Impact Wear of the Protective Cr3C2-Based HVOF-Sprayed Coatings

Abstract

:1. Introduction

2. Experimental

2.1. Sample Preparation

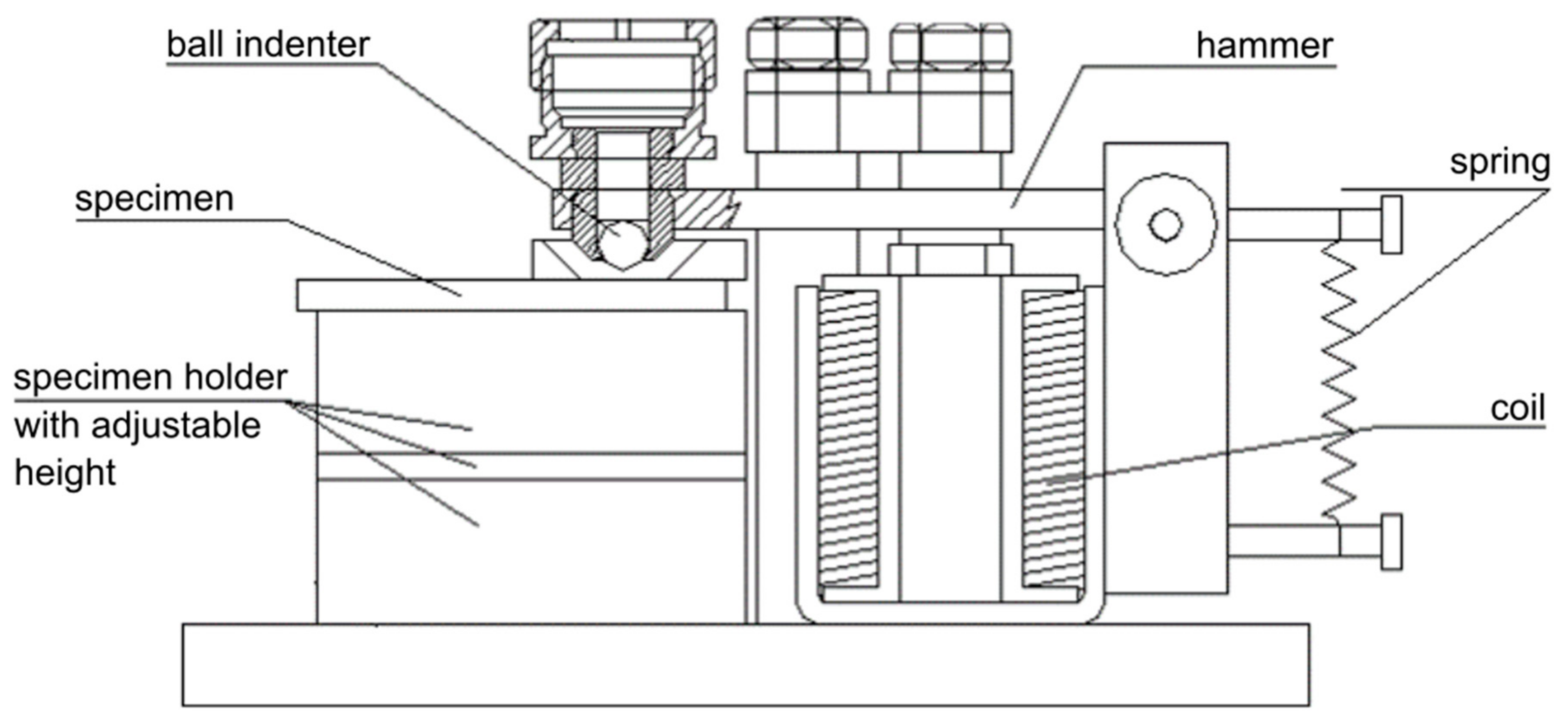

2.2. Dynamic Impact Test

3. Results and Discussion

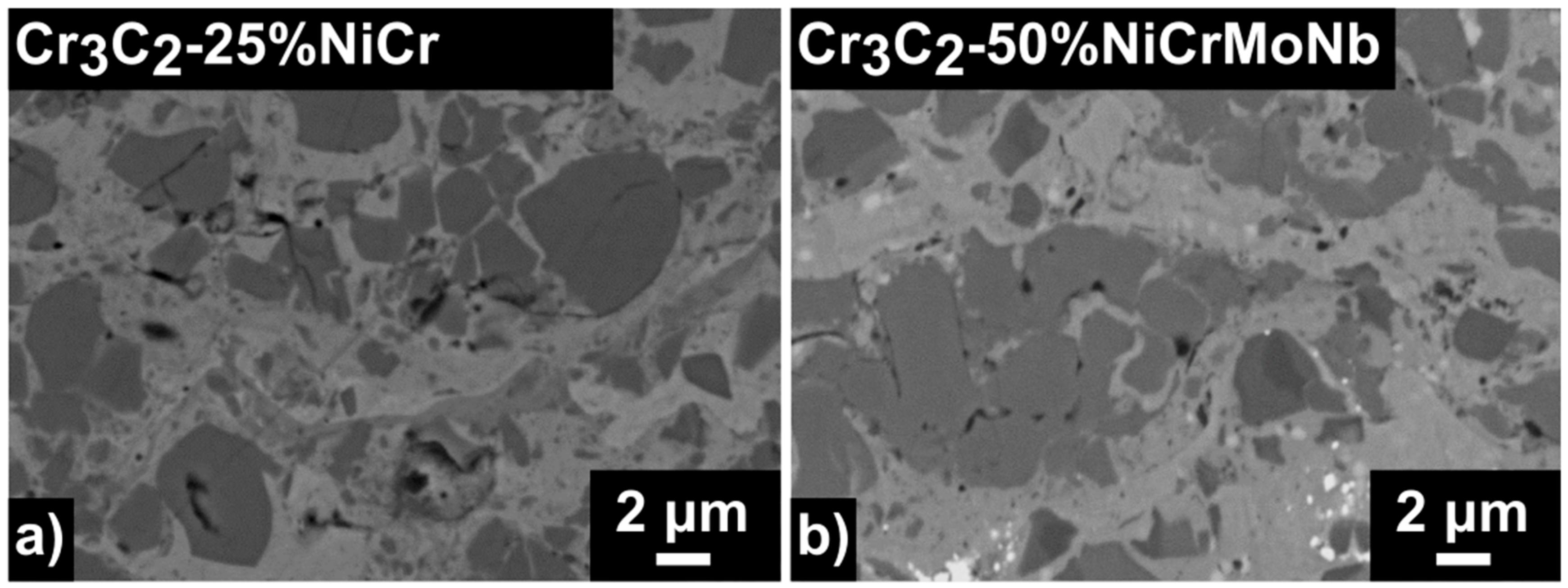

3.1. CrC-Based Coatings Structure and Properties

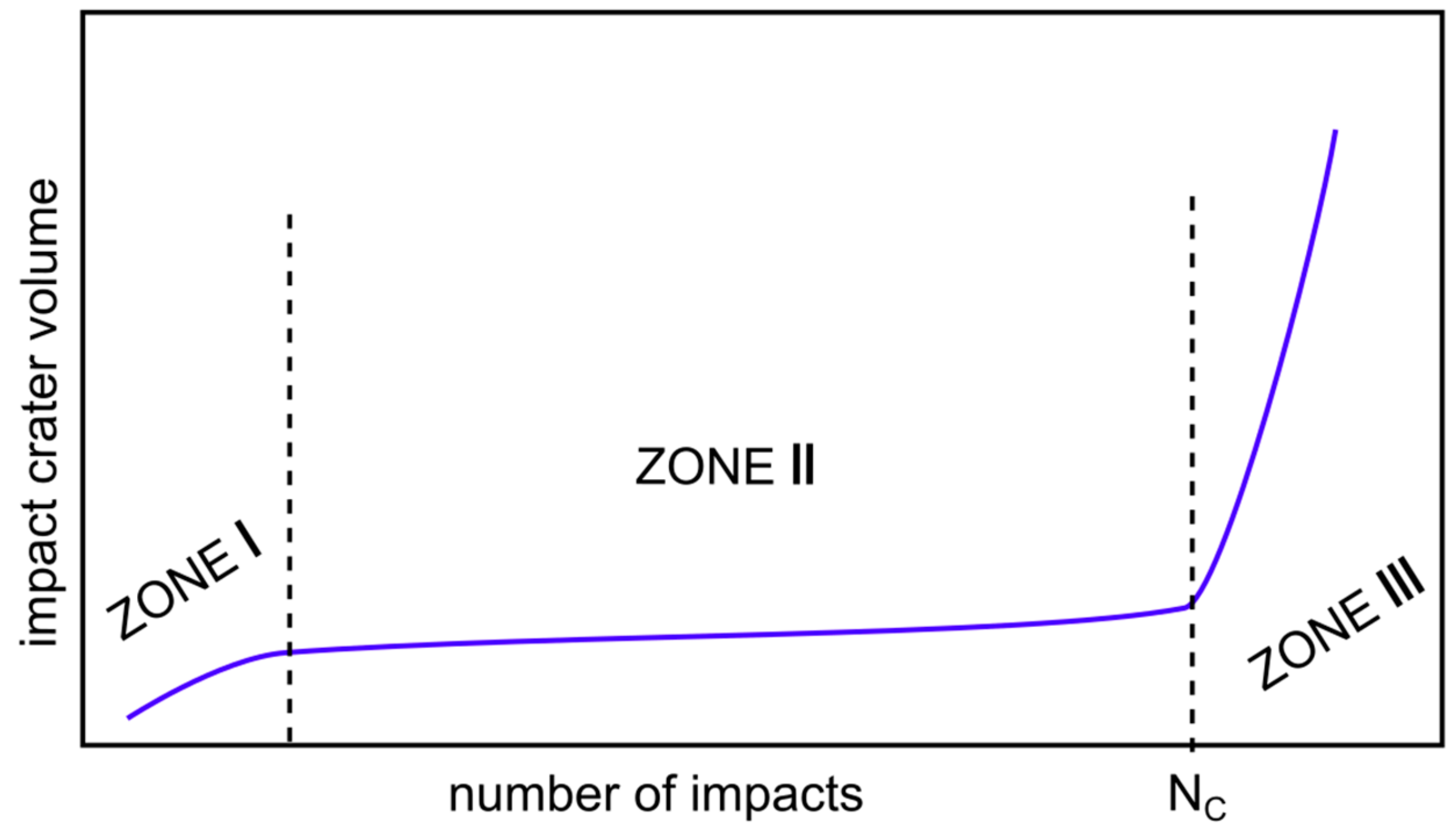

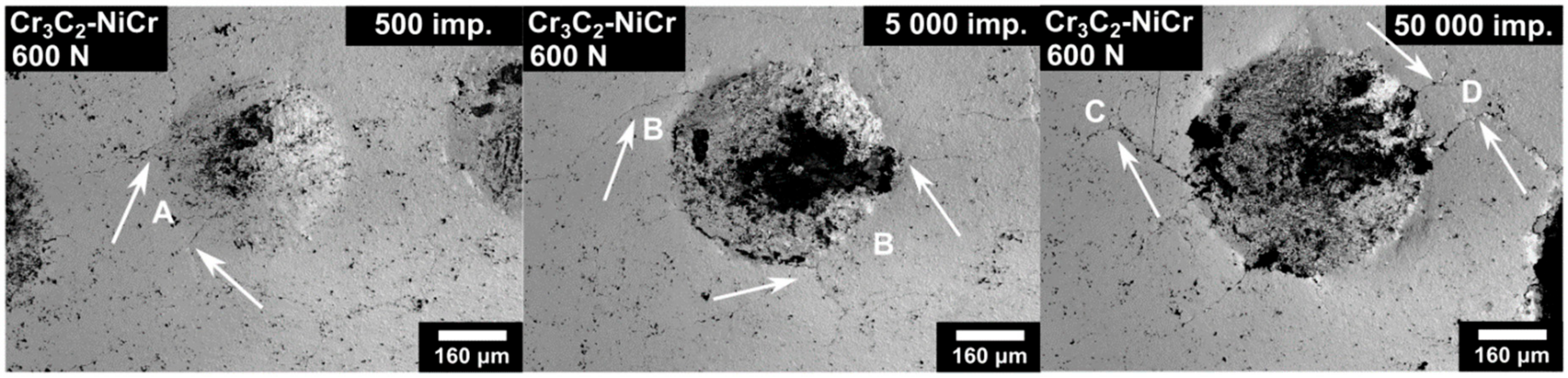

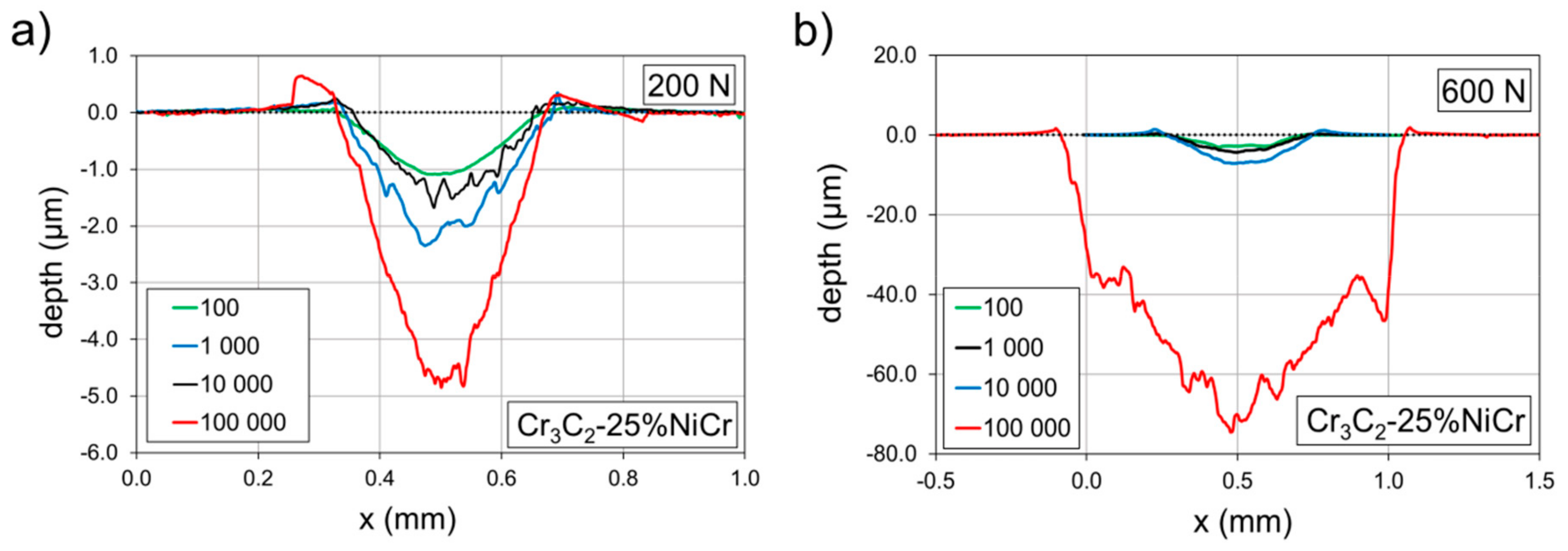

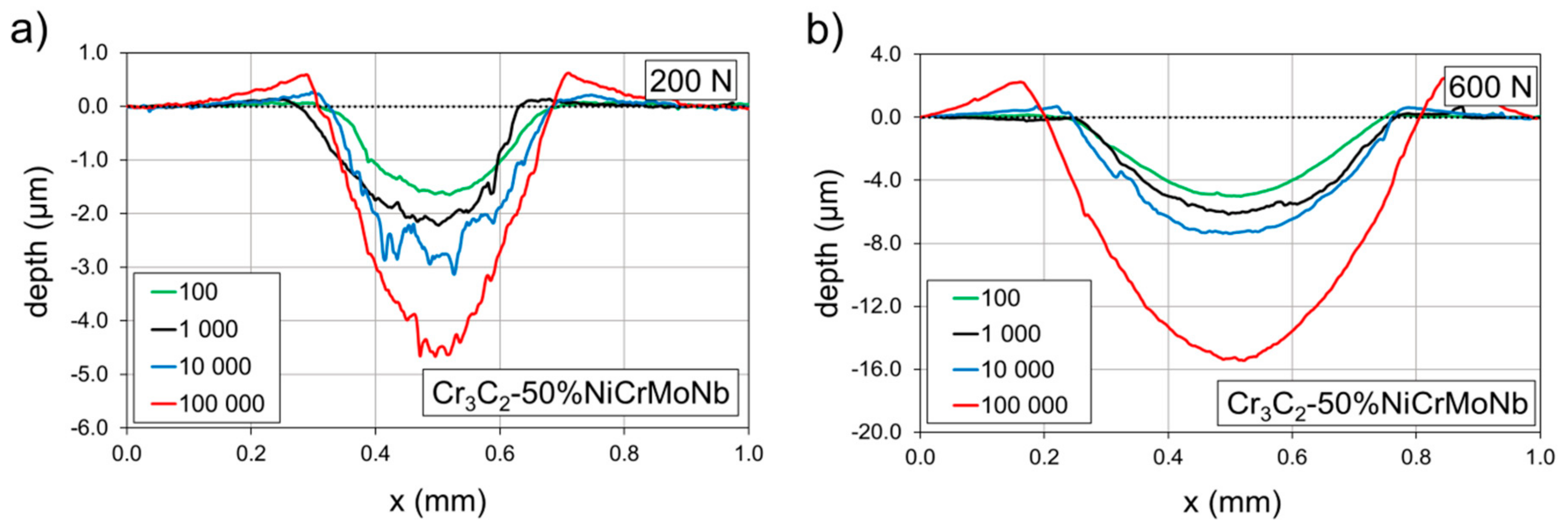

3.2. Impact Behaviour of the CrC-Based Coatings

4. Conclusions

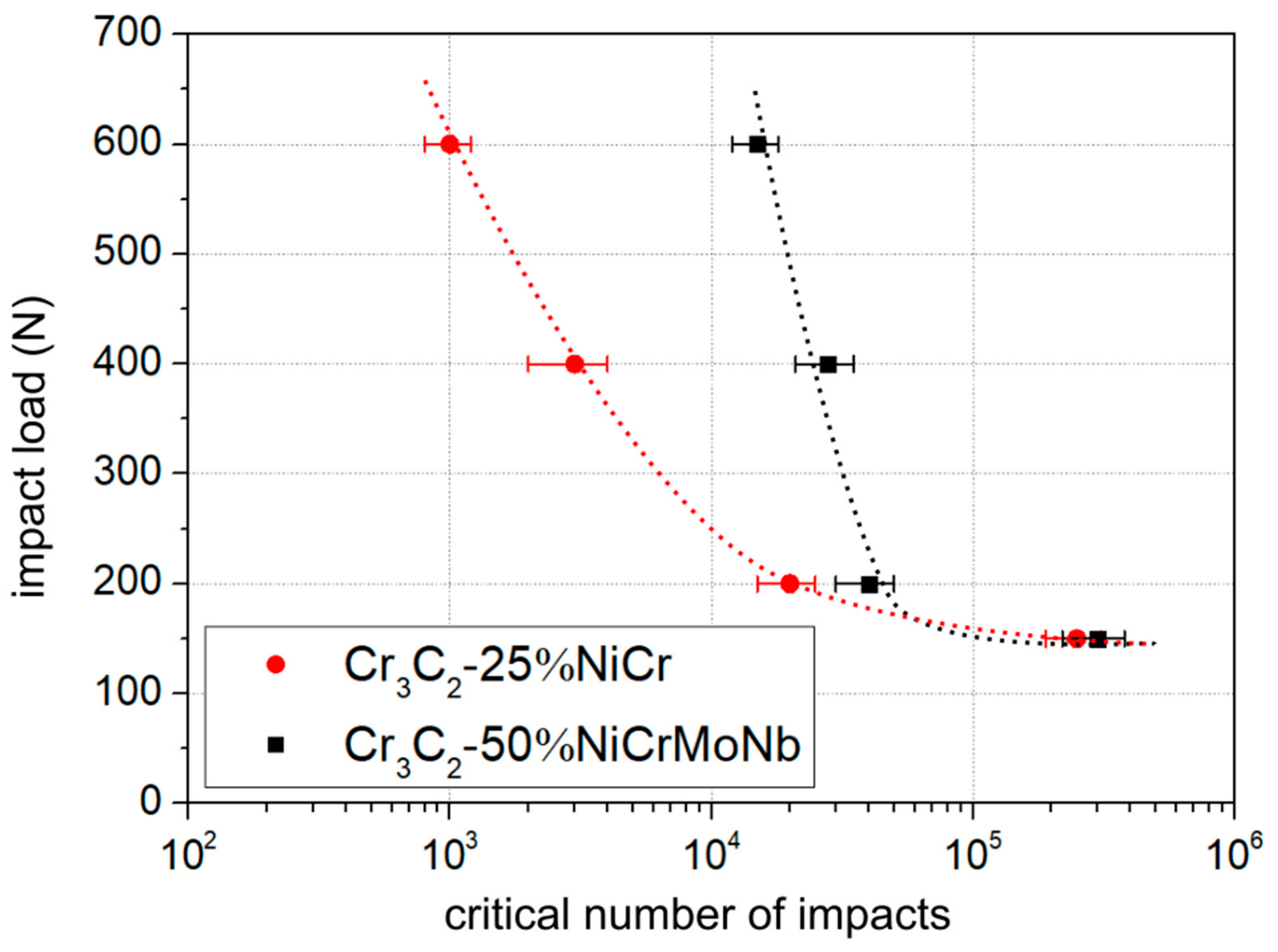

- The critical number of impacts of the thick HVOF-sprayed coatings was estimated using the loading curve and dispersion of values of the average volume of the impact crater.

- Observed dispersion of values of the average volume of the impact crater was the consequence of the different spread of microcracks in the coatings.

- The Cr3C2-50%NiCrMoNb coating exhibited, under the impact load of 200 N, a higher volume of impact craters, and the impact lifetime was nevertheless higher than for the Cr3C2-25%NiCr coating.

- The Cr3C2-50%NiCrMoNb coating exhibited higher impact lifetime than the Cr3C2-25%NiCr coating, probably due to the higher number of ductile metallic matrices.

- The difference between the impact lifetimes of the coatings was the most pronounced at high impact loads.

Author Contributions

Funding

Conflicts of Interest

References

- Pawlowski, L. The Science and Engineering of Thermal Spray Coatings, 2nd ed.; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2008. [Google Scholar]

- Houdková, Š.; Česánek, Z.; Smazalová, E.; Lukac, F. The High-Temperature Wear and Oxidation Behavior of CrC-Based HVOF Coatings. J. Therm. Spray Technol. 2017, 27, 179–195. [Google Scholar] [CrossRef]

- Matikainen, V.; Bolelli, G.; Koivuluoto, H.; Sassatelli, P.; Lusvarghi, L.; Vuoristo, P. Sliding wear behaviour of HVOF and HVAF sprayed Cr 3 C 2 -based coatings. Wear 2017, 2017, 57–71. [Google Scholar] [CrossRef]

- Berger, L.-M. Application of hardmetals as thermal spray coatings. Int. J. Refract. Met. Hard Mater. 2015, 49, 350–364. [Google Scholar] [CrossRef]

- Berger, L.-M. Hardmetals as thermal spray coatings. Powder Met. 2007, 50, 205–214. [Google Scholar] [CrossRef]

- Hussainova, I.; Pirso, J.; Antonov, M.; Juhani, K.; Letunovits, S. Erosion and abrasion of chromium carbide based cermets produced by different methods. Wear 2007, 263, 905–911. [Google Scholar] [CrossRef]

- Bolelli, G.; Berger, L.-M.; Börner, T.; Koivuluoto, H.; Matikainen, V.; Lusvarghi, L.; Lyphout, C.; Markocsan, N.; Nylén, P.; Sassatelli, P.; et al. Sliding and abrasive wear behaviour of HVOF- and HVAF-sprayed Cr3C2–NiCr hardmetal coatings. Wear 2016, 32–50. [Google Scholar] [CrossRef]

- Xie, M.; Lin, Y.; Ke, P.; Wang, S.; Zhang, S.; Zhen, Z.; Ge, L. Influence of Process Parameters on High Velocity Oxy-Fuel Sprayed Cr3C2-25%NiCr Coatings. Coatings 2017, 7, 98. [Google Scholar] [CrossRef]

- Janka, L.; Norpoth, J.; Trache, R.; Thiele, S.; Berger, L.-M. HVOF- and HVAF-Sprayed Cr3C2-NiCr Coatings Deposited from Feedstock Powders of Spherical Morphology: Microstructure Formation and High-Stress Abrasive Wear Resistance Up to 800 °C. J. Therm. Spray Technol. 2017, 26, 1720–1731. [Google Scholar] [CrossRef]

- Guilemany, J.M.; Miguel, J.; Vizcaíno, S.; Lorenzana, C.; Delgado, J.; Sanchez, J. Role of heat treatments in the improvement of the sliding wear properties of Cr3C2–NiCr coatings. Surf. Coat. Technol. 2002, 157, 207–213. [Google Scholar] [CrossRef]

- Matthews, S.; James, B.; Hyland, M. Microstructural influence on erosion behaviour of thermal spray coatings. Mater. Charact. 2007, 58, 59–64. [Google Scholar] [CrossRef]

- Matthews, S.; James, B.; Hyland, M. The role of microstructure in the mechanism of high velocity erosion of Cr3C2–NiCr thermal spray coatings: Part 1—As-sprayed coatings. Surf. Coat. Technol. 2009, 203, 1086–1093. [Google Scholar] [CrossRef]

- Matthews, S.; James, B.; Hyland, M. High temperature erosion of Cr3C2-NiCr thermal spray coatings—The role of phase microstructure. Surf. Coat. Technol. 2009, 203, 1144–1153. [Google Scholar] [CrossRef]

- Matthews, S.; James, B.; Hyland, M. High temperature erosion–oxidation of Cr3C2–NiCr thermal spray coatings under simulated turbine conditions. Corros. Sci. 2013, 70, 203–211. [Google Scholar] [CrossRef]

- Tailor, S.; Vashishtha, N.; Modi, A.; Modi, S.C. Structural and mechanical properties of HVOF sprayed Cr3C2-25%NiCr coating and subsequent erosion wear resistance. Mater. Res. Express 2019, 6, 076435. [Google Scholar] [CrossRef]

- Zhang, H.; Dong, X.; Chen, S. Solid particle erosion-wear behaviour of Cr3C2–NiCr coating on Ni-based superalloy. Adv. Mech. Eng. 2017, 9, 1–9. [Google Scholar] [CrossRef]

- Fantozzi, D.; Matikainen, V.; Uusitalo, M.; Koivuluoto, H.; Vuoristo, P. Effect of Carbide Dissolution on Chlorine Induced High Temperature Corrosion of HVOF and HVAF Sprayed Cr3C2-NiCrMoNb Coatings. J. Therm. Spray Technol. 2017, 27, 220–231. [Google Scholar] [CrossRef]

- Liu, J.; Bai, X.; Chen, T.; Yuan, C. Effects of Cobalt Content on the Microstructure, Mechanical Properties and Cavitation Erosion Resistance of HVOF Sprayed Coatings. Coatings 2019, 9, 534. [Google Scholar] [CrossRef] [Green Version]

- Knotek, O.; Bosserhoff, B.; Schrey, A.; Leyendecker, T.; Lemmer, O.; Esser, S. A new technique for testing the impact load of thin films: The coating impact test. Surf. Coat. Technol. 1992, 54, 102–107. [Google Scholar] [CrossRef]

- Sobota, J.; Grossman, J.; Buršíková, V.; Dupák, L.; Vyskočil, J. Evaluation of hardness, tribological behaviour and impact load of carbon-based hard composite coatings exposed to the influence of humidity. Diam. Relat. Mater. 2011, 20, 596–599. [Google Scholar] [CrossRef]

- Daniel, J.; Souček, P.; Grossman, J.; Zábranský, L.; Bernátová, K.; Buršíková, V.; Fořt, T.; Vašina, P.; Sobota, J. Adhesion and dynamic impact wear of nanocomposite TiC-based coatings prepared by DCMS and HiPIMS. Int. J. Refract. Met. Hard Mater. 2020, 86, 105123. [Google Scholar] [CrossRef]

- Engel, P.A.; Yang, Q. Impact wear of multiplated electrical contacts. Wear 1995, 181, 730–742. [Google Scholar] [CrossRef]

- Bouzakis, K.-D.; Vidakis, N.; Leyendecker, T.; Erkens, G.; Wenke, R. Determination of the fatigue properties of multilayer PVD coatings on various substrates, based on the impact test and its FEM simulation. Thin Solid Films 1997, 308, 315–322. [Google Scholar] [CrossRef]

- Heinke, W.; Leyland, A.; Matthews, A.; Berg, G.; Friedrich, C.; Broszeit, E. Evaluation of PVD nitride coatings, using impact, scratch and Rockwell-C adhesion tests. Thin Solid Films 1995, 270, 431–438. [Google Scholar] [CrossRef]

- Bouzakis, K.-D.; Maliaris, G.; Makrimallakis, S. Strain rate effect on the fatigue failure of thin PVD coatings: An investigation by a novel impact tester with adjustable repetitive force. Int. J. Fatigue 2012, 44, 89–97. [Google Scholar] [CrossRef]

- Bobzin, K.; Zhao, L.; Öte, M.; Königstein, T.; Steeger, M. Impact wear of an HVOF-sprayed Cr 3 C 2 -NiCr coating. Int. J. Refract. Met. Hard Mater. 2018, 70, 191–196. [Google Scholar] [CrossRef]

- David, C.N.; Athanasiou, M.A.; Anthymidis, K.G.; Gotsis, P.K.; Neu, R.; Wallin, K.; Thompson, S.R.; Dean, S.W. Impact Fatigue Failure Investigation of HVOF Coatings. J. ASTM Int. 2008, 5, 101571. [Google Scholar] [CrossRef]

- Kiilakoski, J.; Langlade, C.; Koivuluoto, H.; Vuoristo, P. Characterizing the micro-impact fatigue behavior of APS and HVOF-sprayed ceramic coatings. Surf. Coat. Technol. 2019, 371, 245–254. [Google Scholar] [CrossRef]

- Batista, J.; Godoy, C.; Matthews, A.; Godoy, G.C. Impact testing of duplex and non-duplex (Ti,Al)N and Cr–N PVD coatings. Surf. Coat. Technol. 2003, 163, 353–361. [Google Scholar] [CrossRef]

- Bantle, R.; Matthews, A. Investigation into the impact wear behaviour of ceramic coatings. Surf. Coat. Technol. 1995, 74, 857–868. [Google Scholar] [CrossRef]

- Voevodin, A.; Bantle, R.; Matthews, A. Dynamic impact wear of TiCxNy and Ti-DLC composite coatings. Wear 1995, 185, 151–157. [Google Scholar] [CrossRef]

| Material | Cr3C2-25%NiCr | Cr3C2-50%NiCrMoNb |

|---|---|---|

| Feedstock | Amperit 588.074 | Amperit 595.074 |

| Oxygen | 823 L/min | 872 L/min |

| Fuel | 25.7 L/h | 21.7 L/h |

| Barrel length | 100 mm | 150 cm |

| Spray distance | 360 mm | 330 mm |

| Traverse speed | 250 mm/s | 250 mm/s |

| Feed rate | 70 g/min | 76 g/min |

| Carrier gas | Nitrogen, 6 L/min | Nitrogen, 6 L/min |

| Offset | 6 mm | 6 mm |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Daniel, J.; Grossman, J.; Houdková, Š.; Bystrianský, M. Impact Wear of the Protective Cr3C2-Based HVOF-Sprayed Coatings. Materials 2020, 13, 2132. https://doi.org/10.3390/ma13092132

Daniel J, Grossman J, Houdková Š, Bystrianský M. Impact Wear of the Protective Cr3C2-Based HVOF-Sprayed Coatings. Materials. 2020; 13(9):2132. https://doi.org/10.3390/ma13092132

Chicago/Turabian StyleDaniel, Josef, Jan Grossman, Šárka Houdková, and Martin Bystrianský. 2020. "Impact Wear of the Protective Cr3C2-Based HVOF-Sprayed Coatings" Materials 13, no. 9: 2132. https://doi.org/10.3390/ma13092132

APA StyleDaniel, J., Grossman, J., Houdková, Š., & Bystrianský, M. (2020). Impact Wear of the Protective Cr3C2-Based HVOF-Sprayed Coatings. Materials, 13(9), 2132. https://doi.org/10.3390/ma13092132