Application of Coal Gangue as a Coarse Aggregate in Green Concrete Production: A Review

Abstract

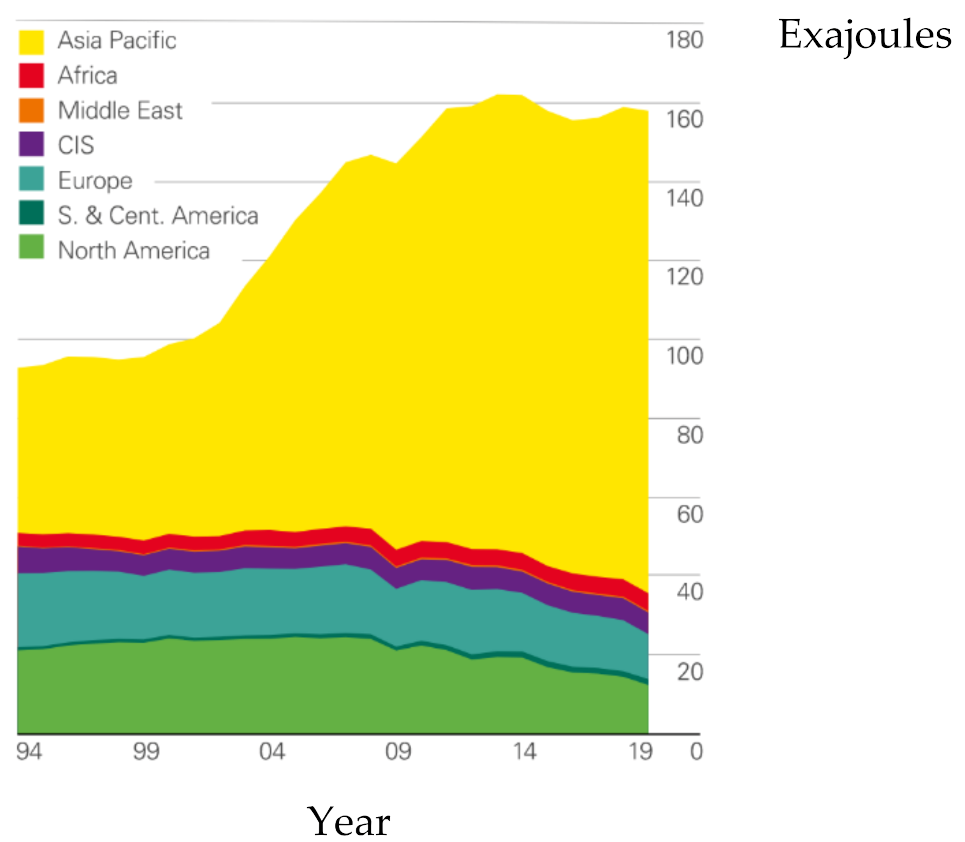

:1. Introduction

2. Utilization of Coal Gangue

3. Methods

- (1)

- The presence of terms “coal gangue” and “coarse aggregate” in the documents;

- (2)

- The considered period: 1990–2020;

- (3)

- The publication form of paper: “Article” or “Review”;

- (4)

- Searching area: “Engineering” and “Material”.

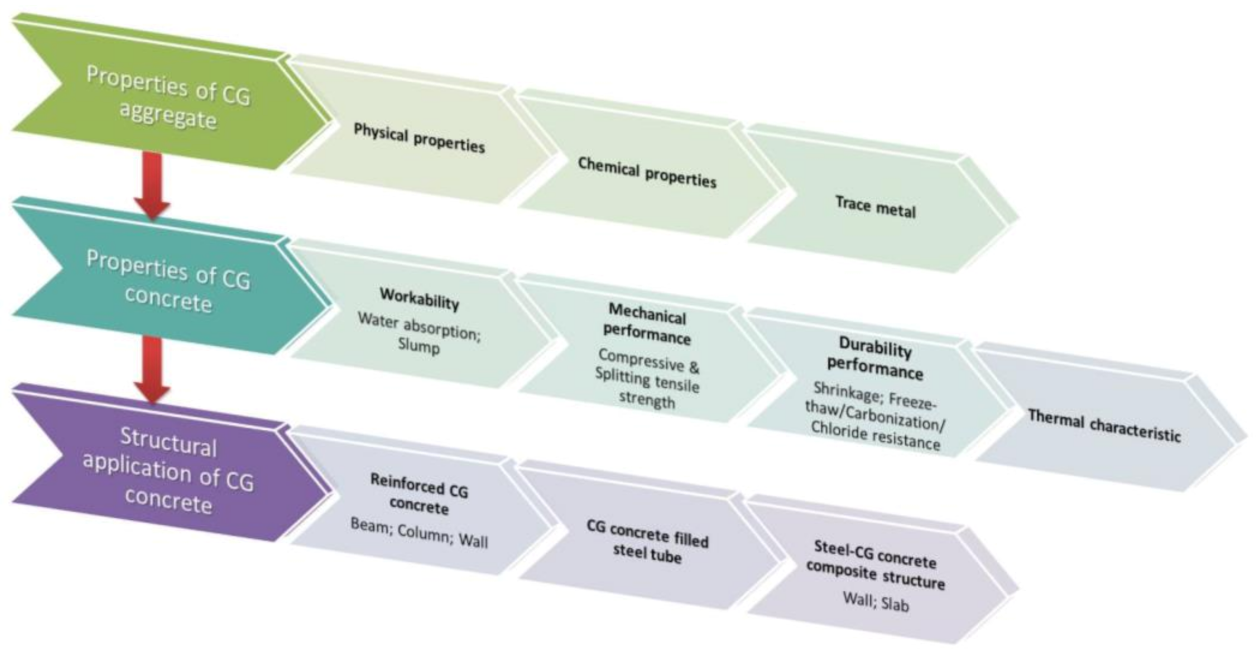

4. Properties of Coal Gangue Aggregate

4.1. Physical Properties

4.2. Chemical Properties

4.3. Trace Metal

5. Properties of Coal Gangue Concrete

5.1. Workability

5.1.1. Water Absorption

5.1.2. Slump

5.2. Mechanical Performance

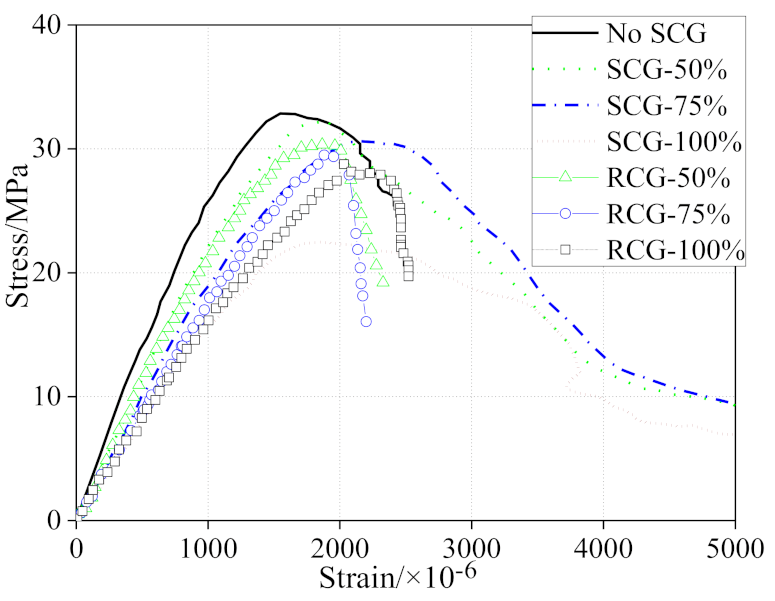

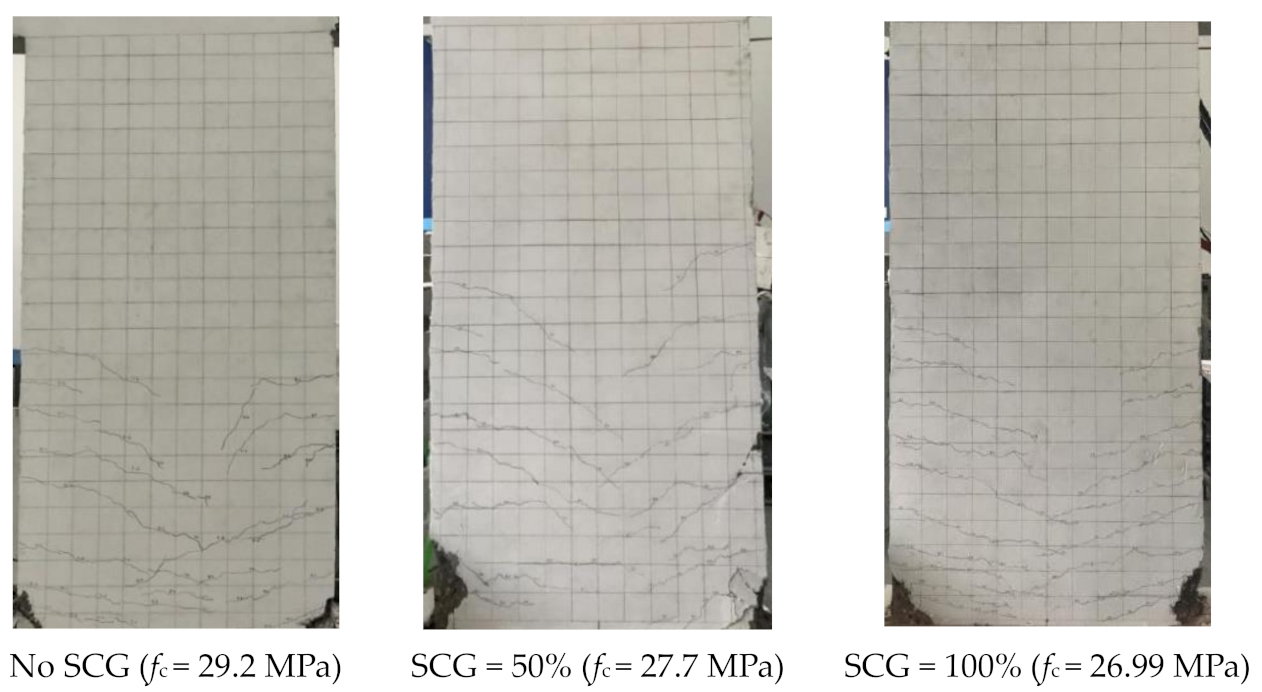

5.2.1. Compressive Strength

5.2.2. Splitting Tensile Strength

5.3. Durability Performance

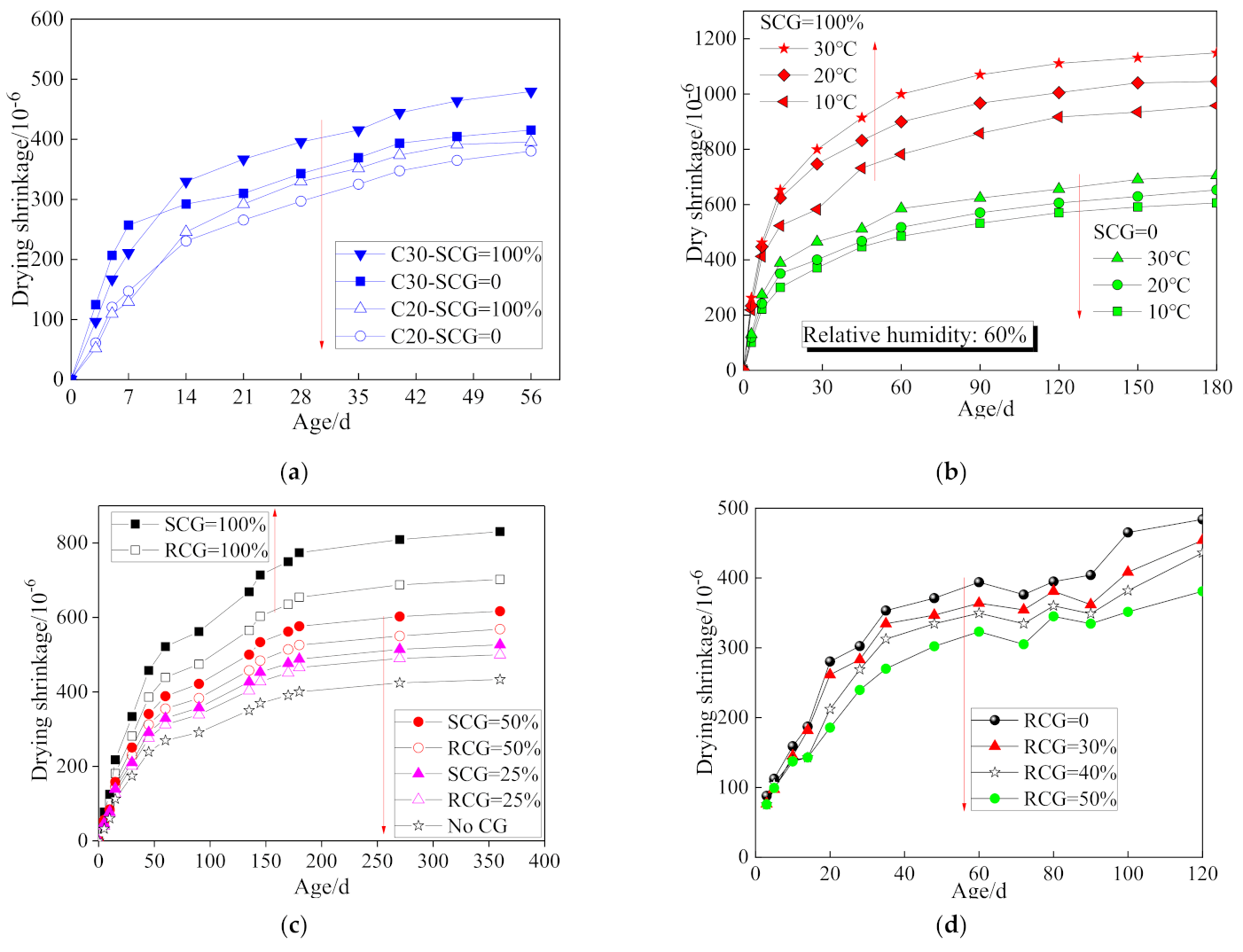

5.3.1. Shrinkage

5.3.2. Freeze−Thaw Resistance

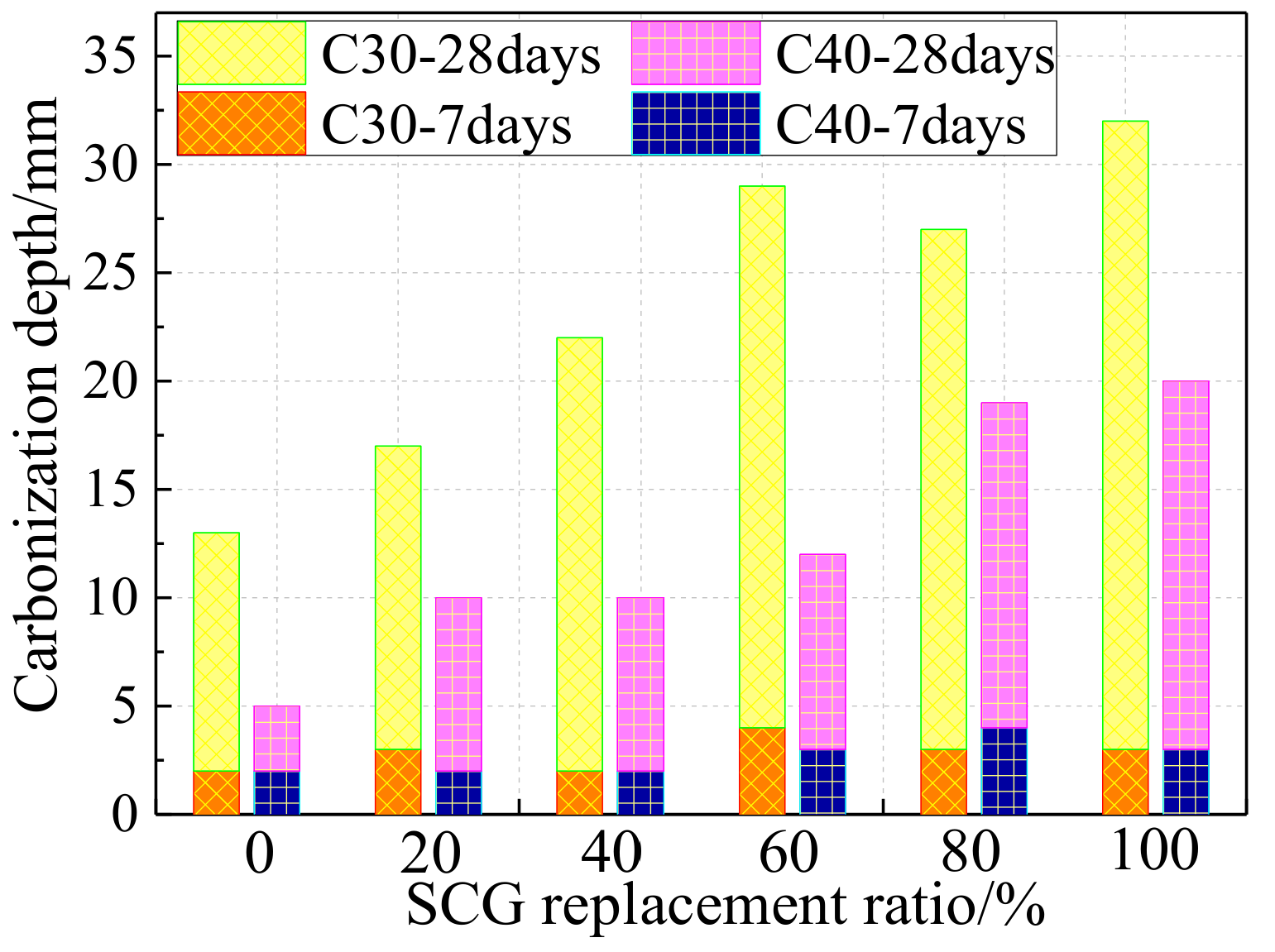

5.3.3. Carbonization Resistance

5.3.4. Chloride Resistance

5.4. Thermal Characteristic

6. Application of Coal Gangue Concrete

6.1. Reinforced Coal Gangue Concrete

6.1.1. Beam

6.1.2. Column

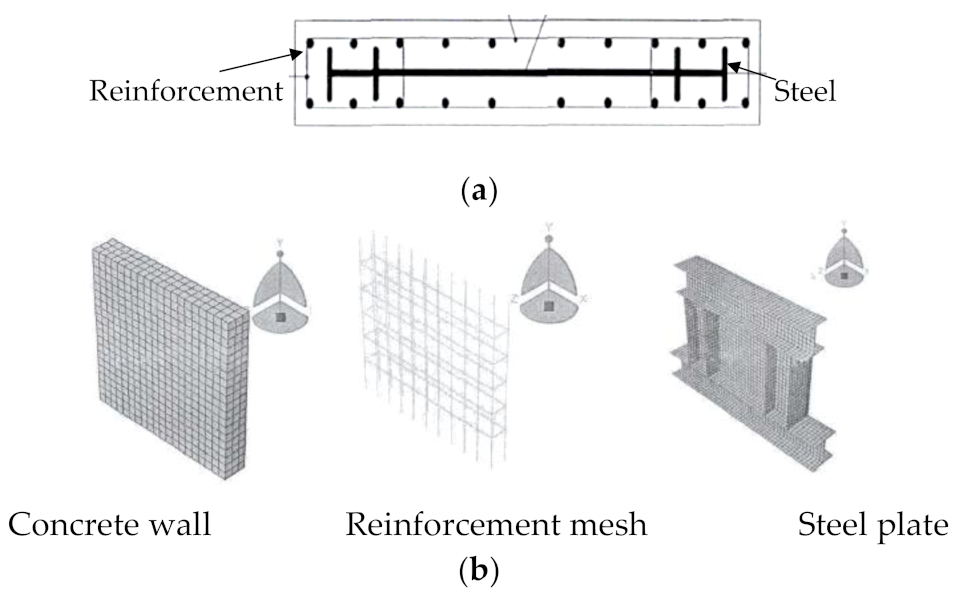

6.1.3. Wall

6.2. Coal Gangue Concrete Filled Steel Tube

6.3. Steel−Coal Gangue Concrete Composite Structure

6.3.1. Wall

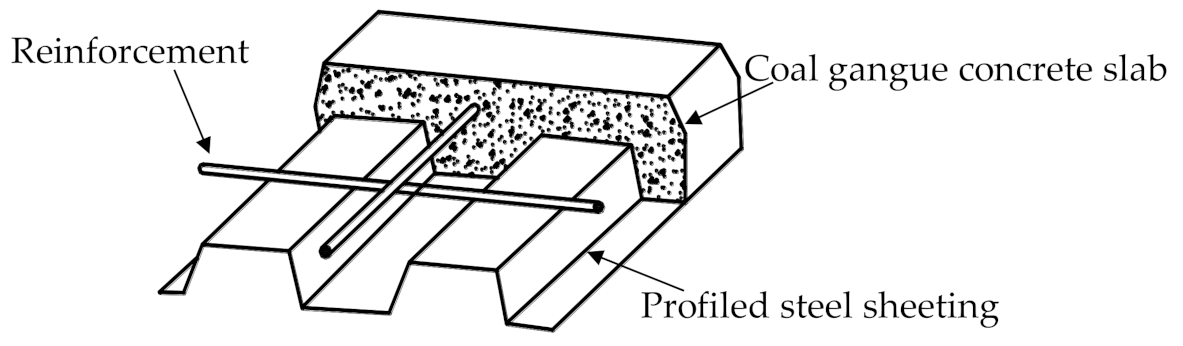

6.3.2. Slab

7. Discussion and Research Gap

- (1)

- The physical properties of RCG and SCG should be investigated comparatively in particular, since they are quite crucial to the properties of coal gangue concrete. In other words, the physical change of coal gangue as a coarse aggregate in concrete mixture before and after spontaneous/artificial combustion should be compared and identified quantitatively.

- (2)

- Even though the main content in the chemical composition of RCG and SCG is actually stable, heavy metal and organic matter leaching of RCG and SCG should be studied comparatively. More specific permission regarding heavy metal and organic matter leaching in coal gangue should be issued by governments to avoid posing environmental, health, and safety concerns.

- (3)

- The workability of coal gangue concrete significantly varies from the gangue origins, which makes the improvement method ineffective in some cases. This phenomenon may be solved if the physical properties of coal gangue are assessed more accurately. A proper index to assess the workability of coal gangue concrete for practical use should also be proposed based on more experimental data.

- (4)

- Even though the degradation effect of coal gangue aggregate on the mechanical properties of coal gangue concrete is obvious, the empirical stress−strain model should be validated against more data. In particular, the elastic modulus and tensile strength of coal gangue concrete have not been described through theoretical models, not to mention bending and creep performance and damage accumulation process.

- (5)

- The studies on the durability performance of coal gangue concrete are directly related to the properties of the coal gangue aggregate. Therefore, the specific properties and replacement ratio of coal gangue should be considered in the prediction formulas regarding the durability performance of coal gangue concrete. More tests on the durability performance of coal gangue concrete are still needed, such as the drying and watering cycle, high temperature, abrasion resistance, and sulfate resistance.

- (6)

- Besides the experimental and theoretical studies on the structural members with coal gangue concrete are rather limited, the durability performance of those has never been studied. Specifically, the interface bonding behavior between the steel component and coal gangue coarse aggregate concrete under the severe environment and long-term loading should be studied in detail. More design methods from formal standards should be modified by considering the properties of coal gangue for practical applications.

8. Conclusions

- (1)

- The physical and chemical properties of rock and spontaneous-combustion coal gangue are generally suitable for being used as a coarse aggregate in green concrete, even though these properties vary from the origin. The short-term heavy metal leachability of coal gangue is also relatively weak. However, more specific permission regarding heavy metal and organic matter leaching in coal gangue should be issued by governments to avoid posing environmental, health, and safety concerns.

- (2)

- Coal gangue concrete is not recommended to be used in subsurface structures, since its water absorption law would be changed by increasing the CG replacement ratio. The slump of coal gangue concrete with a 100% CG content would be reduced by about 10–20%. Adding fly ash, superplasticizer, and additional water are effective and simple ways to enhance the workability of coal gangue concrete. A proper index to assess the workability of coal gangue concrete for practical use should also be proposed based on more experimental data.

- (3)

- The mechanical performance, including compressive strength, elastic modulus, and splitting tensile strength of coal gangue concrete is degraded by raising the CG replacement ratio. This degradation caused by the porous structure of CG varies significantly from the CG origin. Over-low and -high concrete grades are not suggested to be used as coal gangue aggregates, unless extra admixture or specific methods are used. The models for describing the elastic modulus, tensile strength, bending strength, and creep performance of coal gangue concrete are still needed for practical applications.

- (4)

- The porous structure of coal gangue provides more transmission channels for air and liquid in concrete. Therefore, the influence of CG on the durability of coal gangue concrete is more remarkable than on its mechanical performance, which could be reduced by adding super-fine admixture and calcination. In contrast, the porous structure of CG is beneficial in the preparation of thermal insulation concrete. The specific properties and replacement ratio of coal gangue should be considered in the prediction formulas regarding the durability performance of coal gangue concrete.

- (5)

- The application of coal gangue concrete in structural members is still limited. Even though the static and seismic behavior of some structural members using coal gangue concrete has been investigated, the durability of these structural members has never been reported. Specifically, the interface bonding behavior between steel component and coal gangue coarse aggregate concrete under the severe environment and long-term loading should be studied in detail. Among them, concrete filled steel tubes are a preferable configuration for using coal gangue concrete, regarding both the mechanical and durability performance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- BP. BP Statistical Review of World Energy; BP: London, UK, 2019. [Google Scholar]

- Zhang, Y.L.; Ling, T.C. Reactivity activation of waste coal gangue and its impact on the properties of cement-based materials—A review. Constr. Build. Mater. 2020, 234, 117424. [Google Scholar] [CrossRef]

- Li, D.; Song, X.; Gong, C.; Pan, Z. Research on cementitious behavior and mechanism of pozzolanic cement with coal gangue. Cem. Concr. Res. 2006, 36, 1752–1759. [Google Scholar] [CrossRef]

- Li, J.Y.; Wang, J.M. Comprehensive utilization and environmental risks of coal gangue: A review. J. Clean. Prod. 2019, 239, 117946. [Google Scholar] [CrossRef]

- Jabłońska, B.; Kityk, A.V.; Busch, M.; Huber, P. The structural and surface properties of natural and modified coal gangue. J. Environ. Manag. 2017, 190, 80–90. [Google Scholar] [CrossRef] [PubMed]

- Moghadam, M.J.; Ajalloeian, R.; Hajiannia, A. Preparation and application of alkali-activated materials based on waste glass and coal gangue: A review. Constr. Build. Mater. 2019, 221, 84–98. [Google Scholar] [CrossRef]

- Huang, Y.L.; Li, J.M.; Song, T.Q.; Sun, Q.; Kong, G.; Wang, F. Microstructure of coal gangue and precipitation of heavy metal elements. J. Spectrosc. 2017, 3128549. [Google Scholar] [CrossRef] [Green Version]

- Dong, Z.; Xia, J.; Fan, C.; Cao, J. Activity of calcined coal gangue fine aggregate and its effect on the mechanical behavior of cement mortar. Constr. Build. Mater. 2015, 100, 6–69. [Google Scholar] [CrossRef] [Green Version]

- Cheng, Y.; Hongqiang, M.; Hongyu, C.; Jiaxin, W.; Jing, S.; Zonghui, L.; Mingkai, Y. Preparation and characterization of coal gangue geopolymers. Constr. Build. Mater. 2018, 187, 318–326. [Google Scholar] [CrossRef]

- Ma, X.W.; Liu, J.H.; Shi, C.J. A review on the use of LWA as an internal curing agent of high performance cement-based materials. Constr. Build. Mater. 2019, 218, 385–393. [Google Scholar] [CrossRef]

- Cong, X.; Lu, S.; Yao, Y.; Wang, Z. Fabrication and characterization of self-ignition coal gangue autoclaved aerated concrete. Mater. Des. 2016, 97, 155–162. [Google Scholar] [CrossRef]

- Wang, Q.; Li, Z.; Zhang, Y.; Zhang, H.; Zhou, M.; Fang, Y. Influence of coarse coal gangue aggregates on elastic modulus and drying shrinkage behaviour of concrete. J. Build. Eng. 2020, 32, 101748. [Google Scholar] [CrossRef]

- Cheng, W.H. The Influence of Argillaceous Shale Coal Gangue on Normal Temperature and High Temperature Performance of Concrete; Harbin Institute of Technology: Harbin, China, 2015. [Google Scholar]

- Wu, X.F.; Zhou, M.; Cui, Z.L. The experiment research on concrete strength influence of self combustion coal gangue coarse aggregate. Ind. Constr. 2009, 39, 81–85. [Google Scholar]

- Zhou, M.; Dou, Y.; Zhang, Y.; Zhang, Y.; Zhang, B. Effects of the variety and content of coal gangue coarse aggregate on the mechanical properties of concrete. Constr. Build. Mater. 2019, 220, 386–395. [Google Scholar] [CrossRef]

- Zhu, Z.Z. The Development of Coal Gangue Concrete and Its Performance Test; Anhui University of Science and Technology: Huainan, China, 2014. [Google Scholar]

- Duan, X.M. Study on the Micro-Structure and Physical-Mechanical Performance of Concrete with Coal Gangue as Aggregate; China University of Mining and Technology: Xuzhou, China, 2014. [Google Scholar]

- Miao, H.Y.; Zhang, Z.P.; Gong, L.; Wang, P. College of Architecture and Civil Engineering, Taiyuan University of Technology. Experimental study on coal gangue thermal insulation glazed hollow bead concrete. Concrete 2017, 2, 152–160. [Google Scholar]

- Zhang, Y.; Ma, G.; Liu, Y.; Li, Z. Mix design for thermal insulation concrete using waste coal gangue as aggregate. Mater. Res. Innov. 2015, 19 (Suppl. S5), 878–884. [Google Scholar] [CrossRef]

- Zhang, J.X.; Chen, W.L.; Yang, R.J. Experimental study on basic properties of coal gangue aggregate. J. Build. Mater. 2010, 13, 739–743. [Google Scholar]

- Bai, C.N.; Li, L.H.; Sheng, Y.; Long, G.C.; Ma, K.L. The effects of coal gangue as coarse aggregate on mechanical property of concrete. Sichuan Build. Mater. 2018, 44, 1–3. [Google Scholar]

- Fang, Q.C. Study on preparation and properties of shale gangue concrete. Sichuan Build. Sci. 2017, 43, 107–111. [Google Scholar]

- Guan, X.; Qiu, J.; Song, H.; Qin, Q.; Zhang, C. Stress-strain behaviour and acoustic emission characteristic of gangue concrete under axial compression in frost environment. Constr. Build. Mater. 2019, 220, 476–488. [Google Scholar] [CrossRef]

- Ma, H.Q.; Yi, C.; Zhu, H.G.; Dong, Z.C.; Chen, H.Y.; Wang, J.X.; Li, D.Y. Compressive strength and durability of coal gangue aggregate concrete. Mater. Rep. B 2018, 32, 2390–2395. [Google Scholar]

- Wang, A.G.; Zhu, Y.Y.; Xu, H.Y.; Liu, K.W.; Jing, Y.; Sun, D.S. Research progress on coal gangue aggregate for concrete. Bull. Chin. Ceram. Soc. 2019, 38, 2076–2086. [Google Scholar]

- Guo, Y.X.; Zhang, Y.Y.; Cheng, F.Q. Industrial development and prospect about comprehensive utilization of coal gangue. CIESC J. 2014, 65, 2443–2453. [Google Scholar]

- Wang, C.; Ni, W.; Zhang, S.-Q.; Wang, S.; Gai, G.-S.; Wang, W.-K. Preparation and properties of autoclaved aerated concrete using coal gangue and iron ore tailings. Constr. Build. Mater. 2016, 104, 109–115. [Google Scholar] [CrossRef]

- Koshy, N.; Dondrob, K.; Hu, L.; Wen, Q.; Meegoda, J.N. Synthesis and characterization of geopolymers derived from coal gangue, fly ash and red mud. Constr. Build. Mater. 2019, 206, 287–296. [Google Scholar] [CrossRef]

- Frías, M.; de Rojas, M.I.S.; García, R.; Valdés, A.J.; Medina, C. Effect of activated coal mining wastes on the properties of blended cement. Cem. Concr. Compos. 2012, 34, 678–683. [Google Scholar] [CrossRef]

- Sun, Z.H.; Liu, K.P.; Wang, M.Q.; Wang, Z.M.; Yang, F.F. Study on activation properties of spontaneous combustion coal gangue. J. Build. Mater. 2013, 16, 497–502. [Google Scholar]

- Wang, J.; Qin, Q.; Hu, S.; Wu, K. A concrete material with waste coal gangue and fly ash used for farmland drainage in high groundwater level areas. J. Clean. Prod. 2016, 112, 631–638. [Google Scholar] [CrossRef]

- Guan, X.; Chen, J.; Qiu, J.; Gao, Y.; Gao, J. Damage evaluation method based on ultrasound technique for gangue concrete under freezing-thawing cycles. Constr. Build. Mater. 2020, 246, 118437. [Google Scholar] [CrossRef]

- Chen, Y.W.; Sun, Q.; Wang, N.; Niu, W.Y. Experimental study on the spontaneous combustion coal gangue concrete. Concrete 2014, 10, 63–65. [Google Scholar]

- Zhang, Y.; Wang, Q.; Zhou, M.; Fang, Y.; Zhang, Z. Mechanical properties of concrete with coarse spontaneous combustion gangue aggreagate (SCGA): Experimental investigation and prediction methodology. Constr. Build. Mater. 2020, 255, 119337. [Google Scholar] [CrossRef]

- Zhu, K. Study on performance of lightweight aggregate concrete with fly ash and gangue. Railw. Eng. 2014, 3, 118–121. [Google Scholar]

- Li, Y.J.; Yan, X.P.; Guo, R.Q.; Zhou, M. Study on the gradual loss in slump of the spontaneous combustion coal gangue full-lightweight concrete mixture. Bull. Chin. Ceram. Soc. 2013, 32, 727–731. [Google Scholar]

- Zhou, M.; Wang, Q.; Mu, S. The effects on workability of concrete mixture of spontaneous combustion coal gangue coarse aggregate characteristics. Non-Met. Mines 2013, 36, 8–11. [Google Scholar]

- Chen, B.P. Strength of gangue concrete. Ind. Constr. 1994, 7, 29–32. [Google Scholar]

- Wang, Z.S.; Zhao, N. Properties of steel fiber reinforced coal gangue coarse aggregate concrete. Wuhan Univ. J. Nat. Sci. 2014, 19, 262–268. [Google Scholar] [CrossRef]

- Yang, Q.B.; Lu, M.X.; Luo, Y.B. Effects of surface-activated coal gangue aggregates on properties of cement-based materials. J. Wuhan Univ. Technol.-Mater. Sci. Ed. 2013, 28, 1118–1121. [Google Scholar] [CrossRef]

- Cui, Z.L.; Li, J. Effect of coarse aggregate with different water absorption on strength and drying shrinkage of concrete. Bull. Chin. Ceram. Soc. 2016, 35, 2396–2399. [Google Scholar]

- Cui, Z.L.; Hao, J.L.; Chen, L.; Lan, Y. Experimental study on strength and drying shrinkage crack of spontaneous combustion gangue concrete. Non-Met. Mines 2015, 38, 76–78. [Google Scholar]

- Wang, Q.; Zhao, Z.Q.; Liu, Y.Q.; Liu, S. Research on shrinkage performance of coal gangue concrete. Concrete 2015, 10, 68–70. [Google Scholar]

- Qiu, J.S.; Zheng, J.J.; Guan, X.; Gu, S.; Pan, D.; Zhang, C. Capillary water absorption properties of coal gangue concrete under freezing-thawing circumstance. J. Build. Mater. 2017, 20, 881–885. [Google Scholar]

- Zhang, J.X.; Chen, W.L.; Jin, S.S.; Chen, C.-Z.; Yang, R.-J. Investigation on durability of coal gangue aggregate concrete. J. Beijing Univ. Technol. 2011, 37, 116–125. [Google Scholar]

- Li, Y.J.; Han, J.J.; Xing, Y.; Yan, X.P.; Zhang, X. Research on the freezing and thawing cycle test of coal gangue aggregate concrete. Concrete 2013, 12, 100–103. [Google Scholar]

- Zhou, M.; Zhao, H.M.; Wang, R.; Chen, C.; Qu, H.-L. Effect of admixture on impermeability and frost resistance of spontaneous combustion gangue sand-lightweight concrete. Bull. Chin. Ceram. Soc. 2015, 34, 131–137. [Google Scholar]

- Zhang, X.D.; Li, Q.W.; Song, Y. Study of anti-freezing agent on frost resistance of coal gangue concrete mixing with water reducers. Non-Met. Mines. 2016, 39, 48–51. [Google Scholar]

- Zhu, K.; Yuan, S.L.; Ma, X.W. Study of the road performance of fiber reinforced coal gangue light-weight aggregate concrete. China Concr. Cem. Prod. 2015, 6, 58–61. [Google Scholar]

- Sun, J.Y.; Lu, L.G. Coupled effect of axially distributed load and carbonization on permeability of concrete. Constr. Build. Mater. 2015, 79, 9–13. [Google Scholar] [CrossRef]

- Chen, Y.W.; Ding, Z.Y.; Zhu, J.S.; Sun, X.W. Experimental study on the spontaneous combustion coal gangue concrete. Concrete 2015, 5, 87–89. [Google Scholar]

- Li, Q.W.; Zhang, X.D.; Li, G.X.; Li, Y.; Zhang, J. Study on carbonation depth of spontaneous combustion coal gangue lightweight aggregate concrete. Chin. J. Environ. Eng. 2016, 10, 2616–2620. [Google Scholar]

- Li, Y.J.; Xing, Y.; Han, J.J.; Cao, S. Experimental research on gas permeability and carbonation resistance of coal gangue aggregates. Non-Met. Mines 2016, 39, 17–20. [Google Scholar]

- Yi, C.; Ma, H.Q.; Zhu, H.G.; Dong, Z.C.; Su, Z.J.; Zhang, Y.T.; Chu, Z. Investigation on anti-carbonation performance of coal gangue coarse aggregate concrete. J. Build. Mater. 2017, 20, 787–793. [Google Scholar]

- Zhou, M.; Tian, B.Y.; Wang, Q.; Mou, S.; Pu, B.C. Experimental study on the influence of spontaneous combustion gangue coarse aggregate on sand lightweight concrete performance. Bull. Chin. Ceram. Soc. 2013, 32, 2231–2237. [Google Scholar]

- Wang, Q.; Liu, S.; Wang, J.B.; Li, M.; Liu, Y. Research on resistance to chloride ion of the coal gangue coarse aggregate concrete. Concrete 2016, 8, 36–38. [Google Scholar]

- Li, Y.J.; Xing, Y. Experiment study on chloride ion penetration of coal gangue concrete. Non-Met. Mines 2016, 39, 11–13. [Google Scholar]

- Zhou, M.; Li, G.N.; Zhang, Q.; Cui, H. Study on application of spontaneous combustion coal gangue aggregate in ready-mixed concrete. J. Build. Mater. 2015, 18, 830–835. [Google Scholar]

- Feng, J.X. Coal Gangue Type of Self-Compacting Concrete Beam Bending Performance Test Research; Yianbian University: Yianbian, China, 2017. [Google Scholar]

- Wang, Q.H.; Li, Z.; Zhou, M.; Zhang, Y.Z. Effects of spontaneous-combustion coal gangue aggregate replacement ratio on flexural behavior of reinforced concrete beams. J. Build. Struct. 2020, 41, 64–74. [Google Scholar]

- Li, G.N. Study of Flexural Behavior on Spontaneous Combustion Gangue Aggregate Reinforced Concrete Beam; Liaoning Technical University: Liaoning, China, 2015. [Google Scholar]

- Bai, G.L.; Zhu, C.; Wang, J.W.; Li, X.X.; Liu, H.; Lu, G.K. Experimental study on shear behavior of coal gangue concrete beams. J. Build. Struct. 2020, 41, 49–55. [Google Scholar]

- Liu, H.Q. Experimental Study on Bearing Capacity of Coal Gangue Concrete Column; Xi’an University of Architecture and Technology: Xi’an, China, 2019. [Google Scholar]

- Li, Y.J.; Yan, X.P.; Zhang, X.; Geng, X.; Zhang, J. Experimental research on seismic behavior of reinforced concrete column composed of coal gangue aggregate. J. China Coal Soc. 2013, 38, 1006–1011. [Google Scholar]

- Wang, S.X. Experimental Study on Seismic Performance of Coal Gangue Concrete Shear Wall under Horizontal Reciprocating Load; Liaoning Technical University: Liaoning, China, 2020. [Google Scholar]

- Zhuang, Y.Z. Mechanical properties of self-combusted gangue reinforced concrete shear walls under low-cyclic load. J. Zhejiang Univ. 2000, 34, 325–330. [Google Scholar]

- Tan, X.M.; Guo, M.H.; Wang, F.M. Earthquake-resistant behavior of low-rise self-combusted gangue reinforced concrete shear wall. J. South China Univ. Technol. Nat. Sci. 1999, 27, 67–73. [Google Scholar]

- Li, G.C.; Liu, Z.Y.; Yang, L.Z. The constitutive equation and strength criterion on core concrete of gangue concrete filled steel tube. J. Northeast. Univ. Nat. Sci. 2002, 23, 64–66. [Google Scholar]

- Li, G.C.; Xu, Z.; Zhang, C.Y. Finite element analysis of gangue concrete-filled steel tubular beam-columns. J. Shenyang Jianzhu Univ. Nat. Sci. 2010, 26, 1052–1057. [Google Scholar]

- Zhang, N.; Zheng, C.; Zhao, Z.; Yang, B. Experimental investigations on compression behavior of GFRP-coal gangue concrete-steel tubular columns. J. Build. Mater. 2020, 9, 1–10. [Google Scholar]

- Zhang, H.B. Experimental Study on Bearing Capacity of Self Compacting Concrete-Filled Steel Pipe Short Column under Axial Compression; Yanbian University: Yanbian, China, 2018. [Google Scholar]

- Gao, S.; Zhao, G.; Guo, L.; Zhou, L.; Yuan, K. Utilization of coal gangue as coarse aggregates in structural concrete. Constr. Build. Mater. 2020, 268, 121212. [Google Scholar] [CrossRef]

- Peng, Q. Experimental Study on the Mechanical Properties of the Coal Gangue Concrete Shear Wall with Internal Steel Plate; Shenyang Jianzhu University: Shenyang, China, 2015. [Google Scholar]

- Liu, H. Study on Seismic Performance of a Steel Plate Gangue Concrete Composite Shear Wall; Shenyang Jianzhu University: Shenyang, China, 2015. [Google Scholar]

- GB/T 17431.1-2010. Lightweight Aggregates and Its Test Methods-Part 1: Lightweight Aggregates; Standardization Administration of China: Beijing, China, 2010. [Google Scholar]

- Li, G.C.; Chang, C.; Qu, Z.S. Mechanics function of composite slab with gangue concrete and profiled sheeting. J. Liaoning Tech. Univ. 2003, 22, 61–63. [Google Scholar]

- Li, Z.H. Finite Element Analysis of Profiled Steel Sheet-Coal Gangue Lightweight Aggregate Concert Composite Slabs; Taiyuan University of Technology: Taiyuan, China, 2008. [Google Scholar]

- Javed, M.F.; Amin, M.N.; Shah, M.I.; Khan, K.; Iftikhar, B.; Farooq, F.; Aslam, F.; Alyousef, R.; Alabduljabbar, H. Applications of gene expression programming and regression techniques for estimating compressive strength of bagasse ash based concrete. Crystals 2020, 10, 737. [Google Scholar] [CrossRef]

- Rehman, S.K.U.; Kumarova, S.; Memon, S.A.; Javed, M.F.; Jameel, M. A review of microscal, rheological, mechanical, thermoelectrical and piezoresistive properties of graphene based cement composite. Nanomaterials 2020, 10, 2076. [Google Scholar]

- Rehman, S.K.U.; Ibrahim, Z.; Memon, S.A.; Javed, M.F.; Khushnood, R.A. A sustainable graphene based cement composite. Sustainability 2017, 9, 1229. [Google Scholar] [CrossRef] [Green Version]

| Type | Region of China | Province | Apparent Density (kg/m3) | Bulk Density (kg/m3) | Water Absorption (%) | Crushing Value (%) | Void Ratio (%) | Ref. |

|---|---|---|---|---|---|---|---|---|

| SCG | Northeast | Heilongjiang | 2588 | 1289 | 3.8 | 18.9 | 50.2 | [13] |

| Liaoning | 2497 | - | 9.80 | 25.2 | - | [12] | ||

| Liaoning | 2630 | 1550 | 8.5 | 16.6 | 22.0 | [14] | ||

| Liaoning | 2276 | 1220 | 7.55 | 21.2 | 52.8 | [15] | ||

| South | Anhui | 2630 | 976 | 9.2 | 16.6 | 57.9 | [16] | |

| Jiangsu | 2624 | 1430 | 4.88 | 24.4 | - | [17] | ||

| RCG | Northeast | Liaoning | 2653 | 1489 | 3.15 | 9.9 | 49.5 | [15] |

| North | Shanxi | 2083 | 1130 | 4.7 | 18.7 | - | [18] | |

| Shanxi | 2689 | 1201 | 11.4 | 18.1 | - | [19] | ||

| Beijing | 2640 | - | 1.8 | 22.6 | - | [20] | ||

| Henan | 2510 | 1320 | 1.7 | 19.1 | 47.5 | [21] | ||

| Henan | 2540 | 1264 | 3.9 | 17.9 | 51.5 | [22] | ||

| Northwest | Shaanxi | 2090 | - | 4.92 | 19.0 | - | [23] | |

| South | Jiangsu | 2712 | - | 1.7 | 16.8 | - | [24] | |

| Jiangsu | 2620 | 1612 | 3.9 | 18.6 | [17] |

| Minerals | Czechoslovakia | Germany | Spain | Britain | USSR | China |

|---|---|---|---|---|---|---|

| Illite | 10–45 | 41–66 | 20–60 | 10–31 | 5–30 | 10–30 |

| Kaolinite | 24–45 | 4–25 | 3–30 | 10–40 | 1–60 | 10–67 |

| Chlorite | 0–15 | 1–3 | 0–7 | 2–7 | -- | 2–11 |

| Quartz | 10–50 | 13–27 | 5–57 | 15–25 | -- | 15–35 |

| Iron ore | 0–25 | 0.5–5 | -- | 2-10 | 0.2–8 | 2–10 |

| Organic matters | 0–25 | 5–10 | 4–30 | 5–25 | 8–40 | 5–25 |

| Type | Region | Province | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | Na2O | K2O | TiO2 | P2O5 | SO3 | Loss | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RCG | Northeast of China | Heilongjiang | 61.0 | 23.6 | 6.70 | 1.18 | 0.52 | - | - | - | - | - | 2.50 | [11] |

| Heilongjiang | 34.1 | 26.0 | 0.49 | 0.67 | 0.61 | - | 0.16 | - | - | 0.28 | 32.8 | [27] | ||

| Liaoning | 50.3 | 26.3 | 6.11 | 7.74 | 2.00 | 1.10 | 3.28 | 1.13 | 0.15 | 0.93 | - | [15] | ||

| North of China | Beijing | 49.9 | 24.4 | 6.42 | 0.82 | 1.59 | 1.46 | 2.06 | 0.88 | - | 0.12 | 11.8 | [3] | |

| Shandong | 48.8 | 19.0 | 4.47 | 2.03 | 2.29 | 1.43 | 0.19 | - | - | - | 16.8 | [3] | ||

| Henan | 59.9 | 20.7 | 6.70 | 2.00 | 1.80 | 0.65 | 2.40 | - | - | 1.53 | - | [7] | ||

| Shanxi | 35.1 | 16.8 | 27.3 | 3.82 | 1.60 | - | - | - | - | 3.00 | 0.83 | [19] | ||

| Hebei | 48.3 | 23.1 | 4.30 | 4.10 | 1.70 | 0.10 | 1.50 | 0.80 | 0.10 | 1.00 | 14.7 | [28] | ||

| Northwest of China | Shaanxi | 49.5 | 33.3 | 7.60 | 6.09 | 0.97 | 0.52 | 0.94 | 0.83 | - | - | - | [23] | |

| South of China | Jiangsu | 55.5 | 18.2 | 5.42 | 3.38 | 1.23 | 0.64 | 1.67 | - | - | 0.64 | 13.3 | [3] | |

| Jiangsu | 59. 8 | 29.4 | 1.44 | 0.68 | 0.51 | 0.08 | 1.76 | - | - | - | - | [8] | ||

| Poland | - | 58.9 | 20.5 | 6.63 | 0.35 | 1.93 | 0.54 | 3.19 | 1.05 | 0.06 | 0.17 | 5.50 | [5] | |

| Italy | No. 1 | 43.7 | 21.4 | 5.57 | 0.89 | 0.77 | 0.11 | 0.16 | 1.05 | 0.16 | 1.02 | 25.2 | [29] | |

| No. 2 | 46.8 | 17.2 | 7.67 | 7.60 | 0.99 | 0.15 | 2.40 | 0.78 | 0.16 | 0.34 | 15.8 | |||

| No. 3 | 57.2 | 18.7 | 6.25 | 1.86 | 1.42 | 0.46 | 3.59 | 0.95 | 0.14 | 0.08 | 9.28 | |||

| SCG | Northeast of China | Liaoning | 55.6 | 21.0 | 6.57 | 3.65 | 2.50 | 1.90 | 4.10 | 0.84 | 0.24 | 0.82 | - | [15] |

| North of China | Shanxi | 56.6 | 36.8 | 1.95 | 0.62 | 0.22 | 0.42 | - | 2.10 | - | - | - | [9] | |

| Northwest of China | Shaanxi | 55.2 | 31.1 | 2.94 | 1.31 | 0.75 | 0.12 | 1.13 | 1.12 | 0.07 | - | 5.94 | [30] | |

| Italy | No. 1 | 56.4 | 26.3 | 6.42 | 1.06 | 1.07 | 4.02 | 0.17 | 1.21 | 0.20 | 0.65 | 2.38 | [29] | |

| No. 2 | 52.3 | 19.5 | 8.35 | 8.41 | 1.21 | 2.65 | 0.20 | 0.85 | 0.17 | 0.49 | 5.61 | |||

| No. 3 | 61.9 | 20.2 | 6.77 | 2.00 | 1.57 | 3.78 | 0.53 | 1.01 | 0.15 | 0.11 | 1.81 |

| Type | Region | Province | As | Ba | Cd | Co | Cr | Cu | Hg | Mo | Ni | Pb | Sn | Zn | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RCG | China | Jiangsu | 27.3 | - | 0.58 | - | 42.3 | 24.3 | 0.24 | - | 20.5 | 4.32 | - | 39.5 | [31] |

| SCG | Italy | No. 1 | - | - | - | - | 190 | - | - | - | 56 | 11 | - | 27 | [29] |

| No. 2 | - | - | - | - | 228 | - | - | - | 43 | 5 | - | 46 | |||

| No. 3 | - | - | - | - | 308 | - | - | - | 57 | 10 | - | 37 | |||

| RCG | Poland | - | <2 | 84.5 | 2.9 | 14.6 | 61.9 | 48.3 | 0.04 | <2 | 41.2 | 20 | 3 | 89.5 | [5] |

| Permission content in Poland | 20 | 200 | 4 | 20 | 150 | 150 | 2 | 10 | 100 | 100 | 20 | 300 | [5] | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, S.; Zhang, S.; Guo, L. Application of Coal Gangue as a Coarse Aggregate in Green Concrete Production: A Review. Materials 2021, 14, 6803. https://doi.org/10.3390/ma14226803

Gao S, Zhang S, Guo L. Application of Coal Gangue as a Coarse Aggregate in Green Concrete Production: A Review. Materials. 2021; 14(22):6803. https://doi.org/10.3390/ma14226803

Chicago/Turabian StyleGao, Shan, Sumei Zhang, and Lanhui Guo. 2021. "Application of Coal Gangue as a Coarse Aggregate in Green Concrete Production: A Review" Materials 14, no. 22: 6803. https://doi.org/10.3390/ma14226803

APA StyleGao, S., Zhang, S., & Guo, L. (2021). Application of Coal Gangue as a Coarse Aggregate in Green Concrete Production: A Review. Materials, 14(22), 6803. https://doi.org/10.3390/ma14226803