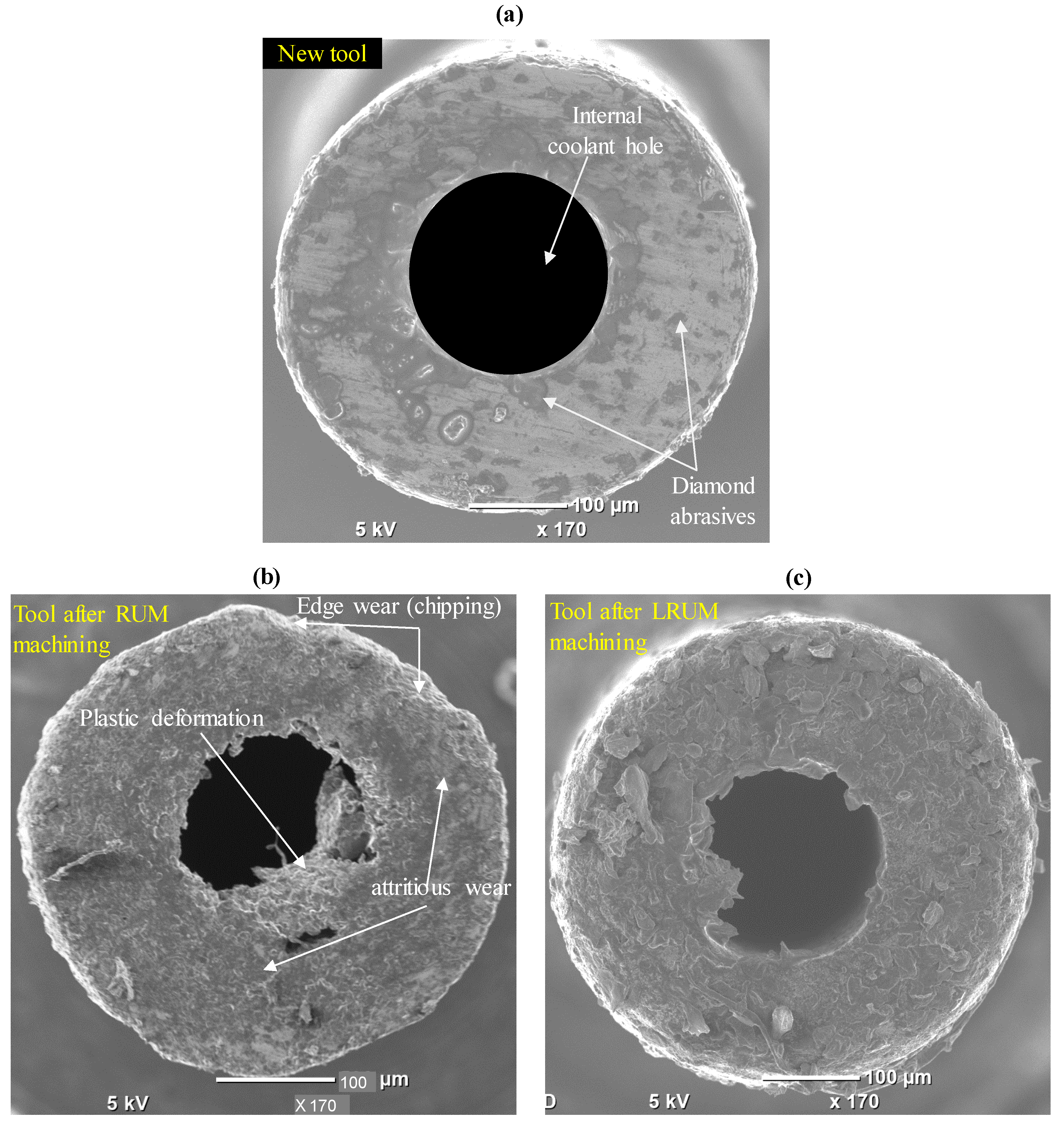

3.4. Tool Wear

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Schneider, F.; Das, J.; Kirsch, B.; Linke, B.; Aurich, J.C. Sustainability in ultra precision and micro machining: A review. Int. J. Precis. Eng. Manuf. Green Technol. 2019, 6, 601–610. [Google Scholar] [CrossRef] [Green Version]

- Hasan, M.; Zhao, J.; Jiang, Z. Micromanufacturing of composite materials: A review. Int. J. Extrem. Manuf. 2019, 1, 012004. [Google Scholar] [CrossRef]

- Ruggeri, S.; Fontana, G.; Fassi, I. Micro-assembly. In Micro-Manufacturing Technologies and Their Applications; Springer: Berlin, Germany, 2017. [Google Scholar] [CrossRef]

- Fallahi, H.; Zhang, J.; Phan, H.P.; Nguyen, N.T. Flexible microfluidics: Fundamentals, recent developments, and applications. Micromachines 2019, 10, 830. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ahmed, N.; Darwish, S.; Alahmari, A.M. Laser ablation and laser-hybrid ablation processes: A review. Mater. Manuf. Process. 2016, 31, 1121–1142. [Google Scholar] [CrossRef]

- Cheng, C.; Tsai, X.; Chen, J. Micromachining of stainless steel with controllable ablation depth using femtosecond laser pulses. Int. J. Adv. Manuf. Technol. 2016, 1947–1954. [Google Scholar] [CrossRef]

- Sunderlal, S.; Kr, P.; Khare, A.; Joshi, S.N. Effect of laser beam conditioning on fabrication of clean micro-channel on stainless steel 316L using second harmonic of Q-switched Nd: YAG laser. Opt. Laser Technol. 2018, 99, 107–117. [Google Scholar] [CrossRef]

- Tangwarodomnukun, V.; Wuttisarn, T. Evolution of milled cavity in the multiple laser scans of titanium alloy under a flowing water layer. Int. J. Adv. Manuf. Technol. 2017, 92, 293–302. [Google Scholar] [CrossRef]

- Darwish, S.; Ahmed, N.; Alahmari, A.M. A study of micro-channel size and spatter dispersion for laser beam micro-milling. Mater. Manuf. Process. 2017, 32, 171–184. [Google Scholar] [CrossRef]

- Chen, J.; Zhou, X.; Lin, S.; Tu, Y. A prediction-correction scheme for microchannel milling using femtosecond laser. Opt. Lasers Eng. 2017, 91, 115–123. [Google Scholar] [CrossRef]

- Teixidor, D.; Orozco, F. Effect of process parameters in nanosecond pulsed laser micromachining of PMMA-based microchannels at near-infrared and ultraviolet wavelengths. Int. J. Adv. Manuf. Technol. 2013, 67, 1651–1664. [Google Scholar] [CrossRef]

- Prakash, S.; Kumar, S. Experimental investigations and analytical modeling of multi-pass CO2 laser processing on PMMA. Precis. Eng. 2017, 49, 220–234. [Google Scholar] [CrossRef]

- Mccann, R.; Bagga, K.; Groarke, R.; Stalcup, A. Microchannel fabrication on cyclic olefin polymer substrates via 1064 nm Nd: YAG laser ablation. Appl. Surf. Sci. 2016, 387, 603–608. [Google Scholar] [CrossRef] [Green Version]

- Prakash, S.; Kumar, S. Fabrication of microchannels on transparent PMMA using CO2 laser (10.6 µm) for microfluidic applications: An experimental investigation. Int. J. Precis. Eng. Manuf. 2015, 16, 361–366. [Google Scholar] [CrossRef]

- Nieto, D.; Delgado, T.; Flores-arias, M.T. Fabrication of microchannels on soda-lime glass substrates with a Nd: YVO4 laser. Opt. Lasers Eng. 2014, 63, 11–18. [Google Scholar] [CrossRef]

- Bulushev, E.; Bessmeltsev, V.; Dostovalov, A.; Goloshevsky, N.; Wolf, A. High-speed and crack-free direct-writing of microchannels on glass by an IR femtosecond laser. Opt. Lasers Eng. 2016, 79, 39–47. [Google Scholar] [CrossRef]

- Chang, T.; Chen, Z.; Lee, Y.; Li, Y.; Wang, C. Ultrafast laser ablation of soda-lime glass for fabricating micro fl uidic pillar array channels. Microelectron. Eng. 2016, 158, 95–101. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, L.; Deng, J.; Meng, R.; Zou, X.; Wu, F. Fabrication of micro-scale textured grooves on green ZrO2 ceramics by pulsed laser ablation. Ceram. Int. 2017, 43, 6519–6531. [Google Scholar] [CrossRef]

- Garcia-Giron, A.; Sola, D.; Pena, J.I. Liquid-assisted laser ablation of advanced ceramics and glass-ceramic materials. Appl. Surf. Sci. 2016, 363, 548–554. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, Y.; Zhang, J.; Liu, Y.; Yang, X.; Zhang, Q. Micromachining features of TiC ceramic by femtosecond pulsed laser. Ceram. Int. 2015, 41, 6525–6533. [Google Scholar] [CrossRef]

- Adelmann, B.; Hellmann, R. Rapid micro hole laser drilling in ceramic substrates using single mode fiber laser. J. Mater. Process. Technol. 2015, 221, 80–86. [Google Scholar] [CrossRef]

- Zhang, J.; Long, Y.; Liao, S.; Lin, H.T.; Wang, C. Effect of laser scanning speed on geometrical features of Nd:YAG laser machined holes in thin silicon nitride substrate. Ceram. Int. 2017, 43, 2938–2942. [Google Scholar] [CrossRef]

- Leitz, K.H.; Redlingshöer, B.; Reg, Y.; Otto, A.; Schmidt, M. Metal ablation with short and ultrashort laser pulses. Phys. Procedia 2011, 12, 230–238. [Google Scholar] [CrossRef] [Green Version]

- Gaudiuso, C.; Volpe, A.; Ancona, A. One-step femtosecond laser stealth dicing of quartz. Micromachines 2020, 11, 327. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Oosterbeek, R.N.; Ward, T.; Corazza, C.; Bodley, O.; Ashforth, S.; Rodda, A.; Simpson, M.C. Fast femtosecond laser ablation for efficient cutting of sintered alumina and quartz substrates. In Proceedings of the 2016 Conference on Lasers Electro-Optics, San Jose, CA, USA, 5–10 June 2016; pp. 1–13. [Google Scholar] [CrossRef]

- Olbrich, M.; Punzel, E.; Lickschat, P.; Weißmantel, S.; Horn, A. Investigation on the ablation of thin metal films with femtosecond to picosecond-pulsed laser radiation. Phys. Procedia 2016, 83, 93–103. [Google Scholar] [CrossRef] [Green Version]

- Kataria, R.; Kumar, J. Ultrasonic machining: A review. Adv. Mater. Res. 2016, 1137, 61–78. [Google Scholar] [CrossRef]

- Li, Z.; Yuan, S.; Zhang, C. Research on the rotary ultrasonic facing milling of ceramic matrix composites. Procedia CIRP 2016, 56, 428–433. [Google Scholar] [CrossRef] [Green Version]

- Abdo, B.M.A.; El-tamimi, A.; Nasr, E.A. Rotary ultrasonic machining of alumina ceramic: An experimental investigation of tool path and tool overlapping. Appl. Sci. 2020, 10, 1667. [Google Scholar] [CrossRef] [Green Version]

- Sreehari, D.; Kumar, A. On form accuracy and surface roughness in micro-ultrasonic machining of silicon microchannels. Precis. Eng. 2018, 53, 300–309. [Google Scholar] [CrossRef]

- Ning, F.; Wang, H.; Hu, Y.; Cong, W.; Zhang, M.; Li, Y. Rotary ultrasonic surface machining of CFRP composites: A comparison with conventional surface grinding. Procedia Manuf. 2017, 10, 557–567. [Google Scholar] [CrossRef]

- Lv, D.; Huang, Y.; Wang, H.; Tang, Y.; Wu, X. Improvement effects of vibration on cutting force in rotary ultrasonic machining of BK7 glass. J. Mater. Process. Technol. 2013, 213, 1548–1557. [Google Scholar] [CrossRef]

- Fernando, P.; Zhang, M.; Pei, Z.; Cong, W. Intermittent and continuous rotary ultrasonic machining of K9 glass: An experimental investigation. J. Manuf. Mater. Process. 2017, 1, 20. [Google Scholar] [CrossRef] [Green Version]

- Wang, Q.; Cong, W.; Pei, Z.J.; Gao, H.; Kang, R. Rotary ultrasonic machining of potassium dihydrogen phosphate (KDP) crystal: An experimental investigation on surface roughness. J. Manuf. Process. 2009, 11, 66–73. [Google Scholar] [CrossRef]

- Jiao, Y.; Hu, P.; Pei, Z.J.; Treadwell, C. Rotary ultrasonic machining of ceramics: Design of experiments. Int. J. Manuf. Technol. Manag. 2005, 7, 192–206. [Google Scholar] [CrossRef]

- Singh, R.P.; Singhal, S.; Singh, R.P.; Singhal, S. Rotary ultrasonic machining: A review. Mater. Manuf. Process. 2017, 31, 1795–1824. [Google Scholar] [CrossRef]

- Thoe, T.B. Review on ultrasonic machining. Int. J. Mach. Tools Manuf. 1998, 38, 239–255. [Google Scholar] [CrossRef]

- Unune, D.R.; Mali, H.S. Current status and applications of hybrid micro-machining processes: A review. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2015, 229, 1681–1693. [Google Scholar] [CrossRef]

- Singh, R.; Melkote, S.N. Characterization of a hybrid laser-assisted mechanical micromachining (LAMM) process for a difficult-to-machine material. Int. J. Mach. Tools Manuf. 2007, 47, 1139–1150. [Google Scholar] [CrossRef]

- Fortunato, A.; Guerrini, G.; Melkote, S.N.; Bruzzone, A.A.G. A laser assisted hybrid process chain for high removal rate machining of sintered silicon nitride. CIRP Ann. Manuf. Technol. 2015, 64, 189–192. [Google Scholar] [CrossRef]

- Tangwarodomnukun, V.; Wang, J.; Huang, C.Z.; Zhu, H.T. Heating and material removal process in hybrid laser-waterjet ablation of silicon substrates. Int. J. Mach. Tools Manuf. 2014, 79, 1–16. [Google Scholar] [CrossRef]

- Al-Ahmari, A.M.A.; Rasheed, M.S.; Mohammed, M.K.; Saleh, T. A hybrid machining process combining micro-EDM and laser beam machining of nickel-titanium-based shape memory alloy. Mater. Manuf. Process. 2016, 31, 447–455. [Google Scholar] [CrossRef]

- Kizaki, T.; Ito, Y.; Tanabe, S.; Kim, Y.; Sugita, N.; Mitsuishi, M. Laser-assisted machining of zirconia ceramics using a diamond bur. Procedia CIRP 2016, 42, 497–502. [Google Scholar] [CrossRef]

- Trotta, G.; Vázquez, R.M.; Volpe, A.; Modica, F.; Ancona, A.; Fassi, I.; Osellame, R. Disposable optical stretcher fabricated by microinjection moulding. Micromachines 2018, 9, 388. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Abdo, B.M.A.; Anwar, S.; El-Tamimi, A.M.; Alahmari, A.M.; Abouel Nasr, E. Laser micro-milling of bio-lox forte ceramic: An experimental analysis. Precis. Eng. 2018, 53, 179–193. [Google Scholar] [CrossRef]

- Samant, A.N.; Dahotre, N.B. Laser machining of structural ceramics—A review. J. Eur. Ceram. Soc. 2009, 29, 969–993. [Google Scholar] [CrossRef]

- Leone, C.; Genna, S.; Tagliaferri, F.; Palumbo, B.; Dix, M. Experimental investigation on laser milling of aluminium oxide using a 30 W Q-switched Yb: YAG fiber laser. Opt. Laser Technol. 2016, 76, 127–137. [Google Scholar] [CrossRef]

- Singh, R.P.; Singhal, S. Investigation of machining characteristics in rotary ultrasonic machining of alumina ceramic. Mater. Manuf. Process. 2017, 32, 309–326. [Google Scholar] [CrossRef]

- Maccauro, G.; Iommetti, P.R.; Manicone, P.F.; Raffaelli, L. Zirconia and Alumina Bioceramic Biocompatibility; Nova Science Publishers Inc.: Hauppauge, NY, USA, 2012; Available online: https://www.scopus.com/inward/record.uri?eid=2-s2.0-84892057573&partnerID=40&md5=38ef11eb8bf1e7387699a8666ab9570d (accessed on 20 November 2019).

- CeramTec—The Ceramic Experts. Available online: https://www.ceramtec.com/ (accessed on 17 March 2020).

- Whitesides, G.M. The origins and the future of microfluidics. Nature 2006, 442, 368–373. [Google Scholar] [CrossRef]

- Farhan Shafique, M.; Laister, A.; Clark, M.; Miles, R.E.; Robertson, I.D. Fabrication of embedded microfluidic channels in low temperature co-fired ceramic technology using laser machining and progressive lamination. J. Eur. Ceram. Soc. 2011, 31, 2199–2204. [Google Scholar] [CrossRef]

- Ong, S.E.; Zhang, S.; Du, H.J.; Fu, Y.Q. Fundamental principles and applications of microfluidic systems. Front. Biosci. 2008, 13, 2757–2773. [Google Scholar] [CrossRef] [Green Version]

- Guarino, S.; Ponticelli, G.S.; Giannini, O.; Genna, S.; Trovalusci, F. Laser milling of yttria-stabilized zirconia by using a Q-switched Yb: YAG fiber laser: Experimental analysis. Int. J. Adv. Manuf. Technol. 2017, 94, 1373–1385. [Google Scholar] [CrossRef]

- Li, J.; Ji, L.; Hu, Y.; Bao, Y. Precise micromachining of yttria-tetragonal zirconia polycrystal ceramic using 532 nm nanosecond laser. Ceram. Int. 2016, 42, 4377–4385. [Google Scholar] [CrossRef]

- Abdo, B.M.A.; Ahmed, N.; El-Tamimi, A.M.; Anwar, S.; Alkhalefah, H.; Nasr, E.A. Laser beam machining of zirconia ceramic: An investigation of micro-machining geometry and surface roughness. J. Mech. Sci. Technol. 2019, 33, 1817–1831. [Google Scholar] [CrossRef]

- Abdo, B.M.A.; El-Tamimi, A.M.; Anwar, S.; Umer, U.; Alahmari, A.M.; Ghaleb, M.A. Experimental investigation and multi-objective optimization of Nd:YAG laser micro-channeling process of zirconia dental ceramic. Int. J. Adv. Manuf. Technol. 2018, 98, 1–18. [Google Scholar] [CrossRef]

- Wang, J.; Shimada, K.; Mizutani, M.; Kuriyagawa, T. Effects of abrasive material and particle shape on machining performance in micro ultrasonic machining. Precis. Eng. 2018, 51, 373–387. [Google Scholar] [CrossRef]

- Sandeep, K.; Akshay, D. Fabrication of microchannels using rotary tool micro-USM: An experimental investigation on tool wear reduction and form accuracy improvement. J. Manuf. Process. 2018, 32, 802–815. [Google Scholar] [CrossRef]

- Jain, A.K.; Pandey, P.M. Experimental studies on tool wear in μ-RUM process. Int. J. Adv. Manuf. Technol. 2016, 85, 2125–2138. [Google Scholar] [CrossRef]

- Abdo, B.M.A.; Anwar, S.; El-tamimi, A.M.; Nasr, E.A. Experimental analysis on the influence and optimization of µ-RUM parameters in machining alumina bioceramic. Materials 2019, 12, 616. [Google Scholar] [CrossRef] [Green Version]

- Abdo, B.M.A.; Anwar, S.; El-tamimi, A. Machinability study of biolox forte ceramic by milling microchannels using rotary ultrasonic machining. J. Manuf. Process. 2019, 43, 175–191. [Google Scholar] [CrossRef]

- Prakash, S.; Kumar, S. Fabrication of rectangular cross-sectional microchannels on PMMA with a CO2 laser and underwater fabricated copper mask. Opt. Laser Technol. 2017, 94, 180–192. [Google Scholar] [CrossRef]

- Umer, U.; Khan, M.; Al-ahmari, A. Multi-response optimization of machining parameters in micro milling of alumina ceramics using Nd: YAG laser. Measurement 2017, 95, 181–192. [Google Scholar] [CrossRef]

- Gupta, K.; Gupta, M.K. Developments in nonconventional machining for sustainable production: A state-of-the-art review. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2019, 233, 4213–4232. [Google Scholar] [CrossRef]

- Holmberg, J.; Berglund, J.; Wretland, A.; Beno, T. Evaluation of surface integrity after high energy machining with EDM, laser beam machining and abrasive water jet machining of alloy 718. Int. J. Adv. Manuf. Technol. 2019, 100, 1575–1591. [Google Scholar] [CrossRef] [Green Version]

- Kuriakose, S.; Patowari, P.K.; Bhatt, J. Machinability study of Zr-Cu-Ti metallic glass by micro hole drilling using micro-USM. J. Mater. Process. Technol. 2017, 240, 42–51. [Google Scholar] [CrossRef]

- Cheema, M.S.; Singh, P.K.; Tyagi, O.; Dvivedi, A.; Sharma, A.K. Tool wear and form accuracy in ultrasonically machined microchannels. Meas. J. Int. Meas. Confed. 2016, 81, 85–94. [Google Scholar] [CrossRef]

| Property | Value (Unit) |

|---|---|

| Fracture toughness | 3.3 (MPa·m1/2) |

| Compressive strength | 5500 (MPa) |

| Tensile strength | 665 (MPa) |

| Bulk density | 3.98 (g/cm3) |

| Poisson’s ratio | 0.22–0.25 |

| Vickers hardness | 1900 (HV 1) |

| Young’s modulus | 413 (GPa) |

| Thermal conductivity 20 °C | 30 (W/mK) |

| Thermal expansion coefficient | 5.4 (10−6 1/K) |

| Melting point | 2277 (°F) |

| Cross-Sections | Channel Size (µm) | |

|---|---|---|

| Depth | Width | |

| Rectangular | 500 | 300 |

| 500 | 800 | |

| 800 | 400 | |

| Square | 500 | 500 |

| 800 | 800 | |

| LBM Input Parameters | Range | RUM Input Parameters | Levels |

|---|---|---|---|

| Laser intensity | 88%–96% | Spindle speed | 2000–7000 rpm |

| Scanning speed | 100–400 mm/s | Feed rate | 0.4–1 mm/min |

| Pulse frequency | 5–12 kHz | Depth of cut | 0.025–0.1 mm |

| Layer thickness | 2 µm | Vibration amplitude | 5–25 µm |

| Track displacement | 10 µm | Vibration frequency | 20–32 kHz |

| Parameter | Value |

|---|---|

| Number of generations | 100 |

| Probability of direction cross-over | 0.5 |

| Probability of selection | 0.05 |

| Probability of mutation | 0.1 |

| DNA string mutation ratio | 0.05 |

| Random generator seed | 1 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abdo, B.M.A.; Mian, S.H.; El-Tamimi, A.; Alkhalefah, H.; Moiduddin, K. Micromachining of Biolox Forte Ceramic Utilizing Combined Laser/Ultrasonic Processes. Materials 2020, 13, 3505. https://doi.org/10.3390/ma13163505

Abdo BMA, Mian SH, El-Tamimi A, Alkhalefah H, Moiduddin K. Micromachining of Biolox Forte Ceramic Utilizing Combined Laser/Ultrasonic Processes. Materials. 2020; 13(16):3505. https://doi.org/10.3390/ma13163505

Chicago/Turabian StyleAbdo, Basem M. A., Syed Hammad Mian, Abdualziz El-Tamimi, Hisham Alkhalefah, and Khaja Moiduddin. 2020. "Micromachining of Biolox Forte Ceramic Utilizing Combined Laser/Ultrasonic Processes" Materials 13, no. 16: 3505. https://doi.org/10.3390/ma13163505

APA StyleAbdo, B. M. A., Mian, S. H., El-Tamimi, A., Alkhalefah, H., & Moiduddin, K. (2020). Micromachining of Biolox Forte Ceramic Utilizing Combined Laser/Ultrasonic Processes. Materials, 13(16), 3505. https://doi.org/10.3390/ma13163505