Texturing and Phase Evolution in Ti-6Al-4V: Effect of Electron Beam Melting Process, Powder Re-Using, and HIP Treatment

Abstract

:1. Introduction

- Four groups of EBM-made samples produced under different conditions were systematically investigated.

- In one study, we explored both the effect of powder degradation due to repeatable re-use and the effect of HIP treatment on the additively manufactured samples.

- Based on previously obtained mechanical tests results (i.e., ‘macro’ results), we thoroughly investigated the selected four groups of samples by EBSD technique to obtain the microstructure characteristics (i.e., ‘micro’ results).

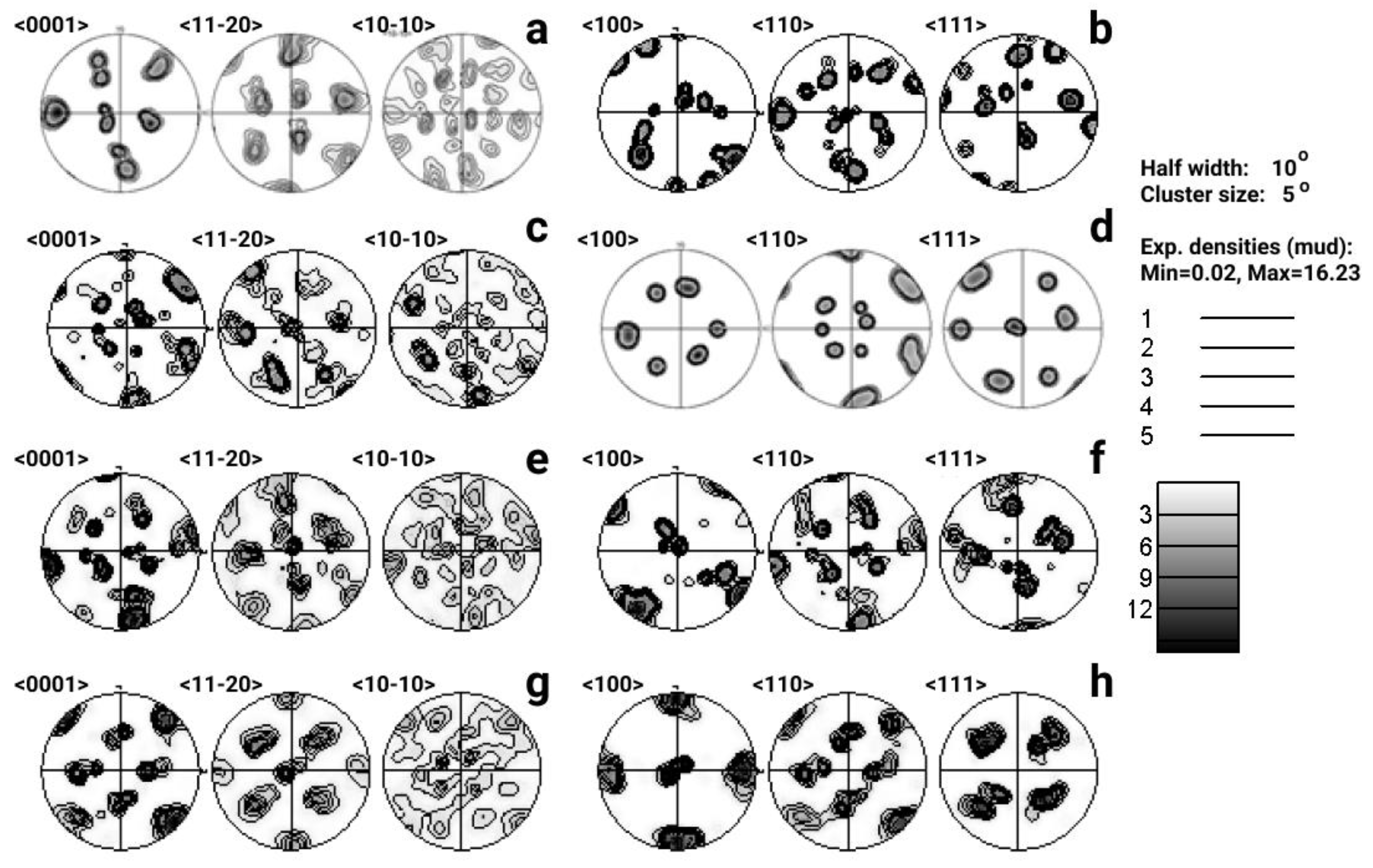

- We showed the process of phase recrystallization occurring during EBM and HIP, and analyzed texture of solidification and phase transformations formed during primary melting.

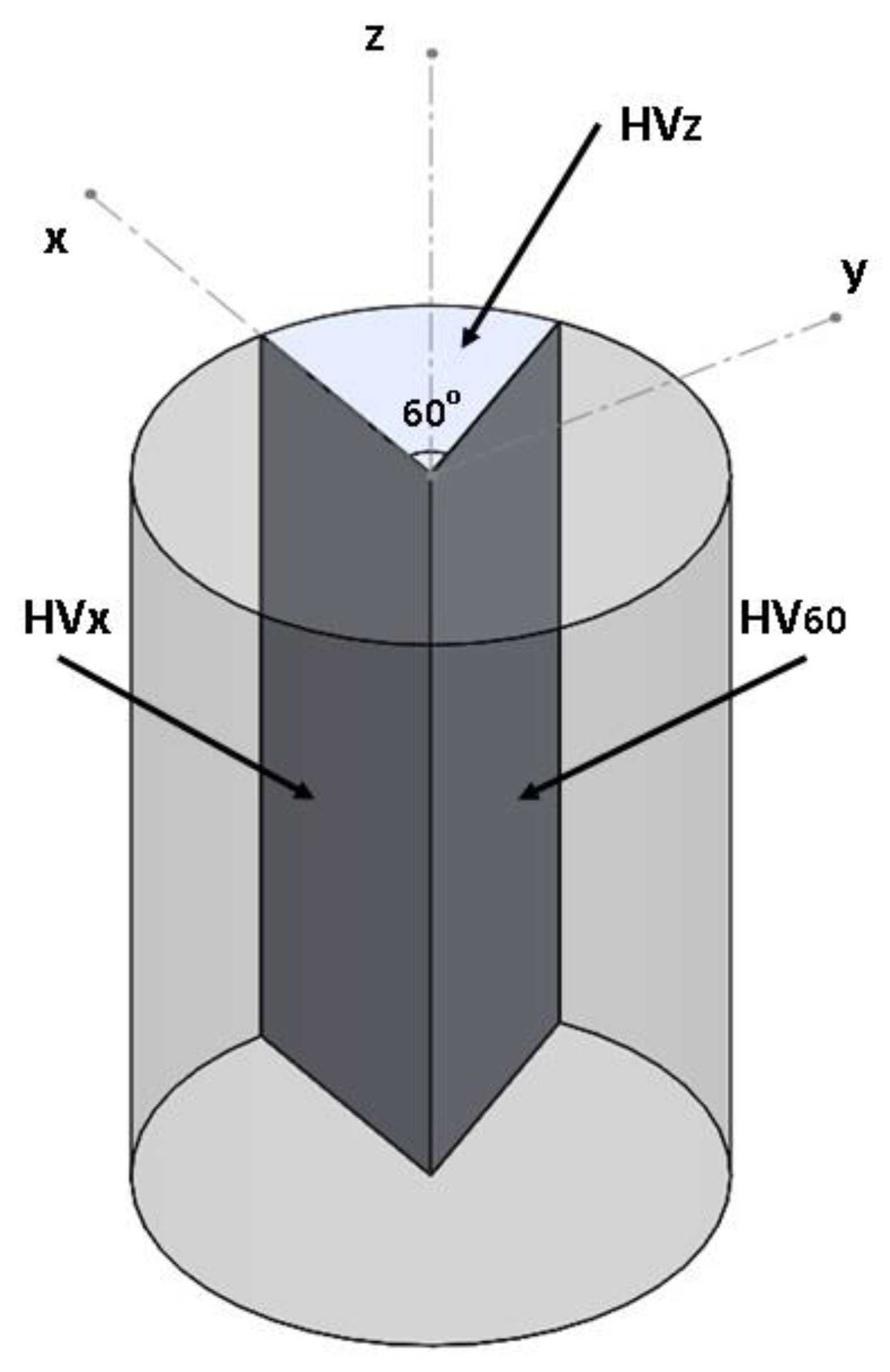

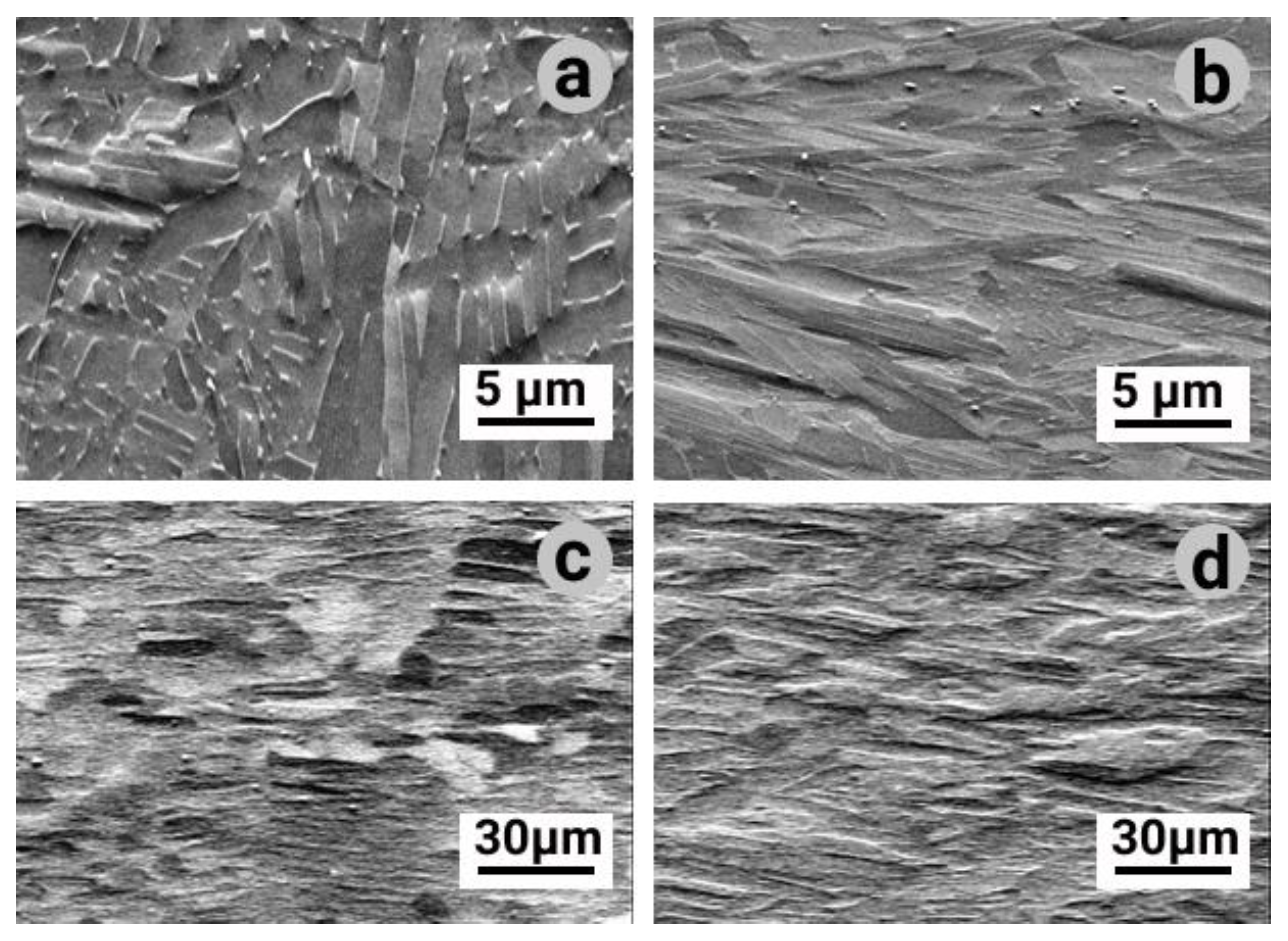

2. Materials and Methods

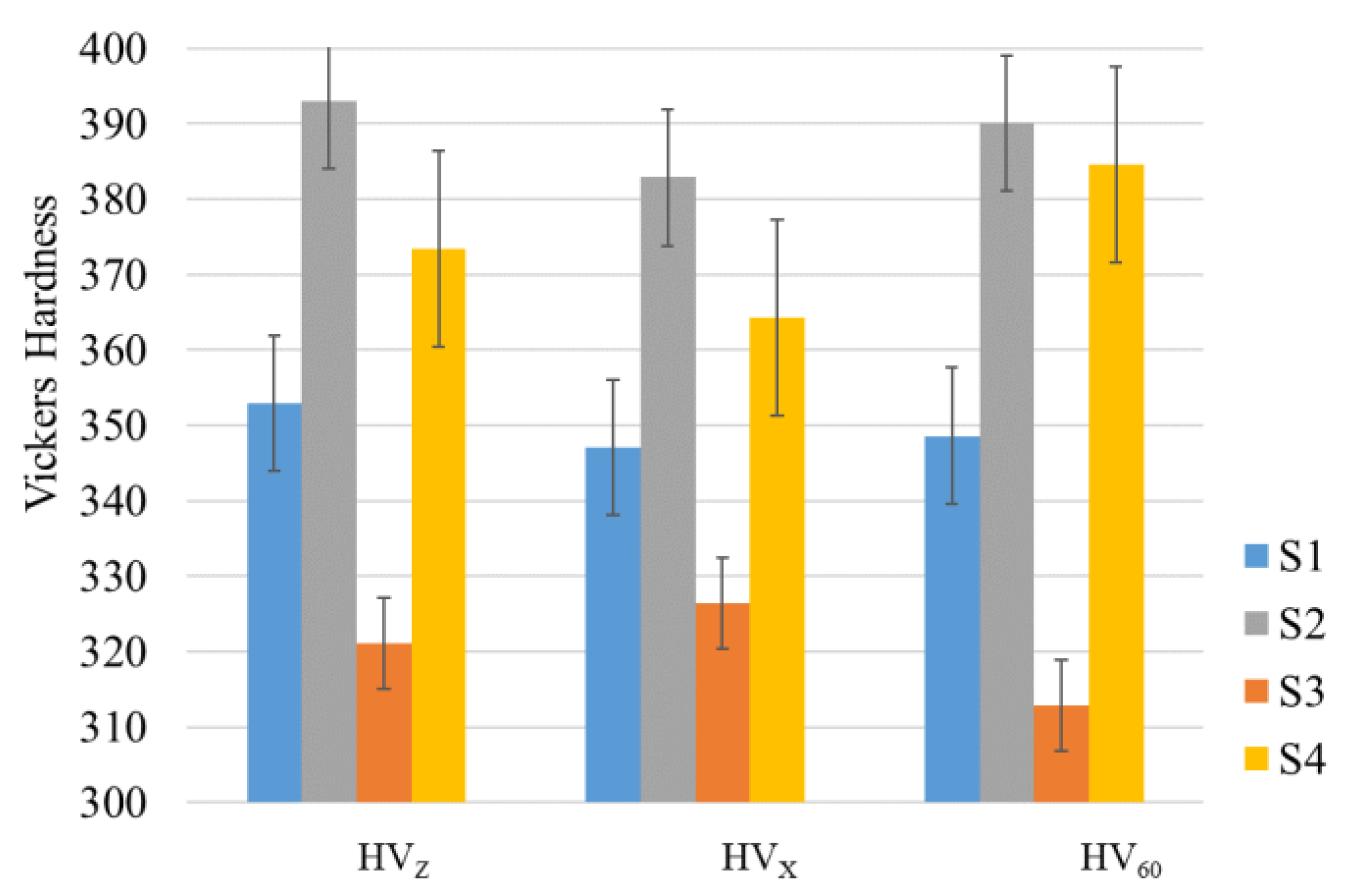

- S1-samples were additively manufactured by EBM from new powder and investigated in as-built state;

- S2-samples were additively manufactured by EBM from re-used powder and investigated in as-built state;

- S3-samples were additively manufactured by EBM from new powder and investigated after HIP treatment;

- S4-samples were additively manufactured by EBM from re-used powder investigated after HIP treatment.

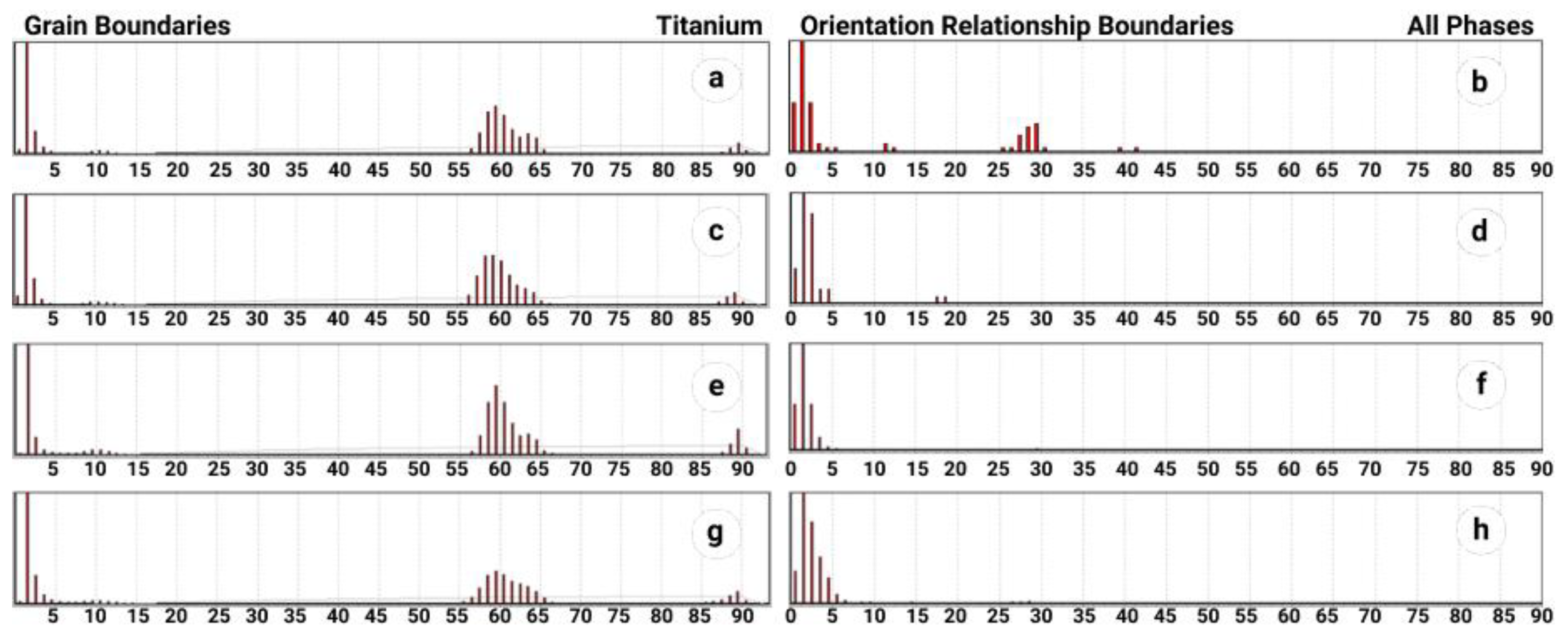

3. Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Katz-Demyanetz, A.; Popov, V.V.; Kovalevsky, A.; Safranchik, D.; Koptyug, A. Powder-bed additive manufacturing for aerospace application: Techniques, metallic and metal/ceramic composite materials and trends. Manuf. Rev. 2019, 6, 5. [Google Scholar] [CrossRef] [Green Version]

- Dutta, B.; Froes, F.H. Additive Manufacturing Technology. In The Additive Manufacturing (AM) of Titanium Alloys; Elsevier Inc.: Amsterdam, The Netherlands, 2016; pp. 25–40. [Google Scholar] [CrossRef]

- Uhlmann, E.; Kersting, R.; Klein, T.B.; Cruz, M.F.; Borille, A.V. Additive Manufacturing of Titanium Alloy for Aircraft Components. In Procedia CIRP; Elsevier: Amsterdam, The Netherlands, 2015; pp. 55–60. [Google Scholar] [CrossRef]

- Chudinova, E.; Surmeneva, M.; Koptioug, A.; Scoglund, P.; Surmenev, R. Additive manufactured Ti6Al4V scaffolds with the RF- magnetron sputter deposited hydroxyapatite coating. J. Physics Conf. Ser. 2016, 669, 012004. [Google Scholar] [CrossRef] [Green Version]

- Cronskär, M.; Rännar, L.-E.; Bäckström, M.; Nilsson, K.G.; Samuelsson, B. Patient-Specific Clavicle Reconstruction Using Digital Design and Additive Manufacturing. J. Mech. Des. Trans. ASME 2015, 137, 111418. [Google Scholar] [CrossRef]

- Popov, V.V.; Muller-Kamskii, G.; Katz-Demyanetz, A.; Kovalevsky, A.; Usov, S.; Trofimcow, D.; Dzhenzhera, G.; Koptyug, A. Additive manufacturing to veterinary practice: Recovery of bony defects after the osteosarcoma resection in canines. Biomed. Eng. Lett. 2019, 9, 97–108. [Google Scholar] [CrossRef]

- Sarvankar, S.G.; Yewale, S.N. Additive Manufacturing in Automobile Industry. Int. J. Res. Aeronaut. Mech. Eng. 2019, 7, 1–10. [Google Scholar]

- Waterman, A. World’s First 3D Printed Bike. 2014. Available online: https://www.pinkbike.com/news/Worlds-first-3D-printed-bike-2014.html (accessed on 24 December 2019).

- Baudana, G.; Biamino, S.; Ugues, D.; Lombardi, M.; Fino, P.; Pavese, M.; Badini, C. Titanium aluminides for aerospace and automotive applications processed by Electron Beam Melting: Contribution of Politecnico di Torino. Met. Powder Rep. 2016, 71, 193–199. [Google Scholar] [CrossRef]

- Wohlers Associates. Wohlers Report 2020. 3D Printing and Additive Manufacturing State of the Industry: Annual Worldwide Progress Report; Wohlers Associates: Fort Collins, CO, USA, 2020; ISBN 978-0-9913332-6-4. Available online: https://wohlersassociates.com/2020report.htm (accessed on 11 April 2021).

- Murr, L.; Quinones, S.; Gaytan, S.; Lopez, M.; Rodela, A.; Martinez, E.; Hernandez, D.; Medina, F.; Wicker, R. Microstructure and mechanical behavior of Ti–6Al–4V produced by rapid-layer manufacturing, for biomedical applications. J. Mech. Behav. Biomed. Mater. 2009, 2, 20–32. [Google Scholar] [CrossRef] [PubMed]

- Hernández-Nava, E.; Mahoney, P.; Smith, C.J.; Donoghue, J.; Todd, I.; Tammas-Williams, S. Additive manufacturing titanium components with isotropic or graded properties by hybrid electron beam melting/hot isostatic pressing powder processing. Sci. Rep. 2019, 9, 4070. [Google Scholar] [CrossRef]

- Ghods, S.; Schultz, E.; Wisdom, C.; Schur, R.; Pahuja, R.; Montelione, A.; Arola, D.; Ramulu, M. Electron beam additive manufacturing of Ti6Al4V: Evolution of powder morphology and part microstructure with powder reuse. Materialia 2020, 9, 100631. [Google Scholar] [CrossRef]

- Tang, H.P.; Qian, M.; Liu, N.; Zhang, X.Z.; Yang, G.Y.; Wang, J. Effect of Powder Reuse Times on Additive Manufacturing of Ti-6Al-4V by Selective Electron Beam Melting. JOM 2015, 67, 555–563. [Google Scholar] [CrossRef]

- Wei, C.; Ma, X.; Yang, X.; Zhou, M.; Wang, C.; Zheng, Y.; Zhang, W.; Li, Z. Microstructural and property evolution of Ti6Al4V powders with the number of usage in additive manufacturing by electron beam melting. Mater. Lett. 2018, 221, 111–114. [Google Scholar] [CrossRef]

- Sun, Y.; Aindow, M.; Hebert, R.J. The effect of recycling on the oxygen distribution in Ti-6Al-4V powder for additive manufacturing. Mater. High Temp. 2017, 35, 217–224. [Google Scholar] [CrossRef]

- Schur, R.; Ghods, S.; Wisdom, C.; Pahuja, R.; Montelione, A.; Arola, D.; Ramulu, M. Mechanical anisotropy and its evolution with powder reuse in Electron Beam Melting AM of Ti6Al4V. Mater. Des. 2021, 200, 109450. [Google Scholar] [CrossRef]

- Popov, V.V.; Katz-Demyanetz, A.; Garkun, A.; Bamberger, M. The effect of powder recycling on the mechanical properties and microstructure of electron beam melted Ti-6Al-4 V specimens. Addit. Manuf. 2018, 22, 834–843. [Google Scholar] [CrossRef]

- Zhao, Q.; Chen, Y.; Xu, Y.; Torrens, R.; Bolzoni, L.; Yang, F. Cost-affordable and qualified powder metallurgy metastable beta titanium alloy by designing short-process consolidation and processing. Mater. Des. 2021, 200, 109457. [Google Scholar] [CrossRef]

- Neikter, M.; Huang, A.; Wu, X. Microstructural characterization of binary microstructure pattern in selective laser-melted Ti-6Al-4V. Int. J. Adv. Manuf. Technol. 2019, 104, 1381–1391. [Google Scholar] [CrossRef] [Green Version]

- Antonysamy, A.; Meyer, J.; Prangnell, P. Effect of build geometry on the β-grain structure and texture in additive manufacture of Ti6Al4V by selective electron beam melting. Mater. Charact. 2013, 84, 153–168. [Google Scholar] [CrossRef]

- de Formanoir, C.; Michotte, S.; Rigo, O.; Germain, L.; Godet, S. Electron beam melted Ti–6Al–4V: Microstructure, texture and mechanical behavior of the as-built and heat-treated material. Mater. Sci. Eng. A 2016, 652, 105–119. [Google Scholar] [CrossRef]

- Wang, X.; Chou, K. EBSD study of beam speed effects on Ti-6Al-4V alloy by powder bed electron beam additive manufacturing. J. Alloys Compd. 2018, 748, 236–244. [Google Scholar] [CrossRef]

- Ganor, Y.I.; Tiferet, E.; Vogel, S.C.; Brown, D.W.; Chonin, M.; Pesach, A.; Hajaj, A.; Garkun, A.; Samuha, S.; Shneck, R.Z.; et al. Tailoring Microstructure and Mechanical Properties of Additively-Manufactured Ti6Al4V Using Post Processing. Materials 2021, 14, 658. [Google Scholar] [CrossRef]

- Popov, V.; Katz-Demyanetz, A.; Garkun, A.; Muller, G.; Strokin, E.; Rosenson, H. Effect of Hot Isostatic Pressure treatment on the Electron-Beam Melted Ti-6Al-4V specimens. Procedia Manuf. 2018, 21, 125–132. [Google Scholar] [CrossRef]

- Leon, A.; Levy, G.K.; Ron, T.; Shirizly, A.; Aghion, E. The effect of hot isostatic pressure on the corrosion performance of Ti-6Al-4 V produced by an electron-beam melting additive manufacturing process. Addit. Manuf. 2020, 33, 101039. [Google Scholar] [CrossRef]

- Popov, V.; Grilli, M.; Koptyug, A.; Jaworska, L.; Katz-Demyanetz, A.; Klobčar, D.; Balos, S.; Postolnyi, B.O.; Goel, S. Powder Bed Fusion Additive Manufacturing Using Critical Raw Materials: A Review. Materials 2021, 14, 909. [Google Scholar] [CrossRef] [PubMed]

- del Guercio, G.; Galati, M.; Saboori, A. Innovative Approach to Evaluate the Mechanical Performance of Ti–6Al–4V Lattice Structures Produced by Electron Beam Melting Process. Met. Mater. Int. 2021, 27, 55–67. [Google Scholar] [CrossRef]

- Ghods, S.; Schur, R.; Schultz, E.; Pahuja, R.; Montelione, A.; Wisdom, C.; Arola, D.; Ramulu, M. Powder reuse and its contribution to porosity in additive manufacturing of Ti6Al4V. Materialia 2021, 15, 100992. [Google Scholar] [CrossRef]

- Soltani-Tehrani, A.; Pegues, J.; Shamsaei, N. Fatigue behavior of additively manufactured 17-4 PH stainless steel: The effects of part location and powder re-use. Addit. Manuf. 2020, 36, 101398. [Google Scholar] [CrossRef]

- Powell, D.; Rennie, A.E.; Geekie, L.; Burns, N. Understanding powder degradation in metal additive manufacturing to allow the upcycling of recycled powders. J. Clean. Prod. 2020, 268, 122077. [Google Scholar] [CrossRef]

- Cordova, L.; Bor, T.; de Smit, M.; Campos, M.; Tinga, T. Measuring the spreadability of pre-treated and moisturized powders for laser powder bed fusion. Addit. Manuf. 2020, 32, 101082. [Google Scholar] [CrossRef]

- Soundarapandiyan, G.; Khan, R.; Johnston, C.; Chen, B.; Fitzpatrick, M. Effect of postprocessing thermal treatments on electron-beam powder bed–fused Ti6Al4V. Mater. Des. Process. Commun. 2020, 3, e168. [Google Scholar] [CrossRef] [Green Version]

- Popov, V.; Katz-Demyanetz, A.; Bamberger, M. Heat Transfer and Phase Formation through EBM 3D-Printing of Ti-6Al-4V Cylindrical Parts. Defect Diffus. Forum 2018, 383, 190–195. [Google Scholar] [CrossRef]

- Wang, S.; Aindow, M.; Starink, M. Effect of self-accommodation on α/α boundary populations in pure titanium. Acta Mater. 2003, 51, 2485–2503. [Google Scholar] [CrossRef]

- van Bohemen, S.; Kamp, A.; Petrov, R.; Kestens, L.; Sietsma, J. Nucleation and variant selection of secondary α plates in a β Ti alloy. Acta Mater. 2008, 56, 5907–5914. [Google Scholar] [CrossRef]

- Tong, V.; Joseph, S.; Ackerman, A.K.; Dye, D.; Britton, B. Using transmission Kikuchi diffraction to characterise α variants in an α+β titanium alloy. J. Microsc. 2017, 267, 318–329. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- DeMott, R.; Collins, P.; Kong, C.; Liao, X.; Ringer, S.; Primig, S. 3D electron backscatter diffraction study of α lath morphology in additively manufactured Ti-6Al-4V. Ultramicroscopy 2020, 218, 113073. [Google Scholar] [CrossRef]

- Suwas, S.; Ray, R.K. Crystallographic Texture of Materials, 1st ed.; Springer: London, UK, 2014. [Google Scholar] [CrossRef]

- Lobanov, M.L.; Borodina, M.D.; Danilov, S.V.; Pyshmintsev, I.Y.; Struin, A.O. Texture Inheritance on Phase Transition in Low-Carbon, Low-Alloy Pipe Steel after Thermomechanical Controlled Processing. Steel Transl. 2017, 47, 710–716. [Google Scholar] [CrossRef]

- Lobanov, M.L.; Redikul’Tsev, A.A.; Rusakov, G.M.; Danilov, S.V. Interrelation Between the Orientations of Deformation and Recrystallization in Hot Rolling of Anisotropic Electrical Steel. Met. Sci. Heat Treat. 2015, 57, 492–497. [Google Scholar] [CrossRef]

- ASM International. Properties and Selection: Nonferrous Alloys and Special-Purpose Materials Was; ASM International: Materials Park, OH, USA, 1990. [Google Scholar] [CrossRef]

- Seyda, V.; Kaufmann, N.; Emmelmann, C. Investigation of Aging Processes of Ti-6Al-4 V Powder Material in Laser Melting. Phys. Procedia 2012, 39, 425–431. [Google Scholar] [CrossRef] [Green Version]

- Lobanov, M.L.; Pyshmintsev, I.Y.; Urtsev, V.N.; Danilov, S.V.; Urtsev, N.; Redikultsev, A.A. Texture Inheritance in the Ferrito-Martensite Structure of Low-Alloy Steel after Thermomechanical Controlled Processing. Phys. Met. Metallogr. 2019, 120, 1180–1186. [Google Scholar] [CrossRef]

- Lobanov, M.L.; Rusakov, G.M.; Redikul’Tsev, A.A.; Belikov, S.V.; Karabanalov, M.S.; Struina, E.R.; Gervas’Ev, A.M. Investigation of Special Misorientations in Lath Martensite of Low-Carbon Steel Using the Method of Orientation Microscopy. Phys. Met. Metallogr. 2016, 117, 254–259. [Google Scholar] [CrossRef]

| Ref | Powder Characterization | Powder Bed Fusion (PBF) | Powder Used for PBF | Effect of Powder Re-Use | HIP | EBSD Charact. | |||

|---|---|---|---|---|---|---|---|---|---|

| EBM | SLM | New | Re-Used | Samples of New Powder | Samples of Re-Used Powder | ||||

| [13] | V | V | X | V | V | V | X | X | X |

| [14] | V | V | X | V | V | V | X | X | X |

| [16] | V | V | X | V | V | V | X | X | X |

| [17] | V | V | X | V | V | V | X | X | X |

| [18] | V | V | X | V | V | V | V | V | X |

| [20] | X | X | V | V | X | X | X | X | V |

| [21] | X | V | X | V | X | X | X | X | V |

| [23] | X | V | X | V | X | X | X | X | V |

| [24] | X | V | X | V | X | X | V | X | X |

| [25] | X | V | X | V | X | X | V | X | X |

| [28] | X | V | X | V | X | X | X | X | X |

| [29] | V | V | X | V | V | V | X | X | X |

| [30] | V | X | V | V | V | V | X | X | X |

| [31] | V | V | V | X | X | V | X | X | X |

| [32] | V | X | V | V | V | V | X | X | X |

| [33] | V | V | X | V | X | X | V | X | X |

| This work | V | V | X | V | V | V | V | V | V |

| Layer Thickness, μm | Alternating Angle between Layers | Beam Scan Speed, mm/s | Beam Power, W | Beam Focus Diameter, μm | Max. Beam Power, kW | Number of Contour Passes | Hatching Distance, μm |

|---|---|---|---|---|---|---|---|

| 50 | 90 | 4530 | 1250 | 400 | 3 | 2 | 100 |

| Sample | Powder Used for EBM | Application of HIP | dα, μm | Vβ, % |

|---|---|---|---|---|

| S1 | «virgin» | - | 1.8 ± 0.3 | 3.3 ± 0.3 |

| S2 | «reused» | - | 1.5 ± 0.3 | 1.7 ± 0.1 |

| S3 | «virgin» | + | 2.5 ± 0.3 | 4.7 ± 0.3 |

| S4 | «reused» | + | 2.7 ± 0.3 | 4.5 ± 0.3 |

| Sample | “Virgin” powder | S1 sample—as-built from “virgin” powder | S3 sample—HIPed sample manufactured from “virgin” powder | ASTM req. % |

| Oxygen content, % | 0.124 | 0.116 | 0.126 | 0.20 max |

| Sample | Re-used powder after 69th cycle | S1 sample—as-built from re-used powder | S3 sample—HIPed sample manufactured from re-used powder | |

| Oxygen content, % | 0.324 | 0.336 | 0.350 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Popov, V.V.; Lobanov, M.L.; Stepanov, S.I.; Qi, Y.; Muller-Kamskii, G.; Popova, E.N.; Katz-Demyanetz, A.; Popov, A.A. Texturing and Phase Evolution in Ti-6Al-4V: Effect of Electron Beam Melting Process, Powder Re-Using, and HIP Treatment. Materials 2021, 14, 4473. https://doi.org/10.3390/ma14164473

Popov VV, Lobanov ML, Stepanov SI, Qi Y, Muller-Kamskii G, Popova EN, Katz-Demyanetz A, Popov AA. Texturing and Phase Evolution in Ti-6Al-4V: Effect of Electron Beam Melting Process, Powder Re-Using, and HIP Treatment. Materials. 2021; 14(16):4473. https://doi.org/10.3390/ma14164473

Chicago/Turabian StylePopov, Vladimir V., Mikhail L. Lobanov, Stepan I. Stepanov, Yuanshen Qi, Gary Muller-Kamskii, Elena N. Popova, Alexander Katz-Demyanetz, and Artemiy A. Popov. 2021. "Texturing and Phase Evolution in Ti-6Al-4V: Effect of Electron Beam Melting Process, Powder Re-Using, and HIP Treatment" Materials 14, no. 16: 4473. https://doi.org/10.3390/ma14164473

APA StylePopov, V. V., Lobanov, M. L., Stepanov, S. I., Qi, Y., Muller-Kamskii, G., Popova, E. N., Katz-Demyanetz, A., & Popov, A. A. (2021). Texturing and Phase Evolution in Ti-6Al-4V: Effect of Electron Beam Melting Process, Powder Re-Using, and HIP Treatment. Materials, 14(16), 4473. https://doi.org/10.3390/ma14164473