Analysis of the Reasons for the Tearing of Strips of High-Strength Electrical Steels in Tandem Cold Rolling

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

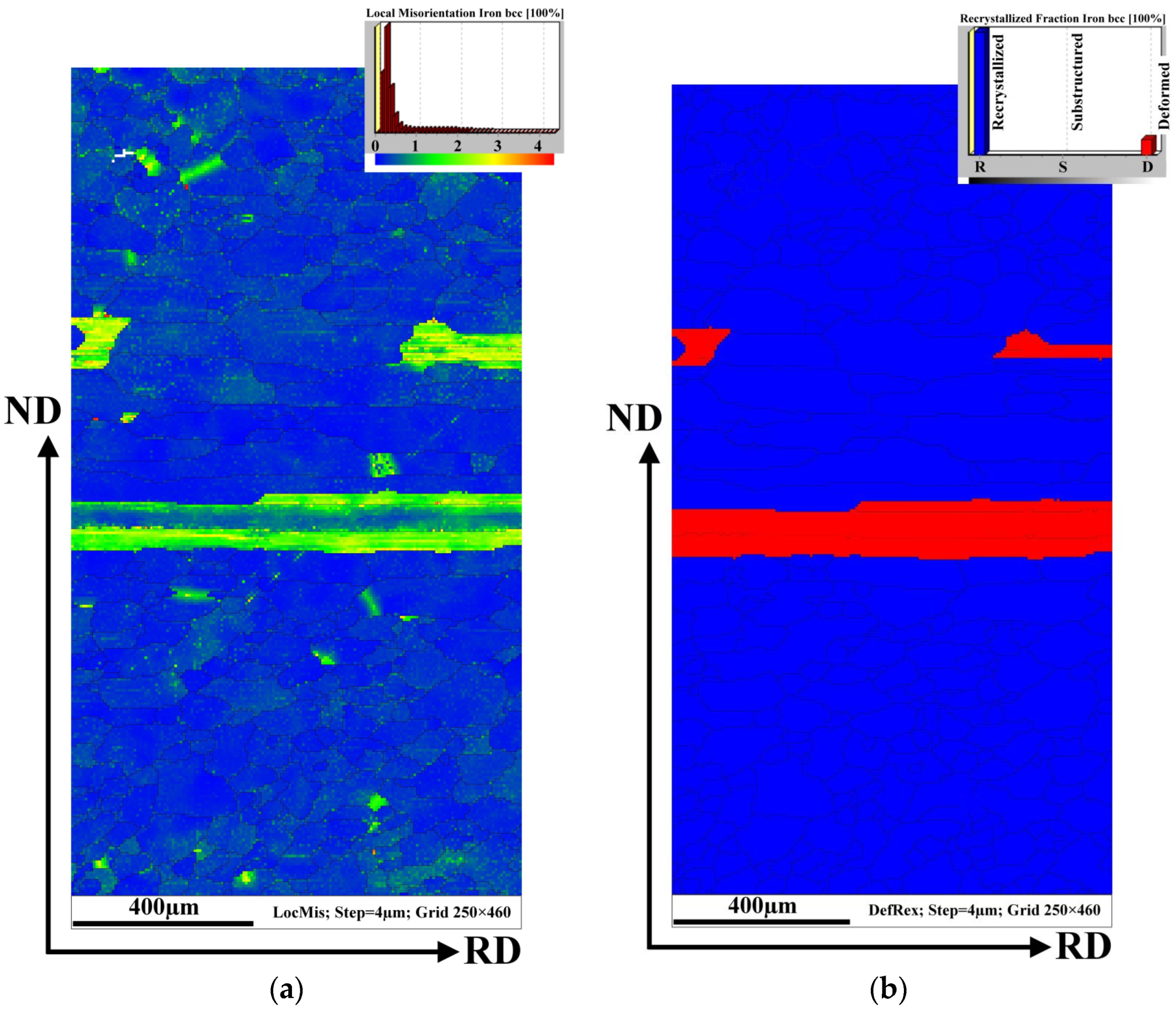

3.1. Microstructure of the Hot Band

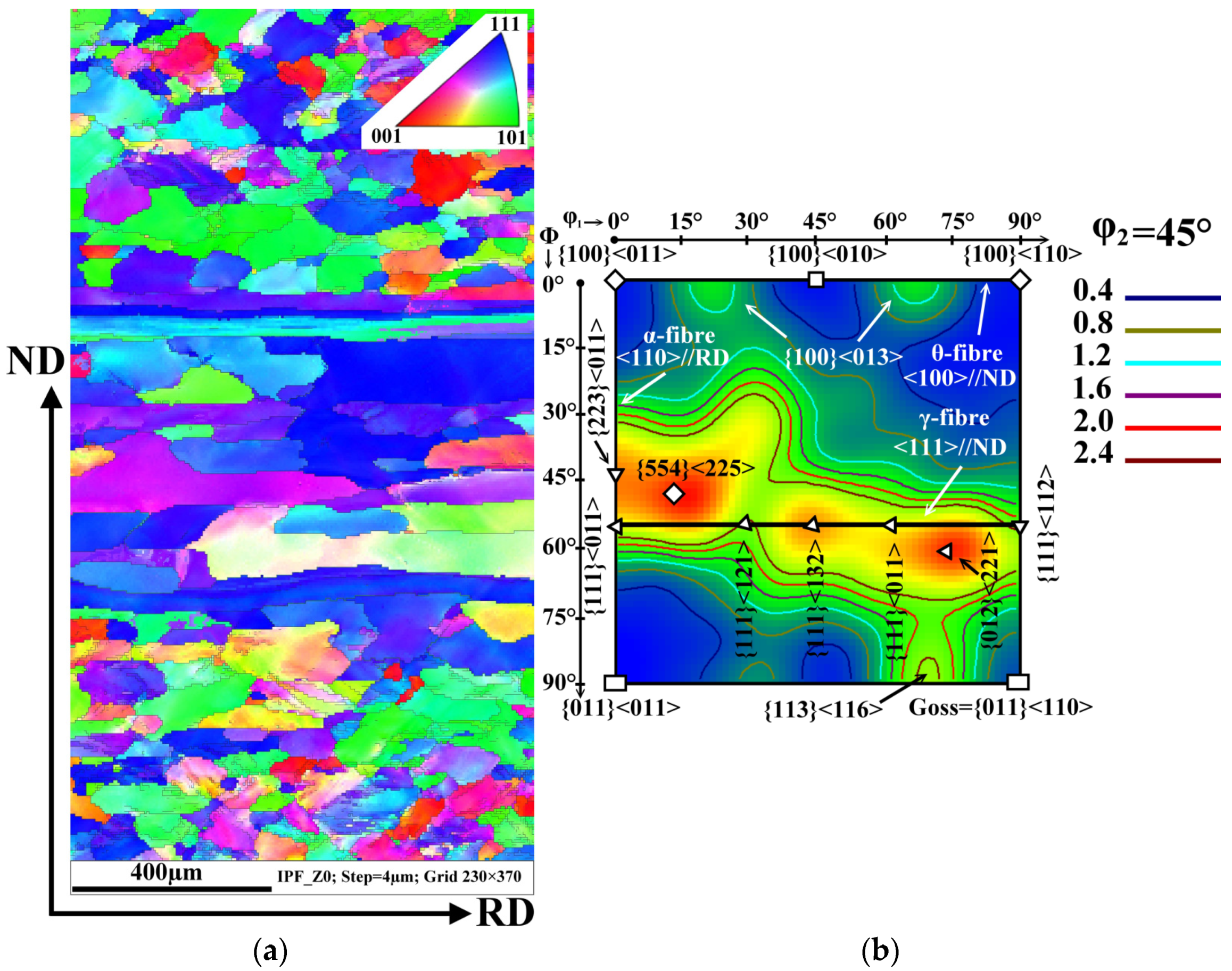

3.2. Texture and Local Misorientation Profile

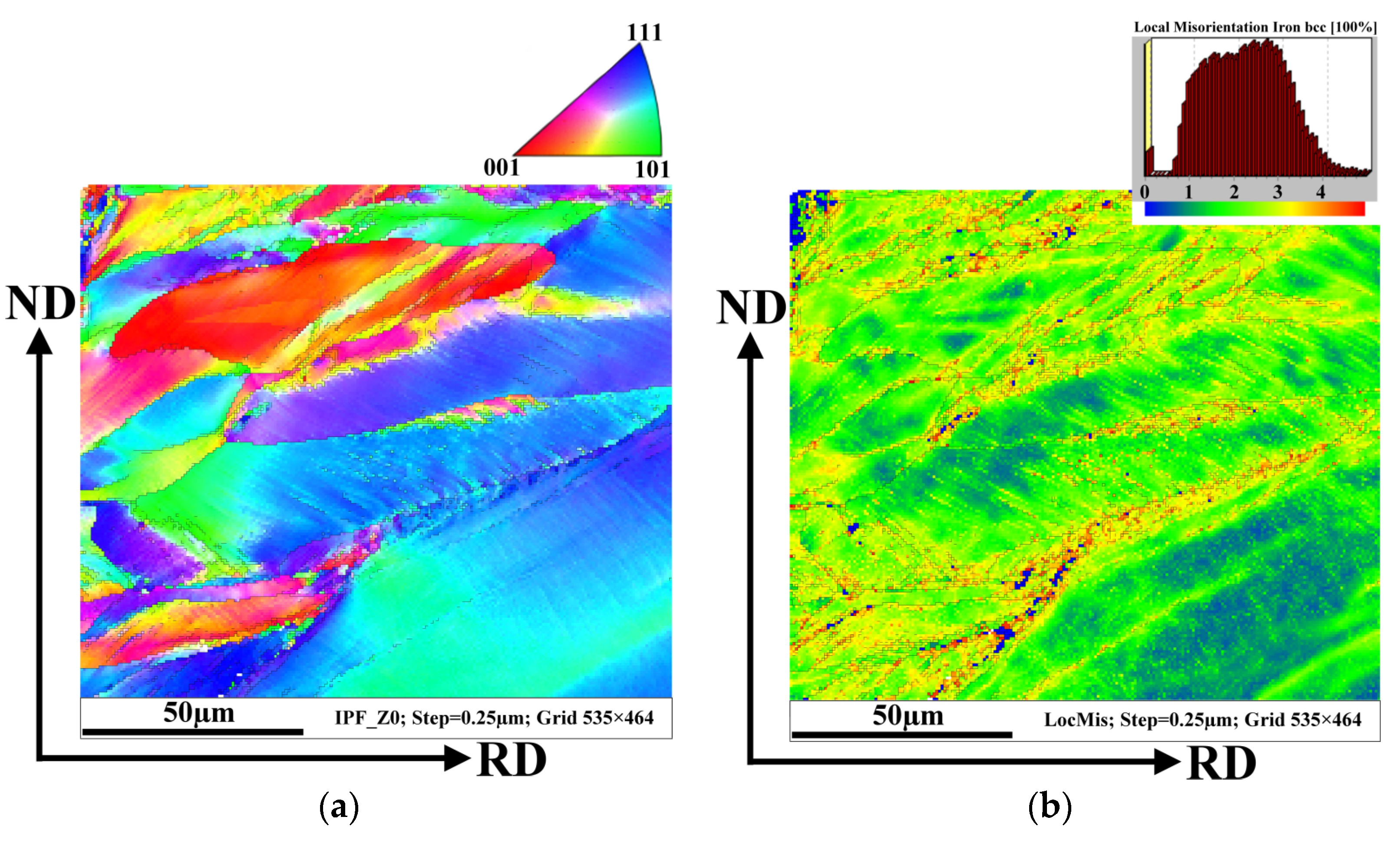

3.3. Microstructure and Texture of Specimens Subjected to a Tensile Test

3.4. Fractographic Analysis

4. Conclusions

- The microstructure of investigated hot band was characterized by a highly inhomogeneous morphology and size of grain structures across the band thickness. It was found that the microstructure was not fully recrystallized and the highly deformed regions were still presented in its central part. The results pointed to the fact that the parameters of hot rolling deformation or those of the box annealing heat treatment were likely not suitable for achieving the homogenous recrystallized microstructure throughout the whole thickness of hot bands.

- The analysis of crystallographic orientation has clearly shown that experimental hot strips exhibited the gradient crystallographic texture with strong intensity deformation texture {111}<uvw> in its middle part.

- The misorientation measurements through the cross-section of the ruptured hot band revealed two zones of plastic mechanical strains. One of them was formed between the surface of the sample and elongated hereditary grain structures and was characterized by high-intensity dislocation density, mostly in the vicinity of the zig-zag irregular grain boundaries as well as in the inside of elongated deformed grains. The lowest value of plastic deformation was detected in the central part of the sample thickness.

- The fractographic analysis of crack nucleation has clearly shown that the formation of intergranular cracks takes place only in the central part of the sample cross-section on the boundaries between the grains with a zig-zag morphology and elongated deformed structures.

- By comparing performed microstructural, textural, misorientation, and fractographic analyses it can be concluded that the mechanical plastic strain gradient was created through the hot band cross-section during the cold rolling reduction. Consequently, the motion of dislocations was slowed down on the elongated grains due to the dislocation pile-up effects leading to the plasticity exhaustion. The gradual formation of mechanical cracks inevitably resulted in observed tearing of strips of high-strength electrical steel during high-speed tandem cold rolling.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fang, F.; Lu, X.; Zhang, Y.X.; Wang, Y.; Jiao, H.T.; Cao, G.M.; Yuan, G.; Xu, Y.B.; Misra, R.D.K.; Wang, G.D. Influence of cold rolling direction on texture, inhibitor and magnetic properties in strip-cast grain-oriented 3% silicon steel. J. Magn. Magn. Mater. 2017, 427, 339–346. [Google Scholar] [CrossRef]

- Ivo, R.F.; Rodrigues, D.A.; Bezerra, G.M.; Freitas, F.N.C.; Abreu, H.F.; Filho, P.R. Non-grain oriented electrical steel photomicrograph classification using transfer learning. J. Mater. Res. Technol. 2020, 9, 8580–8591. [Google Scholar] [CrossRef]

- Hilinski, E. Recent developments in semiprocessed cold rolled magnetic lamination steel. J. Magn. Magn. Mater. 2006, 304, 172–177. [Google Scholar] [CrossRef]

- Steiner Petrovič, D.; Markoli, B.; Ceh, M. The nanostructure of non-oriented electrical steel sheets. J. Magn. Magn. Mater. 2010, 322, 3041–3048. [Google Scholar] [CrossRef]

- Xia, C.; Wang, H.; Wu, Y.; Wang, H. Joining of the laminated electrical steels in motor manufacturing: A review. Materials 2020, 13, 4583. [Google Scholar] [CrossRef]

- Senda, K.; Uesaka, M.; Yoshizaki, S.; Oda, Y. Electrical steels and their evaluation for automobile motors. World Electr. Veh. J. 2019, 10, 31. [Google Scholar] [CrossRef] [Green Version]

- You, D.; Park, H. Developmental trajectories in electrical steel technology using patent information. Sustainability 2018, 10, 2728. [Google Scholar] [CrossRef]

- Stoecker, A.; Leuning, N.; Hameyer, K.; Wei, X.; Hirt, G.; Korte-Kerzel, S.; Prahl, U.; Kawalla, R. Correlating magnetic properties of ferritic NO electrical steel containing 2.4 m.%Si with hot strip microstructure. J. Magn. Magn. Mater. 2020, 501, 166431. [Google Scholar] [CrossRef]

- Schneider, J.; Guangqiang, L.; Franke, A.; Zhou, B. Evolution of microstructure at hot band annealing of ferritic FeSi steels. J. Magn. Magn. Mater. 2017, 424, 26–32. [Google Scholar] [CrossRef]

- Leuning, N.; Steentjes, S.; Hameyer, K. Effect of grain size and magnetic texture on iron-loss components in NO electrical steel at different frequencies. J. Magn. Magn. Mater. 2019, 469, 373–382. [Google Scholar] [CrossRef]

- Jiao, H.; Xu, Y.; Zhao, L.; Misra, R.D.K.; Tang, Y.; Liu, D.; Hu, Y.; Zhao, M.; Shen, M. Texture evolution in twin-roll strip cast non-oriented electrical steel with strong cube and goss texture. Acta Mater. 2020, 188, 311–325. [Google Scholar] [CrossRef]

- Wang, Y.Q.; Zhang, X.M.; Zu, G.Q.; Guan, Y.; Ji, G.F.; Mista, R.D.K. Effect of hot band annealing on microstructure, texture and magnetic properties of non-oriented electrical steel processed by twin-roll strip casting. J. Magn. Magn. Mater. 2018, 460, 41–53. [Google Scholar] [CrossRef]

- Petryshynets, I.; Kováč, F.; Fuzer, J.; Falat, L.; Puchý, V.; Kollár, P. Evolution of power losses in bending rolled fully finished no electrical steel treated under unconventional annealing conditions. Materials 2019, 12, 2200. [Google Scholar] [CrossRef] [Green Version]

- Petryshynets, I.; Kováč, F.; Petrov, B.; Falat, L.; Puchý, V. Improving the magnetic properties of non-oriented electrical steels by secondary recrystallization using dynamic heating conditions. Materials 2019, 12, 1914. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yanez-Ros, T.; Calvillo, P.R.; Colas, R.; Houbaert, Y. Workability and straining behavior of high silicon steels (3.0–6.3% Si) by hot torsion and RT compression test. Mater. Sci. Forum 2007, 429, 4422–4427. [Google Scholar] [CrossRef]

- Zu, G.; Wang, Y.; Zhao, J.; Yan, Y.; Zhang, X.; Ran, X.; Jiang, Z. Revealing the recrystallization behavior of an excellent strip casting 4.5 wt% Si non-oriented electrical steel. Mater. Charact. 2020, 163, 110310. [Google Scholar] [CrossRef]

- Hou, D.; Fang, F.; Wang, Y.; Zhang, Y.; Zhang, X.; Misra, R.D.K.; Yuan, G. Nanoprecipitation behavior and resultant mechanical and magnetic properties in Fe–Si–Ni–Al–Mn high strength non-oriented silicon steel. Mater. Sci. Eng. 2021, 819, 141529. [Google Scholar] [CrossRef]

- Schulte, M.; Steentjes, S.; Leuning, N.; Bleck, W.; Hameyer, K. Effect of manganese in high silicon alloyed non-oriented electrical steel sheets. J. Magn. Magn. Mater. 2019, 477, 372–381. [Google Scholar] [CrossRef]

- Almeida, A.A.; Paolinelli, S.C.; Landgraf, F.J.G. Effect of the silicon content on the hysteresis loss of non-oriented steels. IEEE Trans. Magn. 2019, 55, 2002404. [Google Scholar] [CrossRef]

- Oda, Y.; Kohno, M.; Honda, A. Recent development of non-oriented electrical steel sheet for automobileelectrical devices. J. Magn. Magn. Mater. 2008, 320, 2430–2435. [Google Scholar] [CrossRef]

- Leuning, N.; Steentjes, S.; Heller, M.; Korte-Kerzel, S.; Hameyer, K. On the correlation of crystallographic macro-texture and magnetic magnetization anisotropy in non-oriented electrical steel. J. Magn. Magn. Mater. 2019, 490, 165485. [Google Scholar] [CrossRef]

- Pedrossa, J.S.M.; Paolinelli, S.C.; Cota, A.B. Influence of initial annealing on structure evolution and magnetic properties of 3.4% Si non-oriented steel during final annealing. J. Magn. Magn. Mater. 2015, 393, 146–150. [Google Scholar] [CrossRef]

- Sidor, J.J.; Verbeken, K.; Gomes, E.; Schneider, J.; Calvillo, P.R.; Kestens, L.A.I. Through process texture evolution and magnetic properties of high Si non-oriented electrical steels. Mater. Charact. 2012, 71, 49–57. [Google Scholar] [CrossRef]

- Lee, H.H.; Jung, J.; Yoon, J.I.; Kim, J.K.; Kim, H.S. Modeling the evolution of recrystallization texture for a non-grain oriented electrical steel. Comput. Mater. Sci. 2018, 149, 57–64. [Google Scholar] [CrossRef]

- Cheng, L.; Zhang, N.; Yang, P.; Mao, W.M. Retaining {100} texture from initial columnar grains in electrical steels. Scr. Mater. 2012, 67, 899–902. [Google Scholar] [CrossRef]

- Sandova Robles, J.A.; Salas Zamarripa, A.; Guerrero Mata, M.P.; Cabrera, J. Texture evolution of experimental silicon steel grades. Part I: Hot rolling. J. Magn. Magn. Mater. 2017, 429, 367–371. [Google Scholar] [CrossRef] [Green Version]

- Rusnák, J.; Malega, P.; Svetlík, J.; Rudy, V.; Šmajda, N. The research of the rolling speed influence on the mechanism of strip breaks in the steel rolling process. Materials 2020, 13, 3509. [Google Scholar] [CrossRef]

- Hu, Z.; Wei, Z.; Ma, X.; Sun, H.; Yang, J. Multi-parameter deep-perception and many-objective autonomous-control of rolling schedule on high speed cold tandem mill. ISA Trans. 2020, 102, 193–207. [Google Scholar] [CrossRef]

- Li, Z.H.; Xie, S.K.; Wang, G.D.; Liu, H.T. Dependence of recrystallization behavior and magnetic properties on grain size prior to cold rolling in high silicon non-oriented electrical steel. J. Alloys Compd. 2021, 888, 161576. [Google Scholar] [CrossRef]

- Tanaka, Y.; Takaki, S.; Tsuchiyama, T.; Uemori, R. Effect of grain size on the yield stress of coild worked iron. ISIJ Int. 2018, 58, 1927–1933. [Google Scholar] [CrossRef] [Green Version]

- Zhang, B.; Liang, Y.; Wen, S.; Wang, S.; Shi, X.; Ye, F.; Lin, J. High-strength low-iron-loss silicon steels fabricated by cold rolling. J. Magn. Magn. Mater. 2019, 474, 51–55. [Google Scholar] [CrossRef]

- Soares, G.C.; Gonzalez, B.M.; Santos, L.A. Strain hardening behavior and microstructural evolution during plastic deformation of dual phase, non-grain oriented electrical and AISI 304 steels. Mater. Sci. Eng. A 2017, 684, 577–585. [Google Scholar] [CrossRef]

- Qin, J.; Yang, J.; Zhang, Y.; Zhou, Q.; Cao, Y. Strong {1 0 0}<0 1 2>-{4 1 1}<1 4 8> recrystallization textures in heavily hot-rolled non-oriented electrical steels. Mater. Lett. 2020, 259, 126844. [Google Scholar] [CrossRef]

- Mehdi, M.; He, Y.; Hilinski, E.J.; Kestens, L.A.I.; Edrisy, A. The evolution of cube ({001}<100>) texture in non-oriented electrical steel. Acta Mater. 2020, 185, 540–554. [Google Scholar] [CrossRef]

- Wang, J.H.; Yang, P.; Mao, W.M.; Cui, F. Orientation gradient on surface of non-oriented electrical steel annealed by γ-α transformation. J. Iron Steel Res. Int. 2020, 27, 88–95. [Google Scholar] [CrossRef]

- Sidor, Y.; Kovac, F.; Kvackaj, T. Grain growth phenomena and heat transport in non-oriented electrical steels. Acta Mater. 2007, 55, 1711–1722. [Google Scholar] [CrossRef]

- Mehdi, M.; He, Y.; Hilinski, E.J.; Edrisy, A. Effect of skin pass rolling reduction rate on the texture evolution of a non-oriented electrical steel after inclined cold rolling. J. Magn. Magn. Mater. 2017, 429, 148–160. [Google Scholar] [CrossRef]

- Du, Y.; Zhou, Q.; Jia, Q.; Shi, Y.; Wang, H.; Wang, J. Imparities of shear avalanches dynamic evolution in a metallic glass. Mater. Res. Lett. 2020, 8, 357–363. [Google Scholar] [CrossRef]

- Hansen, N. Hall-Petch relation and boundary strengthening. Scr. Mater. 2004, 51, 801–806. [Google Scholar] [CrossRef]

- Fedorov, A.A.; Gutkin, M.Y.; Oviďko, I.A. Transformations of grain boundary dislocation pile-ups in nano- and polycrystalline materials. Acta Mater. 2003, 51, 887–898. [Google Scholar] [CrossRef]

- He, Y.; Hilinski, E.J. Texture and magnetic properties of non-oriented electrical steels processed by an unconventional cold rolling scheme. J. Magn. Magn. Mater. 2016, 405, 337–352. [Google Scholar] [CrossRef]

- Hayakawa, Y.; Kurosawa, M. Orientation relationship between primary and secondary recrystallized texture in electrical steel. Acta Mater. 2002, 50, 4527–4534. [Google Scholar] [CrossRef]

- Jiaoa, H.T.; Xub, Y.B.; Zhaoa, L.Z.; Misrac, R.D.K.; Tanga, Y.C.; Zhaoa, M.J.; Liua, D.J.; Hua, Y.; Shena, M.X. Microstructural evolution and magnetic properties in strip cast non-oriented silicon steel produced by warm rolling. Mater. Charact. 2019, 156, 109876. [Google Scholar] [CrossRef]

- Pittner, J.; Simaan, M.A.; Samaras, N.S. A Novel Approach for Optimal Control of Continuous Tandem Cold Metal Rolling. IEEE Ind. Appl. Annu. Meet. 2007, 9877497. [Google Scholar]

- Armstromg, R.W. Dislocation pile-ups, strength properties and fracture. Rev. Adv. Mater. Sci. 2017, 48, 1–12. [Google Scholar]

- Katiyar, T.; Giessen, E.V. Effective mobility of BCC dislocations in two-dimensional discrete dislocation plasticity. Comput. Mater. Sci. 2021, 187, 110129. [Google Scholar] [CrossRef]

- Kobayashi, S.; Inomata, T.; Kobayashi, H.; Tsurekawa, S.; Watanabe, T. Effects of grain boundary- and triple junction-character on intergranular fatigue crack nucleation in polycrystalline aluminum. J. Mater. Sci. 2008, 43, 3792–3799. [Google Scholar] [CrossRef]

- Chen, B.; Jiang, J.; Dunne, F.P.E. Is stored energy density the primary meso-scale mechanistic driver for fatigue crack nucleation. Int. J. Plast. 2018, 101, 213–229. [Google Scholar] [CrossRef]

- Nagoshi, T.; Kozu, S.; Inoue, Y.; O’Rourke, B.E.; Harada, Y. Fatigue damage assessment of SUS316L using EBSD and PALSmeasurements. Mater. Charact. 2019, 154, 61–66. [Google Scholar] [CrossRef]

- Humphreys, F.J.; Hatherly, M. (Eds.) Recrystallisation and Related Annealing Phenomena, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2004. [Google Scholar]

- Gussev, M.N.; Leonard, K.J. In situ SEM-EBSD analysis of plastic deformation mechanisms in neutron-irradiated austenitic steel. J. Nucl. Mater. 2019, 517, 45–56. [Google Scholar] [CrossRef]

- Hashmati, M.; Haghani, R.; Emrani, M.A.; Ande, A. On the strength prediction of adhesively bonded FRP-steel joints using cohesive zone modelling. Theor. Appl. Fract. Mech. 2018, 93, 64–78. [Google Scholar] [CrossRef]

- Aikawa, T.; Kawabata, T. Consideration on the toughness difference depending on the direction of brittle crack propagation in very thick steel. Procedia Struct. Integr. 2019, 21, 173–184. [Google Scholar] [CrossRef]

| Si | C | Mn | Al | P | Fe | Other Elements |

|---|---|---|---|---|---|---|

| 3.21 | 0.006 | 0.25 | 0.18 | 0.04 | 97.95 | <0.094 |

| Rp0.2, [MPa] | Rm, [MPa] | |

|---|---|---|

| Rolling direction | 475 ± 11 | 595 ± 15 |

| Transverse direction | 503 ± 13 | 639 ± 14 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Petryshynets, I.; Kováč, F.; Falat, L. Analysis of the Reasons for the Tearing of Strips of High-Strength Electrical Steels in Tandem Cold Rolling. Materials 2021, 14, 7124. https://doi.org/10.3390/ma14237124

Petryshynets I, Kováč F, Falat L. Analysis of the Reasons for the Tearing of Strips of High-Strength Electrical Steels in Tandem Cold Rolling. Materials. 2021; 14(23):7124. https://doi.org/10.3390/ma14237124

Chicago/Turabian StylePetryshynets, Ivan, František Kováč, and Ladislav Falat. 2021. "Analysis of the Reasons for the Tearing of Strips of High-Strength Electrical Steels in Tandem Cold Rolling" Materials 14, no. 23: 7124. https://doi.org/10.3390/ma14237124

APA StylePetryshynets, I., Kováč, F., & Falat, L. (2021). Analysis of the Reasons for the Tearing of Strips of High-Strength Electrical Steels in Tandem Cold Rolling. Materials, 14(23), 7124. https://doi.org/10.3390/ma14237124