Micropipes in SiC Single Crystal Observed by Molten KOH Etching

Abstract

:1. Introduction

2. Experiment

3. Results and Discussion

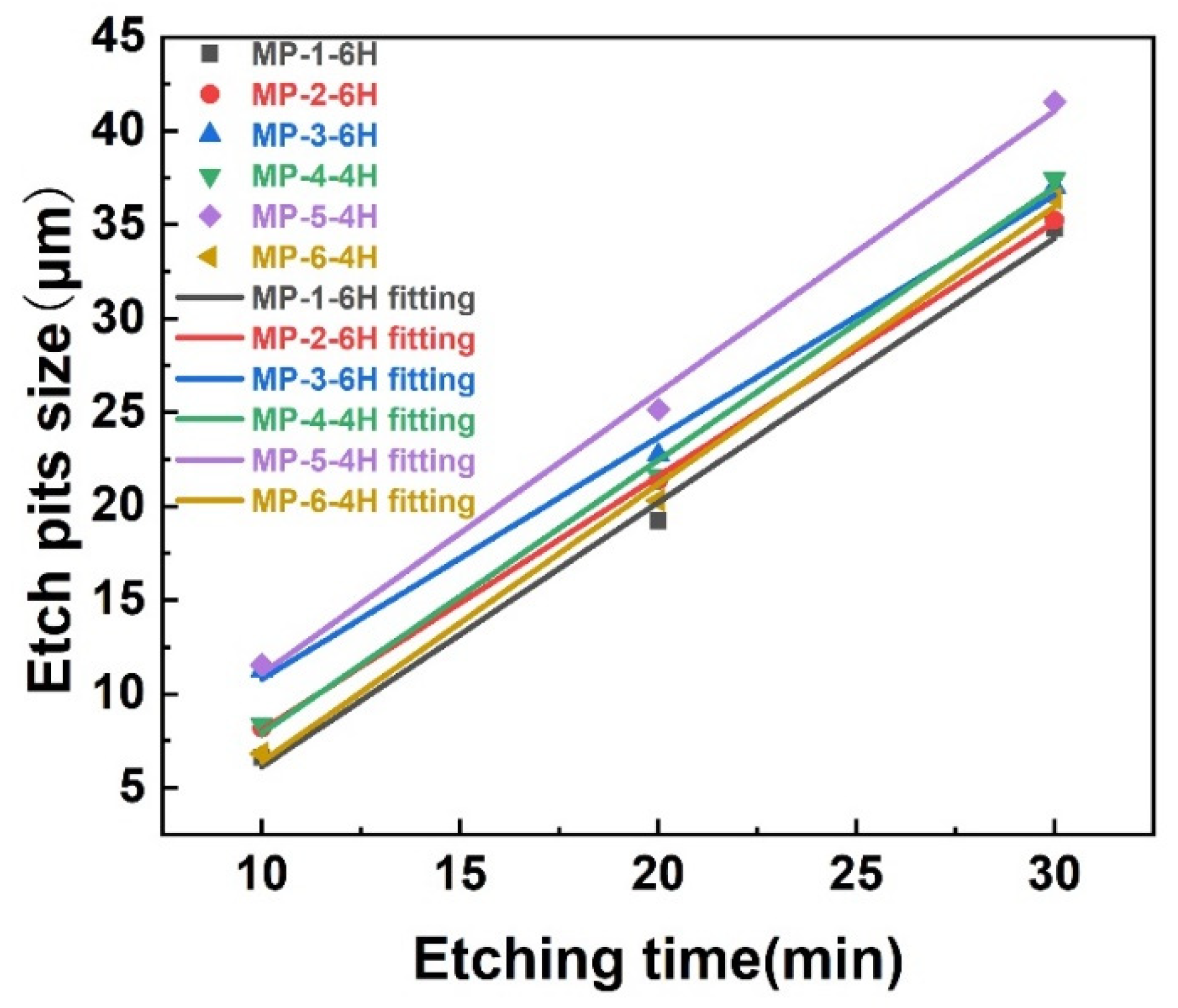

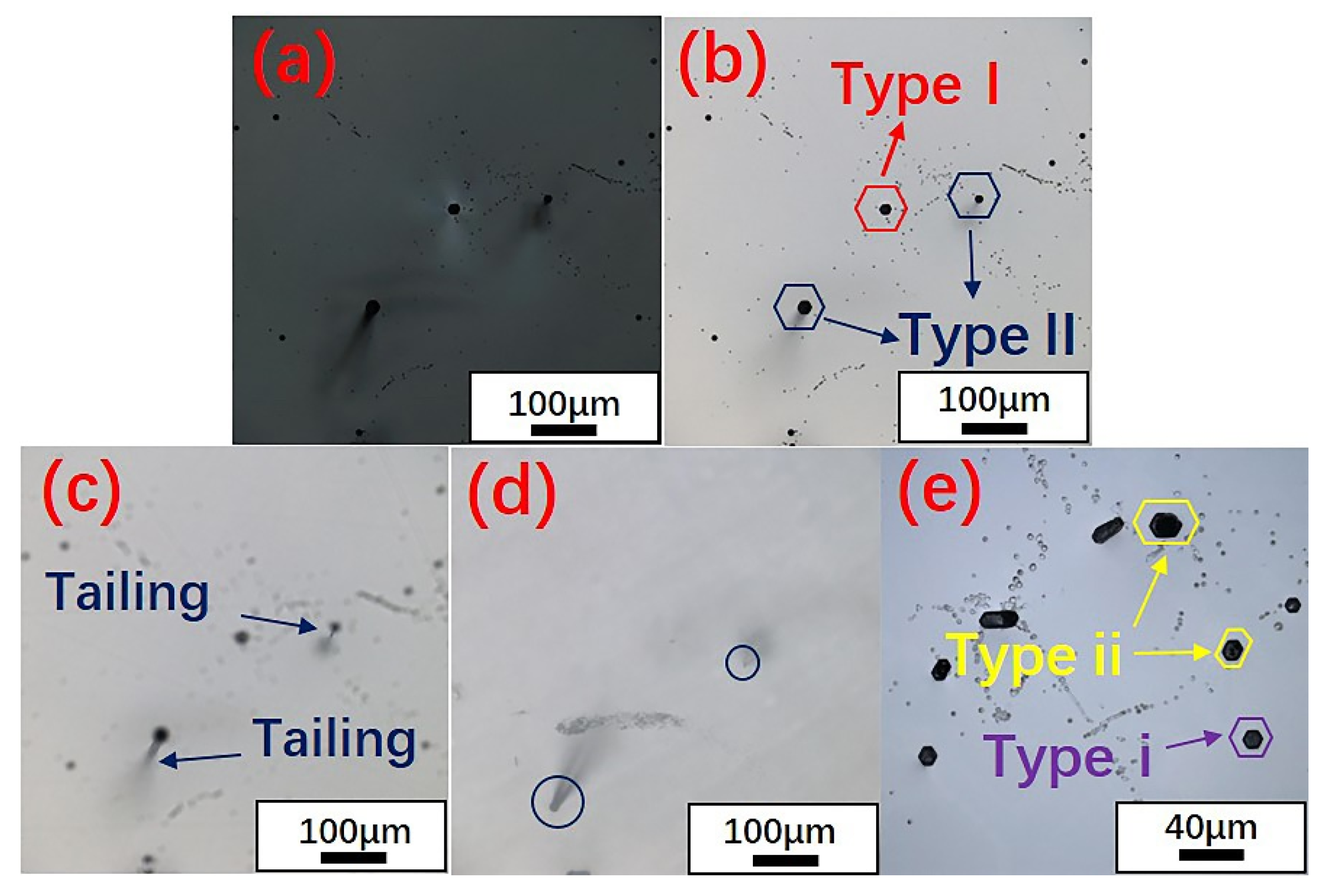

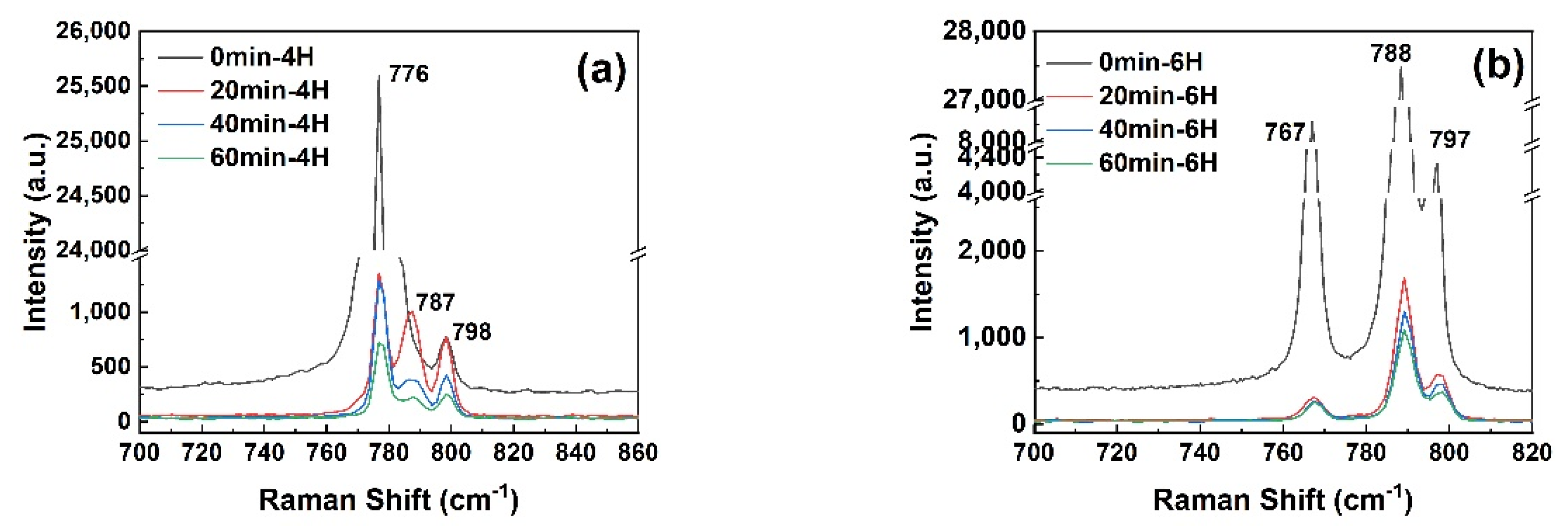

3.1. The Morphologies of Micropipe Etch Pits and the Etching Rates of Different Polytypes

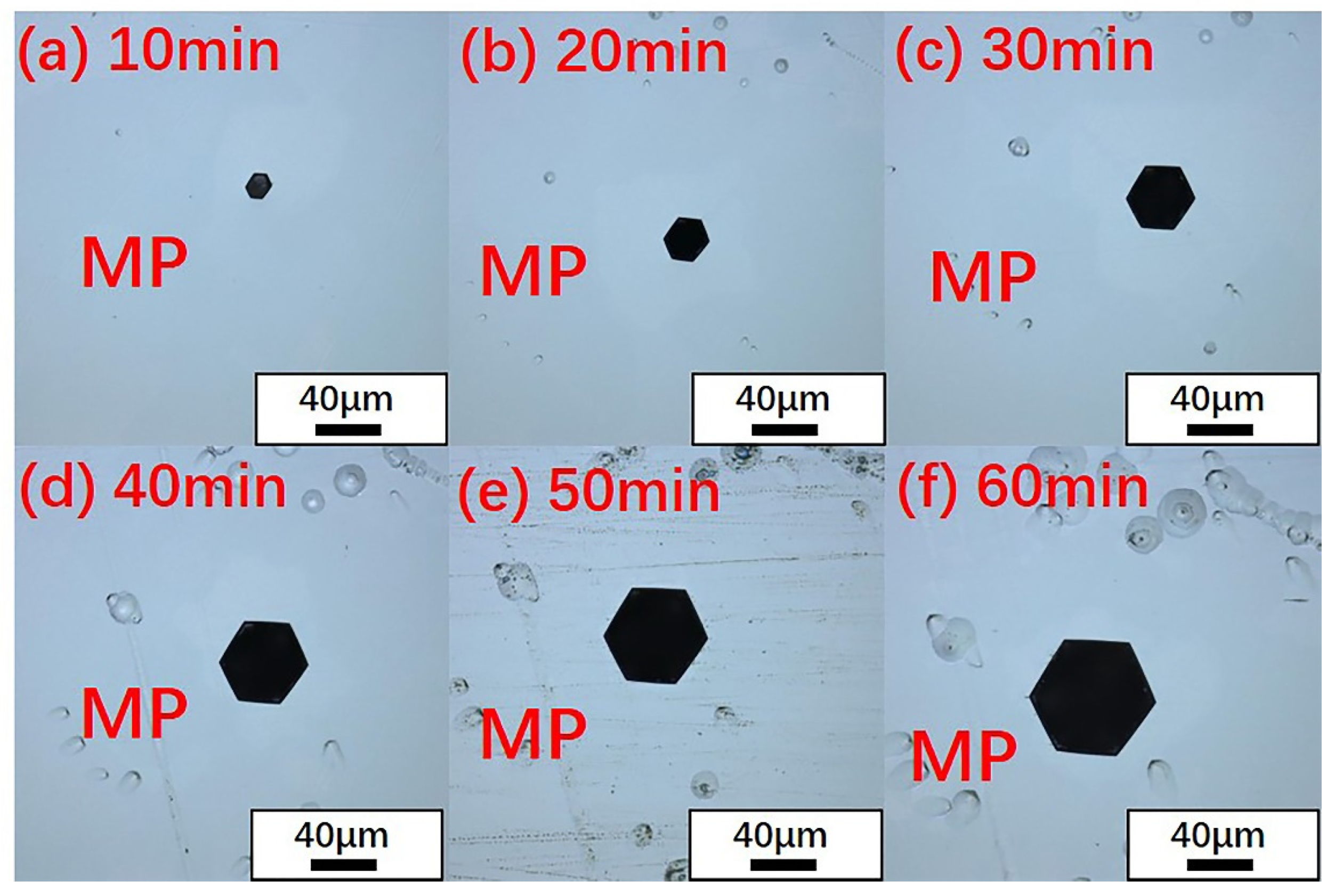

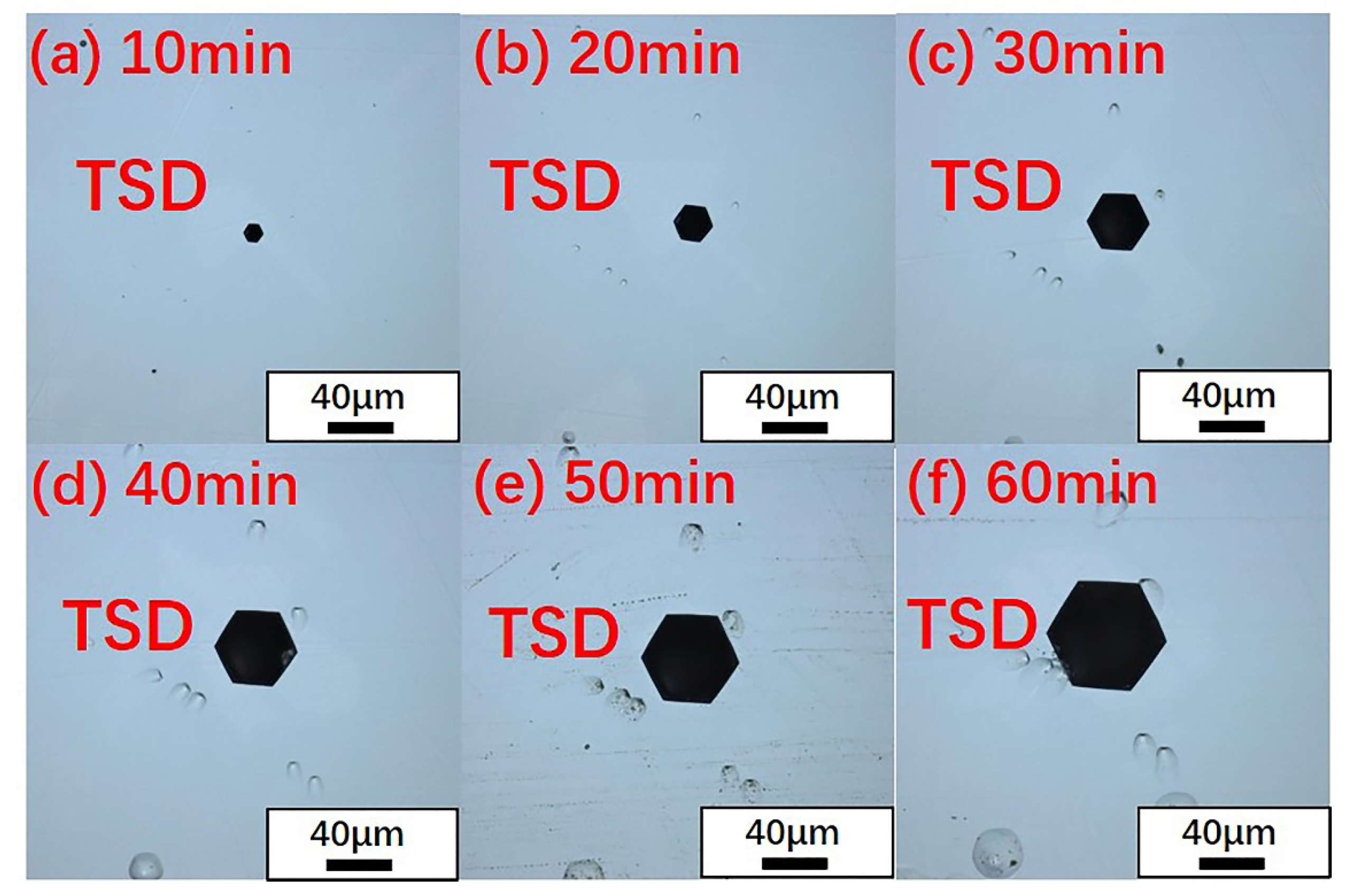

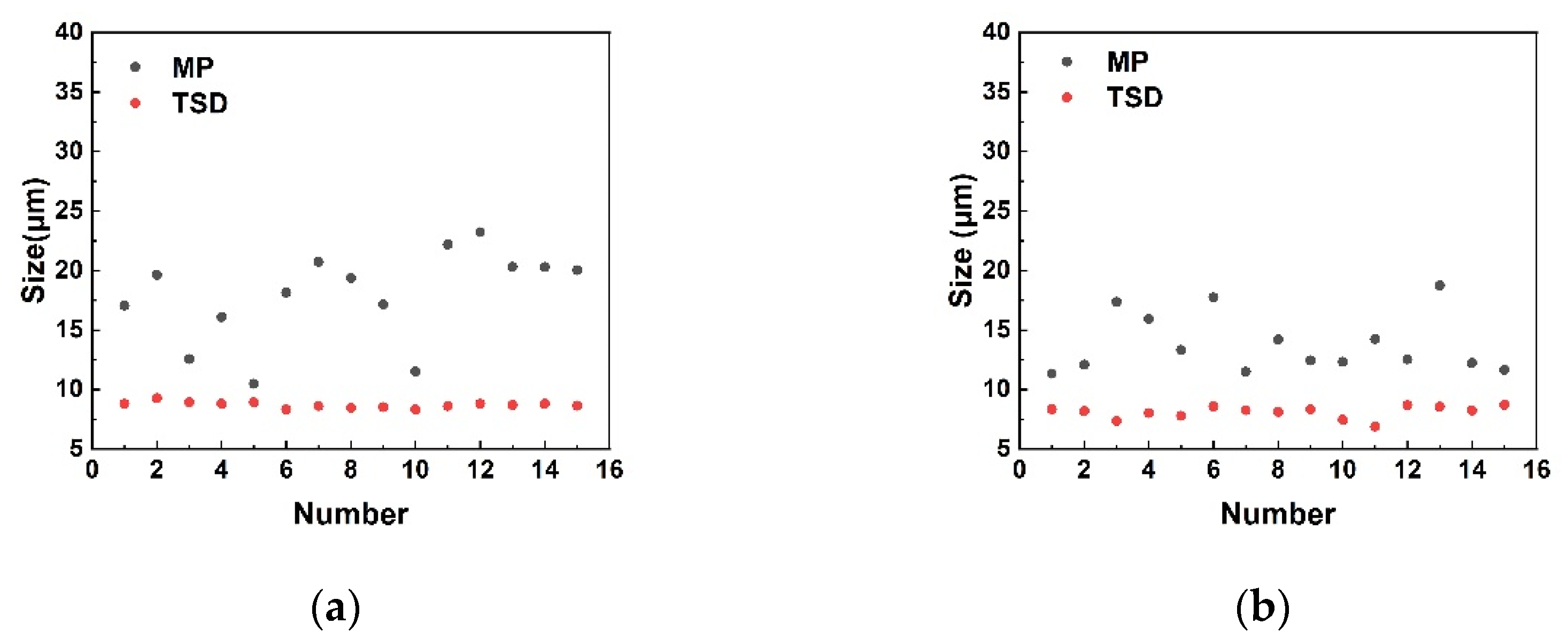

3.2. Exploration of Etching Conditions to Distinguish TSDs and Micropipe Etch Pits

3.3. The Classification of Micropipe Etch Pits

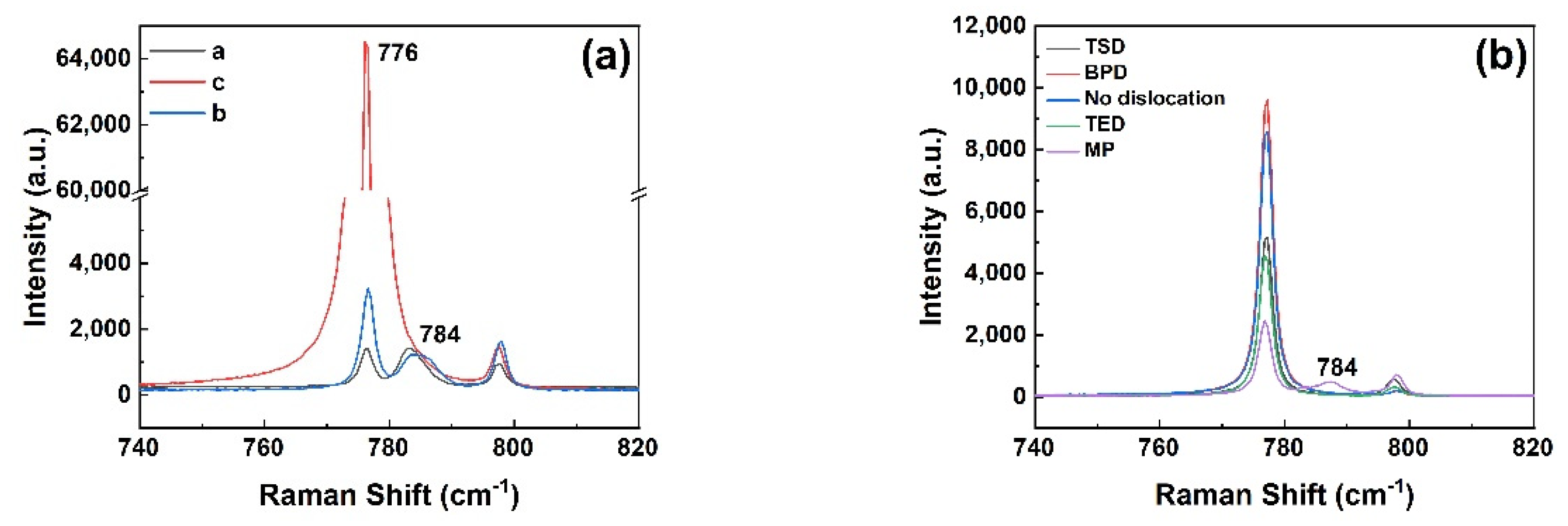

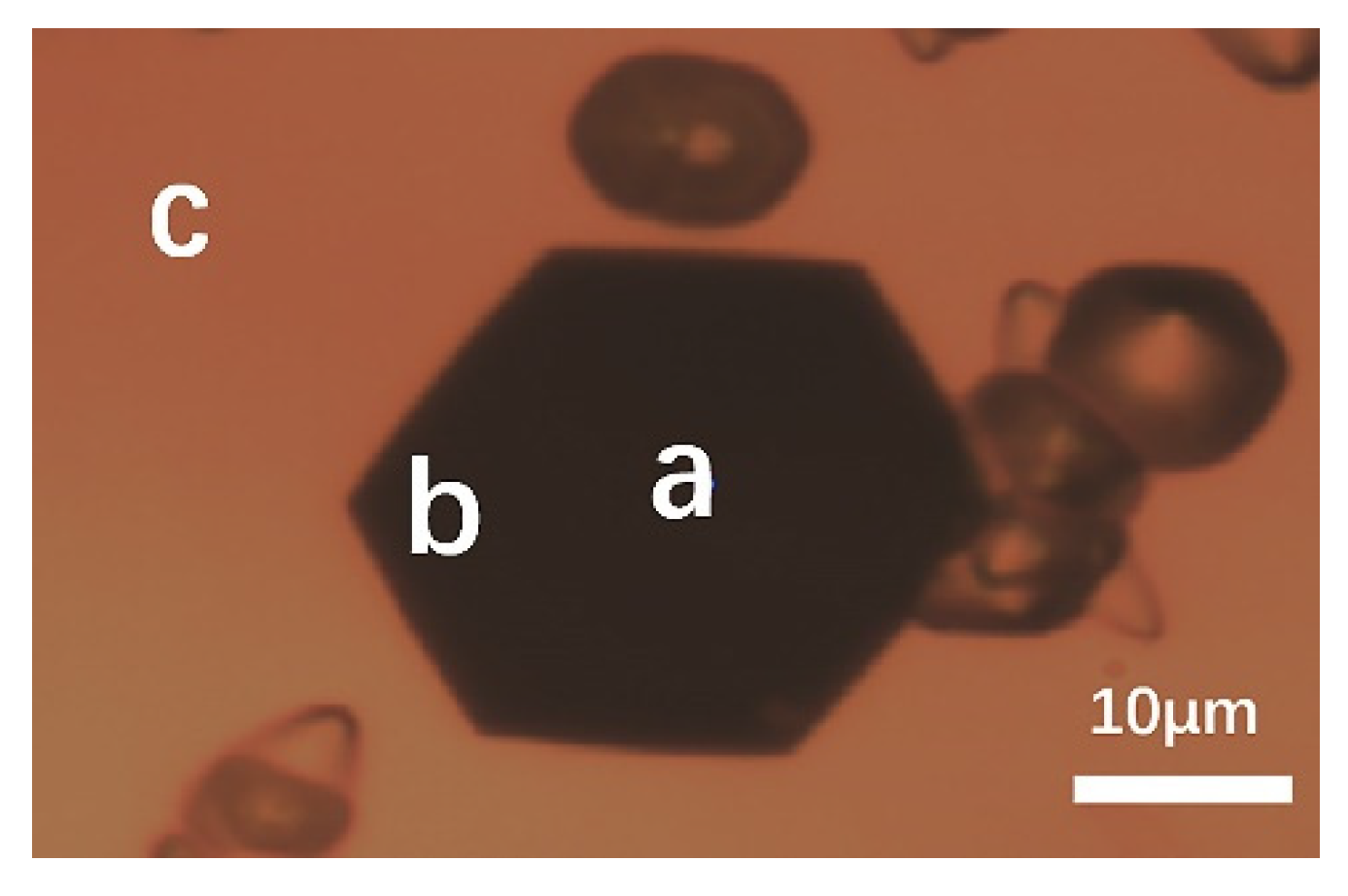

3.4. Raman Spectra of Micropipe Etch Pits

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Skowronski, M.; Ha, S. Degradation of Hexagonal Silicon-Carbide-Based Bipolar Devices. J. Appl. Phys. 2006, 99, 1–24. [Google Scholar] [CrossRef]

- Muench, W.V.; Pfaffeneder, I. Breakdown Field in Vapor-Grown Silicon-Carbide P-N-Junctions. J. Appl. Phys. 1977, 48, 4831–4833. [Google Scholar] [CrossRef]

- Slack, G.A. Thermal Conductivity of Pure and Impure Silicon, Silicon Carbide, Diamond. J. Appl. Phys. 1964, 35, 3460–3466. [Google Scholar] [CrossRef]

- Wang, X.; Cooper, J.A. High-Voltage n-Channel IGBTs On Free-Standing 4H-SiC Epilayers. IEEE T. Electron Dev. 2010, 57, 511–515. [Google Scholar] [CrossRef]

- Matsunami, H.; Kimoto, T. Step-Controlled Epitaxial Growth of SiC: High Quality Homoepitaxy. Mat. Sci. Eng. R. 1997, 20, 125–166. [Google Scholar] [CrossRef]

- Leonard, R.T.; Khlebnikov, Y.; Powell, A.R.; Basceri, C. 100 mm 4HN-SiC Wafers with Zero Micropipe Density. Mater. Sci. Forum. 2009, 600, 7–10. [Google Scholar] [CrossRef]

- Frank, F.C. Capillary Equilibria of Dislocated Crystals. Acta Crystallogr. 1951, 4, 497–501. [Google Scholar] [CrossRef]

- Neudeck, P.G.; Powell, J.A. Performance Limiting Micropipe Defects in Silicon-Carbide Wafers. IEEE Electr. Device L. 1994, 15, 63–65. [Google Scholar] [CrossRef] [Green Version]

- Kato, T.; Ohsato, H.; Okamoto, A.; Sugiyama, N.; Okuda, T. The Photoelastic Constant and Internal Stress Around Micropipe Defects of 6H-SiC Single Crystal. Mater. Sci. Eng. B. 1999, 57, 147–149. [Google Scholar] [CrossRef]

- Nakamura, D.; Kimoto, T. Transformation of Hollow-Core Screw Dislocations: Transitional Configuration of Superscrew Dislocations. Jpn. J. Appl. Phys. 2020, 59, 1–9. [Google Scholar] [CrossRef]

- Arora, A.; Patel, A.; Yadav, B.S.; Goyal, A.; Thakur, O.P.; Garg, A.K.; Raman, R. Study On Evolution of Micropipes From Hexagonal Voids in 4H-SiC Crystals by Cathodoluminescence Imaging. Microsc. Microanal. 2021, 27, 215–226. [Google Scholar] [CrossRef]

- Lin, S.; Chen, Z.; Feng, X.; Yang, Y.; Li, L.; Wang, Z.; Pan, P.; Wan, J.; Wang, H.; Ba, Y.; et al. Observation of Polytype Stability in Different-Impurities-Doped 6H-SiC Crystals. Diam. Relat. Mater. 2011, 20, 516–519. [Google Scholar] [CrossRef]

- Nakashima, S.; Nakatake, Y.; Harima, H.; Katsuno, M.; Ohtani, N. Detection of Stacking Faults in 6H-SiC by Raman Scattering. Appl. Phys. Lett. 2000, 77, 3612–3614. [Google Scholar] [CrossRef]

- Lu, Y.M.; Leu, I.C. Qualitative Study of Beta Silicon Carbide Residual Stress by Raman Spectroscopy. Thin Solid Film. 2000, 377, 389–393. [Google Scholar] [CrossRef]

- Burton, J.C.; Sun, L.; Pophristic, M.; Lukacs, S.J.; Long, F.H.; Feng, Z.C.; Ferguson, I.T. Spatial Characterization of Doped SiC Wafers by Raman Spectroscopy. J. Appl. Phys. 1998, 84, 6268–6273. [Google Scholar] [CrossRef]

- Lin, S.; Chen, Z.; Li, L.; Ba, Y.; Liu, S.; Yang, M. Investigation of Micropipes in 6H-SiC by Raman Scattering. Physica B 2012, 407, 670–673. [Google Scholar] [CrossRef]

- Jiang, L.D.; Plank, N.; Cheung, R.; Brown, R.; Mount, A. Surface Characterization of Inductively Coupled Plasma Etched SiC in SF6/O2. Microelectron. Eng. 2003, 67–68, 369–375. [Google Scholar] [CrossRef]

- Sagar, A.; Lee, C.D.; Feenstra, R.M.; Inoki, C.K.; Kuan, T.S. Morphology and Effects of Hydrogen Etching of Porous SiC. J. Appl. Phys. 2002, 92, 4070–4074. [Google Scholar] [CrossRef] [Green Version]

- Shor, J.S.; Kurtz, A.D. Photoelectrochemical Etching of 6H-SiC. J. Electrochem. Soc. 1994, 141, 778–781. [Google Scholar] [CrossRef]

- Berg, N.G.; Malherbe, J.B.; Botha, A.J.; Friedland, E. Thermal Etching of SiC. Appl. Surf. Sci. 2012, 258, 5561–5566. [Google Scholar] [CrossRef]

- Xie, K.; Flemish, J.R.; Zhao, J.H.; Buchwald, W.R.; Casas, L. Low Damage and Residue-Free Dry-Etching of 6H-SiC Using Electron-Cyclotron-Resonance Plasma. Appl. Phys. Lett. 1995, 67, 368–370. [Google Scholar] [CrossRef]

- Grodzicki, M.; Mazur, P.; Zuber, S.; Urbanik, G.; Ciszewski, A. Empty Core Screw Dislocations Formed On 6H-SiC(0001) During Hydrogen Etching. Thin Solid Film. 2008, 516, 7530–7537. [Google Scholar] [CrossRef]

- Hallin, C.; Bakin, A.S.; Owman, F.; Martensson, P.; Kordina, O.; Janzen, E. Study of the Hydrogen Etching of Silicon Carbide Substrates. Inst. Phys. Conf. Ser. 1996, 142, 613–616. [Google Scholar]

- Bondokov, R.T.; Tipirneni, N.; Cherednichenko, D.I.; Sudarshan, T.S. Modification of 6H-SiC Surface Defect Structure During Hydrogen Etching. Mater. Sci. Forum 2004, 457, 431–434. [Google Scholar] [CrossRef]

- Wu, P.; Yoganathan, M.; Zwieback, I.; Chen, Y.; Dudley, M. Characterization of Dislocations and Micropipes in 4H n+ SiC Substrates. Mater. Sci. Forum 2009, 600, 333–336. [Google Scholar]

- Habuka, H.; Furukawa, K.; Tanaka, K.; Katsumi, Y.; Iizuka, S.; Fukae, K.; Kato, T. Etch Pits On 4H-SiC Surface Produced by ClF3 Gas. Mater. Sci. Forum 2011, 679, 286–289. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, R.; Zhang, Y.; Liu, D.; Deng, H. Indiscriminate Revelation of Dislocations in Single Crystal SiC by Inductively Coupled Plasma Etching. J. Eur. Ceram. Soc. 2019, 39, 2831–2838. [Google Scholar] [CrossRef]

- Bondokov, R.T.; Khlebnikov, I.I.; Lashkov, T.; Tupitsyn, E.; Stratiy, G.; Khlebnikov, Y.; Sudarshan, T.S. A Method for Defect Delineation in Silicon Carbide Using Potassium Hydroxide Vapor. Jpn. J. Appl. Phys. 2002, 41, 7312–7316. [Google Scholar] [CrossRef]

- Yao, Y.; Ishikawa, Y.; Sugawara, Y.; Saitoh, H.; Danno, K.; Suzuki, H.; Kawai, Y.; Shibata, N. Dislocation Revelation in Highly Doped N-Type 4H-SiC by Molten KOH Etching with Na2O2 Additive. Mater. Sci. Forum. 2011, 679, 290–293. [Google Scholar] [CrossRef]

- Mahajan, S.; Rokade, M.V.; Ali, S.T.; Rao, K.S.; Munirathnam, N.R.; Prakash, T.L.; Amalnerkar, D.P. Investigation of Micropipe and Defects in Molten KOH Etching of 6H N-Silicon Carbide (SiC) Single Crystal. Mater. Lett. 2013, 101, 72–75. [Google Scholar] [CrossRef]

- Fukunaga, K.; Suda, J.; Kimoto, T. Anisotropic Etching of Single Crystalline SiC Using Molten KOH for SiC Bulk Micromachining. Proc. SPIE 2006, 6109, 1–8. [Google Scholar]

- Yao, Y.; Ishikawa, Y.; Sugawara, Y.; Sato, K.; Shirai, T.; Danno, K.; Suzuki, H.; Sakamoto, H.; Bessho, T.; Dierre, B.; et al. Cross-Sectional Observation of Stacking Faults in 4H-SiC by KOH Etching On Nonpolar {1-100} Face, Cathodoluminescence Imaging, and Transmission Electron Microscopy. Jpn. J. Appl. Phys. 2014, 53, 1–8. [Google Scholar] [CrossRef]

- Sakwe, S.A.; Jang, Y.; Wellmann, P.J. Defect Etching of Non-Polar and Semi-Polar Faces in SiC. Mater. Sci. Forum 2007, 556, 243–246. [Google Scholar] [CrossRef]

- Gotoh, M.; Tawara, T.; Nakamura, S.; Tamori, T.; Kuboki, Y.; Yonezawa, Y.; Nishiura, M. Dislocation-Related Etch Protrusions Formed On 4H-SiC (000-1) Surfaces by Molten KOH Etching. Mater. Res. Soc. Symp. Proc. 2006, 911, 193–198. [Google Scholar] [CrossRef]

- Yang, Y.; Chen, Z. Identification of SiC Polytypes by Etched Si-face Morphology. Mat. Sci. Semicon. Proc. 2009, 12, 113–117. [Google Scholar] [CrossRef]

- Li, J.; Yu, C.; Liu, Q.; Lu, W.; Feng, Z.; Yang, F. Investigation of Basal Plane Dislocations in 4H-SiC Homogeneous Epitaxial Material. Semicond. Technol. 2013, 38, 938–941. [Google Scholar]

- Sakwe, S.A.; Muller, R.; Wellmann, P.J. Optimization of KOH Etching Parameters for Quantitative Defect Recognition in N- and P-Type Doped SiC. J. Cryst. Growth 2006, 289, 520–526. [Google Scholar] [CrossRef]

- Suda, J.; Shoji, H.; Kimoto, T. Origin of Etch Hillocks Formed on On-Axis SiC(0001) Surfaces by Molten KOH Etching. Jpn. J. Appl. Phys. 2011, 50, 1–2. [Google Scholar] [CrossRef]

- Katsuno, M.; Ohtani, N.; Takahashi, J.; Yashiro, H.; Kanaya, M. Mechanism of Molten KOH Etching of SiC Single Crystals: Comparative Study with Thermal Oxidation. Jpn. J. Appl. Phys. 1999, 38, 4661–4665. [Google Scholar] [CrossRef]

- Huang, X.R.; Dudley, M.; Vetter, W.M.; Huang, W.; Wang, S.; Carter, C.H. Direct Evidence of Micropipe-Related Pure Superscrew Dislocations in SiC. Appl. Phys. Lett. 1999, 74, 353–355. [Google Scholar] [CrossRef]

- Pernot, E.; Hartwig, J.; Pons, M.; Madar, R. Giant Burgers Vector Micropipe-Dislocations in Silicon Carbide Investigated by Atomic Force Microscopy. Mater. Sci. Forum. 2006, 527, 435–438. [Google Scholar] [CrossRef]

- Kato, T.; Ohsato, H.; Okuda, T. Origin of the Internal Stress Around the Micropipe of 6H-SiC Single Crystal. Mater. Sci. Forum. 2000, 338, 449–452. [Google Scholar] [CrossRef]

- Ma, X.Y.; Sudarshan, T. Nondestructive Defect Characterization of SiC Substrates and Epilayers. J. Electron. Mater. 2004, 33, 450–455. [Google Scholar] [CrossRef]

- Nakashima, S.; Harima, H. Raman Investigation of SiC Polytypes. Phys. Stat. Sol. (A) 1997, 162, 39–63. [Google Scholar] [CrossRef]

- Shin, Y.J.; Kim, W.J.; Kim, H.Y.; Bahng, W. Dislocation Analysis of 4H-and 6H-SiC Single Crystals Using micro-Raman Spectroscopy. Mater. Sci. Forum. 2013, 740, 481–484. [Google Scholar] [CrossRef]

- Nakashima, S.; Kitamura, T.; Kato, T.; Kojima, K.; Kosugi, R.; Okumura, H.; Tsuchida, H.; Ito, M. Determination of Free Carrier Density in the Low Doping Regime of 4H-SiC by Raman Scattering. Appl. Phys. Lett. 2008, 93, 1–3. [Google Scholar] [CrossRef]

| Etching Time (min) | Size of the Micropipe Etch Pits (µm) | Size of TSDs (µm) | Difference (µm) |

|---|---|---|---|

| 10 | 15.54 | 11.02 | 4.52 |

| 20 | 25.62 | 21.84 | 3.78 |

| 30 | 35.73 | 32.46 | 3.27 |

| 40 | 45.81 | 43.14 | 2.67 |

| 50 | 56.04 | 53.91 | 2.13 |

| 60 | 67.04 | 65.63 | 1.41 |

| Defects Types | LOPC Mode (cm−1) | Carrier Concentration (cm−3) |

|---|---|---|

| TSD | 965.6 | 1.85 × 1017 |

| BPD | 965.6 | 1.85 × 1017 |

| TED | 965.2 | 1.35 × 1017 |

| No dislocation region | 965.6 | 1.85 × 1017 |

| MP | 969.3 | 6.40 × 1017 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Yu, J.; Hu, G.; Peng, Y.; Xie, X.; Hu, X.; Chen, X.; Xu, X. Micropipes in SiC Single Crystal Observed by Molten KOH Etching. Materials 2021, 14, 5890. https://doi.org/10.3390/ma14195890

Wang H, Yu J, Hu G, Peng Y, Xie X, Hu X, Chen X, Xu X. Micropipes in SiC Single Crystal Observed by Molten KOH Etching. Materials. 2021; 14(19):5890. https://doi.org/10.3390/ma14195890

Chicago/Turabian StyleWang, Hejing, Jinying Yu, Guojie Hu, Yan Peng, Xuejian Xie, Xiaobo Hu, Xiufang Chen, and Xiangang Xu. 2021. "Micropipes in SiC Single Crystal Observed by Molten KOH Etching" Materials 14, no. 19: 5890. https://doi.org/10.3390/ma14195890

APA StyleWang, H., Yu, J., Hu, G., Peng, Y., Xie, X., Hu, X., Chen, X., & Xu, X. (2021). Micropipes in SiC Single Crystal Observed by Molten KOH Etching. Materials, 14(19), 5890. https://doi.org/10.3390/ma14195890