A Textile Waste Fiber-Reinforced Cement Composite: Comparison between Short Random Fiber and Textile Reinforcement

Abstract

:1. Introduction

2. Materials and Methods

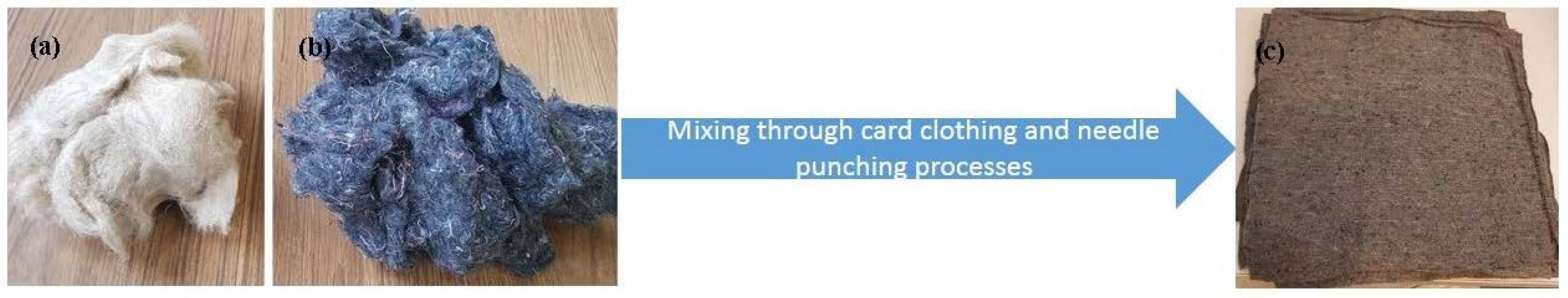

2.1. Materials

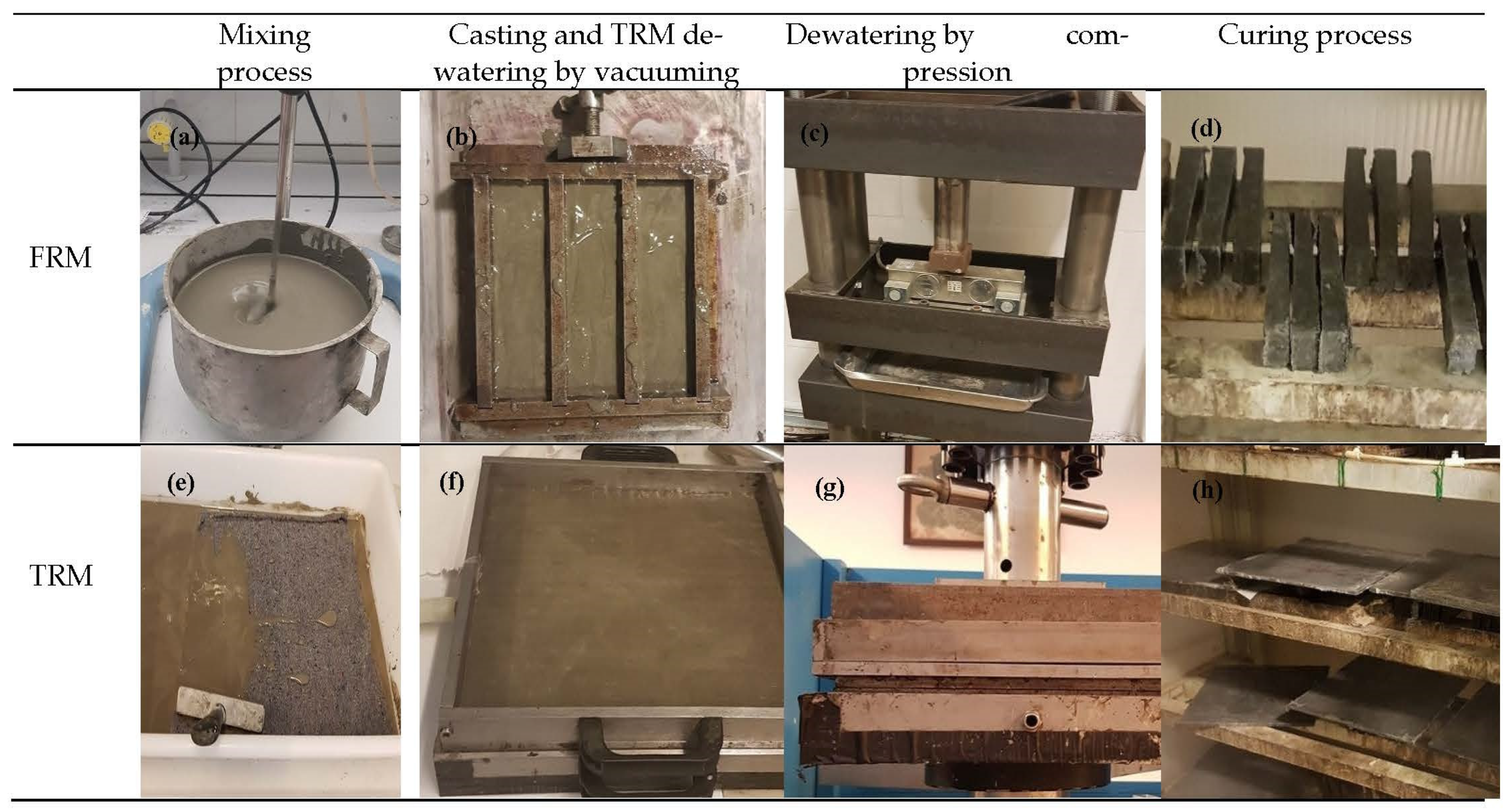

2.2. Sample Preparation

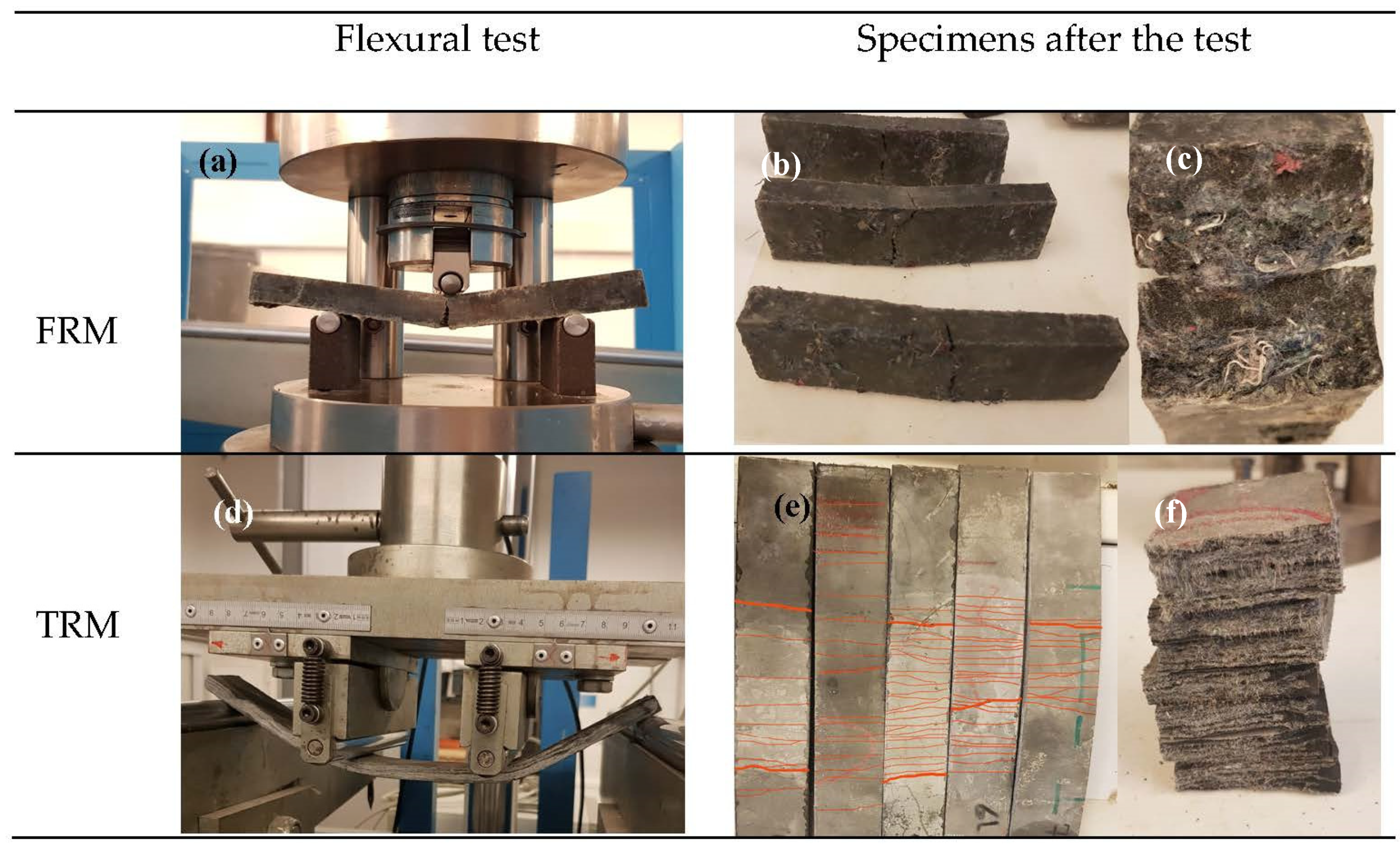

2.3. Flexural Tensile Strength Test and Toughness

2.4. Durability Test and Microscope Analyses

2.5. Drying Shrinkage Test

3. Results and Discussion

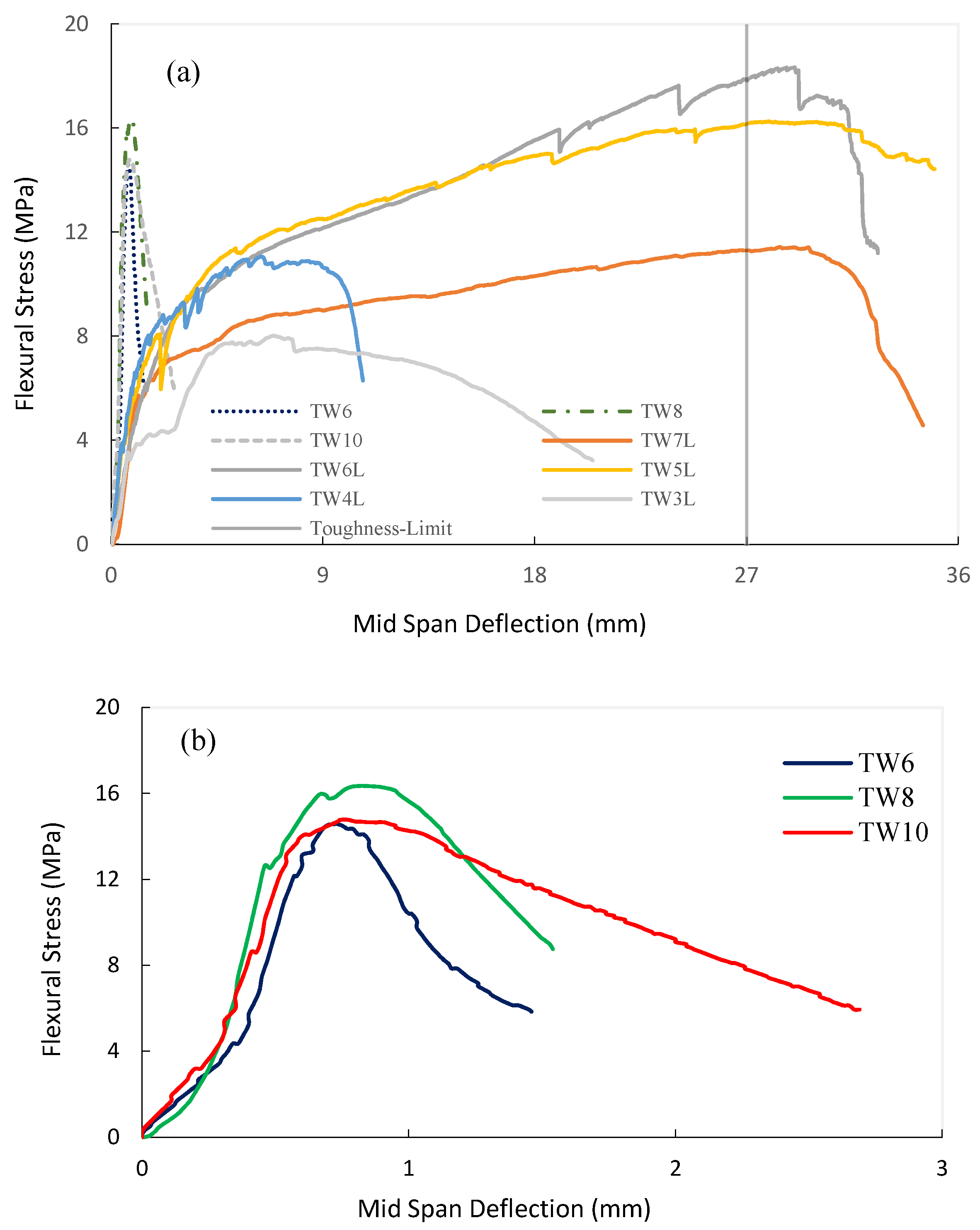

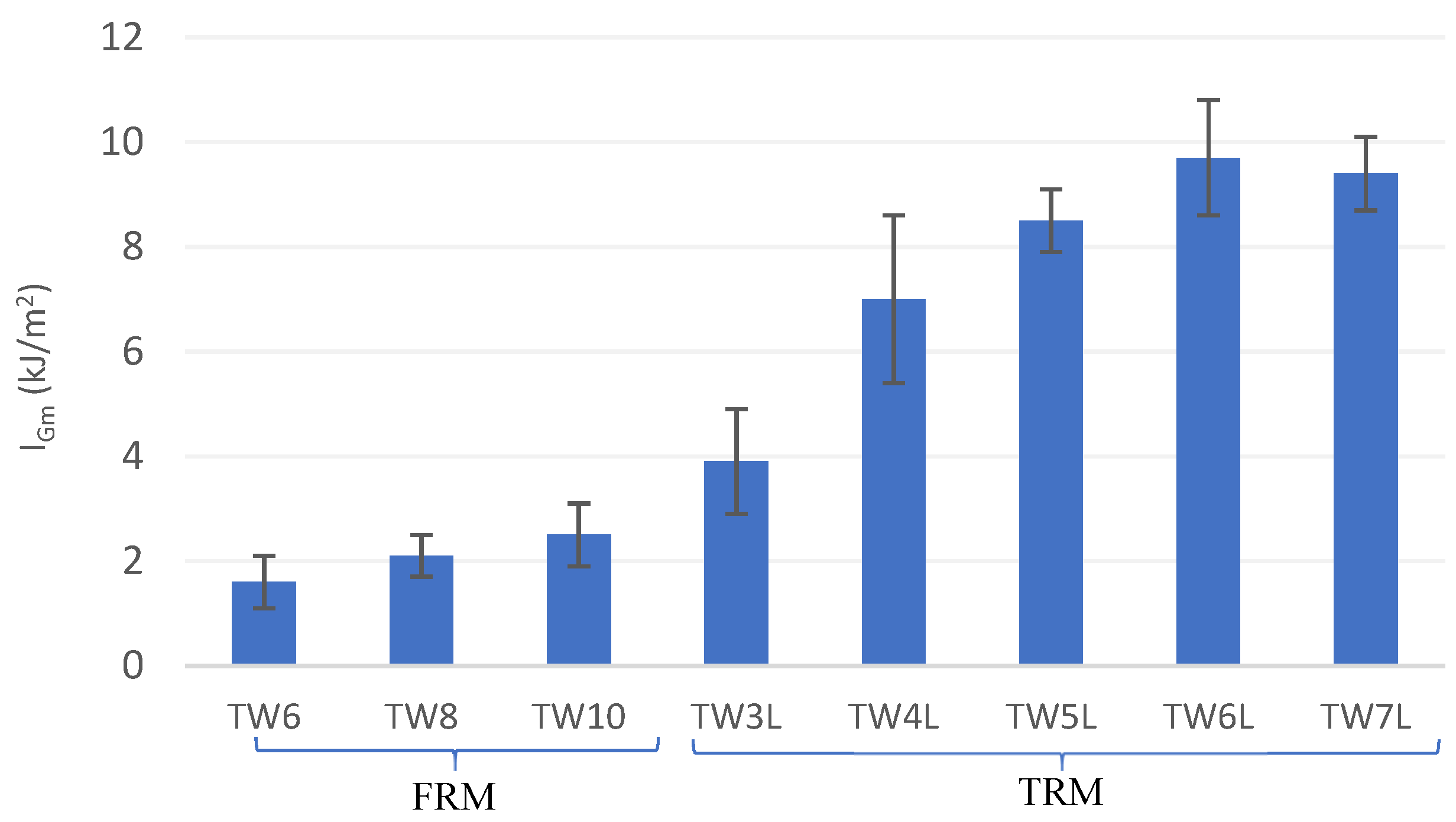

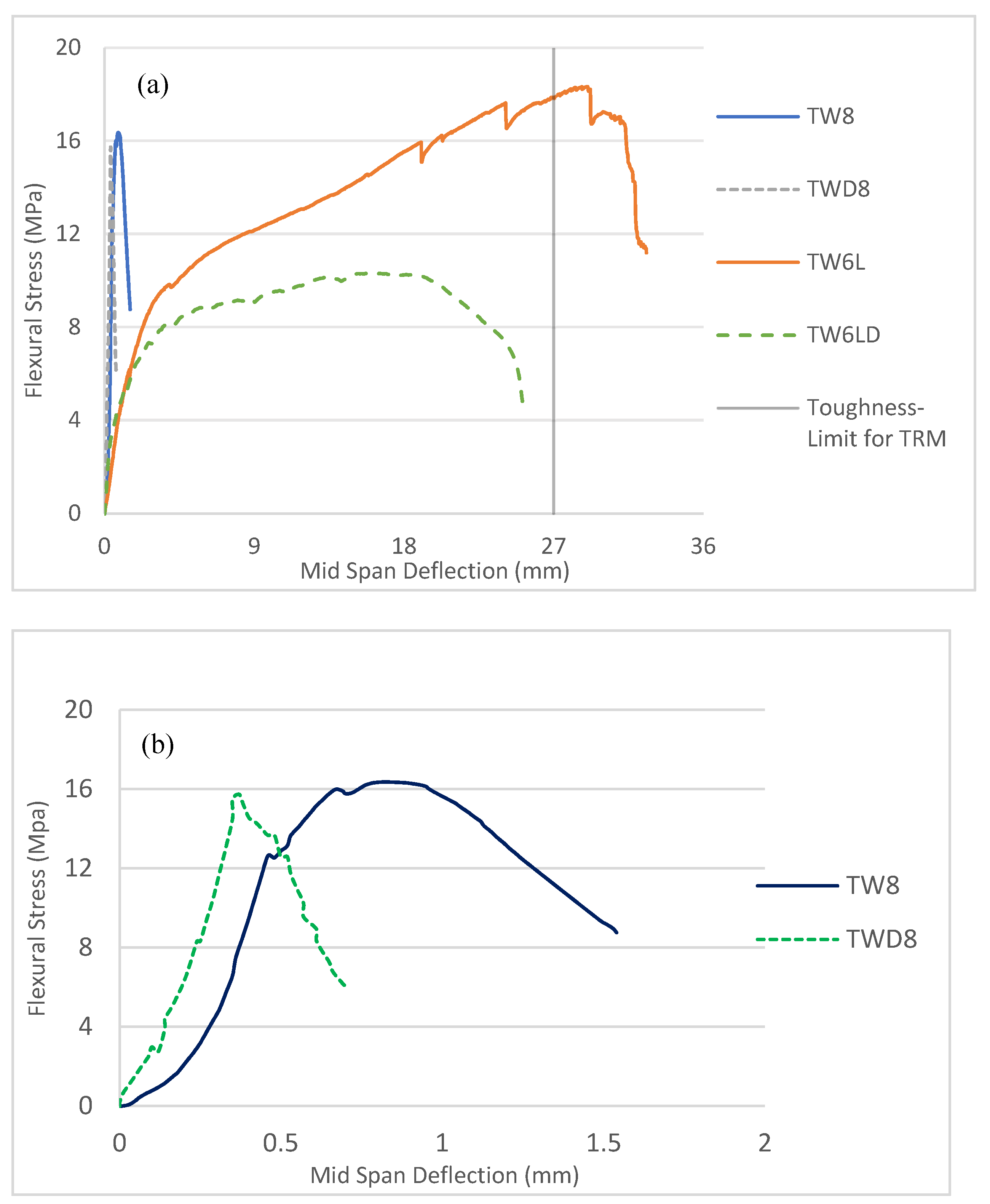

3.1. Flexural Test on Unaged Composites

3.2. Flexural Test on Aged Composites

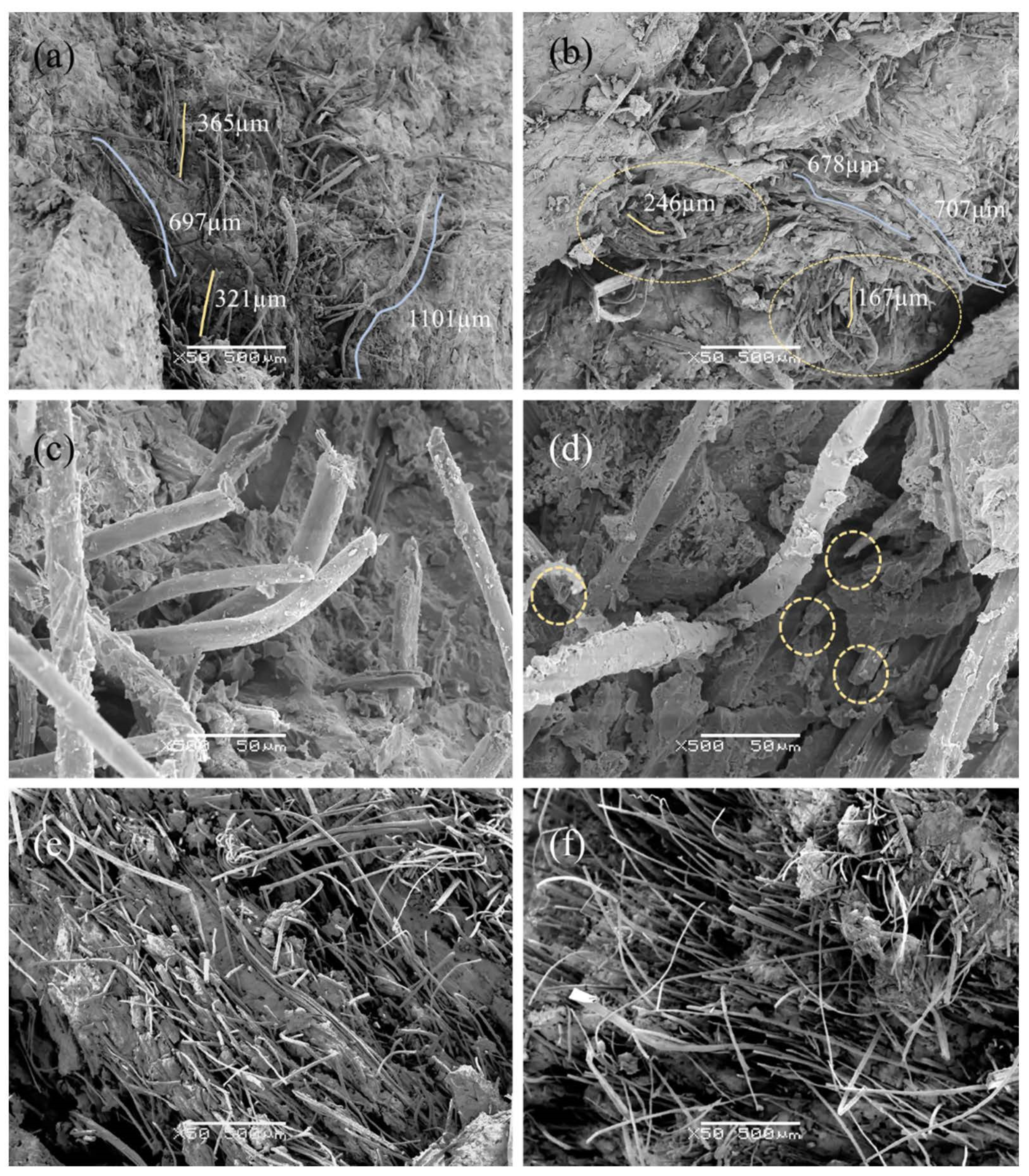

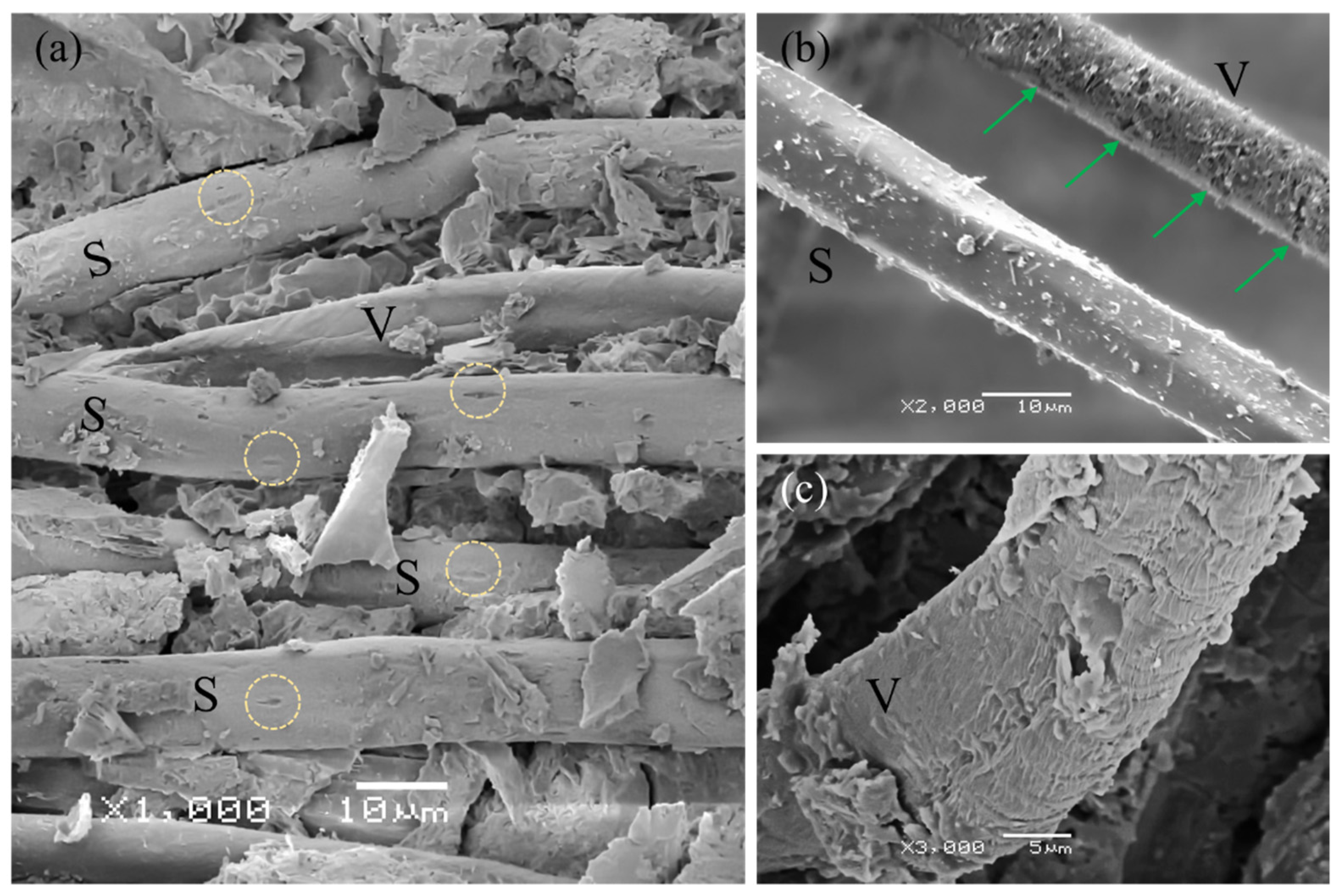

3.3. SEM Observations

3.4. Shrinkage

4. Conclusions

- The pre-cracking flexural performances of both unaged 6-layer nonwoven TRM and FRM with 8% of fibers were comparable. However, the post-cracking flexural performance and especially the energy absorption capacity of the former were significantly superior (by four times) compared to the latter. The results suggest that randomly distributed short fibers from textile waste have limitations in terms of mechanical performance due to limited cracking capacity and maximum mixable amount of these fibers.

- Both composites were subjected to an accelerated aging process that primarily affected the energy absorption of the materials. Nonetheless, the toughness and stiffness of the aged TRM were greater (three times) than the aged FRM. SEM observations confirmed that accelerated aging was associated with an increase in fiber fracture and a decrease in fiber pull-out, especially in vegetable fibers, due to the alkali attack. Nonetheless, modifying the matrix with pozzolanic materials such as silica fume could improve the durability of this composite.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kvočka, D.; Lešek, A.; Knez, F.; Ducman, V.; Panizza, M.; Tsoutis, C.; Bernardi, A. Life cycle assessment of prefabricated geopolymeric façade cladding panels made from large fractions of recycled construction and demolition waste. Materials 2020, 13, 3931. [Google Scholar] [CrossRef] [PubMed]

- Abd Rashid, A.F.; Yusoff, S. A review of life cycle assessment method for building industry. Renew. Sustain. Energy Rev. 2015, 45, 244–248. [Google Scholar] [CrossRef] [Green Version]

- Ütebay, B.; Çelik, P.; Çay, A. Textile wastes: Status and perspectives. In Waste in Textile and Leather Sectors; IntechOpen: London, UK, 2020. [Google Scholar] [CrossRef]

- Nautiyal, H.; Shree, V.; Khurana, S.; Kumar, N. Recycling Potential of Building Materials: A Review; Springer: Singapore, 2015; pp. 31–50. [Google Scholar]

- Ardanuy, M.; Claramunt, J.; Filho, R.D.T. Cellulosic fiber reinforced cement-based composites: A review of recent research. Constr. Build. Mater. 2015, 79, 115–128. [Google Scholar] [CrossRef] [Green Version]

- de Andrade Silva, F.; Mobasher, B.; Toledo Filho, R.D. Cracking mechanisms in durable sisal fiber reinforced cement composites. Cem. Concr. Compos. 2009, 31, 721–730. [Google Scholar] [CrossRef]

- Torres, B.; Ivorra, S.; Baeza, F.J.; Estevan, L.; Varona, B. Textile Reinforced Mortars (TRM) for repairing and retrofitting masonry walls subjected to in-plane cyclic loads. An experimental approach. Eng. Struct. 2021, 231, 111742. [Google Scholar] [CrossRef]

- Gonzalez-Lopez, L.; Claramunt, J.; Hsieh, Y.L.; Ventura, H.; Ardanuy, M. Surface modification of flax nonwovens for the development of sustainable, high performance, and durable calcium aluminate cement composites. Compos. Part. B Eng. 2020, 191, 107955. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Jalali, S. Cementitious building materials reinforced with vegetable fibres: A review. Constr. Build. Mater 2011, 25, 575–581. [Google Scholar] [CrossRef] [Green Version]

- Ferrara, G.; Caggegi, C.; Martinelli, E.; Gabor, A. Shear capacity of masonry walls externally strengthened using Flax-TRM composite systems: Experimental tests and comparative assessment. Constr. Build. Mater. 2020, 261. [Google Scholar] [CrossRef]

- Correia, C.; Francisco, S.; Savastano, H.; Moacyr, V. Utilization of vegetal fibers for production of reinforced cementitious materials. RILEM Tech Lett. 2017, 2, 145–154. [Google Scholar] [CrossRef] [Green Version]

- Ramirez, M.; Claramunt, J.; Ventura, H.; Ardanuy, M. Evaluation of the mechanical performance and durability of binary blended CAC-MK/natural fiber composites. Constr. Build. Mater. 2019. [Google Scholar] [CrossRef]

- Mercedes, L.; Gil, L.; Bernat-maso, E. Mechanical performance of vegetal Fabric Reinforced Cementitious Matrix (FRCM) composites. Constr. Build. Mater. 2018, 175, 161–173. [Google Scholar] [CrossRef]

- Villanueva, A.; Delgado, L.; Luo, Z.; Eder, P.; Catarino, A.S.; Litten, D. Study on the selection of waste streams for end-of-waste assessment. JRC Sci. Tech. Rep. 2010. [Google Scholar] [CrossRef]

- Lu, J.J.; Hamouda, H. Current status of fiber waste recycling and its future. Adv. Mater. Res. 2014, 878, 122–131. [Google Scholar] [CrossRef]

- The Limitations of Textile Recycling—Recovery. Available online: https://www.recovery-worldwide.com/en/artikel/the-limitations-of-textile-recycling_3411757.html (accessed on 15 January 2021).

- Briga-Sa, A.; Nascimento, D.; Teixeira, N.; Pinto, J.; Caldeira, F.; Varum, H.; Paiva, A. Textile waste as an alternative thermal insulation building material solution. Constr. Build. Mater. 2013, 38, 155. [Google Scholar] [CrossRef]

- Zhou, X.; Zheng, F.; Li, H.; Lu, C. An environment-friendly thermal insulation material from cotton stalk fibers. Energy Build. 2010, 42, 1070–1074. [Google Scholar] [CrossRef]

- el Wazna, M.; el Fatihi, M.; el Bouari, A.; Cherkaoui, O. Thermo physical characterization of sustainable insulation materials made from textile waste. J. Build. Eng. 2017, 12, 196–201. [Google Scholar] [CrossRef]

- Paiva, A.; Varum, H.; Caldeira, F.; Sá, A.; Nascimento, D.; Teixeira, N. Textile Subwaste as a Thermal Insulation Building Material. Constr. Build. Mater. 2013, 38, 155–160. [Google Scholar]

- Lee, Y.; Joo, C. Sound absorption properties of recycled polyester fibrous assembly absorbers. Autex Res. J. 2003, 3, 78–84. [Google Scholar]

- Tiuc, A.-E.; Vermeşan, H.; Gabor, T.; Vasile, O. Improved sound absorption properties of polyurethane foam mixed with textile waste. Energy Procedia 2016, 85, 559–565. [Google Scholar] [CrossRef] [Green Version]

- Rajput, D.; Bhagade, S.S.; Raut, S.P.; Ralegaonkar, R.V.; Mandavgane, S.A. Reuse of cotton and recycle paper mill waste as building material. Constr. Build. Mater. 2012, 34, 470–475. [Google Scholar] [CrossRef]

- Binici, H.; Gemci, R.; Aksogan, O.; Kaplan, H. Insulation properties of bricks made with cotton and textile ash wastes. Int. J. Mater. Res. 2010, 101, 894–899. [Google Scholar] [CrossRef]

- Aspiras, F.F.; Manalo, J.R.I. Utilization of textile waste cuttings as building material. J. Mater. Process. Technol. 1995, 48, 379–384. [Google Scholar] [CrossRef]

- Aghaee, K.; Foroughi, M. Mechanical properties of lightweight concrete partition with a core of textile waste. Adv. Civ. Eng. 2013, 2013. [Google Scholar] [CrossRef]

- Zhan, B.J.; Poon, C.S. Study on feasibility of reutilizing textile effluent sludge for producing concrete blocks. J. Clean. Prod. 2015, 101, 174–179. [Google Scholar] [CrossRef]

- Tran, N.P.; Gunasekara, C.; Law, D.W.; Houshyar, S.; Setunge, S.; Cwirzen, A. Comprehensive review on sustainable fiber reinforced concrete incorporating recycled textile waste. J. Sustain. Cem. Mater. 2021, 1–22. [Google Scholar] [CrossRef]

- Mohammadhosseini, H.; Tahir, M.M.; Sam, A.R.M.; Lim, N.H.A.S.; Samadi, M. Enhanced performance for aggressive environments of green concrete composites reinforced with waste carpet fibers and palm oil fuel ash. J. Clean. Prod. 2018, 185, 252–265. [Google Scholar] [CrossRef]

- Strength, Modulus of Elasticity and Shrinkage Behaviour of Concrete Containing Waste Carpet Fiber. Available online: https://www.geomatejournal.com/node/288 (accessed on 31 May 2021).

- Xuan, W.; Chen, X.; Yang, G.; Dai, F.; Chen, Y. Impact behavior and microstructure of cement mortar incorporating waste carpet fibers after exposure to high temperatures. J. Clean. Prod. 2018, 187, 222–236. [Google Scholar] [CrossRef]

- Mohammadhosseini, H.; Awal, A.S.M.A.; Yatim, J.B.M. The impact resistance and mechanical properties of concrete reinforced with waste polypropylene carpet fibres. Constr. Build. Mater. 2017, 143, 147–157. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, H.C.; Li, V.C. Concrete reinforcement with recycled fibers. J. Mater. Civ. Eng. 2000, 12, 314–319. [Google Scholar] [CrossRef]

- Wu, X.; Zhou, J.; Kang, T.; Wang, F.; Ding, X.; Wang, S. Laboratory investigation on the shrinkage cracking of waste fiber-reinforced recycled aggregate concrete. Materials 2019, 12, 1196. [Google Scholar] [CrossRef] [Green Version]

- Meddah, M.S.; Bencheikh, M. Properties of concrete reinforced with different kinds of industrial waste fibre materials. Constr. Build. Mater. 2009, 23, 3196–3205. [Google Scholar] [CrossRef]

- doi Reis, J.M.L. Effect of textile waste on the mechanical properties of polymer concrete. Mater. Res. 2009, 12, 63–67. [Google Scholar] [CrossRef]

- Booya, E.; Gorospe, K.; Ghaednia, H.; Das, S. Free and restrained plastic shrinkage of cementitious materials made of engineered kraft pulp fibres. Constr. Build. Mater. 2019, 212, 236–246. [Google Scholar] [CrossRef]

- Soroushian, P.; Ravanbakhsh, S. Control of plastic shrinkage cracking with specialty cellulose fibers. ACI Mater. J. 1998, 95, 429–435. [Google Scholar]

- Jongvisuttisun, P.; Kurtis, K.E. The role of hardwood pulp fibers in mitigation of early-age cracking. Cem. Concr. Compos. 2015, 57, 84–93. [Google Scholar] [CrossRef]

- Filho, R.D.T.; Ghavami, K.; Sanjuán, M.A.; England, G.L. Free, restrained and drying shrinkage of cement mortar composites reinforced with vegetable fibres. Cem. Concr. Compos. 2005, 27, 537–546. [Google Scholar] [CrossRef]

- Silva, F.D.A.; Filho, R.D.T.; Filho, J.D.A.M.; Fairbairn, E.D.M.R. Physical and mechanical properties of durable sisal fiber–cement composites. Constr. Build. Mater. 2010, 24, 777–785. [Google Scholar] [CrossRef]

- Booya, E.; Gorospe, K.; Adesina, A.; Das, S. Permeability characteristics of cementitious materials reinforced with Kraft pulp fibers. 2019, pp. 1–17. Available online: https://www.csce.ca/elf/apps/CONFERENCEVIEWER/conferences/2019/pdfs/PaperPDFVersion_19_0502020352.pdf (accessed on 3 July 2021).

- Booya, E.; Ghaednia, H.; Das, S.; Pande, H. Durability of cementitious materials reinforced with various Kraft pulp fibers. Constr. Build. Mater. 2018, 191, 1191–1200. [Google Scholar] [CrossRef]

- Kawashima, S.; Shah, S.P. Early-age autogenous and drying shrinkage behavior of cellulose fiber-reinforced cementitious materials. Cem. Concr. Compos. 2011, 33, 201–208. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Zureick, A.H.; Cho, B.S.; Scott, D.E. Properties of fibre reinforced concrete using recycled fibres from carpet industrial waste. J. Mater. Sci. 1994, 29, 4191–4199. [Google Scholar] [CrossRef]

- Mohammadhosseini, H.; Alyousef, R.; Lim, N.H.A.S.; Tahir, M.M.; Alabduljabbar, H.; Mohamed, A.M. Creep and drying shrinkage performance of concrete composite comprising waste polypropylene carpet fibres and palm oil fuel ash. J. Build. Eng. 2020, 30, 101250. [Google Scholar] [CrossRef]

- Claramunt, J.; Ventura, H.; Fernández-carrasco, L.J.; Ardanuy, M. Tensile and flexural properties of cement composites reinforced with flax nonwoven fabrics. Materials 2017, 10, 215. [Google Scholar] [CrossRef] [Green Version]

- Rampini, M.C.; Zani, G.; Colombo, M.; Prisco, M. Mechanical Behaviour of TRC Composites: Experimental and analytical approaches. Appl. Sci. 2019, 9, 1492. [Google Scholar] [CrossRef] [Green Version]

- Colombo, I.; Colombo, M.; Magri, A.; Zani, G.; di Prisco, M. Textile reinforced mortar at high temperatures. Appl. Mech. Mater. 2011, 82, 202–207. [Google Scholar] [CrossRef]

- Paper, C.; Colombo, I.G.; Colombo, M.; Magri, A.; Zani, G. Tensile behavior of textile: Influence of multilayer reinforcement. In High Fiber Reinforced Cement Composites 6; Springer: Dordrecht, The Netherlands, 2012; pp. 463–470. [Google Scholar]

- Zani, G.; Colombo, M.; di Prisco, M. High performance cementitious composites for sustainable roofing panels. In Proceedings of the 10th fib International PhD Symposium in Civil Engineering, Milan, Italy, 16 October 2013; pp. 333–338. [Google Scholar]

- Saidi, M.; Gabor, A. Experimental measurement of load-transfer length in textile-reinforced cementitious matrix composites using distributed optical fibres. Eur. J. Environ. Civ. Eng. 2020, 1–19. [Google Scholar] [CrossRef]

- Mercedes, L.; Bernat-Maso, E.; Gil, L. In-plane cyclic loading of masonry walls strengthened by vegetal-fabric-reinforced cementitious matrix (FRCM) composites. Eng. Struct. 2020, 221, 111097. [Google Scholar] [CrossRef]

- Ferrara, G. Mechanical behaviour and durability of flax textiles to be used as reinforcement in TRMs; Springer: Cham, Switzerland, 2021; pp. 47–73. [Google Scholar]

- Ferrara, G.; Pepe, M.; Martinelli, E.; Filho, R.D.T. Tensile behavior of flax textile reinforced lime-mortar: Influence of reinforcement amount and textile impregnation. Cem. Concr. Compos. 2021, 119, 103984. [Google Scholar] [CrossRef]

- Fidelis, M.E.A.; Toledo Filho, R.D.; de Andrade Silva, F.; Mechtcherine, V.; Butler, M.; Hempel, S. The effect of accelerated aging on the interface of jute textile reinforced concrete. Cem. Concr. Compos. 2016, 74, 7–15. [Google Scholar] [CrossRef]

- Caggegi, C.; Lanoye, E.; Djama, K.; Bassil, A.; Gabor, A. Tensile behaviour of a basalt TRM strengthening system: Influence of mortar and reinforcing textile ratios. Compos. Part. B Eng. 2017, 130, 90–102. [Google Scholar] [CrossRef]

- Filho, R.D.T.; Silva, F.D.; Fairbairn, E.M.R.; de Filho, J.M. Durability of compression molded sisal fiber reinforced mortar laminates. Constr. Build. Mater. 2009, 23, 2409–2420. [Google Scholar] [CrossRef]

- Silva, F.D.; Mobasher, B.; Filho, R.D.T. Fatigue behavior of sisal fiber reinforced cement composites. Mater. Sci. Eng. A 2010, 527, 5507–5513. [Google Scholar] [CrossRef]

- de Andrade Silva, F.; Zhu, D.; Mobasher, B.; Soranakom, C.; Toledo Filho, R.D. High speed tensile behavior of sisal fiber cement composites. Mater. Sci. Eng. A 2010, 527, 544–552. [Google Scholar] [CrossRef]

- Sadrolodabaee, P.; Claramunt, J.; Ardanuy, M.; de la Fuente, A. Mechanical and durability characterization of a new textile waste micro-fiber reinforced cement composite for building applications. Case Stud. Constr. Mater. 2021, 14, e00492. [Google Scholar]

- Sadrolodabaee, P.; Claramunt, J.; Ardanuy, M.; de la Fuente, A. Characterization of a textile waste nonwoven fabric reinforced cement composite for non-structural building components. Constr. Build. Mater. 2021, 276, 122179. [Google Scholar] [CrossRef]

- BS EN 494-12. Fibre-Cement Flat Sheets—Product Specification and Test Methods. British Standards Institution: London, UK, 2012. [Google Scholar]

- RILEM—Publications. Available online: https://www.rilem.net/publication/publication/4?id_papier=4003 (accessed on 4 September 2020).

- Claramunt, J.; Ardanuy, M.; García-Hortal, J.A.; Filho, R.D.T. The hornification of vegetable fibers to improve the durability of cement mortar composites. Cem. Concr. Compos. 2011, 33, 586–595. [Google Scholar] [CrossRef]

- Ardanuy, M.; Claramunt, J.; García-Hortal, J.A.; Barra, M. Fiber-matrix interactions in cement mortar composites reinforced with cellulosic fibers. Cellulose 2011, 18, 281–289. [Google Scholar] [CrossRef]

- Zareei, S.A.; Ameri, F.; Bahrami, N.; Shoaei, P.; Musaeei, H.R.; Nurian, F. Green high strength concrete containing recycled waste ceramic aggregates and waste carpet fibers: Mechanical, durability, and microstructural properties. J. Build. Eng. 2019, 26, 100914. [Google Scholar] [CrossRef]

- Khorami, M.; Ganjian, E. The effect of limestone powder, silica fume and fibre content on flexural behaviour of cement composite reinforced by waste Kraft pulp. Constr. Build. Mater. 2013, 46, 142–149. [Google Scholar] [CrossRef]

- Claramunt, J.; Fernández-Carrasco, L.; Ventura, H.; Ardanuy, M. Natural fiber nonwoven reinforced cement composites as sustainable materials for building envelopes. Constr. Build. Mater. 2016, 115, 230–239. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Li, V. Influences of fibers on drying shrinkage of fiber-reinforced cementitious. J. Eng. Mech. 2001, 127, 37–44. [Google Scholar] [CrossRef] [Green Version]

| Composite Type | Code | (w/c)final | Cement (g) | Fiber (g) | Fiber Weight Fraction (%) | Thickness (mm) | Mortar/Fabric Thickness | No. of Specimens |

|---|---|---|---|---|---|---|---|---|

| FRM | TW6 | 0.40 | 1600 | 96 | 6 | 20 | - | 6 |

| TW8 | 0.50 | 1400 | 112 | 8 | 20 | - | 6 | |

| TW10 | 0.50 | 1200 | 120 | 10 | 20 | - | 6 | |

| TW8D | 0.45 | 1400 | 112 | 8 | 20 | - | 6 | |

| TRM | TW3L | 0.40 | 1350 | 42 | 3.1 | 6.5 | 1.95 | 6 |

| TW4L | 0.40 | 1500 | 56 | 3.7 | 8.5 | 1.83 | 6 | |

| TW5L | 0.40 | 1530 | 70 | 4.9 | 9.2 | 1.48 | 6 | |

| TW6L | 0.40 | 1550 | 84 | 5.4 | 10.0 | 1.22 | 6 | |

| TW7L | 0.45 | 1600 | 98 | 6.1 | 10.2 | 0.92 | 6 | |

| TW6LD | 0.40 | 1474 | 84 | 5.7 | 10.0 | 1.22 | 12 |

| Composite Type | Code | LOPm (N/mm2) | MORm (N/mm2) | IGm (kJ/m2) | Km (GPa) | MORm/LOPm |

|---|---|---|---|---|---|---|

| TRM | TW3L | 4.1 (29) | 8.1 (14) | 3.9 (28) | 8.7 (17) | 2.0 |

| TW4L | 4.5 (24) | 12.4 (14) | 7.0 (24) | 10.7 (14) | 2.8 | |

| TW5L | 4.1 (24) | 13.9 (13) | 8.5 (7) | 7.8 (26) | 3.4 | |

| TW6L | 4.6 (19) | 15.5 (12) | 9.7 (12) | 11.3 (21) | 3.4 | |

| TW7L | 4.2 (12) | 12.1 (12) | 9.4 (8) | 10.6 (21) | 2.8 | |

| FRM | TW6 | 12.7 (12) | 14.7 (9) | 1.6 (31) | 4.0 (19) | 1.1 |

| TW8 | 11.1 (10) | 15.6 (20) | 2.1 (19) | 3.9 (15) | 1.4 | |

| TW10 | 10.7 (10) | 14.9 (23) | 2.5 (24) | 3.7 (19) | 1.4 |

| Samples | LOPm* (N/mm2) | MORm* (N/mm2) | IGm* (kJ/m2) | Km* (GPa) | MORm*/LOPm* |

|---|---|---|---|---|---|

| TW8D (FRM) | 13.3 (11) | 15.2 (10) | 1.2 (21) | 4.0 (17) | 1.10 |

| TW6LD (TRM) | 5.1 (31) | 10.0 (27) | 6.8 (33) | 12.0 (5) | 1.96 |

| Samples | Reference | TW6 | TW8 | TW10 | TW3L | TW6L |

|---|---|---|---|---|---|---|

| Max Shrinkage (microstrain) | 2560 | 1490 | 1420 | 1370 | 2550 | 1870 |

| Time (days) | 160 | 56 | 56 | 56 | 84 | 84 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sadrolodabaee, P.; Claramunt, J.; Ardanuy, M.; de la Fuente, A. A Textile Waste Fiber-Reinforced Cement Composite: Comparison between Short Random Fiber and Textile Reinforcement. Materials 2021, 14, 3742. https://doi.org/10.3390/ma14133742

Sadrolodabaee P, Claramunt J, Ardanuy M, de la Fuente A. A Textile Waste Fiber-Reinforced Cement Composite: Comparison between Short Random Fiber and Textile Reinforcement. Materials. 2021; 14(13):3742. https://doi.org/10.3390/ma14133742

Chicago/Turabian StyleSadrolodabaee, Payam, Josep Claramunt, Mònica Ardanuy, and Albert de la Fuente. 2021. "A Textile Waste Fiber-Reinforced Cement Composite: Comparison between Short Random Fiber and Textile Reinforcement" Materials 14, no. 13: 3742. https://doi.org/10.3390/ma14133742

APA StyleSadrolodabaee, P., Claramunt, J., Ardanuy, M., & de la Fuente, A. (2021). A Textile Waste Fiber-Reinforced Cement Composite: Comparison between Short Random Fiber and Textile Reinforcement. Materials, 14(13), 3742. https://doi.org/10.3390/ma14133742