Influence of Different Types of Cemented Carbide Blades and Coating Thickness on Structure and Properties of TiN/AlTiN and TiAlN/a-C:N Coatings Deposited by PVD Techniques for Machining of Wood-Based Materials

Abstract

:1. Introduction

2. Materials and Methods

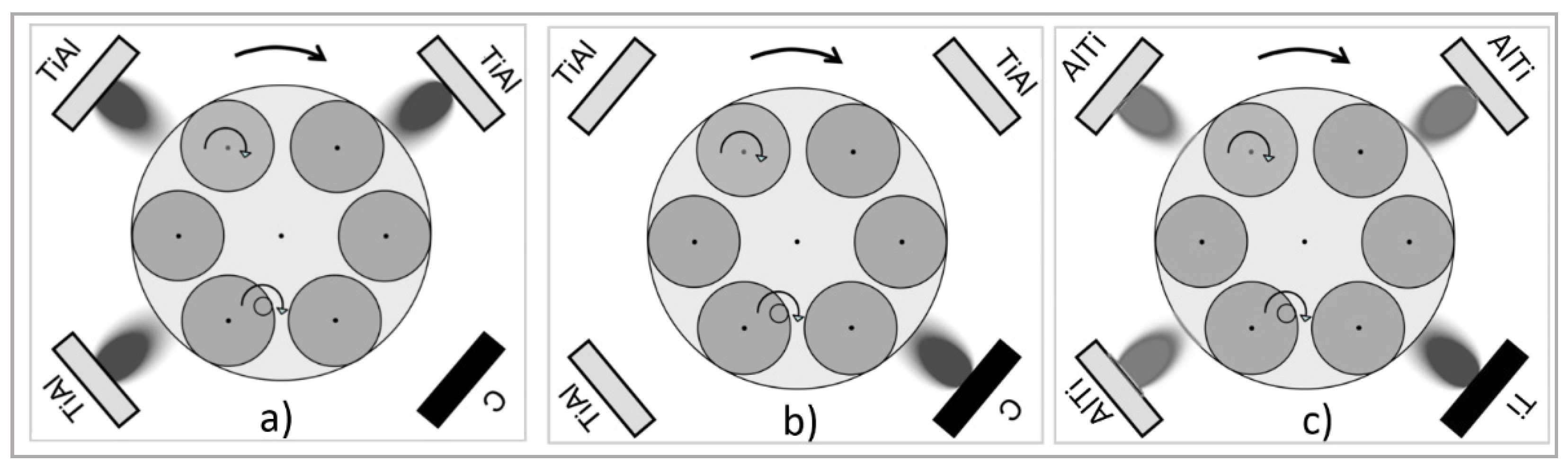

2.1. Coating Preparation

2.2. Characterization of Coatings

2.3. Durability Tests

- D—iameter of tool [m];

- n—rotational spindle speed [1/min];

- VT—feed speed [m/min];

- VC—cutting speed [m/min];

- L—feed distance [m/min];

- Lt—cutting distance.

3. Results

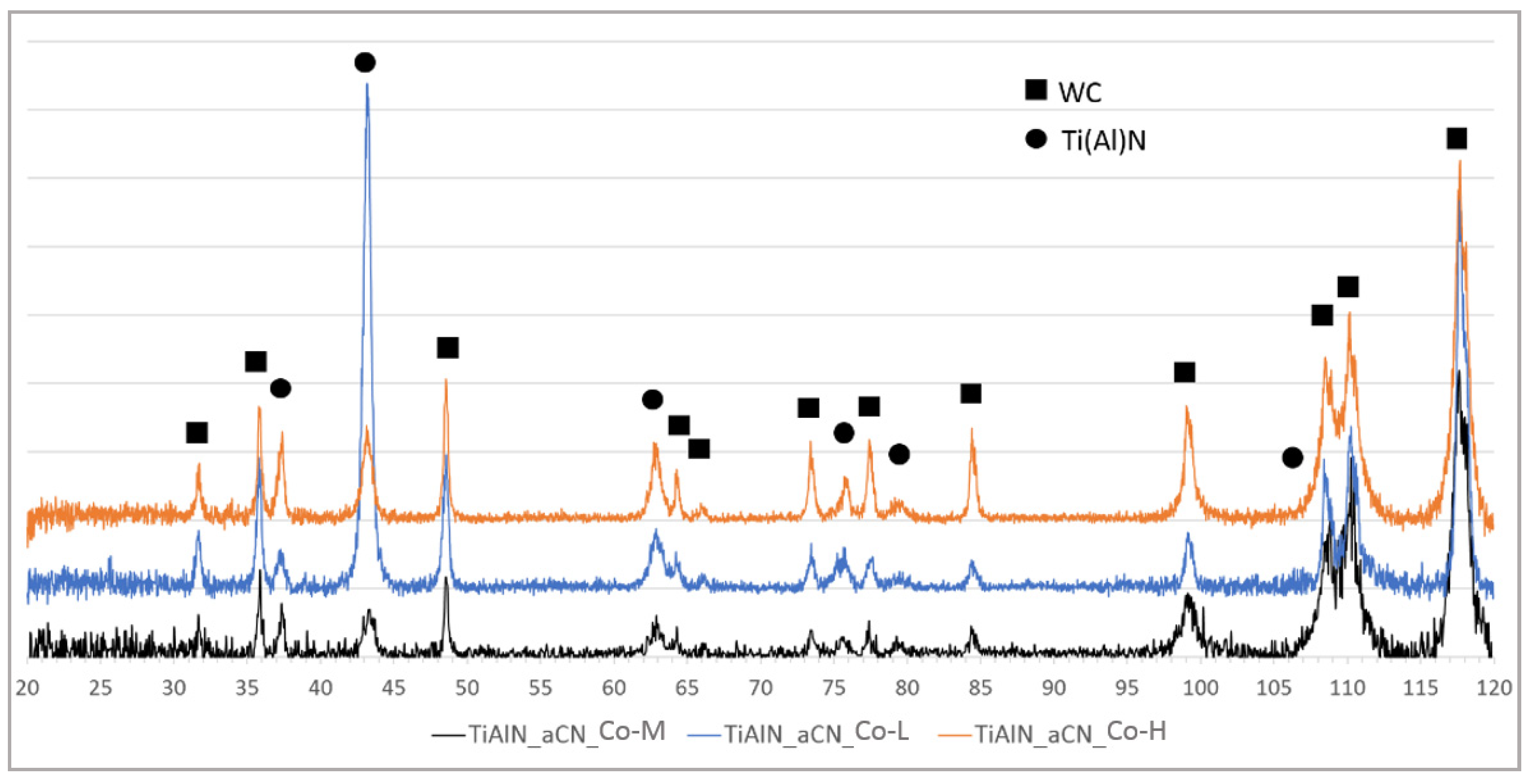

3.1. XRD and TEM Analysis

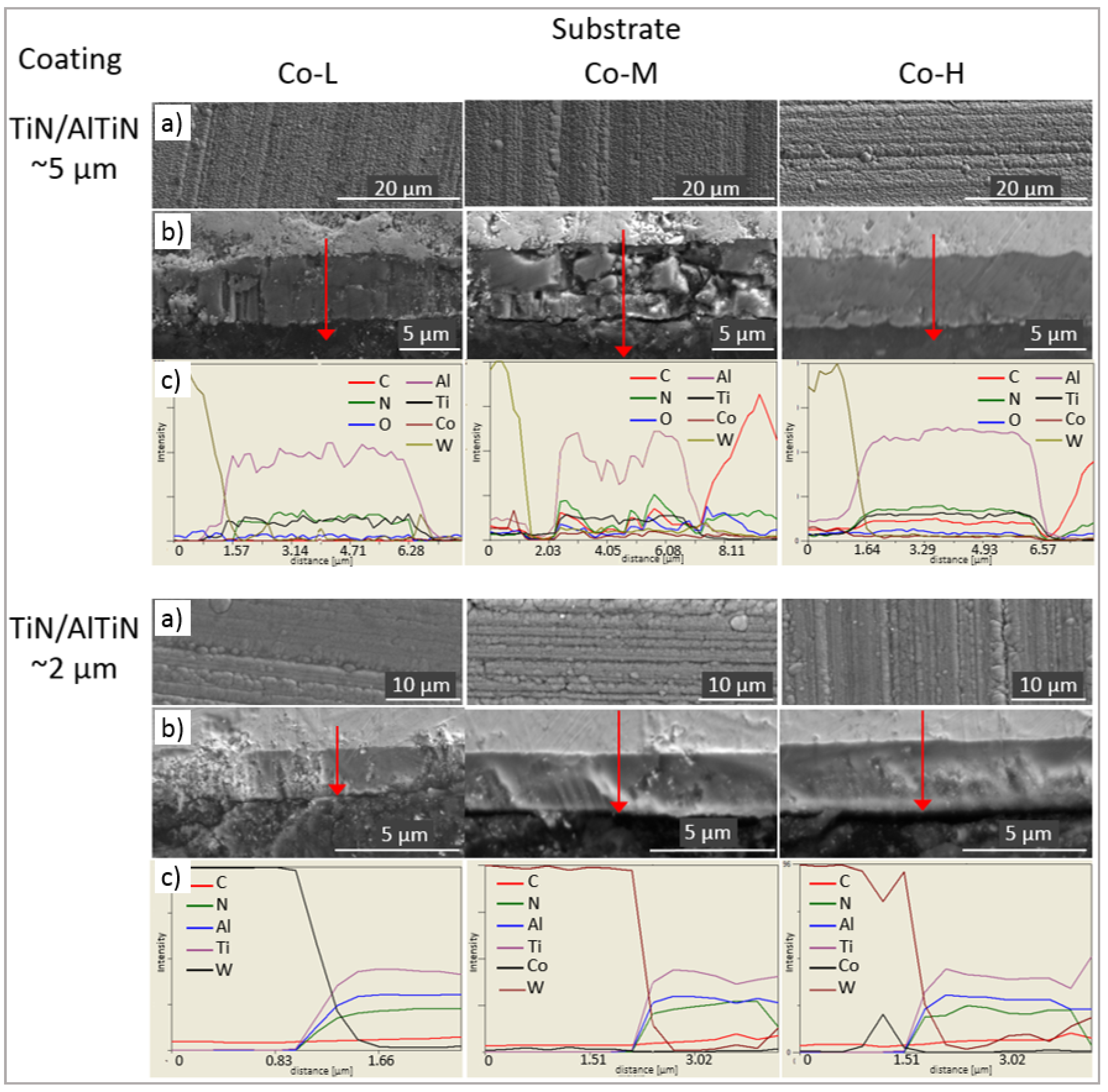

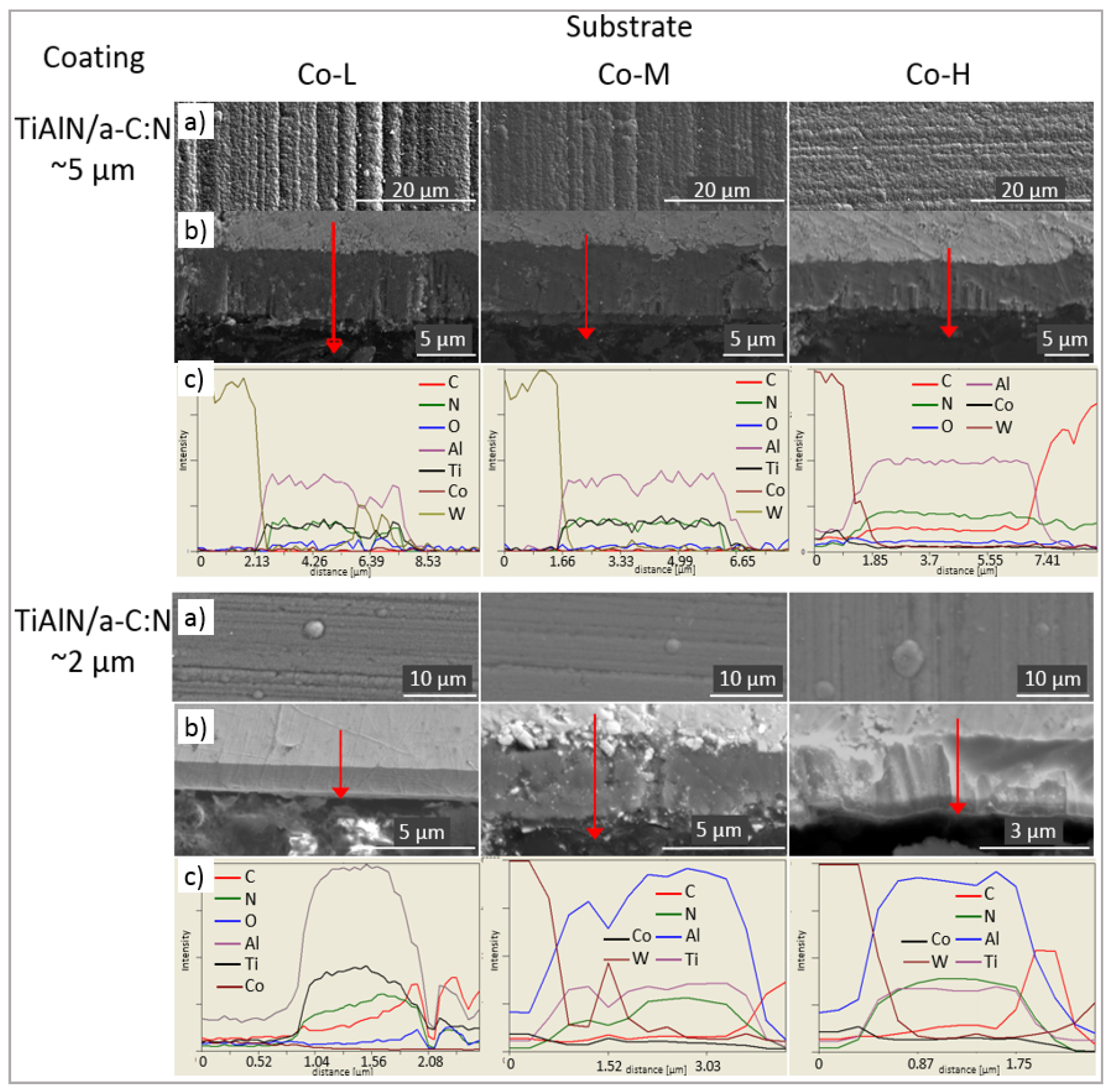

3.2. Microstructure, Chemical Composition and Roughness of Coatings

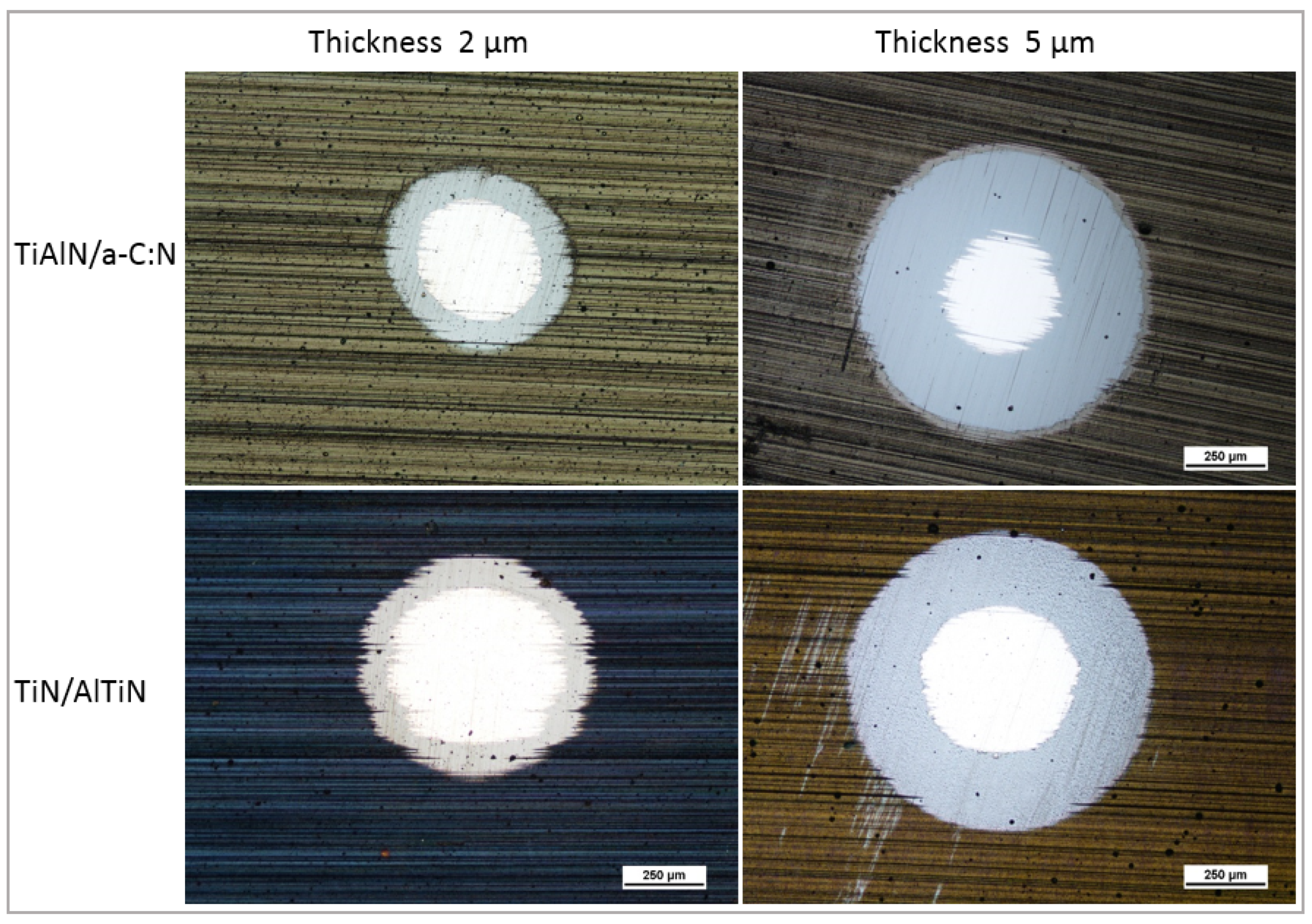

3.3. The Calotest Results

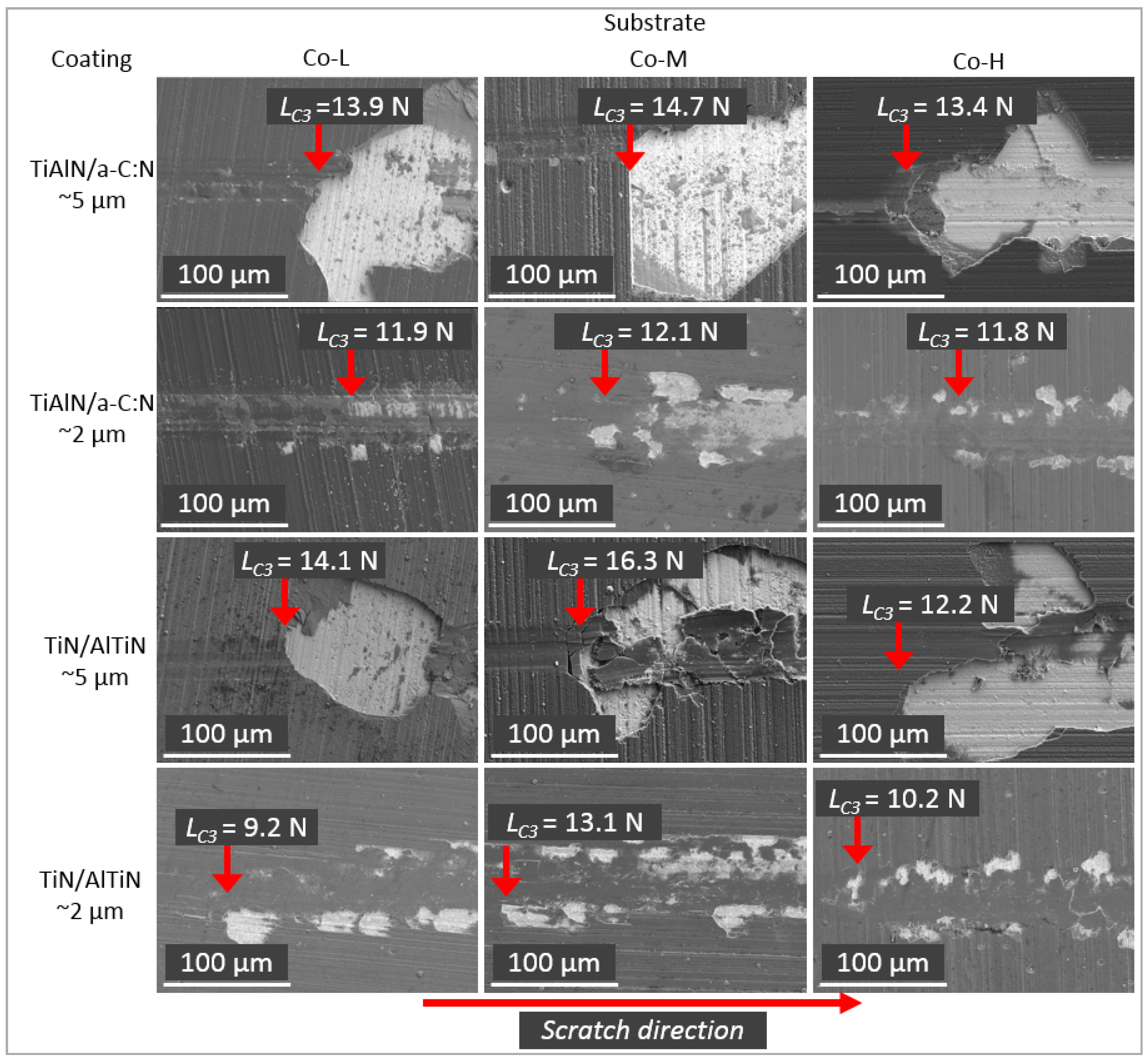

3.4. Adhesion

3.5. Nanohardness

3.6. Durability Tests

4. Conclusions

5. Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Inspektor, A.; Salvador, P.-A. Architecture of PVD coatings for metal cutting applications: A review. Surf. Coat. Technol. 2014, 25725, 138–153. [Google Scholar] [CrossRef]

- Vereschak, A.; Aksenenko, A.; Sitnikov, N.; Migranov, M.; Shevchenko, S.; Sotova, C.; Batako, A.; Andreev, N. Effect of adhesion and tribological properties of modified composite nano-structured multi-layer nitride coatings on WC-Co tools life. Tribol. Int. 2018, 128, 313–327. [Google Scholar] [CrossRef]

- Kohlscheen, J.; Bareiss, K. Effect of Hexagonal Phase Content on Wear. Behaviour of AlTiN Arc PVD Coatings. Coatings 2018, 8, 72. [Google Scholar] [CrossRef] [Green Version]

- Hu, C.; Xu, Y.X.; Chen, L.; Pei, F.; Zhang, L.J.; Du, Y. Structural, mechanical and thermal properties of CrAlNbN coatings. Surf. Coat. Technol. 2018, 349, 894–900. [Google Scholar] [CrossRef]

- Pancielejko, M.; Czyżniewski, A.; Gilewicz, A.; Zavaleyev, V.; Szymański, W. The cutting properties and wear of the knives with DLC and W-DLC coatings, deposited by PVD methods, applied for wood and wood-based materials machining. Arch. Mater. Sci. Eng. 2012, 58, 235–244. [Google Scholar]

- Pancielejko, M.; Czyżniewski, A.; Gilewicz, A.; Szymański, W.; Zavaleyev, V. The influence of the MCVA deposition parameters on the structure and tribological properties of DLC coatings on woodworking HSS tool substrates. Arch. Mater. Sci. Eng. 2013, 64, 160–167. [Google Scholar]

- Precht, W.; Pancielejko, M.; Czyżniewski, A. Structure and tribological properties of carbon and carbon nitride films, obtained by the ARC method. Vacuum 1999, 53, 109–112. [Google Scholar] [CrossRef]

- Faga, M.G.; Settineri, L. Innovative anti-wear coatings on cutting tools for wood machining. Surf. Coat. Technol. 2006, 201, 3002–3007. [Google Scholar] [CrossRef]

- Stueber, M.; Albers, U.; Leiste, H.; Ulrich, S.; Holleck, H.; Barna, P.B.; Kovacs, A.; Hovsepian, P.; Gee, I. Multifunctional nanolaminated PVD coatings in the system Ti–Al–N–C by combination of metastable fcc phases and nanocomposite microstructures. Surf. Coat. Technol. 2006, 200, 6162–6171. [Google Scholar] [CrossRef]

- Sheikh-Ahmad, J.Y.; Morita, T. Tool coatings for wood machining: Problems and prospects. For. Prod. J. 2002, 52, 43–51. [Google Scholar]

- Sheikh-Ahmad, J.Y.; Stewart, J.S.; Feld, H. Failure characteristics of diamond-coated carbides in machining wood-based composites. Wear 2003, 255, 1433–1437. [Google Scholar] [CrossRef]

- Castanho, J.M.; Vieira, M.T. Effect of ductile layers in mechanical behavior of TiAlN thin coatings. J. Mater. Process. Technol. 2003, 143–144, 352–357. [Google Scholar] [CrossRef] [Green Version]

- Beer, P.; Rudnicki, J.; Ciupinski, L.; Djouadi, M.A.; Nouveau, C. Modification by composite coatings of knives made of low alloy steel for wood machining purposes. Sur. Coat. Technol. 2003, 174–175, 434–439. [Google Scholar] [CrossRef]

- Gilewicz, A.; Warcholinski, B.; Myslinski, P.; Szymanski, W. Anti-wear multilayer coatings based on chromium nitride for wood machining tools. Wear 2010, 270, 32–38. [Google Scholar] [CrossRef]

- Warcholinski, B.; Gilewicz, A. Multilayer coatings on tools for woodworking. Wear 2011, 271, 2812–2820. [Google Scholar] [CrossRef]

- Nouveau, C.; Jorand, E.; Deces-Petit Labidi, C.; Djouadi, M.-A. Influence of carbide substrates on tribological properties of chromium and chromium nitride coatings: Application to wood machining. Wear 2005, 258, 157–165. [Google Scholar] [CrossRef]

- Ma, L.W.; Cairney, J.M.; Hoffman, M.J.; Munroe, P.R. Effect of coating thickness on the deformation mechanisms in PVD Ti-coated steel. Surf. Coat. Technol. 2010, 204, 92–98. [Google Scholar] [CrossRef]

- Vereschak, A.; Grigoriev, S.; Sitnikov, N.; Aksenenko, A.; Milovich, F.; Andreev, N.; Oganyan, G.; Bublikov, J. Influence of the Thickness of Multilayer Composite Nano-Structured Coating Ti–TiN–(Ti,Al,Si)N on the Tool Life of Metal-Cutting Tools and the Nature of Wear. Coatings 2019, 9, 730. [Google Scholar] [CrossRef] [Green Version]

- Lin, J.; Moore, J.J.; Mishra, B.; Pinkas, M.; Zhang, X.; Sproul, W.D. CrN/AlN superlattice coatings synthesized by pulsed closed field unbalanced magnetron sputtering with different CrN layer thicknesses. Thin Solid Film. 2009, 517, 5798–5804. [Google Scholar] [CrossRef]

- Seidl, W.M.; Bartosik, M.; Kolozsvari, S.; Bolvardi, H.; Mayhofer, P.H. Influence of coating thickness and substrate on stresses and mechanical properties of (Ti,Al,Ta)N/(Al,Cr)N multilayers. Surf. Coat. Technol. 2018, 347, 92–98. [Google Scholar] [CrossRef]

- Chawla, V.; Holec, D.; Mayrhofer, P.H. Effect of interlayer composition and thickness on the stabilization of cubic AlN in AlN/Ti–Al–N superlattices. Thin Solid Film. 2014, 565, 94–100. [Google Scholar] [CrossRef]

- Tlili, B.; Nouveau, C.; Walock, M.J.; Nasri, M.; Ghrib, T. Effect of layer thickness on thermal properties of multilayer thin films produced by PVD. Vacuum 2012, 86, 1048–1056. [Google Scholar] [CrossRef] [Green Version]

- Fahrussiam, F.; Praja, I.A.; Darmawan, W.; Wahyudi, I.; Nandik, D.; Usuki, H.; Koseki, S. Wear characteristics of multilayer-coated cutting tools in milling wood and wood-based composites. Tribol. Ind. 2016, 38, 66–73. [Google Scholar]

- Djouadi, M.A.; Beer, P.; Marchal, R.; Sokolowska, M.; Lambertin, M.; Precht, W.; Nouveau, C. Antiabrasive coatings: Application for wood processing. Surf. Coat. Technol. 1999, 116–119, 508–516. [Google Scholar] [CrossRef]

- Ononiwu, N.; Akinlabi, E.; Ozoegwu, C. Optimization techniques applied to machinability studies for turningaluminium metal matrix composites: A literature review. Mater. Today Proc. 2021, 44, 1124–1129. [Google Scholar] [CrossRef]

- Nguyen-Dinh, N.; Hejjaji, A.; Zitoune, R.; Bouvet, C.; Salem, M. New tool for reduction of harmful particulate dispersion and to improvemachining quality when trimming carbon/epoxy composites. Compos. Part A Appl. Sci. Manuf. 2020, 131, 105806. [Google Scholar] [CrossRef]

- Djouadi, M.A.; Nouveau, C.; Beer, P.; Lambertin, M. CrxNy hard coatings deposited with PVD method on tool for wood machining. Surf. Coat. Technol. 2000, 133–134, 478–483. [Google Scholar] [CrossRef]

- Gilewicz, A.; Warcholiński, B.; Szymanski, W.; Grimm, W. CrCN/CrN + ta-C multilayer coating for applications in wood processing. Tribol. Int. 2013, 57, 1–7. [Google Scholar] [CrossRef]

- Kong, Y.; Tian, X.; Gong Ch Chu, P.K. Reprint of Enhancement of toughness and wear resistance by CrN/ CrCN multilayered coatings for wood processing. Surf. Coat. Technol. 2018, 355, 318–327. [Google Scholar] [CrossRef]

- Kuleshov, A.K.; Uglov, V.V.; Rusalsky, D.P.; Grishkevich, A.A.; Chayeuski, V.V.; Haranin, V.N. Effect of ZrN and Mo-N coatings and sulfacyyanization on wear of wood-cutting knives. J. Frict. Wear 2014, 35, 201–209. [Google Scholar] [CrossRef]

- Kazlauskas, D.; Jankauskas, V.; Tuckute, S. Research on tribological characteristics of hard metal WC-Co tools with TiAlN and CrN PVD coatings for processing solid oak wood. Coat. Open Access 2020, 10, 632. [Google Scholar] [CrossRef]

- Czarniak, P.; Szymanowski, K.; Panjan, P. Characteristic of the wear of a tool coating based on amorphous carbon during chipboard milling. Ann. Wars. Univ. Life Sci. For. Wood Technol. 2020, 111, 53–59. [Google Scholar]

- Burton, A.W.; Ong, K.; Rea, T.; Chan, I.Y. On the estimation of average crystallite size of zeolites from the Scherrer equation: A critical evaluation of its application to zeolites with one-dimensional pore systems. Microporous Mesoporous Mater. 2009, 117, 75–90. [Google Scholar] [CrossRef]

- Wróbel-Knysak, A.; Kucharska, B. The Abrasion of Al-SI Coatings with Different Silicon Crystal Morphology Applied in Automotive Silencers. Tribologia 2016, 269. [Google Scholar] [CrossRef]

- Czarniak, P.; Szymanowski, K.; Kucharska, B.; Krawczyńska, A.; Sobiecki, J.-R.; Kubacki, J.; Panjan, P. Modification of tools for wood based materials machining with TiAlN/a-CN coating. Mater. Sci. Eng. B 2020, 257, 114540. [Google Scholar] [CrossRef]

- 310 Wood-Based Panels. In Determination of Modulus of Elasticity in Bending and of Bending Strength; European Committee for Standardization: Brussels, Belgium, 1993.

- EN 323—European Standard. In Wood-Based Panels—Determination of Density; CEN: Brussels, Belgium, 1999.

- EN 1534—European Standard. In Wood Flooring. Determination of Resistance to Indentation. Test Method; CEN: Brussels, Belgium, 2002.

- EN 319 Particleboards and Fibreboards. In Determination of Tensile Strength Perpendicular to the Plane of the Board; European Committee for Standardization: Brussels, Belgium, 1993.

- EN 317 Particleboards and Fibreboards. In Determination of Swelling in Thickness after Immersion in Water; European Committee for Standardization: Brussels, Belgium, 1993.

- PN-EN 317 (1999)—Chipboard and fibreboard: Determination of the swelling in thickness after soaking in water. In The Method of Determining the Thickness Swelling of Flat-Pressed and Cross-Pressed Particle Boards and Particle-Cement Boards was Defined, Polish version; Polski Komitet Normalizacyjny: Warszawa, Poland, 1999.

- PN-D-04234, PN-D-04213, PN-D-04213:1964—Chipboard and Fibreboard: Determination of Impregnability; Polski Komitet Normalizacyjny: Warszawa, Poland, 1964.

- ISO 3340:1976—Fibre Building Boards—Determination of sand content: International Organization for Standardization. 1976. Available online: https://cdn.standards.iteh.ai/samples/8621/5dae48ca9b4b408c9001b827ef9a1169/ISO-3340-1976.pdf (accessed on 20 May 2021).

| Property | Value |

|---|---|

| Density [kg/m3] | 650 |

| Flexural strength [N/mm2] | 13.1 |

| Elastic modulus [N/mm2] | 3200 |

| Strength in pull out of screws test [N/mm] | 70.9 |

| Hardness in Brinnel scale [HB] | 2.61 |

| Mineral contamination [%] | 0.18 |

| Swelling 24 h [%] | 25.6 |

| Tensile strength [N/mm2] | 0.37 |

| Impregnability 24 h [%] | 86.5 |

| Crystallite Size [nm] | ||||

|---|---|---|---|---|

| Substrate | Co-L | Co-M | Co-H | |

| Coating | ||||

| TiAlN/a-C:N | 25 ± 2.1 | 25 ± 2.2 | 22 ± 2.0 | |

| TiN/AlTiN | 10 ± 1.1 | 10 ± 1.0 | 13 ± 1.2 | |

| Material | Substrate | Ra [µm] | SD |

|---|---|---|---|

| Co-L | ― | 0.150 | 0.008 |

| Co-M | ― | 0.105 | 0.006 |

| Co-H | ― | 0.098 | 0.005 |

| TiAlN/aCN ~5 µm | Co-L | 0.129 | 0.006 |

| Co-M | 0.092 | 0.005 | |

| Co-H | 0.091 | 0.002 | |

| TiAlN/aCN ~2 µm | Co-L | 0.135 | 0.005 |

| Co-M | 0.103 | 0.009 | |

| Co-H | 0.093 | 0.008 | |

| TiN/AlTiN ~5 µm | Co-L | 0.163 | 0.018 |

| Co-M | 0.205 | 0.001 | |

| Co-H | 0.136 | 0.008 | |

| TiN/AlTiN ~2 µm | Co-L | 0.184 | 0.014 |

| Co-M | 0.201 | 0.012 | |

| Co-H | 0.135 | 0.019 |

| Coating | Substrate | Thickness [µm] |

|---|---|---|

| TiAlN/aCN ~5 µm | Co-L | 6.2 ± 0.05 |

| Co-M | 5.8 ± 0.00 | |

| Co-H | 6.1 ± 0.04 | |

| TiAlN/aCN ~2 µm | Co-L | 1.6 ± 0.1 |

| Co-M | 1.5 ± 0.1 | |

| Co-H | 1.6 ± 0.2 | |

| TiN/AlTiN ~5 µm | Co-L | 5.3 ± 0.2 |

| Co-M | 5.6 ± 0.01 | |

| Co-H | 5.2 ± 0.1 | |

| TiN/AlTiN ~2 µm | Co-L | 1.8 ± 0.1 |

| Co-M | 1.9 ± 0.2 | |

| Co-H | 1.6 ± 0.05 |

| Coating | Substrate | Lc3 [N] | SD |

|---|---|---|---|

| TiAlN/aCN ~5 µm | Co-L | 13.9 | 0.049 |

| Co-M | 14.7 | 0.098 | |

| Co-H | 13.4 | 0.065 | |

| TiAlN/aCN ~2 µm | Co-L | 11.9 | 0.336 |

| Co-M | 12.1 | 0.131 | |

| Co-H | 11.8 | 0.093 | |

| TiN/AlTiN ~5 µm | Co-L | 14.1 | 0.049 |

| Co-M | 16.3 | 0.425 | |

| Co-H | 12.2 | 0.033 | |

| TiN/AlTiN ~2 µm | Co-L | 9.2 | 0.485 |

| Co-M | 13.1 | 0.075 | |

| Co-H | 10.2 | 0.112 |

| Material | Substrate | Nanohardness [GPa] | SD |

|---|---|---|---|

| Co-L | ― | 37.4 | 3.4 |

| Co-M | ― | 36.1 | 4.9 |

| Co-H | ― | 35.4 | 5.8 |

| TiAlN/aCN ~5 µm | Co-L | 14.4 | 1.9 |

| Co-M | 15.7 | 4.2 | |

| Co-H | 12.8 | 1.8 | |

| TiAlN/aCN ~2 µm | Co-L | 18.5 | 0.8 |

| Co-M | 16.0 | 1.8 | |

| Co-H | 15.8 | 3.0 | |

| TiN/AlTiN ~5 µm | Co-L | 20.5 | 2.3 |

| Co-M | 19.6 | 4.5 | |

| Co-H | 23.2 | 6.1 | |

| TiN/AlTiN ~2 µm | Co-L | 27.2 | 6.4 |

| Co-M | 24.8 | 6.4 | |

| Co-H | 24.6 | 5.4 |

| Material | Substrate | Cutting Distance [m] | SD |

|---|---|---|---|

| Co-L | ― | 4909 | 537 |

| Co-M | ― | 4769 | 561 |

| Co-H | ― | 4301 | 1265 |

| TiAlN/aCN ~5 µm | Co-L | 5751 | 199 |

| Co-M | 6592 | 633 | |

| Co-H | 5424 | 1103 | |

| TiAlN/aCN ~2 µm | Co-L | 5674 | 206 |

| Co-M | 5238 | 504 | |

| Co-H | 4947 | 1120 | |

| TiN/AlTiN ~5 µm | Co-L | 7083 | 927 |

| Co-M | 6943 | 898 | |

| Co-H | 6733 | 397 | |

| TiN/AlTiN ~2 µm | Co-L | 5626 | 914 |

| Co-M | 5238 | 504 | |

| Co-H | 6241 | 857 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kucharska, B.; Sobiecki, J.R.; Czarniak, P.; Szymanowski, K.; Cymerman, K.; Moszczyńska, D.; Panjan, P. Influence of Different Types of Cemented Carbide Blades and Coating Thickness on Structure and Properties of TiN/AlTiN and TiAlN/a-C:N Coatings Deposited by PVD Techniques for Machining of Wood-Based Materials. Materials 2021, 14, 2740. https://doi.org/10.3390/ma14112740

Kucharska B, Sobiecki JR, Czarniak P, Szymanowski K, Cymerman K, Moszczyńska D, Panjan P. Influence of Different Types of Cemented Carbide Blades and Coating Thickness on Structure and Properties of TiN/AlTiN and TiAlN/a-C:N Coatings Deposited by PVD Techniques for Machining of Wood-Based Materials. Materials. 2021; 14(11):2740. https://doi.org/10.3390/ma14112740

Chicago/Turabian StyleKucharska, Beata, Jerzy Robert Sobiecki, Pawel Czarniak, Karol Szymanowski, Konrad Cymerman, Dorota Moszczyńska, and Peter Panjan. 2021. "Influence of Different Types of Cemented Carbide Blades and Coating Thickness on Structure and Properties of TiN/AlTiN and TiAlN/a-C:N Coatings Deposited by PVD Techniques for Machining of Wood-Based Materials" Materials 14, no. 11: 2740. https://doi.org/10.3390/ma14112740

APA StyleKucharska, B., Sobiecki, J. R., Czarniak, P., Szymanowski, K., Cymerman, K., Moszczyńska, D., & Panjan, P. (2021). Influence of Different Types of Cemented Carbide Blades and Coating Thickness on Structure and Properties of TiN/AlTiN and TiAlN/a-C:N Coatings Deposited by PVD Techniques for Machining of Wood-Based Materials. Materials, 14(11), 2740. https://doi.org/10.3390/ma14112740