Abstract

Although the efficiency of small-size perovskite solar cells (PSCs) has reached an incredible level of 25.25%, there is still a substantial loss in performance when switching from small size devices to large-scale solar modules. The large efficiency deficit is primarily associated with the big challenge of coating homogeneous, large-area, high-quality thin films via scalable processes. Here, we provide a comprehensive understanding of the nucleation and crystal growth kinetics, which are the key steps for perovskite film formation. Several thin-film crystallization techniques, including antisolvent, hot-casting, vacuum quenching, and gas blowing, are then summarized to distinguish their applications for scalable fabrication of perovskite thin films. In viewing the essential importance of the film morphology on device performance, several strategies including additive engineering, Lewis acid-based approach, solvent annealing, etc., which are capable of modulating the crystal morphology of perovskite film, are discussed. Finally, we summarize the recent progress in the scalable deposition of large-scale perovskite thin film for high-performance devices.

1. Introduction

Organic-inorganic hybrid perovskite thin films are extensively investigated in photovoltaic and other optoelectronic devices, including photodetectors, light-emitting diodes, and memory devices, since the last decade [1,2,3,4,5]. This is mainly related to the remarkable intrinsic properties of perovskite semiconductors, such as low exciton binding energy, high absorption coefficient, long charge diffusion length, high charge carrier mobility, abundant cheap material as well as easy and scalable solution manufacturing [2,6,7,8,9]. This unique blend of features enables the perspective of high-efficiency thin-film photovoltaic devices manufactured by solution spin-coating or other low-cost fabrication methods.

At the early stage of hybrid halide perovskite thin film research, the photovoltaic efficiency was found to be very low. The first research development on perovskite solar cells (PSCs) was reported by Kojima et al. using Pb halide perovskite as a sensitizer in photoelectrochemical devices with 3.8% power conversion efficiency (PCE) in 2009 [10]. The major breakthrough in PSCs was the development of solid-state form devices, which were fabricated by Kim et al. and Lee et al. in 2012, with reported PCEs of >9% and >10.9%, respectively [11,12]. In recent years, the intensive and collective research efforts of the photovoltaic community in the direction to improve perovskite thin-film quality and stability [13,14,15,16] has propelled the performance of PSCs, approaching the single-junction silicon solar cells and the fully industrialized indium gallium diselenide (CIGS) solar cell, displaying bright prospects for its commercialization [17,18].

The perovskite thin film is the core component of PSCs, whose quality and stability would directly determine the cell performance [19]. Many reports confirm that fast nucleation followed by slow crystallization of wet film improves the perovskite thin film morphology [20]. A rapid removal of solvent from perovskite precursors increases the supersaturation, leading to the fast nucleation. The antisolvent extraction technique for quick removal of the solvent is the most successful one to improve thin film morphology for lab-scale devices [21]. Along with antisolvent extraction, other physical techniques, such as hot casting, vacuum quenching, and gas blowing, are also used for the rapid removal of solvents and are more compatible in large-area deposition technologies [22]. In addition to the above physical techniques, the morphology of perovskite thin films can effectively be improved by the use of chemical additives in the precursor solution, which slow down the crystallization process, leading to obtaining preferred grain growth and better morphology [23]. Due to the soft ionic nature of perovskites, surface and grain boundary defects are easily produced during thermal annealing. Therefore, chemical additives improve both morphology and stability of PSCs by the defect passivation [24,25]. Similarly, solvent engineering (to influence the solute particle’s nucleation) and perovskite chemical composition are also beneficial for the improvement in device stability and thin film morphology [26,27].

However, by using spin coating and the above crystallization techniques, all record-efficiency PSCs are fabricated on small active areas, nearly 0.1 cm2 substrates, which contradicts the desires for PSCs commercialization [20]. For commercialization, it is required to fabricate such high-efficiency solar modules with an active area larger than 800 cm2 [28]. It has been reported that the perovskite materials activation energy for nucleation and crystallization (56.6–97.3 kJ·mol−1) is sufficiently lower than the amorphous silicon (280–470 kJ·mol−1) [29,30]. The low crystallization energy required for perovskite growth enables the deposition of perovskite layers by various low-temperature large-scale fabrication technologies. In recent years, the scalable deposition technologies, including slot-die coating, blade-coating, spray-coating, and ink-jet printing, have been applied for large-area solar module fabrication [31,32,33,34]. Some of the spin coating crystallization techniques are still applicable in large-scale deposition methods; therefore, many research institutions and solar energy companies worldwide have accelerated the pace of the commercialization process of PSCs.

For industrial ambitions, in the past few years many research efforts have been made to scale up the perovskite solar cell devices. A solar module with an active area of over 500 cm2 and a PCE of around 12% was fabricated by Solaronix in 2016 [35]. Similarly, another photovoltaic (PV) company, Micro-quanta Semiconductor [36], fabricated a small module with an active area of 17.3 cm2 and reported a world record efficiency of 17.9%. Despite the significant advancements in large-scale fabrication technologies, the efficiencies of large-scale perovskite solar cells are substantially lower than the small area devices. The considerable loss in PCE of large-scale PSCs might be attributed to the challenges of uniformly coating large-scale high-quality perovskite films. From this point of view, the in-depth understanding of the overall features for crystallization and redeveloping novel robust deposition technologies that are compatible with large-area uniform and compact thin-film formation is imperative [37].

In this article, we reviewed in detail the fundamental classical nucleation and crystal growth theories and their application in the developed robust crystallization strategies that have been proved to be capable of producing high-quality of perovskite thin film. Furthermore, some of the most promising scalable thin film deposition techniques used for photovoltaic applications are reviewed and discussed.

2. Fundamental Nucleation Theories and Crystal Growth Models

Homogeneous growth of perovskite thin films is imperative to deliver high efficiency, large and small area PSCs and modules, respectively. The perovskite film growth mechanism is composed of nucleation and crystal growth processes, which play a vital role in the film morphology and the performance of the perovskite PSCs. The fundamental understanding of the factors which influences the nucleation to control the growth of grains in the perovskite crystals is crucial to realize its potential applications. Therefore, in this section, fundamental crystal growth theories and classical nucleation theory are discussed in detail.

2.1. LaMer’s Mechanism

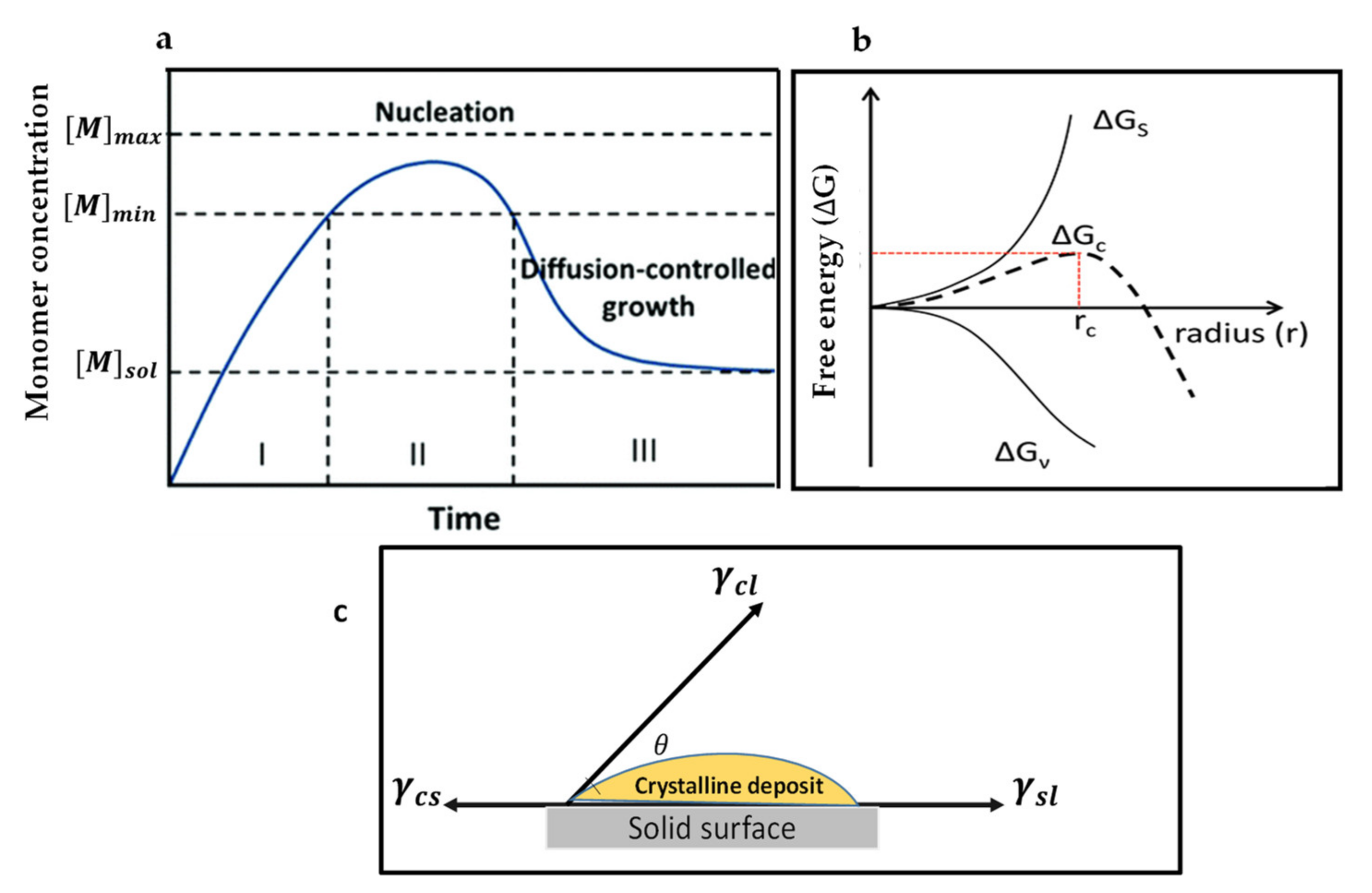

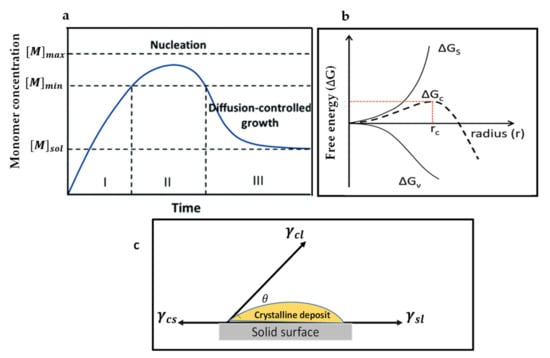

The first crystal growth mechanism is LaMer’s mechanism [38,39], which conceptually describes thin film growth in two ways. (a) When the concentration of growing particles falls below the lowest critical concentration required for nucleation, the development of crystals continues, but the nucleation ceases, this is called diffusion-controlled growth. (b) Surface-process-controlled growth: the growth rate can be controlled by the surface process when the diffusion of the growth species from the bulk to the growth surface is adequately fast. LaMer compared the degree of supersaturation of the solution with the nucleation and growth of crystals, which are regarded as the crucial factors deciding the process for film-forming and, subsequently, the film morphology. During annealing, instantly after the deposition of films, the precursor solution concentration increases to approach supersaturation concentration (Cs), where the development of perovskite nuclei begins to occur (stage I). After stage I, the formed nuclei grow with the supply of monomers via diffusion, whereas the nucleation continues to occur (stage II). When the solute is consuming faster than the evaporation rate of the solvent, at this stage, the solution concentration drops below the Cs, and only the growth of the nuclei occurs without the formation of the additional nuclei (stage III). Figure 1a represents the nucleation and the crystal growth process occurring in three stages as per the LaMer mechanism. The crystal growth mechanism of perovskite films can be regulated by controlling either the nucleation or growth.

Figure 1.

(a) LaMer’s diagram illustrates the nucleation and growth kinetics. Reproduced with the permission from ref. [20], Copyright 2020, Chemical Society Reviews. (b) Illustration of the nucleation theory. G represents the free energy change and is as the function of nuclear radius (r). Reproduced with the permission from ref. [39], Copyright 2019, Advanced Functional Materials. (c) Explanation of the contact angle (θ) for heterogeneous nucleation.

2.2. Von Weimarn’s Theory

Von Weimarn’s theory explains the correlation between the initial supersaturation and the average size of aggregates of a freshly settled phase, which is formed during the nucleation processes in growing systems [40]. Its empirical rules have been applied to comprehend the crystal growth mechanism and have gained fundamental importance in crystal growth theories [41,42]. In brief, the first rule of von Weimarn’s theory argues that, if the initial relative supersaturation decreases, the average crystal size is determined after the crystallization process increases. The second rule suggests that the average crystal size shows a declining tendency as the function of the initial relative supersaturation within a given crystallization time. The first rule is more applicable and well-suited with modern theories as compared to the second rule [41]. On the basis of these rules, nuclei formation and crystal growth are intensely reliant on the supersaturation degree of the solution system. In short, the competition between crystal nucleation and growth can control the average sizes of the crystal clusters. Von Weimarn’s rules can define the rate of nucleation given by (Equation (1) [41]:

where A represents the complex function for molecular-level diffusion, T represents the absolute temperature, kB is the Boltzmann’s constant, G and is the critical free energy of the nucleation is represented by G. It can be defined for a spherical perovskite cluster [43], as given by Equation (2):

where represents the perovskite molecular volume of the crystal, represents the surface free energy of the critical emerged phase, reprents the level of the supersaturation of precursors in perovskite solution. According to Equations (1) and (2), V1 shows an exponential increasing rate with the level of supersaturation.

2.3. Ostwald Ripening

Ostwald ripening [44] is another model to elucidate the particle growth mechanism in a precursor solution, which can be defined as the dissolution of small-sized particles and the redepositing on the surface of larger particles [45,46]. The driving force for this growth process is based on the thermodynamic principle, i.e., the Gibbs-Thomson’s relationship, particles which are smaller in size dissolve quickly because of their larger chemical potential and solubility [47]. A concentration gradient can then be established between particles with different sizes, allowing the existing larger particles to continue growing. Consequently, the concentrations of the growth species can be typically decreased during the Ostwald ripening process, while for the growing particles, the average size increases. The grain growth process in perovskite thin films can be explained by the Ostwald ripening mechanism via coalescence [48,49]. For solution-processed perovskite, the residual solvent molecules, which are embedded in perovskite intermediate films, have a crucial supportive role in the perovskite grain dissolution-recrystallization process during thermal annealing and substantially increase the Ostwald ripening effects. It was stated that perovskite precursor films would become perovskites after releasing the remaining solvent molecules. In the meantime, the small-size perovskite grains can be dissolved in the solvent, and then recrystallize onto the bigger neighboring grains, leading to perovskite grain coarsening by Ostwald.

2.4. Fick’s Law of Diffusion

Fick’s law describes the growth of particles on the growing site from the solution by diffusion process (motion of particles from a region of higher to lower concentration), which comprises two methods: (1) transport of particles from the solution to the crystal surface, (2) the reaction of the growing species on the surface. In the first step, according to Fick’s first law [50], the particles diffusion flux is stated as:

Here, J represents the total flux of particles, r is the radius of particles, D is the diffusion coefficient, and [M] is for the concentration of particles. The concentration gradient around a spherical particle surface can be further derived from the total flux of monomers (J) according to the diffusion-controlled growth.

Here, the rate of surface reaction is denoted by k, the solute concentration at the particle/solution interface is represented by [M]s, and [M]r stands for the solubility of particle. Larger particles are less soluble and grow more quickly than smaller ones as per the Gibbs–Thomson effect. Based on Equations (3) and (4), it can be concluded that the particle growth obviously depends on either the surface reaction or the diffusion process. Thanks to the steady-state of the solute diffusion, the controlled crystal growth can enhance the realization of the homogeneous particles, despite the fact that the monomer concentration at the surface of a particle can reach a value equivalent to that of a bulk solution due to the slow surface reaction (as shown in Figure 1a). Recently, Liu et al. [51] judiciously explored the cation diffusion method following Fick’s second law before the perovskite crystallization at the gel stage by implementing the diffusion model responsible for the phase segregation. They demonstrated the uniform 2D perovskite with the formula of (BA2MA3Pb4I13) thin-film without noteworthy phase segregation. Their results reveal that the local phase distribution in perovskite materials, regardless of the 2D or 3D composition, was very reliant on the gel stage kinetically controlled via diffusion.

2.5. Classical Nucleation and Perovskite Crystal Growth

According to the classical nucleation theory, a nucleus can be regarded as a sphere of the condensed phase [52], and nucleation of particles can be defined as the process in which nuclei with a definite thermodynamic phase act as templates for the crystal to grow [53]. Nucleation takes place when the growing species concentration is adequately higher than the solubility to attain a supersaturated state. Consequently, supersaturation has a significant function in stimulating the process of nucleation. To understand the process of nucleation, the shape of the particle was described as a sphere like a ball. In this case for a spherical particle, the total free energy, which represents the free energy required to stabilize nuclei without dissolving in the solution, could be used to describe the nucleation rate. It is the sum of the bulk-free energy () (which is the free energy between large-size particles and the solute in solution) and the surface free energy () (which is between the surface particle and the bulk particle). Furthermore, is a positive value proportional to r2 (particle radius) and is a negative value proportional to r3 when approaching the supersaturated state. Understandably, the formation of nuclei in the phase of the supersaturated solution depends mainly on the nuclei critical radius (rc) [47]. The nuclei with a radius smaller than the critical radius (rc) have to redissolve into the solution; however, if the radius of nuclei is larger than rc, they can be thermodynamically stable and may exist in the solution. Critical radius (rc) can, therefore, be regarded as the minimum radius in which a nucleus can persist in the solution and continue to grow. For homogeneous nucleation, critical total free energy is given as:

Here, γ represents the surface free energy per unit area, which is surface energy between the supersaturated solution and the crystal surface [54]. The bulk-free energy (Gv) per unit volume also depends on the temperature (T), the Boltzmann constant (kB, degree of supersaturation (S), and molar volume of the nucleus (v). The degree of supersaturation can be written as S = C/CS, where C represents the solute concentration, while Cs represents the solubility limit in the case of supersaturation (C > Cs). Therefore, Gv can be written as:

Here, Vm stands for the monomer’s molar volume in the crystal, considering the surface free energy (4πr2γ, positive) and bulk-free energy (4/3 πr3GV, negative), G(c) is given in Figure 1b. When the nuclei are smaller than rc, they can only redissolve into solution. Therefore, the critical radius can be the minimum size of the nuclei. For homogeneous nucleation, the nucleation rate can be denoted by the Arrhenius type equation [47]:

Here, N represents the number of nuclei, V2 is the molar volume of nuclei, A represents a pre-exponential factor, kB is called as the Boltzmann’s constant, NA represents the Avogadro’s number, S represents the degree of supersaturation, and T represents the temperature. From Equation (3), it can be concluded that the rate of nucleation is strongly influenced by the level of supersaturation [47], surface free energy, and temperature. Moreover, the nucleation rate can be tuned by optimizing the above factors (i.e., high supersaturation, high temperature, and lower surface-free energy). Most of the recently developed methods to improve the quality of perovskite films will be systematically analyzed according to these fundamentals. However, in an actual study, there could be the possibility of the presence of impurities in precursor solutions—the impurity centers which may come from other phases in precursor can reduce the energy barrier, thereby facilitating the occurrence of nucleation [55,56]. Therefore, the heterogeneous nucleation generally occurs considerably easily at such favored sites as compared with the homogeneous nucleation. As the value of Gs is always positive and that of Gv is negative, the maximum free energy essentially is required to form a stable nucleus, which leads to promoting more growth. When the maximum value of free energy is reached, dG/dr should be zero, yielding the critical free energy Gc). The interfacial energy diagram has three phases among a liquid and two solids in contacts, as shown in Figure 1c. The interfacial energies between the liquid and crystalline phases, crystalline phase and solid surface, solid surface, and liquid are represented by the terms γcl, γcs, and γsl, respectively. The contact angle on the solid surface is represented by If < 180°, then there is a high-affinity between nuclei and active centers, which is beneficial to lower the energy barrier to the occurrence of nucleation. The process can be attributed to the substantial drop in the interface energy. Consequently, the free energy for heterogeneous nucleation can be adjusted via using the term ∅, a factor reliant upon . This alteration is similar to that of a homogeneous nucleation process, as defined in Equation (8):

When the contact angle of the solution θ = 180° (involving no affinity among the solid surface and solution at all), then cos θ = −1 and φ = 1, hence, , which implies that both the heterogeneous and homogeneous nucleation critical energies are equivalent. Equation (8) explains that the contact angle of the perovskite precursor on the substrate (heterogeneous nucleation site) can affect the rate of nucleation. Furthermore, when the precursor solution is prepared by using polar solvents, then the hydrophobic substrates ∅ becomes larger, which slows down the rate of nucleation. Cheng et al. [57] revealed that a larger contact angle of perovskite solution on the hydrophobic surface could effectively suppress perovskite film’s nucleation and facilitate the development of a large-size grain because of the improved grain boundary mobility. In their study, they used the hydrophobic substrate for the growth of a thin single-crystal perovskite film. Both the improved ion diffusion on the hydrophobic surface and suppressed nucleation assisted the growth of large-area films [58].

Equations (7) and (9) illustrate that there are four factors that can be managed experimentally to alter the activation energy of the nucleation, which are wettability of the substrate, surface energy, supersaturation level, and temperature. In the perovskite film formation process, the traditional spin coating technique normally produces an inadequate supersaturation because of the moderate rate of evaporation of the most frequently employed solvents for perovskite precursors such as dimethyl sulfoxide (DMSO), (dimethylformamide (DMF), and dimethylacetamide (DMAc), which leads to a low density of heterogeneous nuclei. Alternatively, the crystal growth rate is comparatively fast depending on the solution supersaturation, promoting rapid solute precipitation at those regions with high surface energy. The difference between nucleation and growth rate speeds up the development of large dendritic perovskite structures on very few numbers of nuclei, which can be harmful to perovskite device efficiency. To make a compact perovskite layer with full surface coverage, it is imperative to achieve a high nucleation rate before the crystal growth starts. The most reliable and successful method to improve the nucleation-growth is by influencing the nucleation, using various techniques such as the use of antisolvents, composition engineering, additive engineering, and physical methods. The purpose of both these approaches is to decelerate the crystal growth process and assist nucleation. These approaches are outlined in the following section.

3. Crystallization Techniques for Depositing High-Quality Perovskite Thin Films and Photovoltaic Devices

Based on the analysis of crystal growth models and classical nucleation theory, the nucleation and crystal growth process can influence perovskite films’ morphology. In general, rapid nucleation, followed by the slow growth of the crystal, is necessary for the development of uniform, pin-hole, and defect-free high-quality perovskite films. In the last few years, various advanced methods have been reported to make perovskite films’ quality better as per the above factors, which are presented in this section.

3.1. Antisolvents for Fast Nucleation

Nonpolar solvents that are miscible with host solvents such as DMF and DMSO, but do not dissolve the perovskite precursors, are utilized in perovskite solution. In the one-step coating, the control on the rate of nucleation is relatively challenging as the reaction takes place in a relatively short time due to the fast removal of solvents. Consequently, the device’s reproducibility is identified to be low compared with the devices than the two-step process [59]. The antisolvents can be applied in the spin coating to improve the morphology of perovskite films, which causes the solvents to be extracted quickly from the precursor solutions and gives rise to the fast supersaturation of solute in the perovskite precursor film. Antisolvent dripping is used extensively in the small lab-scale best-performing PSCs [60].

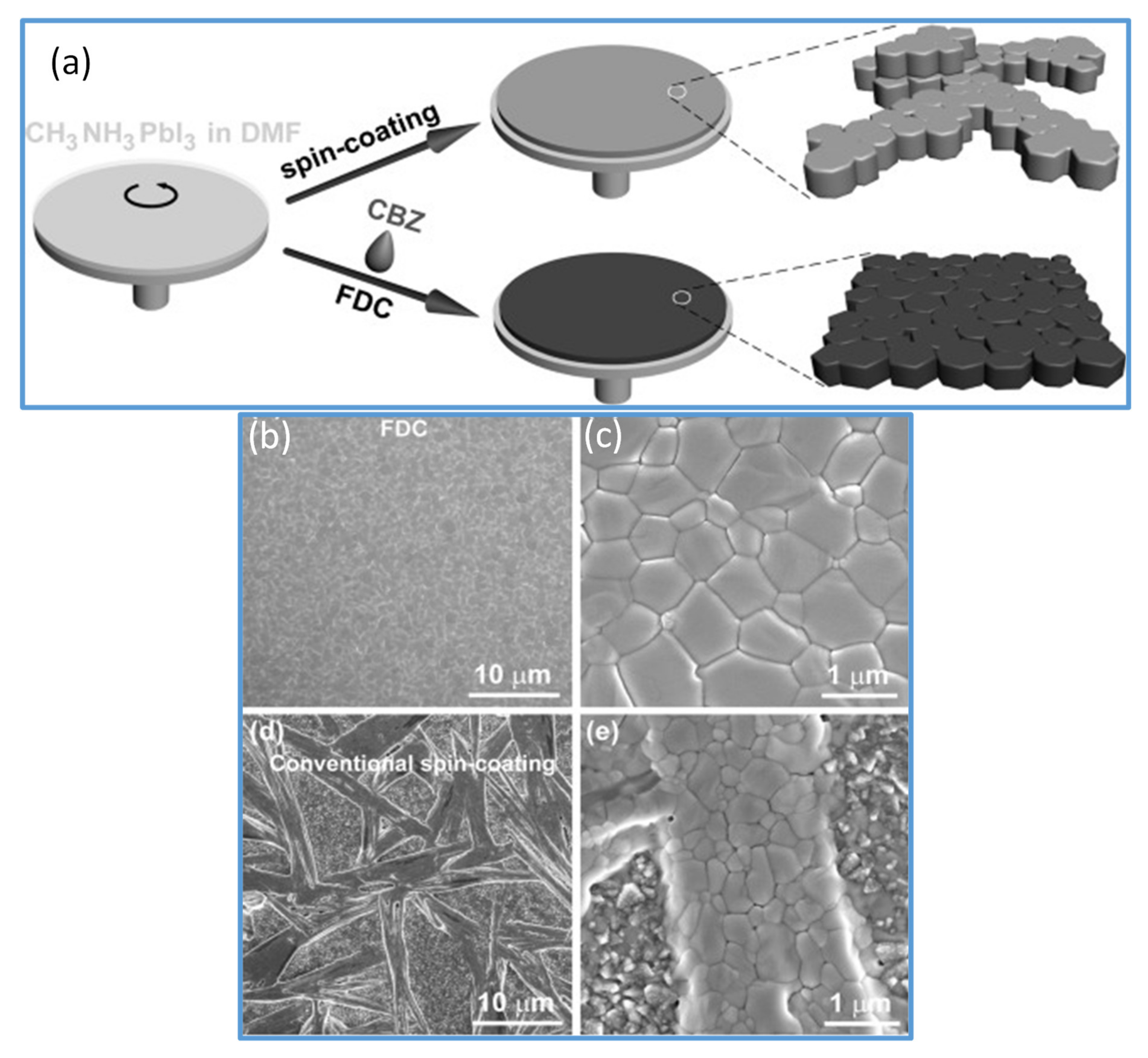

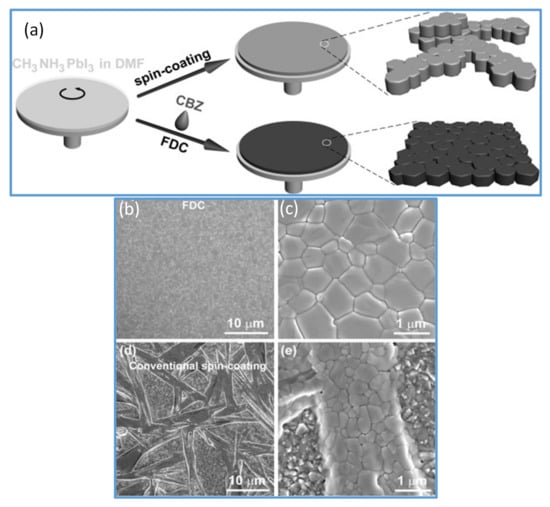

In 2014, Seok et al. [59] introduced this technique in spin coating the perovskite films; since then, it is generally used to achieve smooth and dense perovskite thin films. The objective of solvent soaking techniques is to create uniform nucleation all over the surface of films. Similarly, Xiao et al. further tested the dropping of chlorobenzene (CB) in the course of a spin coating deposition of perovskite solution, resulting in a fast and uniform nucleation across the film, which yielded a super quality, dense, homogeneous, and completely covered perovskite films [61] (as shown in Figure 2a). It is described that CB quickly removes extra DMF solvent and decreases the solubility of the perovskite in the precursor wet film. This will lead to rapidly created supersaturation of the solute, which further encourages the formation of more nuclei, leading to a homogenous perovskite film (Figure 2b,c) with good surface coverage and reproducibility. SEM images of perovskite films fabricated by conventional spin coating are shown in Figure 2d,e for comparison. Based on the achievements of this approach, diverse, environmentally friendly green antisolvent alternatives such as chloroform (CF), toluene [62], chlorobenzene [61], hexane [63], ethyl acetate [64], anisole [65], ethyl ether [66], and mixed ones have been investigated, in coordination with different perovskite formulations and variations of host solvents [67]. A large number of solvents with different physicochemical properties and dielectric constants are systematically studied to reach a more accurate antisolvent selection protocol. The solvents such as CB, toluene (Tol), p-xylene (Xyl), diethyl ether (DE), trifluorotoluene (TFT), and dichloromethane (DCM) are studied. It has been reported that those antisolvents that are completely soluble with the host solvents, and have high both the dielectric constants and boiling points, tend to form smooth superior quality films with well-balanced nucleation and substrate coverage [60]. In recent years, Wang et al. [68] demonstrated the mechanism of green solvents to realize an intermediate phase-controlled FA-based high-efficiency PSCs. They introduced several antisolvents including anisole, diethyl ether (DE), dibutyl ether (DBE), and diisopropyl ether (DIE), in the one-step fabrication of perovskite films from the FA-based perovskite solution. In their analysis, they proposed that during the precipitation crystallization, the intermediate phase is formed and could be identified and controlled through a judicious selection of the polarity of antisolvents. Knowing the intermediate phase formation mechanism has led them to recognize DIE as a green antisolvent with universal perovskite compatibility. They utilized Cs/FA, FA/MA, and Cs/FA/MA, perovskite precursor to achieve champion PCEs of 20.05%, 20.15%, and 21.26%, respectively, with improved repeatability. Their large-area (1 cm2) PSCs showed a PCE of 18.51%.

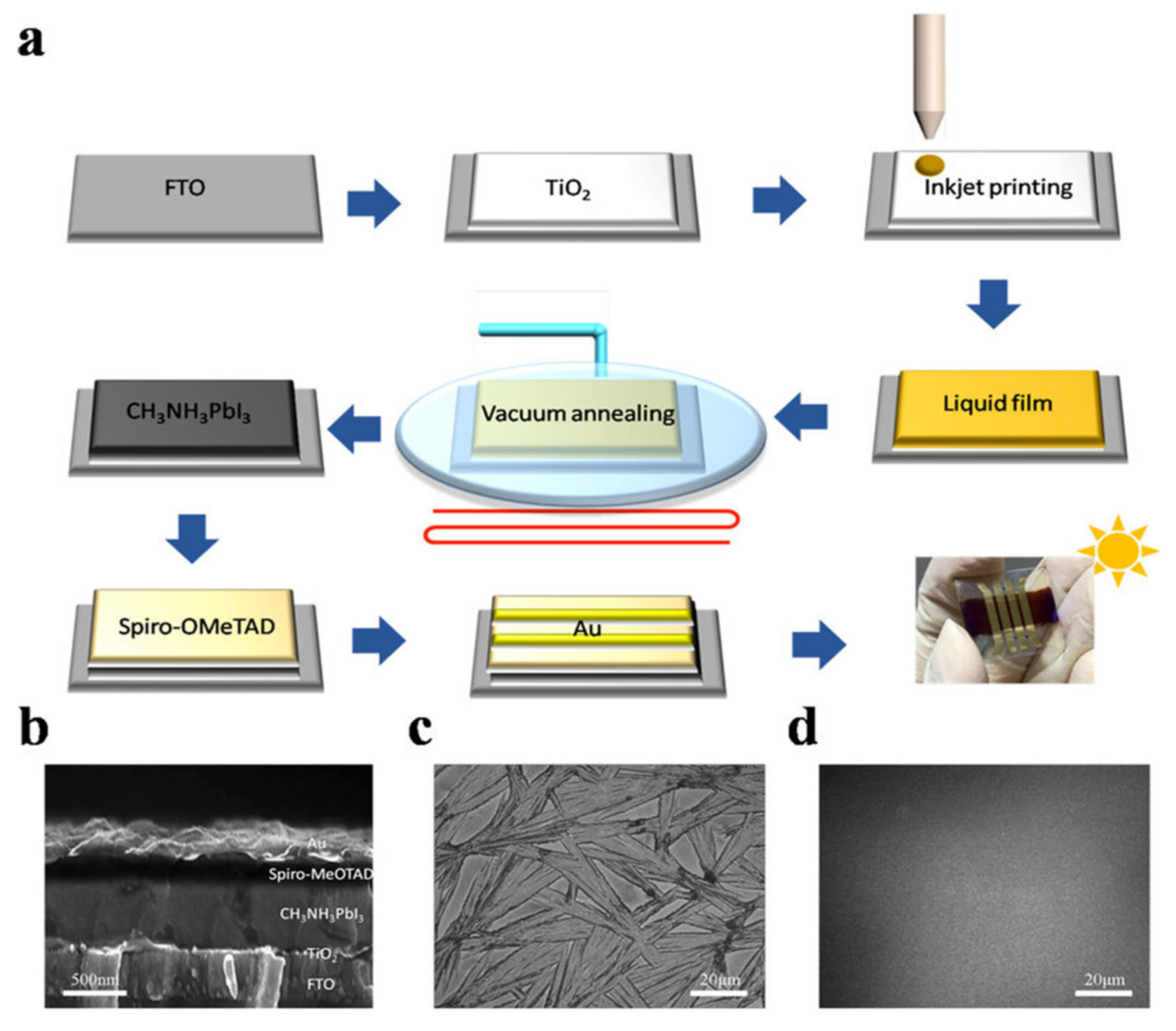

Figure 2.

(a) Represents the spin-coating process and the FDC process to fabricate perovskite films. Spin coating (top) produces a shiny gray film with nonuniform large crystals. A second solvent (CB) is dripped on the wet film during the spin coating to induce fast crystallization producing the uniform size perovskite grains. (b,c) SEM images of CH3NH3PbI3 film fabricated by FDC process using antisolvent (CB). (d,e) SEM images of a film fabricated by conventional spin coating. Reproduced with the permission from ref. [61], Copyright 2014, Agewandte Intl. Ed. Chemie.

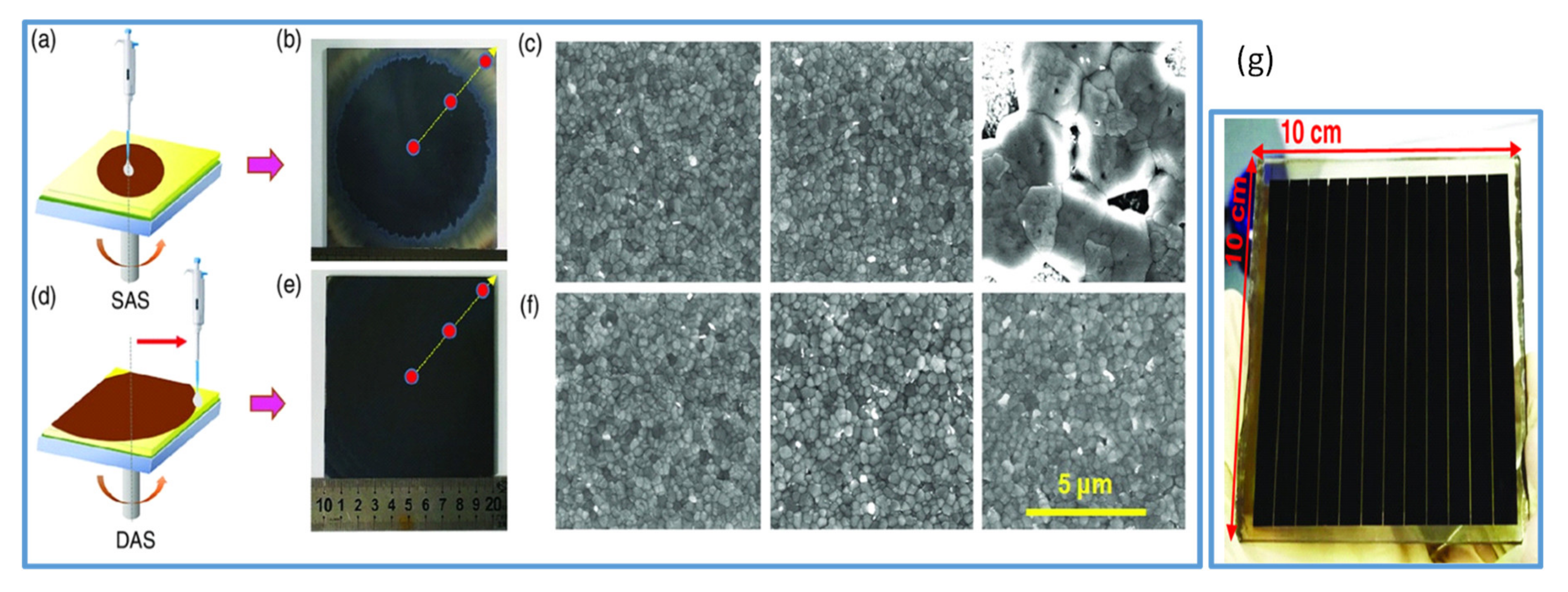

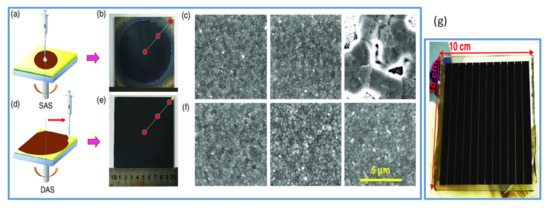

Recently, the perovskite research communities have devoted their efforts to improving the efficiency of the large-area PSCs employing various methods to deposit large-area perovskite films. In 2017, Bu and coworkers employed the green solvent ethyl acetate both in perovskite by antisolvent technique and in the hole transport layer (HTL) during its deposition. By this technique, they improved the quality of perovskite films and the HTL layer, which resulted in a high-efficiency PSC with a PCE of 19.4% in small devices and 14.2% for a module of an area 5 × 5 cm2 [69]. Similarly, in another work, Tongle Bu et al. [21] reported an antisolvent quenching method called dynamic antisolvent (DAS) in the spin coating process to realize large-area smooth perovskite films to achieve high-efficiency perovskite solar modules (as shown in Figure 3d–f). In this simple method, compact and smooth films from mixed-cation perovskite precursors are fabricated. Moreover, the uniformity of the film across the center to edge is significantly improved as compared to the common solvent engineering (Figure 3b,c,e,f for comparison). Thus, top-performing modules (10 × 10 cm2) delivering PCE as high as 17.82% (Figure 3g) and another with a certified efficiency of 17.4% in an aperture area of 53.64 cm2 are obtained. The spraying of an antisolvent that is quite similar to the antisolvent dripping is used to produce high-efficiency PSCs by two-step deposition [70].

Figure 3.

(a) Represents the spin coating with static antisolvent (SAS) process. (b) The photo of 10 × 10 cm2 perovskite film by SAS process. (c) SEM images of perovskite film from the left to right by SAS process. (d) Spin coating with dynamic antisolvent (DAS) process. (e) The photo of the 10 × 10 cm2 large perovskite film by DAS process. (f) SEM images of large 10 × 10 cm2 perovskite films fabricated by DAS process. (g) The photo of the solar module by DAS process. Reproduced with permission from ref. [21], Copyright 2019, Solar RRL.

Besides, the antisolvent spraying process is more suitable for the large-area fabrication of PSCs and, therefore, more beneficial than antisolvent dripping. By spraying antisolvent, a large area (16 cm2) PSCs producing efficiency of up to 12.1% is reported [71]. The antisolvent bathing method was developed to extend the antisolvent strategy to scalable deposition techniques; the perovskite precursor film can be soaked in the antisolvent bath for a short period of time [66]. These are the main achievements in large-area PSCs by the application of the antisolvent technique.

3.2. Hot Casting

In the perovskite film forming process, thermal annealing is generally needed to crystallize the wet perovskite-coated thin films. Wet film annealing is a physical scheme that can improve the solvent molecules’ evaporation rate in the process of the solution-to-solid phase conversion, which can influence the level of supersaturation and accordingly perovskite nucleation process. The heat treatment is typically done at a moderate temperature of around 100 °C for up to a maximum of 1 h to evade the decay of the perovskite [6,10,72,73,74]. Kim et al., based on this general protocol, stated that the high-temperature annealing for few seconds was promising for the growth of perovskite films. A little high temperature could be beneficial for immediate and quick solvent removal to generate a supersaturation for the solute. The precursor supersaturation speeds up the nucleation formation process and endorses a uniform perovskite deposition for efficient PSCs. Therefore, the grain size can be increased from around 300 nm to more than 1 μm by annealing the as-cast perovskite film under 400 °C just for 4 s [75]. In another similar approach, in 2015, Nie and coworkers reported a hot-casting precursor solution to produce continuous, compact, and large grain size perovskite thin films. Hysteresis-free PSCs with PCE of around 18% were achieved, with excellent reproducibility [76]. This technique can be used both ways; either the substrate is heated to a higher temperature or the precursor solution for the rapid evaporation of the solvents. Compared to other methods, it is relatively simple to heat the substrate or the perovskite precursor ink during deposition, which allows this heating method to be used extensively to adjust the thin film morphology. During hot-blade coating [77], in addition, to speed up the rate of solvent extraction, the high temperature could also encourage the solute atoms to decrease the diffusion energy barrier quickly and thus lead to fast grain formation process to achieve a favorable grain size. Employing this technique, a high efficiency (up to 20.3%) [78] was obtained.

3.3. Vacuum Quenching

Many research reports confirm the positive effect of vacuum quenching, which promptly creates supersaturation of the perovskite solute. In 2019, Guo et al. [37] proposed a vacuum-assisted crystallization method for obtaining low-temperature-fabricated perovskite thin films. In this technique, thin films are deposited by blade coating at room temperature instead of elevated temperature. The freshly blade-coated wet films are placed in a vacuum chamber for 2 min then immediately moved for annealing at 100 °C for 10 min to crystallize the films completely. Uniform films with complete substrate coverage and pinhole-free films can be fabricated by this method. Importantly, this technique is quite different than the blade coating at elevated temperatures very close to the boiling point of solvents [79,80,81,82,83]. In another study, Amir et al. [84] proposed the vacuum-controlled meniscus coating, where an optimally performing perovskite film was obtained. They placed the as-coated wet perovskite precursor films in a vacuum chamber for a very short time of only 30 s to keenly remove the solvent in wet film. By this technique, and a natural drying process, they obtained uniform, low surface coverage films with a needle-like morphology. Furthermore, certain analogical approaches, such as gas blowing, solvent annealing, and vacuum flash-assisted solution process (VASP) methods are also reported. A vacuum flash drying method to remove the solvent has been reported many times. Huang et al. [85] used the flow of Ar gas over a spin-coated film to accelerate the removal of solvent. Consequently, they quickly achieved supersaturation, which facilitated the development of further nuclei, converting dendritic shape of crystal with low surface coverage to uniform grains. Therefore, the gas-assisted fabrication of perovskite solar cells demonstrates substantially improved photovoltaic performance as compared to a conventional spin coating process. Using this approach for large-area (>1 cm2) PSCs, PCE values > 20% have been achieved [86]. A system has been developed with further improvement to simultaneously conduct low pressure as well as gas blowing on the wet film; the combined effect of vacuum and gas blowing improves the rate of elimination of solvents [87].

3.4. Gas Blowing

Gas blowing is another still successful physical approach used to produce uniform perovskite films for PSCs. It is mostly used for controlling the drying kinetics during fabrication of thin films. Usually the nitrogen gas (N2) is applied in the gas-blowing process. This technique basically accelerates the rate of evaporation of the precursor solvents and increases the level of supersaturation, thereby regulating the perovskite nucleation and grain growth process. The morphology of the crystallized perovskite thin films is strongly influenced by the rate at which the gas is blowing, therefore, its effect is investigated in many early studies [88,89,90]. By using a gas blowing technique, Li et al. demonstrated antisolvent-free, room temperature, meniscus-coated, uniform, compact, and homogeneous perovskite films under ambient conditions. They reported an air-knife film drying mechanism to fabricate hysteresis-free PSCs with a PCE of 20.26% and 18.76% for an active area of 0.06 cm2 and for 1 cm2, respectively [91].

In summary, the quick removal of solvent from precursors coated on substrate increases the supersaturation degree, which results in fast nucleation and precipitation of the perovskite materials. The first rapid removal of the solvent was realized by dripping the antisolvent onto a spinning perovskite precursor coated substrate. This technique encourages uniform growth and avoids the formation of large dendritic structures. Nevertheless, the dripping of antisolvents in spin coating generates a complex structure throughout the substrate, and better results were obtained with the spray of the antisolvent. Antisolvent spraying was applied to fabricate large area (16 cm2) PSCs and obtained a PCE of 12.1% in its single cell [71]. However, the bottleneck of both antisolvent dripping and spraying is that these techniques are only able to be used in spin coating, and they are not capable of being implemented in a scalable deposition. In further studies, an antisolvent bath approach was proposed, in which the precursor film is soaked in a bath of antisolvent for a short period of time [66]. Although antisolvent bathing is compatible with roll-to-roll continuous fabrication, it is inconvenient to place a substrate with perovskite in a solvent bath for some time. Therefore, further physical techniques (such as hot-casting, gas blowing, vacuum-assisted drying, or a combination of these physical approaches) compatible with scalable deposition were explored. Similarly, smooth, dense, and without pin-hole perovskite thin films were obtained by heating precursor solution or the substrate close to the boiling point of the perovskite precursor solvent in blade coating [77]. However, the elevated temperature will generate point defects because of the volatile nature of the organic component of perovskite. Therefore, vacuum-assisted crystallization is reported in room temperature blade and inkjet printing [37]. Similarly, the gas flow was first utilized to encourage fast crystallization in spin coating. This idea was later employed for slot-die coating via an air blade to assist solvent drying. Another concept to quickly extract the solvent and dry the wet films is the vacuum flash method which utilizes a vacuum for the complete extraction of solvent. The large-area (>1 cm2) PSCs with PCEs > 20% are fabricated by using the vacuum-assisted drying technique. In another work, low pressure and strong gas flow were applied simultaneously on a wet substrate. Their combined effect facilitated the increase of a solvent removal rate. Therefore, it is concluded that the combined effect of the above techniques may give better results.

4. Strategies to Improve Crystal Morphology of Perovskite Thin Film

The performance of PSCs depends greatly on the morphology of the perovskite thin layers. As mentioned in Section 3 the morphology of perovskite thin films is controlled by fast nucleation of perovskite precursors followed by slow crystallization of wet films. Fast nucleation is induced by quickly removing the host solvent by using antisolvents (followed by gas blowing, vacuum quenching, etc.) during the spin coating method as described in the previous section. Similarly, various techniques have been reported which can efficiently slow down the crystallization process. In this section, we will review strategies (such as the use of the additive, Lewis acid-base adduct formation, solvent annealing, solvent additives, etc.) used to improve perovskite crystal morphology by slowing down the crystallization process.

4.1. Use of Additives

The chemistry of the perovskite precursors can greatly influence the nucleation process to facilitate preferred grain growth leading to obtaining a better morphology. For example, adding a small amount of organic or inorganic chemicals in precursor or changing the perovskite’s chemical composition. The high-quality perovskite films are prepared for mini-modules and large area PSCs by applying this technique, so-called additive engineering. It has been widely reported that the use of additives to the perovskite precursor solution could be a useful and consistent method to achieve large size grains in perovskite crystal, suppresses defects, and improves instability, which ultimately enhances the PCE of PSC devices. A large variety of chemical additive has been reported depending on the perovskite composition and the processing route of additives. The additives which have delivered better results include acids (such as HI, HBr, or HCl), metal cations, fullerene derivatives, Lewis acids and bases, surfactants, ammonium salts, and excess amounts of MAI and PbI2 in the precursor solution. Marks et al. used a small quantity of liquid additives HBr, HI, and HCl in the perovskite solution to study their effect on phase transition at room temperature. These additives not only passivate surface defects but also change the optical properties of MAPbI3 optical properties of perovskite [92,93]. Hydrohalic acids used as additive have a two-fold effect of influencing the perovskite film growth: first, additional anions, available by the addition of hydrohalic acids, coordinate with lead ions, and create an intermediate film after the extraction of solvent and consequently suppresses the nucleation of perovskite; [94] secondly, the PH value of the perovskite precursor solution also decreases by the addition of hydrohalic acids which break down smaller clusters or nuclei, thereby considerably suppressing nucleation and crystal growth of individual domains [95]. Moreover, it is described that perovskite thin films coated from a perovskite precursor solution with little extra chloride ions (MAI + PbI2Cl) can exhibit full surface coverage with larger size grains compared to those achieved from a stoichiometric precursor (PbI2 + MAI) [12]. The morphology of perovskite films fabricated from the solution having a small number of extra chloride ion provided by additives in perovskite solutions is identical to those obtained with PbCl2 [96,97,98]. Ke et al. used lead thiocyanate (Pb(SCN)2) as an additive in the perovskite precursor to fabricate large grain perovskite thin films. They assumed that MA+ cations and SCN− anions would react during the perovskite film formation and form HSCN and MA gases, which might support the grain growth and the presence of PbI2 at grain boundaries passivate the defects at GBs, by decreasing dark current [99]. Additionally, surfactants can also be applied in the small as well as large-area fabrication of perovskite films. Huang et al. reported the addition of a small amount of surfactant (L-α-Phosphatidylcholine) into the perovskite (MAPbI3/DMF) precursor solution and blade coated the perovskite films. They demonstrated that the surfactant not only changed the fluid drying dynamics and suppressed the solution flow but also improved the wettability of the perovskite ink on the nonwetting charge transport perovskite films. Furthermore, it also passivated the surface charge defects, and the devices produced over 20% PCE for small-area PSCs and a 15.3% PCE for large area (33.0 cm2) perovskite modules [78]. The use of metallic salts as an additive in perovskite precursor solution to improve the quality of perovskite thin films is also reported by several groups [100]. The addition of a small amount of small in FA or MA-based perovskite precursor solution can partially replace FA+ or MA+ cations, and it can passivate the defects to produce high-quality 3D perovskite films and thereby improve the efficiency and stability. Similarly, other alkali metal cations such as Rb+, K+, and Na+ are also used in perovskite precursors in the form of metal salt. However, these alkali metal ions are only used as an additive to improve perovskite crystal morphology by defect passivation. Their size is much smaller than Cs+, and therefore do not meet the requirement to form a 3D perovskite. Chu and colleagues reported KCl, NaCl, and LiCl as additives to fabricate perovskite film by a two-step method, and both KCl and NaCl led to significantly improved PCEs [101].

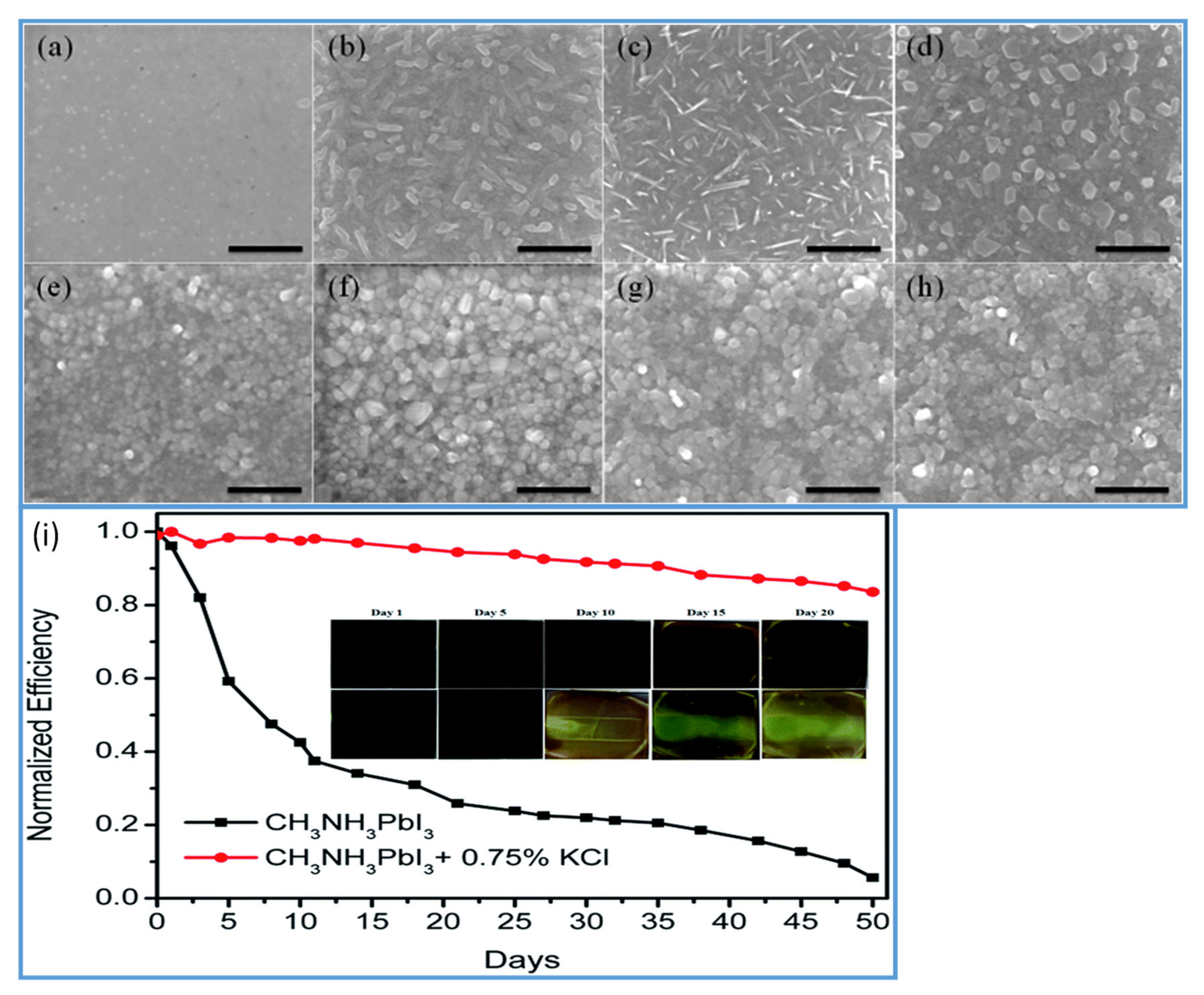

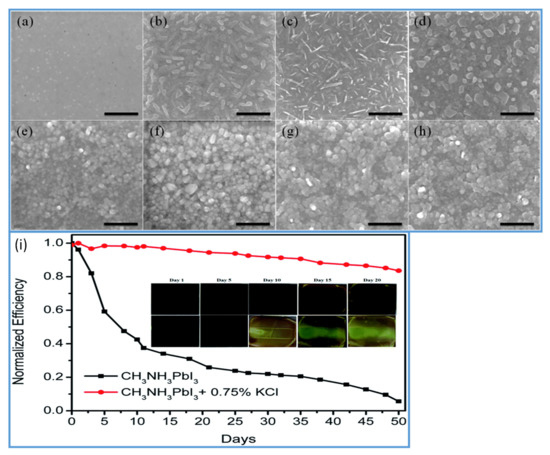

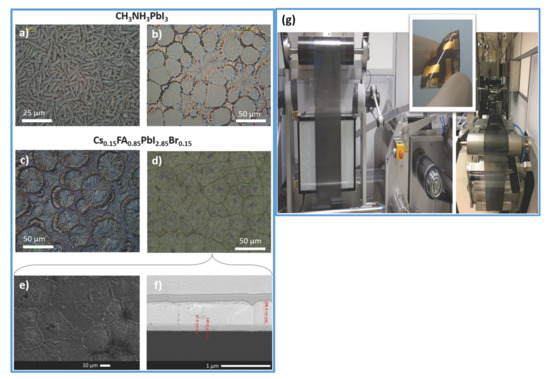

In the two-step method, spin-coated PbI2 and perovskite films prepared without salt additives are noncontinuous with many small pinholes, as shown in Figure 4a,e. Noncontinuous PbI2 films with small crystallite perovskite grains significantly reduce the device performance. More uniform, with large grain size PbI2 and perovskite films can be achieved by using 0.75% KCl salt additive (Figure 4b,f) as compared to the films prepared with 1% NaCl (Figure 4c,g) and 0.25% LiCl (Figure 4d,h). The formation of large grains minimizes the permeability of oxygen and moisture and, thereby, enhances the stability of the device (see Figure 4i). Water as an additive is also investigated in PSCs. It has been reported by some research groups that H2O has harmful effects on perovskite solar cells, as perovskite films easily decompose under a humid environment [102]. In contrast to this, some groups found that an optimized amount of water could support nucleation and crystallization of the perovskite material; as a result, good quality perovskite films were obtained [103]. Chang et al. stated the synergistic effect of the H2O additive and DMF vapor treatment via a two-step spin coating method and fabricated superior quality perovskite films [104]. They demonstrated that a small amount of H2O as additives enabled MAI to penetrate the PbI2 films to form a thick film with a pure MAPbI3 phase and produced large-sized grains by decelerating the crystallization rate of perovskite films. Consequently, they successfully fabricated the high-quality perovskite films and achieved a PCE of 16.7% in a small device of 1.3 cm2 and 15.4% PCE for the mini-perovskite modules of area 11.25 cm2.

Figure 4.

(a–d) SEM images of PbI2 films and (e–g) SEM of images perovskite films. (a and e) prepared without additives. (b,f) with KCl, (c,g) with NaCl, and (d,h) with LiCl additives. (i) Normalized PCEs as a function of days, of PSCs fabricated with and without KCl as an additive. Inset: color changing images of the perovskite films in air with time. Reproduced with permission from ref. [101], Journal of Materials Chemistry A.

4.2. Slow Down Crystallization by Lewis Acid-Base Adduct Formation

The crystallization of perovskites could be slowed down by a simple and practical scheme through a Lewis acid-base adduct formation. An adduct is formed when some base molecule is mixed in the stoichiometric value of perovskite components. Based on the Lewis base theory, an electron pair donating molecules are the bases, while electron-pair accepting molecules are acids [105,106,107,108,109]. Therefore, electron-pair donors such as, oxygen, sulfur, nitrogen-containing monodentate, or bidentate ligands can be used as additives in perovskite precursors, which make an adduct with PbX2. Being strong Lewis acids, Lead (II) halides can easily make adducts with Lewis base molecules. The resulting Lewis acid-base adducts in the precursor solution can raise the solubility of lead halides, slowing down the nucleation process and the growth of crystals. Therefore, by controlling the degree of interaction between Lewis acid-base species using specific Lewis base molecules, the rate of nucleation and crystal growth process can be regulated, and finally, the better-quality perovskite thin films can be realized [59,110,111].

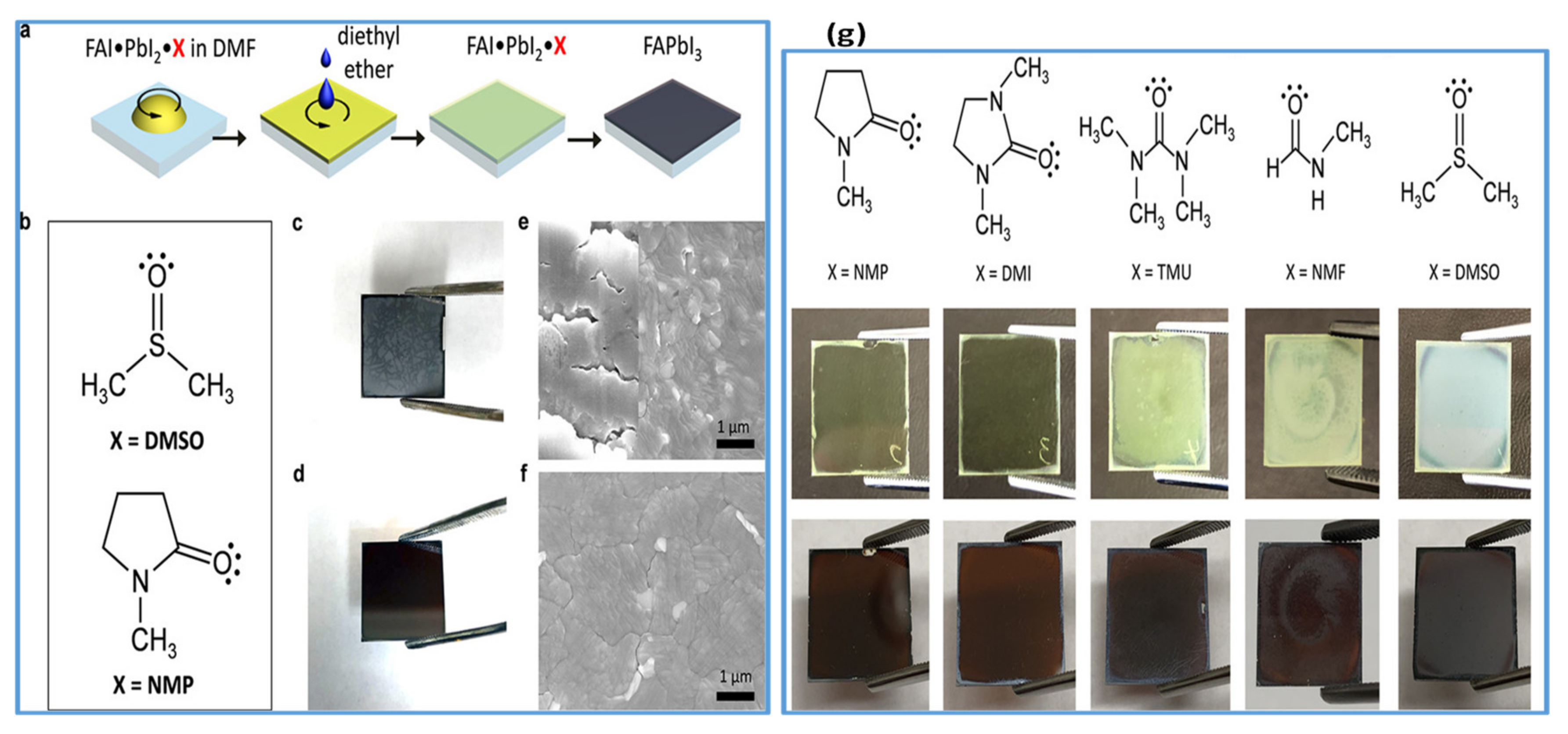

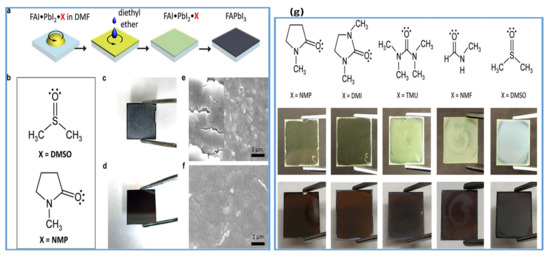

In recent years, DMSO is widely used as an O-donor Lewis base [105,107,109,112,113]. Hence, DMSO can readily form an adduct (PbI2–DMSO–MAI) with perovskite due to its strong basicity compared with DMF. During the competition reaction, this intermediate phase will be established earlier than the change of perovskite precursors to solid crystalline perovskite. The existence of an intermediate phase between DMSO and MAPbI3 perovskite solution is verified by the Park group using infrared spectroscopy technique [105]. In addition to the antisolvent treatment by diethyl ether, intermediate adduct development essentially helps to make ultra-uniform perovskite films. Perovskite films show rod-shaped morphology with incomplete substrate coverage when fabricated without antisolvent treatment. The lower film morphology is caused by the solubility difference between MAI and PbI2 in the host solvent, such as DMF. Therefore, to improve the morphology, another technique was the use of nonpolar solvents such as diethyl ether (DE) to selectively wash the host solvent DMF. However, by washing the host solvent with a nonpolar solvent, the morphology was improved to some extent; still, there were pinholes in perovskite films with host solvent DMF. This indicates that the removal rate of DMF could not be well-managed while washing with nonpolar solvents. Obviously, the DMSO, as a host solvent for perovskite precursors, forms an adduct with perovskite, and facilitates in improving film morphology by retarding the growth of crystals. Depending on its encouraging performance, Wu et al. [114], in a two-step deposition process, employed DMSO as a precursor solvent for PbI2. They described that strong coordination between PbI2 and its host solvent DMSO substantially delayed the crystallization process, thereby leading to smooth and dense PbI2 films. Pinhole-free better-quality perovskite films with a narrow particle size distribution were obtained after reaction with MAI. Similarly, Seok et al. further applied the solvent engineering approach using DMSO to the FAPbI3 system [115]. They reported the intramolecular exchange process which took place between DMSO and FAI while sequentially depositing perovskite films which is expressed as PbI2–DMSO+FAI→PbI2–FAI + DMSO↑ (removal). High-quality perovskite films with uniform large-size grains are obtained by this indirect reaction between FAI and PbI2 as compared to the direct method. However, DMSO has shown to effectively improve the formation of FAPbI3 perovskite films by sequential deposition. However, Park et al. disclosed on the basis of infrared spectroscopy measurements [106] that DMSO did not make a stable adduct with FAI, so the approach could not be realistic to one-step deposition of FAPbI3. On the same strategy, Yang et al. investigated the influence of Lewis bases on the film growth and resulting film morphology. They fabricated FA based perovskite thin films by using various Lewis bases in a one-step spin-coating technique shown in Figure 5a,b. The photos and SEM images of resulting FAPbI3 films are compared (Figure 5c,e for FA-DMSO, and Figure 5d,f for FA-NMP). It can be observed that films formed with DMSO are inhomogeneous and opaque while the films prepared with NMP are homogeneous and semitransparent. They further verified the molecular interaction and adduct forming ability of other Lewis bases DMI, TMU, and NMF with a similar structure to that of NMP and DMSO (Figure 5g). It can also be observed that only DMI formed a stable and uniform adduct film along with NMP. Moreover, NMP used in the precursor can make a stronger coordinate bond with FAI in perovskite solution [109]. It can be confirmed that FAI–PbI2–NMP intermediates would exist stably in the host solvent and influence the preparation of more reproducible FAPbI3 films as compared to DMI.

Figure 5.

(a) Represents the fabrication of FAPbI3 perovskite films by a Lewis base adduct approach. (b) Represents the molecular structure of Lewis bases: dimethyl sulfoxide (DMSO) and N-methyl-2-pyrrolidone (NMP). (c–f) Photographs and SEM images of theFAPbI3 perovskite films. (g). Molecular structures of the Lewis bases used in theFAPbI3 perovskite films (upper panel) Lewis bases perovskite adducts (middle panel) and the crystallized perovskite films (lower panel). Reproduced with permission from ref. [109], Copyright 2018, Journal of the American Chemical Society.

Besides NMP, S-donors such as thiourea with stronger basicity demonstrate good potential as a valid Lewis base in perovskite (particularly FAPbI3) solutions. Fourier transform infrared spectroscopy results expose the dominant interactions of both FAI and PbI2 with thiourea allowing the presence of strong FAI–PbI2–thiourea adducts in their host solvents [106]. The perovskite films fabricated from FAI–PbI2–(DMSO1-xTheoureax) display considerably large size grains and full substrate coverage on the optimized amount of thiourea (x = 0.2); then, the S-donors are more compatible Lewis bases in FA-based perovskites than DMSO.

In the last few years, in addition to S-Donors, N-Donors Lewis-base group has also been studied [116]. Zhang et al. proposed the use of pyridine (Py) additives to fabricate MAPbI3 perovskite films at room temperature by a two-step spin coating process [117]. After the spin coating PbI2, the pyridine vapors react with PbI2 to form PbI2–(Py)2 nanostructure. This nanostructured adduct formation is represented by an equation PbI2(s) + 2Py(g) ↔ PbI2(Py)2(s). In the second step, MAI is spin coated on PbI2–(Py)2; in this step, the perovskite is formed at room temperature by ligand exchange reaction, which is given by the equation PbI2(Py)2(s) + CH3NH3(aq)→CH3NH3PbI3(s) + 2Py(aq). It has been reported that the activation energy is considerably decreased by this technique, which facilitated the room temperature fabrication of high-quality perovskite films. The devices fabricated on a rigid substrate delivered a high efficiency of more than 17% and on a flexible substrate more than 14%, which presents the great potential of this approach to obtain low temperature fabricated high-efficiency PSCs.

Additionally, polymers having S, N, and O donor atoms act as Lewis bases; their use as an additive in perovskite precursor solution not only facilitates the perovskite growth process but also suppress the charge defect states at surface and grain boundaries by making an adduct represented as (Pb2+–Lewis). Most of all, the presence of hydrophobic polymer at perovskite grains act as a barrier to moisture invasion and increases the stability of PSCs [118]. Gratzel et al. [119] introduced the idea of the polymer-template nucleation and growth (PTNG) by using poly (methyl methacrylate) (PMMA) with antisolvents to influence the nucleation and growth process. They described that PMMA lowers the free energy barrier for nucleation and induces heterogeneous nucleation, which is a high order of magnitude faster than that of homogeneous nucleation [120]. Furthermore, it can effectively control the perovskite crystal growth process by creating an adduct with PbI2, which leads to a slow-down of perovskite crystallization to obtain high-quality perovskite films [121]. FTIR spectra have revealed the formation of PMMA–PbI2 adducts. The dual role of PMMA in controlling nucleation and crystal formation process enabled to achieve a certified high efficiency of 21% and extended stability. Nevertheless, it has been claimed that the transportation of charge through the perovskite grains is severely affected by the presence of insulating polymers at the grain boundaries. This reduces the performance of PSCs, and -conjugated polymers are also studied further in this context [122,123,124]. Apart from working the same way to improve the perovskite nucleation and crystallization as insulating polymers do, the -conjugated Lewis-base polymers have shown a better charge transport through the perovskite film by pi-interactions. Consequently, the photocurrent in polymer-incorporated PSCs has been extraordinarily improved. Nevertheless, the effect of insulating or conjugated polymers on the performance of PSCs is still under discussion [123,124]. It has been described in some reports that only those polymers enable the efficient transportation of charges, which are chemically inert [125]. More in-depth studies are required to elucidate the selection standard of Lewis-base polymers for PSCs.

4.3. Solvent Additives

Using a small amount of appropriate solvent additive in the perovskite precursor solution can manipulate the nucleation and thereby facilitate improving the morphology and crystallinity of perovskite thin films. The solvent additive can effectively passivate the point charge defects such as Pb2+ in perovskite surface by forming chelation with Pb2+ resulting in the improvement in the performance of PSCs [126]. 1, 8-Diiodooctane (DIO) is one of the most extensively used solvents as an additive to control the phase separation in organic and polymer solar cells [127,128]. In the perovskite precursor solution, Jen et al. [110] verified that DIO, being a bidentate halogenated additive, could form the temporary chelation with Pb2+ that induces homogeneous nucleation and improve the rate of crystallization, leading to compact and uniform perovskite crystals. Similarly, to investigate the chelation relationship, Eperon et al. introduced a small quantity of HI as an additive in the FAPbI3 precursor solution in DMF solvent. They describe that acidic additive increases the solubility of lead halide in the perovskite solution, slows down the perovskite crystallization process, and positively contributes to obtaining pure perovskite phase high-quality thin films [129]. The effect of acid additives on the growth kinetics of perovskite thin films was further investigated by the Sanith group [130]. The colloidal dispersion is formed instead of the pure solution by dissolving perovskite in pure DMF solvent. The obtained perovskite crystals have rod-shaped colloids and poor morphology [131]. The presence of the hydroiodic acids in the precursor solution can lead to the dissolution of the lead poly halide colloids that serve the nucleation sites for growing perovskites in the as-cast thin films. An extended crystal growth period can be observed with the dissolution of large colloids and fewer nucleation sites, leading to larger polycrystalline grain domains. Heterogeneous nucleation controls the growth process, as nucleation occurs on foreign surfaces or through nuclei. The number of desired heterogeneous nucleation sites may be changed by regulating lead poly halide colloids’ concentration in the solution. The perovskite-growing particles would not impose themselves entirely on each other due to the availability of the least number of growing sites, causing pinholes in the active layer. Thus, the lead poly halide colloids’ concentration must be well controlled and optimized to realize pinhole-free perovskite crystals with large-size grains

4.4. Solvent Annealing

In this method, a solvent is introduced around the perovskite film, which is soluble (or partially soluble) with the perovskite precursors at the time of thermal annealing. Xiao et al. initiated the work by applying the DMF solvent in a closed environment around a perovskite film during the crystallization by thermal annealing [132].

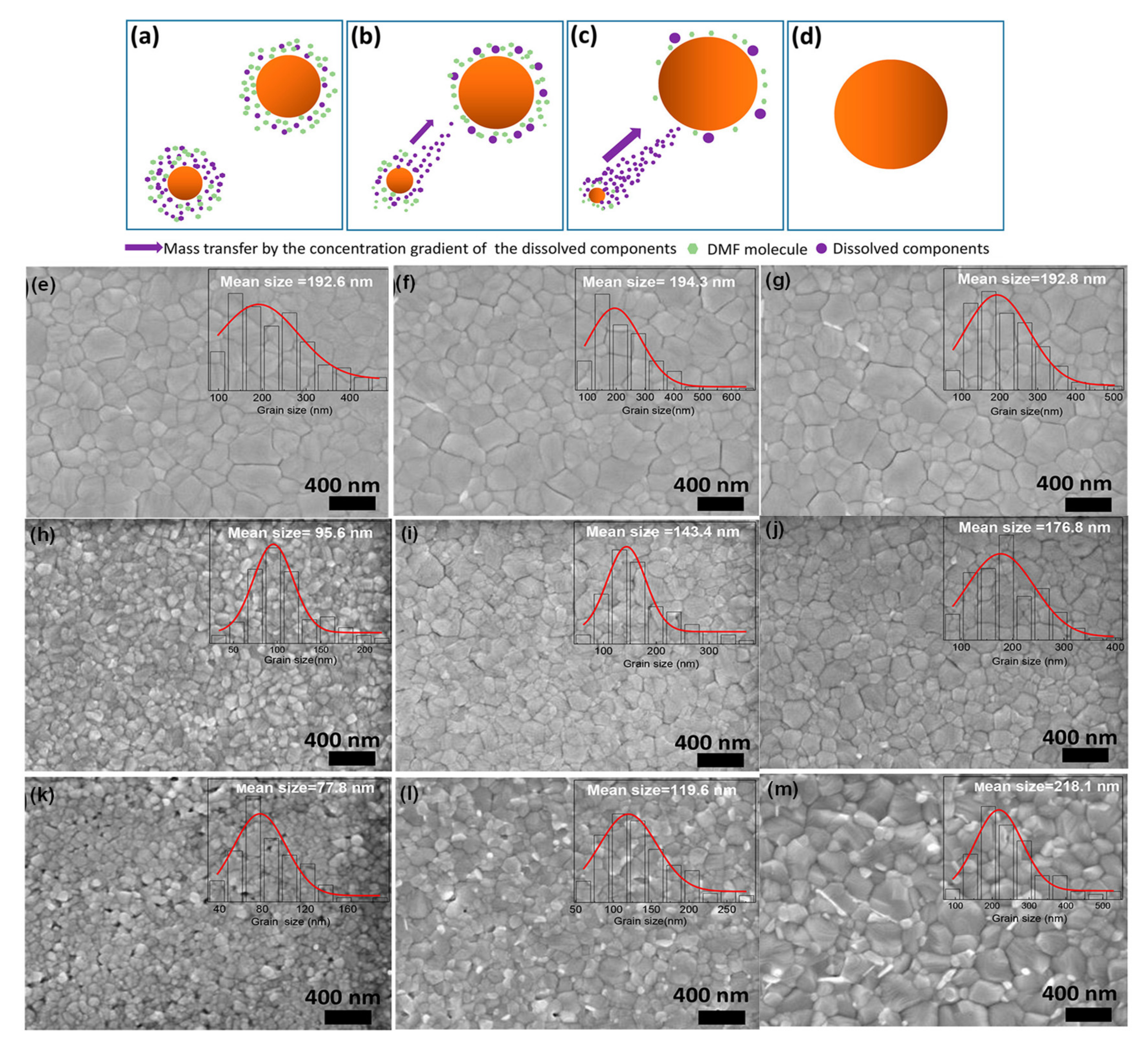

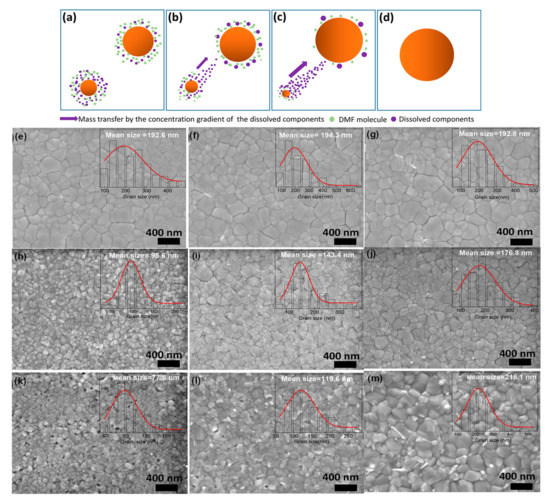

Here, DMF vapors can produce a moist environment that enables precursor’s components to diffuse longer than conventional thermal annealing methods, thus encouraging grain growth and producing large-sized grains. Subsequent studies are conducted to understand the fundamental processes of how solvent annealing (SA) treatment influenced crystallization [133]. Furthermore, Cao and coworkers reported that the important role played by the solvent during the annealing process. They demonstrated that solvent vapors entrenched in the perovskite precursor films can help in coarsening the perovskite grains [134] as shown in Figure 6a–d. However, owing to the rapid escaping of the solvent at high temperatures, the small grains’ dissolution cannot happen. The long annealing time (from 5–15 min) at 100 °C ensure the escape of DMF solvent, and the absence of DMF reduces the Ostwald ripening process, leading to very little change in grain size and morphology (Figure 6e–g). They also characterized the morphology of perovskite annealed for a short time. They found that extended thermal annealing can increase the grain size (Figure 6h–j). The increasing size grain was attributed to the happening of the solvent-mediated Oswald ripening process during prolonged annealing. They further prepared perovskite films by using mixed (DMF and DMSO) host solvents for PbI2. The prominent role of Oswald ripening on the perovskite grain size growth is clearly observed (see Figure 6k–m) by mixing the optimized amount of DMSO, which is a strong base and has a high boiling point than the other component (DMF) of the host solvent. These results endorse the residual solvent’s important function in the occurrence of the Ostwald ripening process with the SA technique. Lastly, it was described that the most frequently used solvents (such as DMSO and DMF) have good solubility for both PbI2 and MAI and definitely can damage the perovskite film in the solvent annealing treatment under the uncontrolled vapor pressure [135]. To address the problem, alcohol vapors are engaged for the solvent annealing process, which has selective solubility for MAI over PbI2. Vapors of different alcohol having different polarities are reported to finely modulate the reaction rate of perovskite precursors and the growth of crystals. This technique helped to remove pinholes and passivated the defects, thereby leading to obtaining better quality perovskite films [135].

Figure 6.

(a–d) The coarsening mechanism of perovskite grains with lengthened annealing time, as per the Ostwald ripening model: (a) initial stage, (b) early stage, (c) middle stage, (d) final stage. (e–g). SEM images of the perovskite films crystallized at 100 °C for long annealing times after removing the residual solvent: (e) 5 min, (f) 10 min, and (g) 15 min. (h–j). SEM images of the perovskite films prepared with short annealing times, which still contain some residual solvent: (h) 2 s, (i) 20 s, and (j) 60 s. (k–m) SEM images of the perovskite films prepared from PbI2/DMF solution with 8% DMSO addition, and then annealed at 100 °C for short annealing times: (k) 10 s, (l) 40 s, and (m) 120 s. Reproduced with permission from ref. [134], Copyright 2018, ACS Applied Energy Materials.

4.5. Nonstoichiometric Composition

During thermal annealing, because of the rapid depletion of the reaction medium (evaporation of solvents), the uniform growth of perovskite grains is relatively challenging. Extended heat treatment can lead to decaying the perovskite films due to the volatile nature of organic components. Therefore, the unequal molar concentration of perovskite components in solution has been found to help in suppressing the recombination at the grain boundaries (GBs), thereby allowing the smooth transfer of charge carriers. Yang et al. [136] have suggested employing a nonstoichiometric perovskite solution with excessive MAI to complement the volatile organic component during the grain formation at a higher temperature. With the use of nonstoichiometric perovskite solution’s large area, smooth perovskite films with improved morphology are achieved. A remarkable efficiency of 15.3% is obtained for the device with an active area of 1.2 cm2. Numerous postfabrication procedures have been established to encourage grain growth. Control of supersaturation is extensively implemented to manage the rate of nucleation, which enables to regulate the grain size of perovskite crystal. In 2014, Im et al. described that the rate of nucleation could be regulated by changing the concentration of CH3NH3I solution in two-step deposition [137]. In this method, spin-coated PbI2 films react in the solution with the MAI, where CH3NH3PbI3 is supersaturated if the MAI concentration becomes higher than the 0.02 m equilibrium concentration. It is obvious that nucleation with 0.063 m MAI solution becomes much faster due to increased MAPbI3 supersaturation in the precursor solution, producing a denser film with smaller size grains than the film based on 0.038 m MAI solution. Following a similar strategy, in 2016, Kim et al. [138,139] observed that a small quantity of excess PbI2 in precursors could impressively enhance the photovoltaic performance of PSCs devices. They proposed a nucleation and growth mechanism for PbI2 employing high-resolution transmission electron microscopy and noticed that apparently, a small extra amount of PbI2 could improve perovskite crystallinity, and thereby, impede ion migrations and decrease recombination. Thus, the addition of an excess amount of PbI2 in the absorber is commonly used by numerous groups as an effective process to improve the performance PSCs. Following the nonstoichiometric composition, Chen et al. showed impressive enhancement in PCE, 0.66% to 12%, by compositional/structural conversion of extra CH3NH3PbI3 to PbI2 occurred mostly at the GBs of the film during thermal annealing. This improvement in efficiency is attributed to the passivation of surface defects [140]. On the other hand, PbI2 can also be merged into perovskite absorbers by the addition of excess PbI2 to the precursor solution, which has been suggested as a means of decreasing J–V hysteresis by hindering ionic migration [139]. In further studies, Nazeeruddin et al. reported that unreacted PbI2 remaining as a secondary phase during dip coating can decrease charge carrier recombination at the perovskite/cathode interface, thereby improving device performance [141].

5. Scalable Fabrication of Perovskite Solar Cells

The fabrication of a smooth and pinhole-free large-area perovskite thin film is critically important to realize PSCs’ commercial application. Until now, the understanding of crystal growth mechanisms and precursor solution chemistry has enabled remarkable progress established on several scalable deposition techniques. This section summarized the significant improvement in the fabrication of large-area perovskite films and PSCs with scalable deposition methods.

5.1. Blade Coating

Blade coating is the most reliable, scalable, and widely used technique adopted in solution-processed perovskite solar cells. Minimum material waste, easy to operate, and compatible with roll-to-roll manufacturing makes it the most promising deposition technique [37]. The thickness of the blade coated film is generally determined by several internal and external factors.

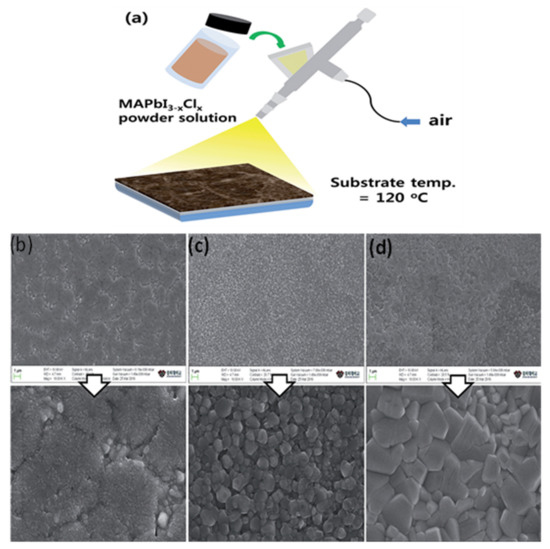

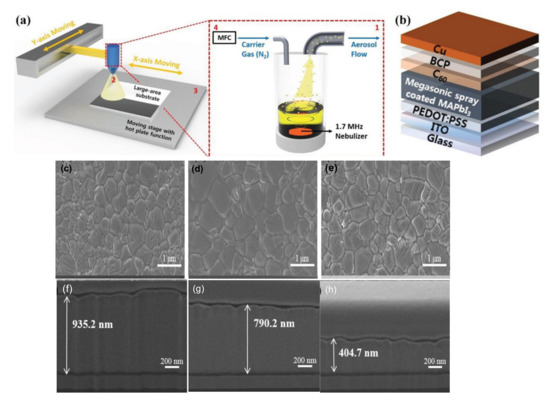

Many research reports reveal that the blade coating produces a uniform wet film from the precursor solution by one-step deposition [79,142]. The applied external processing strategies largely control the quality of the crystallized solid films; therefore, control of the crystallization is critical to obtaining smooth and high-quality thin films during blade deposition. The comparatively slow solvent evaporation rate of freshly blade coated films facilitates larger crystals to grow; however, to obtain compact films with the natural drying process is challenging [143]. Temperature and atmospheric environments during annealing have been found to be crucial to obtain the films with preferred morphology [80]. For instance, both the gas blowing [91] and preheated high-temperature substrate [78] are described as promising approaches to control the perovskite nucleation and crystal, thereby resulting in high-quality perovskite films with decent PCEs of more than 20%. Huang et al. [79] reported the blade coating of perovskite films on a preheated substrate. The substrate’s temperature as high as ≈70–145 °C created a fast supersaturation of the precursor in the solution, leading to the rapid and uniform perovskite crystal growth. Low substrate temperature causes crystallization of intermediate phases with a needle-like shape that obstructs the films’ complete coverage. A coffee-ring-like structure with broad domains was detected after the solvent’s evaporation on the preheated substrate, which is attributed to the convection of the solution.

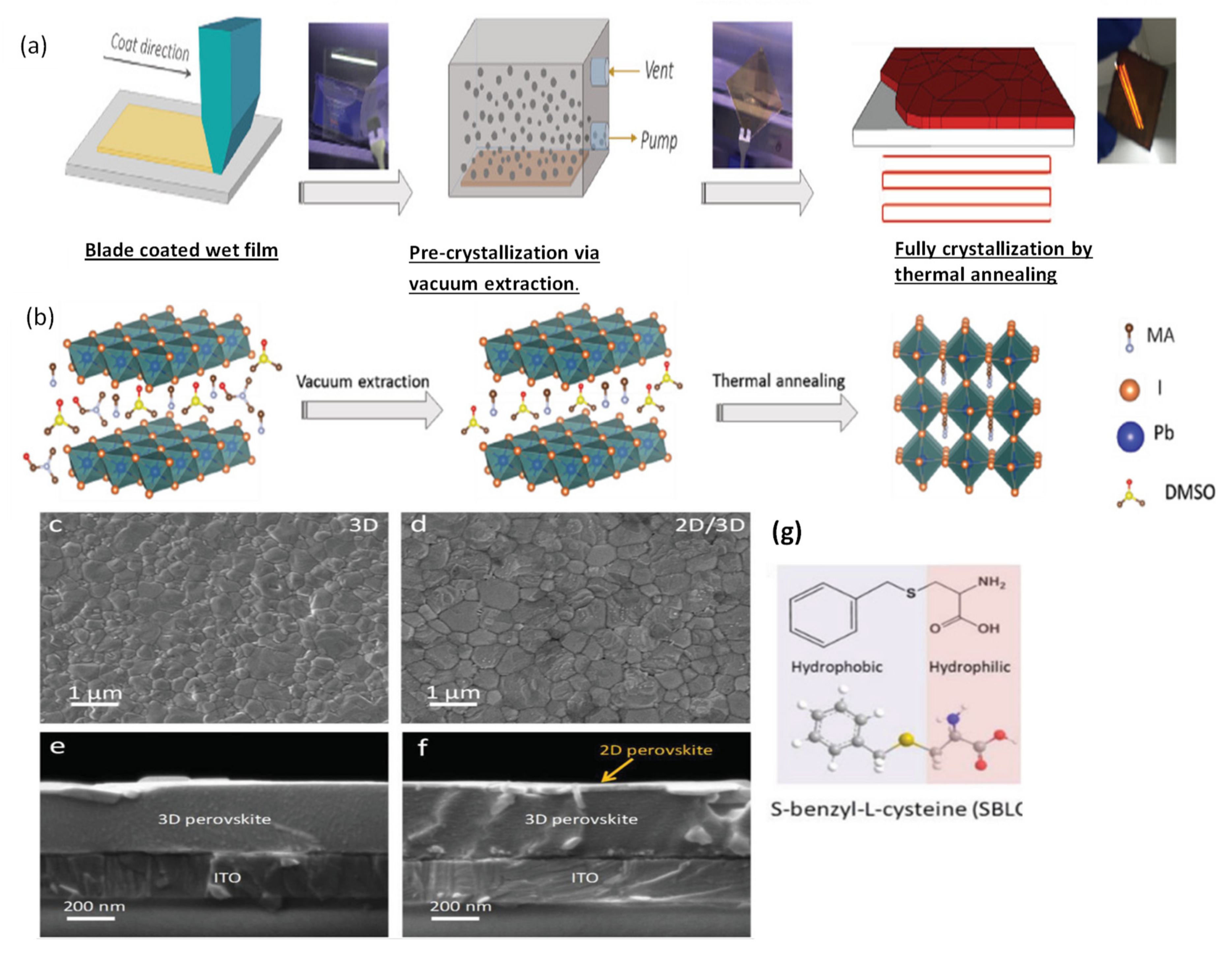

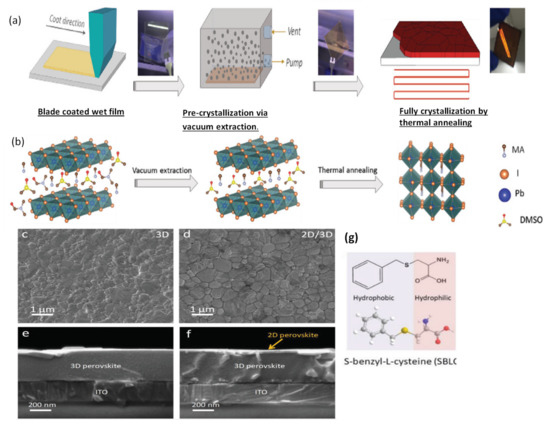

Alternatively, room temperature blade coating and vacuum-assisted crystallization approaches have been reported (see Figure 7a,b), yielding high-quality, pinhole-free perovskite thin films [37]. Using this strategy, Qiu et al. [144] reported the high electronic quality of the environment-friendly, economical biopolymer (poly-l-lysine) passivated perovskite solar cells, yielding an obvious increase in VOC by up to 100 mV. They obtained a high PCE of 19.45% in their blade-coated device. Similarly, following the same crystallization protocol, Hu et al. [145] proposed a 2D/3D mixed perovskite by blade-coating (see Figure 7c,d). First, the 3D MAPbI3 bulk perovskite is blade coated, followed by a thin layered 2D perovskite, which is formed by the judicially selected organic cation (S-benzyl-L-cysteine) as a spacer molecule (Figure 7g). The 2D/3D layered heterostructure makes as a well-defined interface and can be observed in microscopy imaging (shown in Figure 7e,f). It is reported that the two functional groups’ carboxyl and amine present in the spacing molecule of the 2D perovskite facilitates in passivating the surface defects of the 3D perovskite. Consequently, a noticeable increase in open-circuit voltage (VOC) up to 100 mV, and a high efficiency of 20.14% is delivered by the champion device.

Figure 7.

(a) Represents the one-step deposition and vacuum-assisted crystallization of a blade coated perovskite film. (b) Printed precursor colloids then vacuum extraction to create an intermediate film by removing solvent from printed wet film and finally the fully crystallized perovskite film after thermal annealing. Reproduced with permission from ref. [37], Copyright 2019, Advanced Science. (c,d) SEM images of the surface of 3D perovskite film and 2D/3D perovskite film. (e,f) Cross-sectional SEM images of the 3D perovskite film and 2D/3D perovskite film. The 3D and 2D/3D perovskite films are fabricated by blade coating of MAPbI3 precursor without and with addition of 5 mg mL−1 SBLC, respectively. (g) Molecular structure of the SBLC additive. Reproduced with permission from ref. [145], Copyright 2020, Advanced Energy Materials.

Blade coating has been successfully applied for the deposition of thin films for scalable PSCs. Huang et al. [78] used small amounts of surfactant (L-α-Phosphatidylcholine) that vividly changed the fluid’s drying dynamics and increase the adhesion of the perovskite ink on the surface of the nonwetting charge transport layer. The additives facilitated the blade coating of uniform and pinhole-free perovskite films with root-mean-square roughness of 14.5 nm over 1 cm. Furthermore, the surfactant additive passivated the surface defects, resulting in PCE of over 20% in small area devices, 15.3%, and 14.6% in large aperture areas of 33.0 cm2 and 57.2 cm2, respectively.

Similarly, Zhu et al. [142] described the perovskite module’s fabrication via the doctor blading with a total area of 12.6 cm2 and an active area of 11.09 cm2 yielding a PCE of 14.06% from the reverse scan. The little amount of additive MACl was mixed in MAPbI3 perovskite precursor, facilitated crystallization by increasing the rate of grain growth, and shortened the annealing time to obtain better-quality perovskite films. Congping Li et al. [146] used monoammonium porphyrin (ZnP) as a surfactant additive for blade-coating stable large-area perovskite solar cells. They described that the surfactant additive could efficiently passivate the surface defects by firmly attaching to the perovskite surface. Furthermore, the ZnP additive provides a perfect molecular encapsulation to the perovskite surface, thereby avoiding volatile cations to escape. They successfully blade coated smooth and pinhole-free high-quality large area (16 cm2) perovskite films. A high PCE of 18.3% with a large area of 1.96 cm2 was remarkably achieved, while the PCE for the small-area (0.1 cm2) solar cell was up to 20.5%. These results indicate that the addition of ZnP effectively passivated the surface defects, controlled the perovskite grain growth, and facilitated pinhole-free fabrication of perovskite films. Guo et al. [37] developed a controlled crystallization protocol that fulfills the requirement of low-temperature deposition of precursor films, which is extremely needed for large-scale perovskite thin-film fabrication (as shown in Figure 7a). To assess the promising scalability to fabricate large-area PSCs by blade coating method, they fabricated a large-area module with an active area of 10.08 cm2. Their best module having four cells interconnected monolithically in series, displayed a high PCE of up to 15.38%. Notably, the insignificant VOC losses (22.5 mV) for each sub cell show that high-quality 2D/3D heterojunction perovskite films can be deposited on a large scale by one-step blade-coating technology. They obtained VOC of 1.17 V, which is the highest value ever reported in perovskite modules for subcells. Furthermore, it is reported that the lower FF of the module is probably because of the higher series resistance. This drawback is possibly associated with the patterning procedure rather than the perovskite film [145].

In short, currently, blade coating is the most efficient and economy scalable coating technique that produces uniform films for PSCs. However, the disadvantage is that only the perovskite active layers of the most efficient devices were coated by blading or other scalable methods, and the perovskite layer was blade coated in a glovebox under a controlled atmosphere. Therefore, it is of highly required to design suitable perovskite ink chemistries that can be processable in ambient environment and the improvement in coating technique to fully blade coat the efficient PSCs.

5.2. Slot-Die Coating

The slot-die coating is another extensively used scalable organic and perovskite thin-film fabrication technique. In this technique, the precursor is regularly delivered from the coating head towards the substrate [20]; continuous meniscus liquid edge forms in the gap between the substrate and coating head, which is used to derive the spread of liquid film across the substrate. Fast and accurate coating applied to the slot die is useful for large-scale manufacturing with high output [147]. During the coating, the wet film thickness can be estimated by supplied ink quantity and theoretical calculation to control all the processing parameters. In this technique, the morphology of the crystallized perovskite film predominantly relies on the external strategies during the solidification process and the solvent extraction rate.

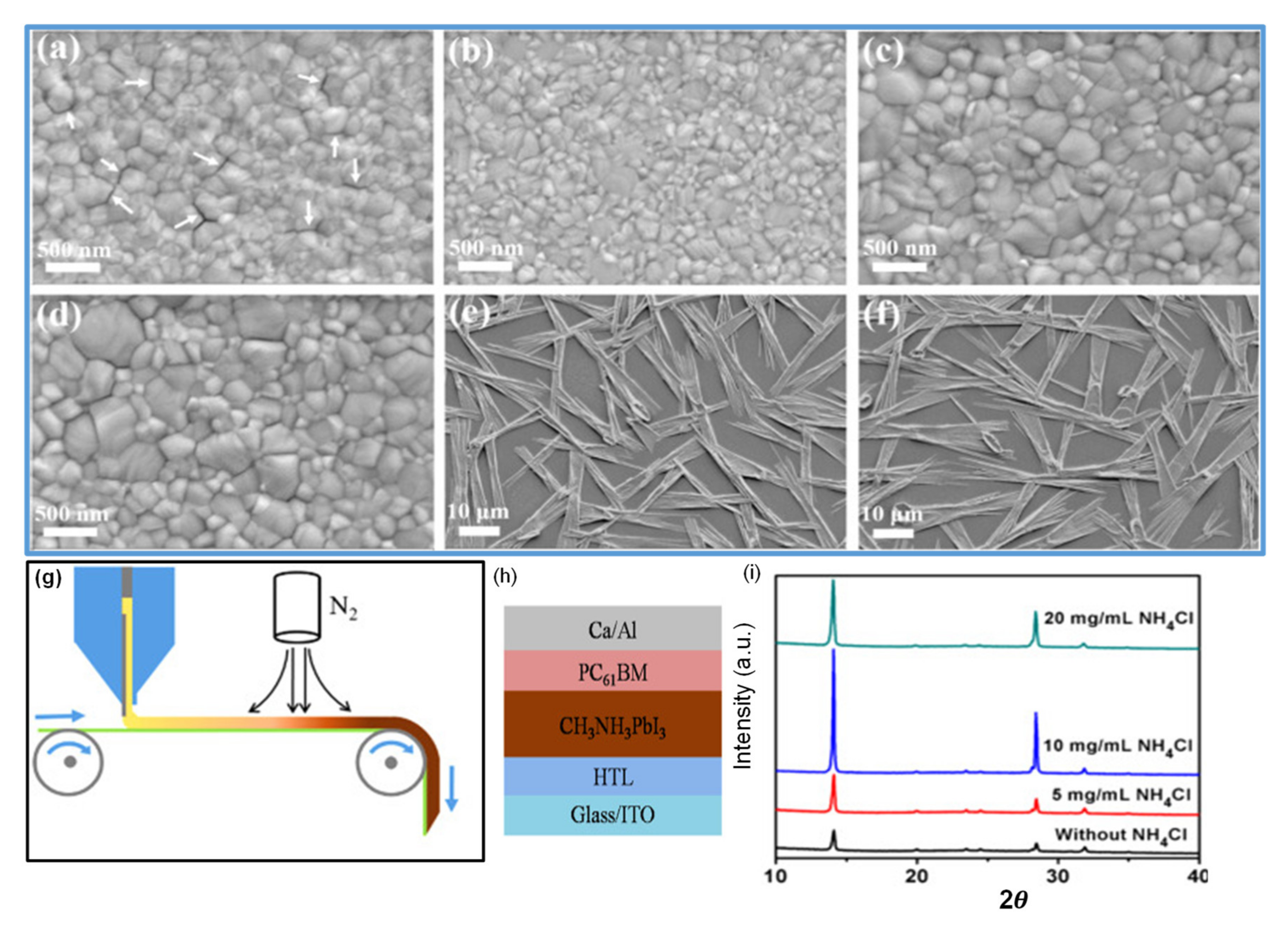

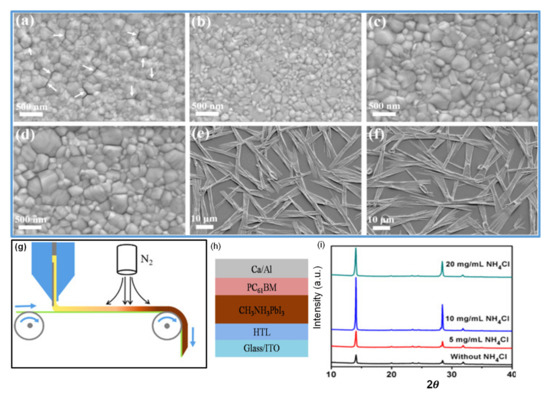

Cotella et al. [148] investigated the influence of air-knife blowing and substrate temperature on the perovskite film formation during the slot-die coating. Preheating the substrate to 65 °C and air-knife blowing during slot-die coating can increase the drying dynamics and accelerate the crystal growth process. Finally, wet perovskite films can be quickly dried, producing a considerably fast precursor supersaturation, leading to heterogeneous nucleation on the surface of the heated substrate. Chemical additives are also used in the perovskite solutions to enhance the degree of crystallinity of solid perovskite films. Zuo et al. [149] demonstrated a simplistic blowing-assisted drop-casting (BADC) method to fabricate CH3NH3PbI3 films for perovskite solar cells (see Figure 8g). The effects of the NH4Cl additive on the morphology of CH3NH3PbI3 films have been investigated by the SEM images. The perovskite films prepared without additives have shown some cracks and pinholes, which result in device shunt resistance (see Figure 8a). Cracks and pinholes disappeared by adding 5 mg mL−1 NH4Cl additive (see Figure 8b). The films prepared with 10 mg mL−1 NH4Cl additive demonstrate a much bigger grain size than without and with 5 mg mL−1 additive (Figure 8c). The grain size is similar in films formed with 20 mg mL−1 NH4Cl additive, but a smaller crystallite size is observed (Figure 8d). They also attempted spin coating of perovskite films under the same condition without and with 10 mg mL−1 NH4Cl additive (see Figure 8e,f). Poor morphology with huge pinholes can be observed in the films. As a result, the optimized 10 mg mL−1 NH4Cl additive, to better the crystallinity (Figure 8i) of the perovskite film, is utilized. They also prepared PSCs in the air with a structure of ITO/m-PEDOT:PSS/CH3NH3PbI3/PCBM/Ca/Al (see Figure 8h) and obtained a maximum PCE of 19.48%. The optimized design is then effectively applied to slot-die coating on a glass substrate and next to roll-to-roll on a flexible substrate, giving the record PCEs of 15.57% and 11.16%, respectively.

Figure 8.

(a–f) SEM images for CH3NH3PbI3 films prepared using different conditions: (a) without NH4Cl additive; (b) 5 mg/mL NH4Cl additive; (c) 10 mg/mL NH4Cl additive; (d) 20 mg/mL NH4Cl additive; (e) spin coating, without NH4Cl additive; (f) spin coating, 10 mg/mL NH4Cl additive. (g) Roll-to-roll continuous preparation of CH3NH3PbI3 films. (h) Device structure of perovskite solar cells. (i) The XRD results. Reproduced with permission from ref. [149], Copyright 2018, Elsevier Nano Energy.

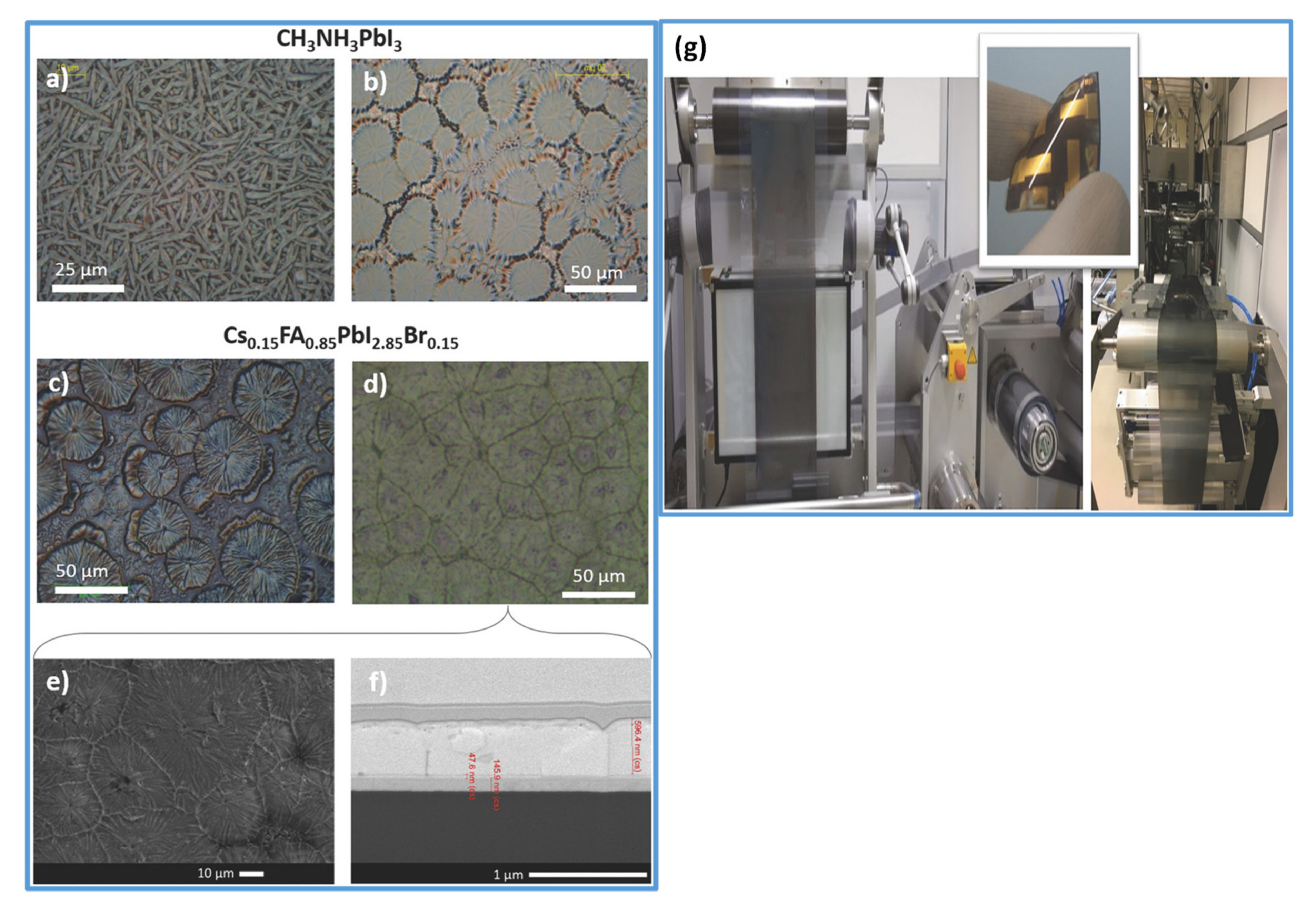

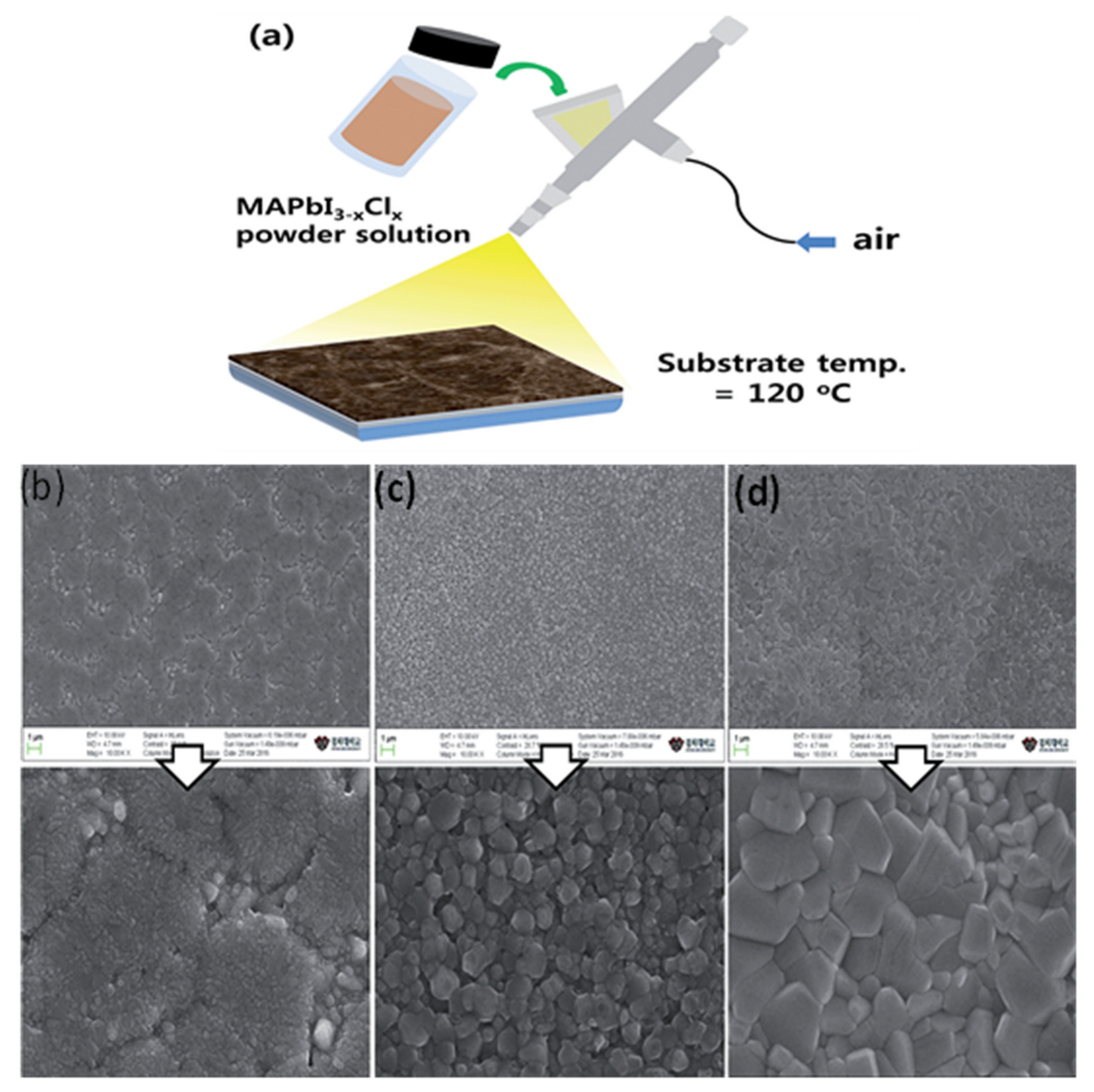

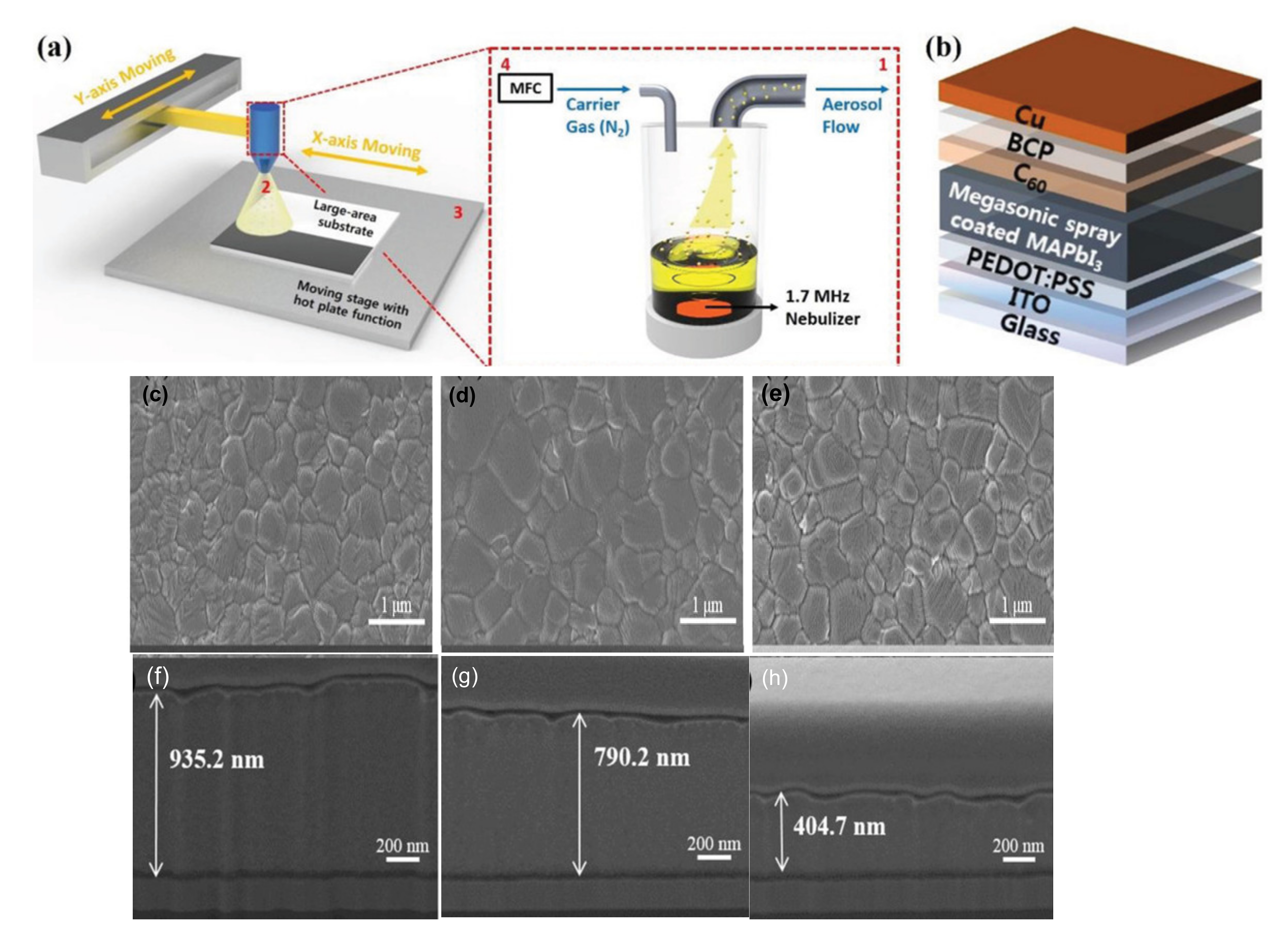

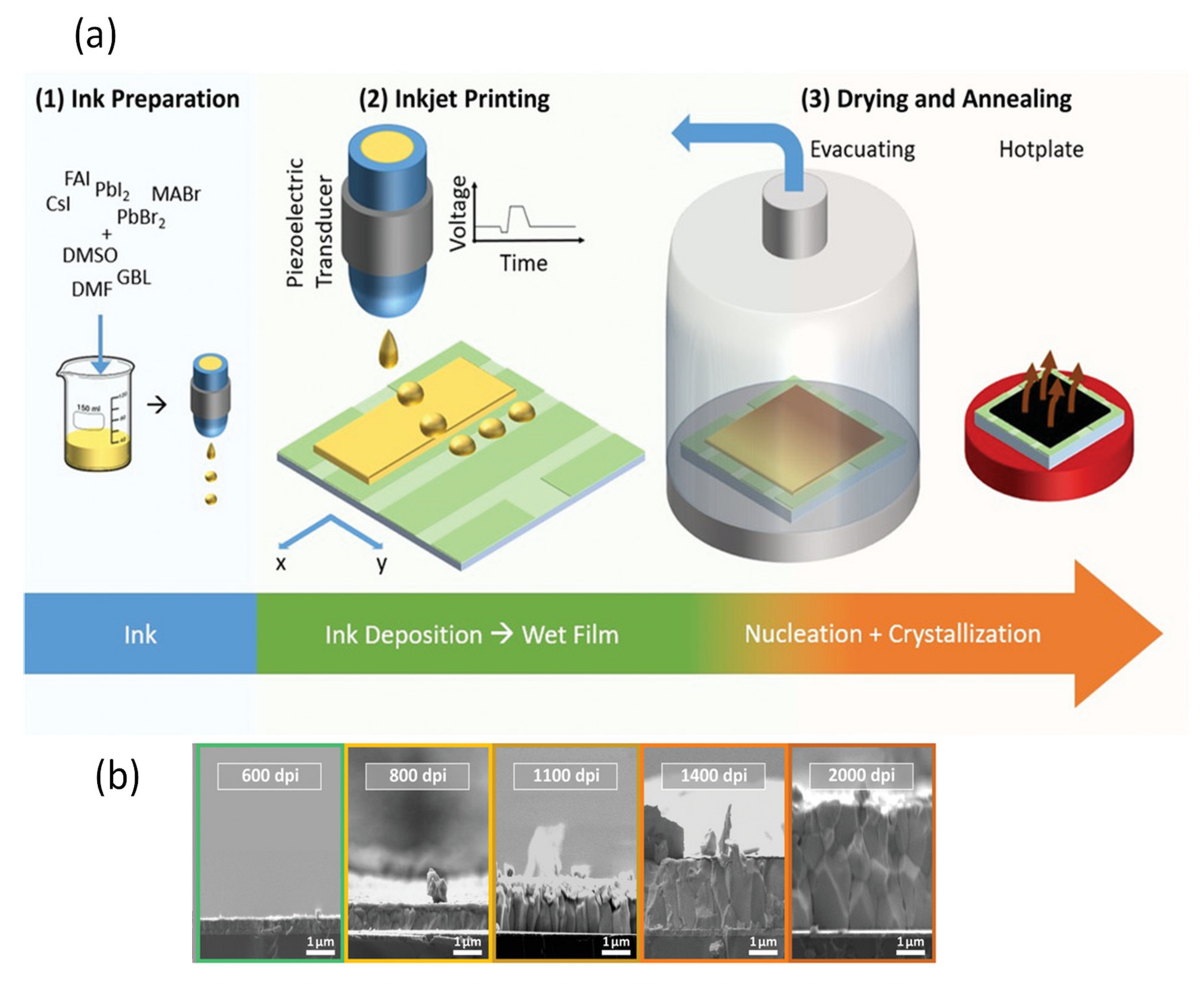

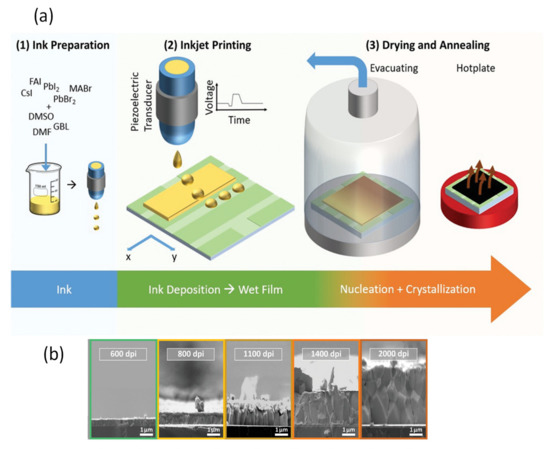

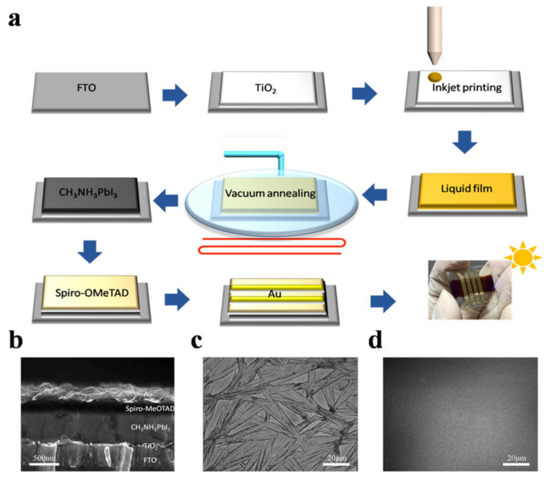

Nevertheless, the slot-die coating also has some drawbacks, such as the wastage of a sufficiently large quantity of perovskite ink to fill up the ink reservoir and the supply pipes during device fabrication. Therefore, this technique is much more expensive for laboratory applications compared to the blade coating. As a result, the slot-die technology is not employed frequently in research labs, and the slot-die coated devices have much lower PCE than blade coating PSCs.