Characterization of Mechanical and Hygroscopic Properties of Individual Canes of Reed

Abstract

1. Introduction

2. Materials and Methods

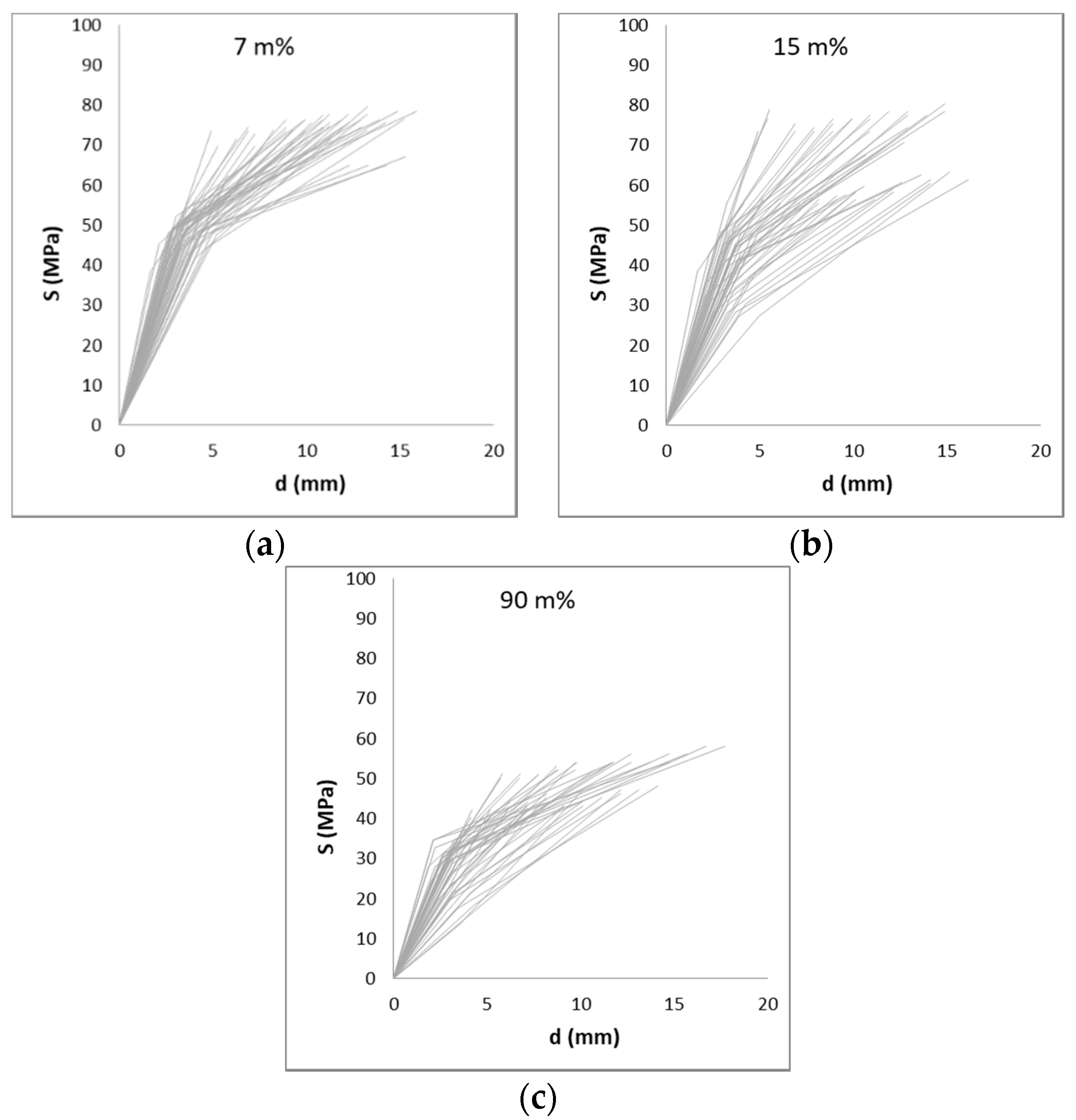

- Sample in the heating unit: the nominal humidity content in the material was 7 m%;

- Room conditions: the nominal humidity content in the material was 15 m%;

- External humidity conditions: the nominal humidity content in the material was 90 m%.

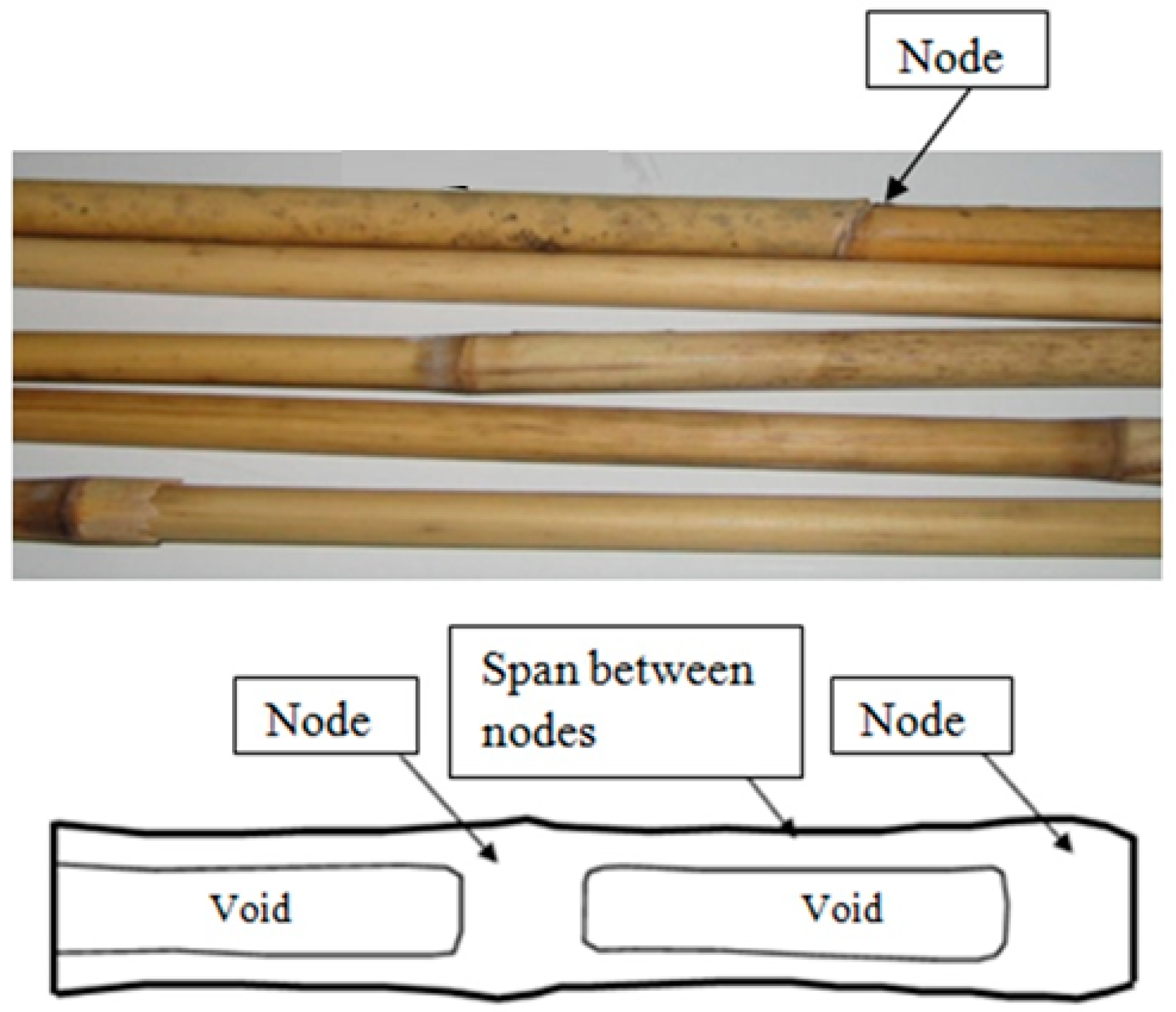

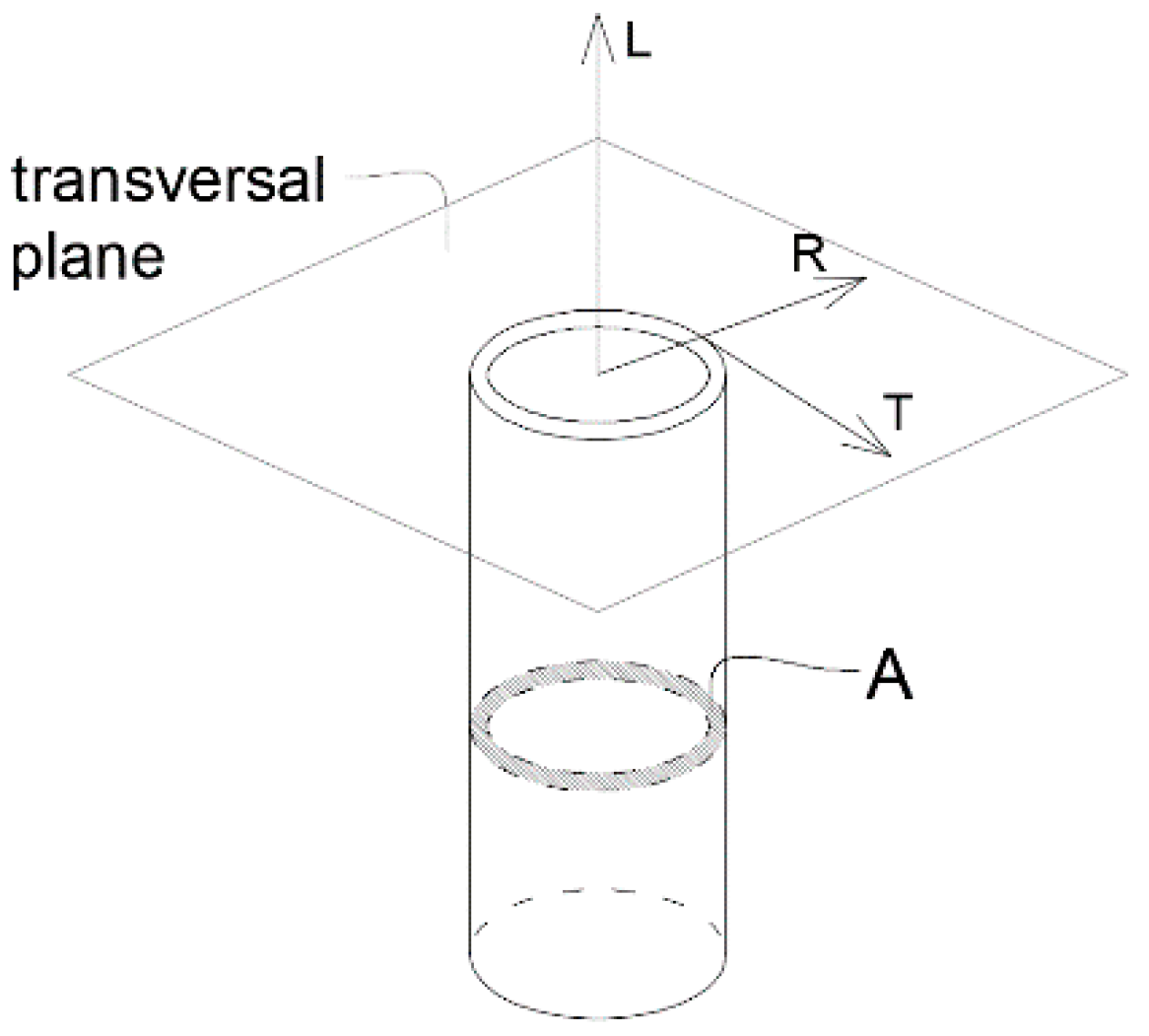

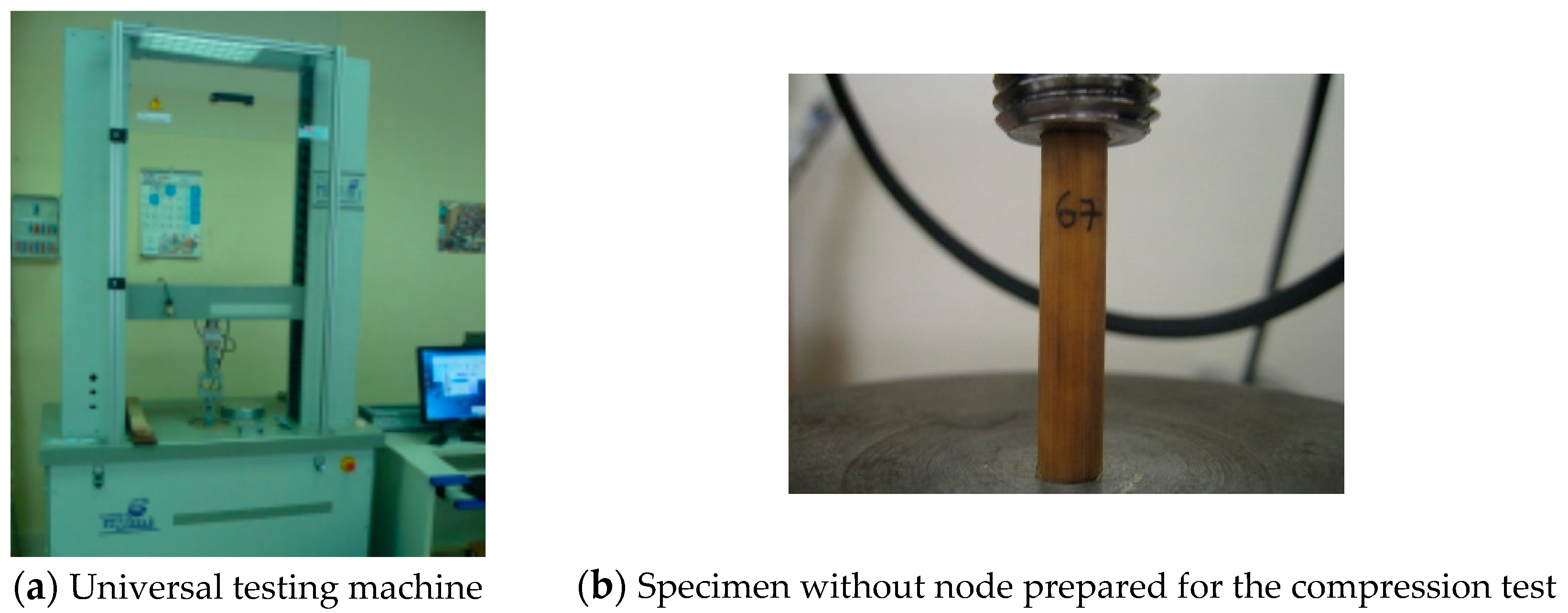

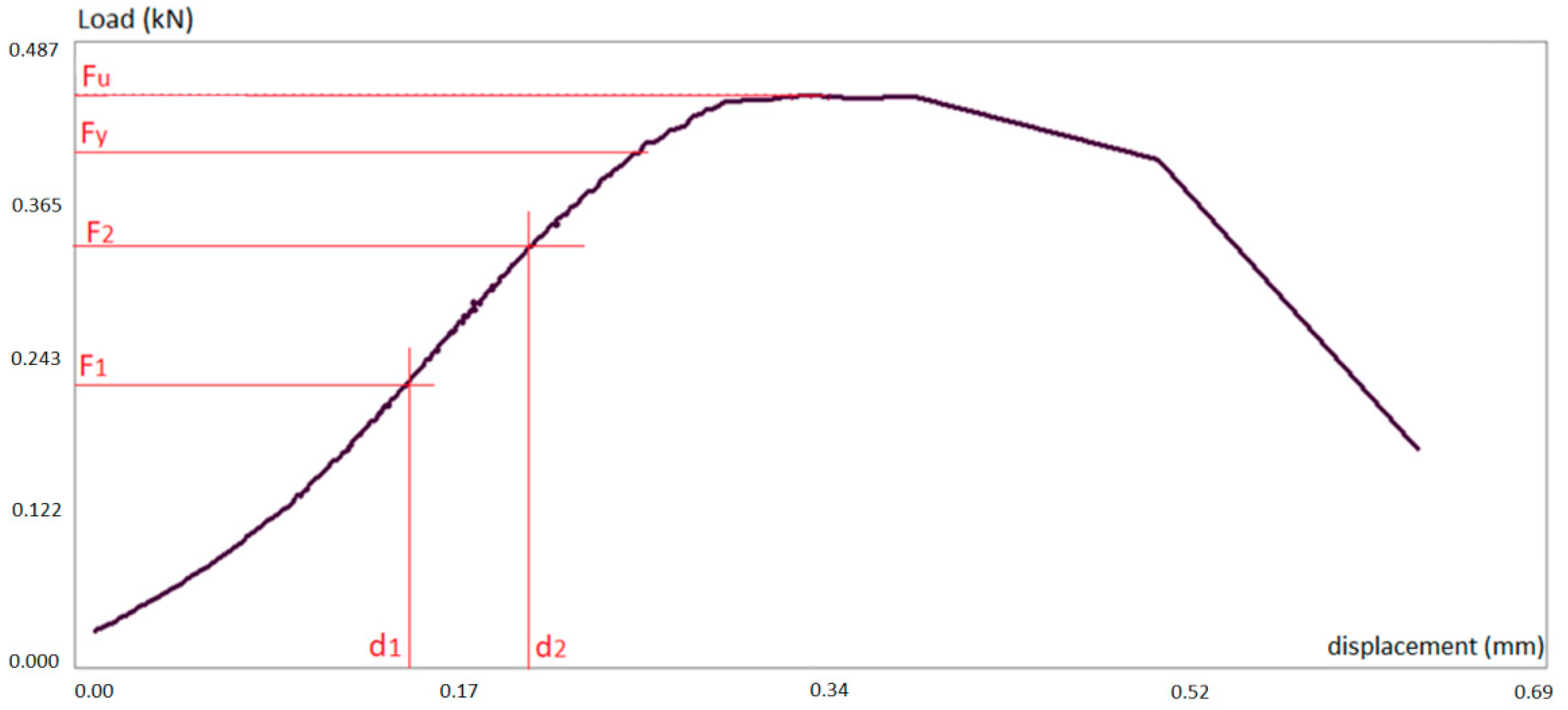

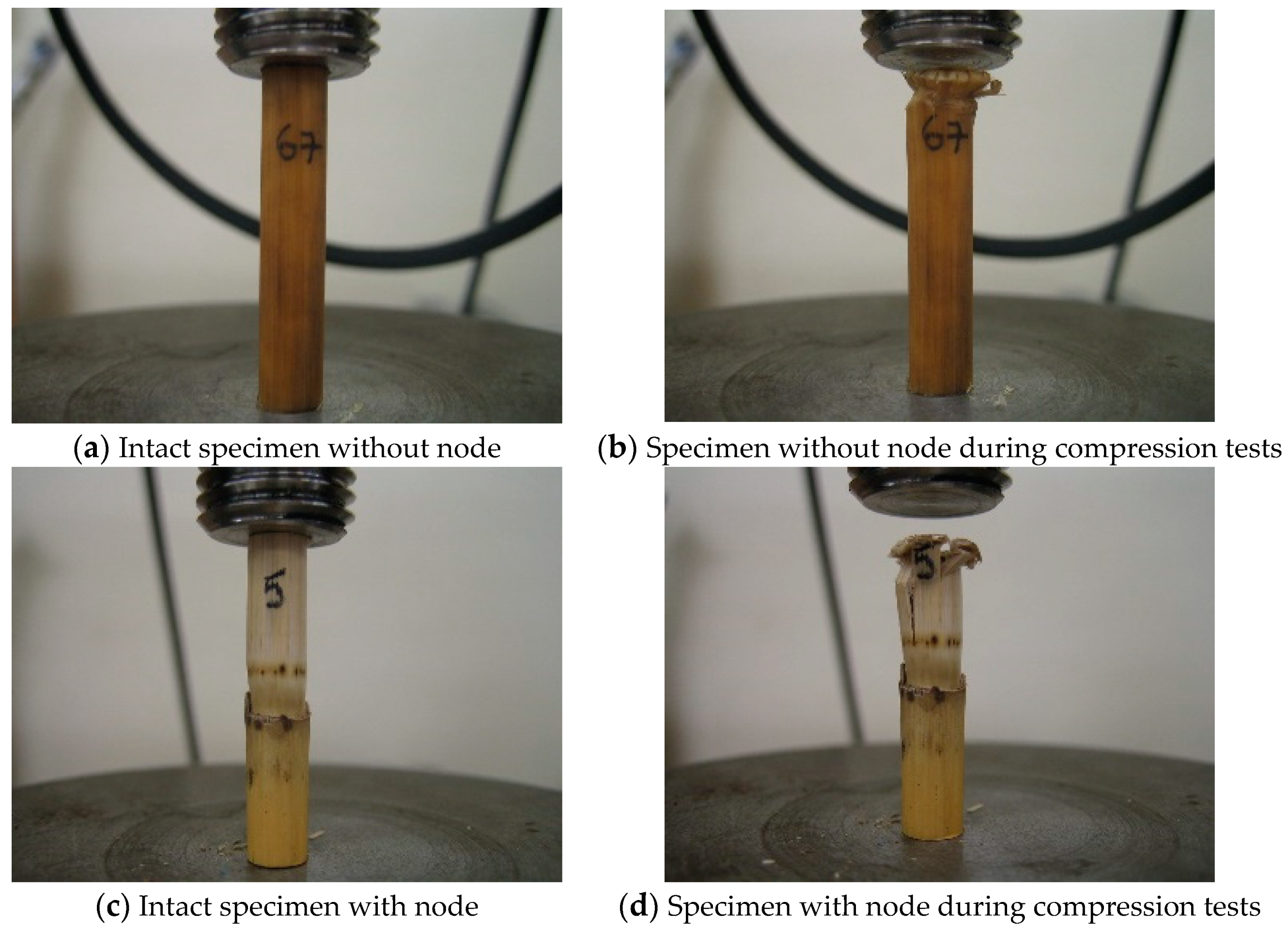

2.1. Compression Test

2.2. Bending Test

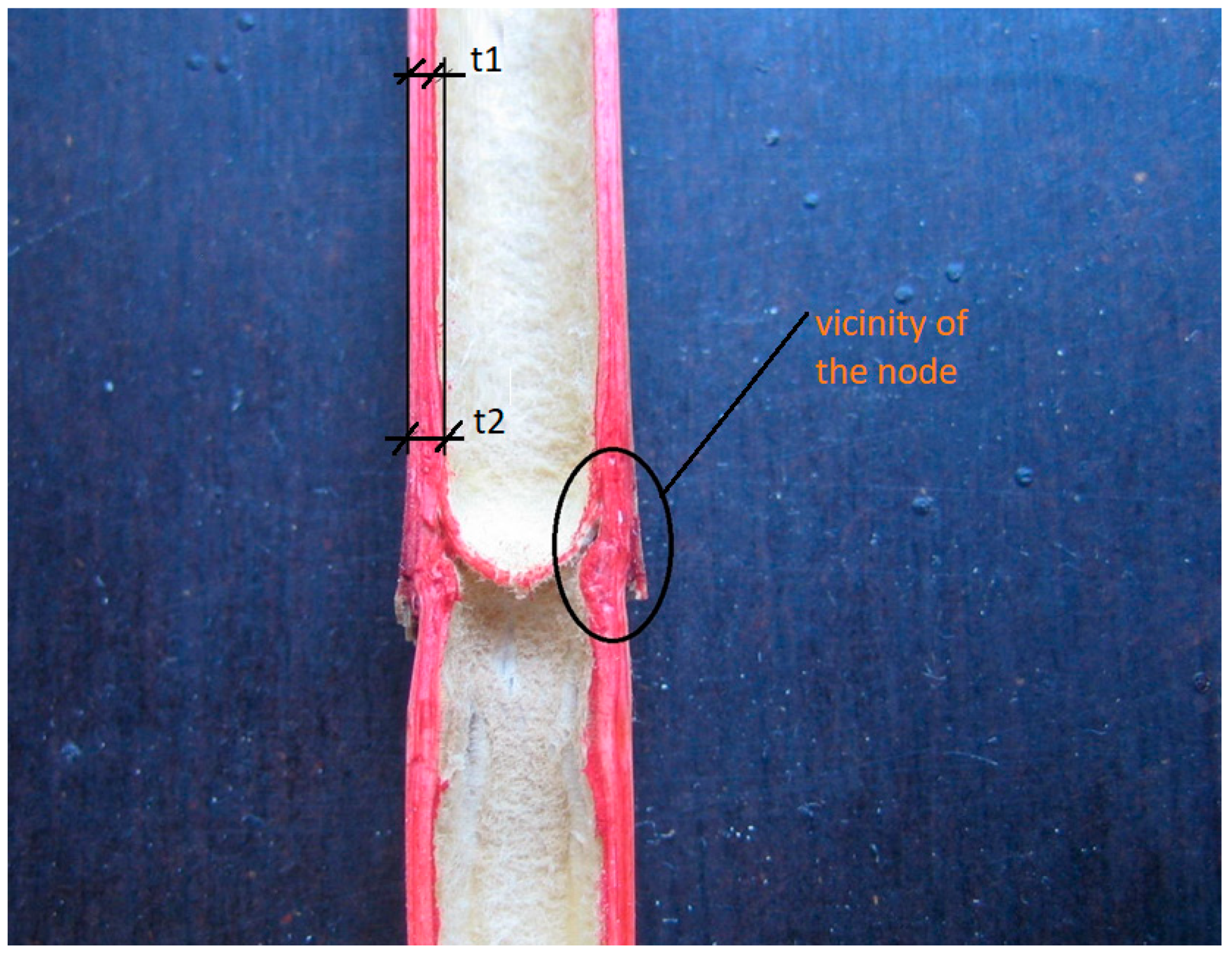

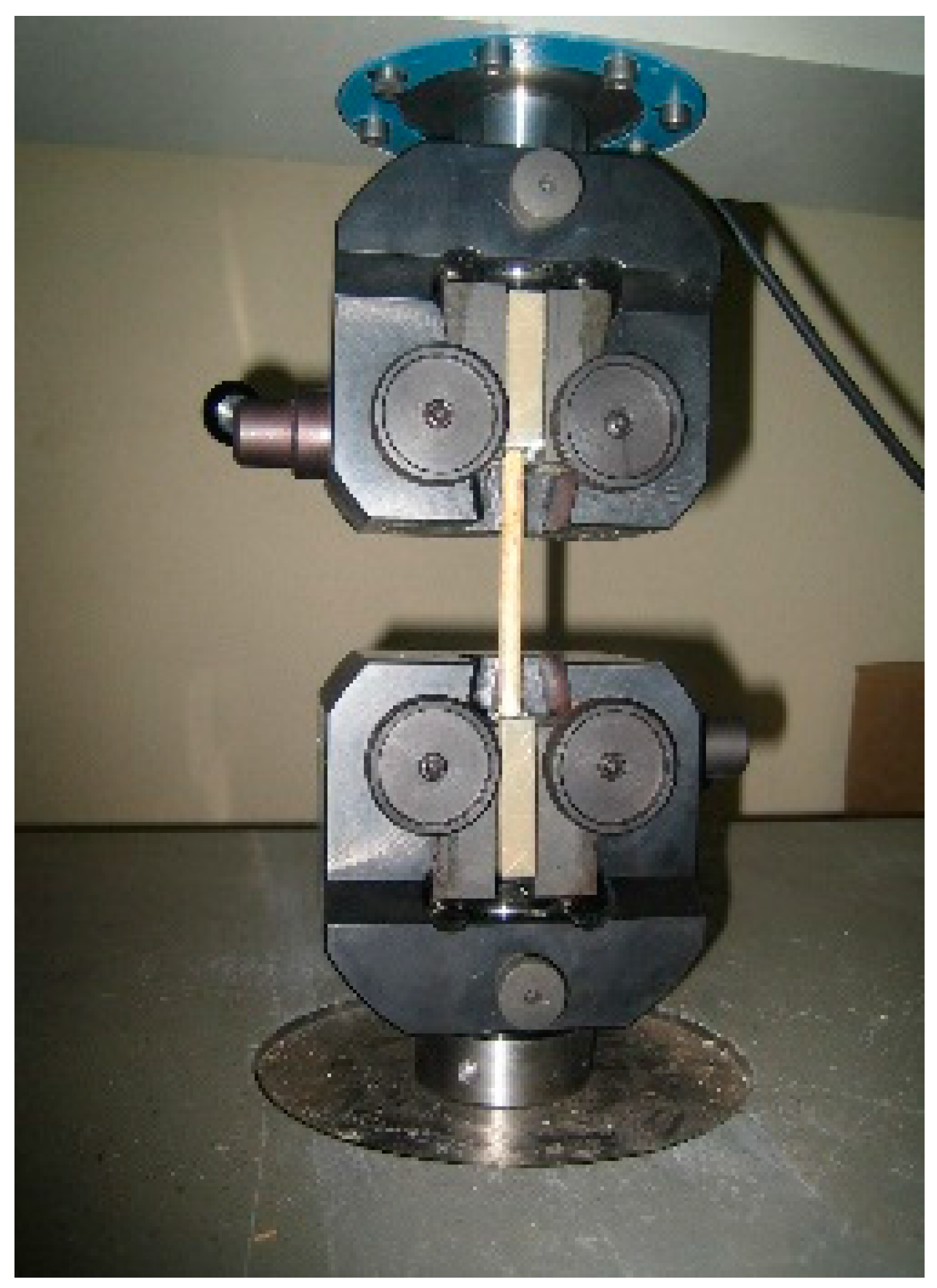

2.3. Tension Test

2.4. Dimensional Change

3. Results and Discussion

3.1. Dimensional Change due to Humidity

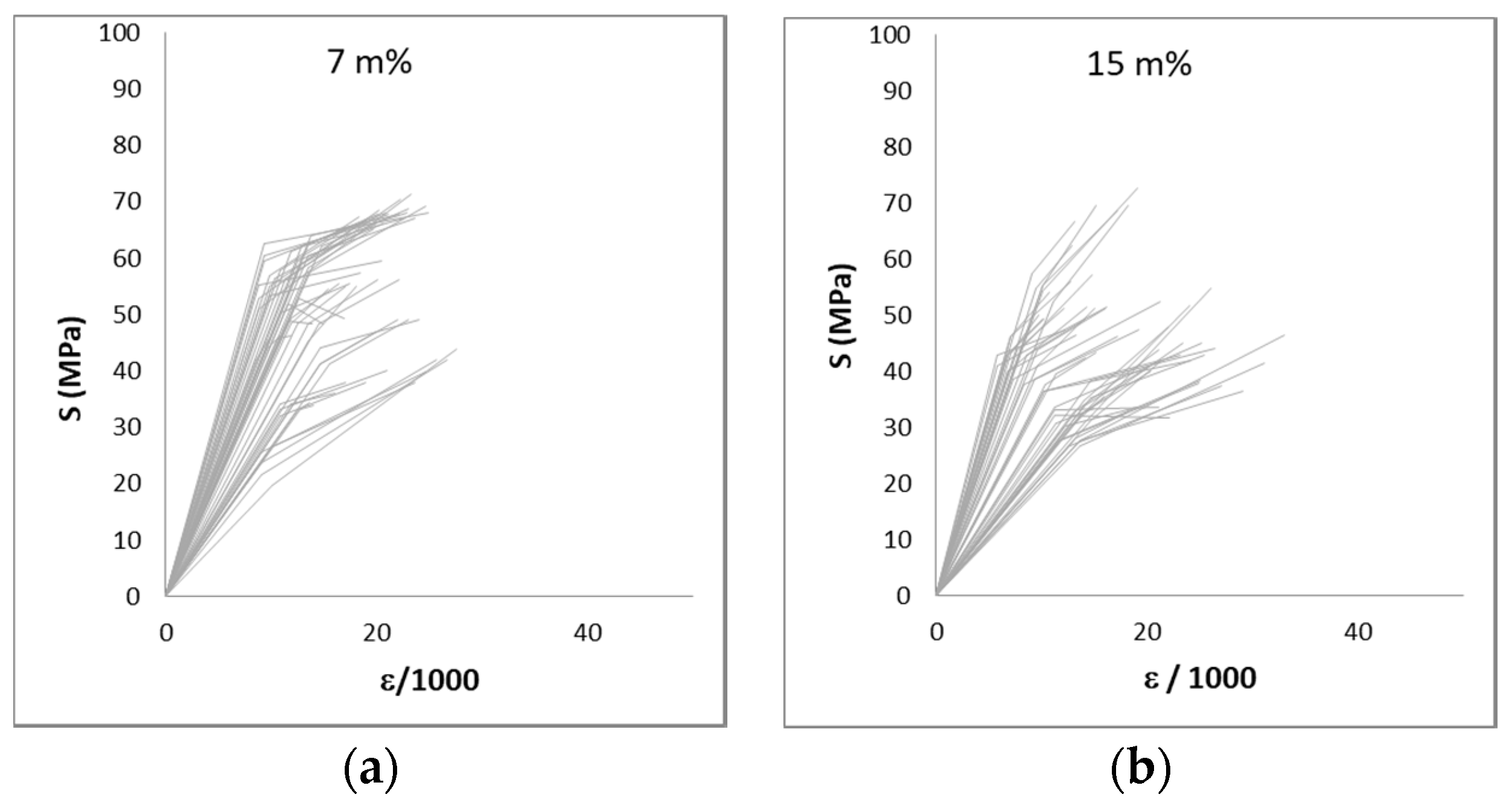

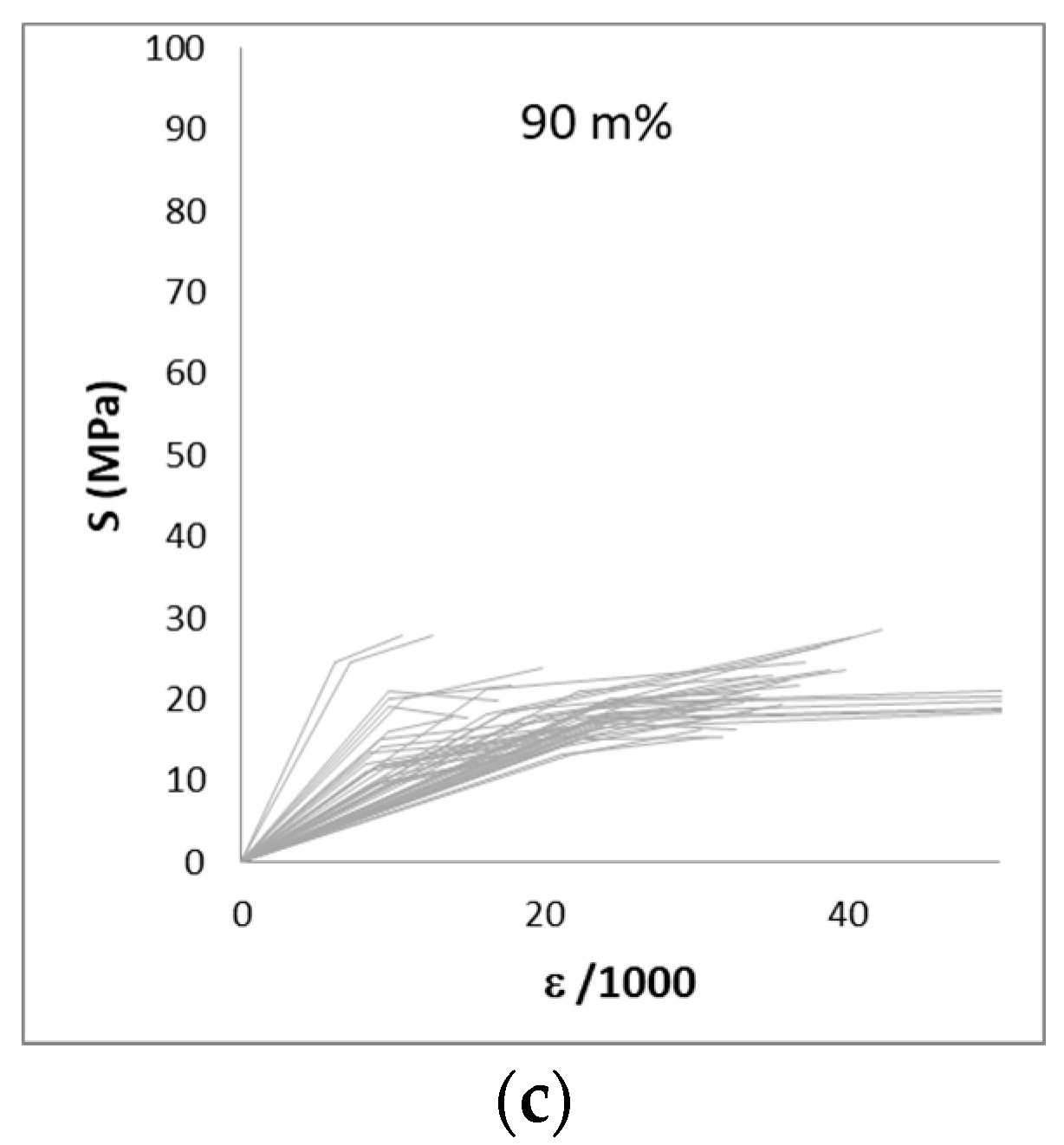

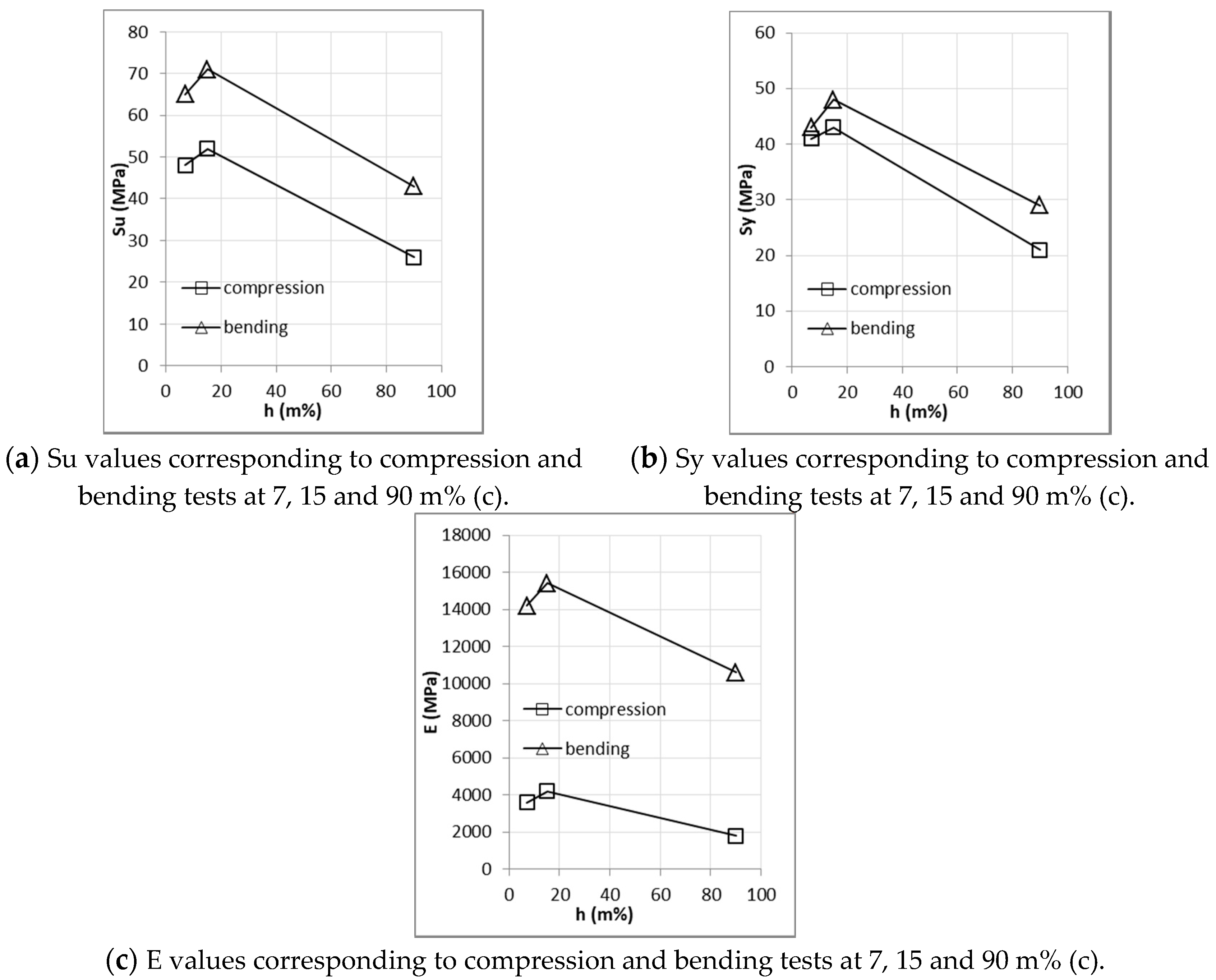

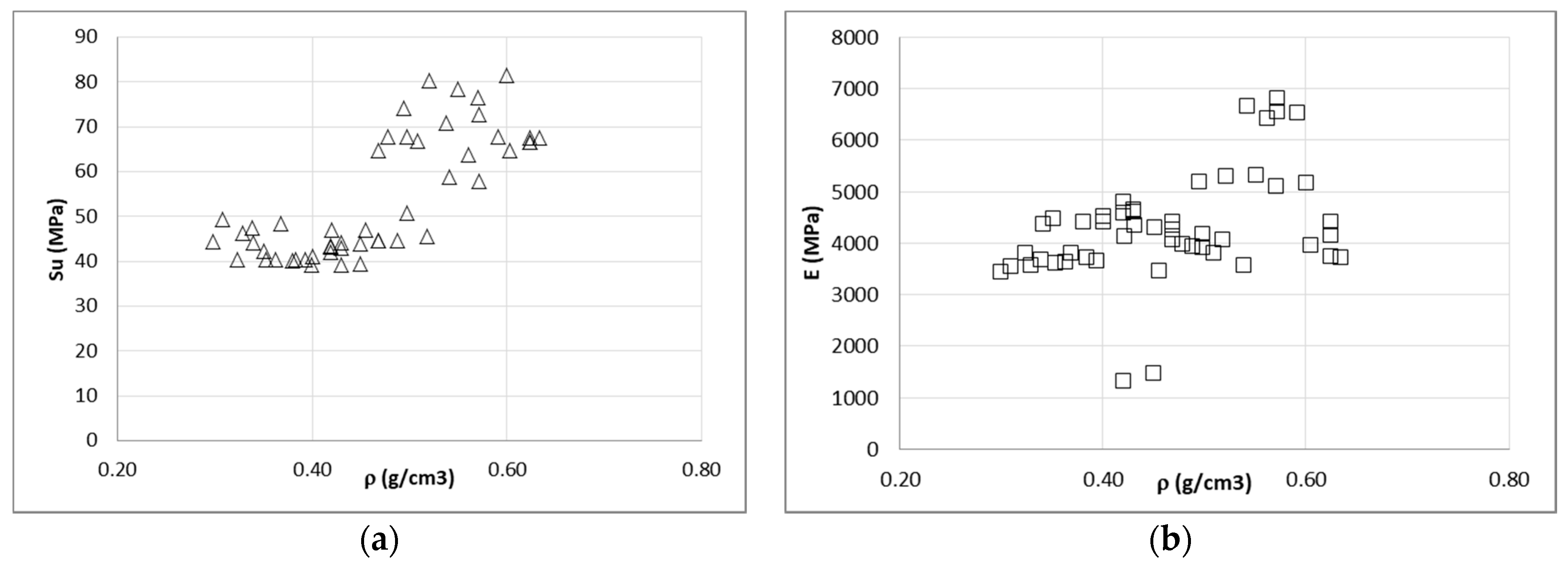

3.2. Strength and Stiffness

3.3. Nodes’ Influence

3.4. Moisture Content Influence

3.5. Density Influence

3.6. Comparison with Steel, Concrete and Timber

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Das, S.C.; Tanaka, N. The effects of breaking or bending the stems of two rhizomatous plants, Phragmites australis and Miscanthus sacchariflorus, on their communities. Landsc. Ecol. Eng. 2007, 3, 131–141. [Google Scholar] [CrossRef]

- Ostendorp, W.; Möller, J. EM-Algorithm as a tool for structure analysis of stands of the common reed (Phragmites australis). Ecol. Model 1991, 53, 27–38. [Google Scholar] [CrossRef]

- Vignote Peña, S.; Martínez Rojas, I. Tecnología de la Madera; Mundi-Prensa: Madrid, Spain, 2006. [Google Scholar]

- Esteban, L.G.; Guindeo, A.; Peraza, C.; De Palacios, P. La Madera y su Anatomía; AMVE Ediciones: Madrid, Spain, 2003. [Google Scholar]

- Reinhardt, H.W.; Salahi, M.H.; Schatz, T. Strength of reed from. Egypt. Mater. Struct. 1995, 28, 345–349. [Google Scholar] [CrossRef]

- Kask, Ü. Guidebook of Reed Business COFREEN (Reed for Bioenergy and Construction); Central Baltic INTERREG IV A Programme (2007–2013); European Union: Brussels, Belgium, 2013. [Google Scholar]

- Chumillas Bea, J. Bioconstrucción y Arquitectura Bioclimática Para La Ejecución de Vivienda Ecológica Unifamiliar; Universitat Politècnica De València: Valencia, Spain, 2018. [Google Scholar]

- Habibi, M.R. Investigation on Possibility of MDF Production from Reeds. In Review of Forests, Wood Products and Wood Biotechnology of Iran and Germany; Institute of Forest Botany, Georg-August-University Göttingen: Göttingen, Germany, 2006; pp. 82–94. [Google Scholar]

- Köbbing, J.F.; Thevs, N.; Zerbe, S. The utilisation of reed (Phragmites australis): A review. Mires Peat 2013, 13, 1–14. [Google Scholar]

- Gabarrón, A.M.; Yepes, J.F.; Pérez, J.P.; Serna, J.B.; Arnold, L.C.; Medrano, F.S. Increase of the flexural strength of construction elements made with plaster (calcium sulfate dihydrate) and common reed (Arundo donax L.). Constr. Build. Mater. 2014, 66, 436–441. [Google Scholar] [CrossRef]

- Díaz, C.; Jiménez-Espada, M.; Navacerrada, M.A.; Pedrero, A. Acoustic properties of reed panels. Mater. Construcción 2012, 62, 55–66. [Google Scholar] [CrossRef]

- Jimenez-Espada, M.; Diaz-Sanchidrián, C. Airborne Sound Insulation Properties of Reed: The Development of Different Construction Systems Based on Reed Panels, INTER-NOISE and NOISE-CON Congress and Conference Proceedings; Institute of Noise Control Engineering: Reston, VA, USA, 2010; pp. 1382–1388. [Google Scholar]

- Mahdavi, M.; Clouston, P.L.; Arwade, S.R. A low-technology approach toward fabrication ofqqas laminated bamboo lumber. Constr. Build. Mater. 2012, 29, 257–262. [Google Scholar] [CrossRef]

- Ghavami, K. Bamboo as reinforcement in structural concrete elements. Cement Concr. Compos. 2005, 27, 637–649. [Google Scholar] [CrossRef]

- Moroz, J.G.; Lissel, S.L.; Hagel, M.D. Performance of bamboo reinforced concrete masonry shear walls. Constr. Build Mater. 2014, 61, 125–137. [Google Scholar] [CrossRef]

- Salau, M.A.; Adegbite, I.; Ikponmwosa, E.E. Characteristic strength of concrete column reinforced with bamboo strips. J. Sustain. Dev. 2012, 5, 133. [Google Scholar]

- Jiménez-Espada, M.; Bobadilla-Maldonado, I.; González-Escobar, R. Preliminary study on the bending elastic behaviour of Hungarian reed stems. In Proceedings of the 17th International Nondestructive Testing and Evaluation of Wood Symposium, Sopron, Hungary, 14–16 September 2011. [Google Scholar]

- Coops, H.; Van der Velde, G. Effects of waves on helophyte stands: Mechanical characteristics of stems of Phragmites australis and Scirpus lacustris. Aquat. Bot. 1996, 53, 175–185. [Google Scholar] [CrossRef]

- Jiménez-Espada, M. Caracterización Mecánica, Acústica y Térmica de Carrizo Húngaro (Phragmites australis). Durabilidad y Aplicaciones; Universidad Politécnica de Madrid: Madrid, Spain, 2011. [Google Scholar]

- Ostendorp, W. Estimation of mechanical resistance of lakeside Phragmites stands. Aquat. Bot. 1995, 51, 87–101. [Google Scholar] [CrossRef][Green Version]

- Ukshini, E.; Dirckx, J.J.J. Longitudinal and Transversal Elasticity of Natural and Artificial Materials for Musical Instrument Reeds. Materials 2020, 13, 4566. [Google Scholar] [CrossRef]

- Shah, D.U.; Reynolds, T.P.; Ramage, M.H. The strength of plants: Theory and experimental methods to measure the mechanical properties of stems. J. Exp. Bot. 2017, 68, 4497–4516. [Google Scholar] [CrossRef] [PubMed]

- Song, J.; Surjadi, J.U.; Hu, D.; Lu, Y. Fatigue characterization of structural bamboo materials under flexural bending. Int. J. Fatigue 2017, 100, 126–135. [Google Scholar] [CrossRef]

- Keogh, L.; O’Hanlon, P.; O’Reilly, P.; Taylor, D. Fatigue in bamboo. Int. J. Fatigue. 2015, 75, 51–56. [Google Scholar] [CrossRef]

- Dosdall, R.; Jülich, W.; Schauer, F. Impact of heat treatment of the water reed Phragmites communis Trin. used for thatching on its stability, elasticity and resistance to fungal decomposition. Int. Biodeterior. Biodegrad. 2015, 103, 85–90. [Google Scholar] [CrossRef]

- Pude, R.; Banaszuk, P.; Trettin, R.; Noga, G. Suitability of Phragmites for lightweight concrete. J. Appl. Bot. Food Qual. 2005, 79, 141. [Google Scholar]

- UNE EN 408:2011 Timber Structures—Structural Timber and Glued Laminated Timber—Determination of Some Physical And Mechanical Properties; Asociacion Espanola de Normalizacion: Madrid, Spain, 2011.

- UNE-EN 384:2016 Structural timber—Determination of Characteristic Values of Mechanical Properties And Density; Asociacion Espanola de Normalizacion: Madrid, Spain, 2016.

- UNE-EN 13183-1:2002 Moisture content of a piece of sawn timber—Part 1: Determination by Oven Dry Method; Asociacion Espanola de Normalizacion: Madrid, Spain, 2002.

- Timoshenko, S. Strength of Materials, Part 1 and Part, 3rd ed.; Krieger Pub Co.: Malabar, FL, USA, 1983. [Google Scholar]

- Oka, G.M.; Triwiyono, A.; Awaludin, A.; Siswosukarto, S. Effects of node, internode and height position on the mechanical properties of Gigantochloa atroviolacea bamboo. Procedia Eng. 2014, 95, 31–37. [Google Scholar] [CrossRef]

- BS EN 1992-1-1:2004+A1:2014 Eurocode 2: Design of Concrete Structures. Part 1-1: General Rules and Rules for Buildings; British Standards Institute: London, UK, 2014.

- BS EN 1993-1-1:2005+A1:2014 Eurocode 3. Design of steel structures—Part 1-1: General Rules and Rules for Buildings; British Standards Institute: London, UK, 2014.

- BS EN 1995-1-1:2004+A2:2014 Eurocode 5: Design of Timber Structures. General Common Rules and Rules for Buildings; British Standards Institute: London, UK, 2014.

- Shon, C.-S.; Mukashev, T.; Lee, D.; Zhang, D.; Kim, J.R. Can Common Reed Fiber Become an Effective Construction Material? Physical, Mechanical, and Thermal Properties of Mortar Mixture Containing Common Reed Fiber. Sustainability 2019, 11, 903. [Google Scholar] [CrossRef]

- Ferrandez-García, M.T.; Ferrandez-Garcia, A.; Garcia-Ortuño, T.; Ferrandez-Garcia, C.E.; Ferrandez-Villena, M. Assessment of the Physical, Mechanical and Acoustic Properties of Arundo donax L. Biomass in Low Pressure and Temperature Particleboards. Polymers 2020, 12, 1361. [Google Scholar] [CrossRef] [PubMed]

- Richter, M.; Horn, W.; Juritsch, E.; Klinge, A.; Radeljic, L.; Jann, O. Natural Building Materials for Interior Fitting and Refurbishment—What about Indoor Emissions? Materials 2021, 14, 234. [Google Scholar] [CrossRef] [PubMed]

| Type of Load | |||

|---|---|---|---|

| Compression | Bending | Tension | |

| Loading Rate (N/s) | 10 | 3 | 15 |

| Test Time (s) | 60 ± 30 | 60 ± 30 | 60 ± 30 |

| h (m%) | Type of Load | |||

|---|---|---|---|---|

| Compression | Bending | Tension | ||

| Specimen without nodes | 7 | 50 | 50 | - |

| 15 | 50 | 50 | 50 | |

| 90 | 50 | 50 | - | |

| Specimen with nodes | 7 | 50 | 50 | - |

| 15 | 50 | 50 | 50 | |

| 90 | 50 | 50 | - | |

| Δh (m%) | ΔDe (%) | Δt (%) |

|---|---|---|

| 83 | 6.1 | 8.0 |

| Compression | Bending | Tension | |||||||

|---|---|---|---|---|---|---|---|---|---|

| h (m%) | Sy (MPa) | Su (MPa) | E (MPa) | Sy (MPa) | Su (MPa) | E (MPa) | Su (MPa) | E (MPa) | |

| No node | 7 | 41 43 | 48 45 | 3600 40 | 43 6 | 65 9 | 14,200 17 | - | - |

| 15 | 43 25 | 52 23 | 4200 30 | 48 15 | 71 11 | 15,400 19 | 64 34 | 2200 49 | |

| 90 | 21 21 | 26 17 | 1800 33 | 29 8 | 43 8 | 10,600 24 | - | - | |

| With node | 7 | 46 25 | 51 25 | 4600 22 | - | 91 16 | 13,300 15 | - | - |

| 15 | 39 26 | 46 23 | 4700 55 | - | 70 6 | 10,900 4 | 96 21 | 6000 23 | |

| 90 | 16 26 | 19 25 | 1700 69 | - | 49 8 | 12,200 8 | - | - | |

| Material | Syk (MPa) | E (MPa) | Density ρ (kg/m3) | Specific Strength (N·m/kg) | Specific Stiffness (kN·m/kg) |

|---|---|---|---|---|---|

| Reed | 32 | 4200 | 508 | 63.0 | 8.3 |

| Steel S275 | 275 | 210,000 | 7850 | 35.0 | 26.8 |

| Timber C16 | 17 | 8000 | 370 | 45.9 | 21.6 |

| Concrete C25 | 33 | 31,000 | 2350 | 14.0 | 13.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiménez-Espada, M.; Herrero-Adán, D.; González-Escobar, R. Characterization of Mechanical and Hygroscopic Properties of Individual Canes of Reed. Materials 2021, 14, 2193. https://doi.org/10.3390/ma14092193

Jiménez-Espada M, Herrero-Adán D, González-Escobar R. Characterization of Mechanical and Hygroscopic Properties of Individual Canes of Reed. Materials. 2021; 14(9):2193. https://doi.org/10.3390/ma14092193

Chicago/Turabian StyleJiménez-Espada, Montaña, Daniel Herrero-Adán, and Rafael González-Escobar. 2021. "Characterization of Mechanical and Hygroscopic Properties of Individual Canes of Reed" Materials 14, no. 9: 2193. https://doi.org/10.3390/ma14092193

APA StyleJiménez-Espada, M., Herrero-Adán, D., & González-Escobar, R. (2021). Characterization of Mechanical and Hygroscopic Properties of Individual Canes of Reed. Materials, 14(9), 2193. https://doi.org/10.3390/ma14092193