The Influence of Sandblasting Process Parameters of Aerospace Aluminium Alloy Sheets on Adhesive Joints Strength

Abstract

1. Introduction

2. Materials and Methods

2.1. Adherend

2.2. Surface Preparation Methods

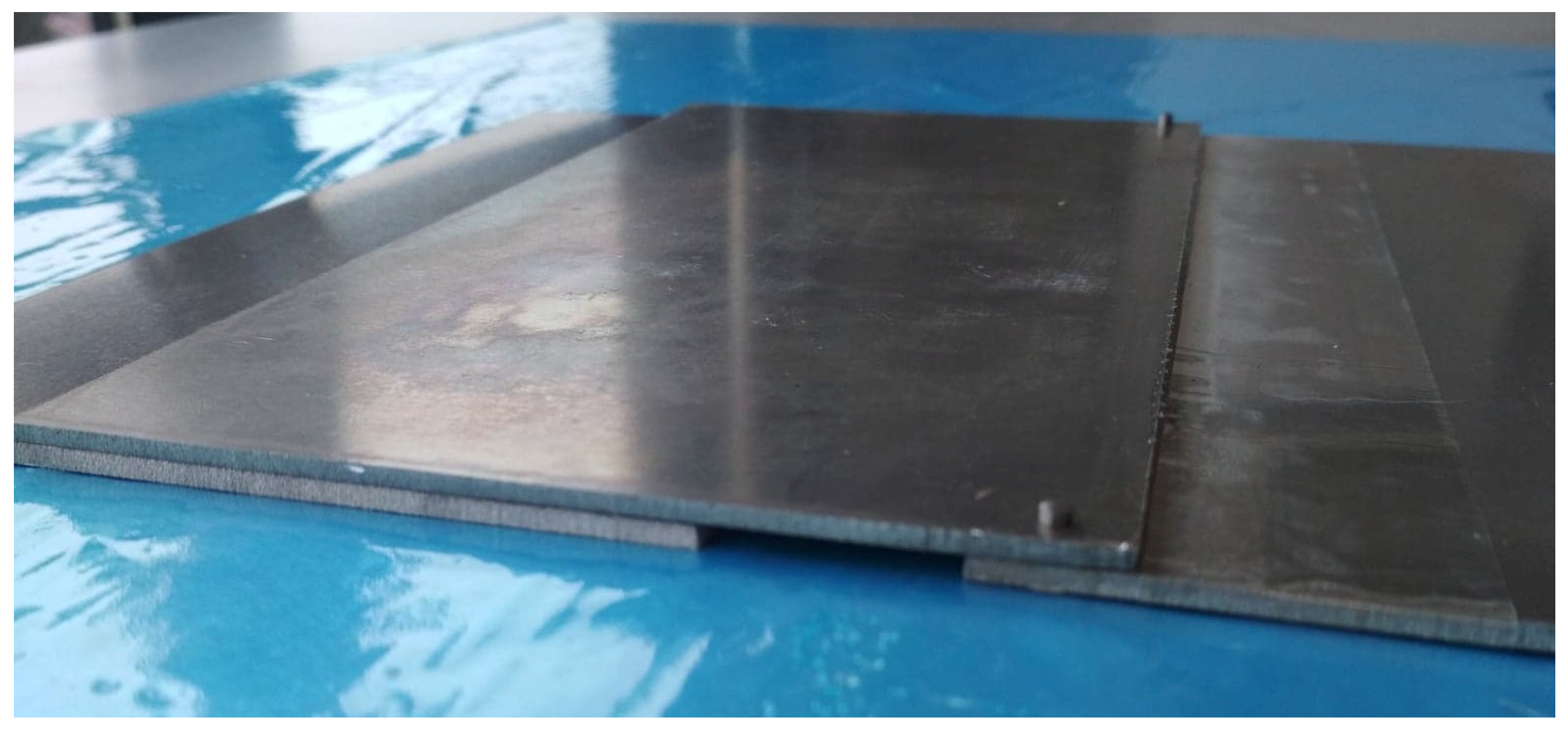

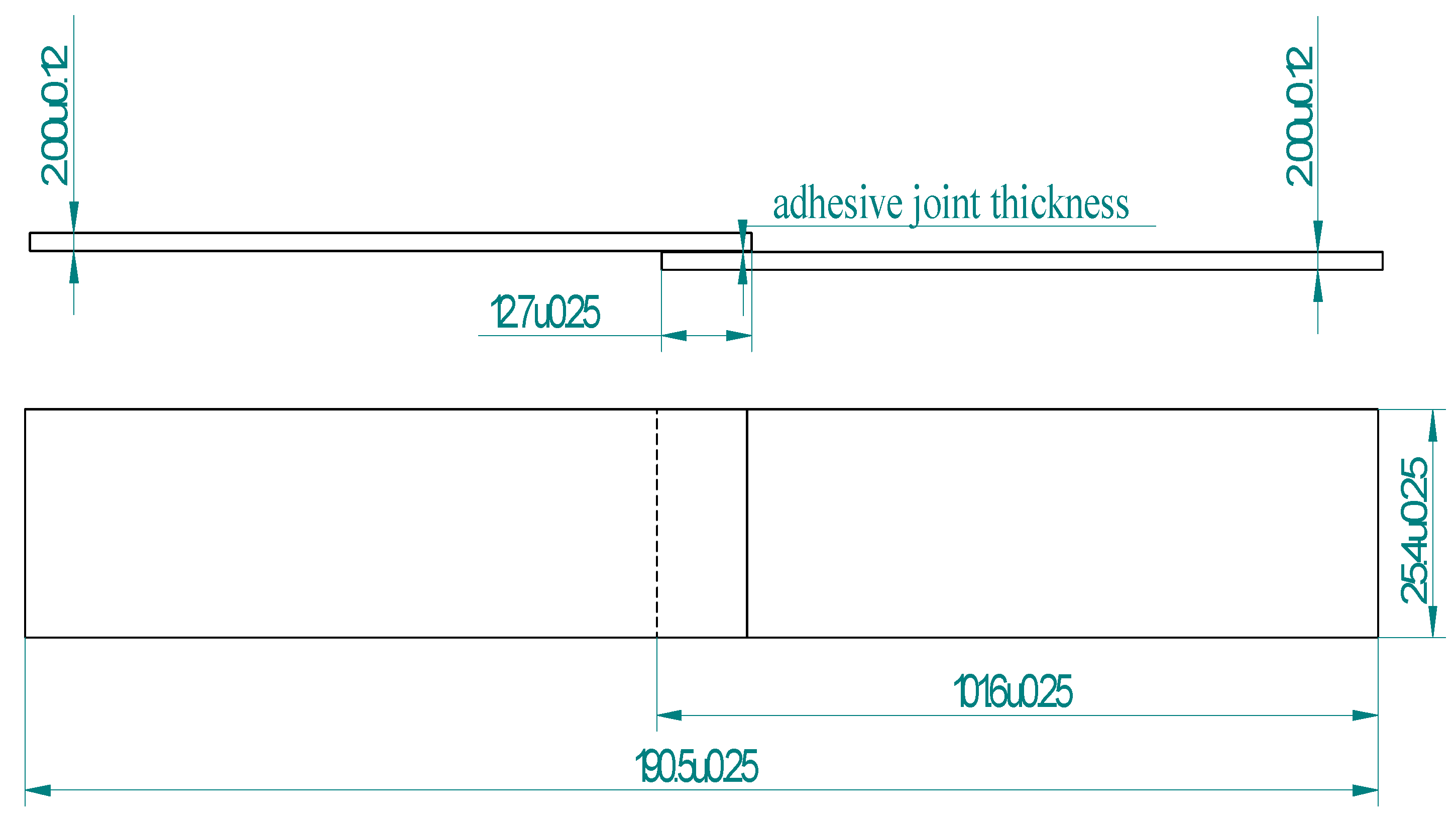

2.3. Shape and Dimension of Adhesive Joints and Specimen Preparation Conditions

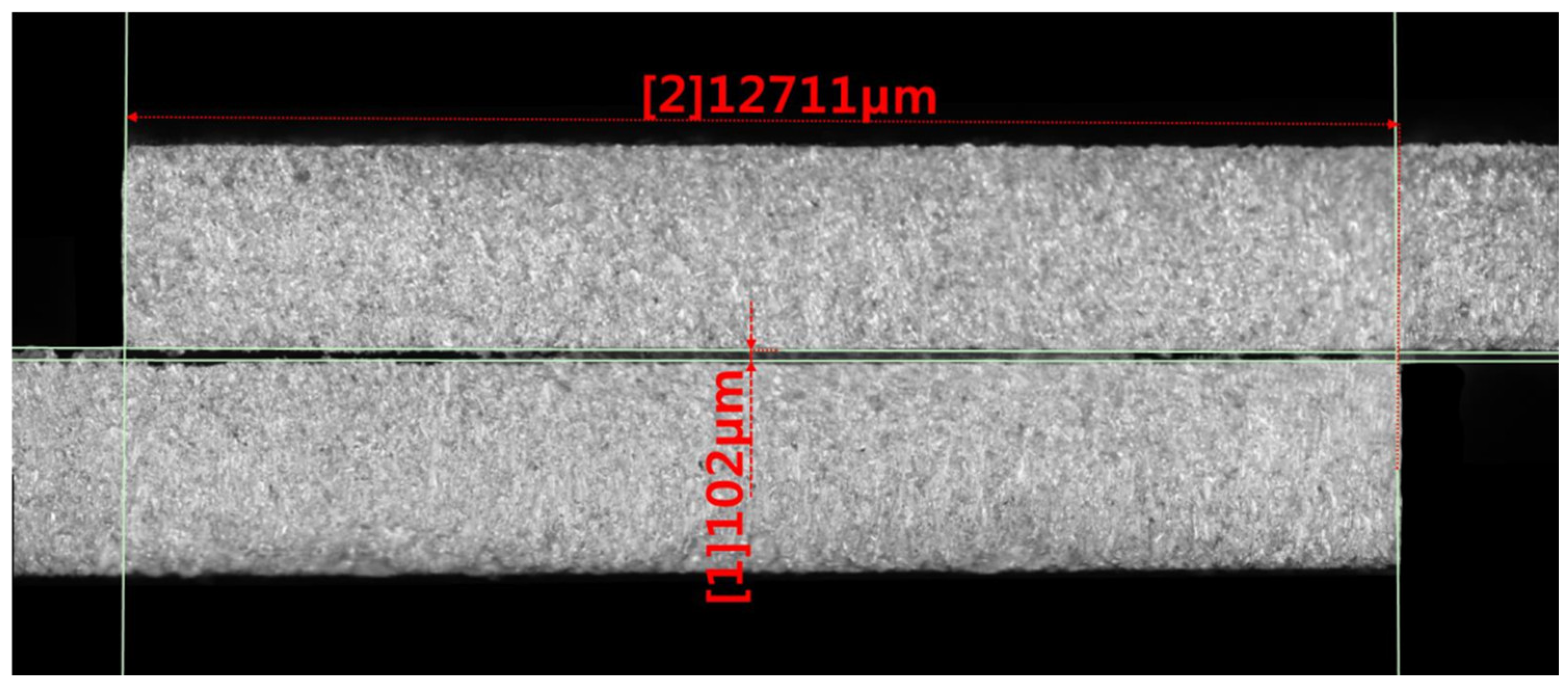

2.4. Surface Roughness

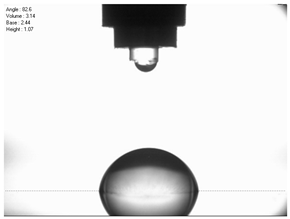

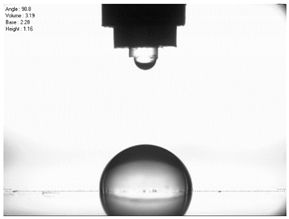

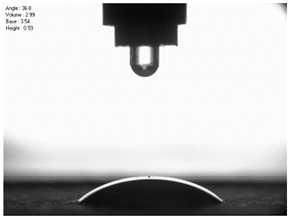

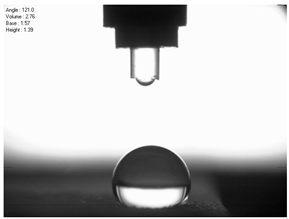

2.5. Surface Energy

2.6. Strength Test

3. Results and Discussion

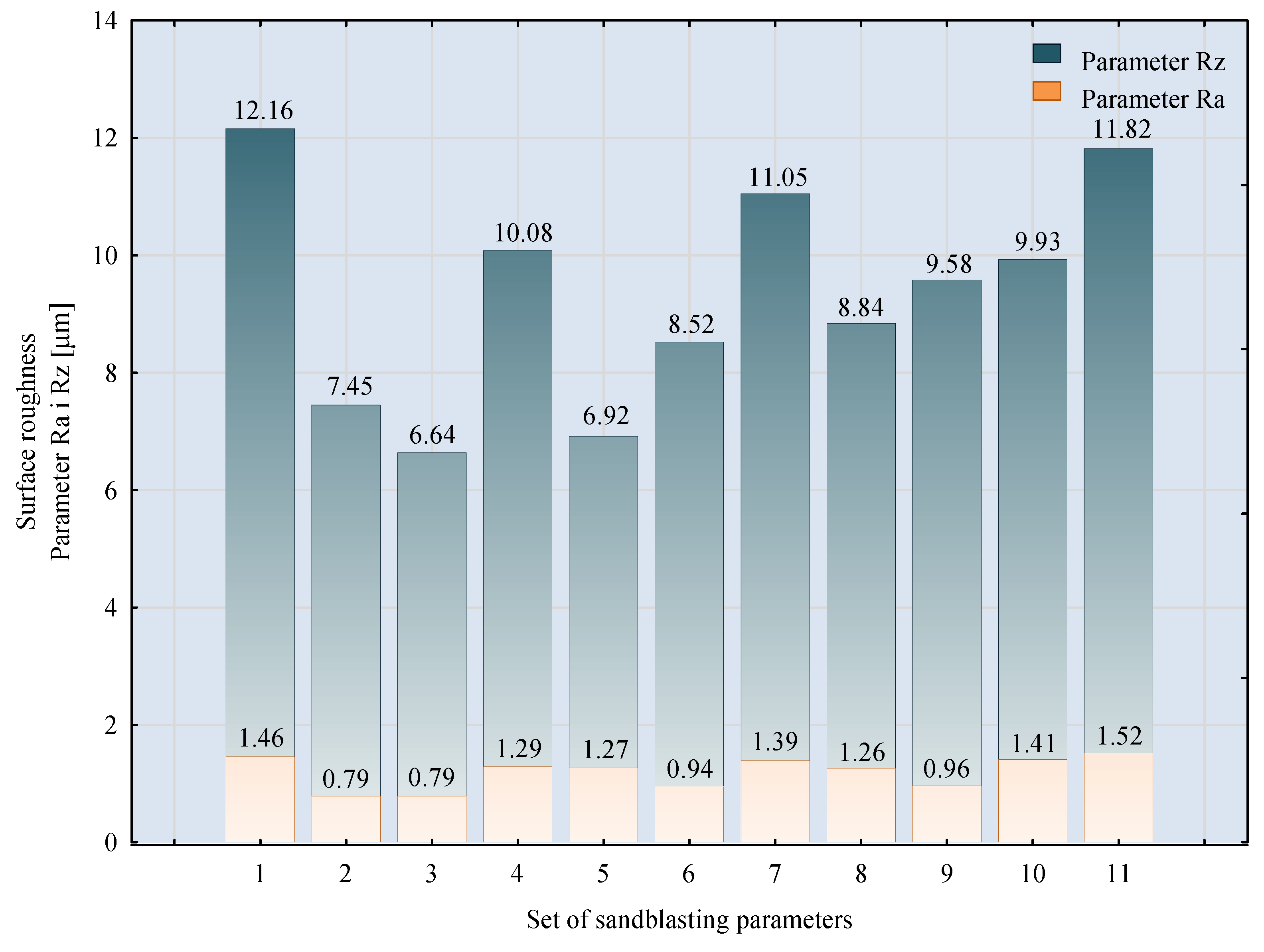

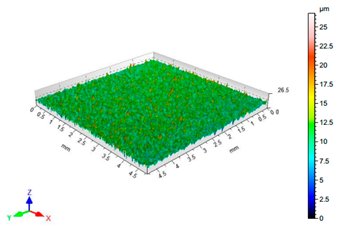

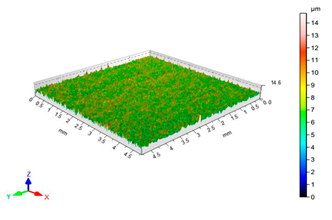

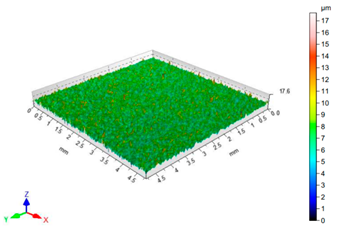

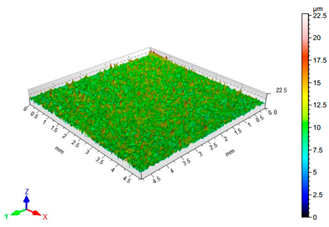

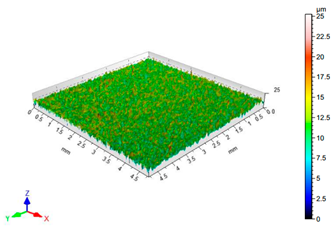

3.1. Surface Roughness

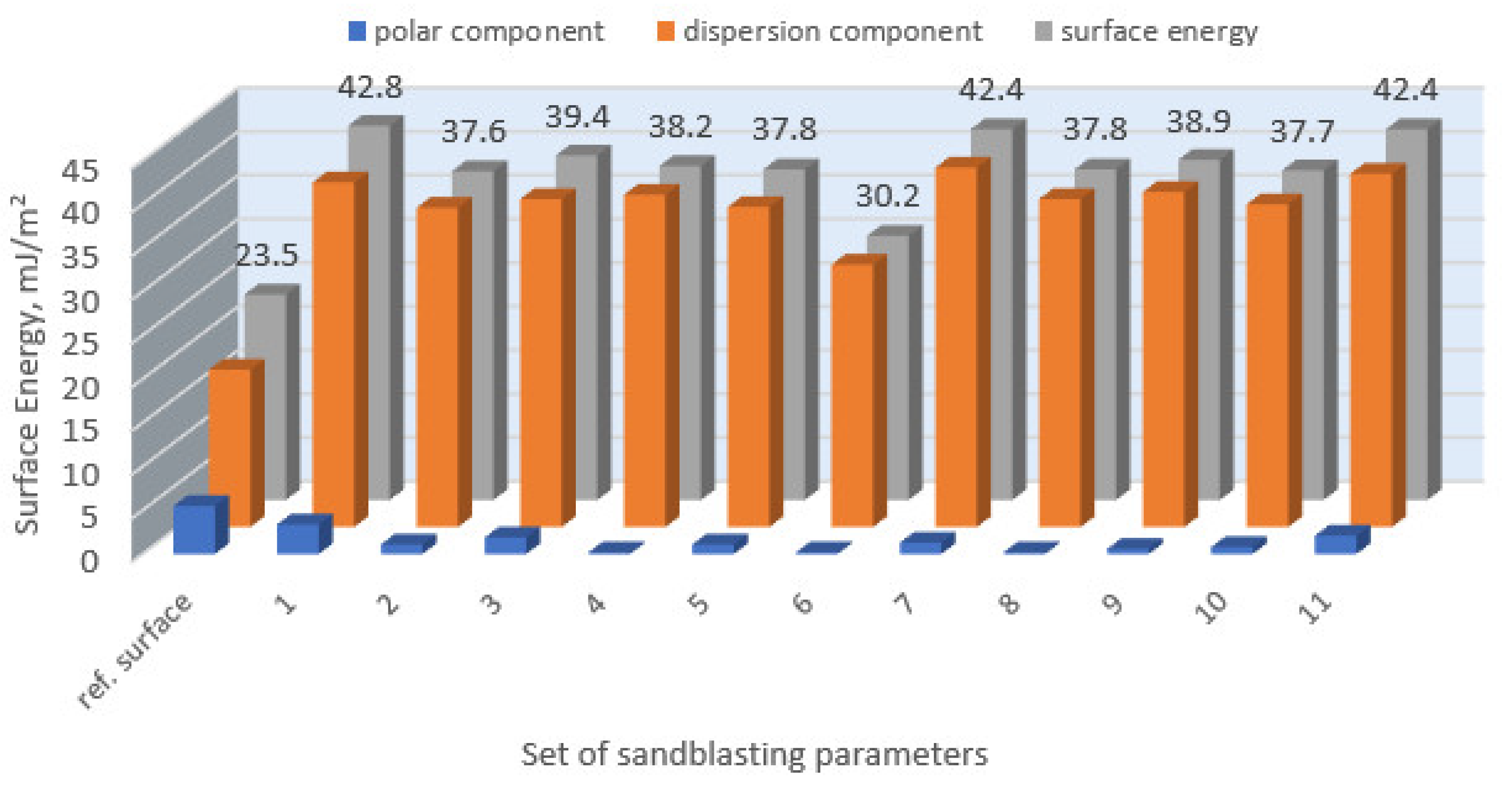

3.2. Surface Energy

3.3. Strength Test Results

4. Discussion

5. Conclusions

- Both the properties of the adhesive (in particular its viscosity) and the geometric structure of the adhesion surface, after the application of certain surface treatment methods, significantly influence the formation of the actual adhesive–binder interface, as this ensures relatively the high strength due to, among other things, the significant role of the mechanical adhesion;

- Increasing the ratio of valley depth to tip height as a result of changing sandblasting parameters, as evidenced by the change in Ra and Rz parameters, has a positive effect on the strength of the adhesive joints;

- Sandblasting parameters have a significant influence on the strength of adhesive joints. The selection of appropriate parameters is a key factor for obtaining a well-developed surface. The tests conducted here have determined that the pressure of the sandblasting process should not be less than Pa, the distance of the nozzle from the sandblasted surface should not be greater than 97 mm, and the speed at which the workpiece is displaced in relation to the nozzle should not be greater than 75 mm/min. Exceeding these parameters results in a decrease of the roughness profile parameters as well as the value of the surface free energy and thus in a decrease of the shear strength of the constituted adhesive joints;

- The joints with the highest strength were prepared by abrasive blasting with the following parameters: nozzle distance from the sample—h = 97 mm, blasting speed—V = 53 mm/min, pressure—P = Pa. In the case of these joints the highest result repeatability was also obtained.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ageorges, C.; Ye, L.; Hou, M. Advances in Fusion Bonding Techniques for Joining Thermoplastic Matrix Composites: A Review. Compos. Part A Appl. Sci. Manuf. 2001, 32, 839–857. [Google Scholar] [CrossRef]

- Martinsen, K.; Hu, S.J.; Carlson, B.E. Joining of Dissimilar Materials. CIRP Ann. 2015, 64, 679–699. [Google Scholar] [CrossRef]

- Wegman, R.F.; van Twisk, J. Surface Preparation Techniques for Adhesive Bonding, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2013; ISBN 978-1-4557-3126-8. [Google Scholar]

- Mahendran, G.; Balasubramanian, V.; Senthilvelan, T. Developing Diffusion Bonding Windows for Joining AZ31B Magnesium–AA2024 Aluminium Alloys. Mater. Des. 2009, 30, 1240–1244. [Google Scholar] [CrossRef]

- Bai, Y.; Yang, X. Novel Joint for Assembly of All-Composite Space Truss Structures: Conceptual Design and Preliminary Study. J. Compos. Constr. 2013, 17, 130–138. [Google Scholar] [CrossRef]

- Campbell, F.C. Manufacturing Technology for Aerospace Structural Materials, 1st ed.; Elsevier: Amsterdam, The Netherlands; Boston, MA, USA, 2006; ISBN 978-1-85617-495-4. [Google Scholar]

- Uddin, M.A.; Chan, H.P. Adhesive technology for photonics. In Advanced Adhesives in Electronics; Elsevier: Amsterdam, The Netherlands, 2011; pp. 214–258. ISBN 978-1-84569-576-7. [Google Scholar]

- Janda, R.; Roulet, J.-F.; Wulf, M.; Tiller, H.-J. A New Adhesive Technology for All-Ceramics. Dent. Mater. 2003, 19, 567–573. [Google Scholar] [CrossRef]

- Yoshida, Y.; Inoue, S. Chemical Analyses in Dental Adhesive Technology. Jpn. Dent. Sci. Rev. 2012, 48, 141–152. [Google Scholar] [CrossRef]

- Vaillancourt, A.; Abele, T. Adhesive Technology: Surface Preparation Techniques on Aluminum; Worcester Polytechnic Institute: Worcester, MA, USA, 2009. [Google Scholar]

- Adams, R.D.; Comyn, J.; Wake, W.C. Structural Adhesive Joints in Engineering, 2nd ed.; Chapman & Hall: London, UK, 1997; ISBN 978-0-412-70920-3. [Google Scholar]

- Banea, M.D.; da Silva, L.F.M. Adhesively Bonded Joints in Composite Materials: An Overview. Proc. IMechE 2009, 223, 1–18. [Google Scholar] [CrossRef]

- Fekete, J.R.; Hall, J.N. Design of auto body. In Automotive Steels; Elsevier: Amsterdam, The Netherlands, 2017; pp. 1–18. ISBN 978-0-08-100638-2. [Google Scholar]

- Słania, J.; Kuk, Ł. Process of Joining Materials to Build Vehicles and Motor-Car Bodies in the Automotive Industry. Weld. Technol. Rev. 2014, 86, 40–46. [Google Scholar]

- Da Silva, L.F.M.; Öchsner, A.; Adams, R.D. (Eds.) Handbook of Adhesion Technology; Springer: Heidelberg, Germany, 2011; ISBN 978-3-642-01168-9. [Google Scholar]

- Messler, R.W. Joining Composite Materials and Structures: Some Thought-Provoking Possibilities. J. Thermoplast. Compos. Mater. 2004, 17, 51–75. [Google Scholar] [CrossRef]

- Messler, R.W. Joining of Materials and Structures: From Pragmatic Process to Enabling Technology; Elsevier: Amsterdam, The Netherlands; Boston, MA, USA, 2004; ISBN 978-0-7506-7757-8. [Google Scholar]

- El-Tantawy, F.; Kamada, K.; Ohnabe, H. Electrical Properties and Stability of Epoxy Reinforced Carbon Black Composites. Mater. Lett. 2002, 57, 242–251. [Google Scholar] [CrossRef]

- Mays, G.; Hutchinson, A.R. Adhesives in Civil Engineering; Cambridge University Press: Cambridge, UK; New York, NY, USA, 1992; ISBN 978-0-521-32677-3. [Google Scholar]

- Saboori, A.; Aversa, A.; Marchese, G.; Biamino, S.; Lombardi, M.; Fino, P. Application of Directed Energy Deposition-Based Additive Manufacturing in Repair. Appl. Sci. 2019, 9, 3316. [Google Scholar] [CrossRef]

- Ziółkowski, M.; Dyl, T. Possible Applications of Additive Manufacturing Technologies in Shipbuilding: A Review. Machines 2020, 8, 84. [Google Scholar] [CrossRef]

- Barnes, T.A.; Pashby, I.R. Joining Techniques for Aluminium Spaceframes Used in Automobiles. J. Mater. Process. Technol. 2000, 99, 72–79. [Google Scholar] [CrossRef]

- Purr, S.; Meinhardt, J.; Lipp, A.; Werner, A.; Ostermair, M.; Glück, B. Stamping Plant 4.0—Basics for the Application of Data Mining Methods in Manufacturing Car Body Parts. Key Eng. Mater. 2015, 639, 21–30. [Google Scholar] [CrossRef]

- Mucha, J.; Kaščák, L.; Spišák, E. Joining the Car-Body Sheets Using Clinching Process with Various Thickness and Mechanical Property Arrangements. Arch. Civ. Mech. Eng. 2011, 11, 135–148. [Google Scholar] [CrossRef]

- Bishopp, J. Chapter 5 Aerospace: A pioneer in structural adhesive bonding. In Handbook of Adhesives and Sealants; Elsevier: Amsterdam, The Netherlands, 2005; Volume 1, pp. 215–347. ISBN 978-0-08-044554-0. [Google Scholar]

- Bhowmik, S.; Bonin, H.W.; Bui, V.T.; Weir, R.D. Durability of Adhesive Bonding of Titanium in Radiation and Aerospace Environments. Int. J. Adhes. Adhes. 2006, 26, 400–405. [Google Scholar] [CrossRef]

- Kwakernaak, A.; Hofstede, J.; Poulis, J.; Benedictus, R. Improvements in bonding metals for aerospace and other applications. In Welding and Joining of Aerospace Materials; Elsevier: Amsterdam, The Nethrerlands, 2012; pp. 229–275. ISBN 978-0-12-819140-8. [Google Scholar]

- Ebnesajjad, S. Adhesives Technology Handbook, 2nd ed.; William Andrew Pub: Norwich, NY, USA, 2008; ISBN 978-0-8155-1533-3. [Google Scholar]

- Da Silva, L.F.M.; Carbas, R.J.C.; Critchlow, G.W.; Figueiredo, M.A.V.; Brown, K. Effect of Material, Geometry, Surface Treatment and Environment on the Shear Strength of Single Lap Joints. Int. J. Adhes. Adhes. 2009, 29, 621–632. [Google Scholar] [CrossRef]

- Rudawska, A.; Maziarz, M.; Miturska, I. Impact of Selected Structural, Material and Exploitation Factors on Adhesive Joints Strength. MATEC Web Conf. 2019, 252, 01006. [Google Scholar] [CrossRef][Green Version]

- Critchlow, G.W.; Yendall, K.A.; Bahrani, D.; Quinn, A.; Andrews, F. Strategies for the Replacement of Chromic Acid Anodising for the Structural Bonding of Aluminium Alloys. Int. J. Adhes. Adhes. 2006, 26, 419–453. [Google Scholar] [CrossRef]

- Rudawska, A.; Zaleski, K.; Miturska, I.; Skoczylas, A. Effect of the Application of Different Surface Treatment Methods on the Strength of Titanium Alloy Sheet Adhesive Lap Joints. Materials 2019, 12, 4173. [Google Scholar] [CrossRef]

- Leahy, W.; Barron, V.; Buggy, M.; Young, T.; Mas, A.; Schue, F.; McCabe, T.; Bridge, M. Plasma Surface Treatment of Aerospace Materials for Enhanced Adhesive Bonding. J. Adhes. 2001, 77, 215–249. [Google Scholar] [CrossRef]

- Romoli, L.; Moroni, F.; Khan, M.M.A. A Study on the Influence of Surface Laser Texturing on the Adhesive Strength of Bonded Joints in Aluminium Alloys. CIRP Ann. 2017, 66, 237–240. [Google Scholar] [CrossRef]

- Santos, M.C.; Machado, A.R.; Sales, W.F.; Barrozo, M.A.S.; Ezugwu, E.O. Machining of Aluminum Alloys: A Review. Int. J. Adv. Manuf. Technol. 2016, 86, 3067–3080. [Google Scholar] [CrossRef]

- Khan, F.; Qayyum, F.; Asghar, W.; Azeem, M.; Anjum, Z.; Nasir, A.; Shah, M. Effect of Various Surface Preparation Techniques on the Delamination Properties of Vacuum Infused Carbon Fiber Reinforced Aluminum Laminates (CARALL): Experimentation and Numerical Simulation. J. Mech. Sci. Technol. 2017, 31, 5265–5272. [Google Scholar] [CrossRef]

- Ramaswamy, K.; O’Higgins, R.M.; Kadiyala, A.K.; McCarthy, M.A.; McCarthy, C.T. Evaluation of Grit-Blasting as a Pre-Treatment for Carbon-Fibre Thermoplastic Composite to Aluminium Bonded Joints Tested at Static and Dynamic Loading Rates. Compos. Part B: Eng. 2020, 185, 107765. [Google Scholar] [CrossRef]

- Bhatt, B.D.; Radhakrishnan, V. Evaluation of Some Machining Processes as Adherend Surface Treatments in Bonding Aluminium. J. Adhes. Sci. Technol. 1989, 3, 383–396. [Google Scholar] [CrossRef]

- Rotella, G.; Alfano, M.; Schiefer, T.; Jansen, I. Evaluation of Mechanical and Laser Surface Pre-Treatments on the Strength of Adhesive Bonded Steel Joints for the Automotive Industry. J. Adhes. Sci. Technol. 2016, 30, 747–758. [Google Scholar] [CrossRef]

- Rudawska, A.; Reszka, M.; Warda, T.; Miturska, I.; Szabelski, J.; Stančeková, D.; Skoczylas, A. Milling as a Method of Surface Pre-Treatment of Steel for Adhesive Bonding. J. Adhes. Sci. Technol. 2016, 30, 2619–2636. [Google Scholar] [CrossRef]

- Prolongo, S.G.; Ureña, A. Effect of Surface Pre-Treatment on the Adhesive Strength of Epoxy–Aluminium Joints. Int. J. Adhes. Adhes. 2009, 29, 23–31. [Google Scholar] [CrossRef]

- Rudawska, A. Surface Free Energy and Geometric Structures of the Surfaces of Selected Epoxy Composites. Polimery 2008, 53, 452–456. [Google Scholar] [CrossRef]

- Tian, Y.; Shen, J.; Hu, S.; Liang, Y.; Bai, P. Effects of Ultrasonic Peening Treatment on Surface Quality of CMT-Welds of Al Alloys. J. Mater. Process. Technol. 2018, 254, 193–200. [Google Scholar] [CrossRef]

- Kang, B.; Ma, H.; Li, J.; Xu, B. Effect of Grinding Parameters on Surface Quality, Microstructure and Rolling Contact Fatigue Behaviors of Gear Steel for Vacuum Pump. Vacuum 2020, 180, 109637. [Google Scholar] [CrossRef]

- Al-Obaid, Y.F. Shot Peening Mechanics: Experimental and Theoretical Analysis. Mech. Mater. 1995, 19, 251–260. [Google Scholar] [CrossRef]

- Kumosa, L. The Effect of Sandblasting on the Initiation of Stress Corrosion Cracking in Unidirectional E-Glass/Polymer Composites Used in High Voltage Composite (Non-Ceramic) Insulators. Compos. Sci. Technol. 2002, 62, 1999–2015. [Google Scholar] [CrossRef]

- Rudawska, A.; Danczak, I.; Müller, M.; Valasek, P. The Effect of Sandblasting on Surface Properties for Adhesion. Int. J. Adhes. Adhes. 2016, 70, 176–190. [Google Scholar] [CrossRef]

- Millman, L.R.; Giancaspro, J.W. Environmental Evaluation of Abrasive Blasting with Sand, Water, and Dry Ice. Int. J. Archit. Eng. Constr. 2012, 1, 174–182. [Google Scholar] [CrossRef]

- Malli, M. Review on Shot Blasting Processes. Int. J. Sci. Res. 2014, 2, 707–709. [Google Scholar]

- Rudawska, A.; Miturska, I. Impact Study of Single Stage and Multi Stage Abrasive Machining on Static Strength of Lap Adhesive Joints of Mild Steel. MATEC Web Conf. 2018, 244, 02006. [Google Scholar] [CrossRef][Green Version]

- Gomes, A.L.; Castillo-Oyagüe, R.; Lynch, C.D.; Montero, J.; Albaladejo, A. Influence of Sandblasting Granulometry and Resin Cement Composition on Microtensile Bond Strength to Zirconia Ceramic for Dental Prosthetic Frameworks. J. Dent. 2013, 41, 31–41. [Google Scholar] [CrossRef] [PubMed]

- Barletta, M. Progress in Abrasive Fluidized Bed Machining. J. Mater. Process. Technol. 2009, 209, 6087–6102. [Google Scholar] [CrossRef]

- Inspection Certificate No 1828896CZ of the Material Supplier Adamet-Niemet.

- BS EN 4400-2:2019—Aerospace Series. Aluminium and Aluminium- and Magnesium-Alloys. Technical Specification. Aluminium and Aluminium Alloy Sheet and Strip. Available online: https://www.mystandards.biz/standard/bsen-4400-2-2019-12.4.2019.html (accessed on 5 October 2021).

- Górecka, R. Theory and Technique of Experimentation; Tadeusz Kościuszko Krakow University of Technology: Krakow, Poland, 1996. [Google Scholar]

- BN-89 6376-02—Industry Standard. Epoxy Resins Epidian 1, 2, 3, 4, 5, 6; Wydawnictwa Normalizacyjne “ALFA”: Warsaw, Poland, 1989. (In Polish)

- Information Catalogue of Ciech S.A. Available online: https://Ciechgroup.Com/Produkty/Chemia-Organiczna/Zywice/Zywice-Epoksydowe/ (accessed on 20 February 2018).

- Bereska, B.; Iłowska, J.; Czaja, K.; Bereska, A. Curing Agents for Epoxy Resins. Chem. Ind. 2014, 93, 443–448. [Google Scholar]

- ASTM D1002—Standard Test Method for Apparent Shear Strength of Single-Lap-Joint Adhesively Bonded Metal Specimens by Tension Loading (Metal-to-Metal); ASTM International: West Conshohocken, PA, USA, 2019.

- PN-EN ISO 25178—Product Geometry Specifications—Geometric Structure of the Surface: Spatial. Available online: https://sklep.pkn.pl/pn-en-iso-25178-600-2019-05e.html (accessed on 5 October 2021).

- Rudawska, A.; Jacniacka, E. Evaluating Uncertainty of Surface Free Energy Measurement by the van Oss-Chaudhury-Good Method. Int. J. Adhes. Adhes. 2018, 82, 139–145. [Google Scholar] [CrossRef]

- Baldan, A. Adhesion Phenomena in Bonded Joints. Int. J. Adhes. Adhes. 2012, 38, 95–116. [Google Scholar] [CrossRef]

- Park, S.-J.; Cho, M.-S.; Lee, J.-R. Studies on the Surface Free Energy of Carbon–Carbon Composites: Effect of Filler Addition on the ILSS of Composites. J. Colloid Interface Sci. 2000, 226, 60–64. [Google Scholar] [CrossRef] [PubMed]

- Ma, C.; Suslov, S.; Ye, C.; Dong, Y. Improving Plasticity of Metallic Glass by Electropulsing-Assisted Surface Severe Plastic Deformation. Mater. Des. 2019, 165, 107581. [Google Scholar] [CrossRef]

- Mao, B.; Liao, Y.; Li, B. Gradient Twinning Microstructure Generated by Laser Shock Peening in an AZ31B Magnesium Alloy. Appl. Surf. Sci. 2018, 457, 342–351. [Google Scholar] [CrossRef]

- Multigner, M.; Ferreira-Barragáns, S.; Frutos, E.; Jaafar, M.; Ibáñez, J.; Marín, P.; Pérez-Prado, M.T.; González-Doncel, G.; Asenjo, A.; González-Carrasco, J.L. Superficial Severe Plastic Deformation of 316 LVM Stainless Steel through Grit Blasting: Effects on Its Microstructure and Subsurface Mechanical Properties. Surf. Coat. Technol. 2010, 205, 1830–1837. [Google Scholar] [CrossRef]

- Li, J.; Du, A.; Fan, Y.; Zhao, X.; Ma, R.; Wu, J. Effect of Shot-Blasting Pretreatment on Microstructures of Hot-Dip Galvanized Coating. Surf. Coat. Technol. 2019, 364, 218–224. [Google Scholar] [CrossRef]

- Staia, M.H.; Ramos, E.; Carrasquero, A.; Roman, A.; Lesage, J.; Chicot, D.; Mesmacque, G. Effect of Substrate Roughness Induced by Grit Blasting upon Adhesion of WC-17% Co Thermal Sprayed Coatings. Thin Solid Films 2000, 377–378, 657–664. [Google Scholar] [CrossRef]

- Rudawska, A.; Szabelski, J.; Abdel Wahab, M.; Miturska, I. Impact of Abrasive Blasting Media on the Strength of Steel Sheets Adhesively Bonded Joints. In Proceedings of the 8th International Conference on Fracture, Fatigue and Wear, Virtual Conference, 26–27 August 2020; pp. 81–95, ISBN 9789811598920. [Google Scholar]

- Mandolfino, C.; Lertora, E.; Gambaro, C. Effect of Surface Pretreatment on the Performance of Adhesive-Bonded Joints. Key Eng. Mater. 2013, 554–557, 996–1006. [Google Scholar] [CrossRef]

| The Element | Contents, % |

|---|---|

| Si | 0.1671 |

| Fe | 0.2153 |

| Cu | 4.0975 |

| Mn | 0.4281 |

| Mg | 1.4405 |

| Cr | 0.0053 |

| Zn | 0.0154 |

| Ti | 0.0191 |

| Al | 93.5699 |

| Mechanical Properties | Value |

|---|---|

| Tensile strength | 447.2 MPa |

| Yield strength | 302.5 MPa |

| Elongation | 16.5% |

| Hardness | 123 HB |

| Thermal conductivity | 170 W/mK |

| Thermal conductivity | 2.78 g/cm3 |

| Parameter | Parameter Value |

|---|---|

| X1—distance of the nozzle from the sample surface | 40 ≤ X1 ≤ 155 [mm] |

| X2—speed of sample displacement | 50 ≤ X2 ≤ 100 [mm/min] |

| X3—sandblasting pressure | ≤ X3 ≤ [Pa] |

| Number of Parameter Sets Sandblasting | X1 | X2 | X3 |

|---|---|---|---|

| Distance of the Nozzle from the Sample Surface (mm) | Speed of Sample Displacement (mm/min) | Sandblasting Pressure (Pa) | |

| 1 | 69 | 62 | |

| 2 | 126 | 62 | |

| 3 | 69 | 87 | |

| 4 | 126 | 87 | |

| 5 | 48 | 75 | |

| 6 | 147 | 75 | |

| 7 | 97 | 53 | |

| 8 | 97 | 96 | |

| 9 | 97 | 75 | |

| 10 | 97 | 75 | |

| 11 | 97 | 75 |

| Properties | Epidian 5 Epoxy Resin |

|---|---|

| Epoxy number | 0.48–0.52 mol/100 g |

| pH value | approx. 7 |

| Viscosity at 25 °C | 20,000–30,000 mPa·s |

| Density at 20 °C | 1.16 g/cm3 |

| Flash point | 266 °C |

| Auto-ignition temperature | 490 °C |

| Melting point | 30–50 °C |

| Boiling point initial | not indicated—decomposition |

| Properties | Polyamide Hardener (PAC Curing Agent) |

|---|---|

| Viscosity at 25 °C | 10,000–25,000 mPa·s |

| Density at 20 °C | 1.10–1.20 g/cm3 |

| Amine number | 290–360 mg KOH/g |

| Gel time (for example, for a composition with Epidian 5 at 20 °C, for a 100 g sample) | 180 min |

| Curing Process Parameter | Parameter Value |

|---|---|

| Pressure | Pa |

| Temperature | 23 ± 2 °C |

| Humidity | 23 ± 3% |

| Time | 7 days |

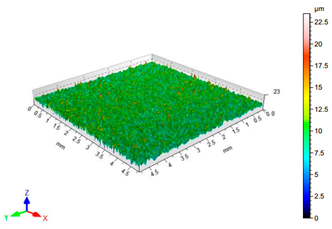

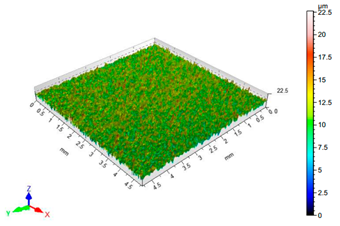

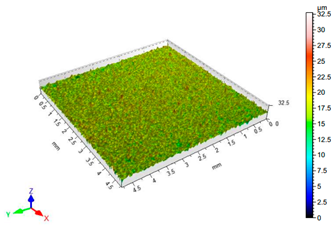

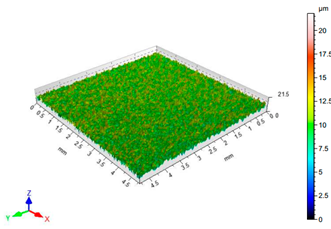

| Number of Parameter Sets Sandblasting | Surface Topography | Surface Profile Height Parameters |

|---|---|---|

| 1 |  | Sa = 1.49 μm Sz = 26.8 μm |

| 2 |  | Sa = 0.82 μm Sz = 14.8 μm |

| 3 |  | Sa = 0.90 μm Sz = 17.7 μm |

| 4 |  | Sa = 1.41 μm Sz = 23.5 μm |

| 5 |  | Sa = 1.57 μm Sz = 22.6 μm |

| 6 |  | Sa = 0.97 μm Sz = 19.0 μm |

| 7 |  | Sa = 1.43 μm Sz = 32.8 μm |

| 8 |  | Sa = 1.31 μm Sz = 21.8 μm |

| 9 |  | Sa = 1.02 μm Sz = 22.7 μm |

| 10 |  | Sa = 1.51 μm Sz = 28.3 μm |

| 11 |  | Sa = 1.58 μm Sz = 25.3 μm |

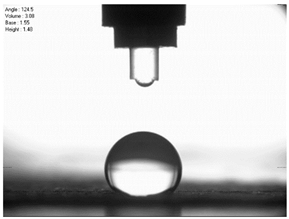

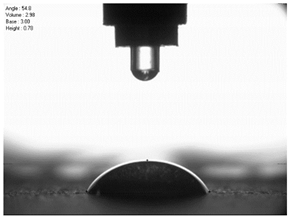

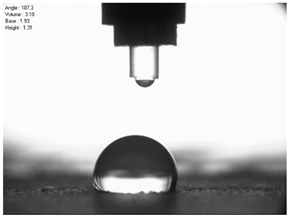

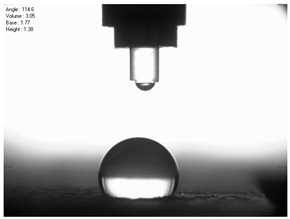

| Number of Parameter sets Sandblasting | Droplet and Value of Contact Angle Measurement with Diiodomethane | Droplet and Value of Contact Angle Measurement with Water |

|---|---|---|

| reference surface |  |  |

| 1 |  |  |

| 2 | ||

| 3 | ||

| 4 | ||

| 5 | ||

| 6 |  |  |

| 7 |  |  |

| 8 | ||

| 9 | ||

| 10 | ||

| 11 |  |  |

| Number of Parameter Sets Sandblasting | The Value of the W Shapiro–Wilk | Level p for the W Shapiro–Wilk |

|---|---|---|

| 1 | 0.946 | 0.711 |

| 2 | 0.939 | 0.649 |

| 3 | 0.726 | 0.017 |

| 4 | 0.974 | 0.905 |

| 5 | 0.791 | 0.087 |

| 6 | 0.884 | 0.357 |

| 7 | 0.889 | 0.352 |

| 8 | 0.844 | 0.177 |

| 9 | 0.927 | 0.580 |

| 10 | 0.973 | 0.898 |

| 11 | 0.791 | 0.068 |

| Number of Parameter Sets Sandblasting | Average Shear Strength Rt (MPa) | Homogeneous Groups | ||||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | ||

| 7 | 19.26 | *** | ||||

| 1 | 17.68 | *** | ||||

| 10 | 17.04 | *** | *** | |||

| 3 | 13.87 | *** | *** | |||

| 8 | 13.31 | *** | ||||

| 5 | 13.13 | *** | ||||

| 4 | 12.28 | *** | *** | |||

| 11 | 12.22 | *** | *** | |||

| 2 | 11.92 | *** | *** | |||

| 6 | 8.84 | *** | *** | |||

| 9 | 7.60 | *** | ||||

| Correlations Indicated Correlation Coefficients Are Significant with p < 0.05 | ||||||

|---|---|---|---|---|---|---|

| Average | Standard Deviation | r (X,Y) | r2 | t | p | |

| Shear strength (MPa) | 13.38 | 3.54 | ||||

| Parameter Ra (μm) | 1.19 | 0.27 | 0.57 | 0.33 | 2.10 | 0.07 |

| Shear strength (MPa) | 13.38 | 3.54 | ||||

| Parameter Rz (μm) | 9.40 | 1.96 | 0.39 | 0.15 | 1.27 | 0.24 |

| Shear strength (MPa) | 13.38 | 3.54 | ||||

| Parameter Sa (μm) | 1.27 | 0.29 | 0.53 | 0.29 | 1.90 | 0.09 |

| Shear strength (MPa) | 13.38 | 3.54 | ||||

| Parameter Sz (μm) | 23.21 | 5.07 | 0.67 | 0.44 | 2.68 | 0.03 |

| Shear strength (MPa) | 13.38 | 3.54 | ||||

| SFE (mJ/m2) | 38.65 | 3.48 | 0.58 | 0.34 | 2.14 | 0.06 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Miturska-Barańska, I.; Rudawska, A.; Doluk, E. The Influence of Sandblasting Process Parameters of Aerospace Aluminium Alloy Sheets on Adhesive Joints Strength. Materials 2021, 14, 6626. https://doi.org/10.3390/ma14216626

Miturska-Barańska I, Rudawska A, Doluk E. The Influence of Sandblasting Process Parameters of Aerospace Aluminium Alloy Sheets on Adhesive Joints Strength. Materials. 2021; 14(21):6626. https://doi.org/10.3390/ma14216626

Chicago/Turabian StyleMiturska-Barańska, Izabela, Anna Rudawska, and Elżbieta Doluk. 2021. "The Influence of Sandblasting Process Parameters of Aerospace Aluminium Alloy Sheets on Adhesive Joints Strength" Materials 14, no. 21: 6626. https://doi.org/10.3390/ma14216626

APA StyleMiturska-Barańska, I., Rudawska, A., & Doluk, E. (2021). The Influence of Sandblasting Process Parameters of Aerospace Aluminium Alloy Sheets on Adhesive Joints Strength. Materials, 14(21), 6626. https://doi.org/10.3390/ma14216626