Influence of Metallic Powder Characteristics on Extruded Feedstock Performance for Indirect Additive Manufacturing

Abstract

1. Introduction

2. Characterisation Techniques and Material

2.1. Experimental Conditions

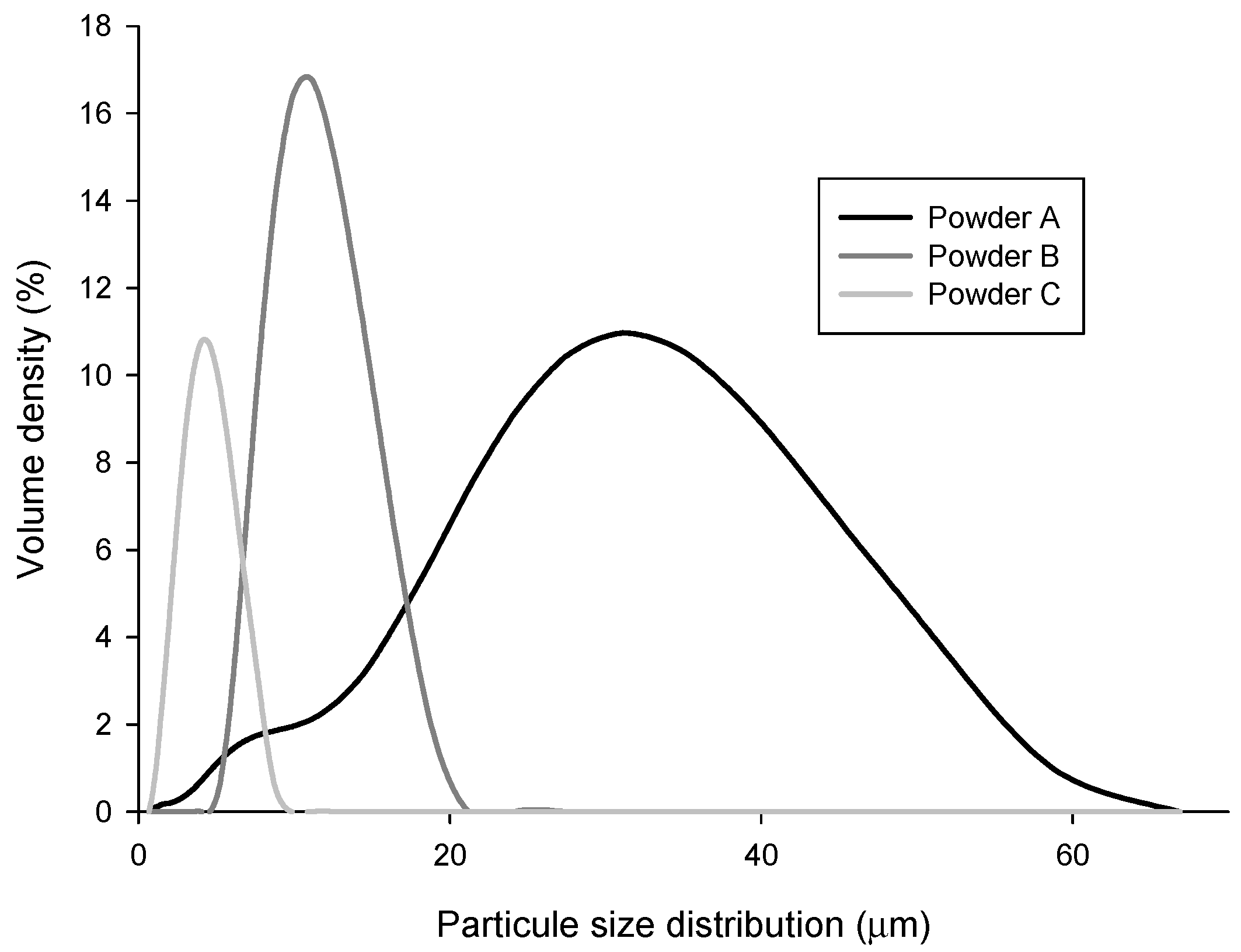

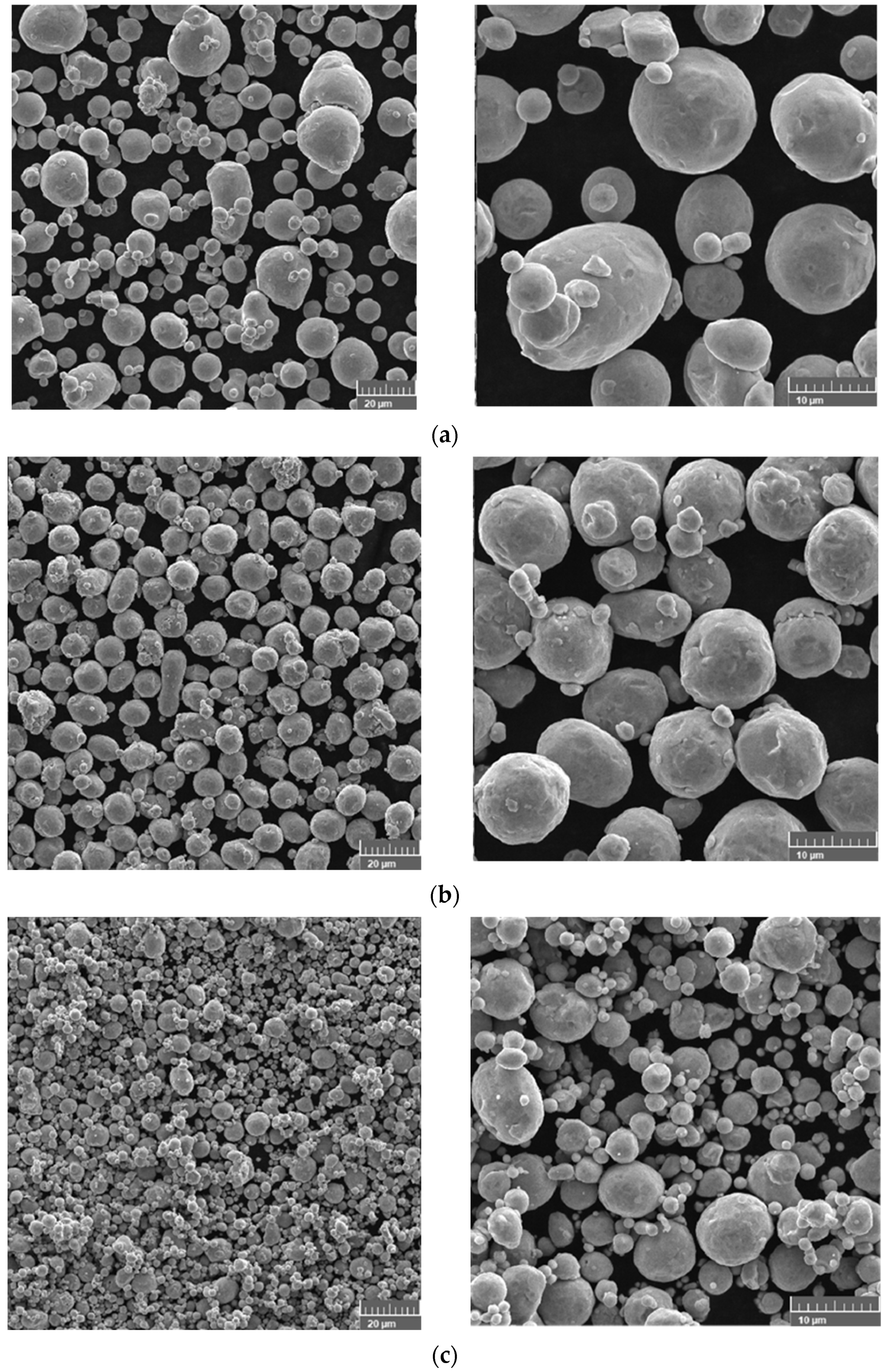

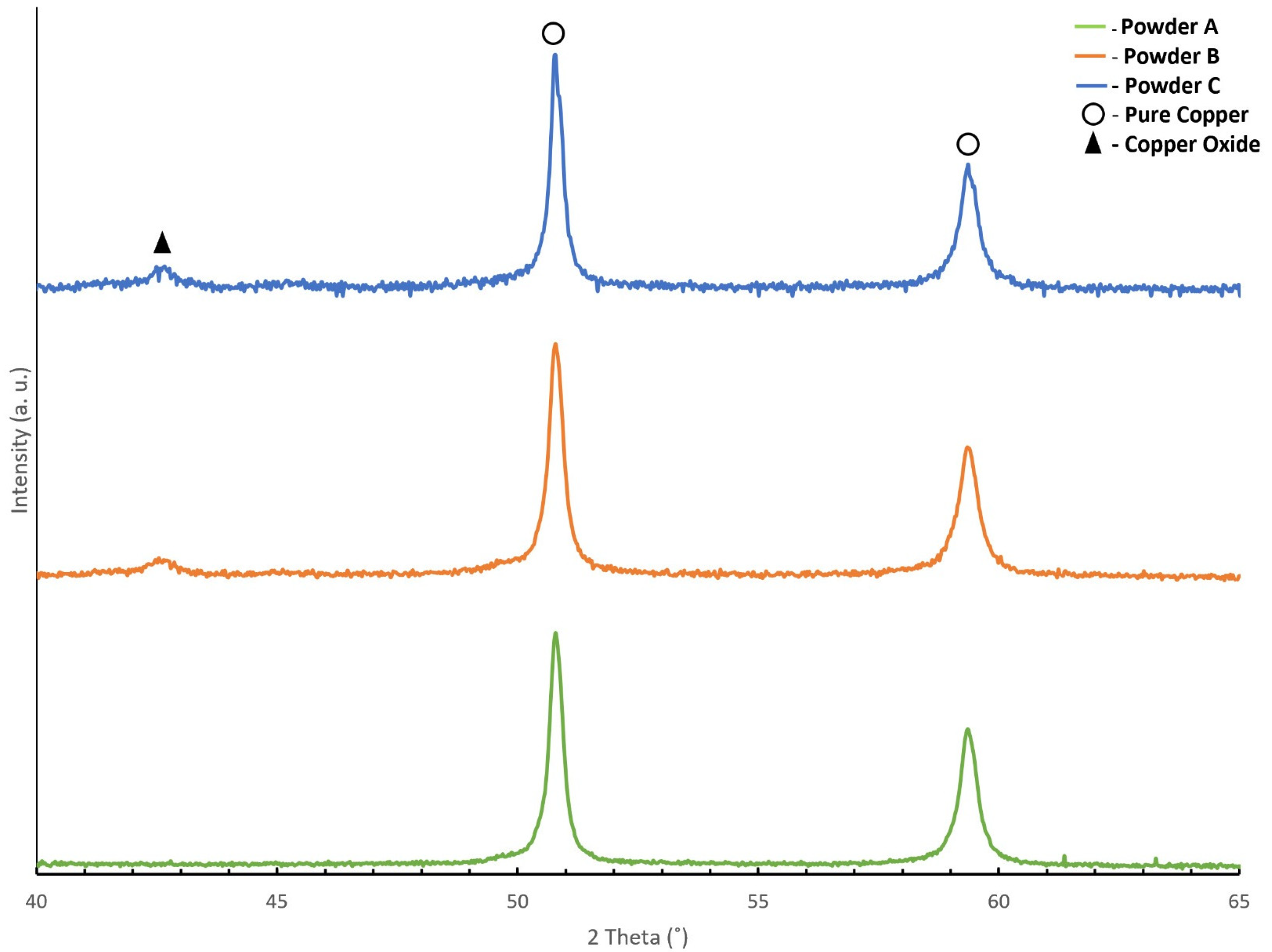

2.2. Copper Powder Characterisation

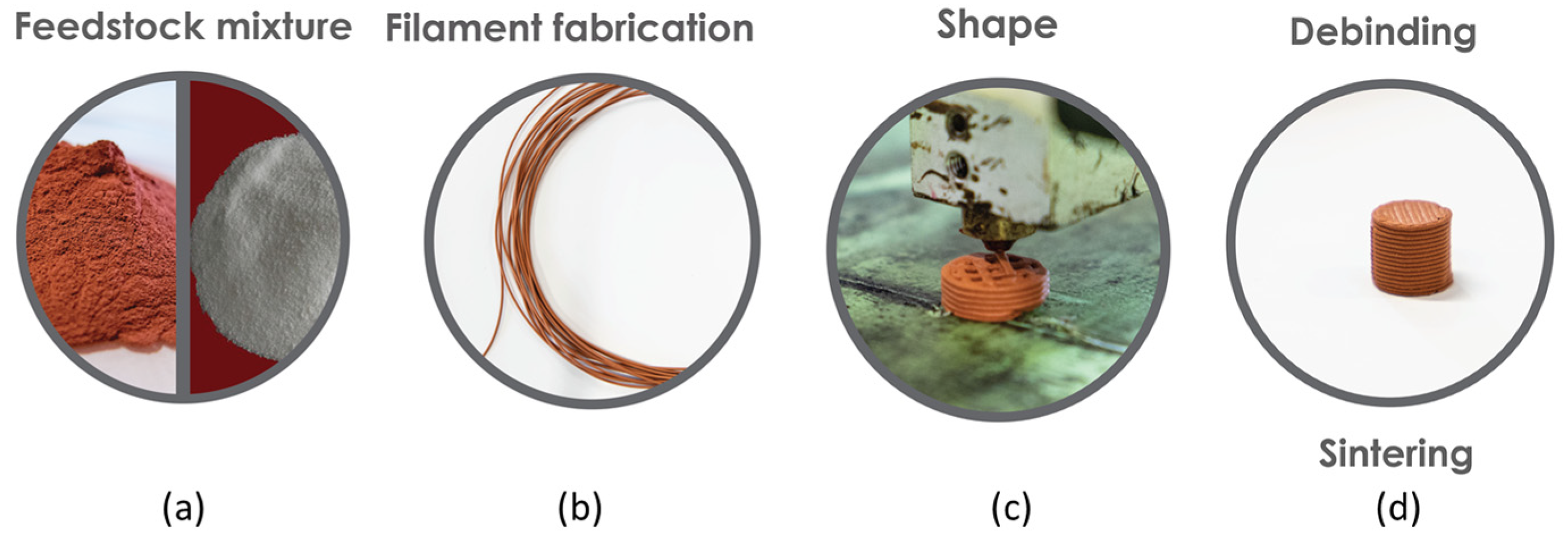

3. Experimental Methodology

3.1. Processing of Filament Feedstocks

3.1.1. Evaluation of CPVC

3.1.2. Filaments

3.2. Three-Dimensional (3D) Printing

3.3. Processing Conditions after Shaping

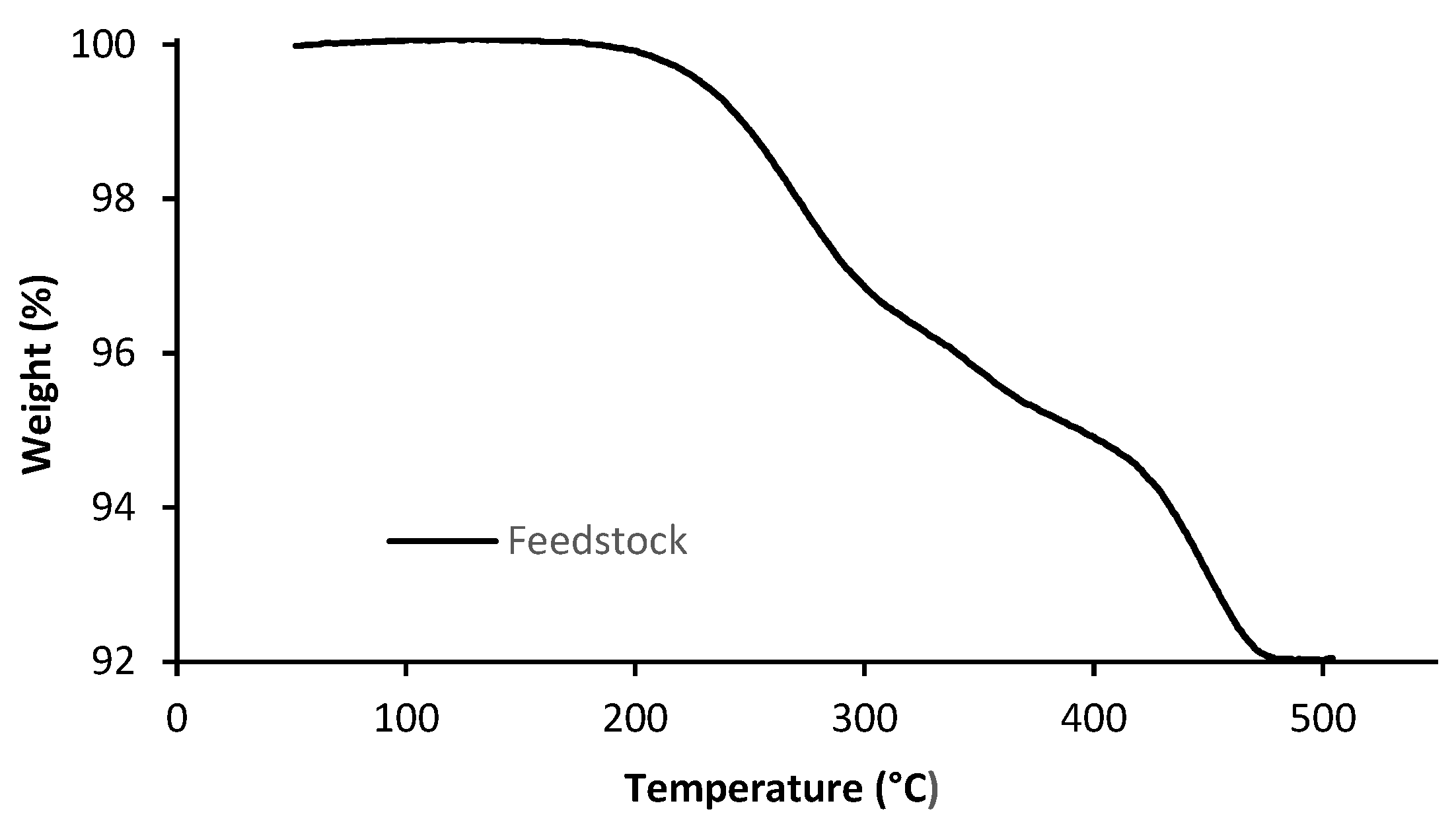

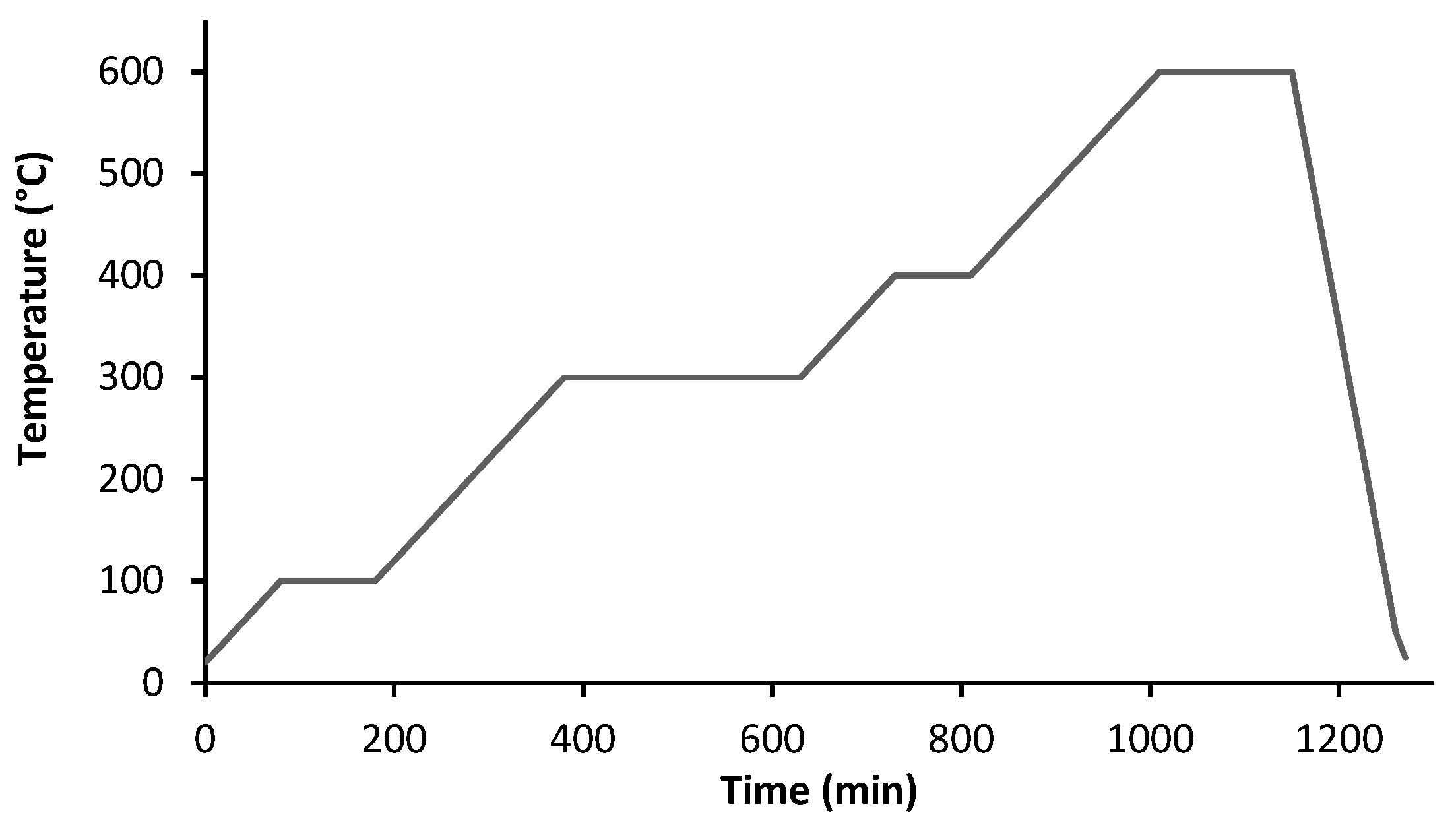

3.3.1. Debinding

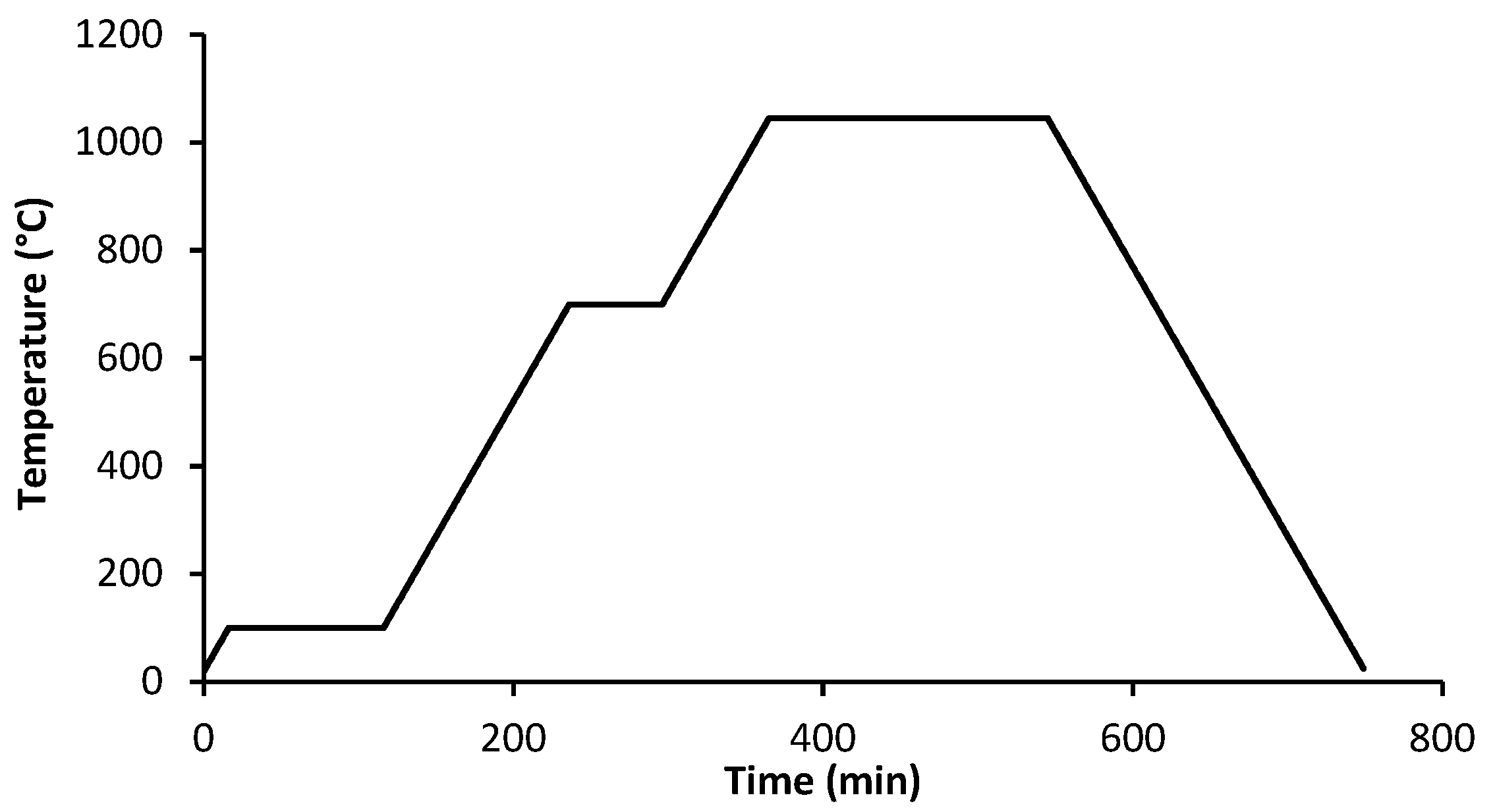

3.3.2. Sintering

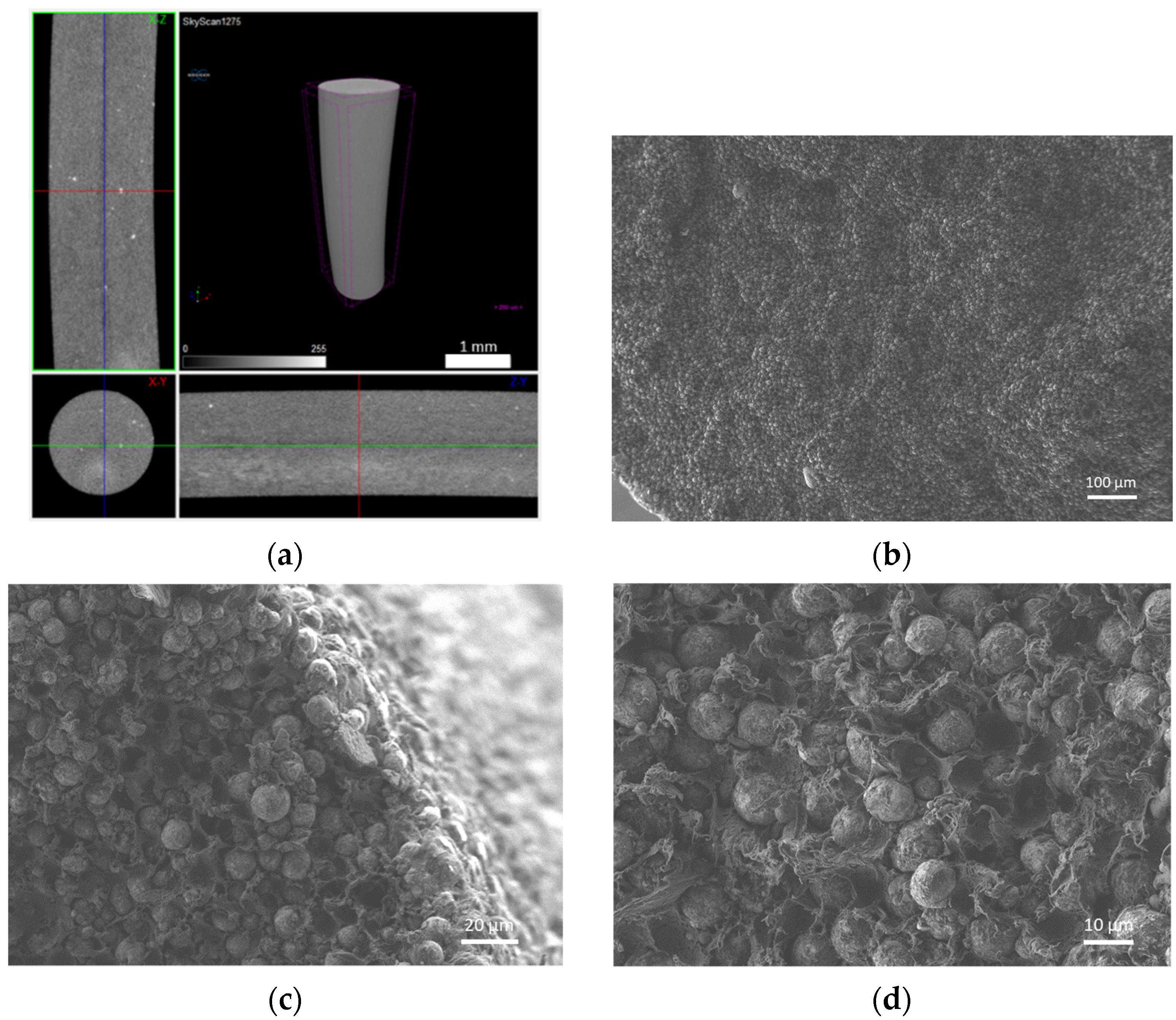

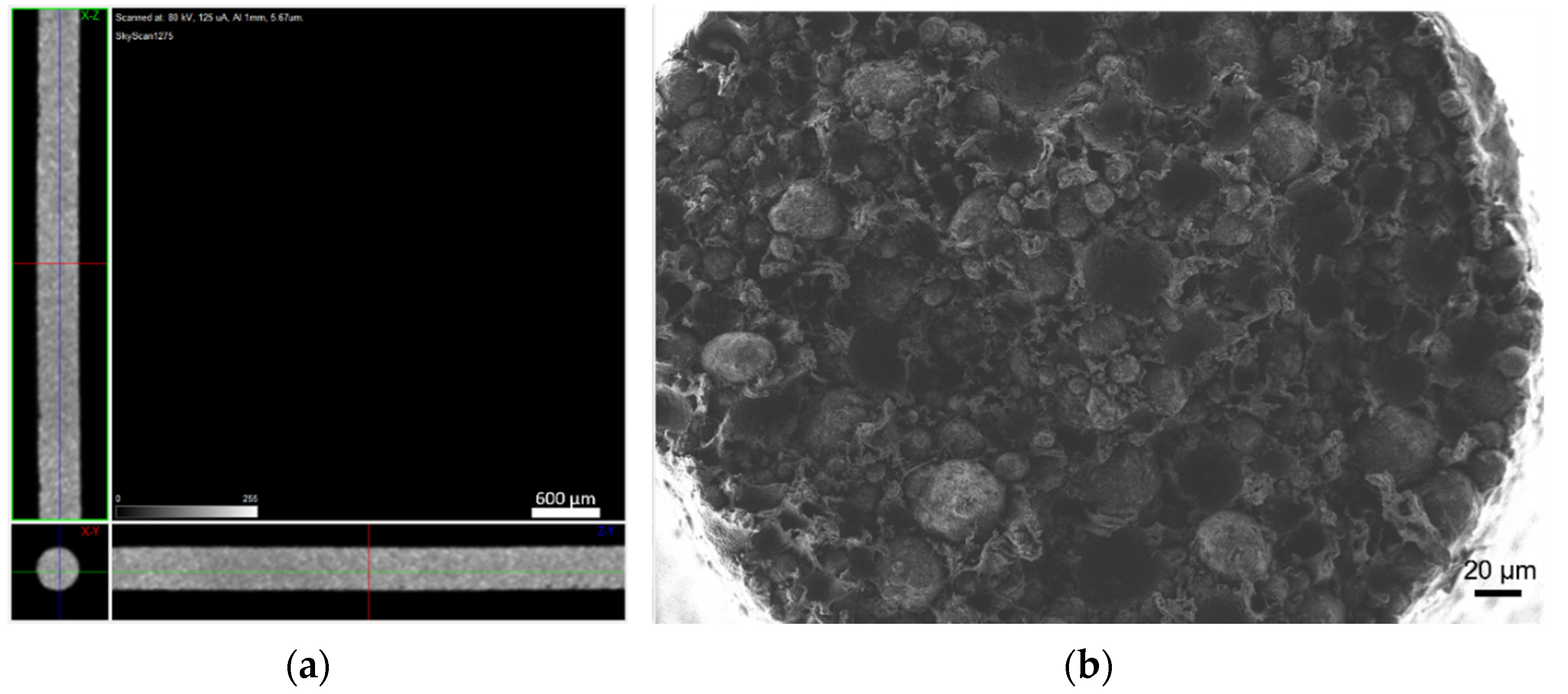

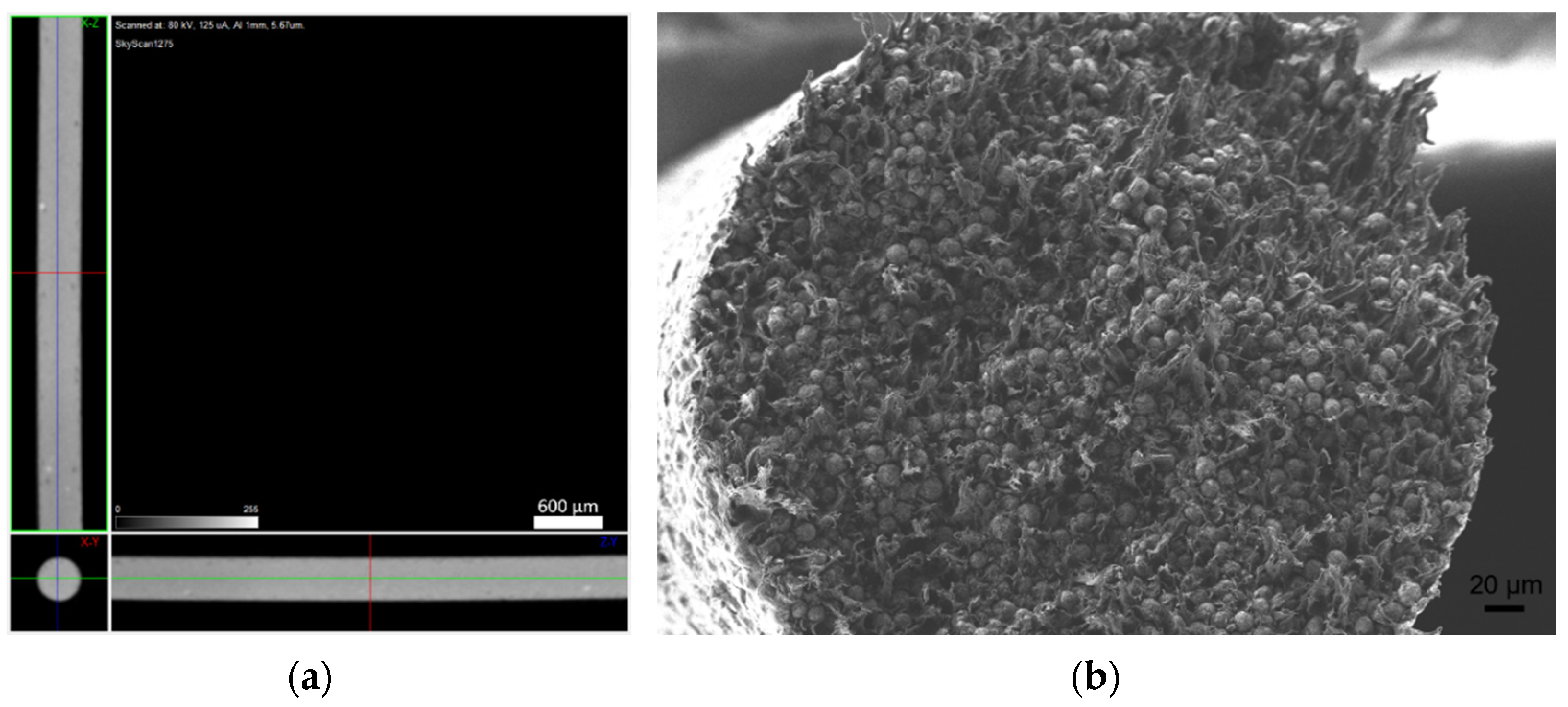

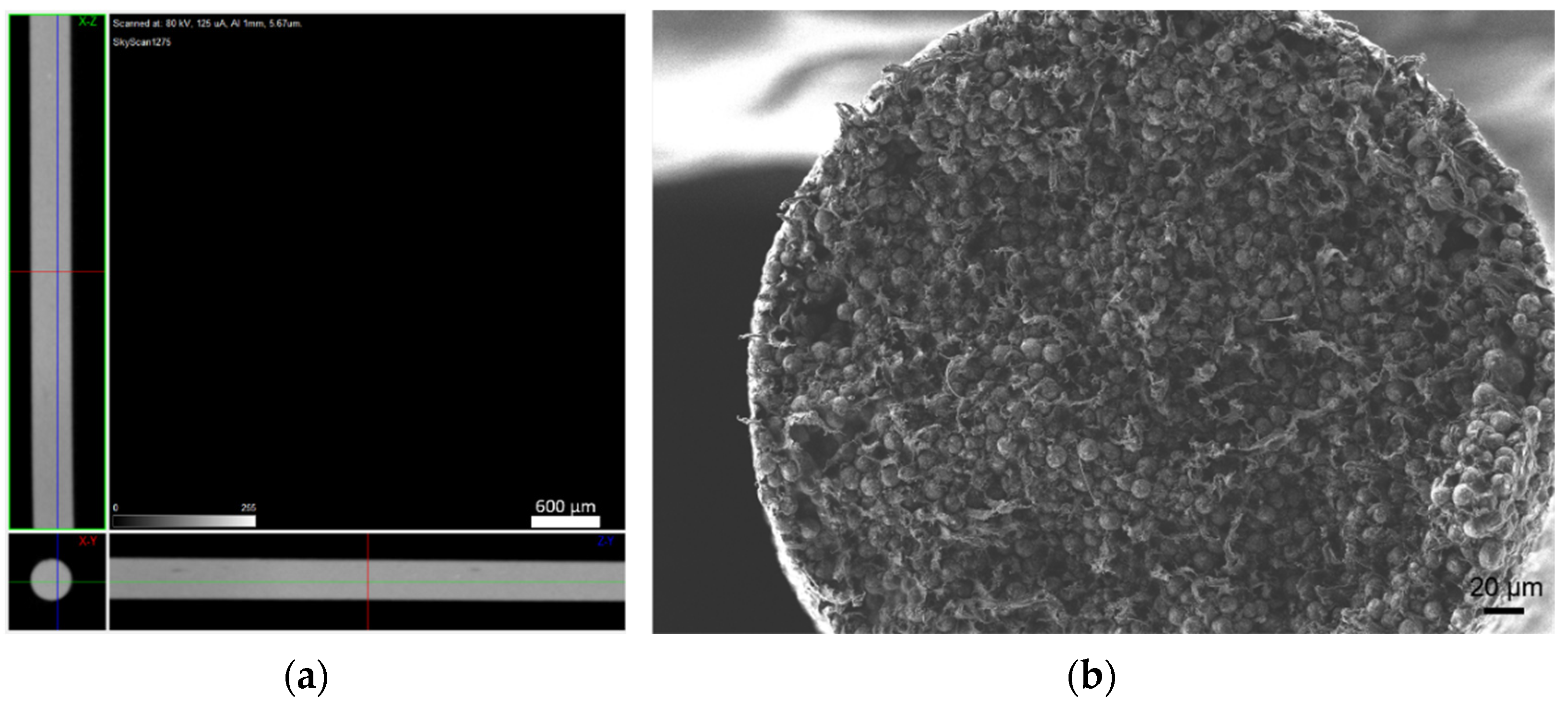

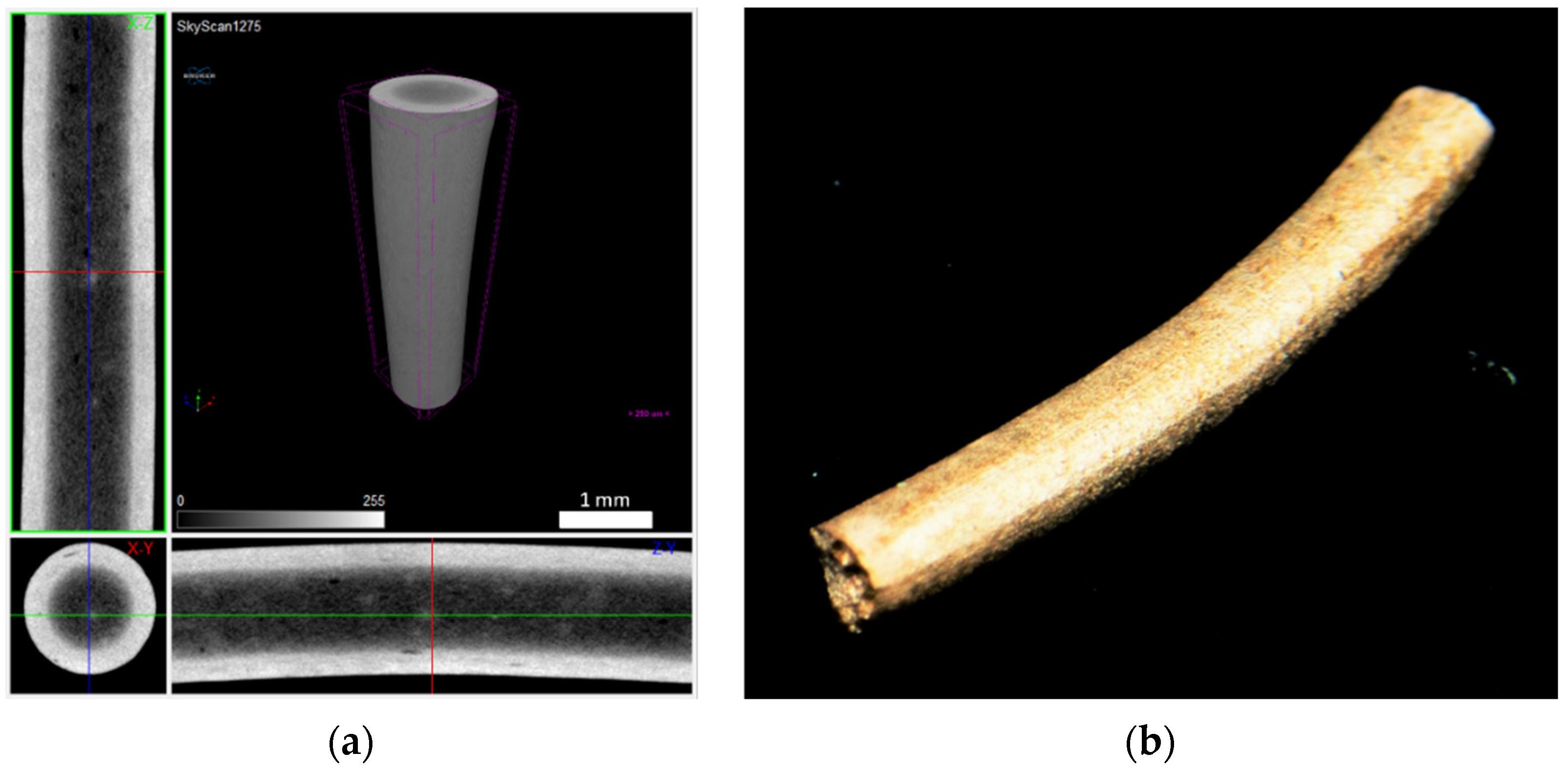

3.3.3. Micrographic Analysis of Green and Sintered Filament

4. Results and Discussion

4.1. Optimisation of Feedstocks for Copper Filaments

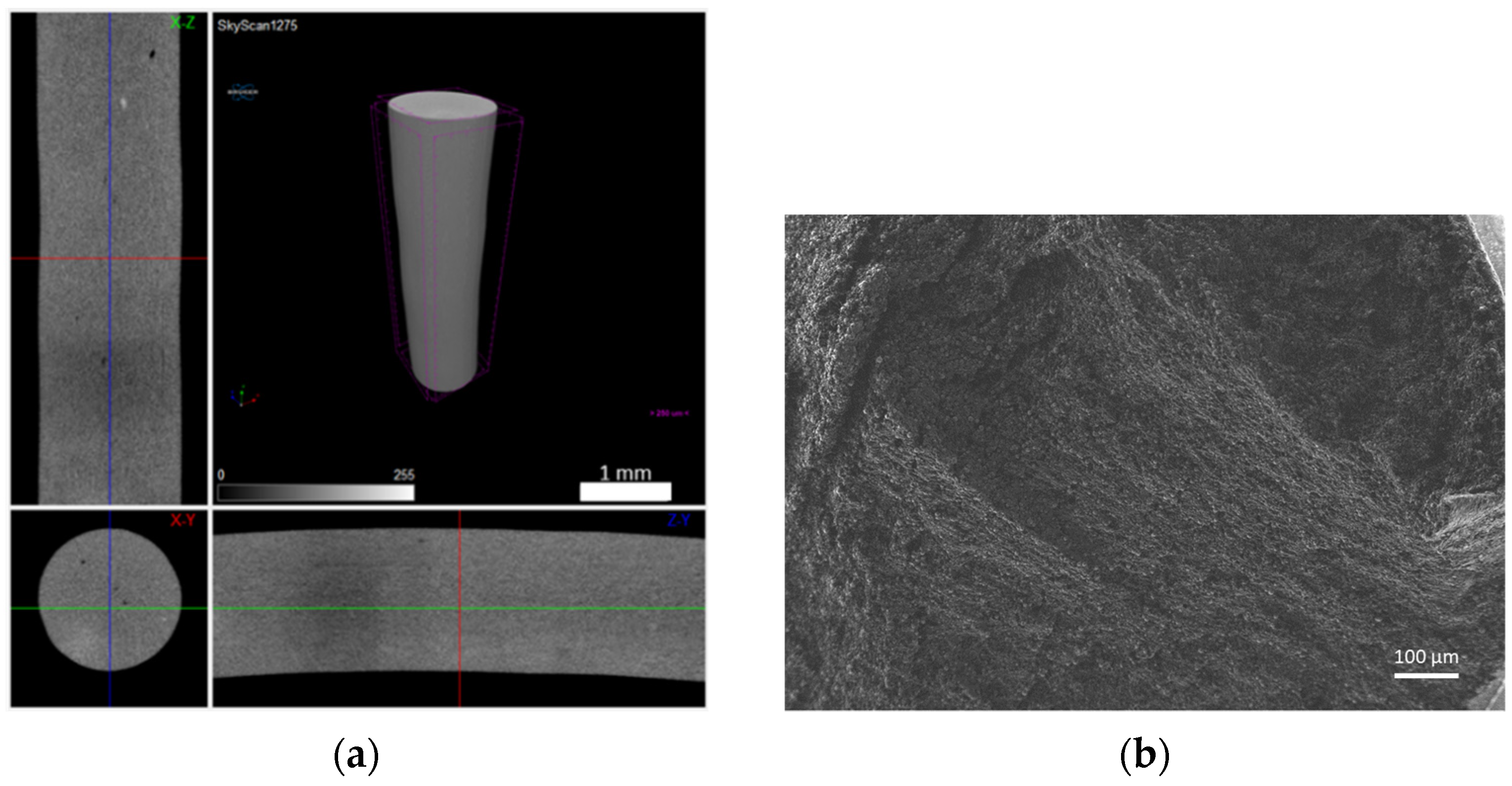

4.2. Green

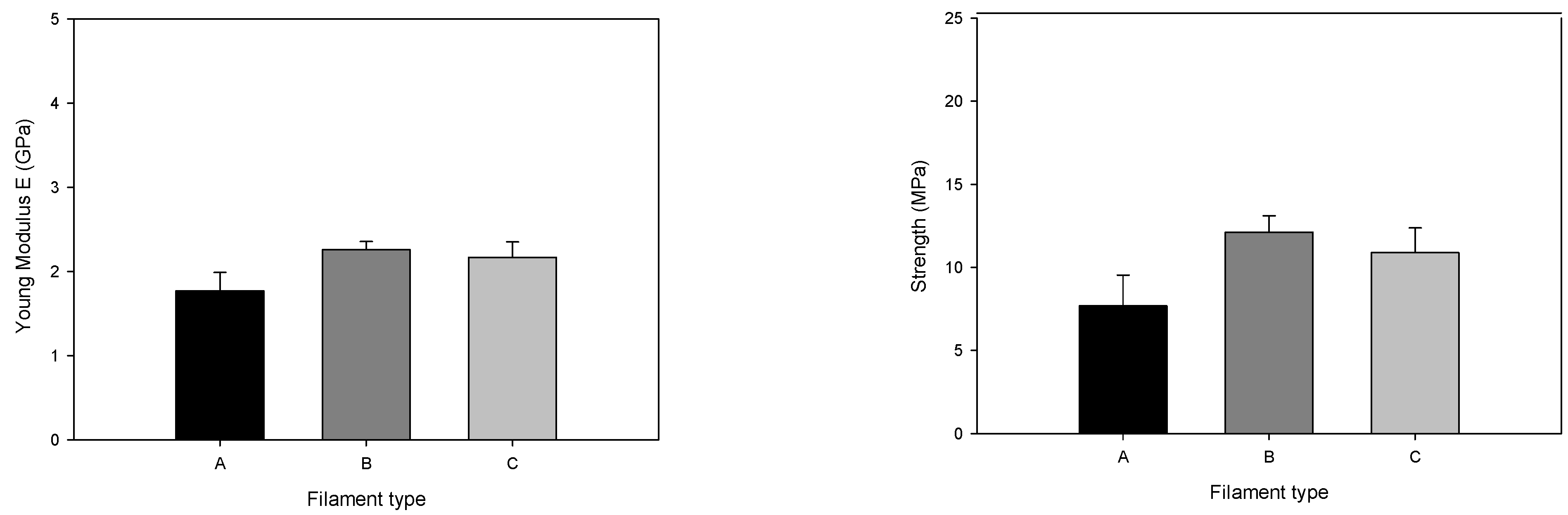

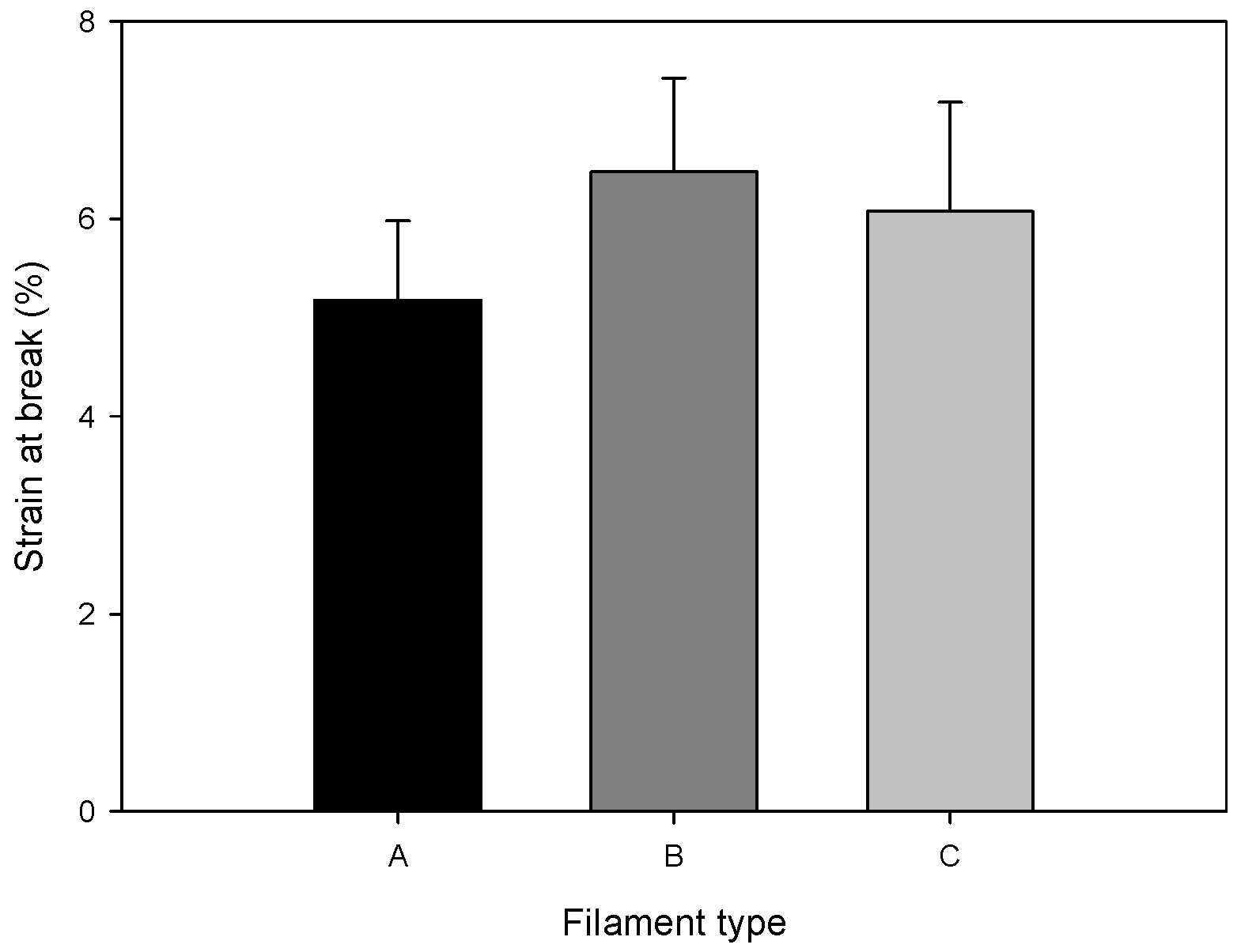

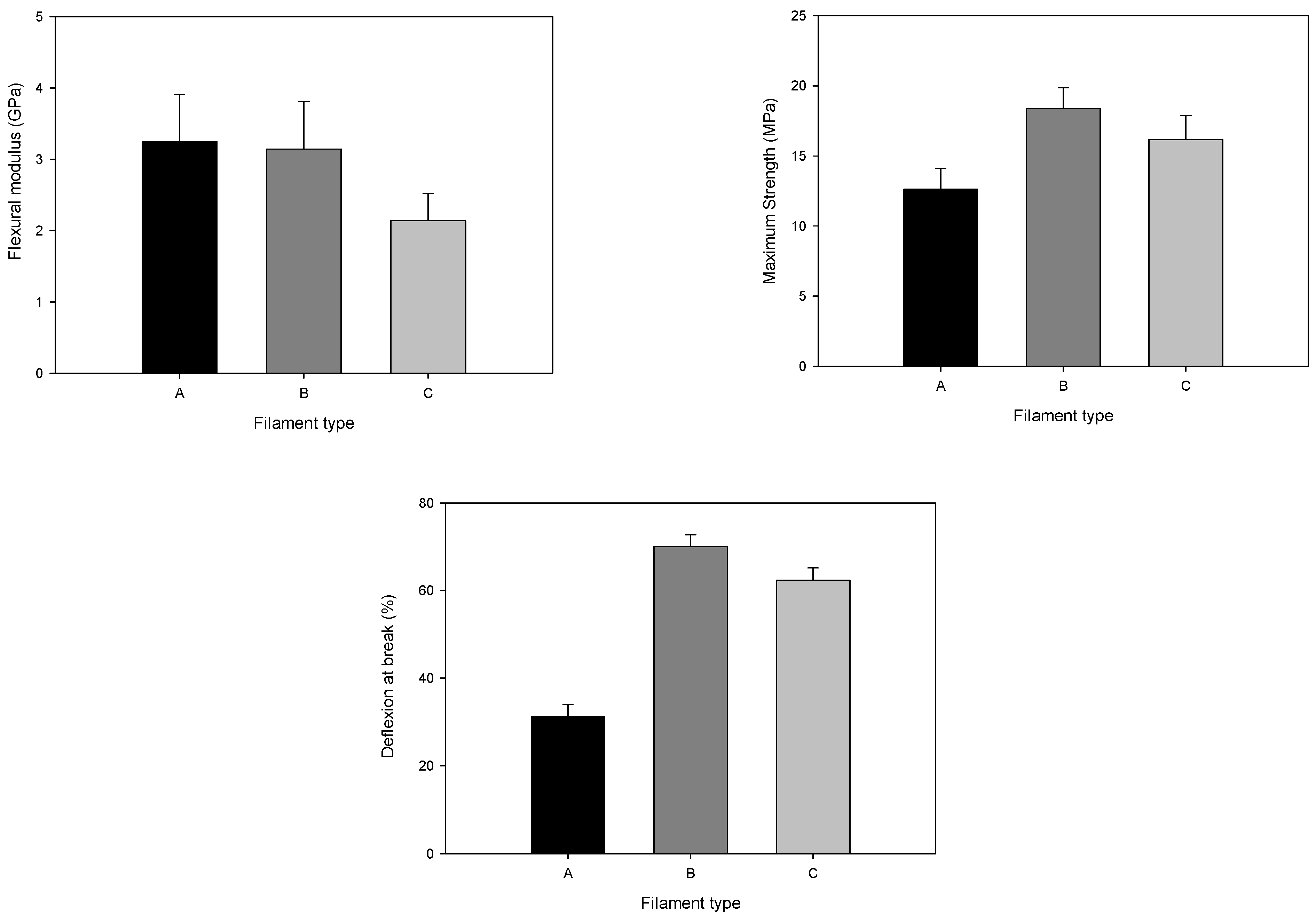

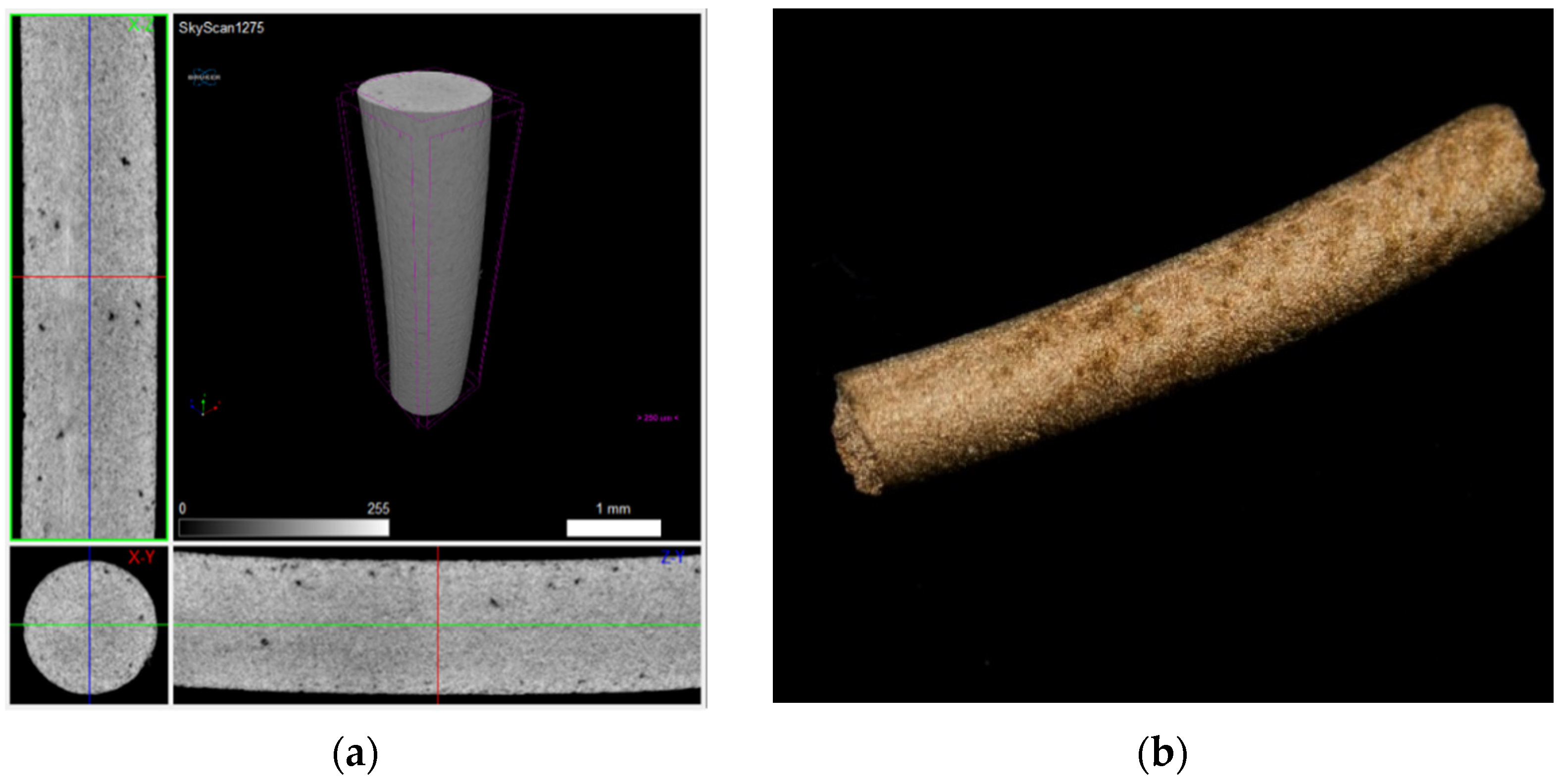

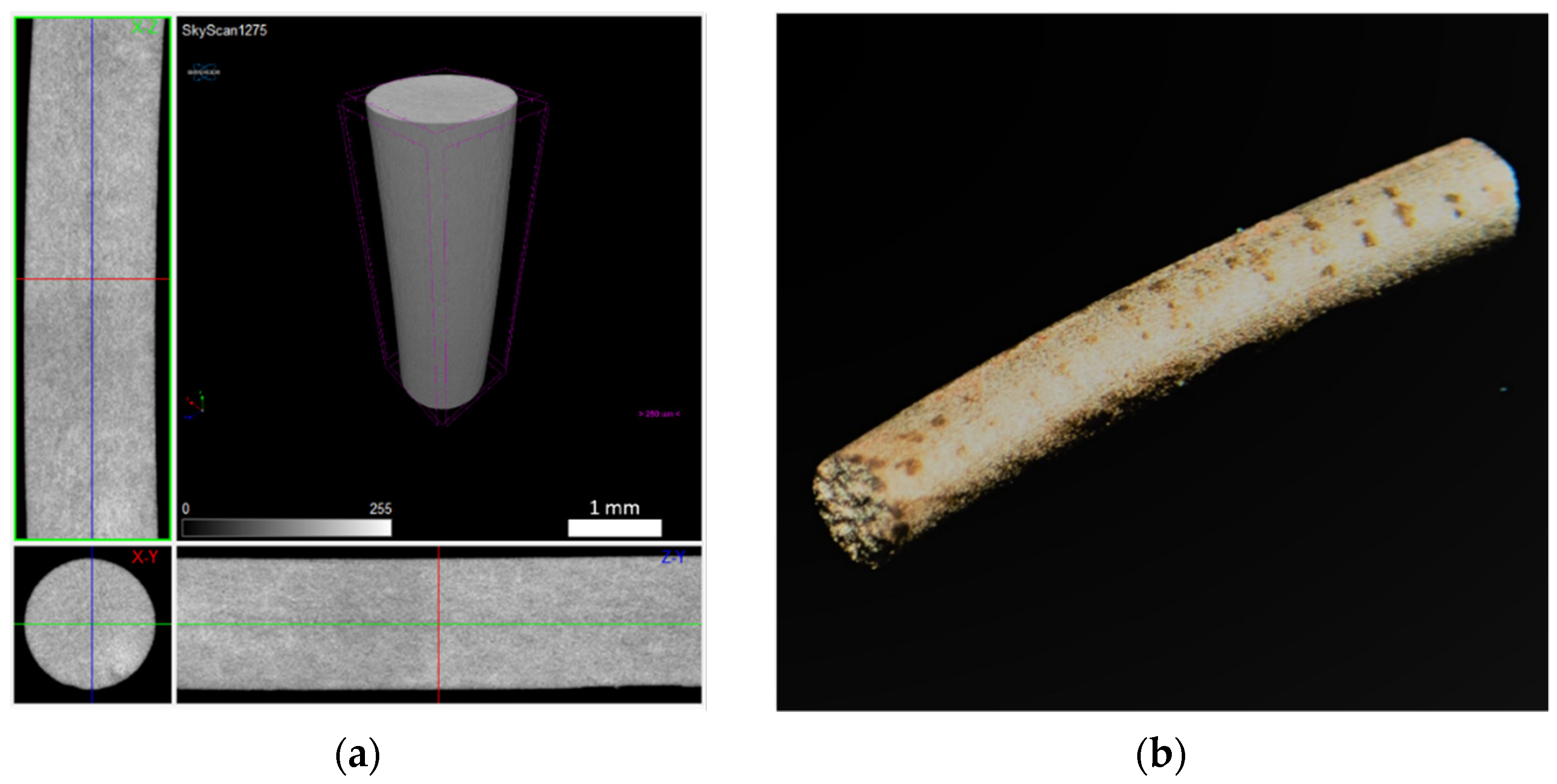

4.2.1. Filaments

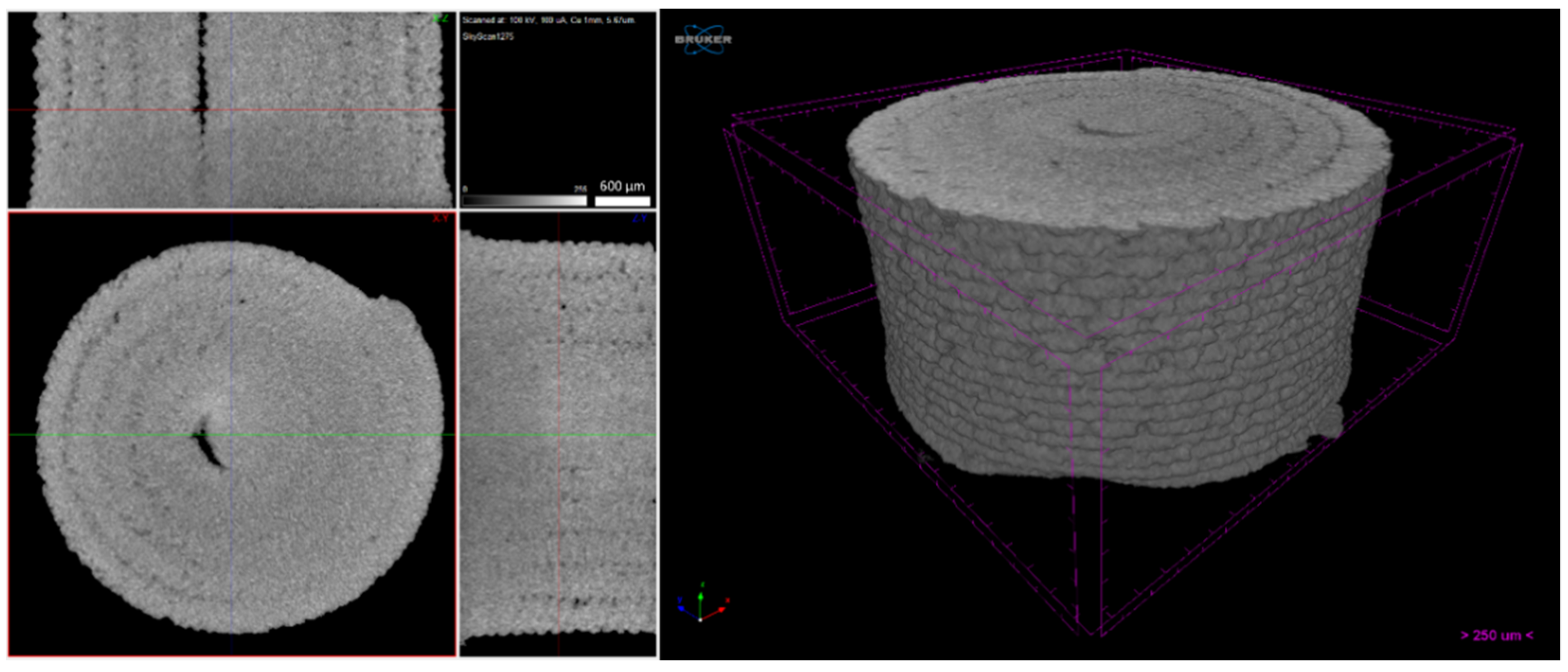

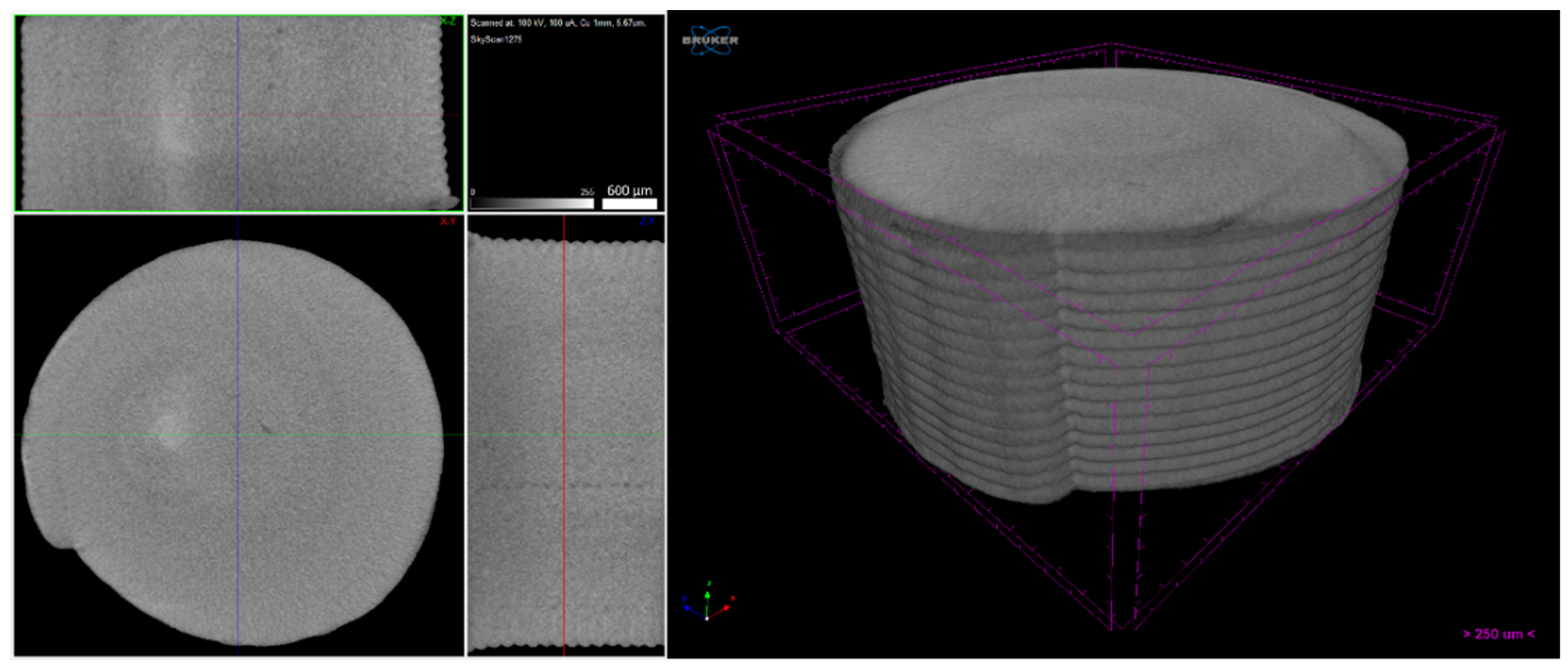

4.2.2. Strands

4.2.3. The 3D Objects after Shaping

4.3. Debinding and Sintering

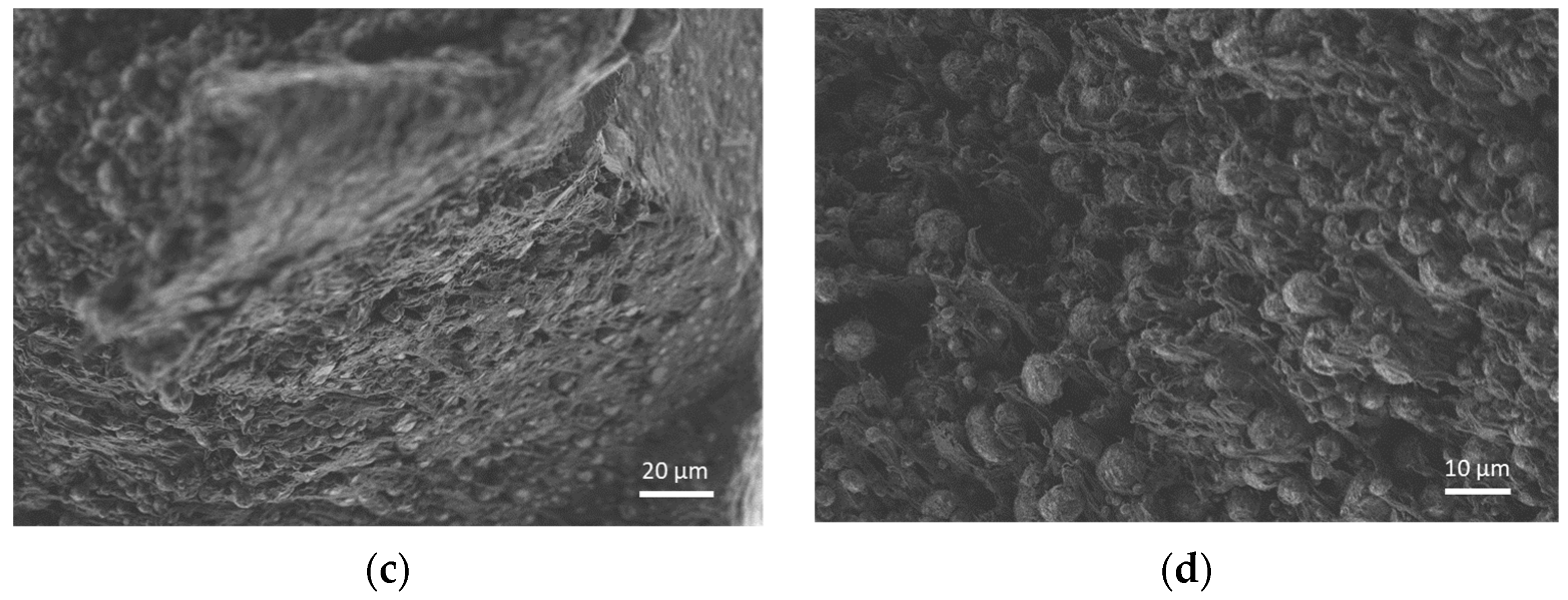

4.4. Microstructures and Hardness

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Singh, S.; Ramakrishna, S.; Singh, R. Material Issues in Additive Manufacturing: A Review. J. Manuf. Process. 2017, 25, 185–200. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive Manufacturing (3D Printing): A Review of Materials, Methods, Applications and Challenges. Compos. Part B Eng. 2018, 143, 172. [Google Scholar] [CrossRef]

- Gonzalez-Gutierrez, J.; Godec, D.; Guráň, R.; Spoerk, M.; Kukla, C. Holzer 3D Printing Conditions Determination for Feedstock Used in Fused Filament Fabrication (FFF) of 17-4PH Stainless Steel Parts. Metalurgija 2018, 57, 117–120. [Google Scholar]

- Orlovská, M.; Chlup, Z.; Bača, Ľ.; Janek, M.; Kitzmantel, M. Fracture and Mechanical Properties of Lightweight Alumina Ceramics Prepared by Fused Filament Fabrication. J. Eur. Ceram. Soc. 2020, 40, 4837–4843. [Google Scholar] [CrossRef]

- Thompson, Y.; Gonzalez-Gutierrez, J.; Kukla, C.; Felfer, P. Fused Filament Fabrication, Debinding and Sintering as a Low Cost Additive Manufacturing Method of 316L Stainless Steel. Addit. Manuf. 2019, 30, 100861. [Google Scholar] [CrossRef]

- ISO/ASTM Additive Manufacturing-General Principles-Terminology (ISO/ASTM DIS 52900:2018). Available online: https://www.techstreet.com/standards/din-en-iso-astm-52900-draft?product_id=2015850 (accessed on 24 May 2020).

- German, R.M.; Bose, A. Injection Molding of Metals and Ceramics; Metal Powder Industry: Princeton, NJ, USA, 1997; ISBN 978-1-878954-61-9. [Google Scholar]

- Goudah, G.; Ahmad, F.; Mamat, O.; Omar, M.A. Preparation and Characterization of Copper Feedstock for Metal Injection Molding. J. Appl. Sci. 2010, 10, 3295–3300. [Google Scholar] [CrossRef]

- Hausnerova, B.; Kitano, T.; Kuritka, I.; Prindis, J.; Marcanikova, L. The Role of Powder Particle Size Distribution in the Processability of Powder Injection Molding Compounds. Int. J. Polym. Anal. Charact. 2011, 16, 141–151. [Google Scholar] [CrossRef]

- Riecker, S.; Clouse, J.; Studnitzky, T.; Andersen, O.; Kieback, B. Fused Deposition Modeling-Opportunities for Cheap Metal AM. In Proceedings of the European Congress and Exhibition on Powder Metallurgy, European PM Conference Proceedings, Hamburg, Germany, 9 October 2016. [Google Scholar]

- Cruz, N.; Santos, L.; Vasco, J.; Barreiros, F.M. Binder System for Fused Deposition of Metals. In Proceedings of the Euro PM2013, Congress & Exhibition, Gothenburg, Sweden, 15 September 2013; pp. 79–84. [Google Scholar]

- Kukla, C.; Gonzalez-Gutierrez, J.; Duretek, I.; Schuschnigg, S.; Holzer, C. Effect of Particle Size on the Properties of Highly-Filled Polymers for Fused Filament Fabrication. In AIP Conference Proceedings; AIP Publishing LLC: Lyon, France, 2017; p. 190006. [Google Scholar]

- Khatri, B.; Lappe, K.; Noetzel, D.; Pursche, K.; Hanemann, T. A 3D-Printable Polymer-Metal Soft-Magnetic Functional Composite—Development and Characterization. Materials 2018, 11, 189. [Google Scholar] [CrossRef]

- Dehdari Ebrahimi, N.; Ju, Y.S. Thermal Conductivity of Sintered Copper Samples Prepared Using 3D Printing-Compatible Polymer Composite Filaments. Addit. Manuf. 2018, 24, 479–485. [Google Scholar] [CrossRef]

- Copper as Electrical Conductive Material with Above-Standard Performance Properties. Available online: http://www.conductivity-app.org/single-article/cu-overview#L15 (accessed on 18 August 2021).

- Huang, J.; Yan, X.; Chang, C.; Xie, Y.; Ma, W.; Huang, R.; Zhao, R.; Li, S.; Liu, M.; Liao, H. Pure Copper Components Fabricated by Cold Spray (CS) and Selective Laser Melting (SLM) Technology. Surf. Coat. Technol. 2020, 395, 125936. [Google Scholar] [CrossRef]

- Sárosi, Z.; Knapp, W.; Kunz, A.; Wegener, K. Evaluation of Reflectivity of Metal Parts by a Thermo-Camera. InfraMation 2010 Proc. 2010, 11. [Google Scholar] [CrossRef]

- El-Wardany, T.I.; She, Y.; Jagdale, V.N.; Garofano, J.K.; Liou, J.J.; Schmidt, W.R. Challenges in Three-Dimensional Printing of High-Conductivity Copper. J. Electron. Packag. 2018, 140, 020907. [Google Scholar] [CrossRef]

- Lykov, P.A.; Safonov, E.V.; Akhmedianov, A.M. Selective Laser Melting of Copper. Mater. Sci. Forum 2016, 843, 284–288. [Google Scholar] [CrossRef]

- Trevisan, F.; Calignano, F.; Lorusso, M.; Lombardi, M.; Manfredi, D.; Fino, P. Selective Laser Melting of Chemical Pure Copper. In Proceedings of the Euro PM2017 Congress & Exhibition, Milan, Italy, 3 October 2017. [Google Scholar]

- Silbernagel, C.; Gargalis, L.; Ashcroft, I.; Hague, R.; Galea, M.; Dickens, P. Electrical Resistivity of Pure Copper Processed by Medium-Powered Laser Powder Bed Fusion Additive Manufacturing for Use in Electromagnetic Applications. Addit. Manuf. 2019, 29, 100831. [Google Scholar] [CrossRef]

- Ikeshoji, T.-T.; Nakamura, K.; Yonehara, M.; Imai, K.; Kyogoku, H. Selective Laser Melting of Pure Copper. JOM 2018, 70, 396–400. [Google Scholar] [CrossRef]

- Colopi, M.; Caprio, L.; Demir, A.G.; Previtali, B. Selective Laser Melting of Pure Cu with a 1 KW Single Mode Fiber Laser. Procedia CIRP 2018, 74, 59–63. [Google Scholar] [CrossRef]

- Jadhav, S.D.; Dadbakhsh, S.; Goossens, L.; Kruth, J.-P.; Van Humbeeck, J.; Vanmeensel, K. Influence of Selective Laser Melting Process Parameters on Texture Evolution in Pure Copper. J. Mater. Process. Technol. 2019, 270, 47–58. [Google Scholar] [CrossRef]

- BASF Launches Ultrafuse 316LX for Fused Filament Fabrication of Metal Parts. Available online: https://www.metal-am.com/basf-launches-ultrafuse-316lx-fused-filament-fabrication-metal-parts/ (accessed on 18 April 2021).

- Ferreira, T.J.; Vieira, M.T. Optimization of MWCNT–Metal Matrix Composites Feedstocks. Ciência Tecnol. Dos Mater. 2017, 29, e87–e91. [Google Scholar] [CrossRef]

- Ferreira, T.J.J. Microinjection Moulding of Austenitic Stainless Steel Reinforced with Carbon Nanotubes. Ph.D. Thesis, University of Coimbra, Coimbra, Portugal, 2018. [Google Scholar]

- Sigma-Aldrich Copper (I) Oxide Material Safety Data Sheet 2014. Available online: https://www.nwmissouri.edu/naturalsciences/sds/c/Copper%20I%20oxide.pdf (accessed on 18 August 2021).

- Cerejo, F.; Gatões, D.; Vieira, M.T. Optimization of Metallic Powder Filaments for Additive Manufacturing Extrusion (MEX). Int. J. Adv. Manuf. Technol. 2021, 115, 2449–2464. [Google Scholar] [CrossRef]

- Strąk, C.; Olesińska, W.; Siedlec, R. Influence of Carbon and Oxygen on Properties of Cu-C-O Composites. Electron. Mater. 2016, 44, 13. [Google Scholar]

- Kreuzeder, M.; Abad, M.-D.; Primorac, M.-M.; Hosemann, P.; Maier, V.; Kiener, D. Fabrication and Thermo-Mechanical Behavior of Ultra-Fine Porous Copper. J. Mater. Sci. 2015, 50, 634–643. [Google Scholar] [CrossRef] [PubMed]

- Hao, H.; Wang, Y.; Jafari Nodooshan, H.R.; Zhang, Y.; Ye, S.; Lv, Y.; Yu, P. The Effects of Sintering Temperature and Addition of TiH2 on the Sintering Process of Cu. Materials 2019, 12, 2594. [Google Scholar] [CrossRef] [PubMed]

| Master Binder | Additives | ||

|---|---|---|---|

| Backbone | Plasticiser | ||

| Vol (%) | 77.5 | 17.5 | 5.0 |

| Density (kg/m3) | 970 | 1025 | 96.5 |

| Powder | D10 [µm] | D50 [µm] | D90 [μm] | ρ [Kg/m3] |

|---|---|---|---|---|

| A | 8.57 | 28.00 | 46.60 | 8896 |

| B | 7.75 | 11.30 | 16.20 | 8648 |

| C | 1.95 | 3.97 | 6.67 | 8427 |

| Powder | Particle Size D50 (μm) | Particle Size Distribution | Shape Factor * | Topography | Phase Composition |

|---|---|---|---|---|---|

| A | 28.00 | Bimodal | ≈1 | Uniform with some satellites | Cu + traces of copper oxide |

| B | 11.30 | Unimodal | ≈1 | Uniform with some satellites | Cu + copper oxide |

| C | 3.97 | Unimodal | ≈1 | Uniform with some satellites | Cu + copper oxide |

| Feedstock | Cu (vol.%) | Binder + Additive (vol.%) | ρ (Kg/m3) | Torque (N·m) |

|---|---|---|---|---|

| A | 61 | 39 | 5345 | 3.8 |

| B | 61 | 39 | 5330 | 5.1 |

| C | 61 | 39 | 5205 | 4.4 |

| Specimens | A | B | C |

|---|---|---|---|

| Microhardness (HV0.1) (10 measurements) | 68 ± 8.9 | 65 ± 2.7 | 80 ± 2.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Santos, C.; Gatões, D.; Cerejo, F.; Vieira, M.T. Influence of Metallic Powder Characteristics on Extruded Feedstock Performance for Indirect Additive Manufacturing. Materials 2021, 14, 7136. https://doi.org/10.3390/ma14237136

Santos C, Gatões D, Cerejo F, Vieira MT. Influence of Metallic Powder Characteristics on Extruded Feedstock Performance for Indirect Additive Manufacturing. Materials. 2021; 14(23):7136. https://doi.org/10.3390/ma14237136

Chicago/Turabian StyleSantos, Cyril, Daniel Gatões, Fábio Cerejo, and Maria Teresa Vieira. 2021. "Influence of Metallic Powder Characteristics on Extruded Feedstock Performance for Indirect Additive Manufacturing" Materials 14, no. 23: 7136. https://doi.org/10.3390/ma14237136

APA StyleSantos, C., Gatões, D., Cerejo, F., & Vieira, M. T. (2021). Influence of Metallic Powder Characteristics on Extruded Feedstock Performance for Indirect Additive Manufacturing. Materials, 14(23), 7136. https://doi.org/10.3390/ma14237136