Seismic Response of Resilient Bridges with SMA-Based Rocking ECC-Reinforced Piers

Abstract

:1. Introduction

2. Resilient Self-Centering Rocking Bridge System with ECC-Reinforced Pier

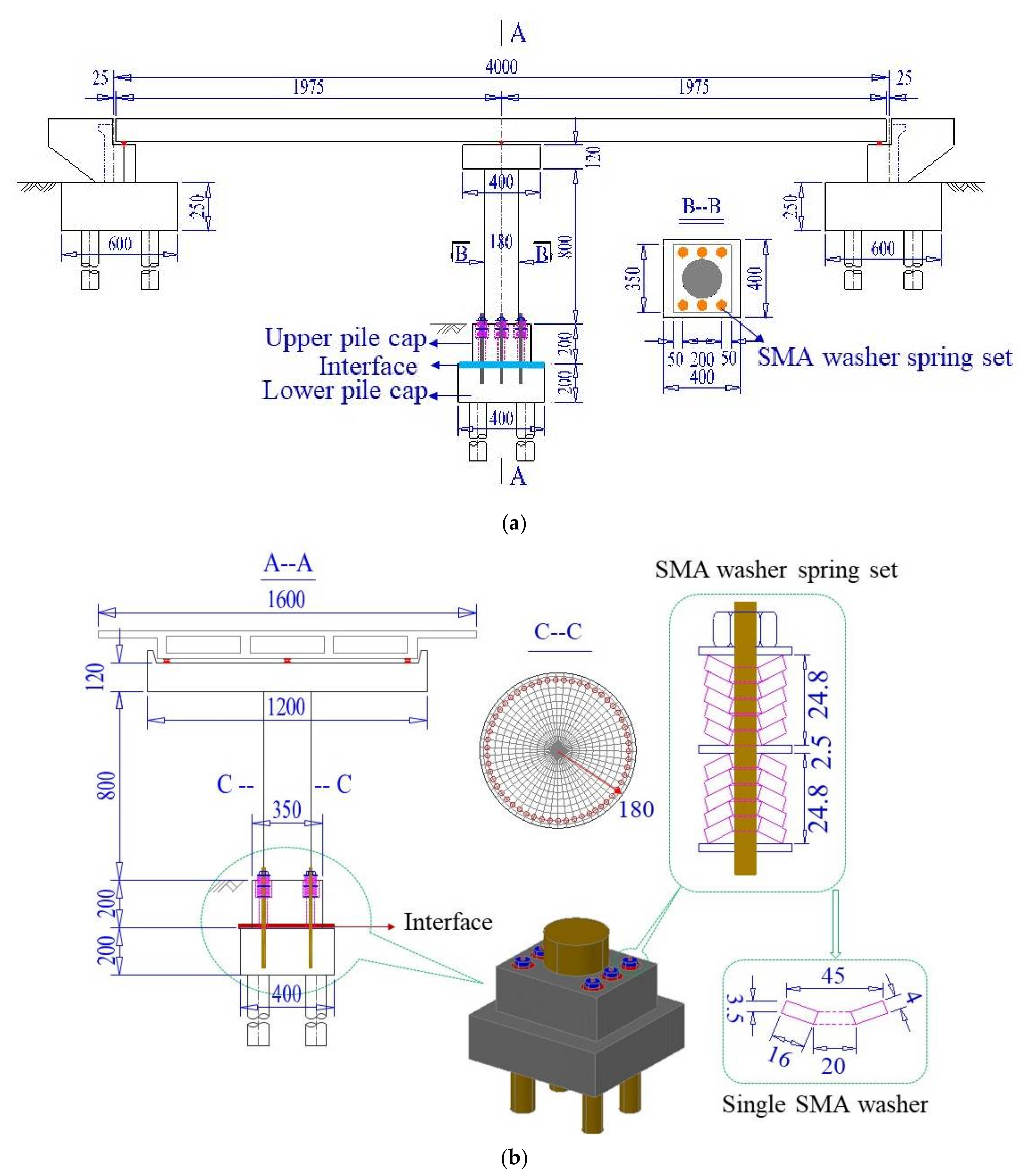

2.1. Configuration of the Rocking Bridge System

2.2. Rocking Mechanism and Seismic Design Objectives of Resilient Bridge System

3. Verification of ECC Material Constitutive Models

3.1. Constitutive Models of ECC Material

3.2. ECC-Reinforced Column and Numerical Verification

3.3. Constitutive Models of SMA Washer

4. Validation of the Numerical Simulation Method for Capturing Rocking Behavior

5. Seismic Responses of the Resilient Bridges with SMA-Based Rocking Piers

5.1. FE Model of Resilient Bridge Systems

5.2. Earthquake Ground Motions

5.3. Comparison of Seismic Responses between the Conventional and Resilient Bridges

5.4. Comparison of Seismic Responses between the RC and ECC-Reinforced Resilient Bridges

6. Conclusions

- All the conventional and the resilient rocking bridge systems with the RC pier or the ECC-reinforced pier can satisfy the seismic design objectives under E1 level earthquakes;

- The proposed resilient rocking bridge system with the RC pier or the ECC-reinforced pier shows superior seismic performance over the conventional bridge in terms of the response such as the curvature ductility of the pier, bearing deformation, drift ratio, and residual drift ratio of the bridge under E2 level earthquakes;

- The resilient rocking bridge with the ECC-reinforced pier can achieve superior damage retrofitting capacity than the resilient rocking bridge with RC pier. The average maximum curvature ductility of the ECC-reinforced pier was only 0.98 but the counterpart of the RC pier was 1.5 which indicates the RC experienced yielding state during E2 level earthquakes;

- Due to the protection mechanism (i.e., self-locking effect) of the SMA washer spring device against overload and the super resilient property of the ECC material, the resilient rocking bridge system shows the excellent damage control capacity;

- The SMA washer spring device cannot only provide restoring force for the resilient bridge system but also can dissipate moderate earthquake energy input.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kawashima, K.; Macrae, G.A.; Hoshikuma, J.-I.; Nagaya, K. Residual Displacement Response Spectrum. J. Struct. Eng. 1998, 124, 523–530. [Google Scholar] [CrossRef]

- Wang, W.; Fang, C.; Shen, D.; Zhang, R.; Ding, J.; Wu, H. Performance assessment of disc spring-based self-centering braces for seismic hazard mitigation. Eng. Struct. 2021, 242, 112527. [Google Scholar] [CrossRef]

- Fang, C.; Wang, W.; Shen, D. Development and Experimental Study of Disc Spring–Based Self-Centering Devices for Seismic Resilience. J. Struct. Eng. 2021, 147, 04021094. [Google Scholar] [CrossRef]

- Wang, W.; Fang, C.; Zhao, Y.; Sause, R.; Hu, S.; Ricles, J. Self-centering friction spring dampers for seismic resilience. Earthq. Eng. Struct. Dyn. 2019, 48, 1045–1065. [Google Scholar] [CrossRef]

- Buckle, I. Overview of seismic design methods for bridges in different countries and future directions. In Proceedings of the Eleventh World Conference on Earthquake Engineering, Acapulco, Mexico, 23–28 June 1996. [Google Scholar]

- Priestley, M.J.N.; Tao, J.R. Seismic Response of Precast Prestressed Concrete Frames With Partially Debonded Tendons. PCI J. 1993, 38, 58–69. [Google Scholar] [CrossRef]

- Mander, J.B.; Cheng, C.-T. Seismic Resistance of Bridge Piers Based on Damage Avoidance Design; Report No. NCEER-97-0014; University at Buffalo: Buffalo, NY, USA, 1997. [Google Scholar]

- Roha, H.; Reinhorn, A.M. Hysteretic behavior of precast segmental bridge piers with superelastic shape memory alloy bars. Eng. Struct. 2010, 32, 3394–3403. [Google Scholar] [CrossRef]

- Roh, H.; Reinhorn, A.M. Analytical modeling of rocking elements. Eng. Struct. 2009, 31, 1179–1189. [Google Scholar] [CrossRef]

- Roh, H.; Reinhorn, A.M. Nonlinear Static Analysis of Structures with Rocking Columns. J. Struct. Eng. 2010, 136, 532–542. [Google Scholar] [CrossRef]

- Cheng, C.-T. Shaking table tests of a self-centering designed bridge substructure. Eng. Struct. 2008, 30, 3426–3433. [Google Scholar] [CrossRef]

- Palermo, A.; Pampanin, S.; Calvi, G.M. Concept and development of hybrid solutions for seismic resistant bridge systems. J. Earthq. Eng. 2005, 9, 899–921. [Google Scholar] [CrossRef]

- Palermo, A.; Pampanin, S.; Marriott, D. Design, Modeling, and Experimental Response of Seismic Resistant Bridge Piers with Posttensioned Dissipating Connections. J. Struct. Eng. 2007, 133, 1648–1661. [Google Scholar] [CrossRef]

- Sakai, J.; Mahin, S.A. Mitigation of residual displacements of circular reinforced concrete bridge columns. In Proceedings of the 13th World Conference on Earthquake Engineering, Vancouver, BC, Canada, 1–6 August 2004. [Google Scholar]

- Pollino, M.; Bruneau, M. Seismic Retrofit of Bridge Steel Truss Piers Using a Controlled Rocking Approach. J. Bridg. Eng. 2007, 12, 600–610. [Google Scholar] [CrossRef] [Green Version]

- Marriott, D.; Pampanin, S.; Palermo, A. Quasi-static and pseudo-dynamic testing of unbonded post-tensioned rocking bridge piers with external replaceable dissipators. Earthq. Eng. Struct. Dyn. 2009, 38, 331–354. [Google Scholar] [CrossRef]

- Kam, W.Y.; Pampanin, S.; Palermo, A.; Carr, A.J. Self-centering structural systems with combination of hysteretic and viscous energy dissipations. Earthq. Eng. Struct. Dyn. 2010, 39, 1083–1108. [Google Scholar] [CrossRef]

- White, S.; Palermo, A. Quasi-Static Testing of Posttensioned Nonemulative Column-Footing Connections for Bridge Piers. J. Bridg. Eng. 2016, 21, 04016025. [Google Scholar] [CrossRef]

- MacRae, G.A.; Priestley, M.J.N. Precast Post-Tensioned Ungrouted Concrete Beam–Column Subassemblage Tests; Report No. SSRP-94/10; University of California: San Diego, CA, USA, 1994. [Google Scholar]

- Fang, C.; Zheng, Y.; Chen, J.; Yam, M.C.; Wang, W. Superelastic NiTi SMA cables: Thermal-mechanical behavior, hysteretic modelling and seismic application. Eng. Struct. 2019, 183, 533–549. [Google Scholar] [CrossRef]

- Billington, S.L.; Yoon, J.K. Cyclic response of unbonded post-tensioned precast concrete columns with ductile fiber-reinforced concrete. J. Bridge Eng. 2004, 9, 353–363. [Google Scholar] [CrossRef]

- Desroches, R.; McCormick, J.; Delemont, M. Cyclic Properties of Superelastic Shape Memory Alloy Wires and Bars. J. Struct. Eng. 2004, 130, 38–46. [Google Scholar] [CrossRef]

- Wilson, J.C.; Wesolowsky, M.J. Shape Memory Alloys for Seismic Response Modification: A State-of-the-Art Review. Earthq. Spectra 2005, 21, 569–601. [Google Scholar] [CrossRef]

- Saiidi, M.S.; O’Brien, M.; Sadrossadat-Zadeh, M. Cyclic Response of Concrete Bridge Columns Using Superelastic Nitinol and Bendable Concrete. ACI Struct. J. 2009, 106, 69–77. [Google Scholar] [CrossRef]

- Youssef, M.A.; Alam, M.S.; Nehdi, M. Experimental Investigation on the Seismic Behavior of Beam-Column Joints Reinforced with Superelastic Shape Memory Alloys. J. Earthq. Eng. 2008, 12, 1205–1222. [Google Scholar] [CrossRef]

- Alam, M.; Youssef, M.; Nehdi, M. Analytical prediction of the seismic behaviour of superelastic shape memory alloy reinforced concrete elements. Eng. Struct. 2008, 30, 3399–3411. [Google Scholar] [CrossRef]

- Zheng, Y.; Dong, Y.; Chen, B.; Ghazanfar, A.A. Seismic damage mitigation of bridges with self-adaptive SMA-cable-based bearings. Smart Struct. Syst. 2019, 24, 127–139. [Google Scholar]

- Zheng, Y.; Dong, Y.; Li, Y. Resilience and life-cycle performance of smart bridges with shape memory alloy (SMA)-cable-based bearings. Constr. Build. Mater. 2018, 158, 389–400. [Google Scholar] [CrossRef]

- Zheng, Y.; Dong, Y. Performance-based assessment of bridges with steel-SMA reinforced piers in a life-cycle context by numerical approach. Bull. Earthq. Eng. 2018, 17, 1667–1688. [Google Scholar] [CrossRef]

- Fang, C.; Liang, D.; Zheng, Y.; Yam, M.C.; Sun, R. Rocking bridge piers equipped with shape memory alloy (SMA) washer springs. Eng. Struct. 2020, 214, 110651. [Google Scholar] [CrossRef]

- Dong, Y.; Frangopol, D.M.; Saydam, D. Time-variant sustainability assessment of seismically vulnerable bridges subjected to multiple hazards. Earthq. Eng. Struct. Dyn. 2013, 42, 1451–1467. [Google Scholar] [CrossRef]

- Fang, C.; Yam, M.C.H.; Lam, C.C.; Xie, L. Cyclic performance of extended end-plate connections equipped with shape memory alloy bolts. J. Constr. Steel Res. 2014, 94, 122–136. [Google Scholar] [CrossRef]

- Roh, H.; Reinhorn, A.M. Modeling and seismic response of structures with concrete rocking columns and viscous dampers. Eng. Struct. 2010, 32, 2096–2107. [Google Scholar] [CrossRef]

- Sharabash, A.M.; Andrawes, B.O. Application of shape memory alloy dampers in the seismic control of cable-stayed bridges. Eng. Struct. 2009, 31, 607–616. [Google Scholar] [CrossRef]

- Yam, M.C.H.; Fang, C.; Lam, C.C.; Zhang, Y. Numerical study and practical design of beam-to-column connections with shape memory alloys. J. Constr. Steel Res. 2015, 104, 177–192. [Google Scholar] [CrossRef]

- Fang, C.; Wang, W.; He, C.; Chen, Y. Self-centring behaviour of steel and steel-concrete composite connections equipped with NiTi SMA bolts. Eng. Struct. 2017, 150, 390–408. [Google Scholar] [CrossRef]

- Wang, W.; Fang, C.; Yang, X.; Chen, Y.; Ricles, J.; Sause, R. Innovative use of a shape memory alloy ring spring system for self-centering connections. Eng. Struct. 2017, 153, 503–515. [Google Scholar] [CrossRef]

- Fang, C.; Yam, M.C.H.; Chan, T.M.; Wang, W.; Yang, X.; Lin, X. A study of hybrid self-centering connections equipped with shape memory alloy washers and bolts. Eng. Struct. 2018, 164, 155–168. [Google Scholar] [CrossRef]

- Wang, W.; Fang, C.; Zhang, A.; Liu, X. Manufacturing and performance of a novel self-centring damper with SMA ring springs for seismic resilience. Struct. Control. Health Monit. 2019, 26, e2337. [Google Scholar] [CrossRef]

- Zheng, Y.; Fang, C.; Liang, D.; Sun, R. An innovative seismic-resilient bridge with shape memory alloy (SMA)-washer-based footing rocking RC piers. J. Intell. Mater. Syst. Struct. 2021, 32, 549–567. [Google Scholar] [CrossRef]

- Varela, S.; Saiidi, M. A bridge column with superelastic NiTi SMA and replaceable rubber hinge for earthquake damage mitigation. Smart Mater. Struct. 2016, 25, 075012. [Google Scholar] [CrossRef]

- Wang, W.; Fang, C.; Liu, J. Self-Centering Beam-to-Column Connections with Combined Superelastic SMA Bolts and Steel Angles. J. Struct. Eng. 2017, 143, 04016175. [Google Scholar] [CrossRef]

- Crisfield, M.A. A consistent co-rotational formulation for non-linear, three-dimensional, beam-elements. Comput. Methods Appl. Mech. Eng. 1990, 1, 131–150. [Google Scholar] [CrossRef]

- Wang, W.; Fang, C.; Liu, J. Large size superelastic SMA bars: Heat treatment strategy, mechanical property and seismic application. Smart Mater. Struct. 2016, 25, 075001. [Google Scholar] [CrossRef]

- Mazzoni, S.; McKenna, F.; Scott, M.H.; Fenves, G.L.; Jeremic, B. Open System for Earthquake Engineering Simulation (Opensees) Command Language Manual; Pacific Earthquake Engineering Research Center, University of California at Berkeley: Berkeley, CA, USA, 2006. [Google Scholar]

- Zhang, N.; Gu, Q.; Dong, Y.; Qian, J.; Zheng, Y. Seismic performance of bridges with ECC-reinforced piers. Soil Dyn. Earthq. Eng. 2021, 146, 106753. [Google Scholar] [CrossRef]

- Han, T.S.; Feenstra, P.H.; Billington, S.L. Simulation of highly ductile fiber-reinforced cement-based composite components under cyclic loading. ACI Struct. J. 2003, 100, 749–757. [Google Scholar]

- Fischer, G.; Li, V.C. Effect of matrix ductility on deformation behavior of steel reinforced ECC flexural members under reversed cyclic loading conditions. ACI Struct. J. 2002, 99, 781–790. [Google Scholar]

- Zheng, Y.; Chen, B.; Chen, W. Elasto-Plastic Seismic Response of RC Continuous Bridge with Foundation-Pier Dynamic Interaction. Adv. Struct. Eng. 2015, 18, 817–836. [Google Scholar] [CrossRef]

- Zheng, Y.; Xiao, X.; Zhi, L.; Wang, G. Evaluation on impact interaction between abutment and steel girder subjected to non-uniform seismic excitation. Shock. Vib. 2015, 2015, 981804. [Google Scholar] [CrossRef]

- Specifications for Seismic Design of Highway Bridges (JTG/T 2231-01—2020); Ministry of Transportation of China: Beijing, China, 2020.

- Fang, C.; Liang, D.; Zheng, Y.; Lu, S. Seismic performance of bridges with novel SMA cable-restrained high damping rubber bearings against near-fault ground motions. Earthq. Eng. Struct. Dyn. 2021, 1–22. [Google Scholar] [CrossRef]

| Earthquake | Curvature Ductility | Bearing Deformation (cm) | Drift Ratio (Residual Drift Ratio) (%) | Uplift Ratio (%) | |||

|---|---|---|---|---|---|---|---|

| No. | Conventional | Resilient | Conventional | Resilient | Conventional | Resilient | Resilient |

| 1 | 1.15 | 0.76 | 11.99 | 7.34 | 1.01 (0.005) | 0.62 (0.008) | 0.07 |

| 2 | 1.15 | 0.92 | 11.91 | 8.70 | 1.00 (0.029) | 0.72 (0.008) | 0.08 |

| 3 | 0.80 | 0.82 | 9.30 | 7.68 | 0.79 (0.002) | 0.65 (0.001) | 0.07 |

| 4 | 0.89 | 1.17 | 10.20 | 11.75 | 0.86 (0.011) | 0.99 (0.013) | 0.30 |

| 5 | 0.74 | 0.70 | 8.77 | 6.95 | 0.74 (0.014) | 0.57 (0.009) | 0.06 |

| 6 | 0.83 | 1.09 | 9.86 | 9.80 | 0.81 (0.027) | 0.83 (0.006) | 0.17 |

| 7 | 0.99 | 0.68 | 10.81 | 6.54 | 0.91 (0.002) | 0.56 (0.008) | 0.05 |

| Avg. value | 0.94 | 0.88 | 10.41 | 8.40 | 0.88 (0.013) | 0.70 (0.008) | 0.11 |

| Earthquake | Curvature Ductility | Bearing Deformation (cm) | Drift Ratio (Residual Drift Ratio) (%) | Uplift Ratio (%) | |||

|---|---|---|---|---|---|---|---|

| No. | Conventional | Resilient | Conventional | Resilient | Conventional | Resilient | Resilient |

| 1 | 3.24 | 1.47 | 20.33 | 19.43 | 1.71 (0.039) | 1.63 (0.009) | 1.01 |

| 2 | 2.70 | 1.73 | 18.38 | 20.77 | 1.54 (0.022) | 1.74 (0.002) | 1.12 |

| 3 | 3.00 | 1.47 | 18.96 | 16.42 | 1.59 (0.057) | 1.38 (0.020) | 0.70 |

| 4 | 3.23 | 1.56 | 19.02 | 17.58 | 1.58 (0.054) | 1.47 (0.009) | 0.86 |

| 5 | 2.95 | 1.31 | 18.37 | 16.17 | 1.54 (0.060) | 1.36 (0.005) | 0.73 |

| 6 | 2.68 | 1.47 | 18.97 | 16.68 | 1.57 (0.046) | 1.39 (0.011) | 0.72 |

| 7 | 3.15 | 1.49 | 19.52 | 17.89 | 1.64 (0.040) | 1.50 (0.001) | 0.86 |

| Avg. value | 2.99 | 1.50 | 19.08 | 17.85 | 1.60 (0.045) | 1.49 (0.008) | 0.86 |

| Earthquake | Curvature Ductility | Bearing Deformation (cm) | Drift Ratio (Residual Drift Ratio) (%) | Uplift Ratio (%) | |||

|---|---|---|---|---|---|---|---|

| No. | Conventional | Resilient | Conventional | Resilient | Conventional | Resilient | Resilient |

| 1 | 0.67 | 0.76 | 11.93 | 10.23 | 0.98 (0.013) | 0.87 (0.014) | 0.08 |

| 2 | 0.62 | 0.93 | 11.17 | 15.03 | 0.94 (0.026) | 1.26 (0.005) | 0.49 |

| 3 | 0.68 | 0.57 | 11.30 | 8.35 | 1.00 (0.035) | 0.69 (0.016) | 0.06 |

| 4 | 0.65 | 0.87 | 11.74 | 13.63 | 0.97 (0.021) | 1.10 (0.017) | 0.32 |

| 5 | 0.63 | 0.62 | 11.13 | 8.66 | 0.94 (0.011) | 0.73 (0.011) | 0.06 |

| 6 | 0.71 | 0.72 | 12.60 | 10.06 | 1.04 (0.035) | 0.83 (0.018) | 0.08 |

| 7 | 0.61 | 0.74 | 10.91 | 10.18 | 0.92 (0.003) | 0.86 (0.014) | 0.08 |

| Avg. value | 0.65 | 0.74 | 11.54 | 10.88 | 0.97 (0.021) | 0.91 (0.014) | 0.17 |

| Earthquake | Curvature Ductility | Bearing Deformation (cm) | Drift ratio (Residual Drift Ratio) (%) | Uplift Ratio (%) | |||

|---|---|---|---|---|---|---|---|

| No. | Conventional | Resilient | Conventional | Resilient | Conventional | Resilient | Resilient |

| 1 | 1.84 | 1.07 | 22.17 | 24.66 | 1.84 (0.137) | 2.07 (0.007) | 1.48 |

| 2 | 1.66 | 0.99 | 21.26 | 20.89 | 1.78 (0.040) | 1.75 (0.006) | 1.08 |

| 3 | 1.88 | 0.93 | 22.15 | 19.31 | 1.86 (0.065) | 1.62 (0.006) | 0.93 |

| 4 | 2.21 | 0.98 | 24.30 | 18.45 | 2.02 (0.080) | 1.32 (0.029) | 0.83 |

| 5 | 1.51 | 0.99 | 19.90 | 19.96 | 1.67 (0.131) | 1.67 (0.011) | 0.98 |

| 6 | 2.04 | 0.92 | 23.24 | 18.54 | 1.93 (0.022) | 1.54 (0.011) | 0.84 |

| 7 | 1.47 | 0.98 | 19.69 | 23.32 | 1.66 (0.037) | 1.95 (0.009) | 1.37 |

| Avg. value | 1.80 | 0.98 | 21.81 | 20.73 | 1.82 (0.073) | 1.70 (0.011) | 1.07 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Chen, K.; Chen, J.; Li, Y.; Yang, D. Seismic Response of Resilient Bridges with SMA-Based Rocking ECC-Reinforced Piers. Materials 2021, 14, 6500. https://doi.org/10.3390/ma14216500

Li X, Chen K, Chen J, Li Y, Yang D. Seismic Response of Resilient Bridges with SMA-Based Rocking ECC-Reinforced Piers. Materials. 2021; 14(21):6500. https://doi.org/10.3390/ma14216500

Chicago/Turabian StyleLi, Xiaogang, Ke Chen, Ji Chen, Yi Li, and Dong Yang. 2021. "Seismic Response of Resilient Bridges with SMA-Based Rocking ECC-Reinforced Piers" Materials 14, no. 21: 6500. https://doi.org/10.3390/ma14216500

APA StyleLi, X., Chen, K., Chen, J., Li, Y., & Yang, D. (2021). Seismic Response of Resilient Bridges with SMA-Based Rocking ECC-Reinforced Piers. Materials, 14(21), 6500. https://doi.org/10.3390/ma14216500