Performance Assessment of Minimum Quantity Castor-Palm Oil Mixtures in Hard-Milling Operation

Abstract

1. Introduction

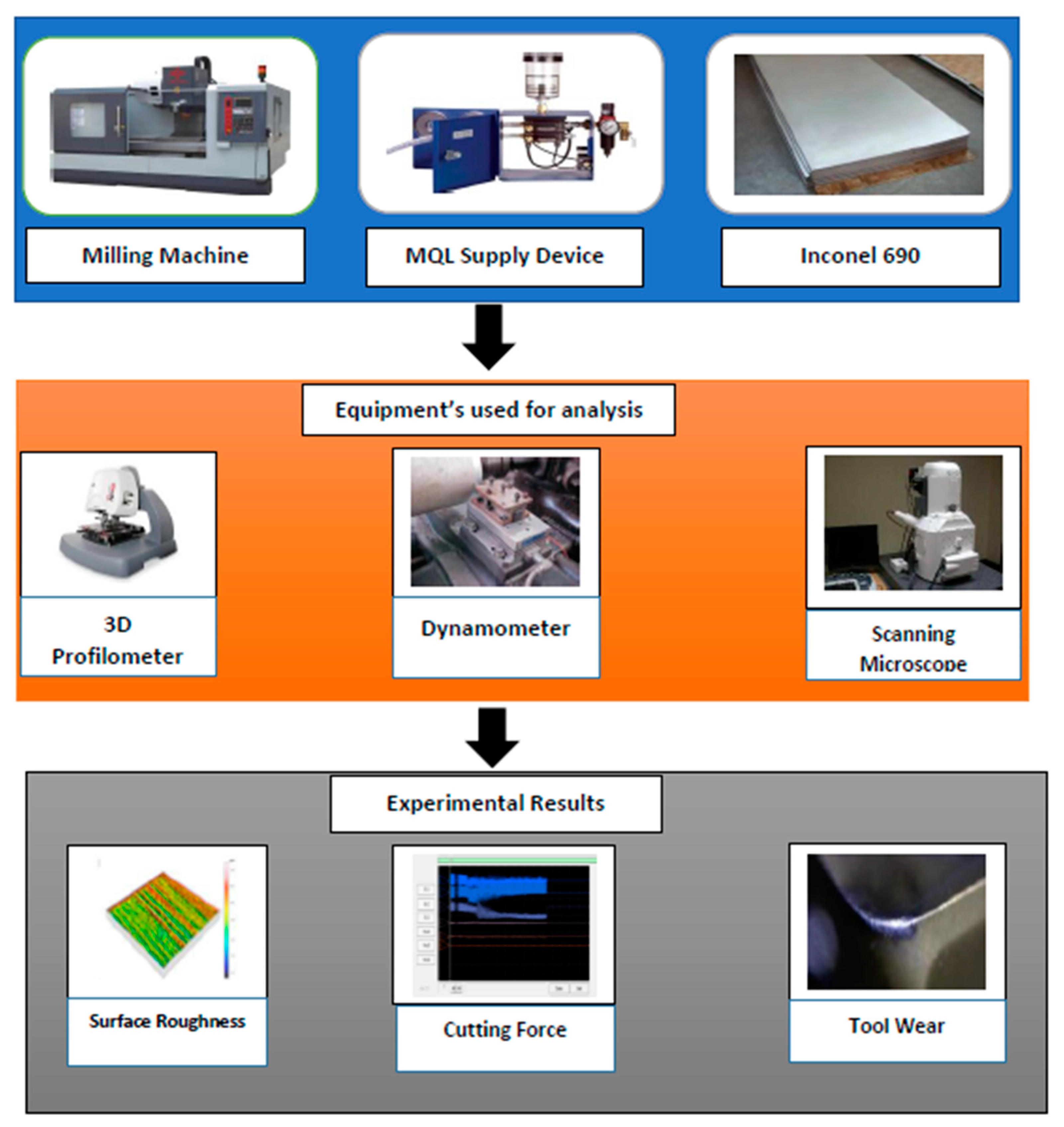

2. Materials and Methods

2.1. Machining Operation

2.2. TOPSIS Based Ranking Strategy with Entropy Weight

- where

- where

- The weight vector: where, and = 1

- The decision matrix (D) is shown in Equation (3):where signifies the performances of the alternatives against the criteria Cj. The raking method of TOPSIS is described below:Step 1: Normalization of the D using Equation (4):Step 2: An essential component of MCDM methods is determining the weight of each criterion. Previous literature has suggested different techniques to generate criteria weights. They can be categorized into the following groups:

- (a)

- Subjective approach: In this approach, the weight of any criteria is defined based on the decision maker’s preferences.

- (b)

- Objective approach: in this approach, weight is directly calculated from the decision matrix.

In the present study, an entropy objective approach has been applied to determine the weightage of the machining responses. The idea of entropy is utilized extensively to calculate the uncertainty related to the information [20,21,22]. The entropy-based weight can be determined from the normalized decision matrix by applying the following steps: - Calculation of entropy by applying Equation (5):

- The diversification strength of the information provided by the outcome under criterion is calculated by Equation (6):

- When the decision-maker has no extra preference information over the criteria, the principle of insufficient reason infers the best weights of the criteria are given in Equation (7):

3. Results and Discussion

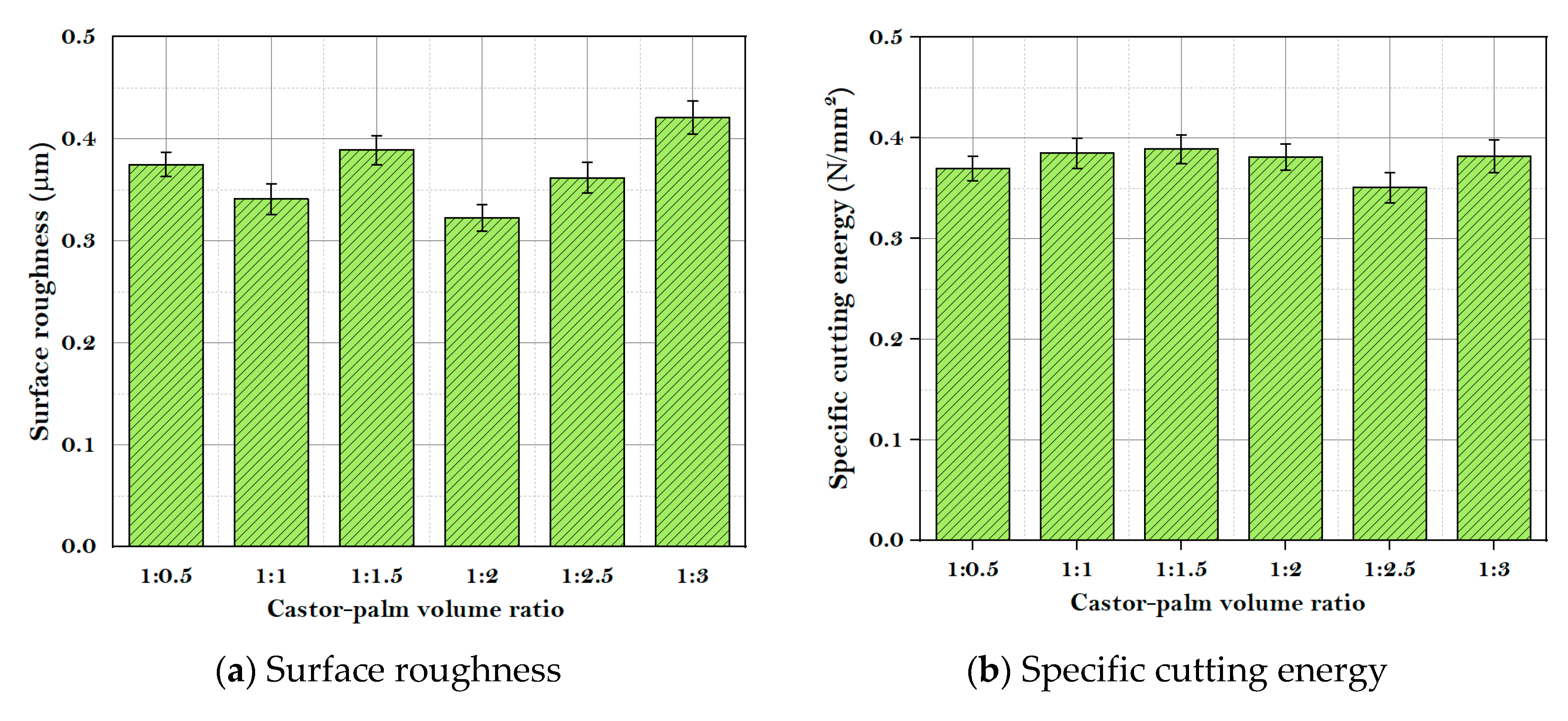

3.1. Variation of Machining Responses with the Castor-Palm Ratio

3.2. Result of the Proposed MCDM Model

3.3. Molecular Structure of Green Mixtures

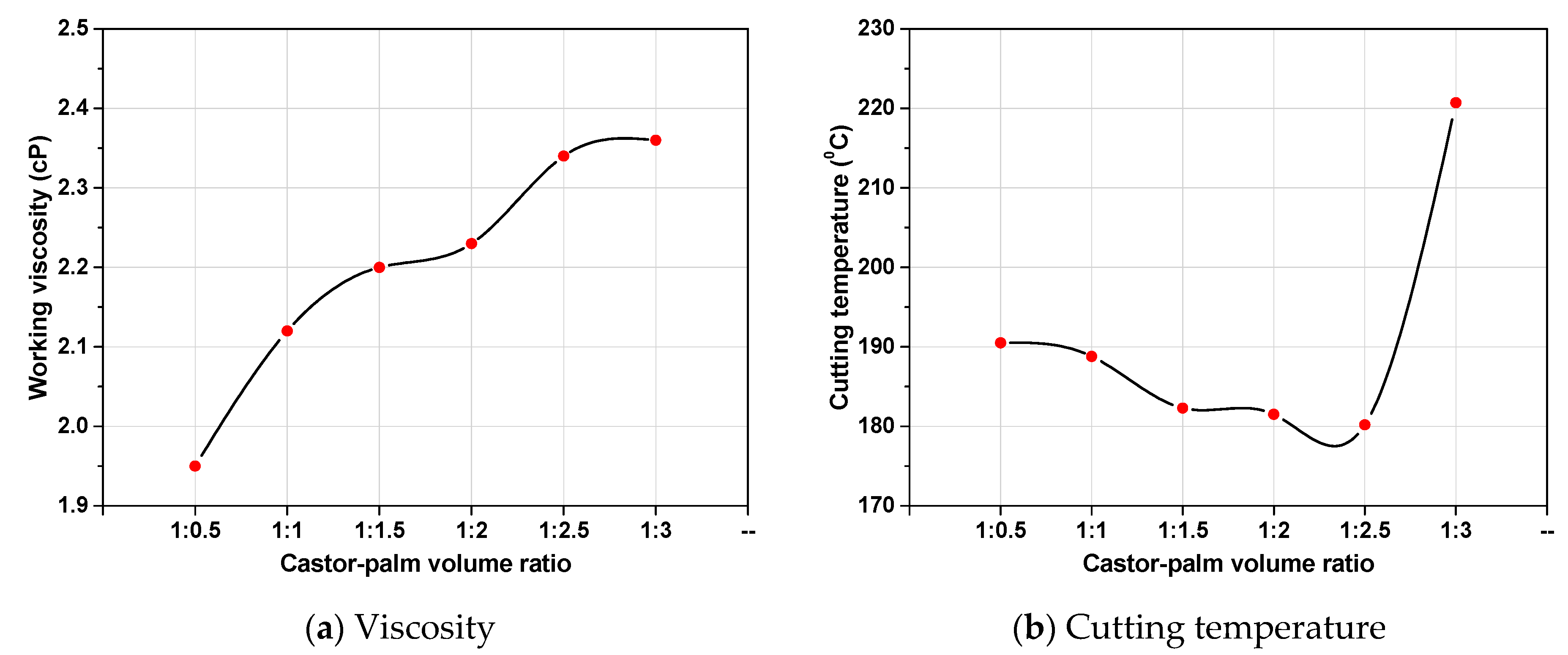

3.4. Viscosity of Green Mixtures

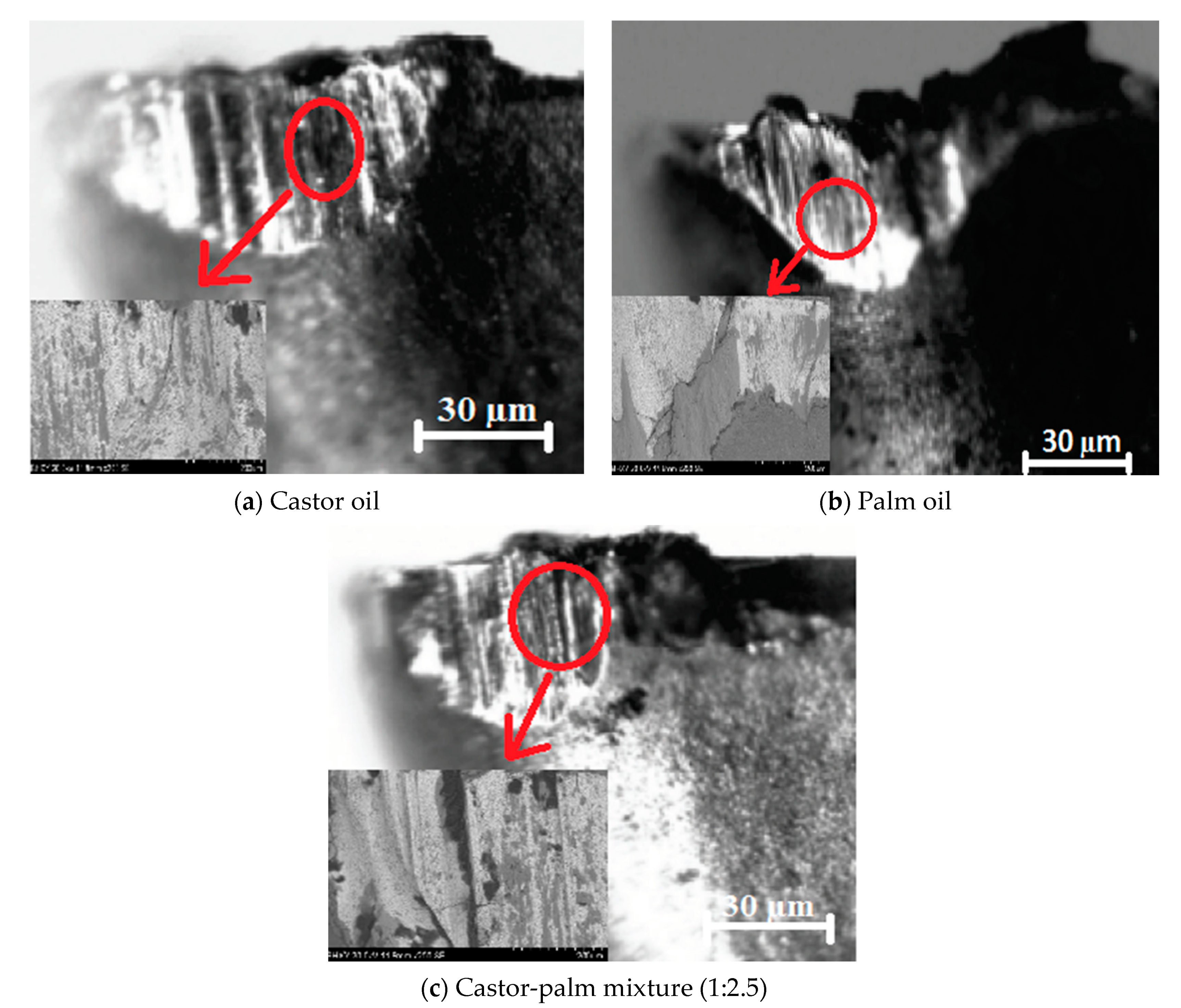

3.5. A Comparative Study

4. Conclusions

- With the increasing volume fraction of palm oil, the value of surface roughness was decreased first, then upsurged. The minimum value of surface roughness was achieved at the castor-palm volume fraction (1:2). Conversely, the maximum value was achieved at 1:3. The minimum specific energy was attained when the castor-palm volume mixture is 1:2.5. Furthermore, the minimum tool wear was founded at 1:1.5.

- To improve the machining economy and efficiency, the selection of proper lubricant is a crucial concern. In this context, Shannon’s entropy-based TOPSIS approach was applied to determine the best castor-palm volume ratio. The ranking of Shannon’s entropy-based TOPSIS conferred that Castor-palm volume fraction (1:2) is best for minimizing machining responses.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| CNC | Computer numerical control |

| MQL | Minimum quantity lubrication |

| SEM | Scanning electron microscope |

| OM | Optical microscope |

| Ra | Surface roughness |

| Fr | Resultant cutting force |

| Esp | Specific energy |

| VB | Tool wear |

| MCDM | Multi-criteria decision-making method |

| TOPSIS | Technique for order preference by similarity to ideal solution |

| PIS | Positive ideal solution |

| NIS | Negative ideal solution |

| RCi | Relative closeness coefficient |

References

- Gupta, M.K.; Mia, M.; Pruncu, C.I.; Kapłonek, W.; Nadolny, K.; Patra, K.; Mikolajczyk, T.; Pimenov, D.Y.; Sarikaya, M.; Sharma, V.S. Parametric optimization and process capability analysis for machining of nickel-based superalloy. Int. J. Adv. Manuf. Technol. 2019, 102, 3995–4009. [Google Scholar] [CrossRef]

- Sen, B.; Mandal, U.K.; Mondal, S.P. Advancement of an Intelligent System Based on ANFIS for Predicting Machining Performance Parameters of Inconel 690—A Perspective of Metaheuristic Approach. Meas. J. Int. Meas. Confed. 2017, 109, 9–17. [Google Scholar] [CrossRef]

- Boubekri, N.; Shaikh, V. Minimum Quantity Lubrication (MQL) in Machining: Benefits and Drawbacks. J. Ind. Intell. Inf. 2014, 3, 205–209. [Google Scholar] [CrossRef]

- Gupta, M.K.; Mia, M.; Singh, G.; Pimenov, D.Y.; Sarikaya, M.; Sharma, V.S. Hybrid cooling-lubrication strategies to improve surface topography and tool wear in sustainable turning of Al 7075-T6 alloy. Int. J. Adv. Manuf. Technol. 2019, 101, 55–69. [Google Scholar] [CrossRef]

- Singh, G.; Pruncu, C.I.; Gupta, M.K.; Mia, M.; Khan, A.M.; Jamil, M.; Pimenov, D.Y.; Sen, B.; Sharma, V.S. Investigations of Machining Characteristics in the Upgraded MQL-Assisted Turning of Pure Titanium Alloys Using Evolutionary Algorithms. Materials 2019, 12, 999. [Google Scholar] [CrossRef] [PubMed]

- Krolczyk, G.M.; Maruda, R.W.; Krolczyk, J.B.; Wojciechowski, S.; Mia, M.; Nieslony, P.; Budzik, G. Ecological trends in machining as a key factor in sustainable production—A review. J. Clean. Prod. 2019, 218, 601–615. [Google Scholar] [CrossRef]

- Belluco, W.; De Chiffre, L. Performance Evaluation of Vegetable-Based Oils in Drilling Austenitic Stainless Steel. J. Mater. Process. Technol. 2004, 148, 171–176. [Google Scholar] [CrossRef]

- Ojolo, S.J.; Amuda, M.O.H.; Ogunmola, O.Y.; Ononiwu, C.U. Experimental Determination of the Effect of Some Straight Biological Oils on Cutting Force during Cylindrical Turning. Rev. Matéria 2008, 13, 650–663. [Google Scholar] [CrossRef]

- Khan, M.M.A.; Mithu, M.A.H.; Dhar, N.R. Effects of Minimum Quantity Lubrication on Turning AISI 9310 Alloy Steel Using Vegetable Oil-Based Cutting Fluid. J. Mater. Process. Technol. 2009, 209, 5573–5583. [Google Scholar] [CrossRef]

- Xavior, M.A.; Adithan, M. Determining the Influence of Cutting Fluids on Tool Wear and Surface Roughness during Turning of AISI 304 Austenitic Stainless Steel. J. Mater. Process. Technol. 2009, 209, 900–909. [Google Scholar] [CrossRef]

- Kuram, E.; Ozcelik, B.; Demirbas, E.; Şık, E. Effects of the Cutting Fluid Types and Cutting Parameters on Surface Roughness and Thrust Force. In Proceedings of the World Congress on Engineering, London, UK, 30 June–2 July 2010. [Google Scholar]

- Sharif, S.; Yusof, N.M.; Idris, M.H.; Ahmad, Z.B.; Sudin, I.; Ripin, A.; MatZin, M.A.H. Feasibility Study of Using Vegetable Oil as a Cutting Lubricant through the Use of Minimum Quantity Lubrication during Machining; Research VOT No. 78055; Unpublished; 2013. [Google Scholar]

- Wang, Y.; Li, C.; Zhang, Y.; Yang, M.; Li, B.; Jia, D.; Hou, Y.; Mao, C. Experimental Evaluation of the Lubrication Properties of the Wheel/Workpiece Interface in Minimum Quantity Lubrication (MQL) Grinding Using Different Types of Vegetable Oils; Elsevier Ltd.: Amsterdam, The Netherlands, 2016; Volume 127. [Google Scholar] [CrossRef]

- Li, B.; Li, C.; Zhang, Y.; Wang, Y.; Jia, D.; Yang, M. Grinding Temperature and Energy Ratio Coefficient in MQL Grinding of High-Temperature Nickel-Base Alloy by Using Different Vegetable Oils as Base Oil. Chin. J. Aeronaut. 2016, 29, 1084–1095. [Google Scholar] [CrossRef]

- Sen, B.; Mia, M.; Mandal, U.K.; Mondal, S.P. GEP-and ANN-based tool wear monitoring: A virtually sensing predictive platform for MQL-assisted milling of Inconel 690. Int. J. Adv. Manuf. Technol. 2019, 105, 395–410. [Google Scholar] [CrossRef]

- Sen, B.; Mia, M.; Mandal, U.K.; Dutta, B.; Mondal, S.P. Multi-objective optimization for MQL-assisted end milling operation: An intelligent hybrid strategy combining GEP and NTOPSIS. Neural. Comput. Appl. 2019, 31, 8693–8717. [Google Scholar] [CrossRef]

- Mutlu, H.; Meier, M.A.R. Castor oil as a renewable resource for the chemical industry. Eur. J. Lipid Sci. Technol. 2010, 112, 10–30. [Google Scholar] [CrossRef]

- Carmenza, M.; Cochard, B.; Flori, A.; Cros, D.; Lopes, R.; Cuellar, T.; Espeout, S.; Syaputra, I.; Villeneuve, P.; Pina, M.; et al. Genetic architecture of palm oil fatty acid composition in cultivated oil palm (Elaeis guineensis Jacq.) compared to its wild relative E. oleifera (HBK) Cortés. PLoS ONE 2014, 9, e95412. [Google Scholar]

- Hwang, C.L.; Yoon, K. Multiple Attribute Decision Making: Methods and Applications; Springer: New York, NY, USA, 1981. [Google Scholar]

- Sharma, A.; Yadava, V. Optimization of Cut Quality Characteristics during Nd:YAG Laser Straight Cutting of Ni-Based Superalloy Thin Sheet Using Grey Relational Analysis with Entropy Measurement. Mater. Manuf. Process. 2011, 26, 1522–1529. [Google Scholar] [CrossRef]

- Tian, Z.P.; Wang, J.Q.; Zhang, H.Y. An Integrated Approach for Failure Mode and Effects Analysis Based on Fuzzy Best-Worst, Relative Entropy, and VIKOR Methods. Appl. Soft Comput. J. 2018, 72, 636–646. [Google Scholar] [CrossRef]

- Yue, C. Entropy-Based Weights on Decision Makers in Group Decision-Making Setting with Hybrid Preference Representations. Appl. Soft Comput. J. 2017, 60, 737–749. [Google Scholar] [CrossRef]

- Aamir, M. Tolouei-Rad, K. Giasin, and A. Nosrati. Recent advances in drilling of carbon fiber–reinforced polymers for aerospace applications: A review. Int. J. Adv. Manuf. Technol. 2019, 105, 2289–2308. [Google Scholar] [CrossRef]

- Aamir, K.; Giasin, M. Tolouei-Rad, and A. Vafadar. A review: Drilling performance and hole quality of aluminium alloys for aerospace applications. J. Mater. Res. Technol. 2020, 9, 12484–12500. [Google Scholar] [CrossRef]

- Sen, B.; Mia, M.; Gupta, M.K.; Rahman, M.A.; Mandal, U.K.; Mondal, S.P. Influence of Al2O3 and palm oil–mixed nano-fluid on machining performances of Inconel-690: IF-THEN rules–based FIS model in eco-benign milling. Int. J. Adv. Manuf. Technol. 2019, 103, 3389–3403. [Google Scholar] [CrossRef]

- Daǧdeviren, M. A Hybrid Multi-Criteria Decision-Making Model for Personnel Selection in Manufacturing Systems. J. Intell. Manuf. 2010, 21, 451–460. [Google Scholar] [CrossRef]

- Mahdavi, I.; Heidarzade, A.; Sadeghpour-Gildeh, B.; Mahdavi-Amiri, N. A General Fuzzy TOPSIS Model in Multiple Criteria Decision Making. Int. J. Adv. Manuf. Technol. 2009, 45, 406–420. [Google Scholar] [CrossRef]

- Rao, R.V. Machinability Evaluation of Work Materials Using a Combined Multiple Attribute Decision-Making Method. Int. J. Adv. Manuf. Technol. 2006, 28, 221–227. [Google Scholar] [CrossRef]

- Thirumalai, R.; Senthilkumaar, J.S. Multi-Criteria Decision Making in the Selection of Machining Parameters for Inconel 718. J. Mech. Sci. Technol. 2013, 27, 1109–1116. [Google Scholar] [CrossRef]

- Patel, V.R.; Dumancas, G.G.; Viswanath, L.C.K.; Maples, R.; Subong, B.J.J. Castor Oil: Properties, Uses, and Optimization of Processing Parameters in Commercial Production. Lipid Insights 2016, 9. [Google Scholar] [CrossRef]

- Sen, B.; Mia, M.; Mandal, U.K.; Mondal, S.P. Synergistic effect of silica and pure palm oil on the machining performances of Inconel 690: A study for promoting minimum quantity nano doped-green lubricants. J. Clean. Prod. 2020, 258, 120755. [Google Scholar] [CrossRef]

- Hsu, S.M.; Gates, R.S. Boundary Lubricating Films: Formation and Lubrication Mechanism. Tribol. Int. 2005, 38, 305–312. [Google Scholar] [CrossRef]

- Li, H.; Niu, S.; Lu, C. Pyrolysis Characteristics of Castor Oil through Thermogravimetric Coupled with Fourier Transform Infrared Spectroscopy. Procedia Eng. 2017, 205, 3705–3710. [Google Scholar] [CrossRef]

| Specification | Description |

|---|---|

| Base metal | Fine-grained cemented carbide |

| Diameter | 6 mm |

| Flutes | 4 |

| Length | 83 mm |

| Rake angle | 6° |

| Helix angle | 30° |

| Clearance angle | 15° |

| Grain size | 1 µm |

| Acid Name | Average Range (%) |

|---|---|

| Ricinoleic acid | 84.5–94 |

| Oleic acid | 3–7 |

| Linoleic acid | 1.5–6 |

| α-Linolenic acid | 0.4–1 |

| Stearic acid | 0.4–1 |

| Palmitic acid | 0.4–1 |

| Dihydroxystearic acid | 0.25–0.6 |

| Others | 0.25–0.6 |

| Acid Name | Average Range (%) |

|---|---|

| Myristic acid | 1 |

| Palmitic acid | 43.5 |

| Stearic acid | 4.3 |

| Oleic acid | 36.6 |

| Linoleic acid | 9.1 |

| Others | 5.5 |

| Specification | Description |

|---|---|

| Pumping elements | 2 (two) |

| Capacity of reservoir | 5 L |

| Operating source | Compressed air |

| Type of spray | Mist spray |

| Functional temperature | −25 °C–75 °C |

| Air pressure | 5–15 Bar |

| Flow rate | 0–300 mL/h |

| Kinematic Viscosity | 25–150 Cst. |

| Parameters | Values |

|---|---|

| Cutting speed | 140 m/min |

| Feed | 0.2 mm/tooth |

| Depth-of-cut | 1.0 mm |

| Flow rate of lubricant | 120 mL/h |

| Nozzle distance | 30 mm |

| Nozzle angle | 15° |

| Pressure | 0.8 MPa |

| Experiment No. | Castor-Palm Oil Volume Ratio | Lubrication Condition |

|---|---|---|

| 1 | 1:0.5 | Minimum Quantity Lubrication |

| 2 | 1:1 | |

| 3 | 1:1.5 | |

| 4 | 1:2 | |

| 5 | 1:2.5 | |

| 6 | 1:3 |

| Machining Performances | Castor Oil | Standard Deviations | Palm Oil | Standard Deviations | Castor-Palm Mixture (1:2) | Standard Deviations |

|---|---|---|---|---|---|---|

| Ra (µm) | 0.351 | 0.005 | 0.384 | 0.042 | 0.322 | 0.074 |

| Esp (N/mm2) | 0.403 | 0.007 | 0.414 | 0.064 | 0.381 | 0.043 |

| VB (mm) | 0.409 | 0.004 | 0.412 | 0.012 | 0.399 | 0.021 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sen, B.; Gupta, M.K.; Mia, M.; Pimenov, D.Y.; Mikołajczyk, T. Performance Assessment of Minimum Quantity Castor-Palm Oil Mixtures in Hard-Milling Operation. Materials 2021, 14, 198. https://doi.org/10.3390/ma14010198

Sen B, Gupta MK, Mia M, Pimenov DY, Mikołajczyk T. Performance Assessment of Minimum Quantity Castor-Palm Oil Mixtures in Hard-Milling Operation. Materials. 2021; 14(1):198. https://doi.org/10.3390/ma14010198

Chicago/Turabian StyleSen, Binayak, Munish Kumar Gupta, Mozammel Mia, Danil Yurievich Pimenov, and Tadeusz Mikołajczyk. 2021. "Performance Assessment of Minimum Quantity Castor-Palm Oil Mixtures in Hard-Milling Operation" Materials 14, no. 1: 198. https://doi.org/10.3390/ma14010198

APA StyleSen, B., Gupta, M. K., Mia, M., Pimenov, D. Y., & Mikołajczyk, T. (2021). Performance Assessment of Minimum Quantity Castor-Palm Oil Mixtures in Hard-Milling Operation. Materials, 14(1), 198. https://doi.org/10.3390/ma14010198