High-Impact Polystyrene Reinforced with Reduced Graphene Oxide as a Filament for Fused Filament Fabrication 3D Printing

Abstract

:1. Introduction

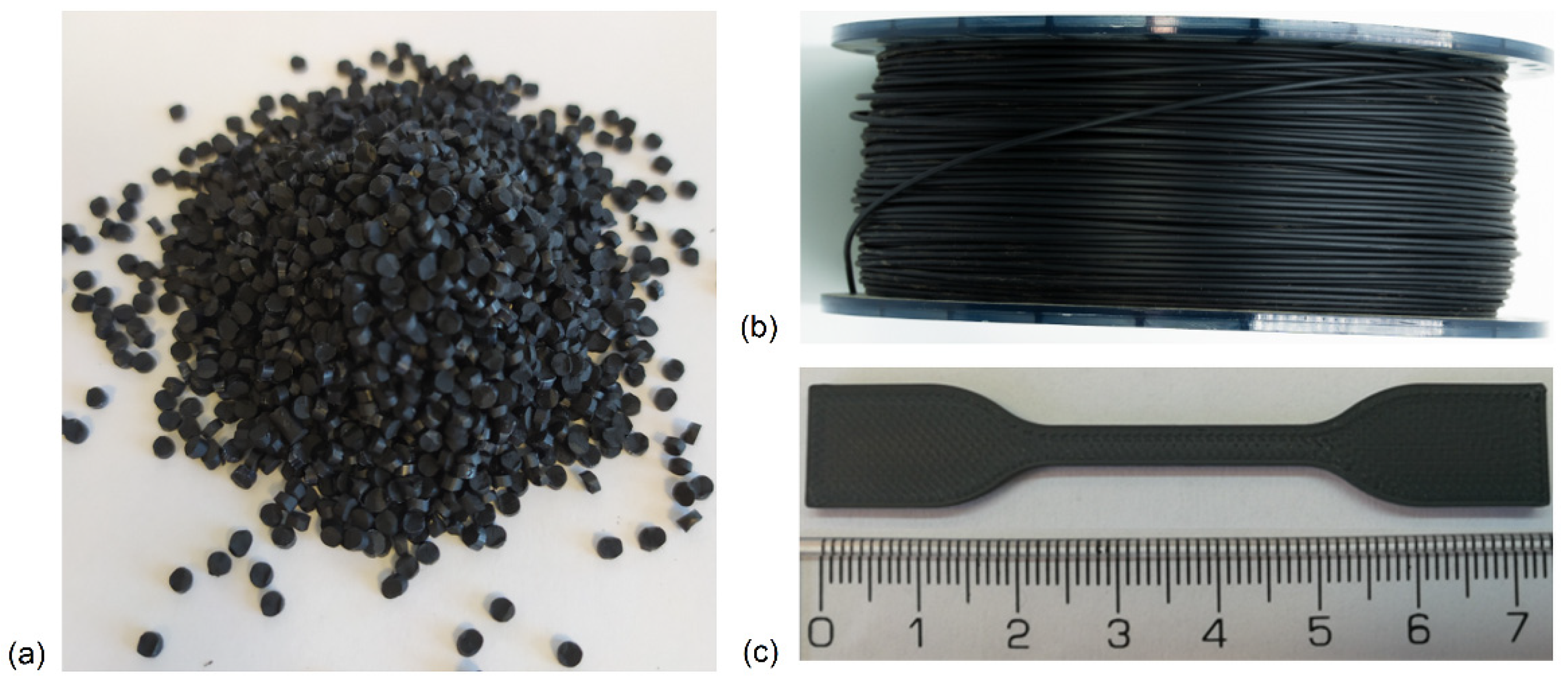

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

2.3. Methods

3. Results and Discussion

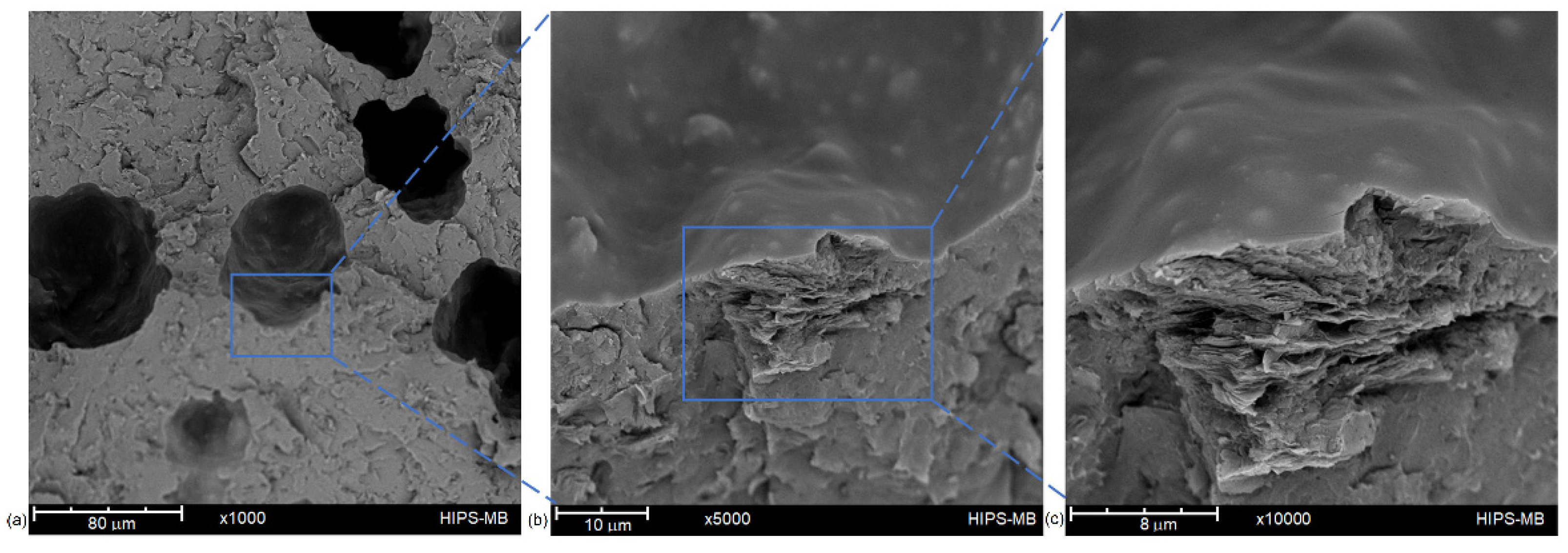

3.1. SEM Analysis

3.2. Chemical Analysis

3.3. Flowability

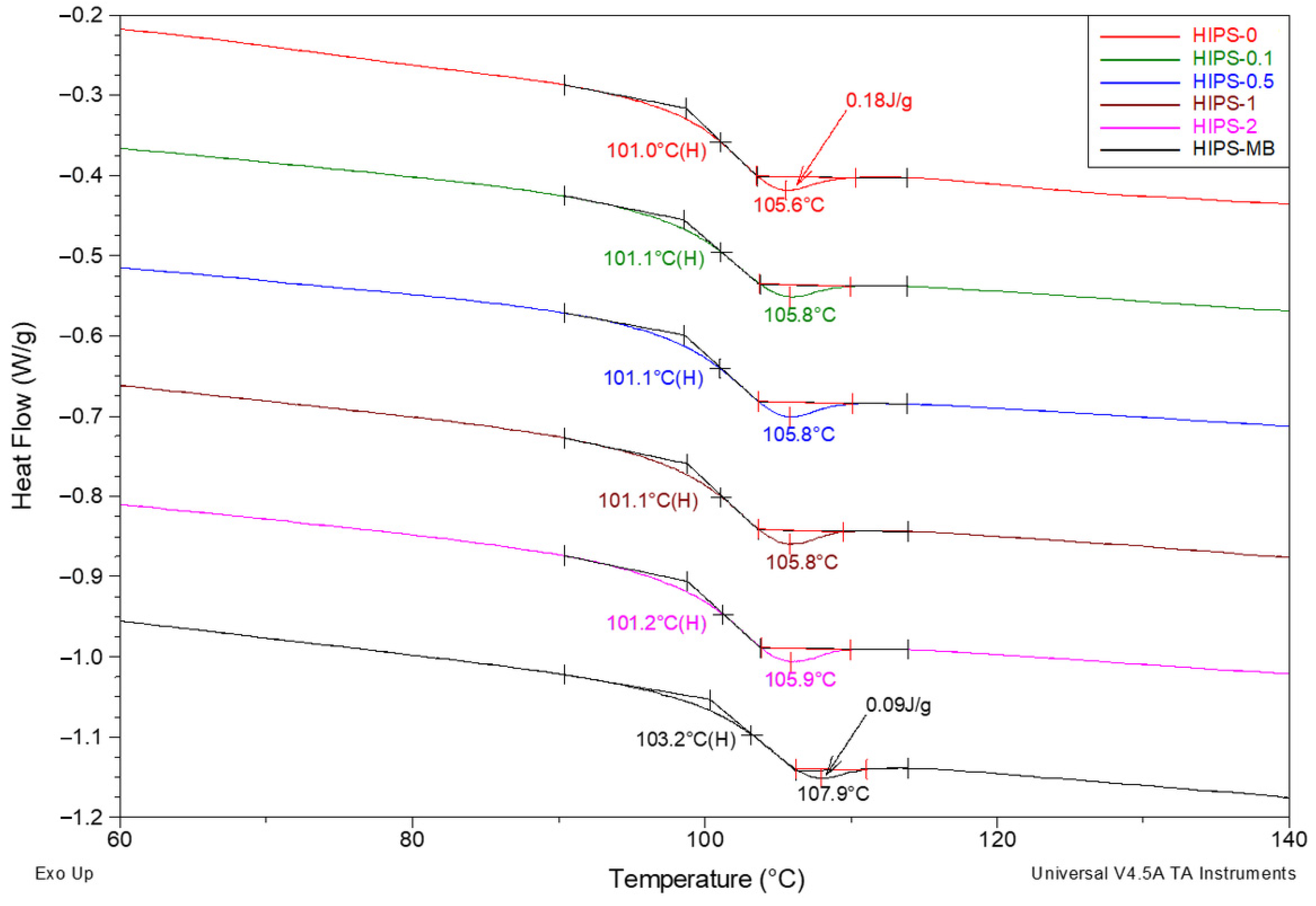

3.4. Thermal Analysis

3.5. Mechanical Properties

3.6. Printability

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lopes, A.J.; Perez, M.A.; Espalin, D.; Wicker, R.B. Comparison of ranking models to evaluate desktop 3D printers in a growing market. Addit. Manuf. 2020, 35, 101291. [Google Scholar] [CrossRef]

- Przekop, R.E.; Kujawa, M.; Pawlak, W.; Dobrosielska, M.; Sztorch, B.; Wieleba, W. Graphite modified polylactide (PLA) for 3D printed (FDM/FFF) sliding elements. Polymers 2020, 12, 1250. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.Y.; An, J.; Chua, C.K. Fundamentals and applications of 3D printing for novel materials. Appl. Mater. Today 2017, 7, 120–133. [Google Scholar] [CrossRef]

- Guo, H.; Lv, R.; Bai, S. Recent advances on 3D printing graphene-based composites. Nano Mater. Sci. 2019, 1, 101–115. [Google Scholar] [CrossRef]

- Conner, B.P.; Manogharan, G.P.; Martof, A.N.; Rodomsky, L.M.; Rodomsky, C.M.; Jordan, D.C.; Limperos, J.W. Making sense of 3-D printing: Creating a map of additive manufacturing products and services. Addit. Manuf. 2014, 1, 64–76. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components—Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Li, N.; Huang, S.; Zhang, G.; Qin, R.; Liu, W.; Xiong, H.; Shi, G.; Blackburn, J. Progress in additive manufacturing on new materials: A review. J. Mater. Sci. Technol. 2019, 35, 242–269. [Google Scholar] [CrossRef]

- Mohan, M.K.; Rahul, A.V.; De Schutter, G.; Van Tittelboom, K. Extrusion-based concrete 3D printing from a material perspective: A state-of-the-art review. Cem. Concr. Compos. 2021, 115, 103855. [Google Scholar] [CrossRef]

- Valino, A.D.; Dizon, J.R.C.; Espera, A.H.; Chen, Q.; Messman, J.; Advincula, R.C. Advances in 3D printing of thermoplastic polymer composites and nanocomposites. Prog. Polym. Sci. 2019, 98, 101162. [Google Scholar] [CrossRef]

- Al-Dulimi, Z.; Wallis, M.; Tan, D.K.; Maniruzzaman, M.; Nokhodchi, A. 3D printing technology as innovative solutions for biomedical applications. Drug Discov. Today 2021, 26, 360–383. [Google Scholar] [CrossRef]

- Beg, S.; Almalki, W.H.; Malik, A.; Farhan, M.; Aatif, M.; Rahman, Z.; Alruwaili, N.K.; Alrobaian, M.; Tarique, M.; Rahman, M. 3D printing for drug delivery and biomedical applications. Drug Discov. Today 2020, 25, 1668–1681. [Google Scholar] [CrossRef]

- Aslanzadeh, S.; Saghlatoon, H.; Honari, M.M.; Mirzavand, R.; Montemagno, C.; Mousavi, P. Investigation on electrical and mechanical properties of 3D printed nylon 6 for RF/microwave electronics applications. Addit. Manuf. 2018, 21, 69–75. [Google Scholar] [CrossRef]

- Tino, R.; Moore, R.; Antoline, S.; Ravi, P.; Wake, N.; Ionita, C.N.; Morris, J.M.; Decker, S.J.; Sheikh, A.; Rybicki, F.J.; et al. COVID-19 and the role of 3D printing in medicine. 3D Print. Med. 2020, 6, 11. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Choong, Y.Y.C.; Tan, H.W.; Patel, D.C.; Choong, W.T.N.; Chen, C.H.; Low, H.Y.; Tan, M.J.; Patel, C.D.; Chua, C.K. The global rise of 3D printing during the COVID-19 pandemic. Nat. Rev. Mater. 2020, 5, 637–639. [Google Scholar] [CrossRef]

- Aydin, A.; Demirtas, Z.; Ok, M.; Erkus, H.; Cebi, G.; Uysal, E.; Gunduz, O.; Ustundag, C.B. 3D printing in the battle against COVID-19. Emergent Mater. 2021, 4, 363–386. [Google Scholar] [CrossRef] [PubMed]

- Turner, B.N.; Strong, R.; Gold, S.A. A review of melt extrusion additive manufacturing processes: I. Process design and modeling. Rapid Prototyp. J. 2014, 20, 192–204. [Google Scholar] [CrossRef]

- Shaqour, B.; Abuabiah, M.; Abdel-Fattah, S.; Juaidi, A.; Abdallah, R.; Abuzaina, W.; Qarout, M.; Verleije, B.; Cos, P. Gaining a better understanding of the extrusion process in fused filament fabrication 3D printing: A review. Int. J. Adv. Manuf. Technol. 2021, 114, 1279–1291. [Google Scholar] [CrossRef]

- Vaes, D.; Van Puyvelde, P. Semi-crystalline feedstock for filament-based 3D printing of polymers. Prog. Polym. Sci. 2021, 118, 101411. [Google Scholar] [CrossRef]

- Ligon, S.C.; Liska, R.; Stampfl, J.; Gurr, M.; Mülhaupt, R. Polymers for 3D Printing and Customized Additive Manufacturing. Chem. Rev. 2017, 117, 10212–10290. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pugliese, R.; Beltrami, B.; Regondi, S.; Lunetta, C. Polymeric Biomaterials for 3D Printing in Medicine: An Overview. Ann. 3D Print. Med. 2021, 2, 100011. [Google Scholar] [CrossRef]

- Jafferson, J.M.; Chatterjee, D. A review on polymeric materials in additive manufacturing. Mater. Today Proc. 2021, 46, 1349–1365. [Google Scholar] [CrossRef]

- Pinho, A.C.; Amaro, A.M.; Piedade, A.P. 3D printing goes greener: Study of the properties of post-consumer recycled polymers for the manufacturing of engineering components. Waste Manag. 2020, 118, 426–434. [Google Scholar] [CrossRef] [PubMed]

- Zander, N.E.; Park, J.H.; Boelter, Z.R.; Gillan, M.A. Recycled Cellulose Polypropylene Composite Feedstocks for Material Extrusion Additive Manufacturing. ACS Omega 2019, 4, 13879–13888. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zander, N.E.; Gillan, M.; Burckhard, Z.; Gardea, F. Recycled polypropylene blends as novel 3D printing materials. Addit. Manuf. 2019, 25, 122–130. [Google Scholar] [CrossRef]

- Zander, N.E.; Gillan, M.; Lambeth, R.H. Recycled polyethylene terephthalate as a new FFF feedstock material. Addit. Manuf. 2018, 21, 174–182. [Google Scholar] [CrossRef]

- Baechler, C.; Devuono, M.; Pearce, J.M. Distributed recycling of waste polymer into RepRap feedstock. Rapid Prototyp. J. 2013, 19, 118–125. [Google Scholar] [CrossRef]

- Katančić, Z.; Travaš-Sejdić, J.; Hrnjak-Murgić, Z. Study of flammability and thermal properties of high-impact polystyrene nanocomposites. Polym. Degrad. Stab. 2011, 96, 2104–2111. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, R.; Farina, I. On the 3D printing of recycled ABS, PLA and HIPS thermoplastics for structural applications. PSU Res. Rev. 2018, 2, 115–137. [Google Scholar] [CrossRef]

- Rovere, J.; Correa, C.A.; Grassi, V.G.; Pizzol, M.F.D. Role of the rubber particle and polybutadiene cis content on the toughness of high impact polystyrene. J. Mater. Sci. 2008, 43, 952–959. [Google Scholar] [CrossRef]

- Wang, F.; Chang, L.; Hu, Y.; Wu, G.; Liu, H. Synthesis and properties of in-situ bulk high impact polystyrene toughened by high cis-1,4 polybutadiene. Polymers 2019, 11, 791. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lin, Y.; Ng, K.M.; Chan, C.M.; Sun, G.; Wu, J. High-impact polystyrene/halloysite nanocomposites prepared by emulsion polymerization using sodium dodecyl sulfate as surfactant. J. Colloid Interface Sci. 2011, 358, 423–429. [Google Scholar] [CrossRef] [PubMed]

- Blok, L.G.; Longana, M.L.; Yu, H.; Woods, B.K.S. An investigation into 3D printing of fibre reinforced thermoplastic composites. Addit. Manuf. 2018, 22, 176–186. [Google Scholar] [CrossRef]

- García, E.; Núñez, P.J.; Chacón, J.M.; Caminero, M.A.; Kamarthi, S. Comparative study of geometric properties of unreinforced PLA and PLA-Graphene composite materials applied to additive manufacturing using FFF technology. Polym. Test. 2020, 91, 106860. [Google Scholar] [CrossRef]

- Foster, C.W.; Down, M.P.; Zhang, Y.; Ji, X.; Rowley-Neale, S.J.; Smith, G.C.; Kelly, P.J.; Banks, C.E. 3D Printed Graphene Based Energy Storage Devices. Sci. Rep. 2017, 7, 42233. [Google Scholar] [CrossRef]

- Caminero, M.Á.; Chacón, J.M.; García-Plaza, E.; Núñez, P.J.; Reverte, J.M.; Becar, J.P. Additive manufacturing of PLA-based composites using fused filament fabrication: Effect of graphene nanoplatelet reinforcement on mechanical properties, dimensional accuracy and texture. Polymers 2019, 11, 799. [Google Scholar] [CrossRef] [Green Version]

- Gnanasekaran, K.; Heijmans, T.; van Bennekom, S.; Woldhuis, H.; Wijnia, S.; de With, G.; Friedrich, H. 3D printing of CNT- and graphene-based conductive polymer nanocomposites by fused deposition modeling. Appl. Mater. Today 2017, 9, 21–28. [Google Scholar] [CrossRef]

- Al Rashid, A.; Khan, S.A.; Al-Ghamdi, S.G.; Koç, M. Additive Manufacturing of Polymer Nanocomposites: Needs and Challenges in Materials, Processes, and Applications. J. Mater. Res. Technol. 2021, 14, 910–941. [Google Scholar] [CrossRef]

- Wei, X.; Li, D.; Jiang, W.; Gu, Z.; Wang, X.; Zhang, Z.; Sun, Z. 3D Printable Graphene Composite. Sci. Rep. 2015, 5, 11181. [Google Scholar] [CrossRef] [Green Version]

- Dul, S.; Fambri, L.; Pegoretti, A. Fused deposition modelling with ABS-graphene nanocomposites. Compos. Part A Appl. Sci. Manuf. 2016, 85, 181–191. [Google Scholar] [CrossRef]

- Zhu, D.; Ren, Y.; Liao, G.; Jiang, S.; Liu, F.; Guo, J.; Xu, G. Thermal and mechanical properties of polyamide 12/graphene nanoplatelets nanocomposites and parts fabricated by fused deposition modeling. J. Appl. Polym. Sci. 2017, 134, 45332. [Google Scholar] [CrossRef]

- Sieradzka, M.; Fabia, J.; Biniaś, D.; Fryczkowski, R.; Janicki, J. The Role of Reduced Graphene Oxide in the Suspension Polymerization of Styrene and Its Effect on the Morphology and Thermal Properties of the Polystyrene/rGO Nanocomposites. Polymers 2020, 12, 1468. [Google Scholar] [CrossRef]

- Ślusarczyk, C.; Sieradzka, M.; Fabia, J.; Fryczkowski, R. Supermolecular Structure of Poly(butylene terephthalate) Fibers Formed with the Addition of Reduced Graphene Oxide. Polymers 2020, 12, 1456. [Google Scholar] [CrossRef] [PubMed]

- Şahin, T.; Sinmazçelik, T.; Şahin, Ş. The effect of natural weathering on the mechanical, morphological and thermal properties of high impact polystyrene (HIPS). Mater. Des. 2007, 28, 2303–2309. [Google Scholar] [CrossRef]

- Kalantari, B.; Mojtahedi, M.R.M.; Sharif, F.; Rahbar, R.S. Effect of Graphene Nanoplatelets Presence on the Morphology, Structure, and Thermal Properties of Polypropylene in Fiber Melt-Spinning Process. Polym. Compos. 2015, 36, 367–375. [Google Scholar] [CrossRef]

- Sanes, J.; Sánchez, C.; Pamies, R.; Avilés, M.D.; Bermúdez, M.D. Extrusion of polymer nanocomposites with graphene and graphene derivative nanofillers: An overview of recent developments. Materials 2020, 13, 549. [Google Scholar] [CrossRef] [Green Version]

- Bian, J.; Lin, H.L.; He, F.X.; Wang, L.; Wei, X.W.; Chang, I.T.; Sancaktar, E. Processing and assessment of high-performance poly(butylene terephthalate) nanocomposites reinforced with microwave exfoliated graphite oxide nanosheets. Eur. Polym. J. 2013, 49, 1406–1423. [Google Scholar] [CrossRef]

- Socrates, G. Infrared and Raman Characteristic Group Frequencies: Tables and Charts, 3rd ed.; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 2001; ISBN 978-0-470-09307-8. [Google Scholar]

- Aumnate, C.; Pongwisuthiruchte, A.; Pattananuwat, P.; Potiyaraj, P. Fabrication of ABS/Graphene oxide composite filament for fused filament fabrication (FFF) 3D Printing. Adv. Mater. Sci. Eng. 2018, 2018, 2830437. [Google Scholar] [CrossRef] [Green Version]

- Akhina, H.; Ramya, K.A.; Gopinathan Nair, M.R.; Saiter-Fourcin, A.; Garda, M.R.; Deshpande, A.P.; Kalarikkal, N.; Thomas, S. Influence of reduced graphene oxide on flow behaviour, glass transition temperature and secondary crystallinity of plasticized poly(vinyl chloride). RSC Adv. 2020, 10, 29247–29256. [Google Scholar] [CrossRef]

- Shi, J.; Yang, J.; Zhou, J.; Ji, H.; Tang, X.; Gao, T. Effect of graphene on thermal stability and mechanical properties of ethylene-vinyl acetate: A molecular dynamics simulation. Mater. Res. Express 2020, 7, 03530. [Google Scholar] [CrossRef]

- Rosa, F.; Négrier, P.; Corvis, Y.; Espeau, P. Crystal structure determination and thermal behavior upon melting of p-synephrine. Thermochim. Acta 2016, 632, 18–22. [Google Scholar] [CrossRef] [Green Version]

- Li, Z.; Reimer, C.; Wang, T.; Mohanty, A.K.; Misra, M. Thermal and mechanical properties of the biocomposites of Miscanthus biocarbon and poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV). Polymers 2020, 12, 1300. [Google Scholar] [CrossRef] [PubMed]

- Antich, P.; Vázquez, A.; Mondragon, I.; Bernal, C. Mechanical behavior of high impact polystyrene reinforced with short sisal fibers. Compos. Part A Appl. Sci. Manuf. 2006, 37, 139–150. [Google Scholar] [CrossRef]

- Amani, M.; Sharif, M.; Kashkooli, A.; Rahnama, N.; Fazli, A. Effect of mixing conditions on the selective localization of graphite oxide and the properties of polyethylene/high-impact polystyrene/graphite oxide nanocomposite blends. RSC Adv. 2015, 5, 77723–77733. [Google Scholar] [CrossRef]

- Zare, Y. Study of nanoparticles aggregation/agglomeration in polymer particulate nanocomposites by mechanical properties. Compos. Part A Appl. Sci. Manuf. 2016, 84, 158–164. [Google Scholar] [CrossRef]

| Parameters | Value |

|---|---|

| Nozzle diameter (mm) | 0.5 |

| Nozzle temperature (°C) | 250 |

| Bed temperature (°C) | 100 |

| Layer height (mm) | 0.2 |

| Print infill (%) | 100 |

| Print speed (mm/s) | 100 |

| Sample | IR (v cm−1) Filament | Assignments |

|---|---|---|

| HIPS-0 HIPS-0.1 HIPS-0.5 HIPS-1 HIPS-2 | 3081 | C–H str. 1 vibrations of the ring |

| 3059 | C–H str. vibrations of the ring | |

| 3025 | C–H str. vibrations of the ring | |

| 2923 | C–H str. in CH2 | |

| 2841; 2849 | C–H str. in tertiary groups | |

| 1943 | overtone bands in aromatic rings | |

| 1870 | overtone bands in aromatic rings | |

| 1803 | overtone bands in aromatic rings | |

| 1744 | overtone bands in aromatic rings | |

| 1665 | overtone bands in aromatic rings | |

| 1601 | C–C str. vibrations of the ring, C–H str. in CH2 groups acyclic | |

| 1492 | C–C str. vibrations of the ring, C–H str. in CH2 groups acyclic | |

| 1451 | C–C str. vibrations of the ring, C–H str. in CH2 groups acyclic | |

| 1375 | C–H str. in tertiary groups | |

| 1327 | C–H def. 2 in rings | |

| 1182 | C–H def. in rings | |

| 1155 | C–H def. in rings | |

| 1069 | C–H def. in rings | |

| 1028 | C–C def. in linear alkanes | |

| 966 | C–C def. in linear alkanes | |

| 907 | C–C def. in linear alkanes | |

| 842 | C–H def. out of the plane | |

| 755 | C–H def. out of the plane | |

| 700 | C–H def. out of the plane | |

| 622 | C–H def. out of the plane | |

| 539 | C–C in alkane skeletal linear |

| Samples | Tensile Strength (MPa) | Young’s Modulus (GPa) | Elongation at Break (%) |

|---|---|---|---|

| HIPS-0 | 19.84 ± 1.25 | 1.21 ± 0.05 | 19.74 ± 3.2 |

| HIPS-0.1 | 19.12 ± 0.57 | 13.74 ± 0.37 | 10.04 ± 2.24 |

| HIPS-0.5 | 22.45 ± 0.88 | 16.94 ± 0.22 | 21.9 ± 2.92 |

| HIPS-1 | 20.48 ± 1.35 | 12.63 ± 0.41 | 8.48 ± 2.46 |

| HIPS-2 | 19.50 ± 0.47 | 14.18 ± 0.31 | 20.06 ± 2.12 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sieradzka, M.; Fabia, J.; Biniaś, D.; Graczyk, T.; Fryczkowski, R. High-Impact Polystyrene Reinforced with Reduced Graphene Oxide as a Filament for Fused Filament Fabrication 3D Printing. Materials 2021, 14, 7008. https://doi.org/10.3390/ma14227008

Sieradzka M, Fabia J, Biniaś D, Graczyk T, Fryczkowski R. High-Impact Polystyrene Reinforced with Reduced Graphene Oxide as a Filament for Fused Filament Fabrication 3D Printing. Materials. 2021; 14(22):7008. https://doi.org/10.3390/ma14227008

Chicago/Turabian StyleSieradzka, Marta, Janusz Fabia, Dorota Biniaś, Tadeusz Graczyk, and Ryszard Fryczkowski. 2021. "High-Impact Polystyrene Reinforced with Reduced Graphene Oxide as a Filament for Fused Filament Fabrication 3D Printing" Materials 14, no. 22: 7008. https://doi.org/10.3390/ma14227008

APA StyleSieradzka, M., Fabia, J., Biniaś, D., Graczyk, T., & Fryczkowski, R. (2021). High-Impact Polystyrene Reinforced with Reduced Graphene Oxide as a Filament for Fused Filament Fabrication 3D Printing. Materials, 14(22), 7008. https://doi.org/10.3390/ma14227008