Study on the Calculation Method of Stress in Strong Constraint Zones of the Concrete Structure on the Pile Foundation Based on Eshelby Equivalent Inclusion Theory

Abstract

:1. Introduction

2. Eshelby Equivalent Inclusion Theory

3. Establishment of Anisotropic Equivalent Mechanical Model of Soil Foundation with Piles

3.1. Elastic Stress–Strain Relationship

3.2. Determination of Elastic Constants

- (1)

- Axial elastic modulus of is:

- (2)

- The elastic modulus of and of the soil foundation with piles are equal along the radius direction of the piles. Radial elastic modulus of and are:

- (3)

- Axial shear modulus of :The shear modulus of and of the soil foundation with piles are equal along the radius direction of the piles. Radial shear modulus of and are:

- (4)

- The Poisson’s ratios of and of the soil foundation with piles are equal along the axial direction of the piles. Axial Poisson’s ratios of and are:According to the derivation of Maxwell’s theorem in Equation (7), the following can be expressed as:

- (5)

- Radial Poisson’s ratio of :

4. Simulation Calculation Model

4.1. Calculation Model

4.2. Load Application

4.3. Feature Points Selection

4.4. Calculation Parameters

4.5. Boundary Condition

5. Calculation Cases

- Case 1

- The pile and soil foundation are simulated as concrete and soil materials, respectively, (Algorithm 1);

- Case 2

- Case 2 The isotropic equivalent pile based on the volume replacement ratio method (Algorithm 2);

- Case 3

- Case 3 The anisotropic equivalent pile based on the volume replacement ratio method (Algorithm 3).

6. Calculation Results and Analysis

7. Engineering Verification

7.1. Finite Element Model and Feature Point Location

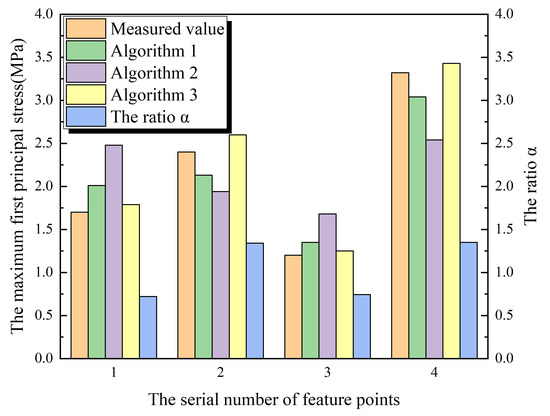

7.2. Calculation Results and Analysis

8. Conclusions

- (1)

- The calculation results of the anisotropic pile foundation algorithm (Algorithm 3) based on the equivalent inclusion theory are closest to the measured values, and the relative error can be reduced by 10%~40% compared with the isotropic equivalent algorithm (Algorithm 2);

- (2)

- Algorithm 2 has the least difficulty in the pretreatment process, the highest efficiency, but the lowest accuracy. If Algorithm 2 is adopted for pile foundation, the first principal stress in the strong confined zones of concrete on pile foundation shall be multiplied by a coefficient. If the selected feature point is more than or equal to 0.5 m away from the free surface, the recommended value of the correction coefficient is , otherwise it is , and the variation range is from 0.72 to 0.76 and 1.32 to 1.36, respectively, and the calculation efficiency is actually improved.

Author Contributions

Funding

Conflicts of Interest

References

- Zhang, Y.P.; Wang, Y.; Li, T. Study of equivalent elastic parameters of composite foundations. Rock Soil Mech. 2011, 32, 2106–2110. [Google Scholar]

- Zheng, J.J.; Liu, Y.; Pan, Y.T.; Hu, J. Statistical evaluation of the load-settlement response of a multicolumn composite foundation. Int. J. Geomech. 2018, 18, 04018015. [Google Scholar] [CrossRef]

- Xu, M.J.; Ni, P.P.; Mei, G.X.; Zhao, Y.L. Time effects on settlement of rigid pile composite foundation: Simplified models. Int. J. Comput. Methods 2018, 15, 1850066. [Google Scholar] [CrossRef]

- Chen, C.F.; Wang, C.Z.; Cao, H.; Li, X. Settlement of gravel pile composite foundation in shore based on orthogonal design and numerical analysis. J. Cent. South Univ. Sci. Technol. 2016, 47, 3824–3831. [Google Scholar]

- Yi, Y.L.; Xi, W.; Liu, S.Y.; Jing, F. Numerical simulation of variable diameter deep mixed columns-treated layered soft ground under highway embankment load. Chin. J. Geotech. Eng. 2013, 35, 433–438. [Google Scholar]

- Lin, B.H.; Fang, H. Research on bearing behavior model of long-short pile high strength composite foundation. Chin. J. Rock Mech. Eng. 2009, 28, 3857–3862. [Google Scholar]

- Luo, Q.; Lu, Q.Y. Settlement calculation of rigid pile composite foundation considering pile-soil relative slip under embankment load. Chin. J. Highw. Transp. 2018, 31, 20–30. [Google Scholar]

- Lü, W.H.; Miao, L.C. Calculation method of pile-soft stress ratio of rigid pile composite foundation. J. Southeast Univ. 2013, 43, 624–628. [Google Scholar]

- Li, B.Q.; Wang, Z.H.; Jiang, Y.H.; Zhu, Z.Y. Temperature control and crack prevention during construction in steep slope dams and stilling basins in high-altitude areas. Adv. Mech. Eng. 2018, 10, 280–294. [Google Scholar] [CrossRef]

- Guo, L.X.; Chen, S.K.; Zhong, L. Simulation computation of heat and moisture transfer in concrete structure. Adv. Eng. Sci. 2011, 4, 47–51. [Google Scholar]

- Zhao, Y.F. Research on the Shear Properties of Bolted Rock Joints and the Mechanical Model of anchoring Rock Mass. Ph.D. Thesis, China Institute Water Resource Hydropower Research, Beijing, China, 2013. [Google Scholar]

- Bie, Y.J.; Qiang, S.; Sun, X. A new formula to estimate final temperature rise of concrete considering ultimate hydration based on equivalent age. Constr. Build. Mater. 2017, 142, 514–520. [Google Scholar] [CrossRef]

- Zhong, R.; Hou, G.P.; Qiang, S. An improved composite element method for the simulation of temperature field in massive concrete with embedded cooling pipe. Appl. Eng. 2017, 124, 1409–1417. [Google Scholar] [CrossRef]

- Wu, J.; Yang, X.H.; Ye, Y. Study of viscoelastic mechanical properties of asphalt mixture based on the eshelby equivalent inclusion method. Eng. Mech. 2012, 29, 244–248. [Google Scholar]

- Huang, B.S.; Hu, X.; Li, G.Q.; Chen, L.S. Analytical modeling of three-layered HMA mixtures. Int. J. Geomech. 2007, 7, 140–148. [Google Scholar] [CrossRef]

- Xiao, Y.C.; Sun, Y.; Yang, Z.Q.; Guo, L.C. Study of the dynamic mechanical behavior of PBX by Eshelby theory. Acta Mech. 2017, 228, 1993–2003. [Google Scholar] [CrossRef]

- Xu, H.F.; Chen, X.; Dong, L.; Yang, Y.R. Equivalent elastic constants of rock containing pore fluid inclusions. J. Basic Sci. Eng. 2017, 25, 369–381. [Google Scholar]

- Hu, M.; Xu, G.Y.; Hu, S.B. Study of equivalent elastic modulus of sand gravel soil with Eshelby tensor and Mori-Tanaka equivalent method. Rock Soil Mech. 2013, 34, 1437–1442. [Google Scholar]

- Liu, J.H.; Xu, S.L.; Zeng, Q. An investigation of thermal conductivity of cement-based composites with multi-scale micromechanical method. J. Build. Mater. 2018, 21, 293–298. [Google Scholar]

- Zhang, C.L.; Wang, B.; Zhu, Y.Z. Dynamic response to plane strain problem of multilayered orthotropic foundation under moving loads. Chinese J. Geotech. Eng. 2018, 40, 2325–2331. [Google Scholar]

- Li, B.; Wang, Y.R.; Zeng, X.W. Dynamic test study of strip foundation on fabric anisotropic ground. J. Vibr. Eng. 2013, 26, 443–450. [Google Scholar]

- Yang, F.; Zhao, L.H.; Yang, J.S. Upper bound ultimate bearing capacity of rough footings on anisotropic and nonhomogeneous clays. Rock Soil Mech. 2010, 31, 2958–2966. [Google Scholar]

- Reccia, E.; Milani, G.; Cecchi, A.; Tralli, A. Full 3D homogenization approach to investigate the behavior of masonry arch bridges: The Venice trans-lagoon railway bridge. Constr. Build. Mater. 2014, 66, 567–586. [Google Scholar] [CrossRef]

- Shen, G.L.; Hu, G.K. Compos. Mech; Tsinghua University Press: Beijing, China, 2006; pp. 39–40. [Google Scholar]

| Category | Elasticity Modulus E0/ MPa | Density ρ/ kg/m3 | Poisson’s Ratio μ | Linear Expansion Coefficient α/ 10−6/K |

|---|---|---|---|---|

| Concrete Structure | 28,000.00 | 2261.00 | 0.167 | 9.48 |

| Pile | 28,000.00 | 2261.00 | 0.167 | 9.48 |

| Silty Clay | 10.00 | 1830.00 | 0.30 | 8.00 |

| Equivalent Pile Foundation (n = 0.156) | 4209.00 | 1895.00 | 0.280 | 8.22 |

| Point Value Series | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

|---|---|---|---|---|---|---|---|---|

| a | 0.00278 | 0.00095 | 1.30000 | 2.20000 | −0.00044 | 0.01837 | 0.01300 | 0.42500 |

| 0.00894 | 0.01210 | 1.01000 | 1.77612 | 0.03599 | 0.01533 | 0.04132 | 0.33607 | |

| 0.00186 | 0.00225 | 1.35000 | 2.38000 | 0.00421 | 0.02047 | 0.00690 | 0.45000 | |

| b | 0.03939 | 0.04154 | 0.49930 | 0.54175 | 0.08690 | 0.18244 | 0.10204 | 0.31978 |

| 0.04876 | 0.06204 | 0.40472 | 0.43066 | 0.11949 | 0.14536 | 0.14888 | 0.26640 | |

| 0.03506 | 0.04306 | 0.54556 | 0.58139 | 0.08006 | 0.19551 | 0.10124 | 0.35938 | |

| c | 0.09100 | 0.10100 | 0.23800 | 0.24000 | 0.14767 | 0.19845 | 0.18000 | 0.24200 |

| 0.10996 | 0.13528 | 0.18748 | 0.20075 | 0.19936 | 0.15648 | 0.23602 | 0.19637 | |

| 0.08500 | 0.10200 | 0.25000 | 0.26800 | 0.14473 | 0.20844 | 0.17300 | 0.26200 | |

| d | 0.15179 | 0.14367 | 0.17196 | 0.15953 | 0.16462 | 0.17532 | 0.20205 | 0.17408 |

| 0.10275 | 0.11155 | 0.13235 | 0.12187 | 0.11908 | 0.13606 | 0.17027 | 0.16357 | |

| 0.13932 | 0.14914 | 0.17563 | 0.16184 | 0.15825 | 0.18041 | 0.22476 | 0.21714 | |

| e | 0.33000 | 0.25800 | 0.20000 | 0.20200 | 0.21326 | 0.19899 | 0.17200 | 0.11000 |

| 0.22849 | 0.18937 | 0.16566 | 0.16015 | 0.16246 | 0.16377 | 0.13309 | 0.08653 | |

| 0.31600 | 0.26000 | 0.22000 | 0.21300 | 0.21932 | 0.21732 | 0.18100 | 0.11500 | |

| f | 0.40500 | 0.29300 | 0.22000 | 0.22200 | 0.24437 | 0.21433 | 0.18300 | 0.08000 |

| 0.25000 | 0.22628 | 0.14846 | 0.14823 | 0.17797 | 0.17157 | 0.15385 | 0.06401 | |

| 0.34400 | 0.31000 | 0.19700 | 0.19700 | 0.24017 | 0.22751 | 0.21000 | 0.08500 |

| Engineering Project | Xiepu Pump Station | Lianghu Pump Station | ||

|---|---|---|---|---|

| Feature Points | 1 | 2 | 3 | 4 |

| Distance from Free Face (m) | 1.30 | 0.20 | 1.0 | 0.11 |

| Distance from the Contact Surface of the Foundation | 2.69 | 1.60 | 4.70 | 1.75 |

| Measured Values | 1.70 | 2.40 | 1.20 | 3.32 |

| Calculated Value of Algorithm 1 (MPa) | 2.01 | 2.13 | 1.35 | 3.04 |

| Calculated Value of Algorithm 2 (MPa) | 2.48 | 1.94 | 1.68 | 2.54 |

| Calculated Value of Algorithm 3 (MPa) | 1.79 | 2.60 | 1.25 | 3.43 |

| The Ratio α | 0.72 | 1.34 | 0.74 | 1.35 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, M.; Zhou, D.; Chen, J.; Hua, X.; Qiang, S. Study on the Calculation Method of Stress in Strong Constraint Zones of the Concrete Structure on the Pile Foundation Based on Eshelby Equivalent Inclusion Theory. Materials 2020, 13, 3815. https://doi.org/10.3390/ma13173815

Yuan M, Zhou D, Chen J, Hua X, Qiang S. Study on the Calculation Method of Stress in Strong Constraint Zones of the Concrete Structure on the Pile Foundation Based on Eshelby Equivalent Inclusion Theory. Materials. 2020; 13(17):3815. https://doi.org/10.3390/ma13173815

Chicago/Turabian StyleYuan, Min, Dan Zhou, Jian Chen, Xia Hua, and Sheng Qiang. 2020. "Study on the Calculation Method of Stress in Strong Constraint Zones of the Concrete Structure on the Pile Foundation Based on Eshelby Equivalent Inclusion Theory" Materials 13, no. 17: 3815. https://doi.org/10.3390/ma13173815