Application of Ultraviolet Laser Working in Cold Ablation Conditions for Cutting Labels Used in Packaging in the Food Industry

Abstract

:1. Introduction

2. Experiment Procedure

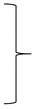

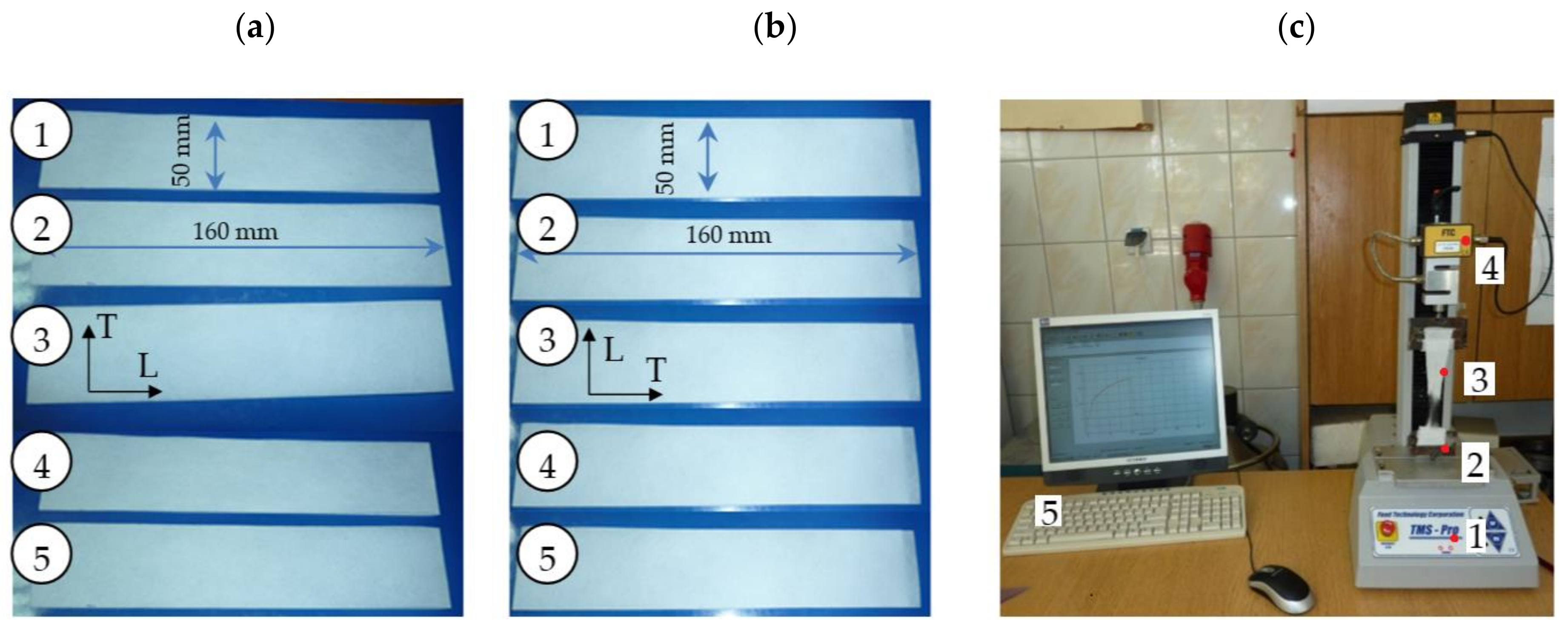

2.1. Material Characteristics

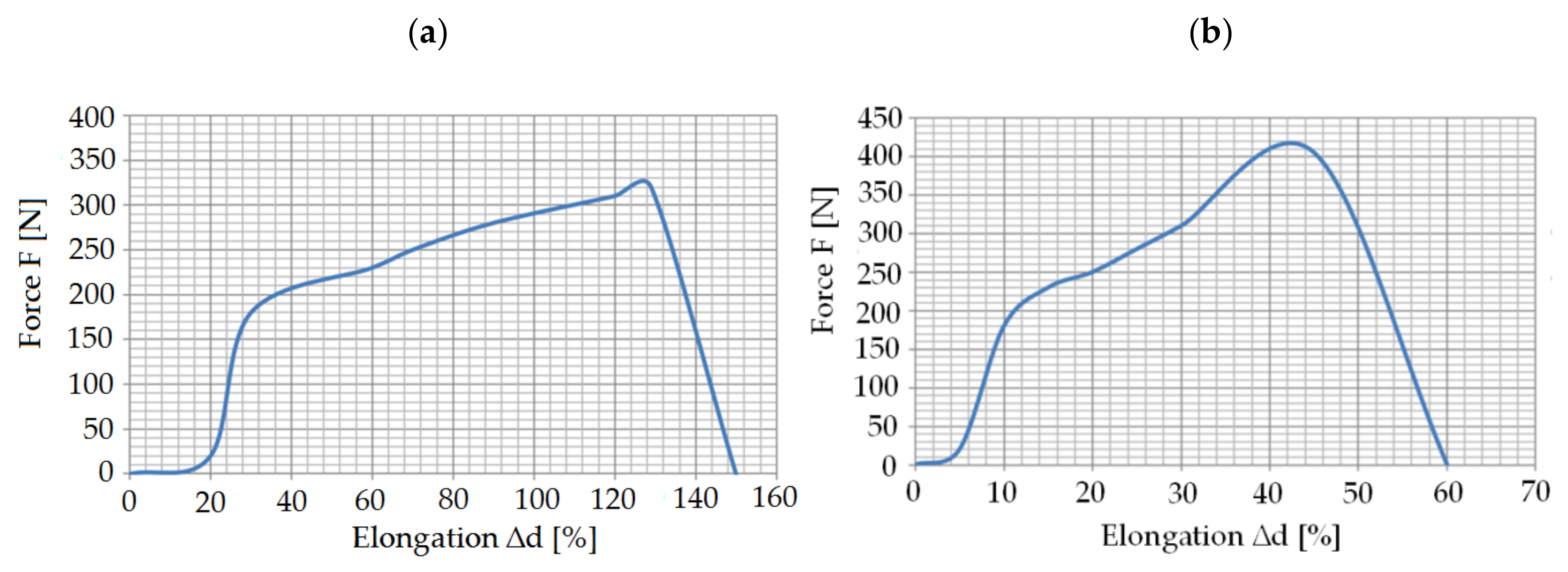

2.2. Ultraviolet (UV) Laser Experimental Setup

2.3. Experimental Research

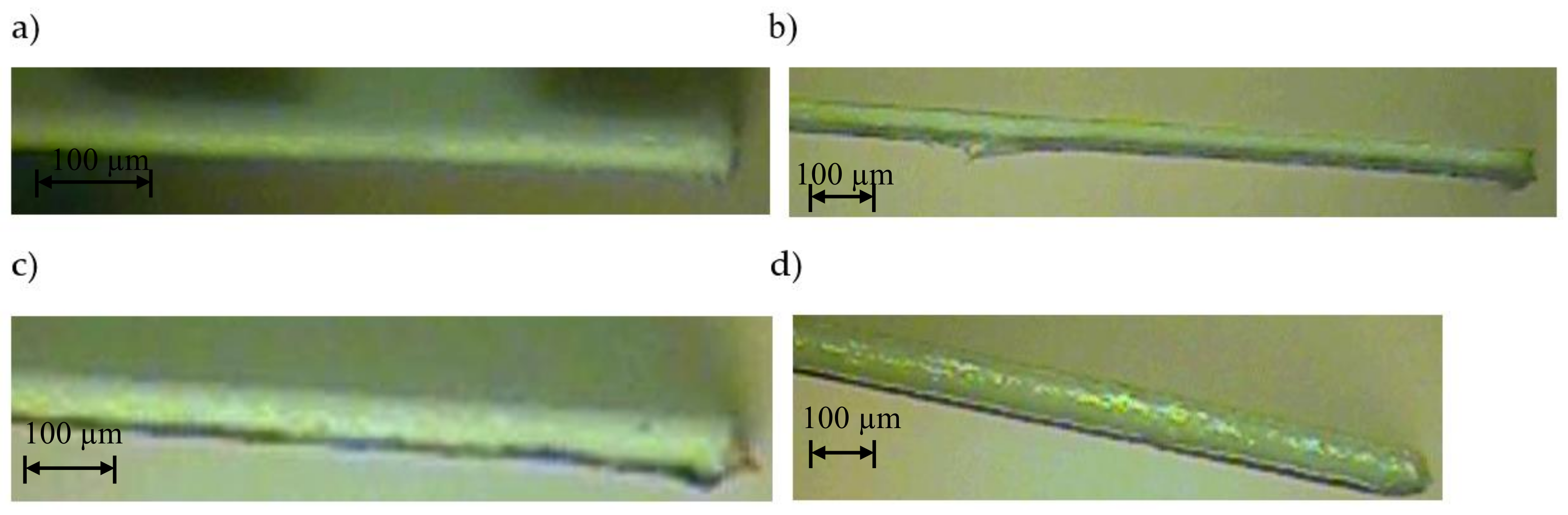

2.4. Experimental Results

3. Process Optimization

| S = f(v, f) → min |  | Degraded zone S → minimum |

| 0.003 ≤ v ≤ 1.5 m/s | Technological range for cutting speed v | |

| 20 ≤ f ≤ 150 kHz | Technological range for the UV laser frequency f |

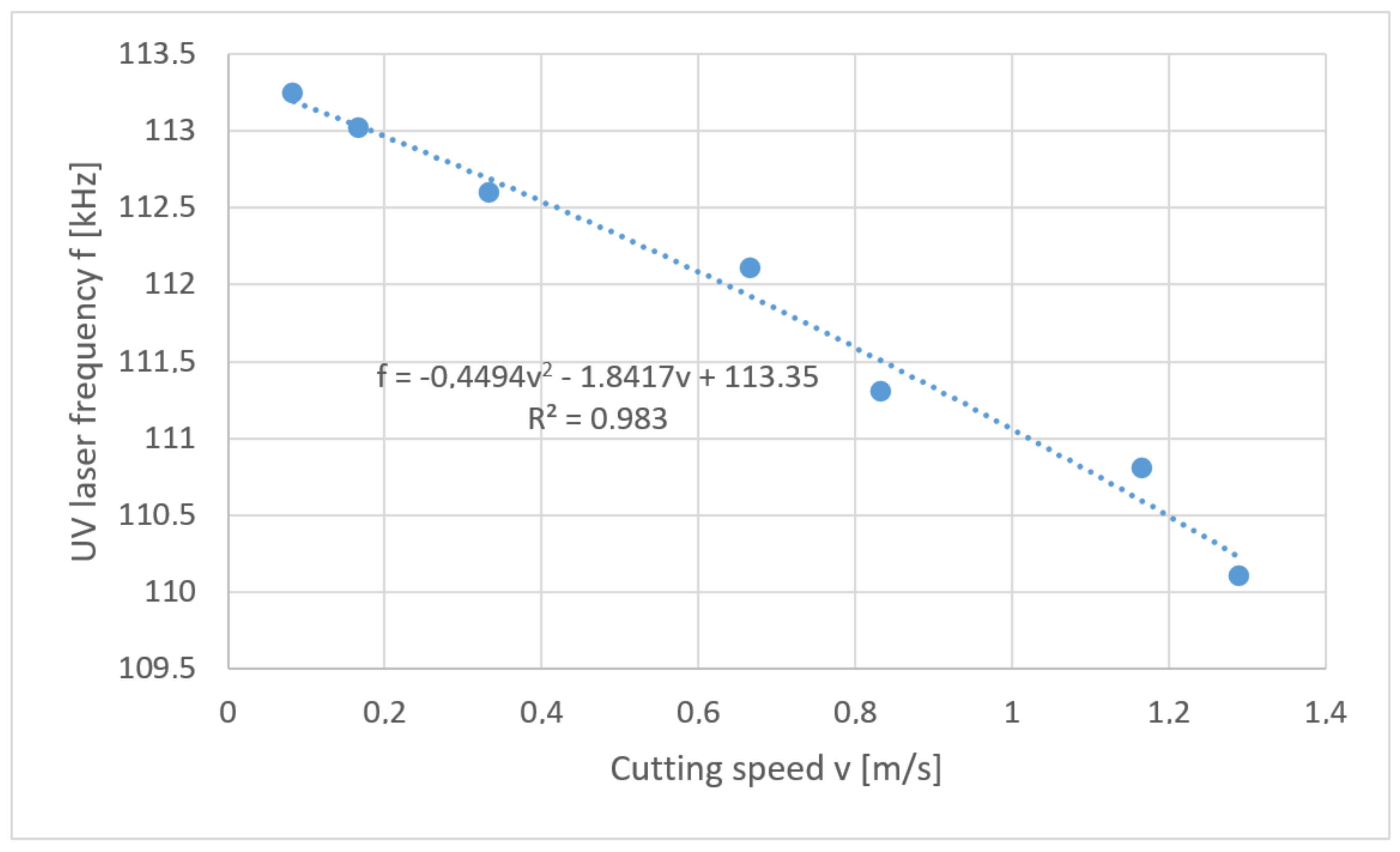

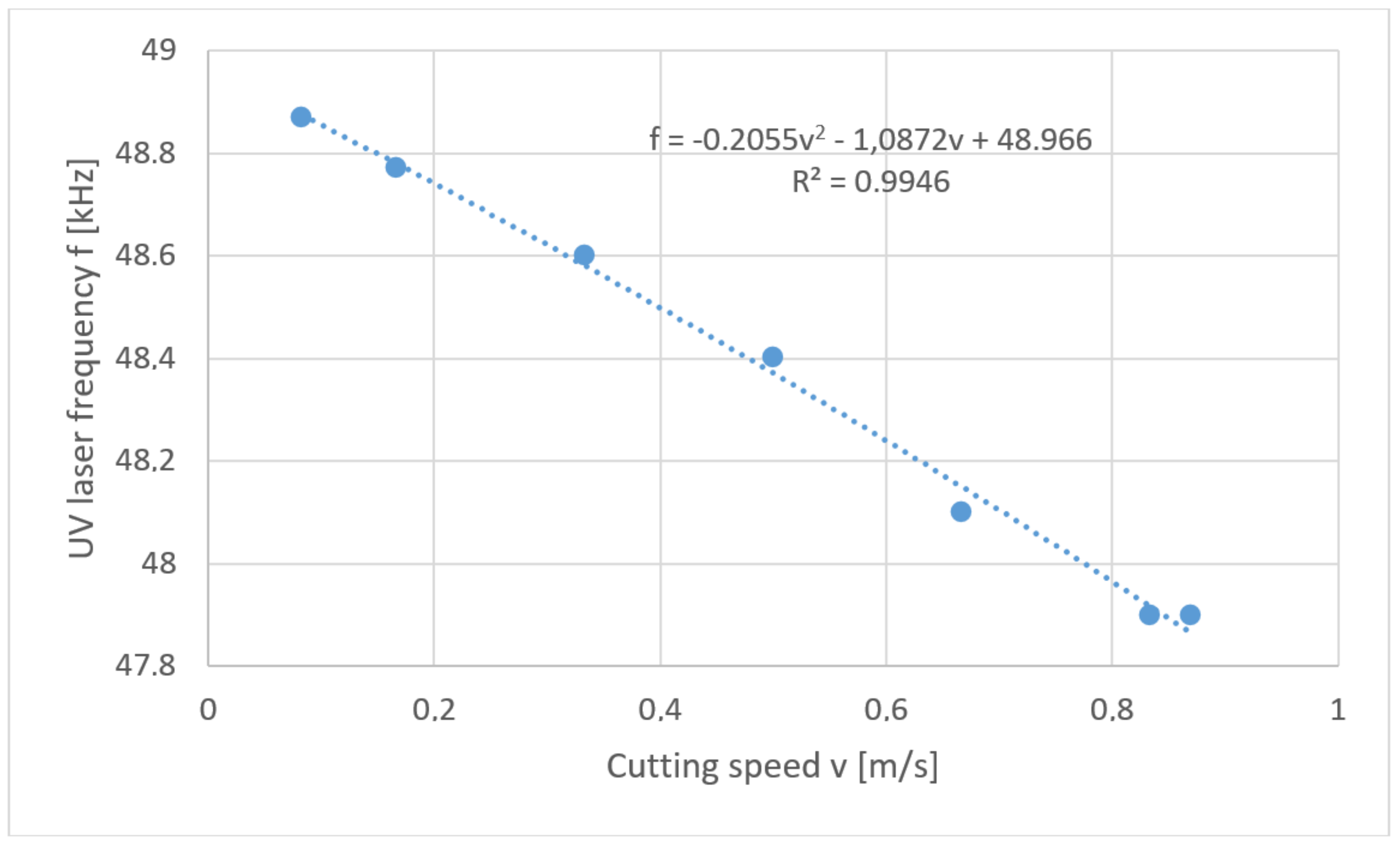

4. Formulation of Reverse Task

| f = f(v) ? |  | What is the relationship between the frequency f of the UV laser beam and the cutting speed v? |

| Assuming that: | ||

| S = f(v, f) → min | Degraded zone S → minimum | |

| 0.003 ≤ v ≤ 1.5 [m/s] | Technological range for cutting speed v | |

| 20 ≤ f ≤ 150 [kHz] | Technological range for the UV laser frequency f |

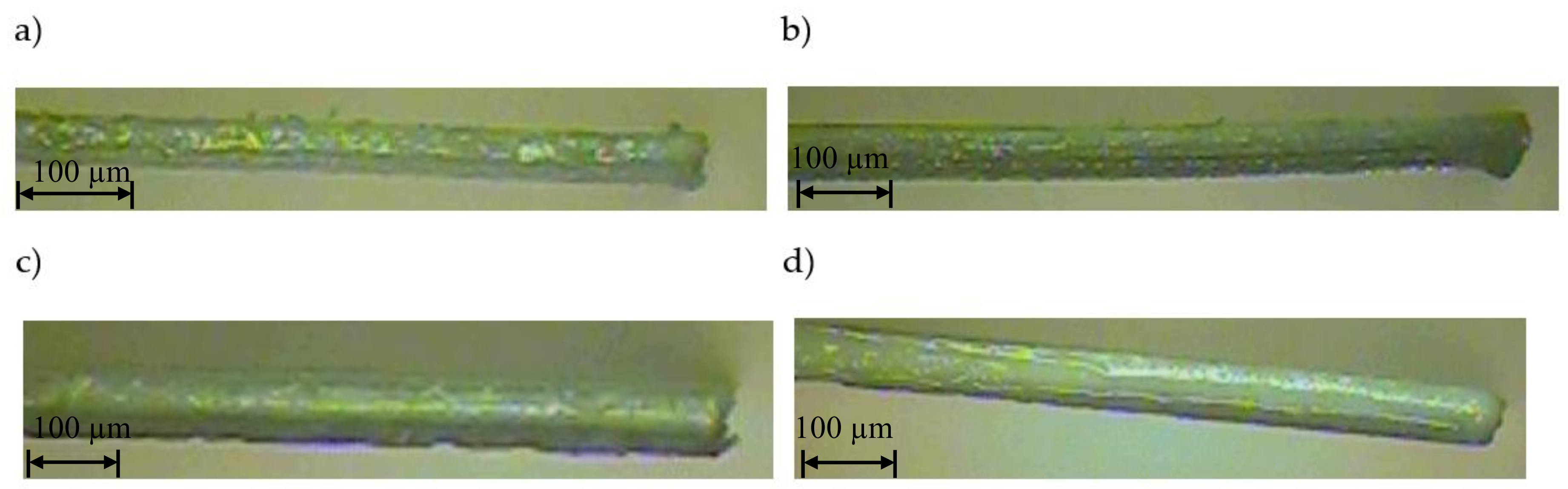

5. Experimental Research for Optimal Values of Decision Variables

6. Conclusions

- Due to the fact that there are no qualitative features, i.e., carbon deposit, detached zone, and zone of color changes in foils, a new quality criterion has been developed for assessing the quality of UV laser cutting of polypropylene foils. A zone with changed physical properties (e.g., different edge strength) was found compared to the native material, and therefore this area was called a degraded zone and further tests were carried out for such a quality feature.

- In each of the examined cases (for samples after optimization) no exceedances of the size of defects of the cut labels were found, which would eliminate the developed method from industrial applications, as no:

- —

- changes in the thickness of the material being cut (adversely if the thickness increases—this may occur in the event of carbon deposits or foil delamination),

- —

- the width of the discoloration zone coincides with the width of the degraded zone and its value does not exceed in the examined cases of acceptable value s ≤ 0.17 mm.

- Developed mathematical models (different for each foil thickness t) were optimized by two methods: the graphic method and gradient method. The results obtained are presented in common charts while obtaining the compliance of solutions.

- In addition, for technological reasons it was necessary to develop and solve an inverse task that allows obtaining optimal values of the width of the degraded zone S by changing the source frequency f as a function of the set cutting speed (function f = f (v)).

- The optimization process followed by the solution of the reverse task for each case of foil thickness separately allows the process to be controlled (in terms of efficiency, energy consumption) and at the same time high-quality end products to be obtained.

- Implementing control of the laser device models of source frequency changes as a function of the set cutting speed (function f = f (v)) allows optimal values of the width of the degraded zone S to be obtained.

- The obtained results confirm that the developed research methodology is correct and can be the basis for further research on the process of cutting the UV laser of other materials.

- Further studies of the laser cutting of foil with a UV laser in real conditions with high cutting speeds and acceleration for sheets with minimum dimensions of 1 × 1 m are planned on the modified settings of technological parameters (for example: focus and size of the spot, mirror- to-material distance) in order to increase the efficiency of the process.

Author Contributions

Funding

Conflicts of Interest

References

- Giles, G.A.; Bain, D.R. Technology of Plastics Packaging for the Customer Market; CRC Press: Boca Raton, FL, USA, 2001. [Google Scholar]

- Beswick, R.H.d.; Dunn, D.J. Plastics in Packaging. Western Europe and North America; Rapra Technology Limited: Shropshire, UK, 2002. [Google Scholar]

- Mao, H.; Zhou, F.; Liu, Y.; Hua, L. Numerical and experimental investigation of the discontinuous dot indenter in the fine-blanking process. J. Man. Proc. 2016, 24, 90–99. [Google Scholar] [CrossRef]

- Du, H.; Fan, W.F.; Zhang, Z.M. Comparative study of the process fracture between fine-blanking with negative clearance and conventional blanking. Adv. Mat. Res. 2010, 97–101, 191–194. [Google Scholar] [CrossRef]

- Bohdal, L. Application of FEM and vision-based methods to analysis of shearing processes in the aspect of scrap reduction. Ann. Set Environ. Prot. 2015, 17, 90–103. [Google Scholar]

- Bohdal, Ł.; Patyk, R.; Tandecka, K.; Gontarz, S.; Jackiewicz, D. Influence of shear-slitting parameters on workpiece formation, cut edge quality and selected magnetic properties for grain-oriented silicon steel. J. Man. Proc. Part A 2020, 56, 1007–1026. [Google Scholar] [CrossRef]

- Miraouri, I.; Boujelbene, M.; Bayraktar, E. Analysis of roughness and heat affected zone of steel plates obtained by laser cutting. Adv. Mat. Res. 2014, 974, 169–173. [Google Scholar]

- Caiazzo, F.; Ciurcio, F.; Daurelio, G.; Minutolo, F.M.C. Laser cutting of different polymeric plastics (PE, PP and PC) by CO2 laser beam. J. Mat. Proc. Technol. 2005, 159, 279–285. [Google Scholar] [CrossRef]

- Eltawahni, H.A.; Olabi, A.G.; Benyounis, K.Y. Effect of process parameters and optimization of CO2 laser cutting of ultra high performance polyethylene. Mat. Des. 2010, 31, 4029–4038. [Google Scholar] [CrossRef] [Green Version]

- Abrao, A.M.; Faria, P.E.; Rubio, J.C.C.; Reis, P.; Davim, J.P. Drilling of fiber reinforced plastics: A review. J. Mater. Process. Technol. 2007, 186, 1–7. [Google Scholar] [CrossRef]

- Uebel, M.; Bliedtner, J. Laser precision cutting of high-melting metal foils. Proc. Eng. 2014, 69, 99–103. [Google Scholar] [CrossRef]

- Kukiełka, L.; Patyk, R.; Bohdal, Ł.; Napadłek, W.; Gryglicki, R.; Kasprzak, P. Investigations of polyprophylene foil cutting process using fiber Nb: YAG and diode Nd: YVO4 lasers. ACTA Mech. Aut. 2019, 13, 107–112. [Google Scholar]

- Stępak, B.; Antończak, A.J.; Abramski, K.M. Optimization of femtosecond laser cutting of a biodegradable polymer for medical devices manufacturing. Photonics Lett. Pol. 2016, 8, 116–118. [Google Scholar] [CrossRef] [Green Version]

- Assaf, Y.; Kietzig, A.-M. Optical and chemical effects governing femtosecond laser-induced structure formation on polymer surfaces. Mater. Today Commun. 2018, 14, 169–179. [Google Scholar] [CrossRef] [Green Version]

- Kerse, C.; Kalaycıoglu, H.; Elahi, P.; Çetin, B.; Kesim, D.K.; Akçaalan, Ö.; Yavas, S.; Asık, M.D.; Öktem, B.; Hoogland, H.; et al. Ablation cooled material removal with ultrafast bursts of pulses. Nature 2016, 537, 84–88. [Google Scholar] [CrossRef] [PubMed]

- Nowak, K.M.; Baker, H.J.; Hall, D.R. A model for ‘cold’ laser ablation of green state ceramic materials. Appl. Phys. A Mat. Sci. Proc. 2008, 91, 341–348. [Google Scholar] [CrossRef]

- Witkowski, G.; Tofl, S.; Mulczyk, K. Efect of laser beam trajectory on pocket geometry in laser micromachining. Open Eng. 2020, 10, 830–838. [Google Scholar] [CrossRef]

- Garasz, K.; Kocik, M.; Petrov, T. Experimental investigations on ultrashort laser ablation for micro and nanomachining of materials. J. Phys. Conf. Ser. 2019, 1186, 012028. [Google Scholar] [CrossRef]

- Mirza, I.; Bulgakova, N.M.; Tomáštík, J.; Michálek, V.; Haderka, O.; Fekete, L.; Mocek, T. Ultrashort pulse laser ablation of dielectrics: Tresholds, mechanisms, role of breakdown. Sci. Rep. 2016, 6, 39133. [Google Scholar] [CrossRef]

- Oosterbeek, R.N.; Ashforth, S.; Bodley, O.; Cather Simpson, M. Measuring the ablation threshold fluence in femtosecond laser micromachining with vortex and Bessel pulses. Opt. Exp. 2018, 26, 34558–34568. [Google Scholar] [CrossRef]

- Rethfeld, B.; Ivanov, D.S.; Anisimov, S.I.; Garcia, M.E. Modelling ultrafast laser ablation. J. Phys. D Appl. Phys. 2017, 50, 193001. [Google Scholar] [CrossRef]

- Sotnikov, A.; Laux, H.; Stritzker, B. Experimental and numerical optimization of beam shapes for short-pulse ultraviolet laser cutting processing. Phys. Proc. 2010, 5, 137–146. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Faghri, A. Melting of a subcooled mixed powder bed with constant heat flux heating. Int. J. Heat Mass Transf. 1999, 42, 1775. [Google Scholar] [CrossRef]

- Wang, X.C.; Li, Z.L.; Chen, T.; Lok, B.K.; Low, D.K.Y. 355 nm DPSS UV laser cutting of FR4 and BT/epoxy-based PCB substrates. Opt. Lasers Eng. 2008, 46, 404–409. [Google Scholar] [CrossRef]

- Pfeifenberger, M.J.; Mangang, M.; Wurster, S.; Reiser, J.; Hohenwarter, A.; Pfleging, W.; Kiener, D.; Pippan, R. The use of femtosecond laser ablation as a novel tool for rapid micro-mechanical sample preparation. Mat. Des. 2017, 121, 109–118. [Google Scholar] [CrossRef]

- He, F.; Yu, J.; Tan, Y.; Chu, W.; Zhou, C.; Cheng, Y.; Sugioka, K. Tailoring femtosecond 1.5-µm Bessel beams for manufacturing high-aspect-ratio through-silicon vias. Sci. Rep. 2017, 7, 40785. [Google Scholar]

- Terakawa, M. Femtosecond Laser Processing of Biodegradable Polymers. Appl. Sci. 2018, 8, 1123. [Google Scholar] [CrossRef] [Green Version]

- Malinauskas, M.; Žukauskas, A.; Hasegawa, S.; Hayasaki, Y.; Mizeikis, V.; Buividas, R.; Juodkazis, S. Ultrafast laser processing of materials: From science to industry. Light Sci. Appl. 2016, 5, e16133. [Google Scholar] [CrossRef] [Green Version]

- Chen, G.; Wang, Y.; Zhang, J.; Bi, J. An analytical solution for two-dimensional modeling of repetitive long pulse laser heating material. Int. J. Heat Mass Tran. 2017, 104, 503–509. [Google Scholar] [CrossRef]

- Taylor, L.L.; Scott, R.E.; Qiao, J. Integrating two-temperature and classical heat accumulation models to predict femtosecond laser processing of silicon. Opt. Mater. Express 2018, 648–658. [Google Scholar] [CrossRef]

- Maddah, H.A. Polypropylene as a promising plastic: A.; Review. Am. J. Pol. Sci. 2016, 6, 1–11. [Google Scholar]

- Bauer, F.; Michalowski, A.; Kiedrowski, T.; Nolte, S. Heat accumulation in ultra-short pulsed scanning laser ablation of metals. Opt. Express 2015, 23, 1035–1043. [Google Scholar] [CrossRef]

- Taghleef Industries. Available online: https://www.ti-films.com/ (accessed on 5 November 2020).

- MATSIM Sp. z o.o. Method of Cutting Pieces Out of a Polypropylene Film and a Device for Implementing This Method. Patent application: P.430653 [WIPO ST 10/C PL430653], 4 July 2020. [Google Scholar]

- Kukiełka, L.; Kukiełka, S. Experiment Planner. Computer Program for Planning Exploratory and Proper Experiments as well as Identification and Analysis of the Mathematical Model of the Research Object. User Guide; Technical University of Koszalin: Koszalin, Poland, 2002. [Google Scholar]

- Kukiełka, L. Basics of Engineering Research; PWN: Warsaw, Poland, 2002. [Google Scholar]

- Kukielka, L. Mathematical modelling and numerical simulation of non-linear deformation of the asperity in the burnishing cold rolling operation. In Computational Methods in Contact Mechanics V: Proceedings of the 5th International Conference on Computational Methods in Contact Mechanics, Seville, Spain, 7 June 2001; Book Series: Computational and Experimental Methods; WIT Press: Ashurst, UK, 2001; pp. 317–326. [Google Scholar]

| Sample No. | Sample Thickness t [µm] | Tensile Strength (Breaking Force Fmax) F [N] | Initial Measurement Length of the Sample l [mm] | Elongation Δd [%] | Breaking Engineering Stress σ [MPa] |

|---|---|---|---|---|---|

| 1. | 50 | 187.5 | 100 | 125 | 75 |

| 2. | 60 | 234 | 100 | 128 | 78 |

| 3. | 70 | 287 | 100 | 135 | 82 |

| 4. | 80 | 320 | 100 | 129 | 80 |

| Sample No. | Sample Thickness t [µm] | Tensile Strength (Breaking Force Fmax) F [N] | Initial Measurement Length of the Sample l [mm] | Elongation Δd [%] | Breaking Engineering Stress σ [MPa] |

|---|---|---|---|---|---|

| 1. | 50 | 350 | 100 | 40 | 140 |

| 2. | 60 | 405 | 100 | 45 | 135 |

| 3. | 70 | 525 | 100 | 43 | 150 |

| 4. | 80 | 596 | 100 | 44 | 149 |

| Plan Level | Coded Variables | Real Variables | ||

|---|---|---|---|---|

| v [m/s] | f [kHz] | |||

| 1 | − | − | 0.222 | 39 |

| 2 | + | − | 1.280 | 39 |

| 3 | − | + | 0.222 | 130 |

| 4 | + | + | 1.280 | 130 |

| 5 | +α = 1.414 | 0 | 1.500 | 85 |

| 6 | −α = −1.414 | 0 | 0.003 | 85 |

| 7 | 0 | +α = 1.414 | 0.751 | 150 |

| 8 | 0 | −α = −1.414 | 0.751 | 20 |

| 9 | 0 | 0 | 0.751 | 85 |

| 10 | 0 | 0 | 0.751 | 85 |

| 11 | 0 | 0 | 0.751 | 85 |

| 12 | 0 | 0 | 0.751 | 85 |

| 13 | 0 | 0 | 0.751 | 85 |

| Plan Level | Real Variables | The Width of the Degraded Zone S | ||||

|---|---|---|---|---|---|---|

| v | f | Average | Repeats | |||

| 1 | 2 | 3 | ||||

| [m/s] | [kHz] | [mm] | [mm] | [mm] | [mm] | |

| 1 | 0.222 | 39 | 0.03 | 0.029 | 0.03 | 0.031 |

| 2 | 1.280 | 39 | 0.027 | 0.025 | 0.027 | 0.029 |

| 3 | 0.222 | 130 | 0.0075 | 0.0065 | 0.0073 | 0.0087 |

| 4 | 1.280 | 130 | 0.0125 | 0.0103 | 0.0127 | 0.0145 |

| 5 | 1.500 | 85 | 0.01 | 0.005 | 0.01 | 0.015 |

| 6 | 0.003 | 85 | 0.1 | 0.05 | 0.1 | 0.15 |

| 7 | 0.751 | 150 | 0.0125 | 0.0115 | 0.0125 | 0.0135 |

| 8 | 0.751 | 20 | 0.2 | 0.15 | 0.2 | 0.25 |

| 9 | 0.751 | 85 | 0.01 | 0.005 | 0.01 | 0.015 |

| 10 | 0.751 | 85 | 0.01 | 0.009 | 0.01 | 0.011 |

| 11 | 0.751 | 85 | 0.01 | 0.007 | 0.01 | 0.013 |

| 12 | 0.751 | 85 | 0.01 | 0.005 | 0.012 | 0.013 |

| 13 | 0.751 | 85 | 0.01 | 0.005 | 0.006 | 0.019 |

| Plan Level | Real Variables | The Width of the Degraded Zone S | ||||

|---|---|---|---|---|---|---|

| v | f | Average | Repeats | |||

| 1 | 2 | 3 | ||||

| [m/s] | [kHz] | [mm] | [mm] | [mm] | [mm] | |

| 1 | 0.222 | 39 | 0.015 | 0.014 | 0.015 | 0.017 |

| 2 | 1.280 | 39 | 0.01 | 0.007 | 0.009 | 0.015 |

| 3 | 0.222 | 130 | 0.2 | 0.15 | 0.2 | 0.25 |

| 4 | 1.280 | 130 | 0.2 | 0.15 | 0.2 | 0.25 |

| 5 | 1.500 | 85 | 0.02 | 0.02 | 0.022 | 0.023 |

| 6 | 0.003 | 85 | 0.1 | 0.1 | 0.12 | 0.13 |

| 7 | 0.751 | 150 | 0.14 | 0.21 | 0.27 | 0.29 |

| 8 | 0.751 | 20 | 0.01 | 0.01 | 0.015 | 0.019 |

| 9 | 0.751 | 85 | 0.0075 | 0.0073 | 0.0078 | 0.0086 |

| 10 | 0.751 | 85 | 0.0075 | 0.0072 | 0.0075 | 0.0082 |

| 11 | 0.751 | 85 | 0.0075 | 0.0072 | 0.0075 | 0.0077 |

| 12 | 0.751 | 85 | 0.0075 | 0.0071 | 0.0075 | 0.0078 |

| 13 | 0.751 | 85 | 0.0075 | 0.007 | 0.0075 | 0.0085 |

| Plan Level | Real Variables | The Width of the Degraded Zone S | ||||

|---|---|---|---|---|---|---|

| v | f | Average | Repeats | |||

| 1 | 2 | 3 | ||||

| [m/s] | [kHz] | [mm] | [mm] | [mm] | [mm] | |

| 1 | 0.222 | 39 | 0.0075 | 0.007 | 0.0075 | 0.0085 |

| 2 | 1.280 | 39 | 0.007567 | 0.0075 | 0.0077 | 0.0085 |

| 3 | 0.222 | 130 | 0.005 | 0.005 | 0.0055 | 0.0058 |

| 4 | 1.280 | 130 | 0.0075 | 0.007 | 0.0075 | 0.0079 |

| 5 | 1.500 | 85 | 0.0067 | 0.001 | 0.0015 | 0.005 |

| 6 | 0.003 | 85 | 0.1 | 0.08 | 0.1 | 0.13 |

| 7 | 0.751 | 150 | 0.0075 | 0.0073 | 0.0075 | 0.0079 |

| 8 | 0.751 | 20 | 0.2 | 0.21 | 0.22 | 0.23 |

| 9 | 0.751 | 85 | 0.0125 | 0.0123 | 0.0125 | 0.0128 |

| 10 | 0.751 | 85 | 0.0125 | 0.0123 | 0.0125 | 0.0127 |

| 11 | 0.751 | 85 | 0.010833 | 0.01 | 0.013 | 0.016 |

| 12 | 0.751 | 85 | 0.01 | 0.01 | 0.011 | 0.012 |

| 13 | 0.751 | 85 | 0.01 | 0.01 | 0.011 | 0.013 |

| Plan Level | Real Variables | The Width of the Degraded Zone S | ||||

|---|---|---|---|---|---|---|

| v | f | Average | Repeats | |||

| 1 | 2 | 3 | ||||

| [m/s] | [kHz] | [mm] | [mm] | [mm] | [mm] | |

| 1 | 0.222 | 39 | 0.005 | 0.0045 | 0.005 | 0.0055 |

| 2 | 1.280 | 39 | 0.007567 | 0.0072 | 0.0075 | 0.0077 |

| 3 | 0.222 | 130 | 0.01 | 0.01 | 0.011 | 0.013 |

| 4 | 1.280 | 130 | 0.0075 | 0.007 | 0.0075 | 0.0083 |

| 5 | 1.500 | 85 | 0.005 | 0.005 | 0.0055 | 0.0059 |

| 6 | 0.003 | 85 | 0.1 | 0.08 | 0.11 | 0.13 |

| 7 | 0.751 | 150 | 0.2 | 0.21 | 0.22 | 0.23 |

| 8 | 0.751 | 20 | 0.2 | 0.21 | 0.22 | 0.23 |

| 9 | 0.751 | 85 | 0.01 | 0.01 | 0.012 | 0.013 |

| 10 | 0.751 | 85 | 0.01 | 0.01 | 0.011 | 0.013 |

| 11 | 0.751 | 85 | 0.01 | 0.01 | 0.014 | 0.016 |

| 12 | 0.751 | 85 | 0.01 | 0.01 | 0.012 | 0.014 |

| 13 | 0.751 | 85 | 0.01 | 0.01 | 0.011 | 0.013 |

| Foil Thickness t [µm] | vopt. [m/s] | fopt [kHz] | Sopt [mm] |

|---|---|---|---|

| 50 | 1.29 | 110.1 | 0.0091 |

| 60 | 0.867 | 47.9 | 0.0479 |

| 70 | 1.499 | 112.1 | 0.1121 |

| 80 | 1.5 | 84.8 | 0.0848 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bohdal, Ł.; Kukiełka, L.; Patyk, R.; Gryglicki, R.; Kasprzak, P. Application of Ultraviolet Laser Working in Cold Ablation Conditions for Cutting Labels Used in Packaging in the Food Industry. Materials 2020, 13, 5245. https://doi.org/10.3390/ma13225245

Bohdal Ł, Kukiełka L, Patyk R, Gryglicki R, Kasprzak P. Application of Ultraviolet Laser Working in Cold Ablation Conditions for Cutting Labels Used in Packaging in the Food Industry. Materials. 2020; 13(22):5245. https://doi.org/10.3390/ma13225245

Chicago/Turabian StyleBohdal, Łukasz, Leon Kukiełka, Radosław Patyk, Rafał Gryglicki, and Piotr Kasprzak. 2020. "Application of Ultraviolet Laser Working in Cold Ablation Conditions for Cutting Labels Used in Packaging in the Food Industry" Materials 13, no. 22: 5245. https://doi.org/10.3390/ma13225245

APA StyleBohdal, Ł., Kukiełka, L., Patyk, R., Gryglicki, R., & Kasprzak, P. (2020). Application of Ultraviolet Laser Working in Cold Ablation Conditions for Cutting Labels Used in Packaging in the Food Industry. Materials, 13(22), 5245. https://doi.org/10.3390/ma13225245